Body DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 255 of 2627

ADJUSTABLE PEDAL SWITCH

REMOVAL

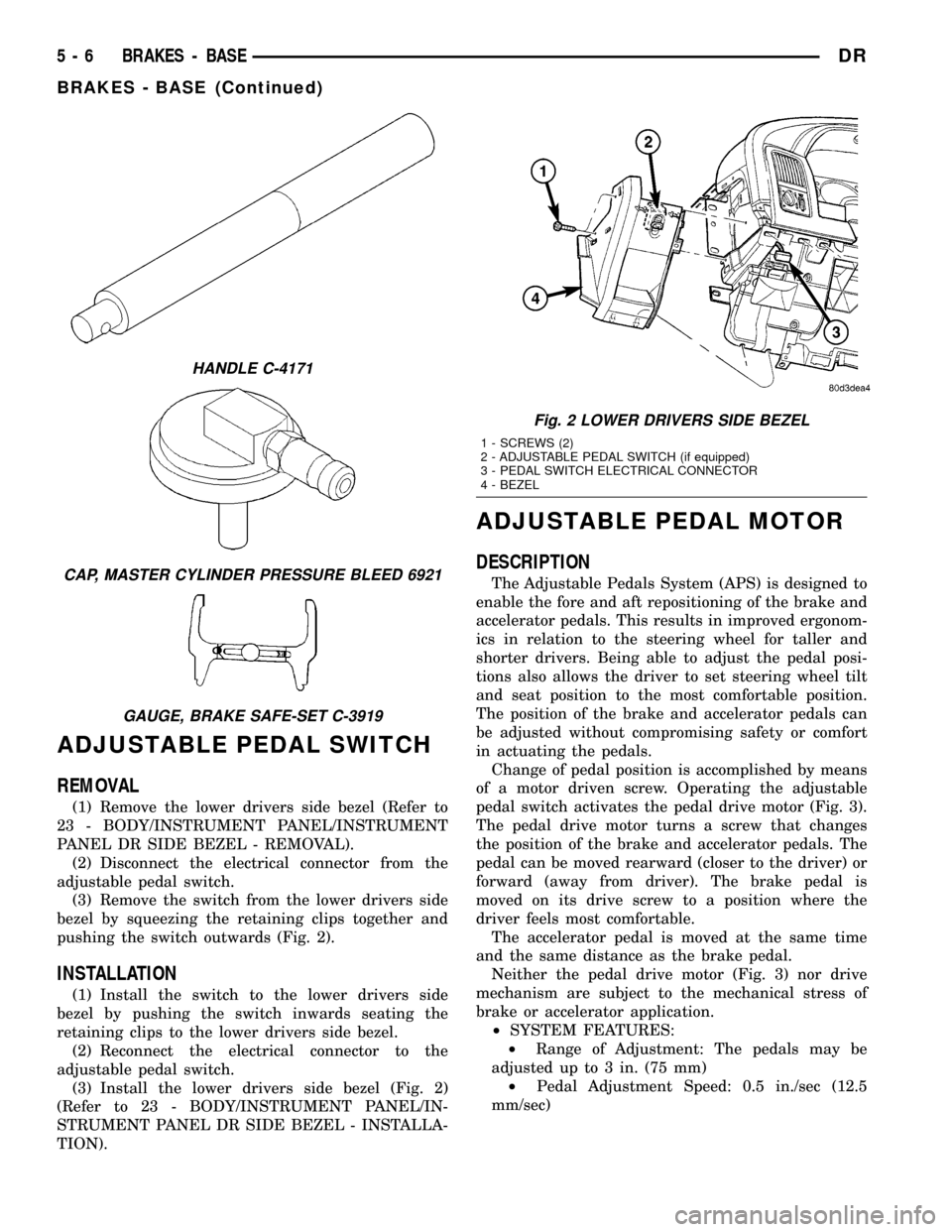

(1) Remove the lower drivers side bezel (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL DR SIDE BEZEL - REMOVAL).

(2) Disconnect the electrical connector from the

adjustable pedal switch.

(3) Remove the switch from the lower drivers side

bezel by squeezing the retaining clips together and

pushing the switch outwards (Fig. 2).

INSTALLATION

(1) Install the switch to the lower drivers side

bezel by pushing the switch inwards seating the

retaining clips to the lower drivers side bezel.

(2) Reconnect the electrical connector to the

adjustable pedal switch.

(3) Install the lower drivers side bezel (Fig. 2)

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL DR SIDE BEZEL - INSTALLA-

TION).

ADJUSTABLE PEDAL MOTOR

DESCRIPTION

The Adjustable Pedals System (APS) is designed to

enable the fore and aft repositioning of the brake and

accelerator pedals. This results in improved ergonom-

ics in relation to the steering wheel for taller and

shorter drivers. Being able to adjust the pedal posi-

tions also allows the driver to set steering wheel tilt

and seat position to the most comfortable position.

The position of the brake and accelerator pedals can

be adjusted without compromising safety or comfort

in actuating the pedals.

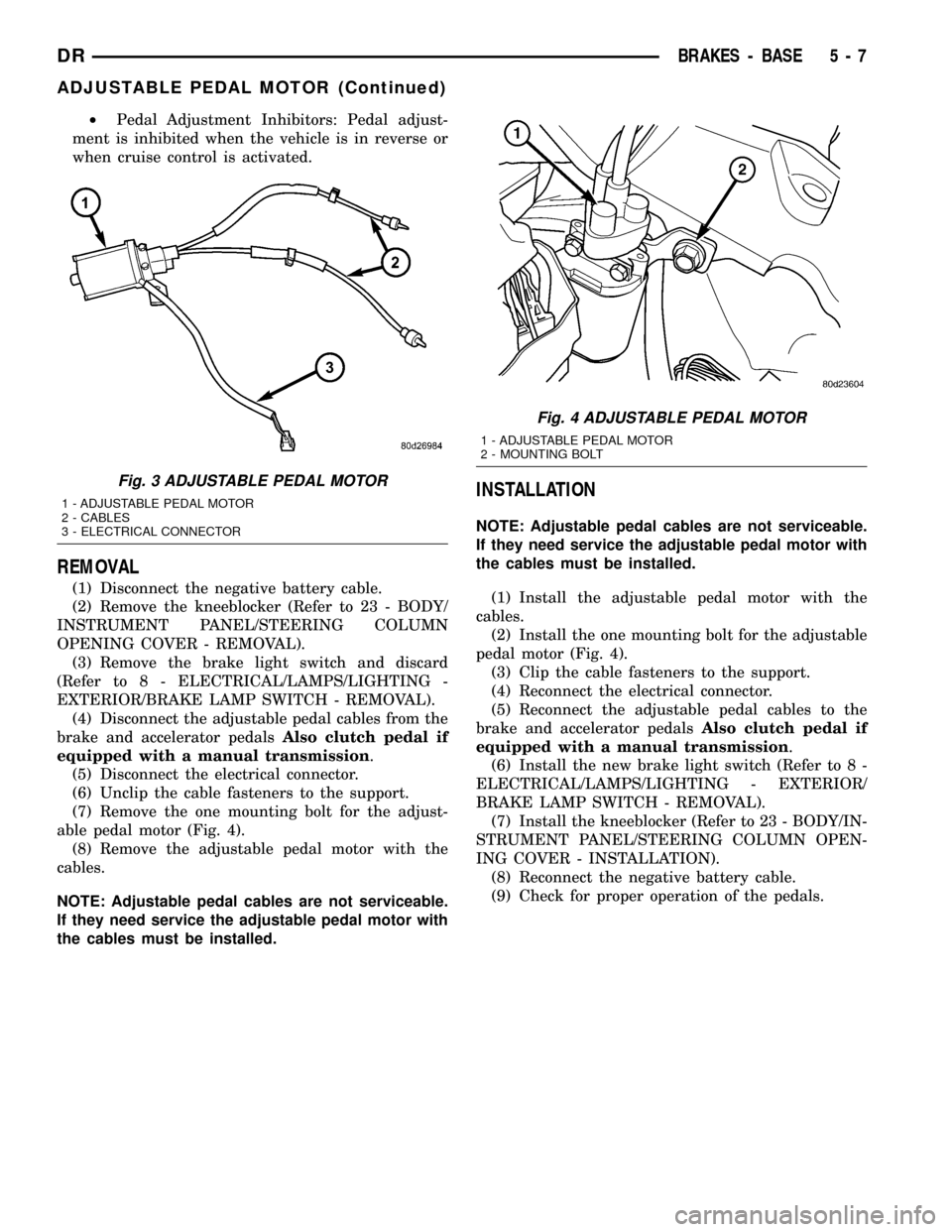

Change of pedal position is accomplished by means

of a motor driven screw. Operating the adjustable

pedal switch activates the pedal drive motor (Fig. 3).

The pedal drive motor turns a screw that changes

the position of the brake and accelerator pedals. The

pedal can be moved rearward (closer to the driver) or

forward (away from driver). The brake pedal is

moved on its drive screw to a position where the

driver feels most comfortable.

The accelerator pedal is moved at the same time

and the same distance as the brake pedal.

Neither the pedal drive motor (Fig. 3) nor drive

mechanism are subject to the mechanical stress of

brake or accelerator application.

²SYSTEM FEATURES:

²Range of Adjustment: The pedals may be

adjusted up to 3 in. (75 mm)

²Pedal Adjustment Speed: 0.5 in./sec (12.5

mm/sec)

HANDLE C-4171

CAP, MASTER CYLINDER PRESSURE BLEED 6921

GAUGE, BRAKE SAFE-SET C-3919

Fig. 2 LOWER DRIVERS SIDE BEZEL

1 - SCREWS (2)

2 - ADJUSTABLE PEDAL SWITCH (if equipped)

3 - PEDAL SWITCH ELECTRICAL CONNECTOR

4 - BEZEL

5 - 6 BRAKES - BASEDR

BRAKES - BASE (Continued)

Page 256 of 2627

²Pedal Adjustment Inhibitors: Pedal adjust-

ment is inhibited when the vehicle is in reverse or

when cruise control is activated.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the kneeblocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(3) Remove the brake light switch and discard

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/BRAKE LAMP SWITCH - REMOVAL).

(4) Disconnect the adjustable pedal cables from the

brake and accelerator pedalsAlso clutch pedal if

equipped with a manual transmission.

(5) Disconnect the electrical connector.

(6) Unclip the cable fasteners to the support.

(7) Remove the one mounting bolt for the adjust-

able pedal motor (Fig. 4).

(8) Remove the adjustable pedal motor with the

cables.

NOTE: Adjustable pedal cables are not serviceable.

If they need service the adjustable pedal motor with

the cables must be installed.

INSTALLATION

NOTE: Adjustable pedal cables are not serviceable.

If they need service the adjustable pedal motor with

the cables must be installed.

(1) Install the adjustable pedal motor with the

cables.

(2) Install the one mounting bolt for the adjustable

pedal motor (Fig. 4).

(3) Clip the cable fasteners to the support.

(4) Reconnect the electrical connector.

(5) Reconnect the adjustable pedal cables to the

brake and accelerator pedalsAlso clutch pedal if

equipped with a manual transmission.

(6) Install the new brake light switch (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL).

(7) Install the kneeblocker (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(8) Reconnect the negative battery cable.

(9) Check for proper operation of the pedals.

Fig. 3 ADJUSTABLE PEDAL MOTOR

1 - ADJUSTABLE PEDAL MOTOR

2 - CABLES

3 - ELECTRICAL CONNECTOR

Fig. 4 ADJUSTABLE PEDAL MOTOR

1 - ADJUSTABLE PEDAL MOTOR

2 - MOUNTING BOLT

DRBRAKES - BASE 5 - 7

ADJUSTABLE PEDAL MOTOR (Continued)

Page 273 of 2627

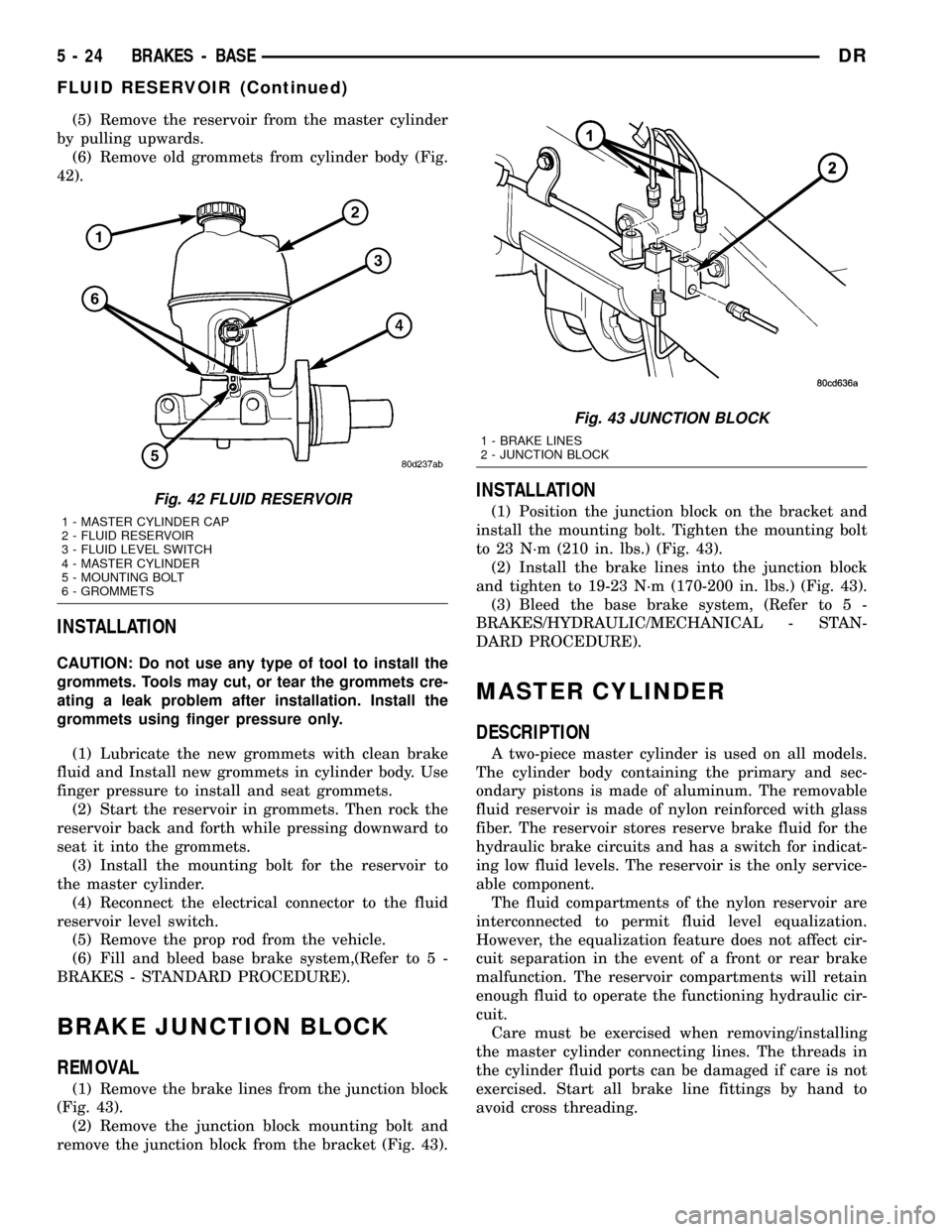

(5) Remove the reservoir from the master cylinder

by pulling upwards.

(6) Remove old grommets from cylinder body (Fig.

42).

INSTALLATION

CAUTION: Do not use any type of tool to install the

grommets. Tools may cut, or tear the grommets cre-

ating a leak problem after installation. Install the

grommets using finger pressure only.

(1) Lubricate the new grommets with clean brake

fluid and Install new grommets in cylinder body. Use

finger pressure to install and seat grommets.

(2) Start the reservoir in grommets. Then rock the

reservoir back and forth while pressing downward to

seat it into the grommets.

(3) Install the mounting bolt for the reservoir to

the master cylinder.

(4) Reconnect the electrical connector to the fluid

reservoir level switch.

(5) Remove the prop rod from the vehicle.

(6) Fill and bleed base brake system,(Refer to 5 -

BRAKES - STANDARD PROCEDURE).

BRAKE JUNCTION BLOCK

REMOVAL

(1) Remove the brake lines from the junction block

(Fig. 43).

(2) Remove the junction block mounting bolt and

remove the junction block from the bracket (Fig. 43).

INSTALLATION

(1) Position the junction block on the bracket and

install the mounting bolt. Tighten the mounting bolt

to 23 N´m (210 in. lbs.) (Fig. 43).

(2) Install the brake lines into the junction block

and tighten to 19-23 N´m (170-200 in. lbs.) (Fig. 43).

(3) Bleed the base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

MASTER CYLINDER

DESCRIPTION

A two-piece master cylinder is used on all models.

The cylinder body containing the primary and sec-

ondary pistons is made of aluminum. The removable

fluid reservoir is made of nylon reinforced with glass

fiber. The reservoir stores reserve brake fluid for the

hydraulic brake circuits and has a switch for indicat-

ing low fluid levels. The reservoir is the only service-

able component.

The fluid compartments of the nylon reservoir are

interconnected to permit fluid level equalization.

However, the equalization feature does not affect cir-

cuit separation in the event of a front or rear brake

malfunction. The reservoir compartments will retain

enough fluid to operate the functioning hydraulic cir-

cuit.

Care must be exercised when removing/installing

the master cylinder connecting lines. The threads in

the cylinder fluid ports can be damaged if care is not

exercised. Start all brake line fittings by hand to

avoid cross threading.

Fig. 42 FLUID RESERVOIR

1 - MASTER CYLINDER CAP

2 - FLUID RESERVOIR

3 - FLUID LEVEL SWITCH

4 - MASTER CYLINDER

5 - MOUNTING BOLT

6 - GROMMETS

Fig. 43 JUNCTION BLOCK

1 - BRAKE LINES

2 - JUNCTION BLOCK

5 - 24 BRAKES - BASEDR

FLUID RESERVOIR (Continued)

Page 274 of 2627

The cylinder reservoir can be replaced when neces-

sary. However, the aluminum body section of the

master cylinder is not a repairable component.

NOTE: If diagnosis indicates that an internal mal-

function has occurred, the aluminum body section

must be replaced as an assembly.

OPERATION

The master cylinder bore contains a primary and

secondary piston. The primary piston supplies

hydraulic pressure to the front brakes. The secondary

piston supplies hydraulic pressure to the rear brakes.

DIAGNOSIS AND TESTING - MASTER

CYLINDER/POWER BOOSTER

(1) Start engine and check booster vacuum hose

connections. A hissing noise indicates vacuum leak.

Correct any vacuum leak before proceeding.

(2) Stop engine and shift transmission into Neu-

tral.

(3) Pump brake pedal until all vacuum reserve in

booster is depleted.

(4) Press and hold brake pedal under light foot

pressure. The pedal should hold firm, if the pedal

falls away master cylinder is faulty (internal leak-

age).

(5) Start engine and note pedal action. It should

fall away slightly under light foot pressure then hold

firm. If no pedal action is discernible, power booster,

vacuum supply, or vacuum check valve is faulty. Pro-

ceed to the POWER BOOSTER VACUUM TEST.

(6) If the POWER BOOSTER VACUUM TEST

passes, rebuild booster vacuum reserve as follows:

Release brake pedal. Increase engine speed to 1500

rpm, close the throttle and immediately turn off igni-

tion to stop engine.

(7) Wait a minimum of 90 seconds and try brake

action again. Booster should provide two or more vac-

uum assisted pedal applications. If vacuum assist is

not provided, booster is faulty.

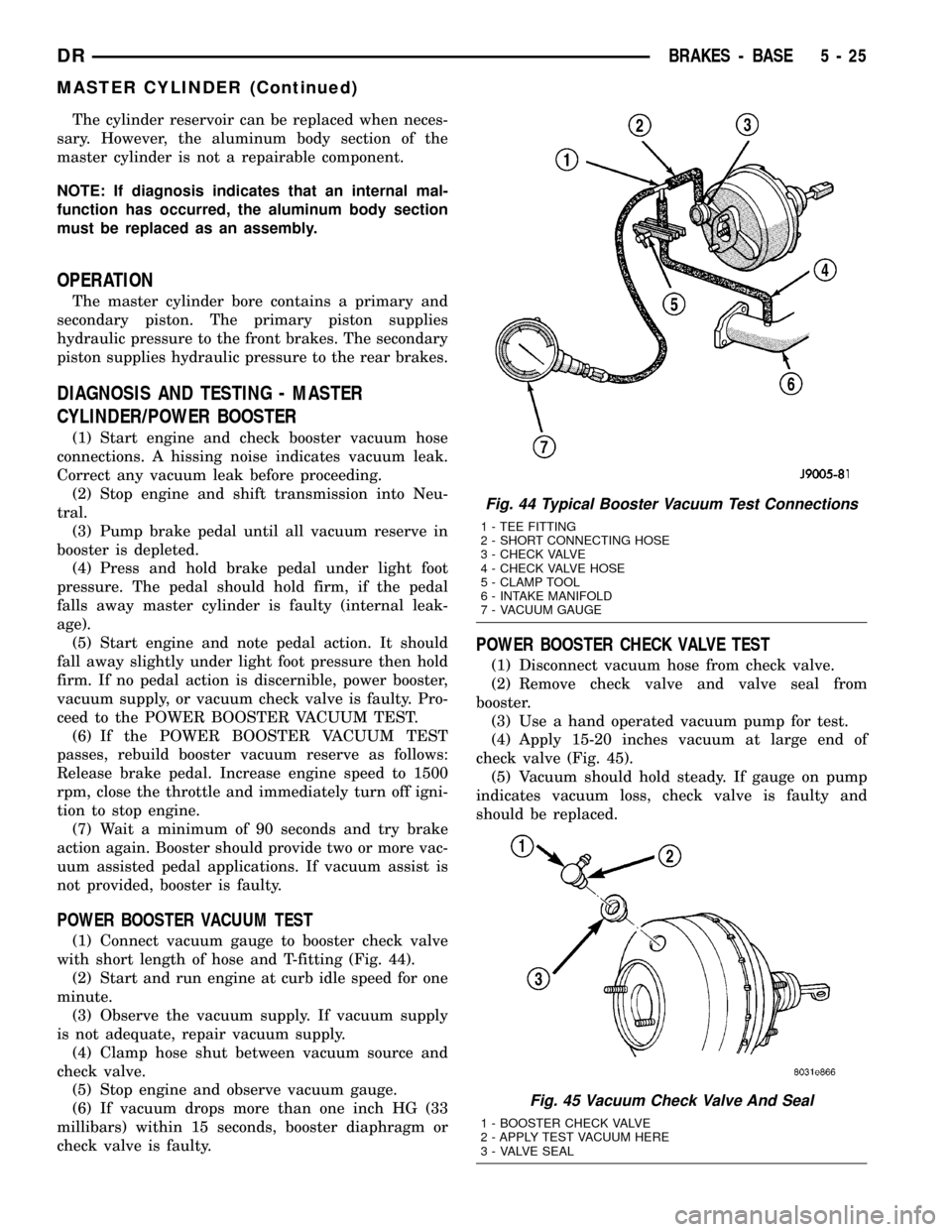

POWER BOOSTER VACUUM TEST

(1) Connect vacuum gauge to booster check valve

with short length of hose and T-fitting (Fig. 44).

(2) Start and run engine at curb idle speed for one

minute.

(3) Observe the vacuum supply. If vacuum supply

is not adequate, repair vacuum supply.

(4) Clamp hose shut between vacuum source and

check valve.

(5) Stop engine and observe vacuum gauge.

(6) If vacuum drops more than one inch HG (33

millibars) within 15 seconds, booster diaphragm or

check valve is faulty.

POWER BOOSTER CHECK VALVE TEST

(1) Disconnect vacuum hose from check valve.

(2) Remove check valve and valve seal from

booster.

(3) Use a hand operated vacuum pump for test.

(4) Apply 15-20 inches vacuum at large end of

check valve (Fig. 45).

(5) Vacuum should hold steady. If gauge on pump

indicates vacuum loss, check valve is faulty and

should be replaced.

Fig. 44 Typical Booster Vacuum Test Connections

1 - TEE FITTING

2 - SHORT CONNECTING HOSE

3 - CHECK VALVE

4 - CHECK VALVE HOSE

5 - CLAMP TOOL

6 - INTAKE MANIFOLD

7 - VACUUM GAUGE

Fig. 45 Vacuum Check Valve And Seal

1 - BOOSTER CHECK VALVE

2 - APPLY TEST VACUUM HERE

3 - VALVE SEAL

DRBRAKES - BASE 5 - 25

MASTER CYLINDER (Continued)

Page 277 of 2627

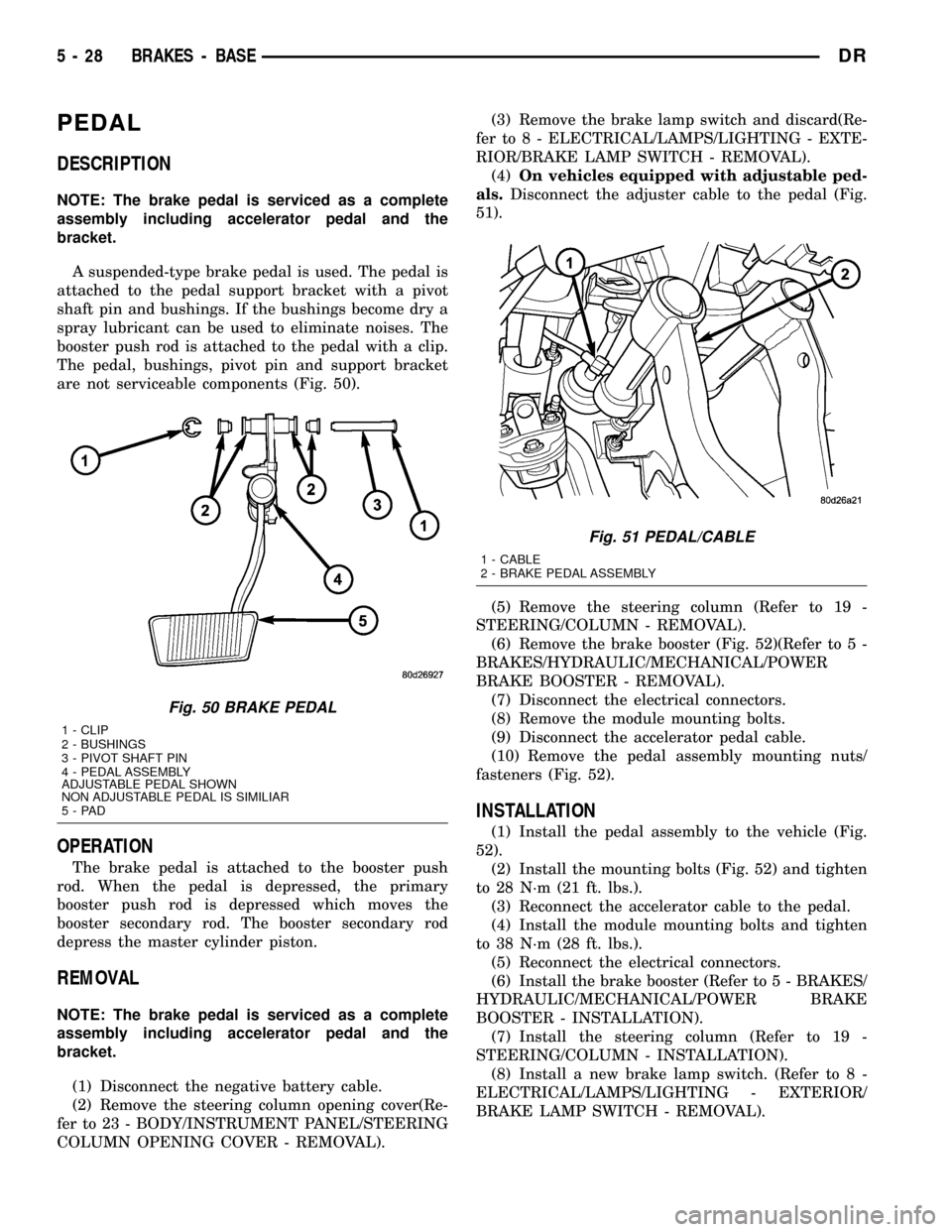

PEDAL

DESCRIPTION

NOTE: The brake pedal is serviced as a complete

assembly including accelerator pedal and the

bracket.

A suspended-type brake pedal is used. The pedal is

attached to the pedal support bracket with a pivot

shaft pin and bushings. If the bushings become dry a

spray lubricant can be used to eliminate noises. The

booster push rod is attached to the pedal with a clip.

The pedal, bushings, pivot pin and support bracket

are not serviceable components (Fig. 50).

OPERATION

The brake pedal is attached to the booster push

rod. When the pedal is depressed, the primary

booster push rod is depressed which moves the

booster secondary rod. The booster secondary rod

depress the master cylinder piston.

REMOVAL

NOTE: The brake pedal is serviced as a complete

assembly including accelerator pedal and the

bracket.

(1) Disconnect the negative battery cable.

(2) Remove the steering column opening cover(Re-

fer to 23 - BODY/INSTRUMENT PANEL/STEERING

COLUMN OPENING COVER - REMOVAL).(3) Remove the brake lamp switch and discard(Re-

fer to 8 - ELECTRICAL/LAMPS/LIGHTING - EXTE-

RIOR/BRAKE LAMP SWITCH - REMOVAL).

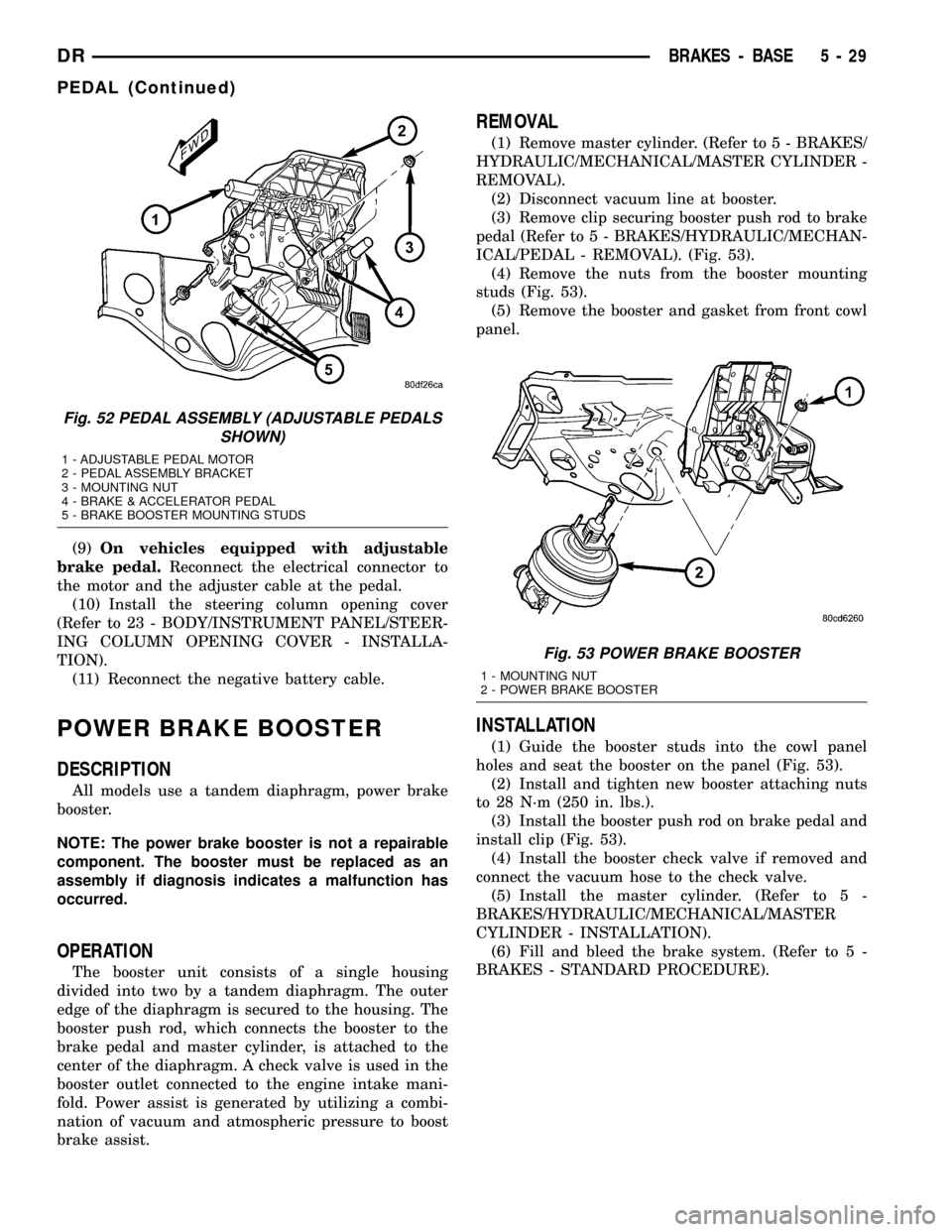

(4)On vehicles equipped with adjustable ped-

als.Disconnect the adjuster cable to the pedal (Fig.

51).

(5) Remove the steering column (Refer to 19 -

STEERING/COLUMN - REMOVAL).

(6) Remove the brake booster (Fig. 52)(Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/POWER

BRAKE BOOSTER - REMOVAL).

(7) Disconnect the electrical connectors.

(8) Remove the module mounting bolts.

(9) Disconnect the accelerator pedal cable.

(10) Remove the pedal assembly mounting nuts/

fasteners (Fig. 52).

INSTALLATION

(1) Install the pedal assembly to the vehicle (Fig.

52).

(2) Install the mounting bolts (Fig. 52) and tighten

to 28 N´m (21 ft. lbs.).

(3) Reconnect the accelerator cable to the pedal.

(4) Install the module mounting bolts and tighten

to 38 N´m (28 ft. lbs.).

(5) Reconnect the electrical connectors.

(6) Install the brake booster (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/POWER BRAKE

BOOSTER - INSTALLATION).

(7) Install the steering column (Refer to 19 -

STEERING/COLUMN - INSTALLATION).

(8) Install a new brake lamp switch. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL).

Fig. 50 BRAKE PEDAL

1 - CLIP

2 - BUSHINGS

3 - PIVOT SHAFT PIN

4 - PEDAL ASSEMBLY

ADJUSTABLE PEDAL SHOWN

NON ADJUSTABLE PEDAL IS SIMILIAR

5-PAD

Fig. 51 PEDAL/CABLE

1 - CABLE

2 - BRAKE PEDAL ASSEMBLY

5 - 28 BRAKES - BASEDR

Page 278 of 2627

(9)On vehicles equipped with adjustable

brake pedal.Reconnect the electrical connector to

the motor and the adjuster cable at the pedal.

(10) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(11) Reconnect the negative battery cable.

POWER BRAKE BOOSTER

DESCRIPTION

All models use a tandem diaphragm, power brake

booster.

NOTE: The power brake booster is not a repairable

component. The booster must be replaced as an

assembly if diagnosis indicates a malfunction has

occurred.

OPERATION

The booster unit consists of a single housing

divided into two by a tandem diaphragm. The outer

edge of the diaphragm is secured to the housing. The

booster push rod, which connects the booster to the

brake pedal and master cylinder, is attached to the

center of the diaphragm. A check valve is used in the

booster outlet connected to the engine intake mani-

fold. Power assist is generated by utilizing a combi-

nation of vacuum and atmospheric pressure to boost

brake assist.

REMOVAL

(1) Remove master cylinder. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/MASTER CYLINDER -

REMOVAL).

(2) Disconnect vacuum line at booster.

(3) Remove clip securing booster push rod to brake

pedal (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/PEDAL - REMOVAL). (Fig. 53).

(4) Remove the nuts from the booster mounting

studs (Fig. 53).

(5) Remove the booster and gasket from front cowl

panel.

INSTALLATION

(1) Guide the booster studs into the cowl panel

holes and seat the booster on the panel (Fig. 53).

(2) Install and tighten new booster attaching nuts

to 28 N´m (250 in. lbs.).

(3) Install the booster push rod on brake pedal and

install clip (Fig. 53).

(4) Install the booster check valve if removed and

connect the vacuum hose to the check valve.

(5) Install the master cylinder. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/MASTER

CYLINDER - INSTALLATION).

(6) Fill and bleed the brake system. (Refer to 5 -

BRAKES - STANDARD PROCEDURE).

Fig. 52 PEDAL ASSEMBLY (ADJUSTABLE PEDALS

SHOWN)

1 - ADJUSTABLE PEDAL MOTOR

2 - PEDAL ASSEMBLY BRACKET

3 - MOUNTING NUT

4 - BRAKE & ACCELERATOR PEDAL

5 - BRAKE BOOSTER MOUNTING STUDS

Fig. 53 POWER BRAKE BOOSTER

1 - MOUNTING NUT

2 - POWER BRAKE BOOSTER

DRBRAKES - BASE 5 - 29

PEDAL (Continued)

Page 286 of 2627

(5) Compress cable end fitting at underbody

bracket and remove the cable from the bracket.

(6) Lower vehicle.

(7) Push ball end of cable out of pedal clevis with

small screwdriver.

(8) Compress cable end fitting at the pedal bracket

and remove the cable (Fig. 68).

(9) Remove the left cowl trim and sill plate.

(10) Pull up the carpet and remove the cable from

the body clip.

(11) Pull up on the cable and remove the cable

with the body grommet.

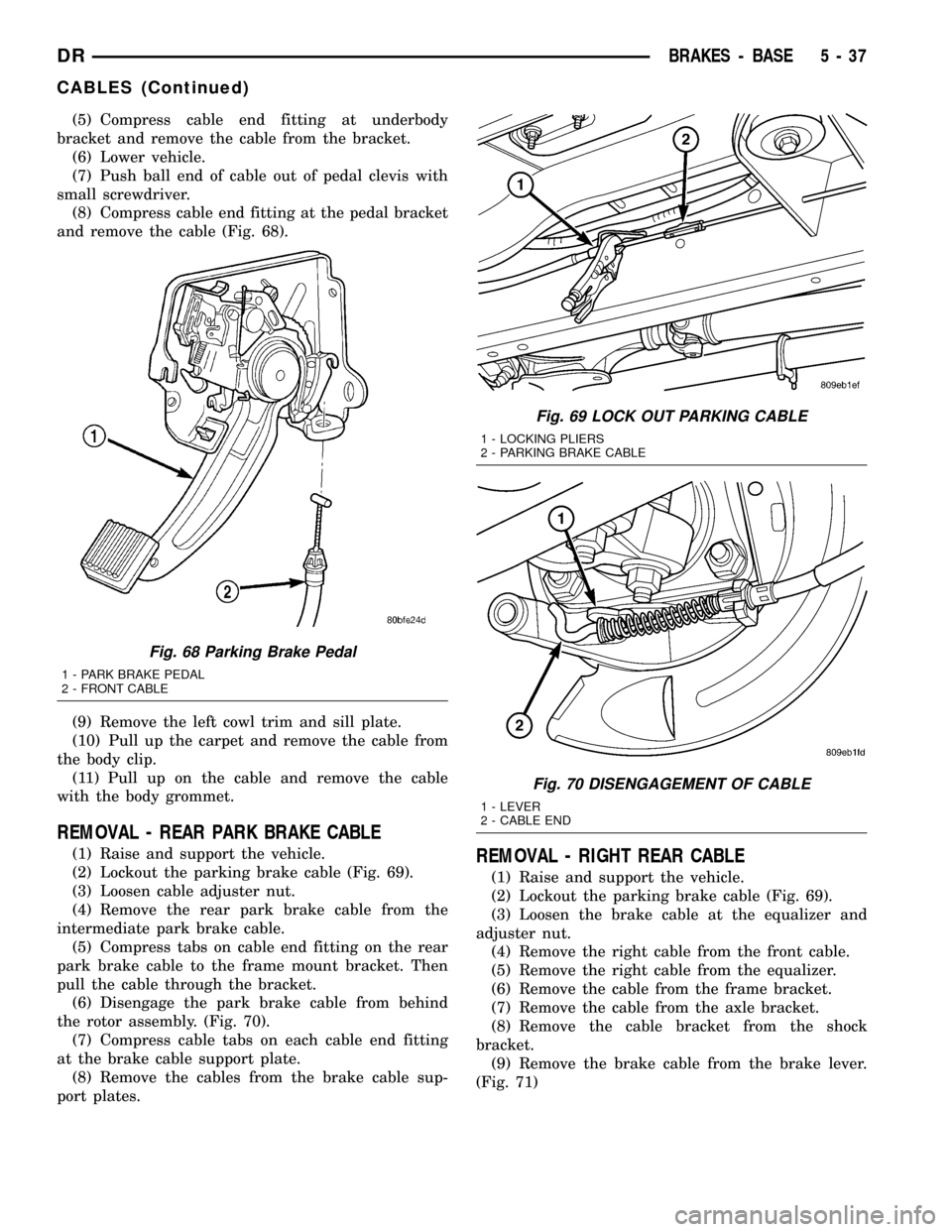

REMOVAL - REAR PARK BRAKE CABLE

(1) Raise and support the vehicle.

(2) Lockout the parking brake cable (Fig. 69).

(3) Loosen cable adjuster nut.

(4) Remove the rear park brake cable from the

intermediate park brake cable.

(5) Compress tabs on cable end fitting on the rear

park brake cable to the frame mount bracket. Then

pull the cable through the bracket.

(6) Disengage the park brake cable from behind

the rotor assembly. (Fig. 70).

(7) Compress cable tabs on each cable end fitting

at the brake cable support plate.

(8) Remove the cables from the brake cable sup-

port plates.REMOVAL - RIGHT REAR CABLE

(1) Raise and support the vehicle.

(2) Lockout the parking brake cable (Fig. 69).

(3) Loosen the brake cable at the equalizer and

adjuster nut.

(4) Remove the right cable from the front cable.

(5) Remove the right cable from the equalizer.

(6) Remove the cable from the frame bracket.

(7) Remove the cable from the axle bracket.

(8) Remove the cable bracket from the shock

bracket.

(9) Remove the brake cable from the brake lever.

(Fig. 71)

Fig. 68 Parking Brake Pedal

1 - PARK BRAKE PEDAL

2 - FRONT CABLE

Fig. 69 LOCK OUT PARKING CABLE

1 - LOCKING PLIERS

2 - PARKING BRAKE CABLE

Fig. 70 DISENGAGEMENT OF CABLE

1 - LEVER

2 - CABLE END

DRBRAKES - BASE 5 - 37

CABLES (Continued)

Page 287 of 2627

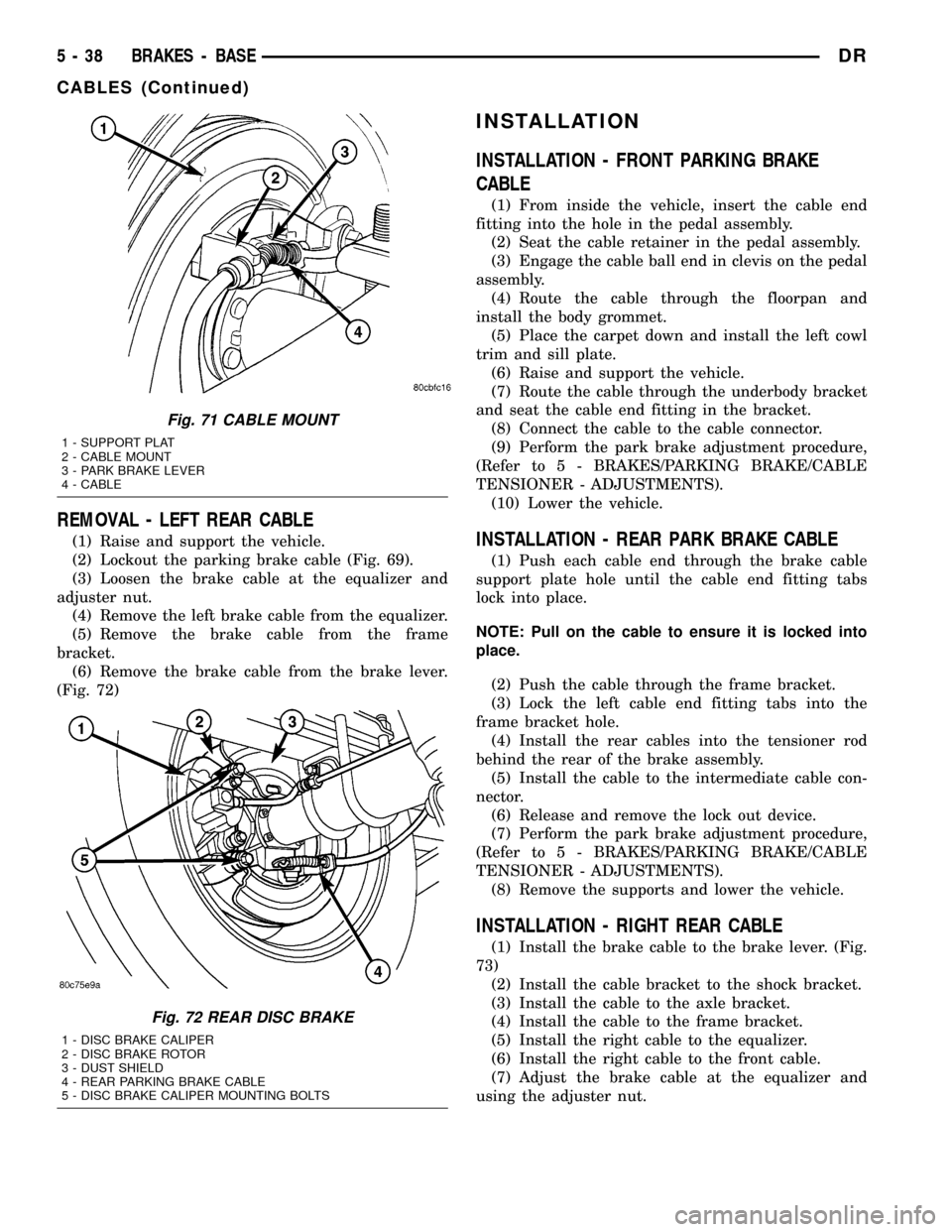

REMOVAL - LEFT REAR CABLE

(1) Raise and support the vehicle.

(2) Lockout the parking brake cable (Fig. 69).

(3) Loosen the brake cable at the equalizer and

adjuster nut.

(4) Remove the left brake cable from the equalizer.

(5) Remove the brake cable from the frame

bracket.

(6) Remove the brake cable from the brake lever.

(Fig. 72)

INSTALLATION

INSTALLATION - FRONT PARKING BRAKE

CABLE

(1) From inside the vehicle, insert the cable end

fitting into the hole in the pedal assembly.

(2) Seat the cable retainer in the pedal assembly.

(3) Engage the cable ball end in clevis on the pedal

assembly.

(4) Route the cable through the floorpan and

install the body grommet.

(5) Place the carpet down and install the left cowl

trim and sill plate.

(6) Raise and support the vehicle.

(7) Route the cable through the underbody bracket

and seat the cable end fitting in the bracket.

(8) Connect the cable to the cable connector.

(9) Perform the park brake adjustment procedure,

(Refer to 5 - BRAKES/PARKING BRAKE/CABLE

TENSIONER - ADJUSTMENTS).

(10) Lower the vehicle.

INSTALLATION - REAR PARK BRAKE CABLE

(1) Push each cable end through the brake cable

support plate hole until the cable end fitting tabs

lock into place.

NOTE: Pull on the cable to ensure it is locked into

place.

(2) Push the cable through the frame bracket.

(3) Lock the left cable end fitting tabs into the

frame bracket hole.

(4) Install the rear cables into the tensioner rod

behind the rear of the brake assembly.

(5) Install the cable to the intermediate cable con-

nector.

(6) Release and remove the lock out device.

(7) Perform the park brake adjustment procedure,

(Refer to 5 - BRAKES/PARKING BRAKE/CABLE

TENSIONER - ADJUSTMENTS).

(8) Remove the supports and lower the vehicle.

INSTALLATION - RIGHT REAR CABLE

(1) Install the brake cable to the brake lever. (Fig.

73)

(2) Install the cable bracket to the shock bracket.

(3) Install the cable to the axle bracket.

(4) Install the cable to the frame bracket.

(5) Install the right cable to the equalizer.

(6) Install the right cable to the front cable.

(7) Adjust the brake cable at the equalizer and

using the adjuster nut.

Fig. 71 CABLE MOUNT

1 - SUPPORT PLAT

2 - CABLE MOUNT

3 - PARK BRAKE LEVER

4 - CABLE

Fig. 72 REAR DISC BRAKE

1 - DISC BRAKE CALIPER

2 - DISC BRAKE ROTOR

3 - DUST SHIELD

4 - REAR PARKING BRAKE CABLE

5 - DISC BRAKE CALIPER MOUNTING BOLTS

5 - 38 BRAKES - BASEDR

CABLES (Continued)

Page 291 of 2627

(12) Rotate rotor to verify that the park brake

shoes are not dragging on the brake drum. If park

brake shoes are dragging, remove rotor and back off

star wheel adjuster one notch and recheck for brake

shoe drag against drum. Continue with the previous

step until brake shoes are not dragging on brake

drum.

(13) Install disc brake caliper on caliper adapter

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

DISC BRAKE CALIPERS - INSTALLATION).

(14) Install wheel and tire.

(15) Tighten the wheel mounting nuts in the

proper sequence until all nuts are torqued to half the

specified torque. Then repeat the tightening sequence

to the full specified torque of 180 N´m (135 ft. lbs.)

1500 & 2500 Series or 195 N´m (145 ft. lbs.) 3500

Series.

(16) Lower vehicle.

(17) Apply and release the park brake pedal one

time. This will seat and correctly adjust the park

brake cables.

CAUTION: Before moving vehicle, pump brake

pedal several times to ensure the vehicle has a firm

enough pedal to stop the vehicle.

NOTE: On a new vehicle or after parking brake lin-

ing replacement, it is recommended that the park-

ing brake system be conditioned prior to use. This

is done by making one stop from 25 mph on dry

pavement or concrete using light to moderate force

on the parking brake foot pedal.

(18) Road test the vehicle to ensure proper func-

tion of the vehicle's brake system.

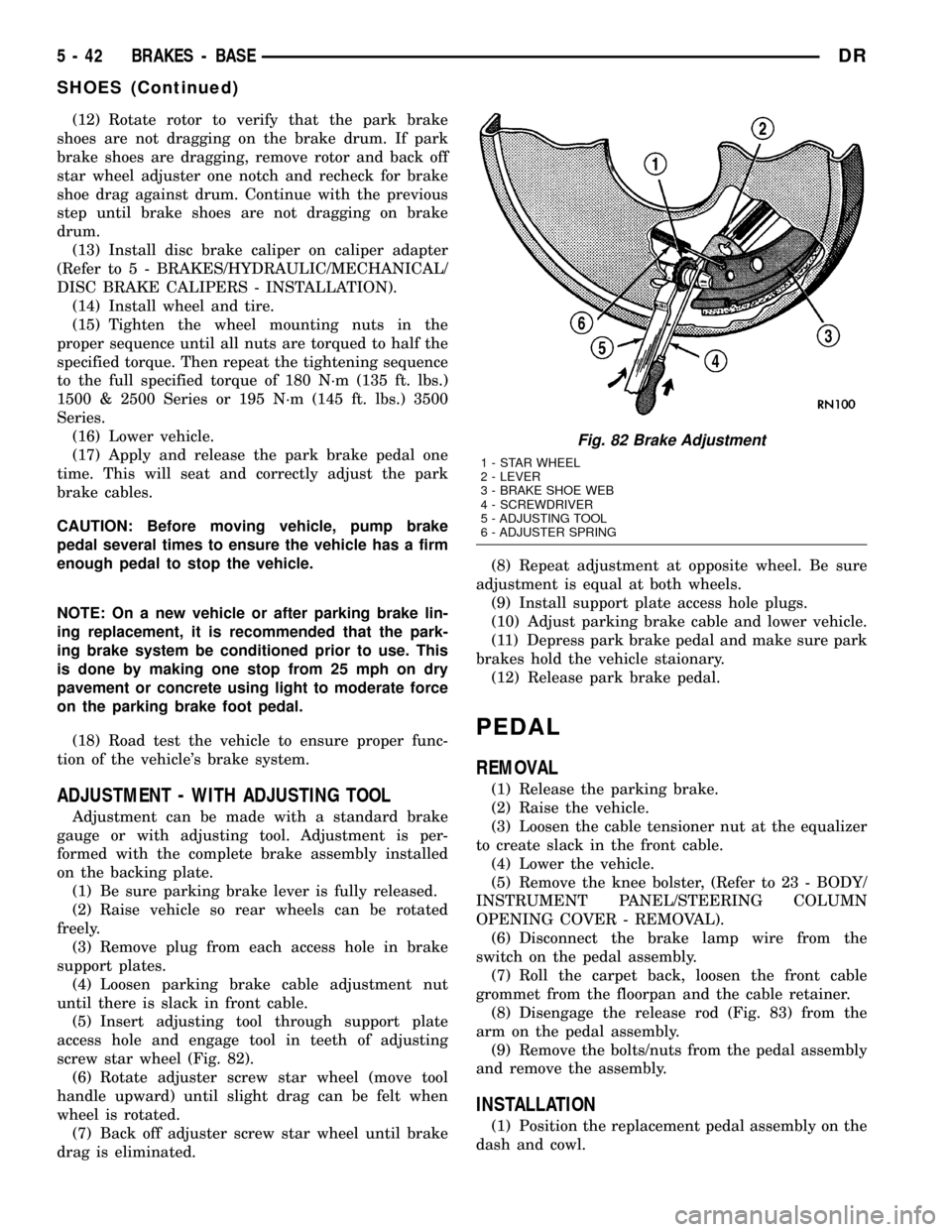

ADJUSTMENT - WITH ADJUSTING TOOL

Adjustment can be made with a standard brake

gauge or with adjusting tool. Adjustment is per-

formed with the complete brake assembly installed

on the backing plate.

(1) Be sure parking brake lever is fully released.

(2) Raise vehicle so rear wheels can be rotated

freely.

(3) Remove plug from each access hole in brake

support plates.

(4) Loosen parking brake cable adjustment nut

until there is slack in front cable.

(5) Insert adjusting tool through support plate

access hole and engage tool in teeth of adjusting

screw star wheel (Fig. 82).

(6) Rotate adjuster screw star wheel (move tool

handle upward) until slight drag can be felt when

wheel is rotated.

(7) Back off adjuster screw star wheel until brake

drag is eliminated.(8) Repeat adjustment at opposite wheel. Be sure

adjustment is equal at both wheels.

(9) Install support plate access hole plugs.

(10) Adjust parking brake cable and lower vehicle.

(11) Depress park brake pedal and make sure park

brakes hold the vehicle staionary.

(12) Release park brake pedal.

PEDAL

REMOVAL

(1) Release the parking brake.

(2) Raise the vehicle.

(3) Loosen the cable tensioner nut at the equalizer

to create slack in the front cable.

(4) Lower the vehicle.

(5) Remove the knee bolster, (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(6) Disconnect the brake lamp wire from the

switch on the pedal assembly.

(7) Roll the carpet back, loosen the front cable

grommet from the floorpan and the cable retainer.

(8) Disengage the release rod (Fig. 83) from the

arm on the pedal assembly.

(9) Remove the bolts/nuts from the pedal assembly

and remove the assembly.

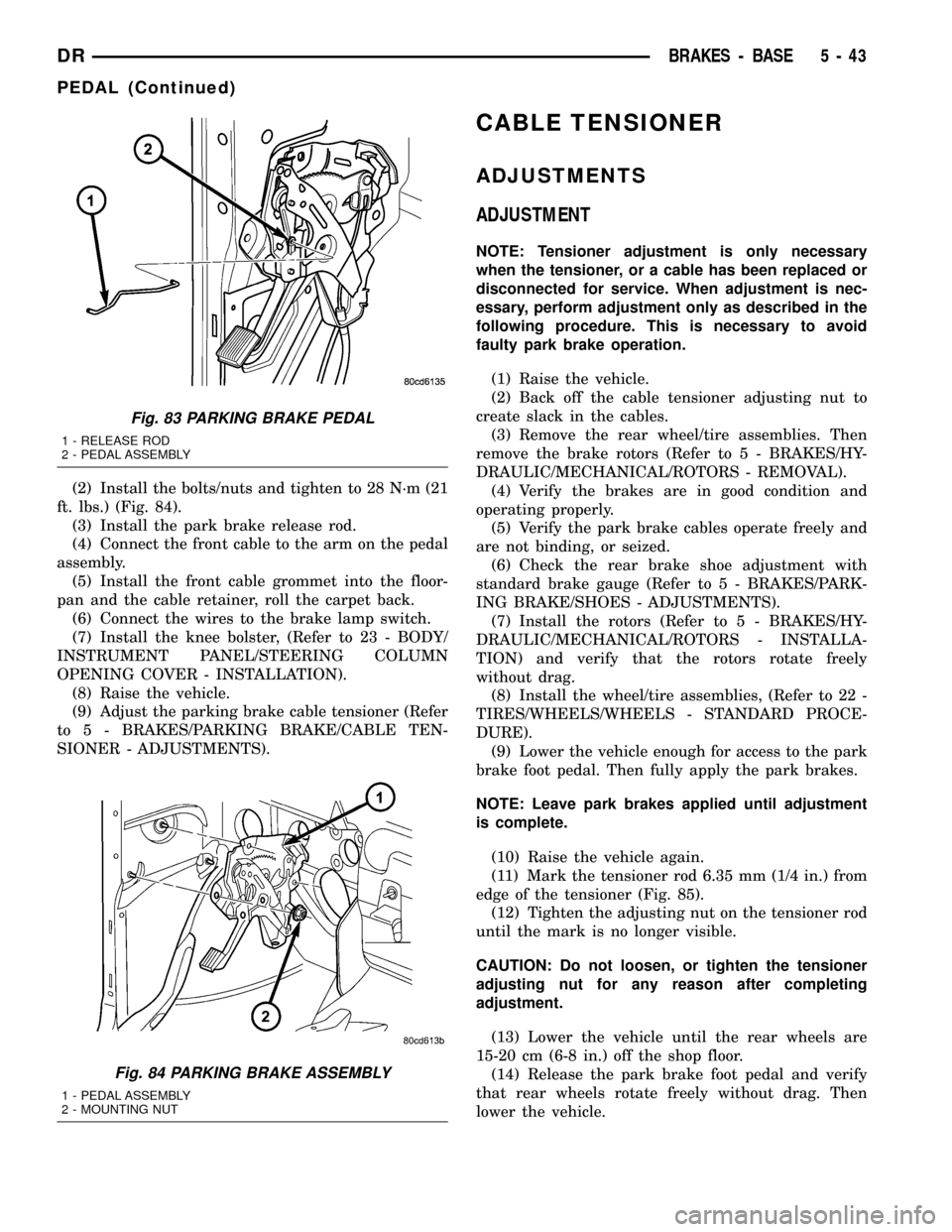

INSTALLATION

(1) Position the replacement pedal assembly on the

dash and cowl.

Fig. 82 Brake Adjustment

1 - STAR WHEEL

2 - LEVER

3 - BRAKE SHOE WEB

4 - SCREWDRIVER

5 - ADJUSTING TOOL

6 - ADJUSTER SPRING

5 - 42 BRAKES - BASEDR

SHOES (Continued)

Page 292 of 2627

(2) Install the bolts/nuts and tighten to 28 N´m (21

ft. lbs.) (Fig. 84).

(3) Install the park brake release rod.

(4) Connect the front cable to the arm on the pedal

assembly.

(5) Install the front cable grommet into the floor-

pan and the cable retainer, roll the carpet back.

(6) Connect the wires to the brake lamp switch.

(7) Install the knee bolster, (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - INSTALLATION).

(8) Raise the vehicle.

(9) Adjust the parking brake cable tensioner (Refer

to 5 - BRAKES/PARKING BRAKE/CABLE TEN-

SIONER - ADJUSTMENTS).

CABLE TENSIONER

ADJUSTMENTS

ADJUSTMENT

NOTE: Tensioner adjustment is only necessary

when the tensioner, or a cable has been replaced or

disconnected for service. When adjustment is nec-

essary, perform adjustment only as described in the

following procedure. This is necessary to avoid

faulty park brake operation.

(1) Raise the vehicle.

(2) Back off the cable tensioner adjusting nut to

create slack in the cables.

(3) Remove the rear wheel/tire assemblies. Then

remove the brake rotors (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - REMOVAL).

(4) Verify the brakes are in good condition and

operating properly.

(5) Verify the park brake cables operate freely and

are not binding, or seized.

(6) Check the rear brake shoe adjustment with

standard brake gauge (Refer to 5 - BRAKES/PARK-

ING BRAKE/SHOES - ADJUSTMENTS).

(7) Install the rotors (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION) and verify that the rotors rotate freely

without drag.

(8) Install the wheel/tire assemblies, (Refer to 22 -

TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(9) Lower the vehicle enough for access to the park

brake foot pedal. Then fully apply the park brakes.

NOTE: Leave park brakes applied until adjustment

is complete.

(10) Raise the vehicle again.

(11) Mark the tensioner rod 6.35 mm (1/4 in.) from

edge of the tensioner (Fig. 85).

(12) Tighten the adjusting nut on the tensioner rod

until the mark is no longer visible.

CAUTION: Do not loosen, or tighten the tensioner

adjusting nut for any reason after completing

adjustment.

(13) Lower the vehicle until the rear wheels are

15-20 cm (6-8 in.) off the shop floor.

(14) Release the park brake foot pedal and verify

that rear wheels rotate freely without drag. Then

lower the vehicle.

Fig. 83 PARKING BRAKE PEDAL

1 - RELEASE ROD

2 - PEDAL ASSEMBLY

Fig. 84 PARKING BRAKE ASSEMBLY

1 - PEDAL ASSEMBLY

2 - MOUNTING NUT

DRBRAKES - BASE 5 - 43

PEDAL (Continued)