IPM DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2531 of 2627

DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM LEAKS

WARNING: R-134a SERVICE EQUIPMENT OR VEHI-

CLE A/C SYSTEM SHOULD NOT BE PRESSURE

TESTED OR LEAK TESTED WITH COMPRESSED

AIR. MIXTURE OF AIR and R-134a CAN BE COM-

BUSTIBLE AT ELEVATED PRESSURES. THESE MIX-

TURES ARE POTENTIALLY DANGEROUS AND MAY

RESULT IN FIRE OR EXPLOSION CAUSING INJURY

OR PROPERTY DAMAGE.

AVOID BREATHING A/C REFRIGERANT AND LUBRI-

CANT VAPOR OR MIST. EXPOSURE MAY IRRITATE

EYES, NOSE AND THROAT. USE ONLY APPROVED

SERVICE EQUIPMENT MEETING SAE REQUIRE-

MENTS TO DISCHARGE R-134a SYSTEM. IF ACCI-

DENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

NOTE: The refrigerant system does come from the

factory with a yellow tracer dye already installed to

aid in detection of leaks.

If the A/C system is not cooling properly, determine

if the refrigerant system is fully charged with

R-134a. This is accomplished by performing a system

Charge Level-Check or Fill. If while performing this

test A/C liquid line pressure is less than 345 kPa (50

psi) proceed to System Empty procedure. If liquid

line pressure is greater than 345 kPa (50 psi) proceed

to System Low procedure. If the refrigerant system is

empty or low in refrigerant charge, a leak at any line

fitting or component seal is likely. A review of the fit-

tings, lines and components for oily residue is an

indication of the leak location. To detect a leak in the

refrigerant system, perform one of the following pro-

cedures as indicated by the symptoms.

SYSTEM EMPTY

(1) Evacuate the refrigerant system to the lowest

degree of vacuum possible (approx. 28 in Hg.). Deter-

mine if the system holds a vacuum for 15 minutes. If

vacuum is held, a leak is probably not present. If sys-

tem will not maintain vacuum level, proceed with

this procedure.(2) Prepare a 0.284 Kg. (10 oz.) refrigerant charge

to be injected into the system.

(3) Connect and dispense 0.284 Kg. (10 oz.) of

refrigerant into the evacuated refrigerant system.

(4) Proceed to Step 2 of System Low procedure.

SYSTEM LOW

(1) Determine if there is any (R-134a) refrigerant

in the system.

(2) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run for five minutes with the system

set to the following:

²Transmission in Park or Neutral with parking

brake set

²Engine idling at 700 rpm

²A/C controls set in 100 percent outside air

²Blower switch in the high A/C position

²A/C in the ON position

²Open all windows

CAUTION: A leak detector designed for R-12 refrig-

erant (only) will not detect leaks in a R-134a refrig-

erant system.

(4) Shut off the vehicle and wait 2 to 7 minutes.

Then use an Electronic Leak Detector that is

designed to detect R-134a type refrigerant and search

for leaks. Fittings, lines, or components that appear

to be oily usually indicates a refrigerant leak. To

inspect the evaporator core for leaks, insert the leak

detector probe into the drain tube opening or a heat

duct. A R-134a dye is available to aid in leak detec-

tion, use only DaimlerChrysler approved refrigerant

dye.

24 - 44 PLUMBINGDR

PLUMBING (Continued)

Page 2533 of 2627

STANDARD PROCEDURE - REFRIGERANT

SYSTEM SERVICE EQUIPMENT

WARNING: EYE PROTECTION MUST BE WORN

WHEN SERVICING AN AIR CONDITIONING REFRIG-

ERANT SYSTEM. TURN OFF (ROTATE CLOCKWISE)

ALL VALVES ON THE EQUIPMENT BEING USED

BEFORE CONNECTING TO, OR DISCONNECTING

FROM THE REFRIGERANT SYSTEM. FAILURE TO

OBSERVE THESE WARNINGS MAY RESULT IN PER-

SONAL INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

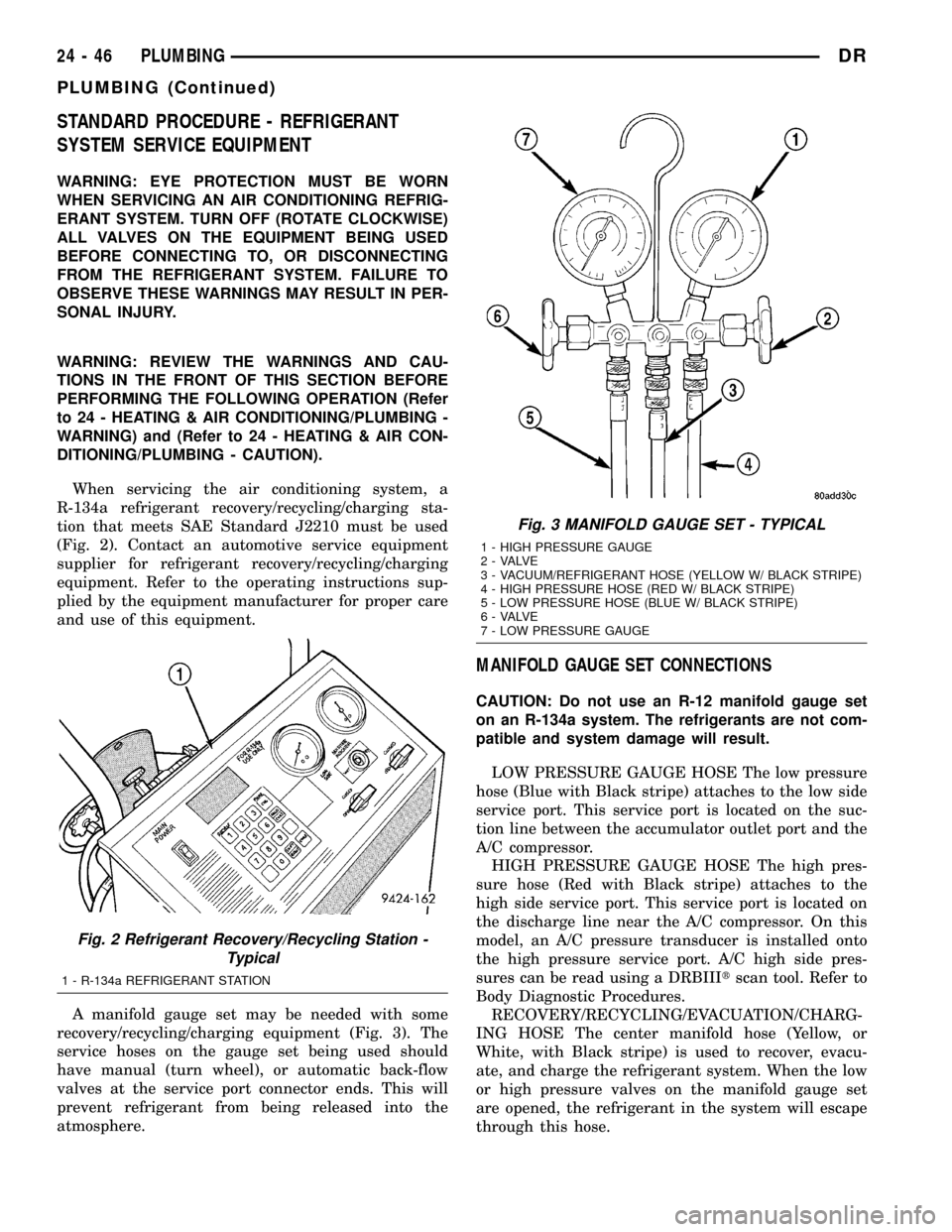

When servicing the air conditioning system, a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 must be used

(Fig. 2). Contact an automotive service equipment

supplier for refrigerant recovery/recycling/charging

equipment. Refer to the operating instructions sup-

plied by the equipment manufacturer for proper care

and use of this equipment.

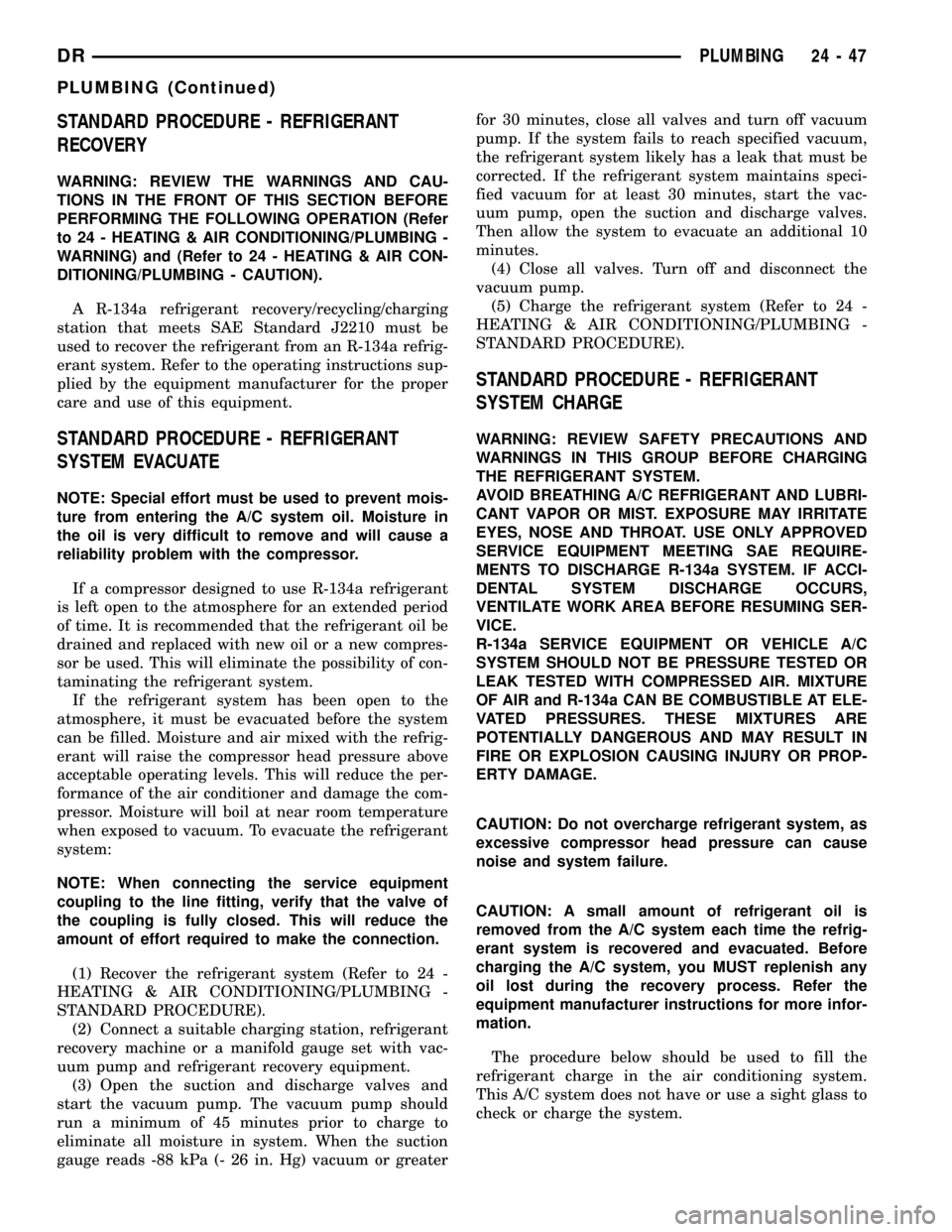

A manifold gauge set may be needed with some

recovery/recycling/charging equipment (Fig. 3). The

service hoses on the gauge set being used should

have manual (turn wheel), or automatic back-flow

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere.

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

LOW PRESSURE GAUGE HOSE The low pressure

hose (Blue with Black stripe) attaches to the low side

service port. This service port is located on the suc-

tion line between the accumulator outlet port and the

A/C compressor.

HIGH PRESSURE GAUGE HOSE The high pres-

sure hose (Red with Black stripe) attaches to the

high side service port. This service port is located on

the discharge line near the A/C compressor. On this

model, an A/C pressure transducer is installed onto

the high pressure service port. A/C high side pres-

sures can be read using a DRBIIItscan tool. Refer to

Body Diagnostic Procedures.

RECOVERY/RECYCLING/EVACUATION/CHARG-

ING HOSE The center manifold hose (Yellow, or

White, with Black stripe) is used to recover, evacu-

ate, and charge the refrigerant system. When the low

or high pressure valves on the manifold gauge set

are opened, the refrigerant in the system will escape

through this hose.

Fig. 2 Refrigerant Recovery/Recycling Station -

Typical

1 - R-134a REFRIGERANT STATION

Fig. 3 MANIFOLD GAUGE SET - TYPICAL

1 - HIGH PRESSURE GAUGE

2 - VALVE

3 - VACUUM/REFRIGERANT HOSE (YELLOW W/ BLACK STRIPE)

4 - HIGH PRESSURE HOSE (RED W/ BLACK STRIPE)

5 - LOW PRESSURE HOSE (BLUE W/ BLACK STRIPE)

6 - VALVE

7 - LOW PRESSURE GAUGE

24 - 46 PLUMBINGDR

PLUMBING (Continued)

Page 2534 of 2627

STANDARD PROCEDURE - REFRIGERANT

RECOVERY

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to recover the refrigerant from an R-134a refrig-

erant system. Refer to the operating instructions sup-

plied by the equipment manufacturer for the proper

care and use of this equipment.

STANDARD PROCEDURE - REFRIGERANT

SYSTEM EVACUATE

NOTE: Special effort must be used to prevent mois-

ture from entering the A/C system oil. Moisture in

the oil is very difficult to remove and will cause a

reliability problem with the compressor.

If a compressor designed to use R-134a refrigerant

is left open to the atmosphere for an extended period

of time. It is recommended that the refrigerant oil be

drained and replaced with new oil or a new compres-

sor be used. This will eliminate the possibility of con-

taminating the refrigerant system.

If the refrigerant system has been open to the

atmosphere, it must be evacuated before the system

can be filled. Moisture and air mixed with the refrig-

erant will raise the compressor head pressure above

acceptable operating levels. This will reduce the per-

formance of the air conditioner and damage the com-

pressor. Moisture will boil at near room temperature

when exposed to vacuum. To evacuate the refrigerant

system:

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Recover the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(2) Connect a suitable charging station, refrigerant

recovery machine or a manifold gauge set with vac-

uum pump and refrigerant recovery equipment.

(3) Open the suction and discharge valves and

start the vacuum pump. The vacuum pump should

run a minimum of 45 minutes prior to charge to

eliminate all moisture in system. When the suction

gauge reads -88 kPa (- 26 in. Hg) vacuum or greaterfor 30 minutes, close all valves and turn off vacuum

pump. If the system fails to reach specified vacuum,

the refrigerant system likely has a leak that must be

corrected. If the refrigerant system maintains speci-

fied vacuum for at least 30 minutes, start the vac-

uum pump, open the suction and discharge valves.

Then allow the system to evacuate an additional 10

minutes.

(4) Close all valves. Turn off and disconnect the

vacuum pump.

(5) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

STANDARD PROCEDURE - REFRIGERANT

SYSTEM CHARGE

WARNING: REVIEW SAFETY PRECAUTIONS AND

WARNINGS IN THIS GROUP BEFORE CHARGING

THE REFRIGERANT SYSTEM.

AVOID BREATHING A/C REFRIGERANT AND LUBRI-

CANT VAPOR OR MIST. EXPOSURE MAY IRRITATE

EYES, NOSE AND THROAT. USE ONLY APPROVED

SERVICE EQUIPMENT MEETING SAE REQUIRE-

MENTS TO DISCHARGE R-134a SYSTEM. IF ACCI-

DENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

R-134a SERVICE EQUIPMENT OR VEHICLE A/C

SYSTEM SHOULD NOT BE PRESSURE TESTED OR

LEAK TESTED WITH COMPRESSED AIR. MIXTURE

OF AIR and R-134a CAN BE COMBUSTIBLE AT ELE-

VATED PRESSURES. THESE MIXTURES ARE

POTENTIALLY DANGEROUS AND MAY RESULT IN

FIRE OR EXPLOSION CAUSING INJURY OR PROP-

ERTY DAMAGE.

CAUTION: Do not overcharge refrigerant system, as

excessive compressor head pressure can cause

noise and system failure.

CAUTION: A small amount of refrigerant oil is

removed from the A/C system each time the refrig-

erant system is recovered and evacuated. Before

charging the A/C system, you MUST replenish any

oil lost during the recovery process. Refer the

equipment manufacturer instructions for more infor-

mation.

The procedure below should be used to fill the

refrigerant charge in the air conditioning system.

This A/C system does not have or use a sight glass to

check or charge the system.

DRPLUMBING 24 - 47

PLUMBING (Continued)

Page 2535 of 2627

After the system has been tested for leaks and

evacuated, a refrigerant (R-134a) charge can be

injected into the system.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) If using a separate vacuum pump close all

valves before disconnecting pump. Connect manifold

gauge set to the A/C service ports.

NOTE: Always refer to the underhood HVAC Speci-

fication label for the refrigerant fill level of the vehi-

cle being serviced.

(2) Measure refrigerant (refer to capacities). Refer

to the instructions provided with the equipment

being used.

(3) Verify engine is shut off. Open the suction and

discharge valves. Open the charge valve to allow the

refrigerant to flow into the system. When the trans-

fer of refrigerant has stopped, close the suction and

discharge valve.

(4) If all of the charge did not transfer from the

dispensing device, put vehicle controls into the fol-

lowing mode:

²Automatic transmission in park or manual

transmission in neutral

²Engine at idle

²A/C mode control set to outside air

²A/C mode control set to panel mode

²A/C temperature control set to full cool

²Blower motor control set on highest speed

²Vehicle windows closed

If the A/C compressor does not engage, test the

compressor clutch control circuit and correct any fail-

ure (Refer to 8 - ELECTRICAL/WIRING DIAGRAM

INFORMATION - DIAGNOSIS AND TESTING).

(5) Open the suction valve to allow the remaining

refrigerant to transfer to the system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH-PRESSURE) VALVE AT THIS TIME.

(6) Close all valves and test the A/C system perfor-

mance.

(7) Disconnect the charging station or manifold

gauge set. Install the service port caps.

REFRIGERANT CHARGE CAPACITY

The R-134a refrigerant system charge capacity for

this vehicle can be found on the underhood HVAC

specfication tag.

A/C COMPRESSOR

DESCRIPTION

DESCRIPTION - A/C COMPRESSOR

The A/C system on models equipped with the 5.9L

engine use a Sanden SD-7 reciprocating swash plate-

type compressor. This compressor has a fixed dis-

placement of 165 cubic centimeter (10.068 cubic

inches) and has both the suction and discharge ports

located on the cylinder head.

The A/C system on models equipped with the 3.7L,

4.7L and 5.7L engines use a Denso 10S17 reciprocat-

ing swash plate-type compressor. This compressor

has a fixed displacement of 170 cubic centimeter and

has both the suction and discharge ports located on

the cylinder head.

A label identifying the use of R-134a refrigerant is

located on both A/C compressors.

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE

A high pressure relief valve is located on the com-

pressor cylinder head, which is on the rear of the

compressor. This mechanical valve is designed to

vent refrigerant from the system to protect against

damage to the compressor and other system compo-

nents, caused by condenser air flow restriction or an

overcharge of refrigerant.

OPERATION

OPERATION - A/C COMPRESSOR

The A/C compressor is driven by the engine

through an electric clutch, drive pulley and belt

arrangement. The compressor is lubricated by refrig-

erant oil that is circulated throughout the refrigerant

system with the refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor, which is then

pumped to the condenser through the compressor dis-

charge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley and clutch

coil are available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes

24 - 48 PLUMBINGDR

PLUMBING (Continued)

Page 2556 of 2627

designs. Useonlyrefrigerant oil of the same type as

recommended to service the refrigerant system

(always refer to the specification tagincluded

with the replacement A/C compressor or the under-

hood A/C system specification tag).

OPERATION

After performing any refrigerant recovery or recy-

cling operation, always replenish the refrigerant sys-

tem with the same amount of the recommended

refrigerant oil as was removed. Too little refrigerant

oil can cause compressor damage, and too much can

reduce air conditioning system performance.

PAG refrigerant oil is much more hygroscopic than

mineral oil, and will absorb any moisture it comes

into contact with, even moisture in the air. The PAG

oil container should always be kept tightly capped

until it is ready to be used. After use, recap the oil

container immediately to prevent moisture contami-

nation.

STANDARD PROCEDURE - REFRIGERANT OIL

LEVEL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

CAUTION: The refrigerant oil in the R-134a A/C sys-

tem is unique depending on the A/C compressor

used. Use only PAG oils that are designed to work

with R-134a refrigerant and the A/C compressor in

the vehicle. Always refer to the underhood A/C Sys-

tem Specification Label for the correct oil designa-

tion.

It is important to have the correct amount of lubri-

cant in the A/C refrigerant system to ensure proper

lubrication of the A/C compressor. Too little lubricant

will result in damage to the compressor. Too much

lubricant will reduce the cooling capacity of the A/C

system and consequently result in higher discharge

air temperatures.

The lubricant used in the compressor is polyalka-

lene glycol PAG lubricant. Only the refrigerant lubri-

cant approved for use with this vehicle should be

used to service the system. Do not use any other

lubricant. The lubricant container should be kept

tightly capped until it is ready for use. Refrigerant

lubricant will quickly absorb any moisture it comes

in contact with.

It will not be necessary to check the oil level in the

A/C compressor or to add oil, unless there has beenan oil loss. An oil loss may occur due to component

replacement, or a rupture or leak from a refrigerant

line, connector fitting, component or component seal.

If a leak occurs, add 30 milliliters (1 fluid ounce) of

the recommended refrigerant oil to the refrigerant

system after the repair has been made. Refrigerant

oil loss will be evident at the leak point by the pres-

ence of a wet, shiny surface around the leak.

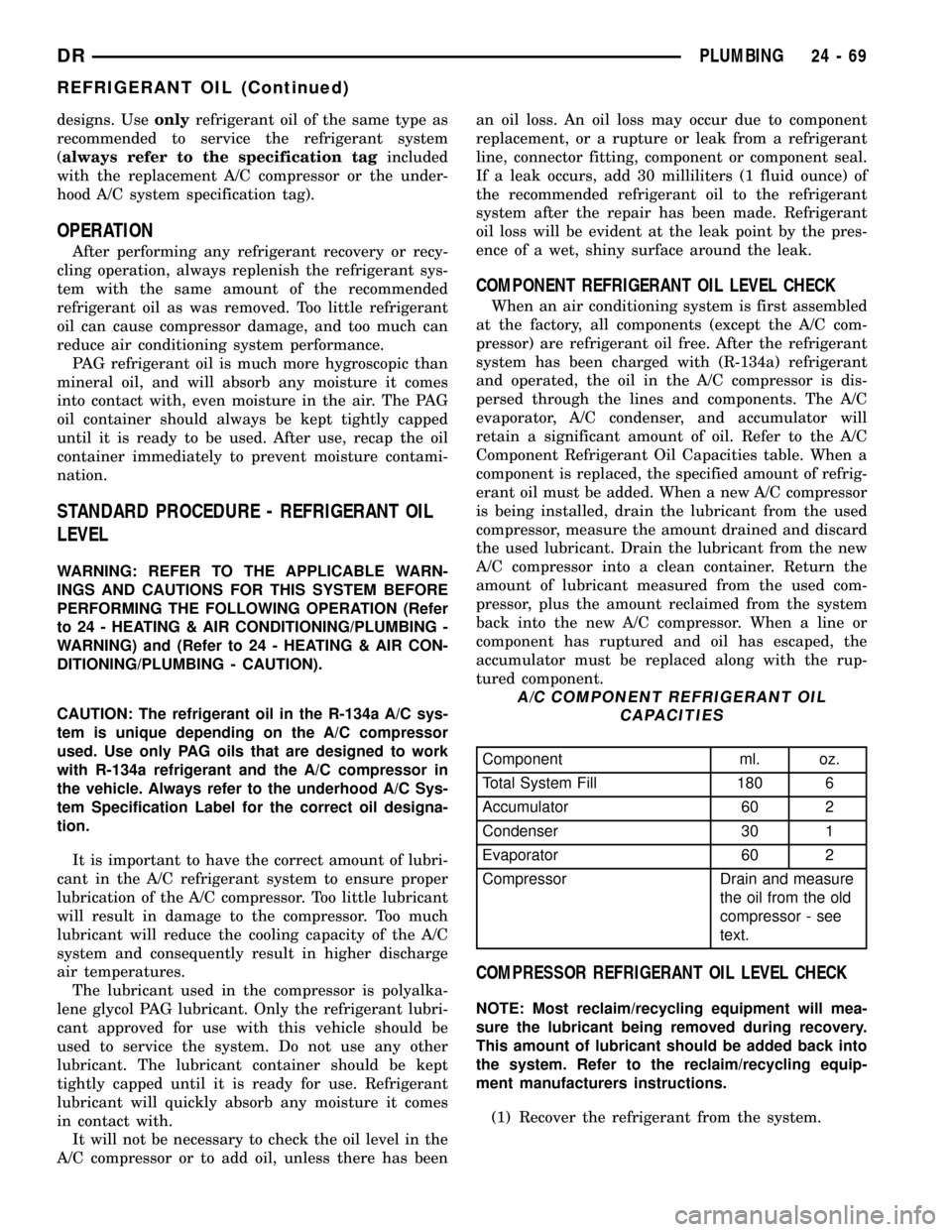

COMPONENT REFRIGERANT OIL LEVEL CHECK

When an air conditioning system is first assembled

at the factory, all components (except the A/C com-

pressor) are refrigerant oil free. After the refrigerant

system has been charged with (R-134a) refrigerant

and operated, the oil in the A/C compressor is dis-

persed through the lines and components. The A/C

evaporator, A/C condenser, and accumulator will

retain a significant amount of oil. Refer to the A/C

Component Refrigerant Oil Capacities table. When a

component is replaced, the specified amount of refrig-

erant oil must be added. When a new A/C compressor

is being installed, drain the lubricant from the used

compressor, measure the amount drained and discard

the used lubricant. Drain the lubricant from the new

A/C compressor into a clean container. Return the

amount of lubricant measured from the used com-

pressor, plus the amount reclaimed from the system

back into the new A/C compressor. When a line or

component has ruptured and oil has escaped, the

accumulator must be replaced along with the rup-

tured component.

A/C COMPONENT REFRIGERANT OIL

CAPACITIES

Component ml. oz.

Total System Fill 180 6

Accumulator 60 2

Condenser 30 1

Evaporator 60 2

Compressor Drain and measure

the oil from the old

compressor - see

text.

COMPRESSOR REFRIGERANT OIL LEVEL CHECK

NOTE: Most reclaim/recycling equipment will mea-

sure the lubricant being removed during recovery.

This amount of lubricant should be added back into

the system. Refer to the reclaim/recycling equip-

ment manufacturers instructions.

(1) Recover the refrigerant from the system.

DRPLUMBING 24 - 69

REFRIGERANT OIL (Continued)

Page 2599 of 2627

ENGINE COOLANT TEMPERATURE

SENSOR - REMOVAL...................7-39

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - DESCRIPTION...............7-44

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - INSTALLATION..............7-45

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - OPERATION.................7-44

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - REMOVAL..................7-45

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - DESCRIPTION................7-46

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - INSTALLATION................7-47

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - OPERATION..................7-46

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - REMOVAL....................7-47

ENGINE COOLANT THERMOSTAT - 8.0L -

DESCRIPTION........................7-48

ENGINE COOLANT THERMOSTAT - 8.0L -

INSTALLATION........................7-49

ENGINE COOLANT THERMOSTAT - 8.0L -

OPERATION..........................7-48

ENGINE COOLANT THERMOSTAT - 8.0L -

REMOVAL...........................7-49

ENGINE COOLANT THERMOSTAT-5.7L -

DESCRIPTION........................7-41

ENGINE COOLANT THERMOSTAT-5.7L -

INSTALLATION........................7-43

ENGINE COOLANT THERMOSTAT-5.7L -

OPERATION..........................7-41

ENGINE COOLANT THERMOSTAT-5.7L -

REMOVAL.............................7-42

ENGINE COOLING SYSTEM

REQUIREMENTS - DESCRIPTION.........24-1

ENGINE COOLING SYSTEM, WARNING....24-42

ENGINE DATA PLATE - DESCRIPTION.....9-248

ENGINE DIAGNOSIS - INTRODUCTION -

DIAGNOSIS AND TESTING......9-183,9-4,9-94

ENGINE DIAGNOSIS - LUBRICATION -

DIAGNOSIS AND TESTING..........9-187,9-7

ENGINE DIAGNOSIS - MECHANICAL -

DIAGNOSIS AND TESTING . . . 9-185,9-188,9-233,

9-6,9-92

ENGINE DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING......9-183,9-4,9-90

ENGINE FIRING ORDER, 3.7L V-6.........8I-4

ENGINE FIRING ORDER, 4.7L V-8.........8I-4

ENGINE GASKET SURFACE

PREPARATION - STANDARD

PROCEDURE.........................9-10

ENGINE OIL - DIESEL ENGINES -

DESCRIPTION.........................0-2

ENGINE OIL AND LUBRICANTS -

DESCRIPTION.........................0-1

ENGINE OIL LEAK - DIAGNOSIS AND

TESTING..................9-152,9-220,9-64

ENGINE OIL LEVEL - STANDARD

PROCEDURE........................9-292

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING.......................9-289

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING, CHECKING.....9-152,9-220,9-65

ENGINE OIL SERVICE - STANDARD

PROCEDURE..........9-153,9-222,9-292,9-71

ENGINE, SPECIAL TOOLS - 4.7L.........9-103

ENGINE, SPECIAL TOOLS - 5.7L.........9-196

ENGINE, SPECIAL TOOLS - 5.9L DIESEL . . 9-246

ENGINE, SPECIFICATIONS - 5.7L........9-192

ENGINE TEMPERATURE GAUGE -

DESCRIPTION.......................8J-24

ENGINE TEMPERATURE GAUGE -

OPERATION.........................8J-24

ENGINE TIMING - VERIFICATION -

STANDARD PROCEDURE...............9-167

ENGINES - CLEANING, RADIATOR FAN -

GAS................................7-34

ENGINES - DESCRIPTION, COOLANT

RECOVERY CONTAINER- GAS

............7-33

ENGINES - DESCRIPTION, ENGINE OIL -

DIESEL

..............................0-2

ENGINES - DESCRIPTION, FAN DRIVE

VISCOUS CLUTCH-GAS

.................7-50

ENGINES - INSPECTION, RADIATOR FAN

- GAS

...............................7-34

ENGINES - INSTALLATION, 3.7, 4.7 AND

5.7L

..........................24-53,24-55ENGINES - INSTALLATION, COOLANT

RECOVERY CONTAINER- GAS............7-33

ENGINES - INSTALLATION, RADIATOR

FAN - GAS...........................7-34

ENGINES - OPERATION, COOLANT

RECOVERY CONTAINER- GAS............7-33

ENGINES - OPERATION, FAN DRIVE

VISCOUS CLUTCH-GAS.................7-50

ENGINES - REMOVAL, 3.7, 4.7 AND 5.7L . 24-52,

24-55

ENGINES - REMOVAL, COOLANT

RECOVERY CONTAINER- GAS............7-33

ENGINES - REMOVAL, RADIATOR FAN -

GAS................................7-33

ENGINES - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM - ALL

GAS................................7-17

ENGINES - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM - ALL

GAS................................7-18

ENHANCED SEATBELT REMINDER

PROGRAMMING - STANDARD

PROCEDURE........................8J-35

ENTRY MODULE - DESCRIPTION,

REMOTE KEYLESS....................8N-7

ENTRY MODULE - DIAGNOSIS AND

TESTING, REMOTE KEYLESS............8N-7

ENTRY MODULE - INSTALLATION,

REMOTE KEYLESS....................8N-8

ENTRY MODULE - OPERATION, REMOTE

KEYLESS............................8N-7

ENTRY MODULE - REMOVAL, REMOTE

KEYLESS............................8N-7

ENTRY TRANSMITTER - DIAGNOSIS AND

TESTING, REMOTE KEYLESS..............8N-8

ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE KEYLESS......8N-9

EQUIPMENT - STANDARD PROCEDURE,

REFRIGERANT SYSTEM SERVICE........24-46

ERASING TRANSMITTER CODES -

STANDARD PROCEDURE..............8M-12

ETC INDICATOR - DESCRIPTION.........8J-25

ETC INDICATOR - OPERATION..........8J-25

EVACUATE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-47

EVAP SYSTEM - DESCRIPTION..........25-10

EVAP SYSTEM - TORQUE..............25-11

EVAPORATOR - DESCRIPTION, A/C.......24-59

EVAPORATOR - INSTALLATION, A/C......24-60

EVAPORATOR - OPERATION, A/C........24-59

EVAPORATOR - REMOVAL, A/C..........24-60

EVAPORATOR TEMPERATURE SENSOR -

DESCRIPTION.......................24-22

EVAPORATOR TEMPERATURE SENSOR -

INSTALLATION.......................24-22

EVAPORATOR TEMPERATURE SENSOR -

OPERATION.........................24-22

EVAPORATOR TEMPERATURE SENSOR -

REMOVAL..........................24-22

EVAP/PURGE SOLENOID - DESCRIPTION . . 25-12

EVAP/PURGE SOLENOID - INSTALLATION . 25-12

EVAP/PURGE SOLENOID - OPERATION....25-12

EVAP/PURGE SOLENOID - REMOVAL.....25-12

EXHAUST MANIFOLD - CLEANING . . 9-163,9-226,

9-298

EXHAUST MANIFOLD - DESCRIPTION....9-161,

9-226,9-74

EXHAUST MANIFOLD - INSPECTION.....9-163,

9-227,9-298

EXHAUST MANIFOLD - INSTALLATION . . . 9-164,

9-227,9-298,9-74

EXHAUST MANIFOLD - OPERATION......9-226

EXHAUST MANIFOLD - REMOVAL . . 9-161,9-226,

9-298,9-74

EXHAUST PIPE - INSPECTION.......11-7,11-8

EXTENSION HOUSING BUSHING AND

SEAL - INSTALLATION................21-440

EXTENSION HOUSING BUSHING AND

SEAL - REMOVAL

...................21-440

EXTENSION HOUSING SEAL -

INSTALLATION

. . . 21-128,21-201,21-507,21-536,

21-85

EXTENSION HOUSING SEAL - REMOVAL

. 21-128,

21-201,21-507,21-536,21-85

EXTENSION HOUSING SEAL AND DUST

BOOT - INSTALLATION

.........21-476,21-571

EXTENSION HOUSING SEAL AND DUST

BOOT - REMOVAL

.............21-476,21-571EXTERIOR - DESCRIPTION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR - DIAGNOSIS AND TESTING,

LAMPS/LIGHTING.....................8L-3

EXTERIOR - OPERATION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR HANDLE - INSTALLATION.....23-21,

23-30

EXTERIOR HANDLE - REMOVAL....23-20,23-30

EXTERIOR LAMPS, SPECIFICATIONS......8L-7

EXTERIOR NAME PLATES -

INSTALLATION.......................23-38

EXTERIOR NAME PLATES - REMOVAL....23-38

FAILURE - DIAGNOSIS AND TESTING,

CYLINDER HEAD GASKET..............9-199

FAN - 5.9L DIESEL - CLEANING,

RADIATOR...........................7-35

FAN - 5.9L DIESEL - INSPECTION,

RADIATOR...........................7-35

FAN - 5.9L DIESEL - INSTALLATION,

RADIATOR...........................7-36

FAN - 5.9L DIESEL - REMOVAL,

RADIATOR...........................7-35

FAN - GAS ENGINES - CLEANING,

RADIATOR...........................7-34

FAN - GAS ENGINES - INSPECTION,

RADIATOR...........................7-34

FAN - GAS ENGINES - INSTALLATION,

RADIATOR...........................7-34

FAN - GAS ENGINES - REMOVAL,

RADIATOR...........................7-33

FAN DRIVE - DIAGNOSIS AND TESTING,

ELECTRONICALLY CONTROLLED

VISCOUS............................7-52

FAN DRIVE - DIAGNOSIS AND TESTING,

VISCOUS............................7-50

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - DESCRIPTION................7-52

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - OPERATION..................7-52

FAN DRIVE VISCOUS CLUTCH-GAS

ENGINES - DESCRIPTION...............7-50

FAN DRIVE VISCOUS CLUTCH-GAS

ENGINES - OPERATION.................7-50

FASCIA - INSTALLATION, FRONT.........13-3

FASCIA - REMOVAL, FRONT.............13-2

FASTENER IDENTIFICATION -

DESCRIPTION......................Intro.-5

FASTENER USAGE - DESCRIPTION......Intro.-8

FENDER - INSTALLATION, FRONT........23-39

FENDER - INSTALLATION, REAR.........23-44

FENDER - REMOVAL, FRONT...........23-39

FENDER - REMOVAL, REAR............23-44

FENDER MARKER LAMP - INSTALLATION . 8L-18

FENDER MARKER LAMP - REMOVAL.....8L-17

FENDER RAIL REPAIR - STANDARD

PROCEDURE, HYDROFORM............13-11

FILL - STANDARD PROCEDURE,

TRANSMISSION...............21-204,21-368

FILL DOOR - INSTALLATION, FUEL.......23-39

FILL DOOR - REMOVAL, FUEL..........23-39

FILLER CAP - DESCRIPTION, FUEL.......25-13

FILLER CAP - OPERATION, FUEL........25-13

FILTER - INSTALLATION, INLET..........14-20

FILTER - INSTALLATION, OIL . 9-155,9-223,9-293,

9-70

FILTER - REMOVAL, INLET.............14-20

FILTER - REMOVAL, OIL . 9-154,9-223,9-293,9-70

FILTER - STANDARD PROCEDURES,

WATER DRAINING AT FUEL............14-47

FILTER / WATER SEPARATOR -

DESCRIPTION, FUEL..................14-50

FILTER / WATER SEPARATOR -

INSTALLATION, FUEL.................14-50

FILTER / WATER SEPARATOR -

OPERATION, FUEL....................14-50

FILTER / WATER SEPARATOR -

REMOVAL, FUEL.....................14-50

FILTER REPLACEMENT - STANDARD

PROCEDURE, FLUID

...........21-203,21-367

FILTER/PRESSURE REGULATOR -

DESCRIPTION, FUEL

...................14-5

FILTER/PRESSURE REGULATOR -

OPERATION, FUEL

.....................14-6

FINESSE SANDING/BUFFING &

POLISHING - DESCRIPTION

............23-74

FINISH - DESCRIPTION, BASECOAT/

CLEARCOAT

.........................23-73

12 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2613 of 2627

RAIL - DESCRIPTION, FUEL INJECTOR....14-78

RAIL - INSTALLATION, FUEL............14-15

RAIL - INSTALLATION, FUEL INJECTOR . . . 14-78

RAIL - OPERATION, FUEL..............14-12

RAIL - OPERATION, FUEL INJECTOR.....14-78

RAIL - REMOVAL, FUEL...............14-13

RAIL - REMOVAL, FUEL INJECTOR.......14-78

RAIL REPAIR - STANDARD PROCEDURE,

HYDROFORM FENDER.................13-11

RAIL TIP REPLACEMENT - STANDARD

PROCEDURE, LIGHT DUTY FRONT

FRAME..............................13-4

RAIL WEATHERSTRIP - INSTALLATION,

DRIP..............................23-91

RAIL WEATHERSTRIP - REMOVAL, DRIP . . 23-91

RAIL WEATHERSTRIP RETAINER -

INSTALLATION, DRIP.................23-92

RAIL WEATHERSTRIP RETAINER -

REMOVAL, DRIP.....................23-92

RANGE SENSOR - DESCRIPTION,

TRANSMISSION...............21-263,21-405

RANGE SENSOR - INSTALLATION,

TRANSMISSION.....................21-266

RANGE SENSOR - OPERATION,

TRANSMISSION...............21-263,21-405

RANGE SENSOR - REMOVAL,

TRANSMISSION.....................21-265

RANGE SENSOR (TRS) - DIAGNOSIS

AND TESTING, TRANSMISSION........21-264

RATINGS, SPECIFICATIONS -

GENERATOR........................8F-20

RE TRANSMISSION, SPECIAL TOOLS....21-191

READING LAMP - DESCRIPTION.........8L-28

READING LAMP - INSTALLATION........8L-29

READING LAMP - OPERATION..........8L-28

READING LAMP - REMOVAL............8L-28

READING/COURTESY LAMP

REPLACEMENT - STANDARD

PROCEDURE.........................8M-3

REAR AXLE - 10 1/2 AA -

ADJUSTMENTS......................3-116

REAR AXLE - 10 1/2 AA - DIAGNOSIS

AND TESTING.......................3-112

REAR AXLE - 10 1/2 AA - INSTALLATION . . 3-116

REAR AXLE - 10 1/2 AA - REMOVAL.....3-115

REAR AXLE - 10 1/2 AA - SPECIAL

TOOLS.............................3-120

REAR AXLE - 10 1/2 AA -

SPECIFICATIONS.....................3-120

REAR AXLE - 11 1/2 AA -

ADJUSTMENTS......................3-144

REAR AXLE - 11 1/2 AA - DIAGNOSIS

AND TESTING.......................3-140

REAR AXLE - 11 1/2 AA - INSTALLATION . . 3-144

REAR AXLE - 11 1/2 AA - REMOVAL.....3-143

REAR AXLE - 11 1/2 AA - SPECIAL

TOOLS.............................3-148

REAR AXLE - 11 1/2 AA -

SPECIFICATIONS.....................3-148

REAR AXLE - 9 1/4 - ADJUSTMENTS......3-83

REAR AXLE - 9 1/4 - DIAGNOSIS AND

TESTING............................3-80

REAR AXLE - 9 1/4 - INSTALLATION......3-83

REAR AXLE - 9 1/4 - REMOVAL..........3-83

REAR AXLE - 9 1/4 - SPECIAL TOOLS.....3-90

REAR AXLE - 9 1/4 - SPECIFICATIONS.....3-90

REAR BEARING - INSTALLATION,

OUTPUT SHAFT.....................21-217

REAR BEARING - REMOVAL, OUTPUT

SHAFT............................21-216

REAR BRAKE HOSE - INSTALLATION......5-12

REAR BRAKE HOSE - REMOVAL..........5-11

REAR BUMPER - INSTALLATION..........13-4

REAR BUMPER - REMOVAL.............13-3

REAR CAB BACK PANEL TRIM -

INSTALLATION.......................23-69

REAR CAB BACK PANEL TRIM -

REMOVAL..........................23-68

REAR CABLE - INSTALLATION, LEFT......5-39

REAR CABLE - INSTALLATION, RIGHT.....5-38

REAR CABLE - REMOVAL, LEFT..........5-38

REAR CABLE - REMOVAL, RIGHT

.........5-37

REAR CENTER SEAT BELT &

RETRACTOR - INSTALLATION

...........8O-45

REAR CENTER SEAT BELT &

RETRACTOR - REMOVAL

..............8O-44

REAR CLUTCH - ASSEMBLY

...........21-249

REAR CLUTCH - CLEANING

...........21-248REAR CLUTCH - DESCRIPTION.........21-247

REAR CLUTCH - DISASSEMBLY........21-248

REAR CLUTCH - INSPECTION..........21-248

REAR CLUTCH - OPERATION..........21-248

REAR DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION........23-93

REAR DOOR GLASS RUN

WEATHERSTRIP - REMOVAL............23-93

REAR DOOR INNER BELT MOLDING -

INSTALLATION.......................23-94

REAR DOOR INNER BELT MOLDING -

REMOVAL..........................23-94

REAR DOOR OUTER BELT MOLDING -

INSTALLATION.......................23-94

REAR DOOR OUTER BELT MOLDING -

REMOVAL..........................23-93

REAR DOOR SILL TRIM COVER -

INSTALLATION.......................23-71

REAR DOOR SILL TRIM COVER -

REMOVAL..........................23-71

REAR DRUM IN HAT BRAKE - CLEANING . . . 5-39

REAR DRUM IN HAT BRAKE -

INSPECTION.........................5-39

REAR DUAL WHEELS - INSTALLATION.....5-35

REAR DUAL WHEELS - REMOVAL........5-34

REAR FENDER - INSTALLATION.........23-44

REAR FENDER - REMOVAL.............23-44

REAR FRAME H-SECTION REPLACEMENT

- STANDARD PROCEDURE.............13-13

REAR MOUNT - INSTALLATION....9-149,9-220,

9-288,9-61

REAR MOUNT - REMOVAL . . . 9-149,9-220,9-288,

9-61

REAR OIL SEAL RETAINER -

INSTALLATION, CRANKSHAFT......9-210,9-277

REAR OIL SEAL RETAINER - REMOVAL,

CRANKSHAFT..................9-209,9-277

REAR OUTBOARD SEAT BELT &

RETRACTOR - INSTALLATION...........8O-47

REAR OUTBOARD SEAT BELT &

RETRACTOR - REMOVAL..............8O-46

REAR PARK BRAKE CABLE -

INSTALLATION........................5-38

REAR PARK BRAKE CABLE - REMOVAL....5-37

REAR PROPELLER SHAFT -

INSTALLATION.........................3-8

REAR PROPELLER SHAFT - REMOVAL......3-8

REAR SEAL AREA LEAKS - DIAGNOSIS

AND TESTING..............9-137,9-209,9-65

REAR SERVO - ASSEMBLY............21-251

REAR SERVO - CLEANING............21-251

REAR SERVO - DESCRIPTION..........21-251

REAR SERVO - DISASSEMBLY.........21-251

REAR SERVO - OPERATION...........21-251

REAR TUBE / HOSE ASSEMBLY -

INSTALLATION........................5-13

REAR TUBE / HOSE ASSEMBLY -

REMOVAL...........................5-12

REAR VIEW MIRROR - REMOVAL........23-69

REAR VIEW MIRROR SUPPORT

BRACKET - INSTALLATION.............23-70

REAR WHEEL ANTILOCK - DIAGNOSIS

AND TESTING

........................5-48

REAR WHEEL INSTALLATION -

STANDARD PROCEDURE, DUAL

.........22-12

REAR WHEEL SPEED SENSOR -

DIAGNOSIS AND TESTING

..............5-49

REAR WHEEL SPEED SENSOR -

INSTALLATION

........................5-48

REAR WHEEL SPEED SENSOR -

REMOVAL

...........................5-48

REAR WHEELHOUSE SPLASH SHIELD -

INSTALLATION

.......................23-41

REAR WHEELHOUSE SPLASH SHIELD -

REMOVAL

..........................23-41

REAR WINDOW DEFOGGER RELAY -

DESCRIPTION

........................8G-2

REAR WINDOW DEFOGGER RELAY -

INSTALLATION

.......................8G-4

REAR WINDOW DEFOGGER RELAY -

OPERATION

..........................8G-3

REAR WINDOW DEFOGGER RELAY -

REMOVAL

...........................8G-3

REAR WINDOW DEFOGGER SWITCH -

DESCRIPTION

........................8G-4

REAR WINDOW DEFOGGER SWITCH -

OPERATION

..........................8G-4REAR WINDOW DEFOGGER SYSTEM -

DIAGNOSIS AND TESTING..............8G-2

RECEIVER - INSTALLATION, ASH........23-51

RECEIVER - REMOVAL, ASH............23-50

RECIRCULATION DOOR - INSTALLATION . . 24-40

RECIRCULATION DOOR - REMOVAL......24-39

RECIRCULATION DOOR ACTUATOR -

DESCRIPTION.......................24-24

RECIRCULATION DOOR ACTUATOR -

INSTALLATION.......................24-25

RECIRCULATION DOOR ACTUATOR -

OPERATION.........................24-24

RECIRCULATION DOOR ACTUATOR -

REMOVAL..........................24-24

RECOVERY - STANDARD PROCEDURE,

REFRIGERANT.......................24-47

RECOVERY CONTAINER- GAS ENGINES -

DESCRIPTION, COOLANT...............7-33

RECOVERY CONTAINER- GAS ENGINES -

INSTALLATION, COOLANT...............7-33

RECOVERY CONTAINER- GAS ENGINES -

OPERATION, COOLANT.................7-33

RECOVERY CONTAINER- GAS ENGINES -

REMOVAL, COOLANT..................7-33

REDUCER - DESCRIPTION, SEAT BELT

TENSION...........................8O-53

REDUCER - DIAGNOSIS AND TESTING,

SEAT BELT TENSION..................8O-54

REDUCER - OPERATION, SEAT BELT

TENSION...........................8O-54

REFACING - STANDARD PROCEDURE . 9-202,9-28

REFACING - STANDARD PROCEDURE,

CYLINDER BLOCK....................9-264

REFILLING COOLING SYSTEM - ALL GAS

ENGINES - STANDARD PROCEDURE......7-18

REFILLING COOLING SYSTEM 5.9L

DIESEL ENGINE - STANDARD

PROCEDURE.........................7-19

REFRIGERANT - DESCRIPTION..........24-67

REFRIGERANT - OPERATION............24-67

REFRIGERANT LINE - DESCRIPTION......24-42

REFRIGERANT LINE COUPLER -

DESCRIPTION.......................24-67

REFRIGERANT LINE COUPLER -

INSTALLATION.......................24-68

REFRIGERANT LINE COUPLER -

OPERATION.........................24-67

REFRIGERANT LINE COUPLER -

REMOVAL..........................24-68

REFRIGERANT LINES - OPERATION......24-42

REFRIGERANT OIL - DESCRIPTION......24-68

REFRIGERANT OIL - OPERATION........24-69

REFRIGERANT OIL LEVEL - STANDARD

PROCEDURE........................24-69

REFRIGERANT RECOVERY - STANDARD

PROCEDURE........................24-47

REFRIGERANT SYSTEM CHARGE -

STANDARD PROCEDURE...............24-47

REFRIGERANT SYSTEM EVACUATE -

STANDARD PROCEDURE...............24-47

REFRIGERANT SYSTEM LEAKS -

DIAGNOSIS AND TESTING.............24-44

REFRIGERANT SYSTEM SERVICE

EQUIPMENT - STANDARD PROCEDURE . . . 24-46

REGULATOR - DESCRIPTION, FUEL

FILTER/PRESSURE.....................14-5

REGULATOR - DESCRIPTION, VOLTAGE . . . 8F-25

REGULATOR - MANUAL - INSTALLATION,

WINDOW......................23-27,23-35

REGULATOR - MANUAL - REMOVAL,

WINDOW......................23-26,23-35

REGULATOR - OPERATION, FUEL

FILTER/PRESSURE.....................14-6

REGULATOR - OPERATION, VOLTAGE.....8F-25

REGULATOR - POWER - INSTALLATION,

WINDOW......................23-26,23-34

REGULATOR - POWER - REMOVAL,

WINDOW......................23-25,23-34

RELAY - DESCRIPTION, A/C

COMPRESSOR CLUTCH...............24-13

RELAY - DESCRIPTION, FOG LAMP......8L-12

RELAY - DESCRIPTION, FUEL HEATER

....14-52

RELAY - DESCRIPTION, FUEL PUMP

.....14-27

RELAY - DESCRIPTION, INTAKE AIR

HEATER

............................14-82

RELAY - DESCRIPTION, PARK LAMP

.....8L-20

RELAY - DESCRIPTION, REAR WINDOW

DEFOGGER

..........................8G-2

26 INDEXDR

Description Group-Page Description Group-Page Description Group-Page