Ignition wire harness DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 457 of 2627

STARTING

TABLE OF CONTENTS

page page

STARTING

DESCRIPTION.........................26

OPERATION...........................26

DIAGNOSIS AND TESTING - STARTING

SYSTEM............................27

SPECIFICATIONS

STARTING SYSTEM...................31

SPECIFICATIONS - TORQUE - STARTING

SYSTEM............................32

STARTER MOTOR

DIAGNOSIS AND TESTING - STARTER

MOTOR .............................32REMOVAL.............................33

INSTALLATION.........................34

STARTER MOTOR RELAY

DESCRIPTION.........................35

OPERATION...........................36

DIAGNOSIS AND TESTING - STARTER RELAY . 36

REMOVAL.............................37

INSTALLATION.........................37

STARTING

DESCRIPTION

The starting system consists of:

²Starter relay

²Starter motor (including an integral starter sole-

noid)

Other components to be considered as part of start-

ing system are:

²Battery

²Battery cables

²Ignition switch and key lock cylinder

²Clutch pedal position switch (manual transmis-

sion)

²Park/neutral position switch (automatic trans-

mission)

²Wire harnesses and connections.

The Battery, Starting, and Charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct operation of

starting/charging systems, all components used in

these 3 systems must perform within specifications.

When attempting to diagnose any of these systems, it

is important that you keep their interdependency in

mind.

The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Powertrain Control Mod-

ule (PCM). Use of an induction-type milliampere

ammeter, volt/ohmmeter, battery charger, carbon pile

rheostat (load tester), and 12-volt test lamp may be

required.Certain starting system components are monitored

by the PCM and may produce a Diagnostic Trouble

Code (DTC). Refer to Diagnostic Trouble Codes in

Emission Control for a list of codes.

OPERATION

The starting system components form two separate

circuits. A high-amperage feed circuit that feeds the

starter motor between 150 and 350 amperes (700

amperes - diesel engine), and a low-amperage control

circuit that operates on less than 20 amperes. The

high-amperage feed circuit components include the

battery, the battery cables, the contact disc portion of

the starter solenoid, and the starter motor. The low-

amperage control circuit components include the igni-

tion switch, the clutch pedal position switch (manual

transmission), the park/neutral position switch (auto-

matic transmission), the starter relay, the electro-

magnetic windings of the starter solenoid, and the

connecting wire harness components.

If the vehicle is equipped with a manual transmis-

sion, it has a clutch pedal position switch installed in

series between the ignition switch and the coil bat-

tery terminal of the starter relay. This normally open

switch prevents the starter relay from being ener-

gized when the ignition switch is turned to the Start

position, unless the clutch pedal is depressed. This

feature prevents starter motor operation while the

clutch disc and the flywheel are engaged. The starter

relay coil ground terminal is always grounded on

vehicles with a manual transmission.

8F - 26 STARTINGDR

Page 459 of 2627

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER ENGAGES,

FAILS TO TURN

ENGINE.1. Battery discharged or

faulty.1. Refer to Battery. Charge or replace battery if required.

2. Starting circuit wiring

faulty.2. Refer to 8, Wiring Diagrams. Test and repair starter

feed and/or control circuits if required.

3. Starter motor faulty. 3. If all other starting system components and circuits test

OK, replace starter motor assembly.

4. Engine seized. 4. Refer to Engine Diagnosis in the Diagnosis and Testing

section of 9, Engine.

STARTER ENGAGES,

SPINS OUT BEFORE

ENGINE STARTS.1. Starter ring gear faulty. 1. Refer to Starter Motor Removal and Installation.

Remove starter motor to inspect starter ring gear.

Replace starter ring gear if required.

2. Starter motor faulty. 2. If all other starting system components and circuits test

OK, replace starter motor assembly.

STARTER DOES NOT

DISENGAGE.1. Starter motor

improperly installed.1. Refer to Starter Motor Removal and Installation.

Tighten starter mounting hardware to correct torque

specifications.

2. Starter relay faulty. 2. Refer to Starter Relay Diagnosis and Testing. Replace

starter relay if required.

3. Ignition switch faulty. 3. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch if required.

4. Starter motor faulty. 4. If all other starting system components and circuits test

OK, replace starter motor.

INSPECTION

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. Before removing any unit

from starting system for repair or diagnosis, perform

the following inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO 8, PASSIVE RESTRAINT SYS-

TEMS, BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY.

²Battery- Visually inspect battery for indica-

tions of physical damage and loose or corroded cable

connections. Determine state-of-charge and cranking

capacity of battery. Charge or replace battery if

required. Refer toBatteryin 8, Battery.Note: If

equipped with diesel engine, a dual battery sys-

tem may be used, and both batteries must be

inspected.

²Ignition Switch- Visually inspect ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer toIgni-

tion Switch and Key Lock Cylinder.²Clutch Pedal Position Switch- If equipped

with manual transmission, visually inspect clutch

pedal position switch for indications of physical dam-

age and loose or corroded wire harness connections.

Refer toClutch Pedal Position Switchin 6,

Clutch.

²Park/Neutral Position Switch- If equipped

with automatic transmission, visually inspect park/

neutral position switch for indications of physical

damage and loose or corroded wire harness connec-

tions. Refer toPark/Neutral Position Switchin

21, Transmission.

²Starter Relay- Visually inspect starter relay

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Motor- Visually inspect starter motor

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Solenoid- Visually inspect starter sole-

noid for indications of physical damage and loose or

corroded wire harness connections.

²Wiring- Visually inspect wire harnesses for

damage. Repair or replace any faulty wiring, as

required. Refer to 8, Wiring Diagrams.

8F - 28 STARTINGDR

STARTING (Continued)

Page 462 of 2627

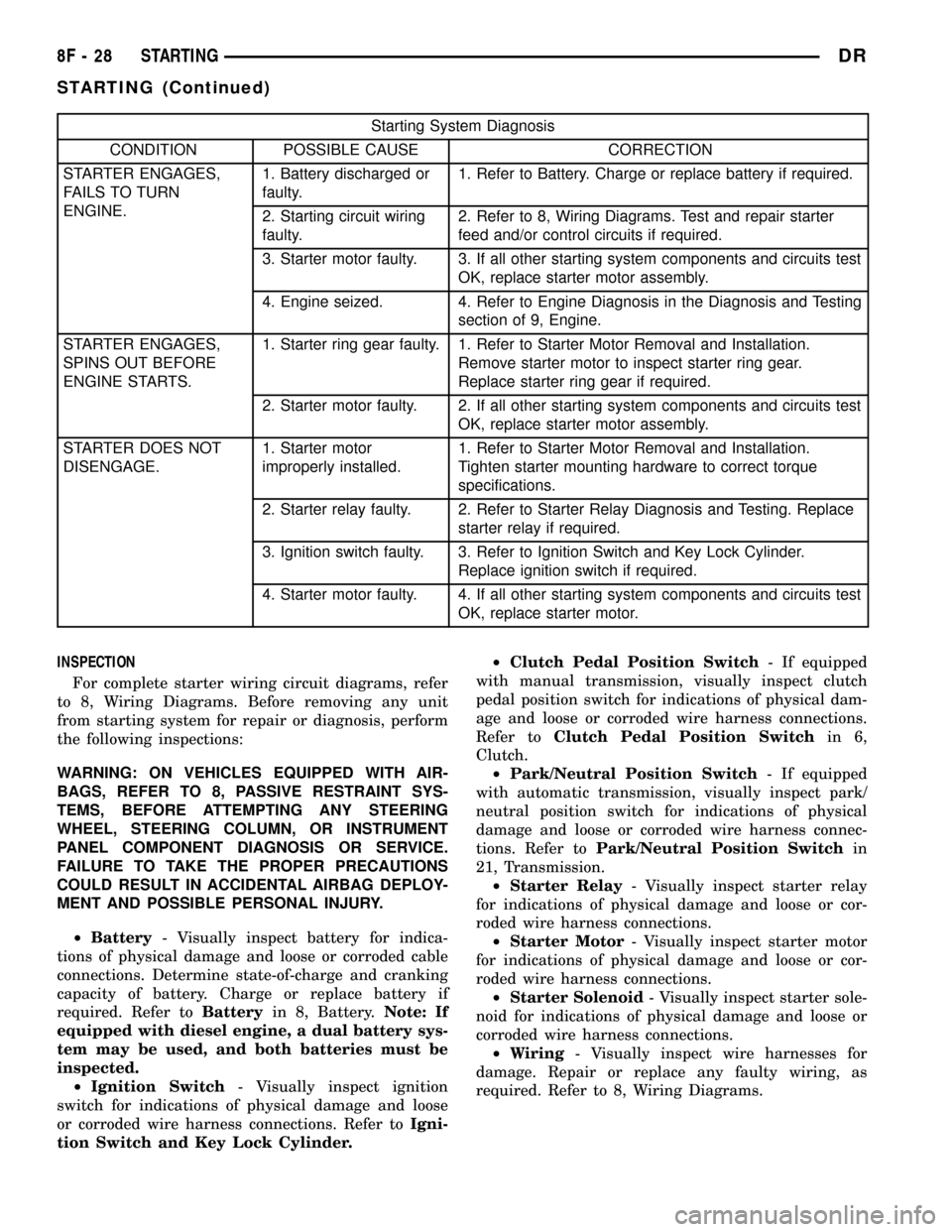

(5) Connect positive lead of voltmeter to starter

housing. Connect negative lead of voltmeter to nega-

tive battery terminal post (Fig. 6). Rotate and hold

ignition switch in Start position. Observe voltmeter.

If reading is above 0.2 volt, correct poor starter to

engine block ground contact.Note: Certain diesel

equipped models use dual batteries. If equipped

with dual battery system, this procedure must

be performed on driver side battery only.

(6) If equipped with dual battery system (certain

diesel equipped models), connect positive lead of volt-

meter to positive battery cable clamp on battery

located on left side of vehicle. Connect negative lead

of voltmeter to positive battery terminal post on bat-

tery located on right side of vehicle. Rotate and hold

ignition switch in Start position. Observe voltmeter.

If reading is above 0.2 volt, clean and tighten battery

cables at both batteries. Repeat test. If reading is

still above 0.2 volt, replace faulty positive battery

cable.

If resistance tests detect no feed circuit problems,

refer toStarter Motorin the Diagnosis and Testing.CONTROL CIRCUIT TESTING

The starter control circuit components should be

tested in the order in which they are listed, as fol-

lows:

²Starter Relay- Refer toStarter RelayDiag-

nosis and Testing.

²Starter Solenoid- Refer toStarter Motor

Diagnosis and Testing.

²Ignition Switch- Refer toIgnition Switch

and Key Lock Cylinder

²Clutch Pedal Position Switch- If equipped

with manual transmission, refer toClutch Pedal

Position Switchin 6, Clutch.

²Park/Neutral Position Switch- If equipped

with automatic transmission, refer toPark/Neutral

Position Switchin 21, Transmission.

²Wire harnesses and connections- Refer to 8,

Wiring Diagrams.

SPECIFICATIONS

STARTING SYSTEM

Starter Motor and Solenoid

Manufacturer Denso Denso

Part Number 56028715AD 4741012

Engine Application 3.7L / 4.7L / 5.7L 5.9L Diesel

Power Rating1.4 Kilowatt / 1.9

Horsepower2.7 Kilowatt / 3.6

Horsepower

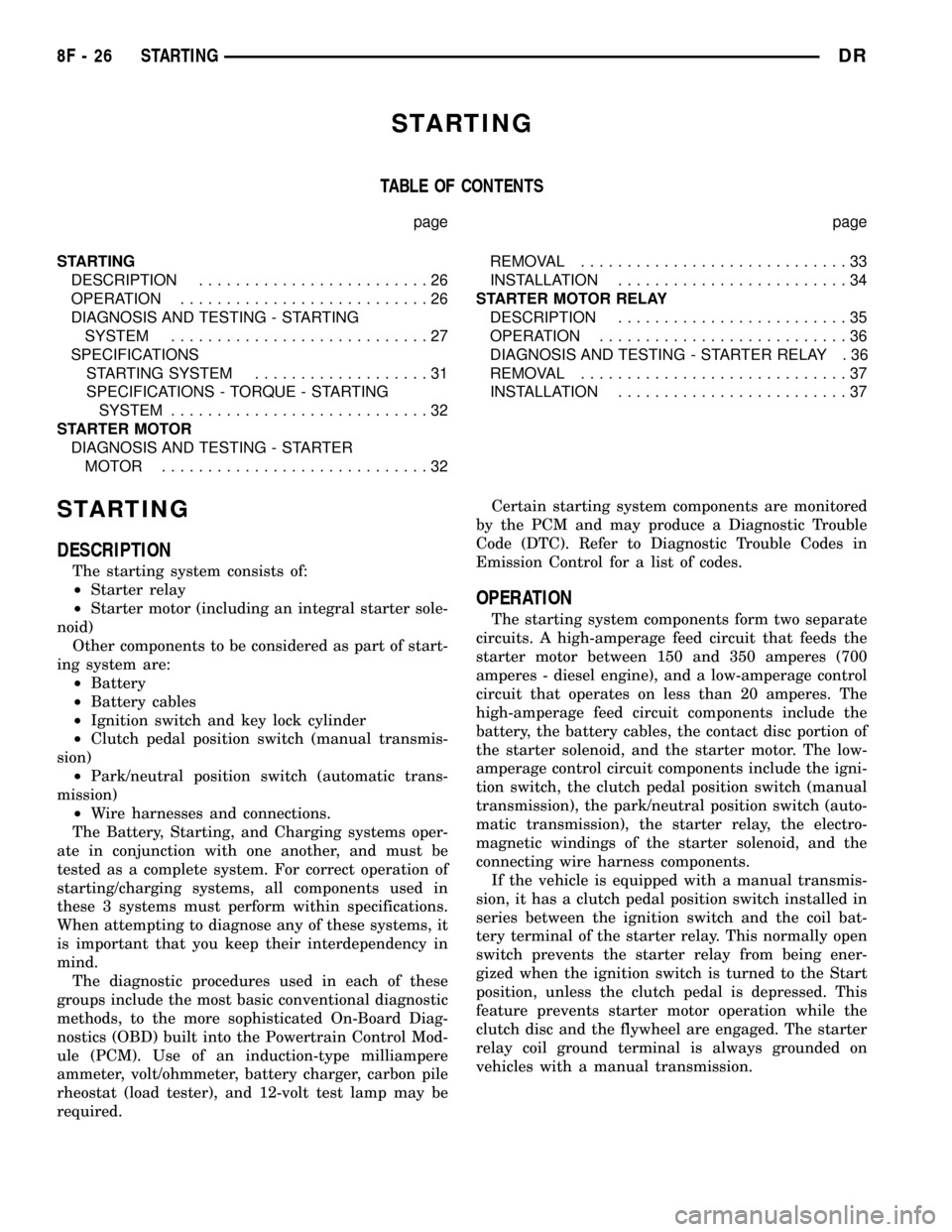

Fig. 5 TEST GROUND CIRCUIT RESISTANCE -

TYPICAL

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

Fig. 6 TEST STARTER GROUND - TYPICAL

1 - STARTER MOTOR

2 - BATTERY

3 - VOLTMETER

DRSTARTING 8F - 31

STARTING (Continued)

Page 466 of 2627

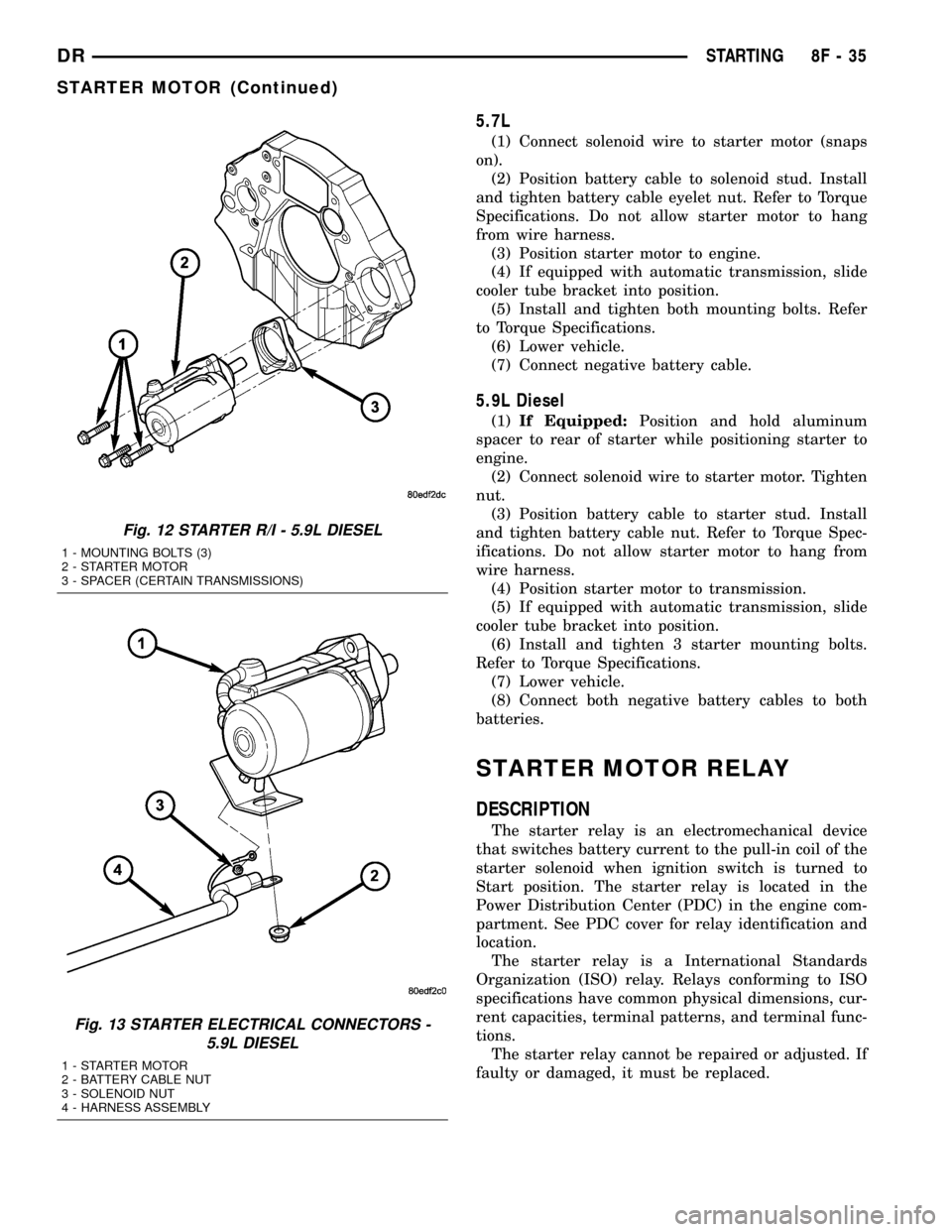

5.7L

(1) Connect solenoid wire to starter motor (snaps

on).

(2) Position battery cable to solenoid stud. Install

and tighten battery cable eyelet nut. Refer to Torque

Specifications. Do not allow starter motor to hang

from wire harness.

(3) Position starter motor to engine.

(4) If equipped with automatic transmission, slide

cooler tube bracket into position.

(5) Install and tighten both mounting bolts. Refer

to Torque Specifications.

(6) Lower vehicle.

(7) Connect negative battery cable.

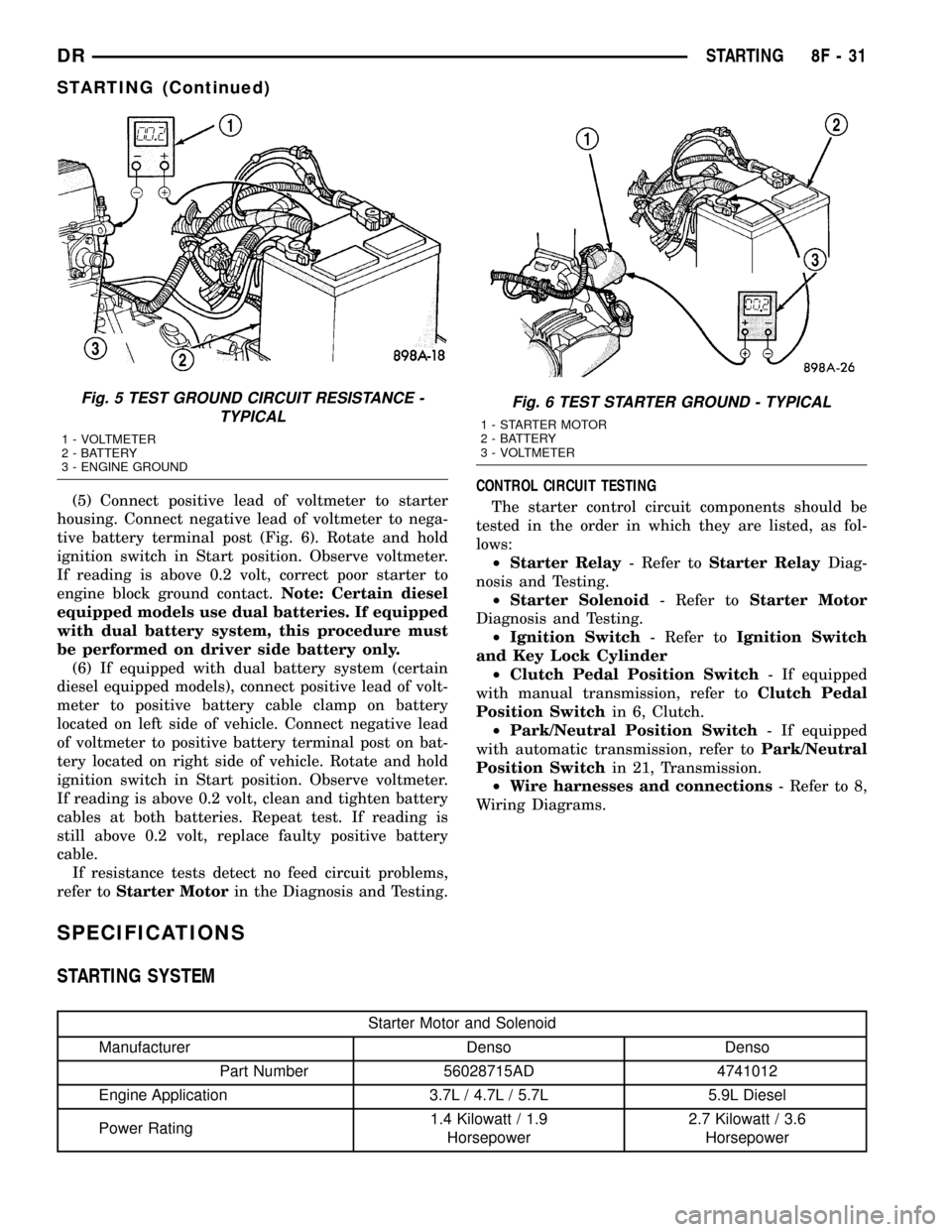

5.9L Diesel

(1)If Equipped:Position and hold aluminum

spacer to rear of starter while positioning starter to

engine.

(2) Connect solenoid wire to starter motor. Tighten

nut.

(3) Position battery cable to starter stud. Install

and tighten battery cable nut. Refer to Torque Spec-

ifications. Do not allow starter motor to hang from

wire harness.

(4) Position starter motor to transmission.

(5) If equipped with automatic transmission, slide

cooler tube bracket into position.

(6) Install and tighten 3 starter mounting bolts.

Refer to Torque Specifications.

(7) Lower vehicle.

(8) Connect both negative battery cables to both

batteries.

STARTER MOTOR RELAY

DESCRIPTION

The starter relay is an electromechanical device

that switches battery current to the pull-in coil of the

starter solenoid when ignition switch is turned to

Start position. The starter relay is located in the

Power Distribution Center (PDC) in the engine com-

partment. See PDC cover for relay identification and

location.

The starter relay is a International Standards

Organization (ISO) relay. Relays conforming to ISO

specifications have common physical dimensions, cur-

rent capacities, terminal patterns, and terminal func-

tions.

The starter relay cannot be repaired or adjusted. If

faulty or damaged, it must be replaced.

Fig. 12 STARTER R/I - 5.9L DIESEL

1 - MOUNTING BOLTS (3)

2 - STARTER MOTOR

3 - SPACER (CERTAIN TRANSMISSIONS)

Fig. 13 STARTER ELECTRICAL CONNECTORS -

5.9L DIESEL

1 - STARTER MOTOR

2 - BATTERY CABLE NUT

3 - SOLENOID NUT

4 - HARNESS ASSEMBLY

DRSTARTING 8F - 35

STARTER MOTOR (Continued)

Page 477 of 2627

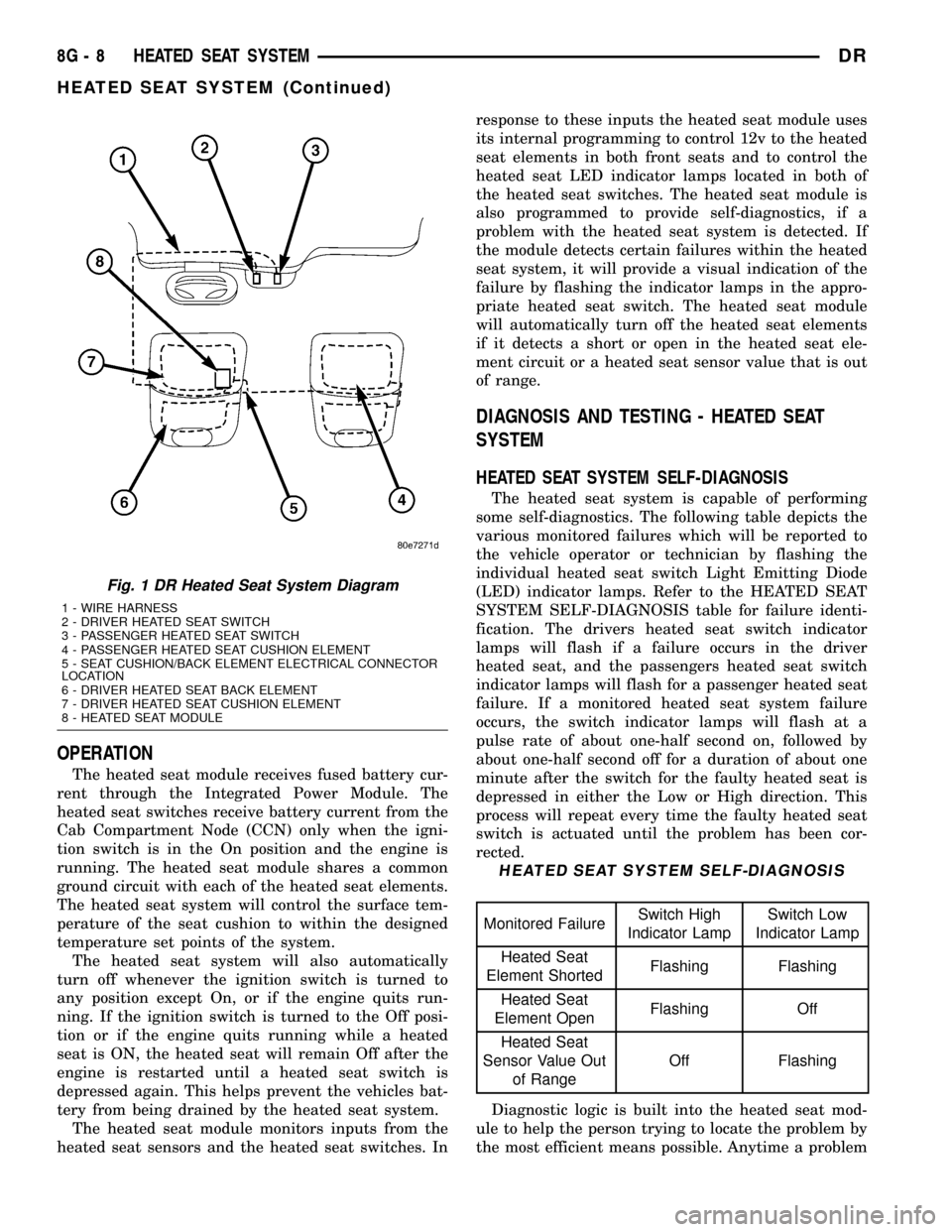

OPERATION

The heated seat module receives fused battery cur-

rent through the Integrated Power Module. The

heated seat switches receive battery current from the

Cab Compartment Node (CCN) only when the igni-

tion switch is in the On position and the engine is

running. The heated seat module shares a common

ground circuit with each of the heated seat elements.

The heated seat system will control the surface tem-

perature of the seat cushion to within the designed

temperature set points of the system.

The heated seat system will also automatically

turn off whenever the ignition switch is turned to

any position except On, or if the engine quits run-

ning. If the ignition switch is turned to the Off posi-

tion or if the engine quits running while a heated

seat is ON, the heated seat will remain Off after the

engine is restarted until a heated seat switch is

depressed again. This helps prevent the vehicles bat-

tery from being drained by the heated seat system.

The heated seat module monitors inputs from the

heated seat sensors and the heated seat switches. Inresponse to these inputs the heated seat module uses

its internal programming to control 12v to the heated

seat elements in both front seats and to control the

heated seat LED indicator lamps located in both of

the heated seat switches. The heated seat module is

also programmed to provide self-diagnostics, if a

problem with the heated seat system is detected. If

the module detects certain failures within the heated

seat system, it will provide a visual indication of the

failure by flashing the indicator lamps in the appro-

priate heated seat switch. The heated seat module

will automatically turn off the heated seat elements

if it detects a short or open in the heated seat ele-

ment circuit or a heated seat sensor value that is out

of range.

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM

HEATED SEAT SYSTEM SELF-DIAGNOSIS

The heated seat system is capable of performing

some self-diagnostics. The following table depicts the

various monitored failures which will be reported to

the vehicle operator or technician by flashing the

individual heated seat switch Light Emitting Diode

(LED) indicator lamps. Refer to the HEATED SEAT

SYSTEM SELF-DIAGNOSIS table for failure identi-

fication. The drivers heated seat switch indicator

lamps will flash if a failure occurs in the driver

heated seat, and the passengers heated seat switch

indicator lamps will flash for a passenger heated seat

failure. If a monitored heated seat system failure

occurs, the switch indicator lamps will flash at a

pulse rate of about one-half second on, followed by

about one-half second off for a duration of about one

minute after the switch for the faulty heated seat is

depressed in either the Low or High direction. This

process will repeat every time the faulty heated seat

switch is actuated until the problem has been cor-

rected.

HEATED SEAT SYSTEM SELF-DIAGNOSIS

Monitored FailureSwitch High

Indicator LampSwitch Low

Indicator Lamp

Heated Seat

Element ShortedFlashing Flashing

Heated Seat

Element OpenFlashing Off

Heated Seat

Sensor Value Out

of RangeOff Flashing

Diagnostic logic is built into the heated seat mod-

ule to help the person trying to locate the problem by

the most efficient means possible. Anytime a problem

Fig. 1 DR Heated Seat System Diagram

1 - WIRE HARNESS

2 - DRIVER HEATED SEAT SWITCH

3 - PASSENGER HEATED SEAT SWITCH

4 - PASSENGER HEATED SEAT CUSHION ELEMENT

5 - SEAT CUSHION/BACK ELEMENT ELECTRICAL CONNECTOR

LOCATION

6 - DRIVER HEATED SEAT BACK ELEMENT

7 - DRIVER HEATED SEAT CUSHION ELEMENT

8 - HEATED SEAT MODULE

8G - 8 HEATED SEAT SYSTEMDR

HEATED SEAT SYSTEM (Continued)

Page 479 of 2627

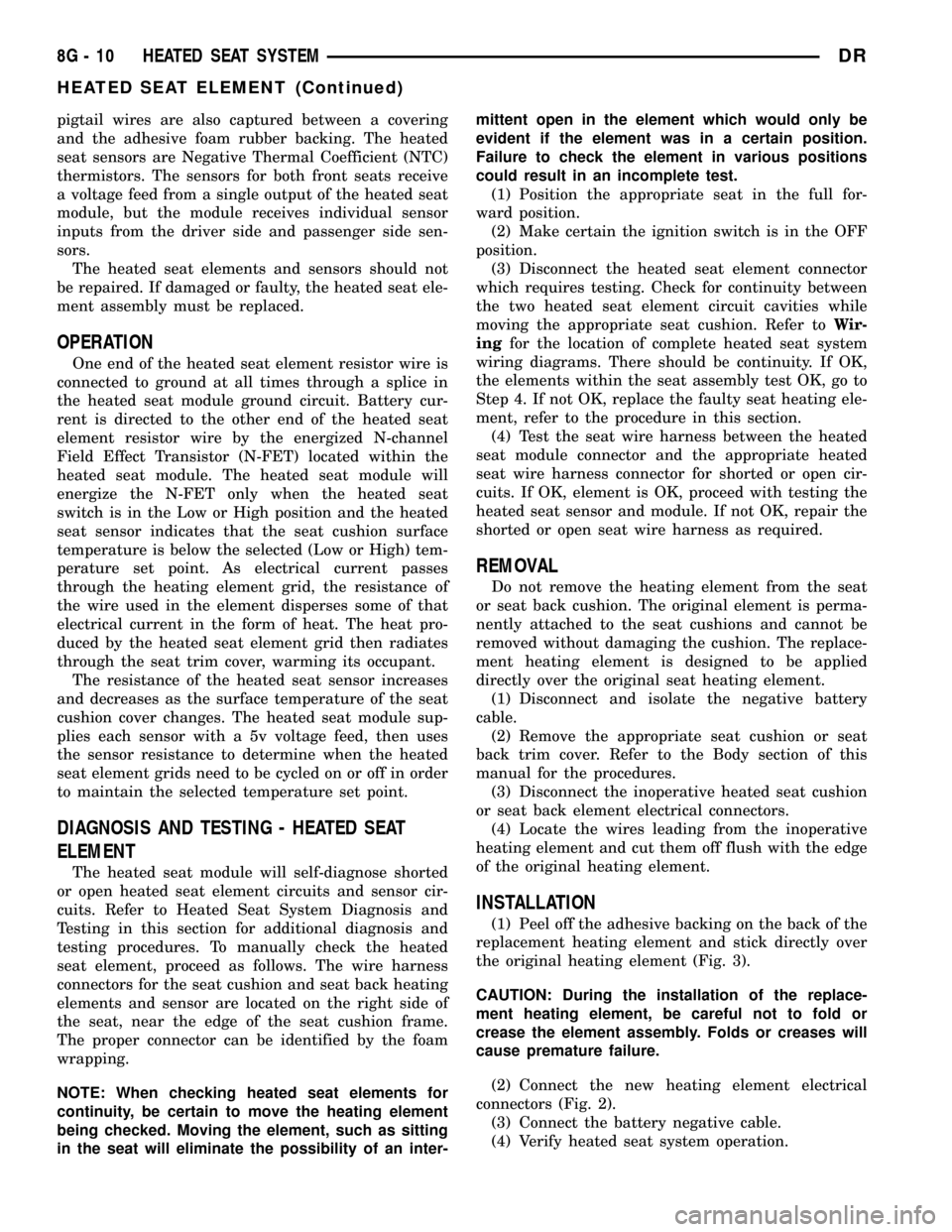

pigtail wires are also captured between a covering

and the adhesive foam rubber backing. The heated

seat sensors are Negative Thermal Coefficient (NTC)

thermistors. The sensors for both front seats receive

a voltage feed from a single output of the heated seat

module, but the module receives individual sensor

inputs from the driver side and passenger side sen-

sors.

The heated seat elements and sensors should not

be repaired. If damaged or faulty, the heated seat ele-

ment assembly must be replaced.

OPERATION

One end of the heated seat element resistor wire is

connected to ground at all times through a splice in

the heated seat module ground circuit. Battery cur-

rent is directed to the other end of the heated seat

element resistor wire by the energized N-channel

Field Effect Transistor (N-FET) located within the

heated seat module. The heated seat module will

energize the N-FET only when the heated seat

switch is in the Low or High position and the heated

seat sensor indicates that the seat cushion surface

temperature is below the selected (Low or High) tem-

perature set point. As electrical current passes

through the heating element grid, the resistance of

the wire used in the element disperses some of that

electrical current in the form of heat. The heat pro-

duced by the heated seat element grid then radiates

through the seat trim cover, warming its occupant.

The resistance of the heated seat sensor increases

and decreases as the surface temperature of the seat

cushion cover changes. The heated seat module sup-

plies each sensor with a 5v voltage feed, then uses

the sensor resistance to determine when the heated

seat element grids need to be cycled on or off in order

to maintain the selected temperature set point.

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENT

The heated seat module will self-diagnose shorted

or open heated seat element circuits and sensor cir-

cuits. Refer to Heated Seat System Diagnosis and

Testing in this section for additional diagnosis and

testing procedures. To manually check the heated

seat element, proceed as follows. The wire harness

connectors for the seat cushion and seat back heating

elements and sensor are located on the right side of

the seat, near the edge of the seat cushion frame.

The proper connector can be identified by the foam

wrapping.

NOTE: When checking heated seat elements for

continuity, be certain to move the heating element

being checked. Moving the element, such as sitting

in the seat will eliminate the possibility of an inter-mittent open in the element which would only be

evident if the element was in a certain position.

Failure to check the element in various positions

could result in an incomplete test.

(1) Position the appropriate seat in the full for-

ward position.

(2) Make certain the ignition switch is in the OFF

position.

(3) Disconnect the heated seat element connector

which requires testing. Check for continuity between

the two heated seat element circuit cavities while

moving the appropriate seat cushion. Refer toWir-

ingfor the location of complete heated seat system

wiring diagrams. There should be continuity. If OK,

the elements within the seat assembly test OK, go to

Step 4. If not OK, replace the faulty seat heating ele-

ment, refer to the procedure in this section.

(4) Test the seat wire harness between the heated

seat module connector and the appropriate heated

seat wire harness connector for shorted or open cir-

cuits. If OK, element is OK, proceed with testing the

heated seat sensor and module. If not OK, repair the

shorted or open seat wire harness as required.

REMOVAL

Do not remove the heating element from the seat

or seat back cushion. The original element is perma-

nently attached to the seat cushions and cannot be

removed without damaging the cushion. The replace-

ment heating element is designed to be applied

directly over the original seat heating element.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate seat cushion or seat

back trim cover. Refer to the Body section of this

manual for the procedures.

(3) Disconnect the inoperative heated seat cushion

or seat back element electrical connectors.

(4) Locate the wires leading from the inoperative

heating element and cut them off flush with the edge

of the original heating element.

INSTALLATION

(1) Peel off the adhesive backing on the back of the

replacement heating element and stick directly over

the original heating element (Fig. 3).

CAUTION: During the installation of the replace-

ment heating element, be careful not to fold or

crease the element assembly. Folds or creases will

cause premature failure.

(2) Connect the new heating element electrical

connectors (Fig. 2).

(3) Connect the battery negative cable.

(4) Verify heated seat system operation.

8G - 10 HEATED SEAT SYSTEMDR

HEATED SEAT ELEMENT (Continued)

Page 481 of 2627

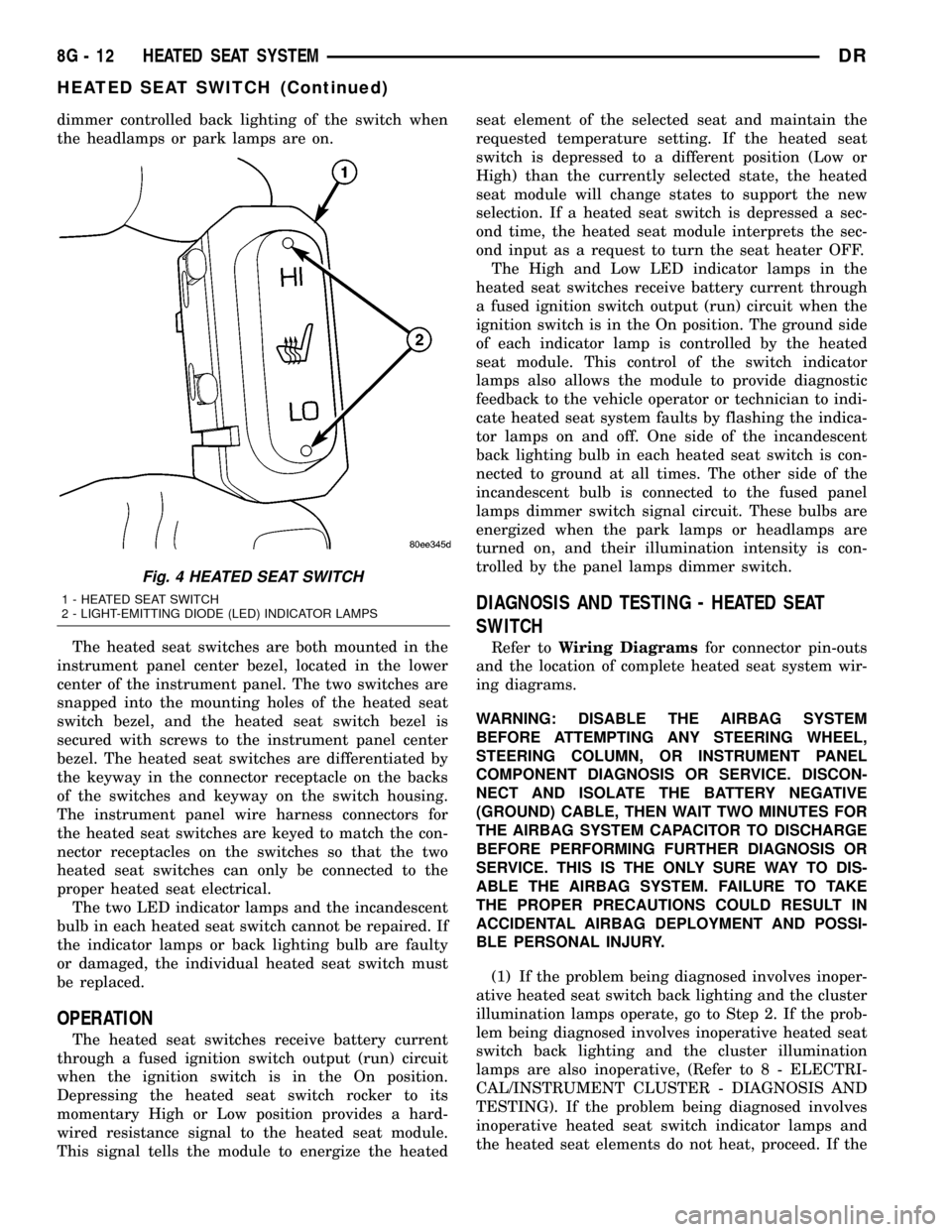

dimmer controlled back lighting of the switch when

the headlamps or park lamps are on.

The heated seat switches are both mounted in the

instrument panel center bezel, located in the lower

center of the instrument panel. The two switches are

snapped into the mounting holes of the heated seat

switch bezel, and the heated seat switch bezel is

secured with screws to the instrument panel center

bezel. The heated seat switches are differentiated by

the keyway in the connector receptacle on the backs

of the switches and keyway on the switch housing.

The instrument panel wire harness connectors for

the heated seat switches are keyed to match the con-

nector receptacles on the switches so that the two

heated seat switches can only be connected to the

proper heated seat electrical.

The two LED indicator lamps and the incandescent

bulb in each heated seat switch cannot be repaired. If

the indicator lamps or back lighting bulb are faulty

or damaged, the individual heated seat switch must

be replaced.

OPERATION

The heated seat switches receive battery current

through a fused ignition switch output (run) circuit

when the ignition switch is in the On position.

Depressing the heated seat switch rocker to its

momentary High or Low position provides a hard-

wired resistance signal to the heated seat module.

This signal tells the module to energize the heatedseat element of the selected seat and maintain the

requested temperature setting. If the heated seat

switch is depressed to a different position (Low or

High) than the currently selected state, the heated

seat module will change states to support the new

selection. If a heated seat switch is depressed a sec-

ond time, the heated seat module interprets the sec-

ond input as a request to turn the seat heater OFF.

The High and Low LED indicator lamps in the

heated seat switches receive battery current through

a fused ignition switch output (run) circuit when the

ignition switch is in the On position. The ground side

of each indicator lamp is controlled by the heated

seat module. This control of the switch indicator

lamps also allows the module to provide diagnostic

feedback to the vehicle operator or technician to indi-

cate heated seat system faults by flashing the indica-

tor lamps on and off. One side of the incandescent

back lighting bulb in each heated seat switch is con-

nected to ground at all times. The other side of the

incandescent bulb is connected to the fused panel

lamps dimmer switch signal circuit. These bulbs are

energized when the park lamps or headlamps are

turned on, and their illumination intensity is con-

trolled by the panel lamps dimmer switch.

DIAGNOSIS AND TESTING - HEATED SEAT

SWITCH

Refer toWiring Diagramsfor connector pin-outs

and the location of complete heated seat system wir-

ing diagrams.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1) If the problem being diagnosed involves inoper-

ative heated seat switch back lighting and the cluster

illumination lamps operate, go to Step 2. If the prob-

lem being diagnosed involves inoperative heated seat

switch back lighting and the cluster illumination

lamps are also inoperative, (Refer to 8 - ELECTRI-

CAL/INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). If the problem being diagnosed involves

inoperative heated seat switch indicator lamps and

the heated seat elements do not heat, proceed. If the

Fig. 4 HEATED SEAT SWITCH

1 - HEATED SEAT SWITCH

2 - LIGHT-EMITTING DIODE (LED) INDICATOR LAMPS

8G - 12 HEATED SEAT SYSTEMDR

HEATED SEAT SWITCH (Continued)

Page 482 of 2627

problem being diagnosed involves inoperative heated

seat switch indicator lamps and the heated seat ele-

ments do heat, go to Step 6. If the problem being

diagnosed involves a heated seat switch indicator

lamp that remains illuminated after the heated seat

has been turned Off, (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/MEMORY

HEATED SEAT/MIRROR MODULE - DIAGNOSIS

AND TESTING).

(2) Disconnect and isolate the battery negative

cable. Remove the heated seat switch and bezel unit

from the instrument panel. Disconnect the heated

seat switch to be tested. Check for continuity

between the ground circuit cavity of the heated seat

switch and a good ground. There should be continu-

ity. If OK, go to Step 3. If not OK, repair the open

ground circuit to ground as required.

(3) Reconnect the battery negative cable. Turn the

park lamps on with the headlamp switch. Rotate the

panel lamps dimmer thumb wheel on the headlamp

switch upward to just before the interior lamps

detent. Check for battery voltage at the fused panel

lamps dimmer circuit cavity of the heated seat

switch. If OK, go to Step 4. If not OK, repair the

open fused panel lamps dimmer switch signal circuit

to the fuse in the Integrated Power Module as

required.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) circuit cavity of the heated seat switch.

If OK, go to Step 5. If not OK, repair the open fused

ignition switch output (run) circuit as required.

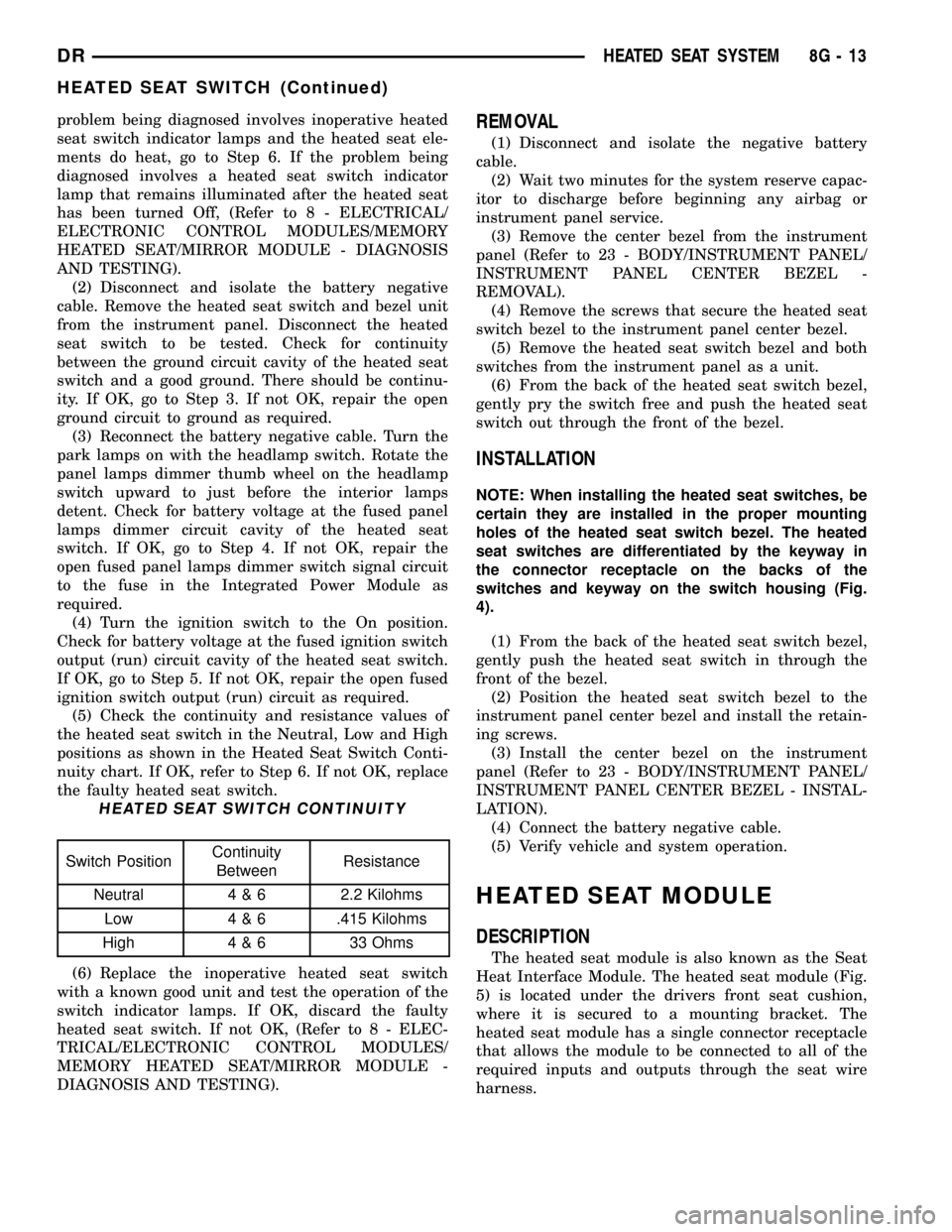

(5) Check the continuity and resistance values of

the heated seat switch in the Neutral, Low and High

positions as shown in the Heated Seat Switch Conti-

nuity chart. If OK, refer to Step 6. If not OK, replace

the faulty heated seat switch.

HEATED SEAT SWITCH CONTINUITY

Switch PositionContinuity

BetweenResistance

Neutral 4 & 6 2.2 Kilohms

Low 4 & 6 .415 Kilohms

High 4 & 6 33 Ohms

(6) Replace the inoperative heated seat switch

with a known good unit and test the operation of the

switch indicator lamps. If OK, discard the faulty

heated seat switch. If not OK, (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/

MEMORY HEATED SEAT/MIRROR MODULE -

DIAGNOSIS AND TESTING).

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Wait two minutes for the system reserve capac-

itor to discharge before beginning any airbag or

instrument panel service.

(3) Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL).

(4) Remove the screws that secure the heated seat

switch bezel to the instrument panel center bezel.

(5) Remove the heated seat switch bezel and both

switches from the instrument panel as a unit.

(6) From the back of the heated seat switch bezel,

gently pry the switch free and push the heated seat

switch out through the front of the bezel.

INSTALLATION

NOTE: When installing the heated seat switches, be

certain they are installed in the proper mounting

holes of the heated seat switch bezel. The heated

seat switches are differentiated by the keyway in

the connector receptacle on the backs of the

switches and keyway on the switch housing (Fig.

4).

(1) From the back of the heated seat switch bezel,

gently push the heated seat switch in through the

front of the bezel.

(2) Position the heated seat switch bezel to the

instrument panel center bezel and install the retain-

ing screws.

(3) Install the center bezel on the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(4) Connect the battery negative cable.

(5) Verify vehicle and system operation.

HEATED SEAT MODULE

DESCRIPTION

The heated seat module is also known as the Seat

Heat Interface Module. The heated seat module (Fig.

5) is located under the drivers front seat cushion,

where it is secured to a mounting bracket. The

heated seat module has a single connector receptacle

that allows the module to be connected to all of the

required inputs and outputs through the seat wire

harness.

DRHEATED SEAT SYSTEM 8G - 13

HEATED SEAT SWITCH (Continued)

Page 486 of 2627

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - HORN SYSTEM . . . 1

HORN

DIAGNOSIS AND TESTING - HORN..........1REMOVAL.............................2

INSTALLATION..........................2

HORN SWITCH

DESCRIPTION..........................2

DIAGNOSIS AND TESTING - HORN SWITCH . . . 2

HORN SYSTEM

DESCRIPTION

The dual-note horn system features dual electro-

magnetic horn units. The horn system includes the

following major components:

²Horn- The two horns are located on the left

side of the engine compartment below the Integrated

Power Module (IPM).

²Horn Switch- The horn switch is molded into

the driver airbag trim cover.

OPERATION

The horn system operates on battery current

received through a fuse in the Integrated Power

Module (IPM). The horn system circuit is designed so

that the system will remain operational, regardless

of the ignition switch position.

DIAGNOSIS AND TESTING - HORN SYSTEM

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIItscan tool and the proper Diag-

nostic Procedures manual.

Refer to the appropriate wiring information.

In most cases, any problem involving continually

sounding horns can be quickly alleviated by removing

the horn fuse from the Integrated Power Module

(IPM).

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

HORN

DIAGNOSIS AND TESTING - HORN

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIItscan tool and the proper Diag-

nostic Procedures manual. The DRBIIItscan

tool can provide confirmation that the PCI data

bus is functional, that all of the electronic mod-

ules are sending and receiving the proper mes-

sages on the PCI data bus, and that the horns

are being sent the proper hard wired outputs

for them to perform their functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

DRHORN 8H - 1

Page 514 of 2627

for more than about 1.6 kilometers (one mile) and

the vehicle speed remains greater than about twenty-

four kilometers-per-hour (fifteen miles-per-hour).

²Vacuum Fluorescent Display Synchroniza-

tion- The EMIC transmits electronic panel lamp

dimming level messages which allows all other elec-

tronic modules on the PCI data bus with Vacuum

Fluorescent Display (VFD) units to coordinate their

illumination intensity with that of the EMIC VFD

units.

²Vehicle Theft Security System- The EMIC

monitors inputs from the door cylinder lock

switch(es), the door ajar switches, the ignition

switch, and the Remote Keyless Entry (RKE) receiver

module, then provides electronic horn and lighting

request messages to the Front Control Module (FCM)

located on the Integrated Power Module (IPM) for

the appropriate VTSS alarm output features.

²Wiper/Washer System Control- The EMIC

provides electronic wiper and/or washer request mes-

sages to the Front Control Module (FCM) located on

the Integrated Power Module (IPM) for the appropri-

ate wiper and washer system features. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS - DESCRIP-

TION).

The EMIC houses six analog gauges and has pro-

visions for up to twenty-three indicators (Fig. 3) or

(Fig. 4). The EMIC includes the following analog

gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Oil Pressure Gauge

²Speedometer

²Tachometer

²Voltage Gauge

Some of the EMIC indicators are automatically

configured when the EMIC is connected to the vehi-

cle electrical system for compatibility with certain

optional equipment or equipment required for regula-

tory purposes in certain markets. While each EMIC

may have provisions for indicators to support every

available option, the configurable indicators will not

be functional in a vehicle that does not have the

equipment that an indicator supports. The EMIC

includes provisions for the following indicators (Fig.

3) or (Fig. 4):

²Airbag Indicator (with Airbag System only)

²Antilock Brake System (ABS) Indicator

(with ABS or Rear Wheel Anti-Lock [RWAL]

brakes only)

²Brake Indicator

²Cargo Lamp Indicator

²Check Gauges Indicator

²Cruise Indicator (with Speed Control only)

²Door Ajar Indicator²Electronic Throttle Control (ETC) Indicator

(with 5.7L Gasoline Engine only)

²Gear Selector Indicator (with Automatic

Transmission only)

²High Beam Indicator

²Lamp Out Indicator

²Low Fuel Indicator

²Malfunction Indicator Lamp (MIL)

²Seatbelt Indicator

²Security Indicator (with Sentry Key Immo-

bilizer & Vehicle Theft Security Systems only)

²Service Four-Wheel Drive Indicator (with

Four-Wheel Drive only)

²Tow/Haul Indicator (with Automatic Trans-

mission only)

²Transmission Overtemp Indicator (with

Automatic Transmission only)

²Turn Signal (Right and Left) Indicators

²Upshift Indicator (with Manual Transmis-

sion only)

²Washer Fluid Indicator

²Wait-To-Start Indicator (with Diesel Engine

only)

²Water-In-Fuel Indicator (with Diesel Engine

only)

Each indicator in the EMIC, except those located

within one of the VFD units, is illuminated by a ded-

icated LED that is soldered onto the EMIC electronic

circuit board. The LED units are not available for

service replacement and, if damaged or faulty, the

entire EMIC must be replaced. Cluster illumination

is accomplished by dimmable incandescent back

lighting, which illuminates the gauges for visibility

when the exterior lighting is turned on. Each of the

incandescent bulbs is secured by an integral bulb

holder to the electronic circuit board from the back of

the cluster housing.

Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the EMIC through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

The EMIC modules for this model are serviced only

as complete units. The EMIC module cannot be

adjusted or repaired. If a gauge, an LED indicator, a

VFD unit, the electronic circuit board, the circuit

DRINSTRUMENT CLUSTER 8J - 5

INSTRUMENT CLUSTER (Continued)