Gauge DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1434 of 2627

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove the air cleaner(Refer to 9 - ENGINE/

AIR INTAKE SYSTEM - REMOVAL).

(3) Remove intake manifold(Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

(4) Remove cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(5) Remove rocker arm assembly and push rod-

s(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - REMOVAL). Identify

push rods to ensure installation in original location.

(6) Remove the cylinder head(Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(7) Remove bolt from tappet guide holder.

(8) Remove tappet guide holder.

(9) Pull tappet out of bore with a twisting motion.

If all tappets are to be removed and reused, identify

tappets to ensure installation in original location.

(10) Check camshaft lobes for abnormal wear.

INSTALLATION

(1) Lubricate tappets.

(2) Install tappets in their original positions.

(3)

Install tappet guide holder. Install the tappet

guide holder bolt and tighten to 12 N´m (106 in. lbs.)

torque.

(4) Install cylinder head(Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

(5) Install pushrods and rocker arm assembly(Re-

fer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - INSTALLATION).

(6) Install cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(7)

Install intake manifold(Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLATION).

(8) Install the air cleaner(Refer to 9 - ENGINE/

AIR INTAKE SYSTEM - INSTALLATION).

(9) Connect the negative cable to the battery.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic tappets have filled with oil and have

become quiet.

(10) Road test vehicle and check for leaks.

PISTON & CONNECTING ROD

DESCRIPTION

CAUTION: Do not use a metal stamp to mark con-

necting rods as damage may result, instead use ink

or a scratch awl.The pistons are made of a high strength aluminum

alloy. Piston skirts are coated with a solid lubricant

(Molykote) to reduce friction and provide scuff resis-

tance. The piston top ring groove and land is anod-

ized. The connecting rods are made of forged

powdered metal, with a ªfractured capº design. A

pressed fit piston pin is used to attach the piston and

connecting rod.

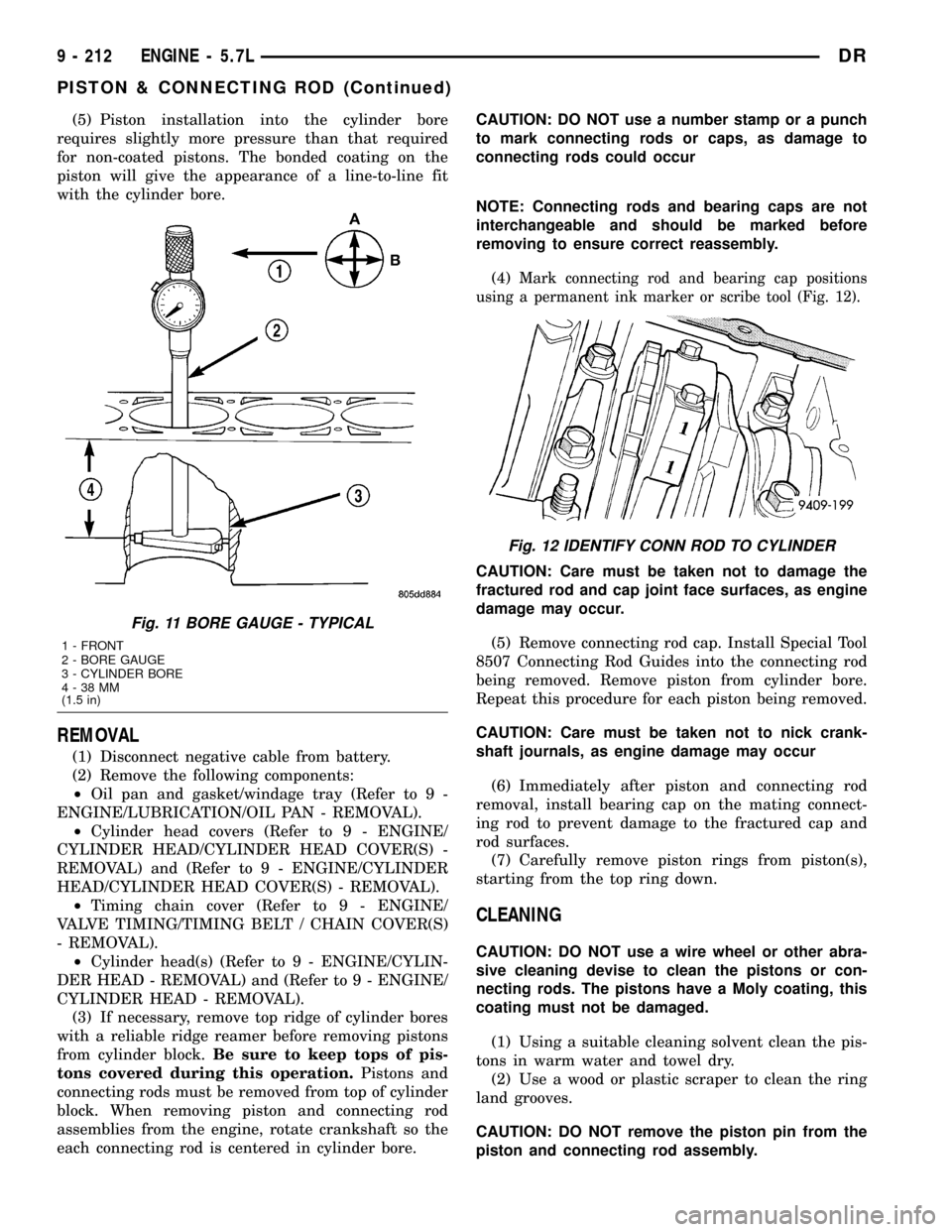

STANDARD PROCEDUREÐPISTON FITTING

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in 0.003 mm (

.0001 in.) INCREMENTS is required. If a bore gauge

is not available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at a point 38.0 mm (1.5 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 11).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled. The

piston-rod assembly is specific for the left cylinder

bank ( odd numbered) and the right cylinder bank (

even numbered) and must not be interchanged.

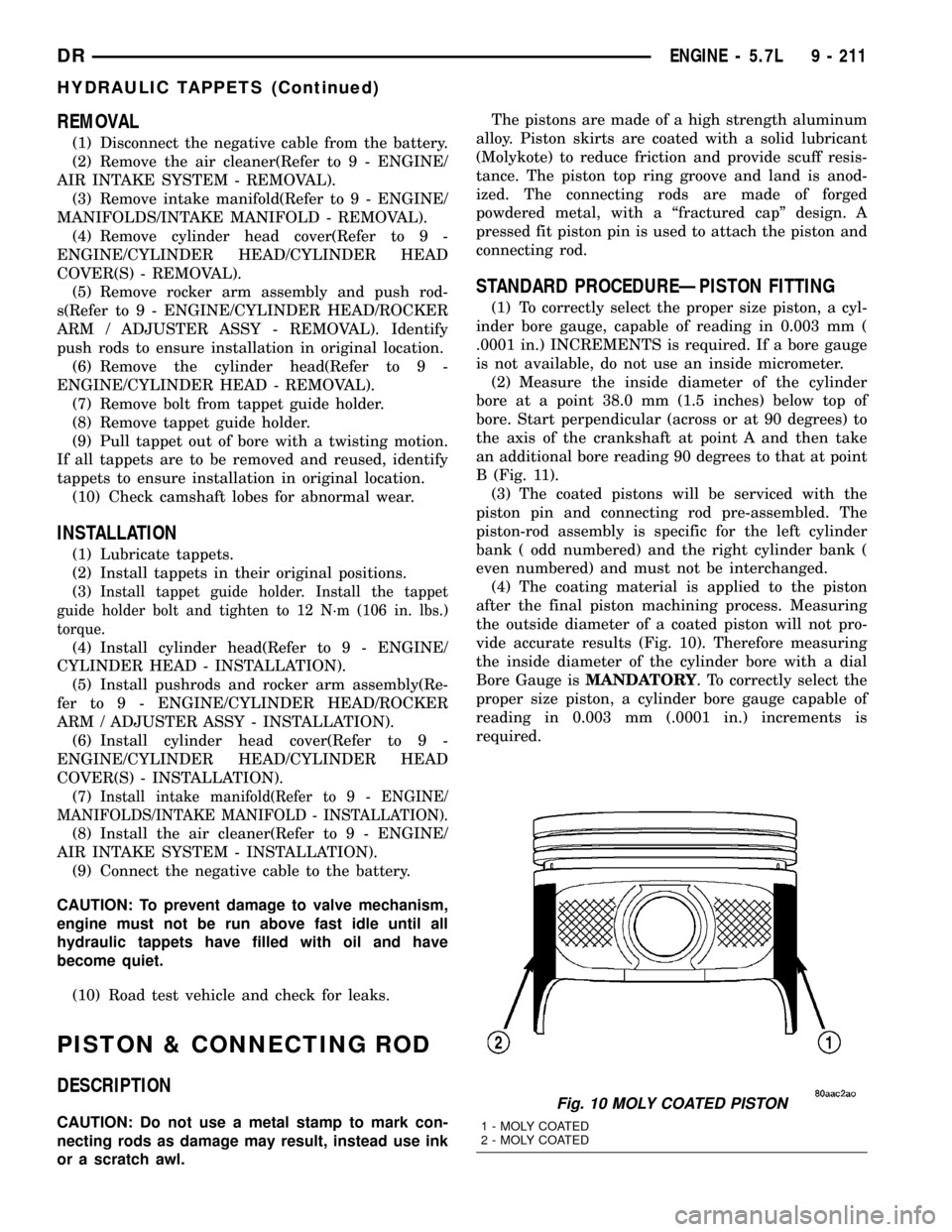

(4) The coating material is applied to the piston

after the final piston machining process. Measuring

the outside diameter of a coated piston will not pro-

vide accurate results (Fig. 10). Therefore measuring

the inside diameter of the cylinder bore with a dial

Bore Gauge isMANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable of

reading in 0.003 mm (.0001 in.) increments is

required.

Fig. 10 MOLY COATED PISTON

1 - MOLY COATED

2 - MOLY COATED

DRENGINE - 5.7L 9 - 211

HYDRAULIC TAPPETS (Continued)

Page 1435 of 2627

(5) Piston installation into the cylinder bore

requires slightly more pressure than that required

for non-coated pistons. The bonded coating on the

piston will give the appearance of a line-to-line fit

with the cylinder bore.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the following components:

²Oil pan and gasket/windage tray (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - REMOVAL).

²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL) and (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - REMOVAL).

²Timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- REMOVAL).

²Cylinder head(s) (Refer to 9 - ENGINE/CYLIN-

DER HEAD - REMOVAL) and (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(3) If necessary, remove top ridge of cylinder bores

with a reliable ridge reamer before removing pistons

from cylinder block.Be sure to keep tops of pis-

tons covered during this operation.Pistons and

connecting rods must be removed from top of cylinder

block. When removing piston and connecting rod

assemblies from the engine, rotate crankshaft so the

each connecting rod is centered in cylinder bore.CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods or caps, as damage to

connecting rods could occur

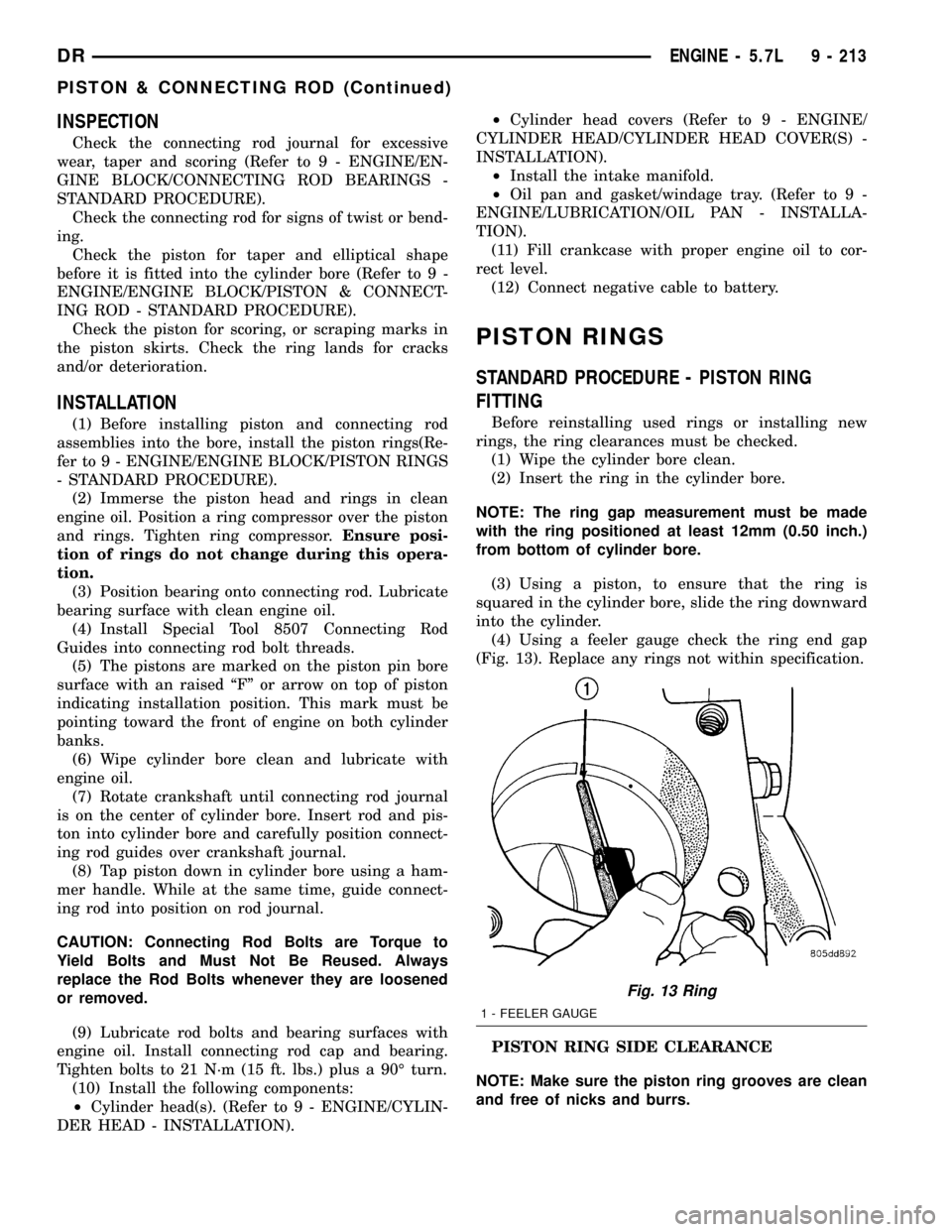

NOTE: Connecting rods and bearing caps are not

interchangeable and should be marked before

removing to ensure correct reassembly.

(4)

Mark connecting rod and bearing cap positions

using a permanent ink marker or scribe tool (Fig. 12).

CAUTION: Care must be taken not to damage the

fractured rod and cap joint face surfaces, as engine

damage may occur.

(5) Remove connecting rod cap. Install Special Tool

8507 Connecting Rod Guides into the connecting rod

being removed. Remove piston from cylinder bore.

Repeat this procedure for each piston being removed.

CAUTION: Care must be taken not to nick crank-

shaft journals, as engine damage may occur

(6) Immediately after piston and connecting rod

removal, install bearing cap on the mating connect-

ing rod to prevent damage to the fractured cap and

rod surfaces.

(7) Carefully remove piston rings from piston(s),

starting from the top ring down.

CLEANING

CAUTION: DO NOT use a wire wheel or other abra-

sive cleaning devise to clean the pistons or con-

necting rods. The pistons have a Moly coating, this

coating must not be damaged.

(1) Using a suitable cleaning solvent clean the pis-

tons in warm water and towel dry.

(2) Use a wood or plastic scraper to clean the ring

land grooves.

CAUTION: DO NOT remove the piston pin from the

piston and connecting rod assembly.

Fig. 11 BORE GAUGE - TYPICAL

1 - FRONT

2 - BORE GAUGE

3 - CYLINDER BORE

4-38MM

(1.5 in)

Fig. 12 IDENTIFY CONN ROD TO CYLINDER

9 - 212 ENGINE - 5.7LDR

PISTON & CONNECTING ROD (Continued)

Page 1436 of 2627

INSPECTION

Check the connecting rod journal for excessive

wear, taper and scoring (Refer to 9 - ENGINE/EN-

GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bend-

ing.

Check the piston for taper and elliptical shape

before it is fitted into the cylinder bore (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in

the piston skirts. Check the ring lands for cracks

and/or deterioration.

INSTALLATION

(1) Before installing piston and connecting rod

assemblies into the bore, install the piston rings(Re-

fer to 9 - ENGINE/ENGINE BLOCK/PISTON RINGS

- STANDARD PROCEDURE).

(2) Immerse the piston head and rings in clean

engine oil. Position a ring compressor over the piston

and rings. Tighten ring compressor.Ensure posi-

tion of rings do not change during this opera-

tion.

(3) Position bearing onto connecting rod. Lubricate

bearing surface with clean engine oil.

(4) Install Special Tool 8507 Connecting Rod

Guides into connecting rod bolt threads.

(5) The pistons are marked on the piston pin bore

surface with an raised ªFº or arrow on top of piston

indicating installation position. This mark must be

pointing toward the front of engine on both cylinder

banks.

(6) Wipe cylinder bore clean and lubricate with

engine oil.

(7) Rotate crankshaft until connecting rod journal

is on the center of cylinder bore. Insert rod and pis-

ton into cylinder bore and carefully position connect-

ing rod guides over crankshaft journal.

(8) Tap piston down in cylinder bore using a ham-

mer handle. While at the same time, guide connect-

ing rod into position on rod journal.

CAUTION: Connecting Rod Bolts are Torque to

Yield Bolts and Must Not Be Reused. Always

replace the Rod Bolts whenever they are loosened

or removed.

(9) Lubricate rod bolts and bearing surfaces with

engine oil. Install connecting rod cap and bearing.

Tighten bolts to 21 N´m (15 ft. lbs.) plus a 90É turn.

(10) Install the following components:

²Cylinder head(s). (Refer to 9 - ENGINE/CYLIN-

DER HEAD - INSTALLATION).²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

INSTALLATION).

²Install the intake manifold.

²Oil pan and gasket/windage tray. (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(11) Fill crankcase with proper engine oil to cor-

rect level.

(12) Connect negative cable to battery.

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING

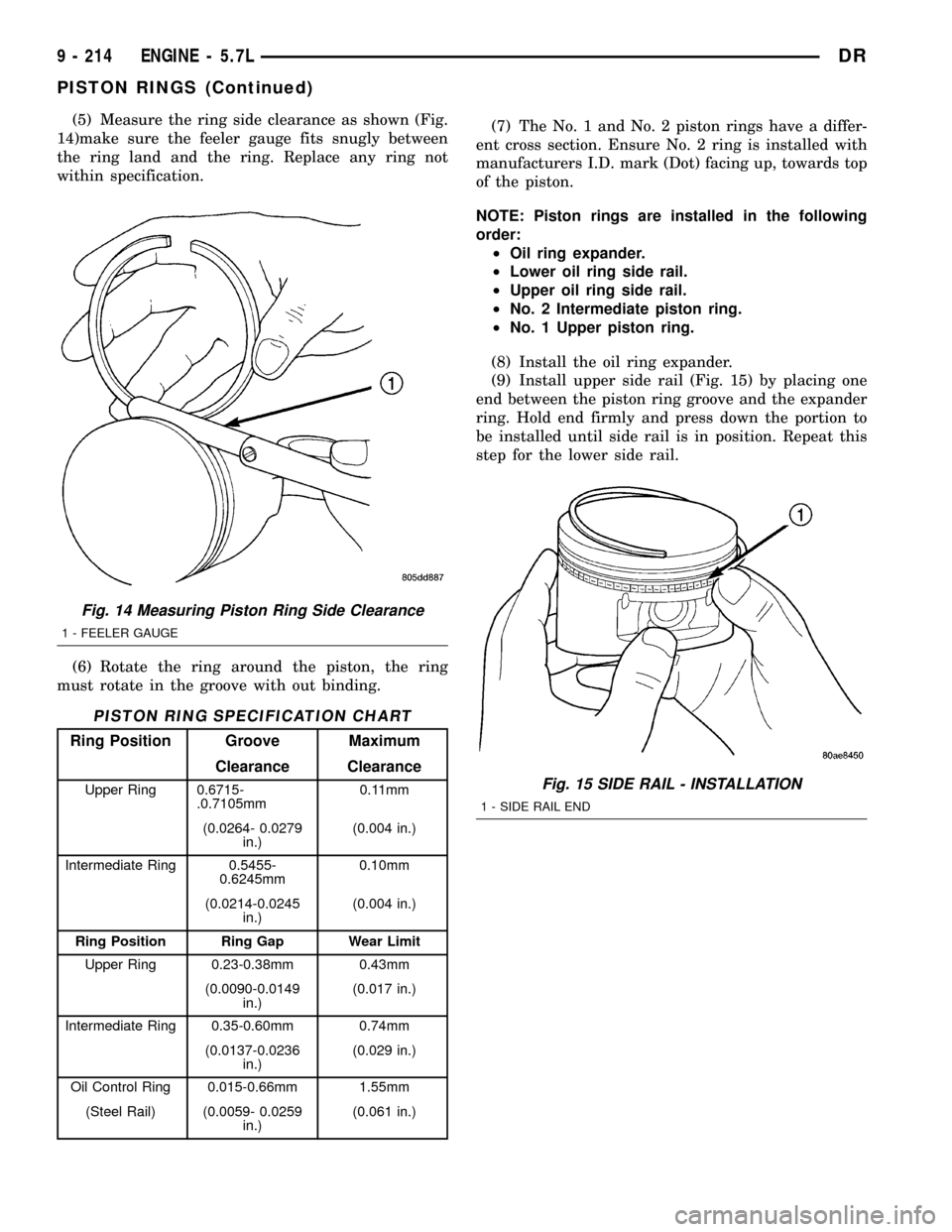

Before reinstalling used rings or installing new

rings, the ring clearances must be checked.

(1) Wipe the cylinder bore clean.

(2) Insert the ring in the cylinder bore.

NOTE: The ring gap measurement must be made

with the ring positioned at least 12mm (0.50 inch.)

from bottom of cylinder bore.

(3) Using a piston, to ensure that the ring is

squared in the cylinder bore, slide the ring downward

into the cylinder.

(4) Using a feeler gauge check the ring end gap

(Fig. 13). Replace any rings not within specification.

PISTON RING SIDE CLEARANCE

NOTE: Make sure the piston ring grooves are clean

and free of nicks and burrs.

Fig. 13 Ring

1 - FEELER GAUGE

DRENGINE - 5.7L 9 - 213

PISTON & CONNECTING ROD (Continued)

Page 1437 of 2627

(5) Measure the ring side clearance as shown (Fig.

14)make sure the feeler gauge fits snugly between

the ring land and the ring. Replace any ring not

within specification.

(6) Rotate the ring around the piston, the ring

must rotate in the groove with out binding.

PISTON RING SPECIFICATION CHART

Ring Position Groove Maximum

Clearance Clearance

Upper Ring 0.6715-

.0.7105mm0.11mm

(0.0264- 0.0279

in.)(0.004 in.)

Intermediate Ring 0.5455-

0.6245mm0.10mm

(0.0214-0.0245

in.)(0.004 in.)

Ring Position Ring Gap Wear Limit

Upper Ring 0.23-0.38mm 0.43mm

(0.0090-0.0149

in.)(0.017 in.)

Intermediate Ring 0.35-0.60mm 0.74mm

(0.0137-0.0236

in.)(0.029 in.)

Oil Control Ring 0.015-0.66mm 1.55mm

(Steel Rail) (0.0059- 0.0259

in.)(0.061 in.)

(7) The No. 1 and No. 2 piston rings have a differ-

ent cross section. Ensure No. 2 ring is installed with

manufacturers I.D. mark (Dot) facing up, towards top

of the piston.

NOTE: Piston rings are installed in the following

order:

²Oil ring expander.

²Lower oil ring side rail.

²Upper oil ring side rail.

²No. 2 Intermediate piston ring.

²No. 1 Upper piston ring.

(8) Install the oil ring expander.

(9) Install upper side rail (Fig. 15) by placing one

end between the piston ring groove and the expander

ring. Hold end firmly and press down the portion to

be installed until side rail is in position. Repeat this

step for the lower side rail.

Fig. 15 SIDE RAIL - INSTALLATION

1 - SIDE RAIL END

Fig. 14 Measuring Piston Ring Side Clearance

1 - FEELER GAUGE

9 - 214 ENGINE - 5.7LDR

PISTON RINGS (Continued)

Page 1443 of 2627

(8) Torque the (3) bolts that attach the front axle

to the left engine bracket to 101 N´m (75 ft. lbs.).

(9) Install the engine oil filter, if removed.

(10) Install the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

(11) Install the skid plate.

(12) Lower the vehicle.

(13) Reconnect the negative battery cable.

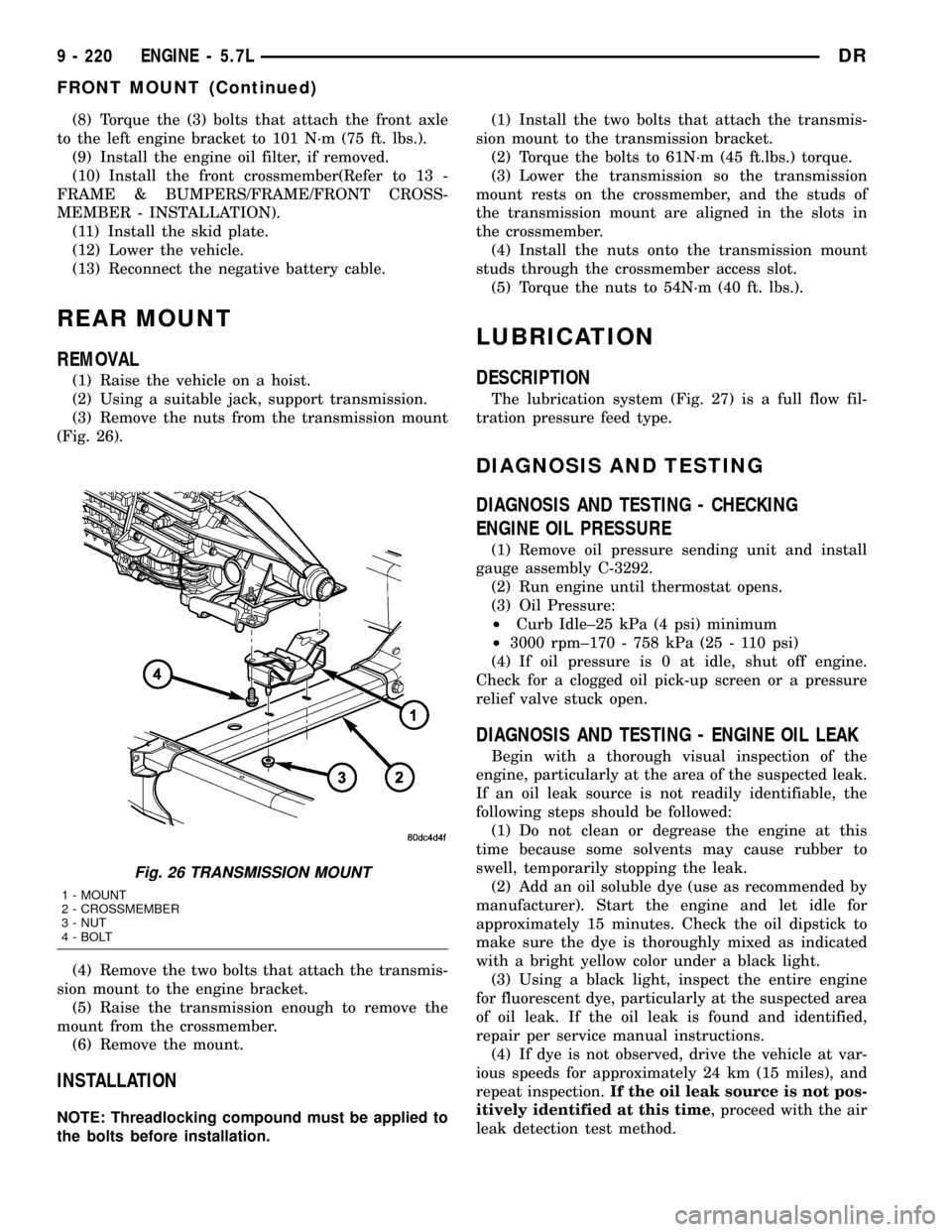

REAR MOUNT

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Using a suitable jack, support transmission.

(3) Remove the nuts from the transmission mount

(Fig. 26).

(4) Remove the two bolts that attach the transmis-

sion mount to the engine bracket.

(5) Raise the transmission enough to remove the

mount from the crossmember.

(6) Remove the mount.

INSTALLATION

NOTE: Threadlocking compound must be applied to

the bolts before installation.(1) Install the two bolts that attach the transmis-

sion mount to the transmission bracket.

(2) Torque the bolts to 61N´m (45 ft.lbs.) torque.

(3) Lower the transmission so the transmission

mount rests on the crossmember, and the studs of

the transmission mount are aligned in the slots in

the crossmember.

(4) Install the nuts onto the transmission mount

studs through the crossmember access slot.

(5) Torque the nuts to 54N´m (40 ft. lbs.).

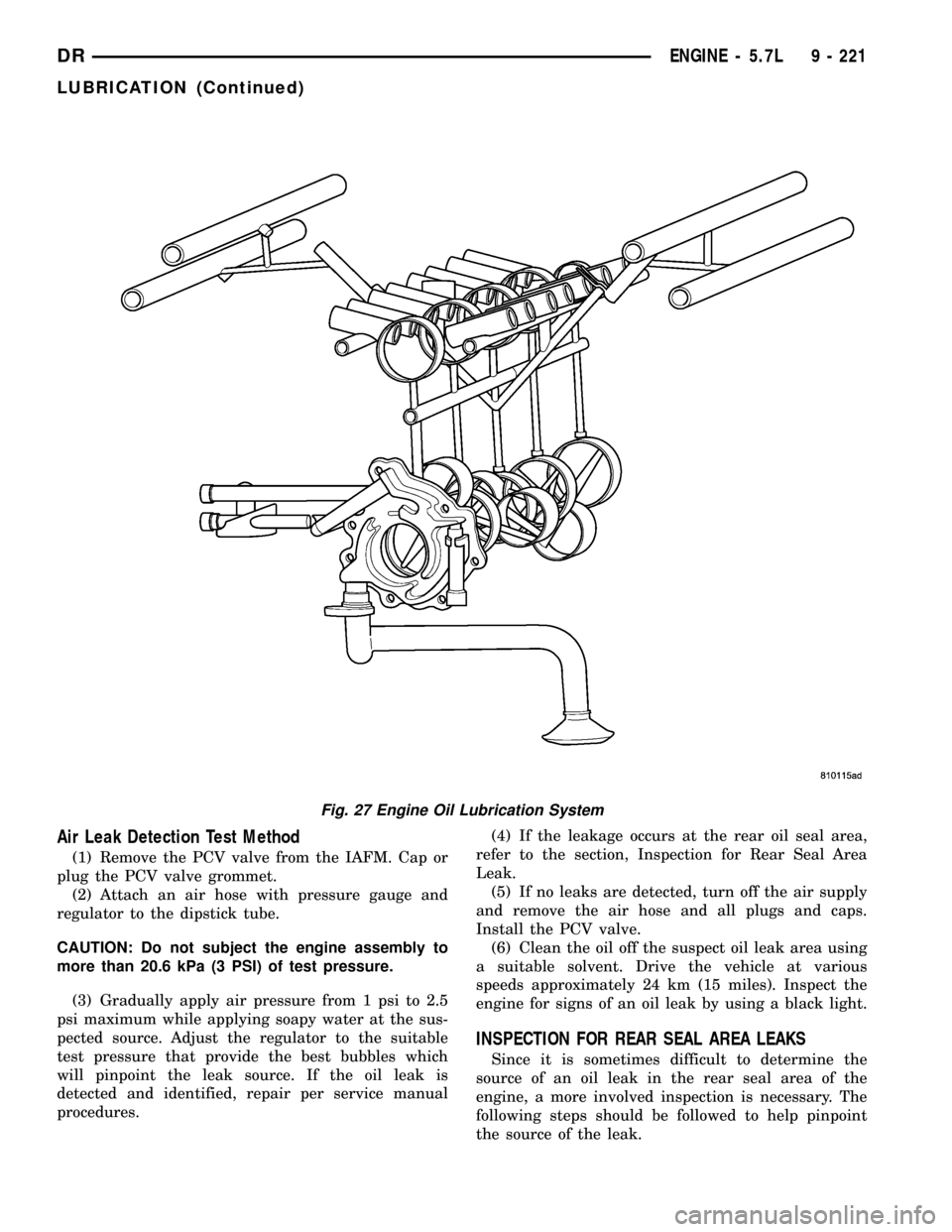

LUBRICATION

DESCRIPTION

The lubrication system (Fig. 27) is a full flow fil-

tration pressure feed type.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CHECKING

ENGINE OIL PRESSURE

(1) Remove oil pressure sending unit and install

gauge assembly C-3292.

(2) Run engine until thermostat opens.

(3) Oil Pressure:

²Curb Idle±25 kPa (4 psi) minimum

²3000 rpm±170 - 758 kPa (25 - 110 psi)

(4) If oil pressure is 0 at idle, shut off engine.

Check for a clogged oil pick-up screen or a pressure

relief valve stuck open.

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.If the oil leak source is not pos-

itively identified at this time, proceed with the air

leak detection test method.

Fig. 26 TRANSMISSION MOUNT

1 - MOUNT

2 - CROSSMEMBER

3 - NUT

4 - BOLT

9 - 220 ENGINE - 5.7LDR

FRONT MOUNT (Continued)

Page 1444 of 2627

Air Leak Detection Test Method

(1) Remove the PCV valve from the IAFM. Cap or

plug the PCV valve grommet.

(2) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kPa (3 PSI) of test pressure.

(3) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.(4) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(5) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the PCV valve.

(6) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

Fig. 27 Engine Oil Lubrication System

DRENGINE - 5.7L 9 - 221

LUBRICATION (Continued)

Page 1447 of 2627

OIL PAN

REMOVAL

(1) Disconnect the negative battery cable.

(2) Install engine support fixture special tool #

8534.Do not raise engine at this time.

(3) Loosen both left and right side engine mount

through bolts. Do not remove bolts.

(4) Remove the structural dust cover, if equipped.

(5) Drain engine oil.

(6) Remove the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - REMOVAL).

CAUTION: Only raise the engine enough to provide

clearance for oil pan removal. Check for proper

clearance at fan shroud to fan and cowl to intake

manifold.

(7) Raise engine using special tool # 8534 to pro-

vide clearance to remove oil pan.

NOTE: Do not pry on oil pan or oil pan gasket. Gas-

ket is integral to engine windage tray and does not

come out with oil pan.

(8) Remove the oil pan mounting bolts and oil pan.

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

(9) Unbolt oil pump pickup tube and remove tube.

(10) Inspect the integral windage tray and gasket

and replace as needed.

INSTALLATION

(1) Clean the oil pan gasket mating surface of the

block and oil pan.

(2) Inspect the integral windage tray and gasket

and replace as needed.

(3) Reinstall the oil pump pickup tube with new

o-ring. Tighten tube to pump fasteners to 28 N´m

(250 in. lbs.).

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

(4) Position the oil pan and install the mounting

bolts and studs.. Tighten the mounting bolts to 12

N´m (105 in.lbs.).

(5) Lower the engine into mounts using special

tool # 8534.

(6) Install both the left and right side engine

mount through bolts. Tighten the nuts to 68 N´m (50

ft. lbs.).(7) Remove special tool # 8534.

(8) Install structural dust cover, if equipped.

(9) Install the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

(10) Fill engine oil.

(11) Reconnect the negative battery cable.

(12) Start engine and check for leaks.

OIL PUMP

REMOVAL

(1) Remove the oil pan and pick-up tube(Refer to 9

- ENGINE/LUBRICATION/OIL PAN - REMOVAL).

(2) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(3) Remove the four bolts, and the oil pump.

CLEANING

(1) Wash all parts in a suitable solvent.

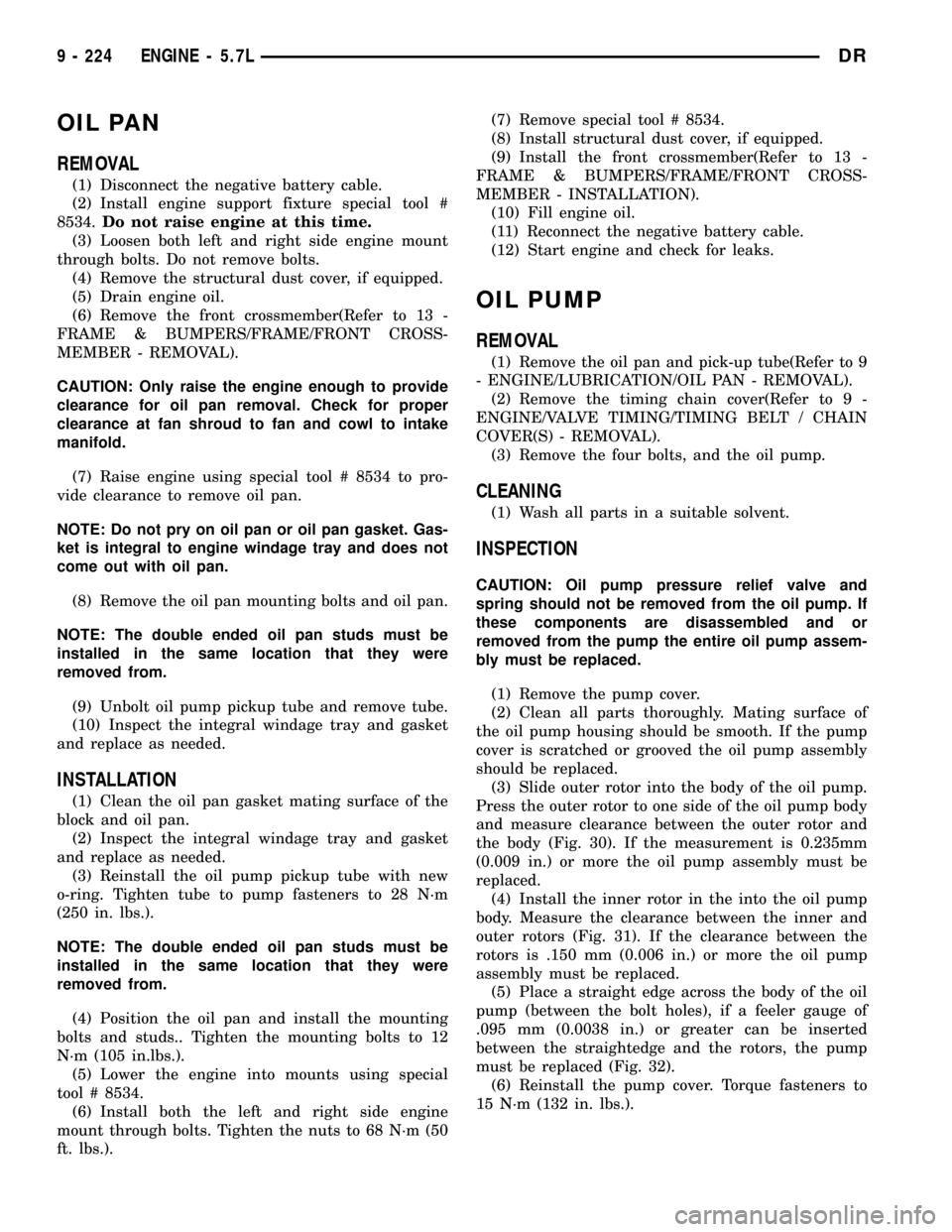

INSPECTION

CAUTION: Oil pump pressure relief valve and

spring should not be removed from the oil pump. If

these components are disassembled and or

removed from the pump the entire oil pump assem-

bly must be replaced.

(1) Remove the pump cover.

(2) Clean all parts thoroughly. Mating surface of

the oil pump housing should be smooth. If the pump

cover is scratched or grooved the oil pump assembly

should be replaced.

(3) Slide outer rotor into the body of the oil pump.

Press the outer rotor to one side of the oil pump body

and measure clearance between the outer rotor and

the body (Fig. 30). If the measurement is 0.235mm

(0.009 in.) or more the oil pump assembly must be

replaced.

(4) Install the inner rotor in the into the oil pump

body. Measure the clearance between the inner and

outer rotors (Fig. 31). If the clearance between the

rotors is .150 mm (0.006 in.) or more the oil pump

assembly must be replaced.

(5) Place a straight edge across the body of the oil

pump (between the bolt holes), if a feeler gauge of

.095 mm (0.0038 in.) or greater can be inserted

between the straightedge and the rotors, the pump

must be replaced (Fig. 32).

(6) Reinstall the pump cover. Torque fasteners to

15 N´m (132 in. lbs.).

9 - 224 ENGINE - 5.7LDR

Page 1448 of 2627

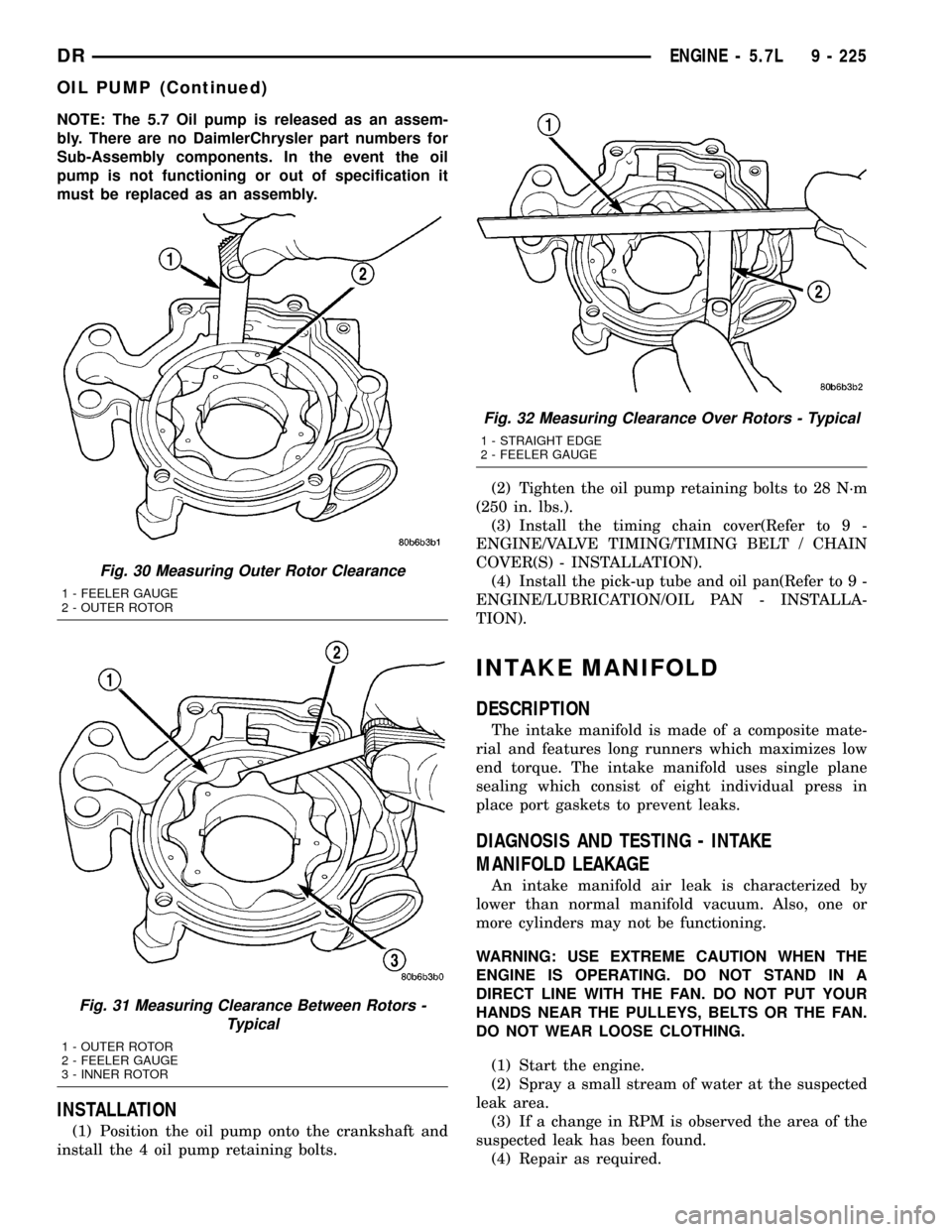

NOTE: The 5.7 Oil pump is released as an assem-

bly. There are no DaimlerChrysler part numbers for

Sub-Assembly components. In the event the oil

pump is not functioning or out of specification it

must be replaced as an assembly.

INSTALLATION

(1) Position the oil pump onto the crankshaft and

install the 4 oil pump retaining bolts.(2) Tighten the oil pump retaining bolts to 28 N´m

(250 in. lbs.).

(3) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(4) Install the pick-up tube and oil pan(Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

INTAKE MANIFOLD

DESCRIPTION

The intake manifold is made of a composite mate-

rial and features long runners which maximizes low

end torque. The intake manifold uses single plane

sealing which consist of eight individual press in

place port gaskets to prevent leaks.

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPM is observed the area of the

suspected leak has been found.

(4) Repair as required.

Fig. 30 Measuring Outer Rotor Clearance

1 - FEELER GAUGE

2 - OUTER ROTOR

Fig. 31 Measuring Clearance Between Rotors -

Typical

1 - OUTER ROTOR

2 - FEELER GAUGE

3 - INNER ROTOR

Fig. 32 Measuring Clearance Over Rotors - Typical

1 - STRAIGHT EDGE

2 - FEELER GAUGE

DRENGINE - 5.7L 9 - 225

OIL PUMP (Continued)

Page 1456 of 2627

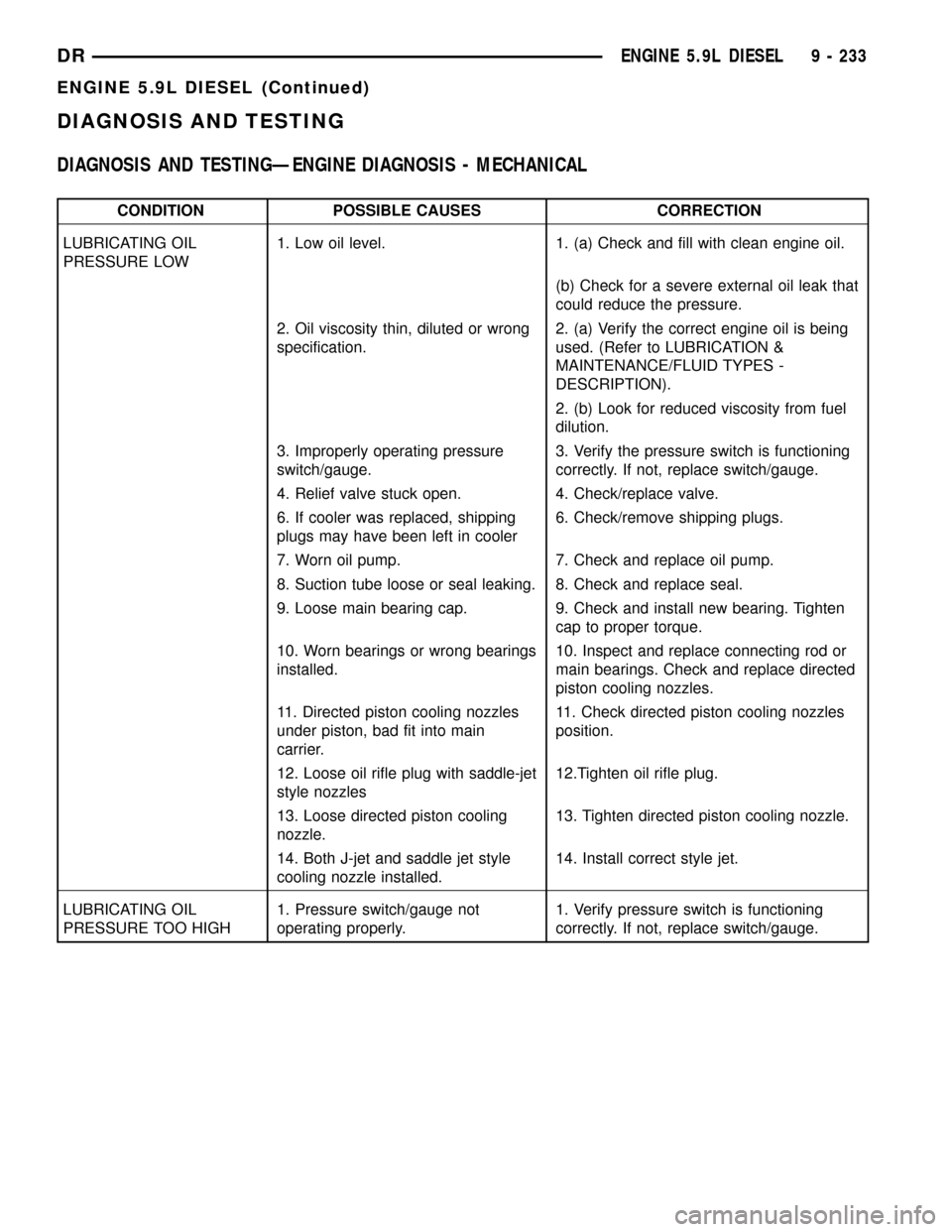

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

LUBRICATING OIL

PRESSURE LOW1. Low oil level. 1. (a) Check and fill with clean engine oil.

(b) Check for a severe external oil leak that

could reduce the pressure.

2. Oil viscosity thin, diluted or wrong

specification.2. (a) Verify the correct engine oil is being

used. (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

DESCRIPTION).

2. (b) Look for reduced viscosity from fuel

dilution.

3. Improperly operating pressure

switch/gauge.3. Verify the pressure switch is functioning

correctly. If not, replace switch/gauge.

4. Relief valve stuck open. 4. Check/replace valve.

6. If cooler was replaced, shipping

plugs may have been left in cooler6. Check/remove shipping plugs.

7. Worn oil pump. 7. Check and replace oil pump.

8. Suction tube loose or seal leaking. 8. Check and replace seal.

9. Loose main bearing cap. 9. Check and install new bearing. Tighten

cap to proper torque.

10. Worn bearings or wrong bearings

installed.10. Inspect and replace connecting rod or

main bearings. Check and replace directed

piston cooling nozzles.

11. Directed piston cooling nozzles

under piston, bad fit into main

carrier.11. Check directed piston cooling nozzles

position.

12. Loose oil rifle plug with saddle-jet

style nozzles12.Tighten oil rifle plug.

13. Loose directed piston cooling

nozzle.13. Tighten directed piston cooling nozzle.

14. Both J-jet and saddle jet style

cooling nozzle installed.14. Install correct style jet.

LUBRICATING OIL

PRESSURE TOO HIGH1. Pressure switch/gauge not

operating properly.1. Verify pressure switch is functioning

correctly. If not, replace switch/gauge.

DRENGINE 5.9L DIESEL 9 - 233

ENGINE 5.9L DIESEL (Continued)

Page 1462 of 2627

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION/LEAKAGE TESTS

CYLINDER COMPRESSION PRESSURE

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure batteries are completely charged and the

engine starter motor is in good operating condition.

Otherwise, the indicated compression pressures may

not be valid for diagnostic purposes.

(1) Disconnect the fuel inlet line to the fuel trans-

fer pump. Plug the fuel line from the fuel tank.

(2) Start the engine and idle until the engine stalls

(runs out of fuel).

(3) Disconnect all three injector wire harness con-

nectors at the rocker housing.

(4) Remove the breather cover and cylinder head

cover.

(5) Remove the high pressure fuel line between the

cylinder head and fuel rail for the cylinder to be

tested. Use tool# 9011 to cap this fuel rail on the cyl-

inder being tested.

(6) Remove the exhaust rocker lever.

(7) Use Tool 9010 to remove the injector and cop-

per sealing washer.

(8) Install the exhaust rocker lever and torque to

36 N´m (27 ft. lbs.).

(9) Cover the remaining rocker levers with clean

shop towels to prevent any oil splatter under the

hood.

(10) Place a rag over the compression test tool fit-

ting. Crank the engine for 2±3 seconds to purge any

fuel that may have drained into the cylinder when

the injector was removed.

(11) Connect the compression test gauge.

(12) Crank the engine for 5 seconds and record the

pressure reading. Repeat this step three times and

calculate the average of the three readings.

NOTE: The minimum cylinder pressure is 350 psi.

Cylinder pressure should be within 20% from cylin-

der to cylinder.

(13) Combustion pressure leakage can be checked

if cylinder pressure is below the specification. Per-

form the leakage test procedure on each cylinder

according to the tester manufacturer instructions.

(14) Upon completion of the test check an erase

any engine related fault codes.

CYLINDER COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss

(1) Start and operate the engine until it attains

normal operating temperature.

(2) Remove the breather cover and cylinder head

cover.

(3) Disconnect all three injector wire harness con-

nectors at the rocker housing.

(4) Bring the cylinder to be tested to TDC.

(5) Remove the high pressure fuel line between the

cylinder head and the fuel rail for the cylinder to be

tested.

(6) Install capping Tool 9011 onto the rail.

(7) Remove the high pressure connector nut and

high pressure connector with Tool 9015.

(8) Remove the exhaust and intake rocker lever.

(9) Use Tool 9010 to remove the injector and cop-

per sealing washer.

(10) Install compression test Tool 9007 into the

injector bore.

(11) Connect the leakage tester and perform the

leakage test procedure on each cylinder according to

the tester manufacturer's instructions.

(12) Upon completion of the test check and erase

any engine related fault codes.

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

DRENGINE 5.9L DIESEL 9 - 239

ENGINE 5.9L DIESEL (Continued)