Head gasket DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1233 of 2627

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier than using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

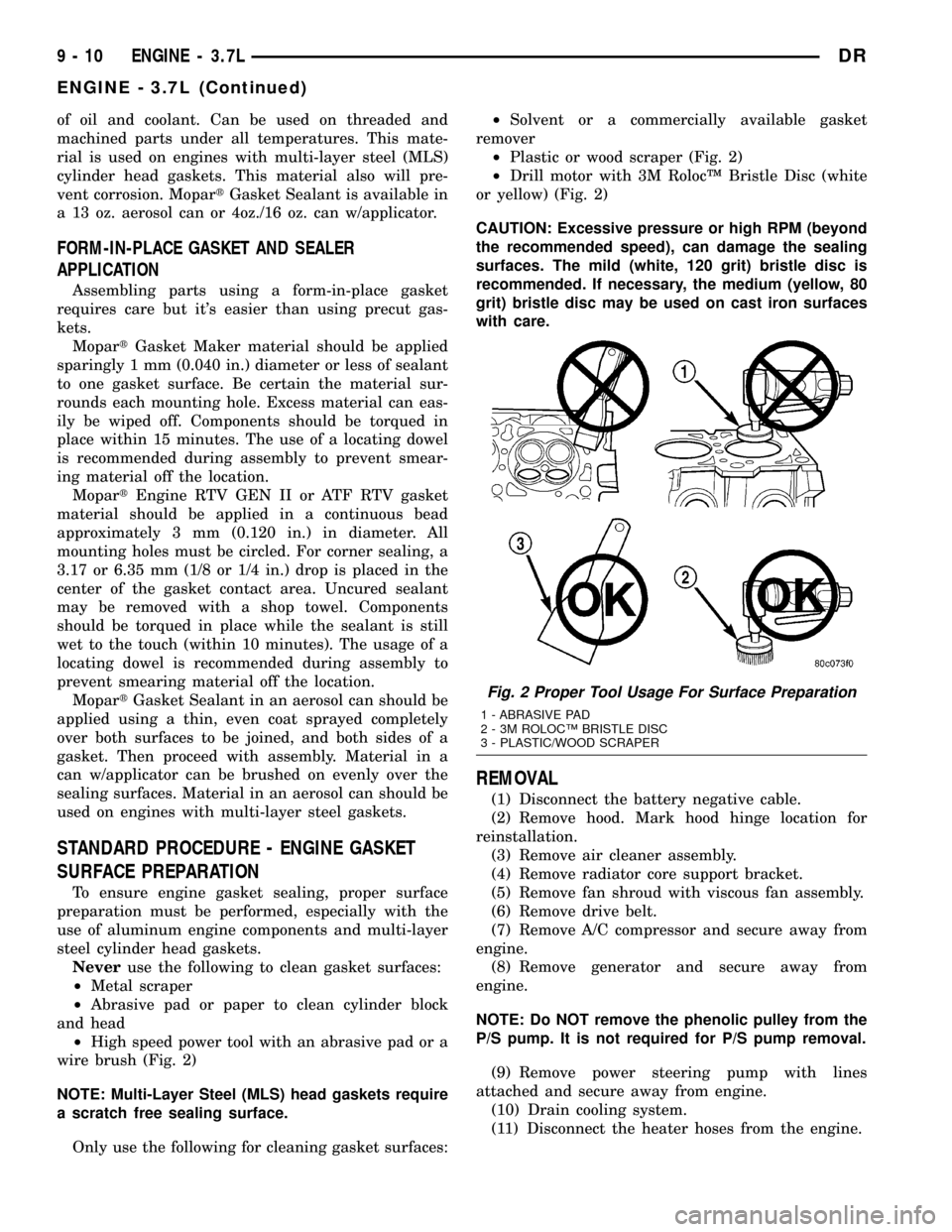

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 2)

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 2)

²Drill motor with 3M RolocŸ Bristle Disc (white

or yellow) (Fig. 2)

CAUTION: Excessive pressure or high RPM (beyond

the recommended speed), can damage the sealing

surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80

grit) bristle disc may be used on cast iron surfaces

with care.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove hood. Mark hood hinge location for

reinstallation.

(3) Remove air cleaner assembly.

(4) Remove radiator core support bracket.

(5) Remove fan shroud with viscous fan assembly.

(6) Remove drive belt.

(7) Remove A/C compressor and secure away from

engine.

(8) Remove generator and secure away from

engine.

NOTE: Do NOT remove the phenolic pulley from the

P/S pump. It is not required for P/S pump removal.

(9) Remove power steering pump with lines

attached and secure away from engine.

(10) Drain cooling system.

(11) Disconnect the heater hoses from the engine.

Fig. 2 Proper Tool Usage For Surface Preparation

1 - ABRASIVE PAD

2 - 3M ROLOCŸ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

9 - 10 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1238 of 2627

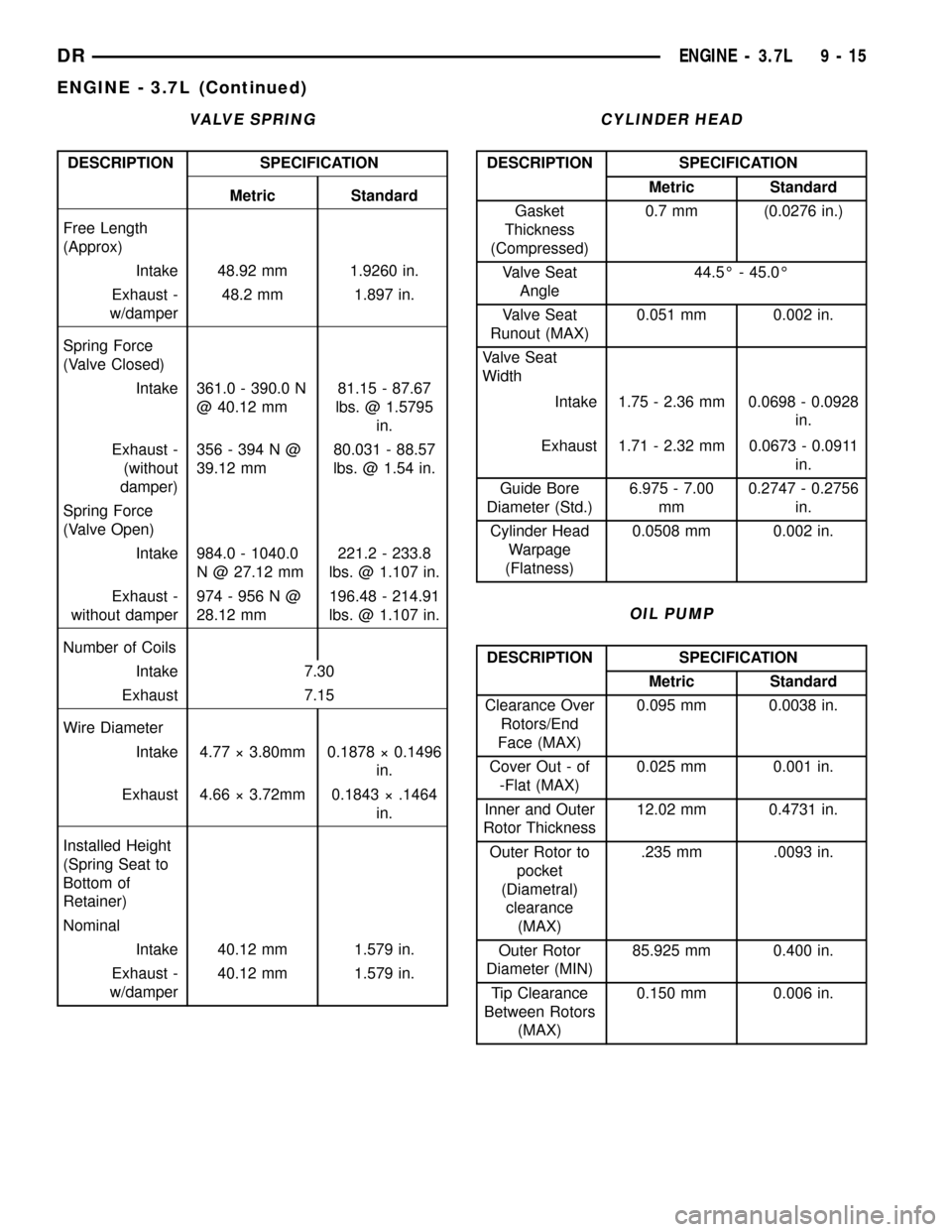

VALVE SPRING

DESCRIPTION SPECIFICATION

Metric Standard

Free Length

(Approx)

Intake 48.92 mm 1.9260 in.

Exhaust -

w/damper48.2 mm 1.897 in.

Spring Force

(Valve Closed)

Intake 361.0 - 390.0 N

@ 40.12 mm81.15 - 87.67

lbs. @ 1.5795

in.

Exhaust -

(without

damper)356-394N@

39.12 mm80.031 - 88.57

lbs. @ 1.54 in.

Spring Force

(Valve Open)

Intake 984.0 - 1040.0

N @ 27.12 mm221.2 - 233.8

lbs. @ 1.107 in.

Exhaust -

without damper974-956N@

28.12 mm196.48 - 214.91

lbs. @ 1.107 in.

Number of Coils

Intake 7.30

Exhaust 7.15

Wire Diameter

Intake 4.77 ý 3.80mm 0.1878 ý 0.1496

in.

Exhaust 4.66 ý 3.72mm 0.1843 ý .1464

in.

Installed Height

(Spring Seat to

Bottom of

Retainer)

Nominal

Intake 40.12 mm 1.579 in.

Exhaust -

w/damper40.12 mm 1.579 in.

CYLINDER HEAD

DESCRIPTION SPECIFICATION

Metric Standard

Gasket

Thickness

(Compressed)0.7 mm (0.0276 in.)

Valve Seat

Angle44.5É - 45.0É

Valve Seat

Runout (MAX)0.051 mm 0.002 in.

Valve Seat

Width

Intake 1.75 - 2.36 mm 0.0698 - 0.0928

in.

Exhaust 1.71 - 2.32 mm 0.0673 - 0.0911

in.

Guide Bore

Diameter (Std.)6.975 - 7.00

mm0.2747 - 0.2756

in.

Cylinder Head

Warpage

(Flatness)0.0508 mm 0.002 in.

OIL PUMP

DESCRIPTION SPECIFICATION

Metric Standard

Clearance Over

Rotors/End

Face (MAX)0.095 mm 0.0038 in.

Cover Out - of

-Flat (MAX)0.025 mm 0.001 in.

Inner and Outer

Rotor Thickness12.02 mm 0.4731 in.

Outer Rotor to

pocket

(Diametral)

clearance

(MAX).235 mm .0093 in.

Outer Rotor

Diameter (MIN)85.925 mm 0.400 in.

Tip Clearance

Between Rotors

(MAX)0.150 mm 0.006 in.

DRENGINE - 3.7L 9 - 15

ENGINE - 3.7L (Continued)

Page 1244 of 2627

AIR CLEANER ELEMENT

REMOVAL

Filter Element Only

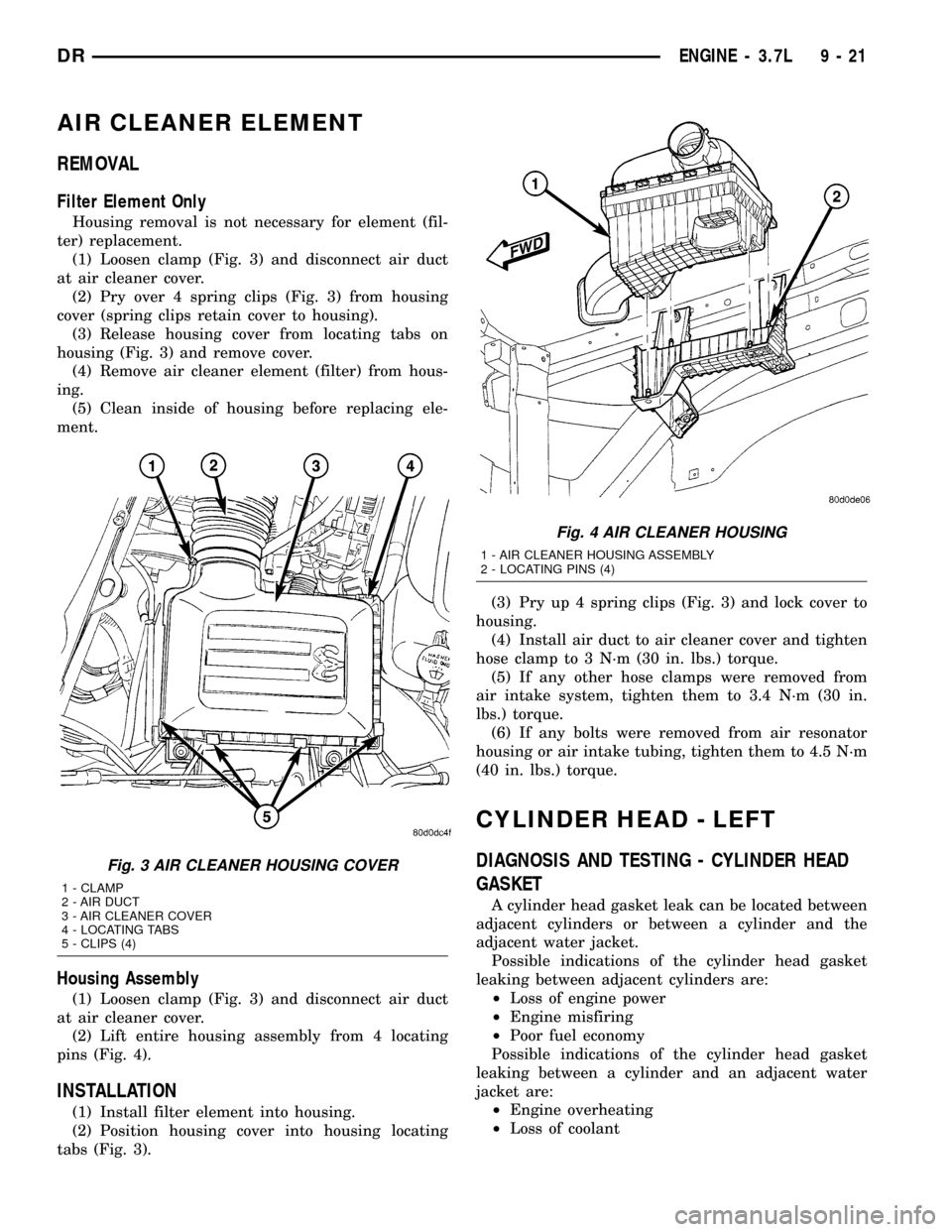

Housing removal is not necessary for element (fil-

ter) replacement.

(1) Loosen clamp (Fig. 3) and disconnect air duct

at air cleaner cover.

(2) Pry over 4 spring clips (Fig. 3) from housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs on

housing (Fig. 3) and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

Housing Assembly

(1) Loosen clamp (Fig. 3) and disconnect air duct

at air cleaner cover.

(2) Lift entire housing assembly from 4 locating

pins (Fig. 4).

INSTALLATION

(1) Install filter element into housing.

(2) Position housing cover into housing locating

tabs (Fig. 3).(3) Pry up 4 spring clips (Fig. 3) and lock cover to

housing.

(4) Install air duct to air cleaner cover and tighten

hose clamp to 3 N´m (30 in. lbs.) torque.

(5) If any other hose clamps were removed from

air intake system, tighten them to 3.4 N´m (30 in.

lbs.) torque.

(6) If any bolts were removed from air resonator

housing or air intake tubing, tighten them to 4.5 N´m

(40 in. lbs.) torque.

CYLINDER HEAD - LEFT

DIAGNOSIS AND TESTING - CYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

Fig. 3 AIR CLEANER HOUSING COVER

1 - CLAMP

2 - AIR DUCT

3 - AIR CLEANER COVER

4 - LOCATING TABS

5 - CLIPS (4)

Fig. 4 AIR CLEANER HOUSING

1 - AIR CLEANER HOUSING ASSEMBLY

2 - LOCATING PINS (4)

DRENGINE - 3.7L 9 - 21

Page 1245 of 2627

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50 - 70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the left side

exhaust manifold.

(4) Drain the engine coolant(Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(5) Lower the vehicle.(6) Remove the intake manifold(Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(7) Remove the master cylinder and booster assem-

bly(Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/POWER BRAKE BOOSTER - REMOVAL).

(8) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(9) Remove the fan shroud and fan blade assem-

bly(Refer to 7 - COOLING/ENGINE/RADIATOR FAN

- REMOVAL).

(10) Remove accessory drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Remove the power steering pump and set

aside.

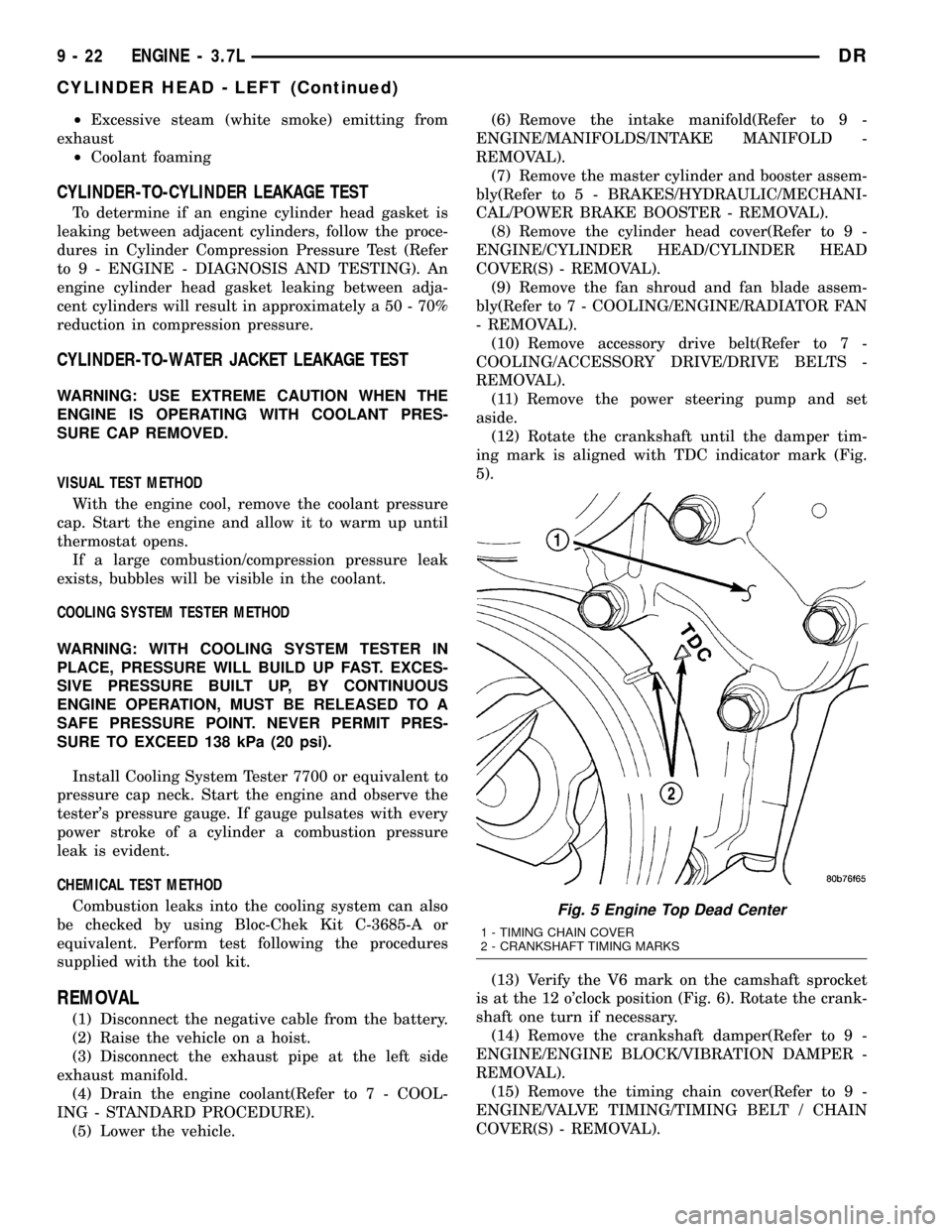

(12) Rotate the crankshaft until the damper tim-

ing mark is aligned with TDC indicator mark (Fig.

5).

(13) Verify the V6 mark on the camshaft sprocket

is at the 12 o'clock position (Fig. 6). Rotate the crank-

shaft one turn if necessary.

(14) Remove the crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(15) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

Fig. 5 Engine Top Dead Center

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

9 - 22 ENGINE - 3.7LDR

CYLINDER HEAD - LEFT (Continued)

Page 1247 of 2627

(20) Remove the left side secondary chain

guide(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

(21) Remove the retaining bolt and the camshaft

drive gear.

CAUTION: Do not allow the engine to rotate. Severe

damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at

the front of the cylinder head. Do not attempt to

remove the cylinder head without removing these

four bolts.

NOTE: The cylinder head is attached to the cylinder

block with twelve bolts.

(22) Remove the cylinder head retaining bolts.

(23) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, due to the design of the cylin-

der head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

INSTALLATION

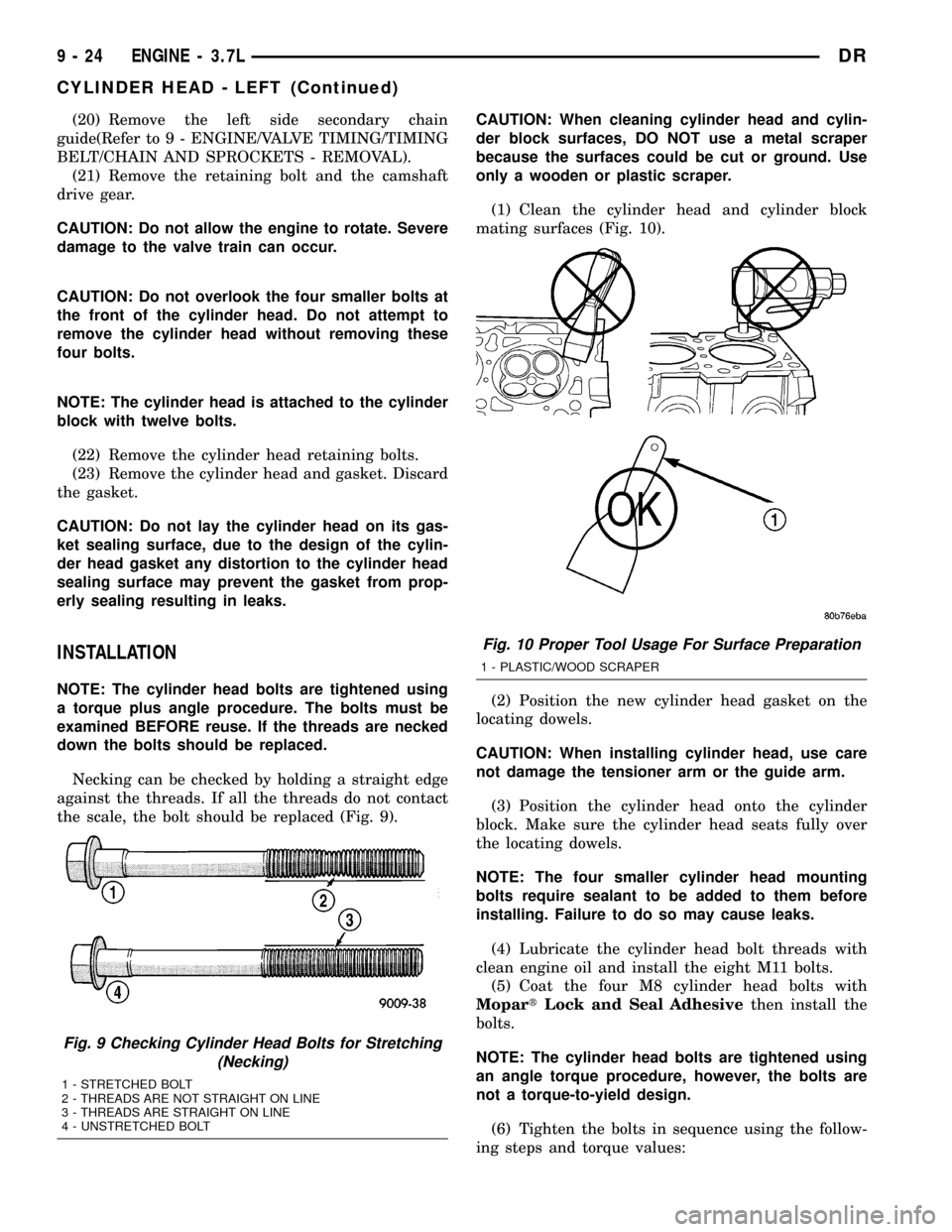

NOTE: The cylinder head bolts are tightened using

a torque plus angle procedure. The bolts must be

examined BEFORE reuse. If the threads are necked

down the bolts should be replaced.

Necking can be checked by holding a straight edge

against the threads. If all the threads do not contact

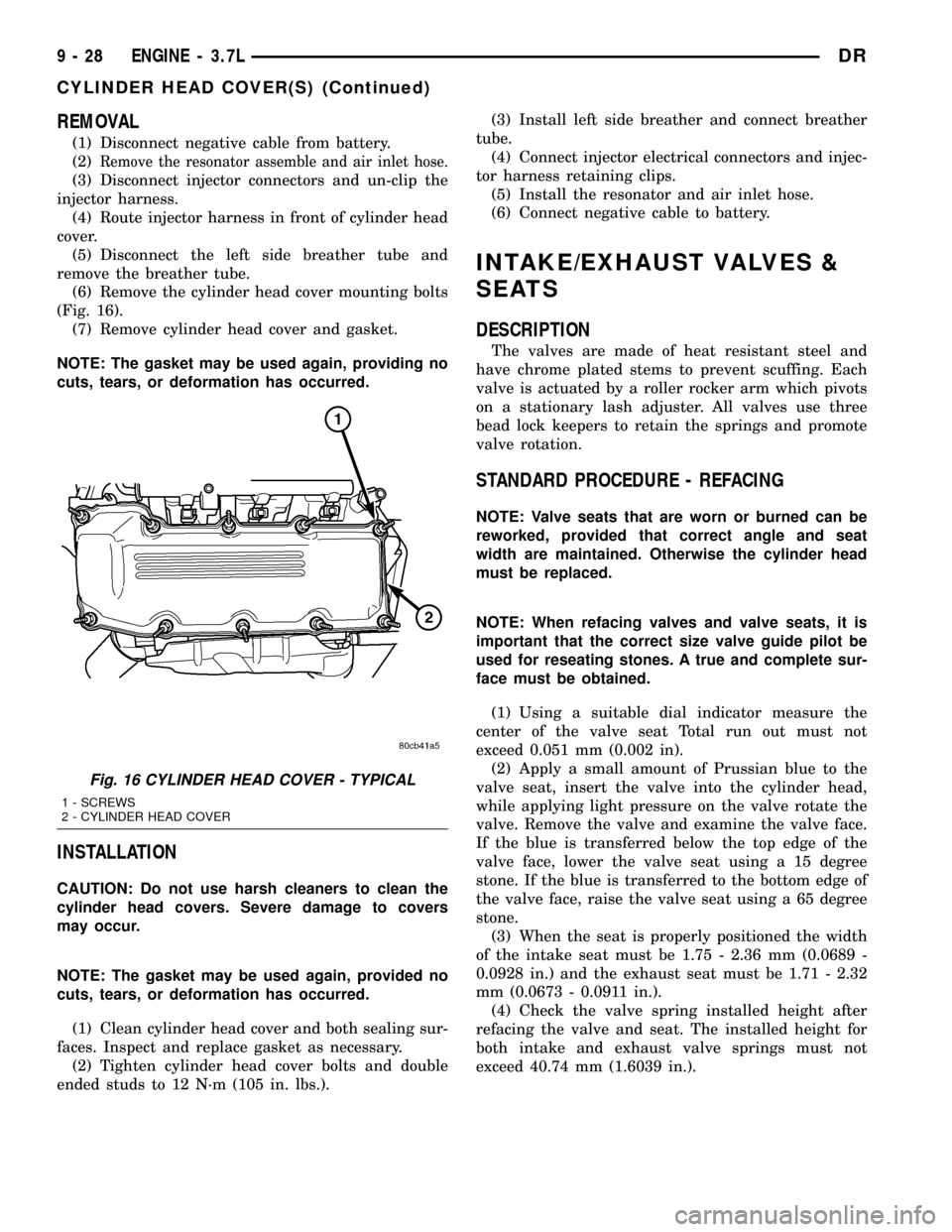

the scale, the bolt should be replaced (Fig. 9).CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper

because the surfaces could be cut or ground. Use

only a wooden or plastic scraper.

(1) Clean the cylinder head and cylinder block

mating surfaces (Fig. 10).

(2) Position the new cylinder head gasket on the

locating dowels.

CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.

(3) Position the cylinder head onto the cylinder

block. Make sure the cylinder head seats fully over

the locating dowels.

NOTE: The four smaller cylinder head mounting

bolts require sealant to be added to them before

installing. Failure to do so may cause leaks.

(4) Lubricate the cylinder head bolt threads with

clean engine oil and install the eight M11 bolts.

(5) Coat the four M8 cylinder head bolts with

MopartLock and Seal Adhesivethen install the

bolts.

NOTE: The cylinder head bolts are tightened using

an angle torque procedure, however, the bolts are

not a torque-to-yield design.

(6) Tighten the bolts in sequence using the follow-

ing steps and torque values:

Fig. 9 Checking Cylinder Head Bolts for Stretching

(Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 10 Proper Tool Usage For Surface Preparation

1 - PLASTIC/WOOD SCRAPER

9 - 24 ENGINE - 3.7LDR

CYLINDER HEAD - LEFT (Continued)

Page 1251 of 2627

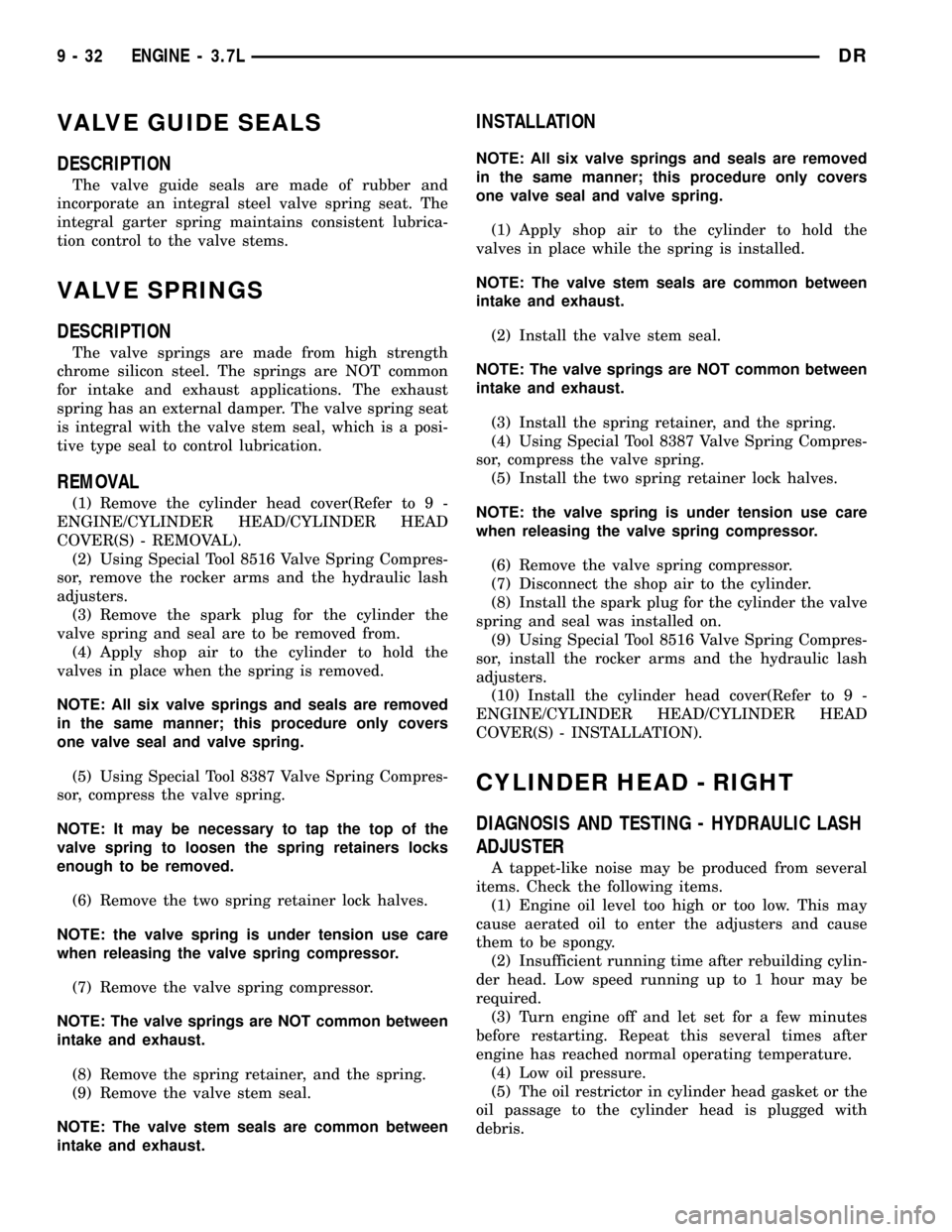

REMOVAL

(1) Disconnect negative cable from battery.

(2)

Remove the resonator assemble and air inlet hose.

(3) Disconnect injector connectors and un-clip the

injector harness.

(4) Route injector harness in front of cylinder head

cover.

(5) Disconnect the left side breather tube and

remove the breather tube.

(6) Remove the cylinder head cover mounting bolts

(Fig. 16).

(7) Remove cylinder head cover and gasket.

NOTE: The gasket may be used again, providing no

cuts, tears, or deformation has occurred.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs.).(3) Install left side breather and connect breather

tube.

(4) Connect injector electrical connectors and injec-

tor harness retaining clips.

(5) Install the resonator and air inlet hose.

(6) Connect negative cable to battery.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel and

have chrome plated stems to prevent scuffing. Each

valve is actuated by a roller rocker arm which pivots

on a stationary lash adjuster. All valves use three

bead lock keepers to retain the springs and promote

valve rotation.

STANDARD PROCEDURE - REFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete sur-

face must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.75 - 2.36 mm (0.0689 -

0.0928 in.) and the exhaust seat must be 1.71 - 2.32

mm (0.0673 - 0.0911 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 40.74 mm (1.6039 in.).

Fig. 16 CYLINDER HEAD COVER - TYPICAL

1 - SCREWS

2 - CYLINDER HEAD COVER

9 - 28 ENGINE - 3.7LDR

CYLINDER HEAD COVER(S) (Continued)

Page 1255 of 2627

VALVE GUIDE SEALS

DESCRIPTION

The valve guide seals are made of rubber and

incorporate an integral steel valve spring seat. The

integral garter spring maintains consistent lubrica-

tion control to the valve stems.

VALVE SPRINGS

DESCRIPTION

The valve springs are made from high strength

chrome silicon steel. The springs are NOT common

for intake and exhaust applications. The exhaust

spring has an external damper. The valve spring seat

is integral with the valve stem seal, which is a posi-

tive type seal to control lubrication.

REMOVAL

(1) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Using Special Tool 8516 Valve Spring Compres-

sor, remove the rocker arms and the hydraulic lash

adjusters.

(3) Remove the spark plug for the cylinder the

valve spring and seal are to be removed from.

(4) Apply shop air to the cylinder to hold the

valves in place when the spring is removed.

NOTE: All six valve springs and seals are removed

in the same manner; this procedure only covers

one valve seal and valve spring.

(5) Using Special Tool 8387 Valve Spring Compres-

sor, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

(6) Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(7) Remove the valve spring compressor.

NOTE: The valve springs are NOT common between

intake and exhaust.

(8) Remove the spring retainer, and the spring.

(9) Remove the valve stem seal.

NOTE: The valve stem seals are common between

intake and exhaust.

INSTALLATION

NOTE: All six valve springs and seals are removed

in the same manner; this procedure only covers

one valve seal and valve spring.

(1) Apply shop air to the cylinder to hold the

valves in place while the spring is installed.

NOTE: The valve stem seals are common between

intake and exhaust.

(2) Install the valve stem seal.

NOTE: The valve springs are NOT common between

intake and exhaust.

(3) Install the spring retainer, and the spring.

(4) Using Special Tool 8387 Valve Spring Compres-

sor, compress the valve spring.

(5) Install the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(6) Remove the valve spring compressor.

(7) Disconnect the shop air to the cylinder.

(8) Install the spark plug for the cylinder the valve

spring and seal was installed on.

(9) Using Special Tool 8516 Valve Spring Compres-

sor, install the rocker arms and the hydraulic lash

adjusters.

(10) Install the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

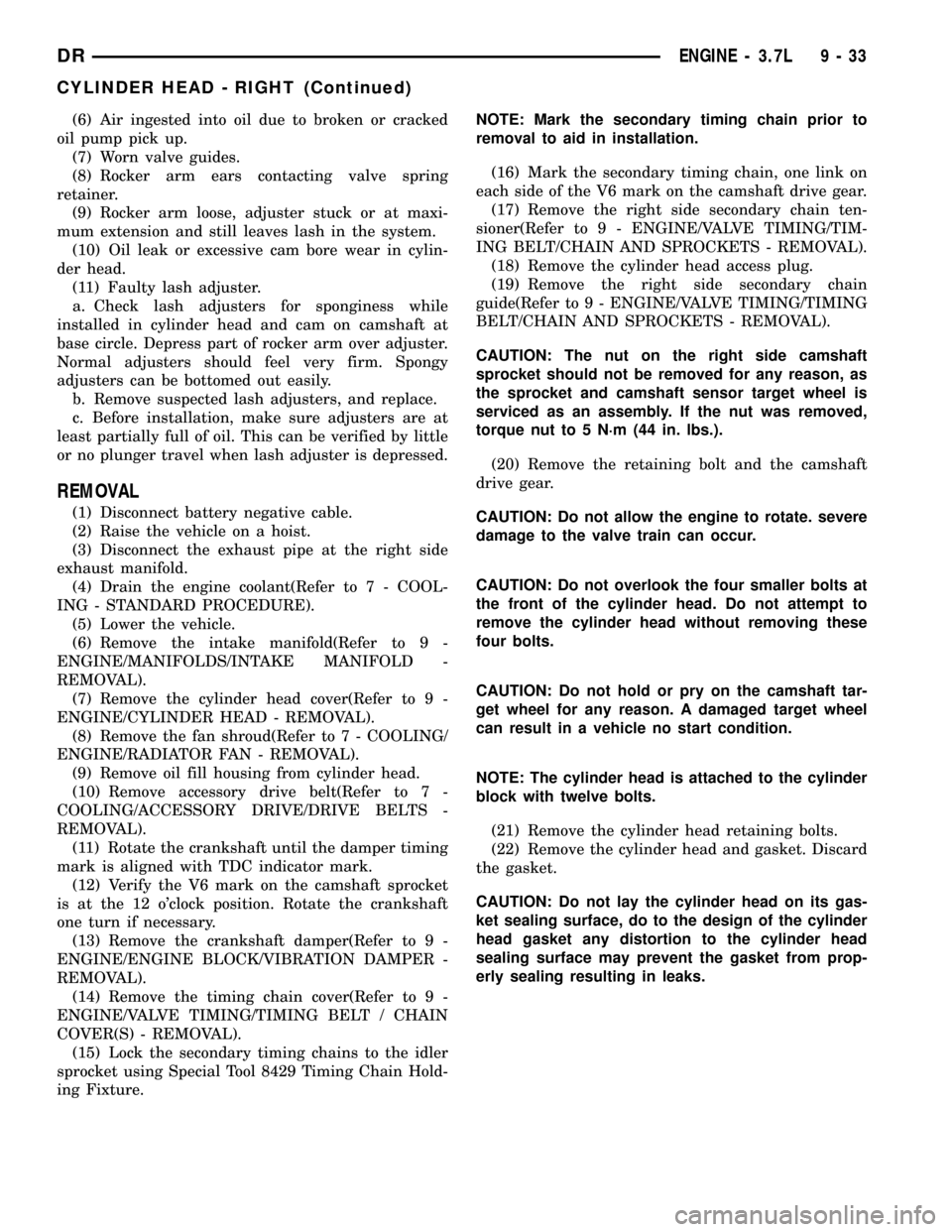

CYLINDER HEAD - RIGHT

DIAGNOSIS AND TESTING - HYDRAULIC LASH

ADJUSTER

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) Turn engine off and let set for a few minutes

before restarting. Repeat this several times after

engine has reached normal operating temperature.

(4) Low oil pressure.

(5) The oil restrictor in cylinder head gasket or the

oil passage to the cylinder head is plugged with

debris.

9 - 32 ENGINE - 3.7LDR

Page 1256 of 2627

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Oil leak or excessive cam bore wear in cylin-

der head.

(11) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head and cam on camshaft at

base circle. Depress part of rocker arm over adjuster.

Normal adjusters should feel very firm. Spongy

adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and replace.

c. Before installation, make sure adjusters are at

least partially full of oil. This can be verified by little

or no plunger travel when lash adjuster is depressed.

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the right side

exhaust manifold.

(4) Drain the engine coolant(Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(5) Lower the vehicle.

(6) Remove the intake manifold(Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(7) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(8) Remove the fan shroud(Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL).

(9) Remove oil fill housing from cylinder head.

(10) Remove accessory drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Rotate the crankshaft until the damper timing

mark is aligned with TDC indicator mark.

(12) Verify the V6 mark on the camshaft sprocket

is at the 12 o'clock position. Rotate the crankshaft

one turn if necessary.

(13) Remove the crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(14) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(15) Lock the secondary timing chains to the idler

sprocket using Special Tool 8429 Timing Chain Hold-

ing Fixture.NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

(16) Mark the secondary timing chain, one link on

each side of the V6 mark on the camshaft drive gear.

(17) Remove the right side secondary chain ten-

sioner(Refer to 9 - ENGINE/VALVE TIMING/TIM-

ING BELT/CHAIN AND SPROCKETS - REMOVAL).

(18) Remove the cylinder head access plug.

(19) Remove the right side secondary chain

guide(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason, as

the sprocket and camshaft sensor target wheel is

serviced as an assembly. If the nut was removed,

torque nut to 5 N´m (44 in. lbs.).

(20) Remove the retaining bolt and the camshaft

drive gear.

CAUTION: Do not allow the engine to rotate. severe

damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at

the front of the cylinder head. Do not attempt to

remove the cylinder head without removing these

four bolts.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason. A damaged target wheel

can result in a vehicle no start condition.

NOTE: The cylinder head is attached to the cylinder

block with twelve bolts.

(21) Remove the cylinder head retaining bolts.

(22) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, do to the design of the cylinder

head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

DRENGINE - 3.7L 9 - 33

CYLINDER HEAD - RIGHT (Continued)

Page 1257 of 2627

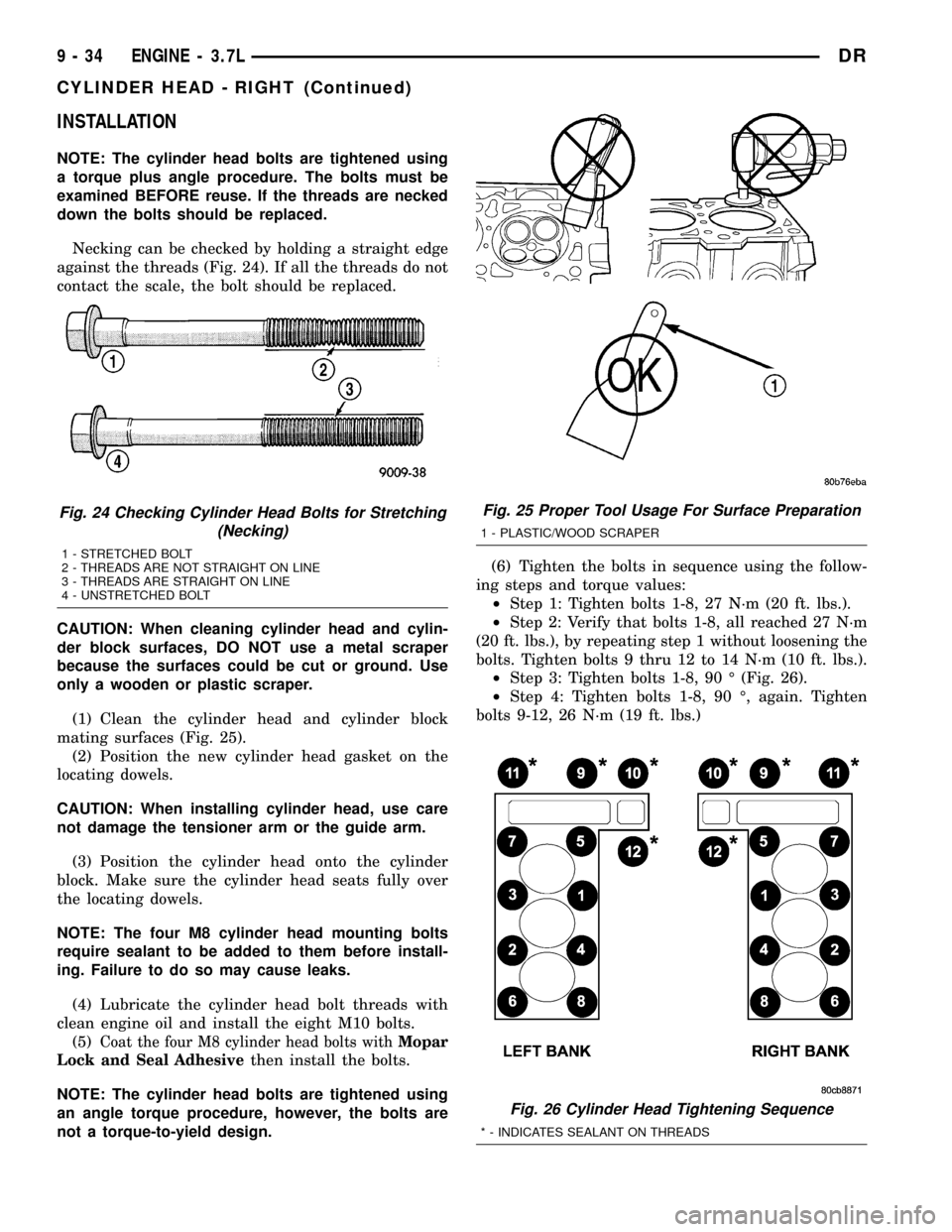

INSTALLATION

NOTE: The cylinder head bolts are tightened using

a torque plus angle procedure. The bolts must be

examined BEFORE reuse. If the threads are necked

down the bolts should be replaced.

Necking can be checked by holding a straight edge

against the threads (Fig. 24). If all the threads do not

contact the scale, the bolt should be replaced.

CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper

because the surfaces could be cut or ground. Use

only a wooden or plastic scraper.

(1) Clean the cylinder head and cylinder block

mating surfaces (Fig. 25).

(2) Position the new cylinder head gasket on the

locating dowels.

CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.

(3) Position the cylinder head onto the cylinder

block. Make sure the cylinder head seats fully over

the locating dowels.

NOTE: The four M8 cylinder head mounting bolts

require sealant to be added to them before install-

ing. Failure to do so may cause leaks.

(4) Lubricate the cylinder head bolt threads with

clean engine oil and install the eight M10 bolts.

(5)

Coat the four M8 cylinder head bolts withMopar

Lock and Seal Adhesive

then install the bolts.

NOTE: The cylinder head bolts are tightened using

an angle torque procedure, however, the bolts are

not a torque-to-yield design.(6) Tighten the bolts in sequence using the follow-

ing steps and torque values:

²Step 1: Tighten bolts 1-8, 27 N´m (20 ft. lbs.).

²Step 2: Verify that bolts 1-8, all reached 27 N´m

(20 ft. lbs.), by repeating step 1 without loosening the

bolts. Tighten bolts 9 thru 12 to 14 N´m (10 ft. lbs.).

²Step 3: Tighten bolts 1-8, 90 É (Fig. 26).

²Step 4: Tighten bolts 1-8, 90 É, again. Tighten

bolts 9-12, 26 N´m (19 ft. lbs.)

Fig. 24 Checking Cylinder Head Bolts for Stretching

(Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 25 Proper Tool Usage For Surface Preparation

1 - PLASTIC/WOOD SCRAPER

Fig. 26 Cylinder Head Tightening Sequence

* - INDICATES SEALANT ON THREADS

9 - 34 ENGINE - 3.7LDR

CYLINDER HEAD - RIGHT (Continued)

Page 1260 of 2627

CYLINDER HEAD COVER(S)

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove air cleaner assembly, resonator assem-

bly and air inlet hose.

(3) Drain cooling system, below the level of the

heater hoses(Refer to 7 - COOLING - STANDARD

PROCEDURE).

(4)

Remove accessory drive belt(Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

(5) Remove air conditioning compressor retaining

bolts and move compressor to the left.

(6) Remove heater hoses.

(7) Disconnect injector and ignition coil connectors.

(8) Disconnect and remove positive crankcase ven-

tilation (PCV) hose.

(9) Remove oil fill tube.

(10) Un-clip injector and ignition coil harness and

move away from cylinder head cover.

(11) Remove right rear breather tube and filter

assembly.

(12) Remove cylinder head cover retaining bolts.

(13) Remove cylinder head cover.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs).

(3) Install right rear breather tube and filter

assembly.

(4) Connect injector, ignition coil electrical connec-

tors and harness retaining clips.

(5) Install the oil fill tube.

(6) Install PCV hose.

(7) Install heater hoses.

(8) Install air conditioning compressor retaining

bolts.

(9) Install accessory drive belt(Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(10) Fill Cooling system(Refer to 7 - COOLING -

STANDARD PROCEDURE).

(11) Install air cleaner assembly, resonator assem-

bly and air inlet hose.

(12) Connect battery negative cable.

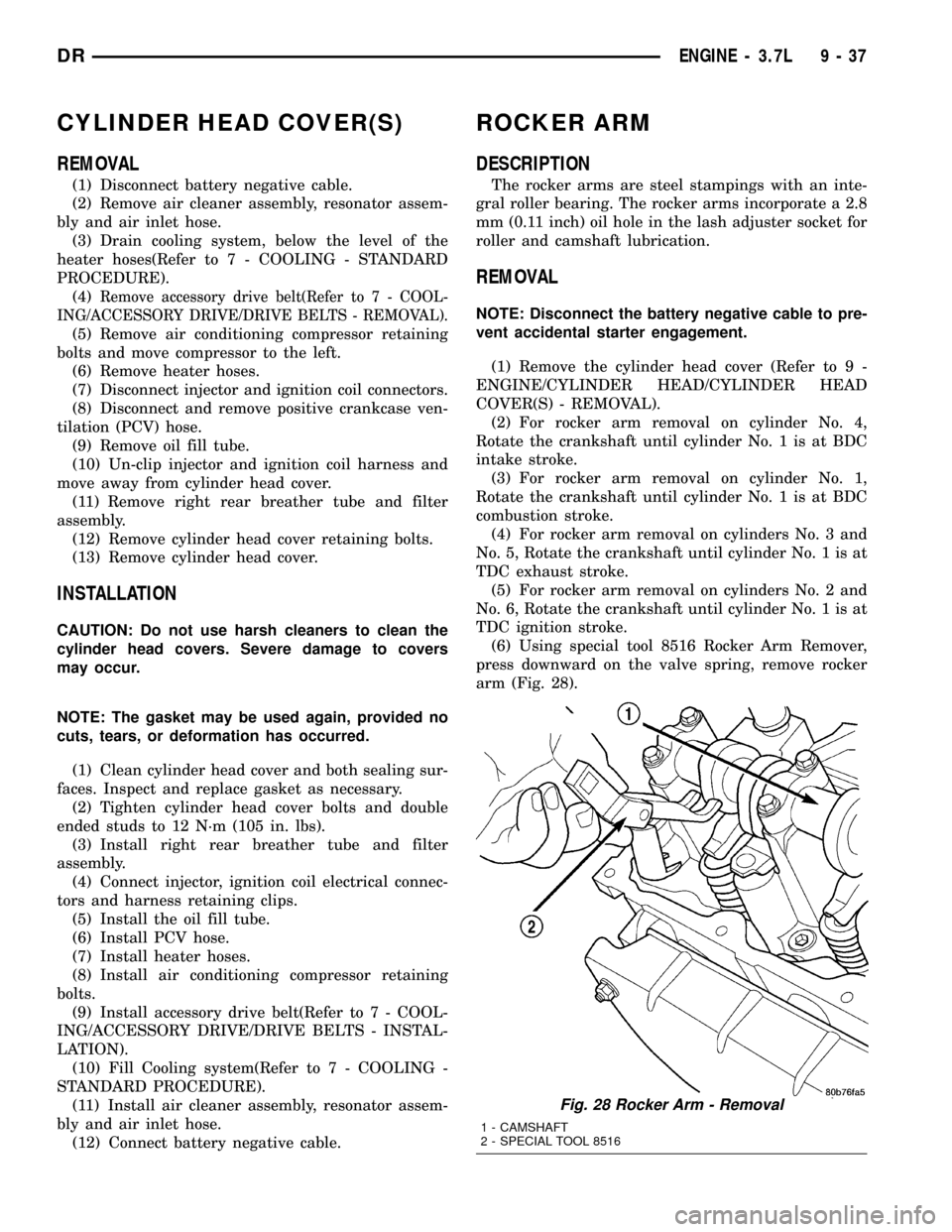

ROCKER ARM

DESCRIPTION

The rocker arms are steel stampings with an inte-

gral roller bearing. The rocker arms incorporate a 2.8

mm (0.11 inch) oil hole in the lash adjuster socket for

roller and camshaft lubrication.

REMOVAL

NOTE: Disconnect the battery negative cable to pre-

vent accidental starter engagement.

(1) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) For rocker arm removal on cylinder No. 4,

Rotate the crankshaft until cylinder No. 1 is at BDC

intake stroke.

(3) For rocker arm removal on cylinder No. 1,

Rotate the crankshaft until cylinder No. 1 is at BDC

combustion stroke.

(4) For rocker arm removal on cylinders No. 3 and

No. 5, Rotate the crankshaft until cylinder No. 1 is at

TDC exhaust stroke.

(5) For rocker arm removal on cylinders No. 2 and

No. 6, Rotate the crankshaft until cylinder No. 1 is at

TDC ignition stroke.

(6) Using special tool 8516 Rocker Arm Remover,

press downward on the valve spring, remove rocker

arm (Fig. 28).

Fig. 28 Rocker Arm - Removal

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

DRENGINE - 3.7L 9 - 37