No start diagnosis DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 351 of 2627

INSTALLATION

(1) Install fan blade assembly to electrically con-

trolled viscous fan drive. Tighten mounting bolts to

24 N´m (18 ft. lbs.) torque.

(2) Position the fan blade/viscous fan drive to the

vehicle as an assembly.

(3) Install the viscous fan drive assembly onto fan

pulley hub shaft (Fig. 4). Tighten mounting nut to

115 N´m (85 ft. lbs.) torque.

(4) Install upper fan shroud. Make sure the upper

shroud locks into the tabs on the lower radiator.

(5) Install two upper shroud mounting bolts.

Tighten to 11.8 N´m (105 in. lbs.) torque.

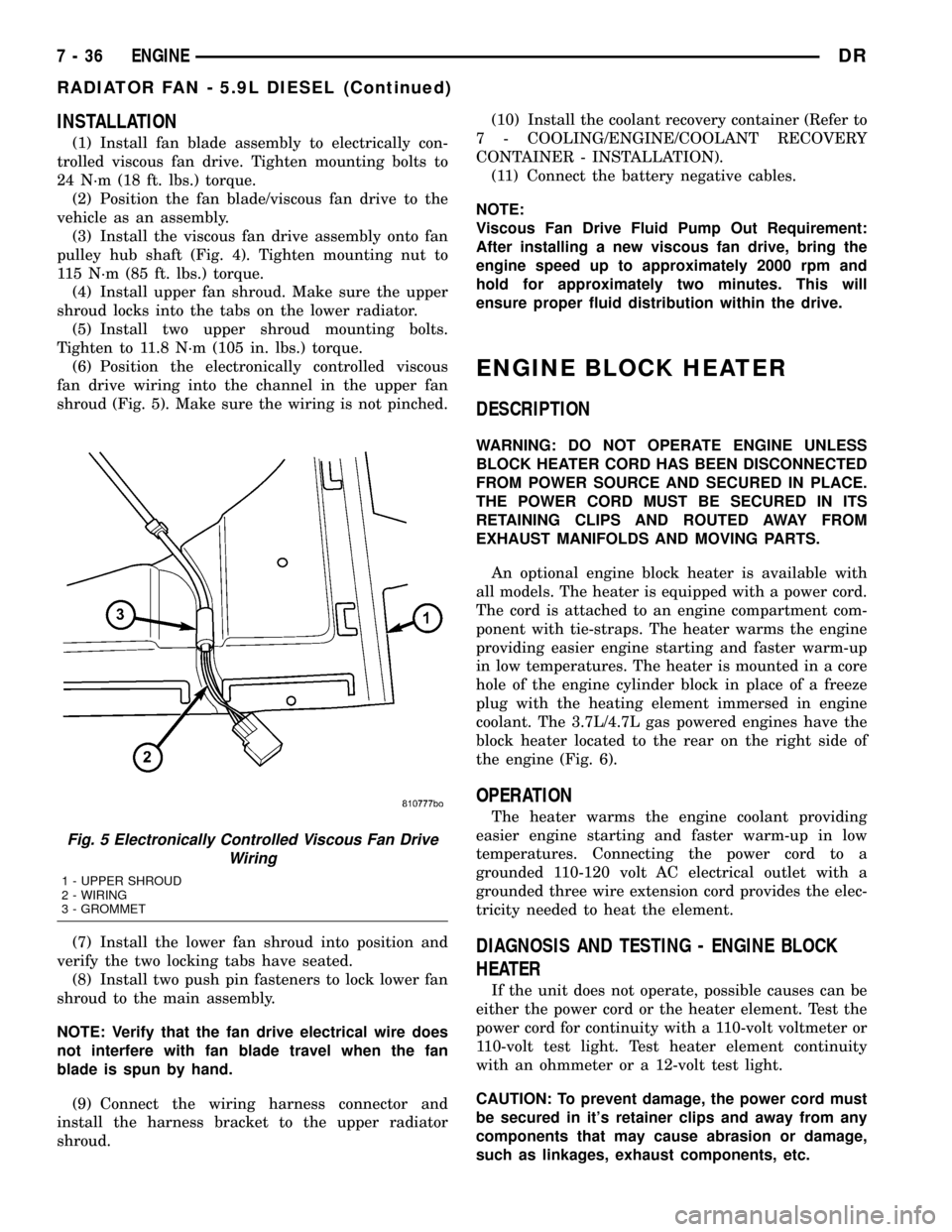

(6) Position the electronically controlled viscous

fan drive wiring into the channel in the upper fan

shroud (Fig. 5). Make sure the wiring is not pinched.

(7) Install the lower fan shroud into position and

verify the two locking tabs have seated.

(8) Install two push pin fasteners to lock lower fan

shroud to the main assembly.

NOTE: Verify that the fan drive electrical wire does

not interfere with fan blade travel when the fan

blade is spun by hand.

(9) Connect the wiring harness connector and

install the harness bracket to the upper radiator

shroud.(10) Install the coolant recovery container (Refer to

7 - COOLING/ENGINE/COOLANT RECOVERY

CONTAINER - INSTALLATION).

(11) Connect the battery negative cables.

NOTE:

Viscous Fan Drive Fluid Pump Out Requirement:

After installing a new viscous fan drive, bring the

engine speed up to approximately 2000 rpm and

hold for approximately two minutes. This will

ensure proper fluid distribution within the drive.

ENGINE BLOCK HEATER

DESCRIPTION

WARNING: DO NOT OPERATE ENGINE UNLESS

BLOCK HEATER CORD HAS BEEN DISCONNECTED

FROM POWER SOURCE AND SECURED IN PLACE.

THE POWER CORD MUST BE SECURED IN ITS

RETAINING CLIPS AND ROUTED AWAY FROM

EXHAUST MANIFOLDS AND MOVING PARTS.

An optional engine block heater is available with

all models. The heater is equipped with a power cord.

The cord is attached to an engine compartment com-

ponent with tie-straps. The heater warms the engine

providing easier engine starting and faster warm-up

in low temperatures. The heater is mounted in a core

hole of the engine cylinder block in place of a freeze

plug with the heating element immersed in engine

coolant. The 3.7L/4.7L gas powered engines have the

block heater located to the rear on the right side of

the engine (Fig. 6).

OPERATION

The heater warms the engine coolant providing

easier engine starting and faster warm-up in low

temperatures. Connecting the power cord to a

grounded 110-120 volt AC electrical outlet with a

grounded three wire extension cord provides the elec-

tricity needed to heat the element.

DIAGNOSIS AND TESTING - ENGINE BLOCK

HEATER

If the unit does not operate, possible causes can be

either the power cord or the heater element. Test the

power cord for continuity with a 110-volt voltmeter or

110-volt test light. Test heater element continuity

with an ohmmeter or a 12-volt test light.

CAUTION: To prevent damage, the power cord must

be secured in it's retainer clips and away from any

components that may cause abrasion or damage,

such as linkages, exhaust components, etc.

Fig. 5 Electronically Controlled Viscous Fan Drive

Wiring

1 - UPPER SHROUD

2 - WIRING

3 - GROMMET

7 - 36 ENGINEDR

RADIATOR FAN - 5.9L DIESEL (Continued)

Page 359 of 2627

(7) Air Conditioned vehicles; Install the generator.

Tighten the bolts to 41 N´m (30 ft. lbs.).

(8) Install the support bracket (generator mount-

ing bracket-to-intake manifold). (Fig. 17). Tighten the

bolts to 54 N´m (40 ft. lbs.).

(9) Install the accessory drive belt (Fig. 18)(Refer

to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - INSTALLATION).

(10) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(11) Connect battery negative cable.

(12) Start and warm the engine. Check for leaks.

ENGINE COOLANT

THERMOSTAT - 3.7L/4.7L

DESCRIPTION

CAUTION: Do not operate the engine without a ther-

mostat, except for servicing or testing.

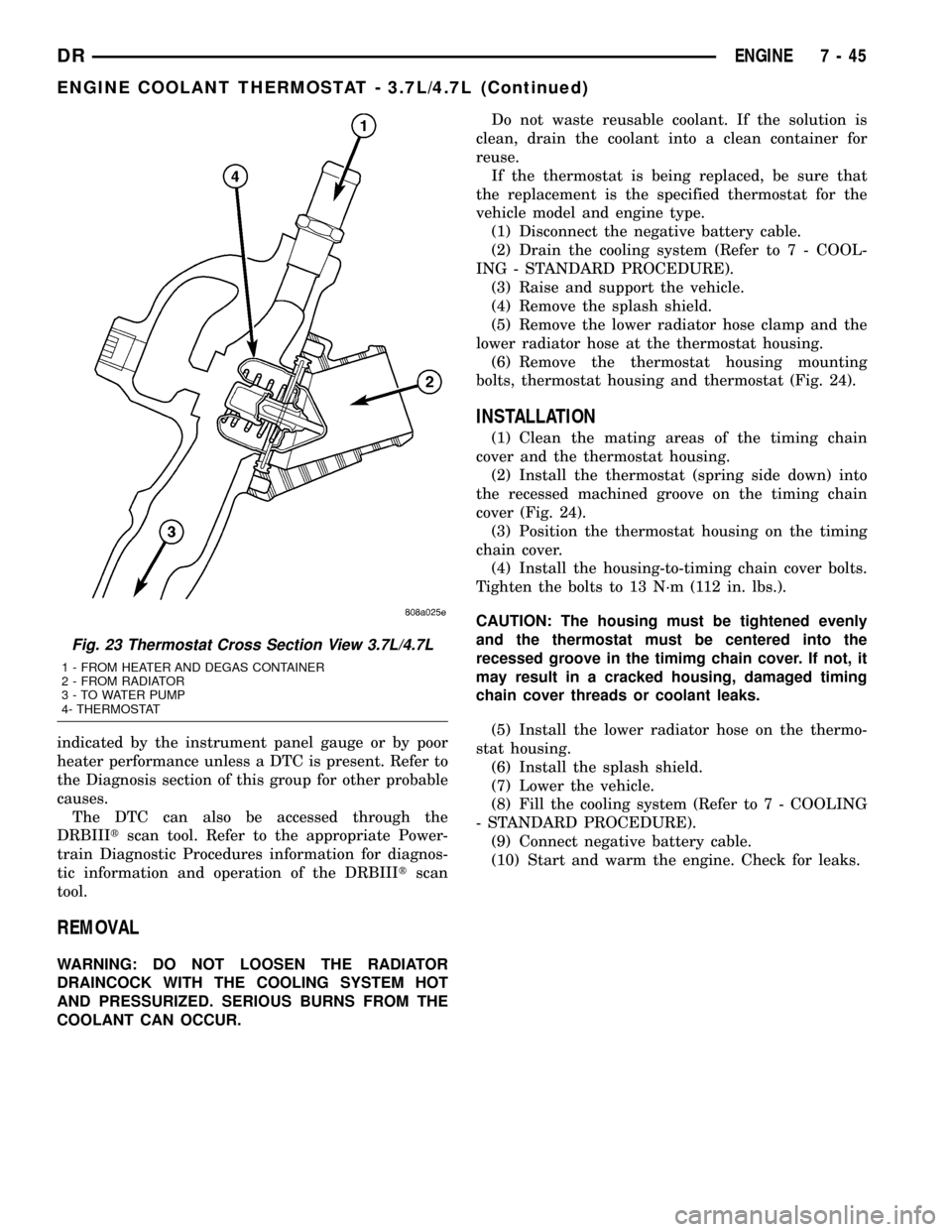

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator. On all engines the

thermostat is closed below 195ÉF (90ÉC). Above this

temperature, coolant is allowed to flow to the radia-

tor. This provides quick engine warm up and overall

temperature control. On the 3.7L4.7L engine the

thermostat is designed to block the flow of the cool-

ant bypass journal by 50% instead of completely

blocking the flow. This design controls coolant tem-

perature more accurately (Fig. 23).The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes other prob-

lems. These are: longer engine warmup time, unreli-

able warmup performance, increased exhaust

emissions and crankcase condensation. This conden-

sation can result in sludge formation.

OPERATION

The wax pellet is located in a sealed container at

the spring end of the thermostat. When heated, the

pellet expands, overcoming closing spring tension

and water pump pressure to force the valve to open.

DIAGNOSIS AND TESTINGÐTHERMOSTAT

ON-BOARD DIAGNOSTICS

Allgasoline powered modelsare equipped with

On-Board Diagnostics for certain cooling system com-

ponents. Refer to On-Board Diagnostics (OBD) in the

Diagnosis section of this group for additional infor-

mation. If the powertrain control module (PCM)

detects low engine coolant temperature, it will record

a Diagnostic Trouble Code (DTC) in the PCM mem-

ory. Do not change a thermostat for lack of heat as

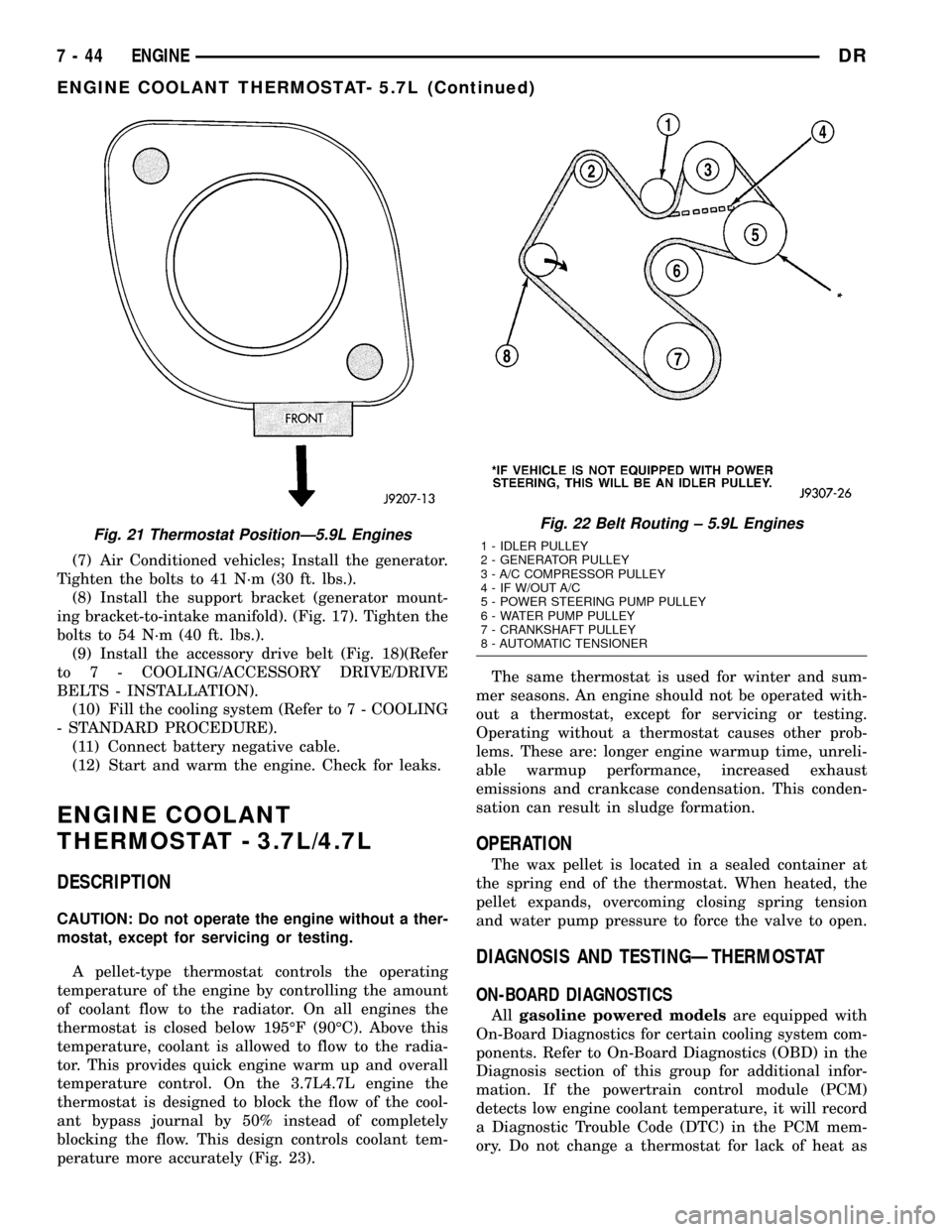

Fig. 21 Thermostat PositionÐ5.9L EnginesFig. 22 Belt Routing ± 5.9L Engines

1 - IDLER PULLEY

2 - GENERATOR PULLEY

3 - A/C COMPRESSOR PULLEY

4 - IF W/OUT A/C

5 - POWER STEERING PUMP PULLEY

6 - WATER PUMP PULLEY

7 - CRANKSHAFT PULLEY

8 - AUTOMATIC TENSIONER

7 - 44 ENGINEDR

ENGINE COOLANT THERMOSTAT- 5.7L (Continued)

Page 360 of 2627

indicated by the instrument panel gauge or by poor

heater performance unless a DTC is present. Refer to

the Diagnosis section of this group for other probable

causes.

The DTC can also be accessed through the

DRBIIItscan tool. Refer to the appropriate Power-

train Diagnostic Procedures information for diagnos-

tic information and operation of the DRBIIItscan

tool.

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE COOLING SYSTEM HOT

AND PRESSURIZED. SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for

reuse.

If the thermostat is being replaced, be sure that

the replacement is the specified thermostat for the

vehicle model and engine type.

(1) Disconnect the negative battery cable.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) Raise and support the vehicle.

(4) Remove the splash shield.

(5) Remove the lower radiator hose clamp and the

lower radiator hose at the thermostat housing.

(6) Remove the thermostat housing mounting

bolts, thermostat housing and thermostat (Fig. 24).

INSTALLATION

(1) Clean the mating areas of the timing chain

cover and the thermostat housing.

(2) Install the thermostat (spring side down) into

the recessed machined groove on the timing chain

cover (Fig. 24).

(3) Position the thermostat housing on the timing

chain cover.

(4) Install the housing-to-timing chain cover bolts.

Tighten the bolts to 13 N´m (112 in. lbs.).

CAUTION: The housing must be tightened evenly

and the thermostat must be centered into the

recessed groove in the timimg chain cover. If not, it

may result in a cracked housing, damaged timing

chain cover threads or coolant leaks.

(5) Install the lower radiator hose on the thermo-

stat housing.

(6) Install the splash shield.

(7) Lower the vehicle.

(8) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(9) Connect negative battery cable.

(10) Start and warm the engine. Check for leaks.

Fig. 23 Thermostat Cross Section View 3.7L/4.7L

1 - FROM HEATER AND DEGAS CONTAINER

2 - FROM RADIATOR

3 - TO WATER PUMP

4- THERMOSTAT

DRENGINE 7 - 45

ENGINE COOLANT THERMOSTAT - 3.7L/4.7L (Continued)

Page 362 of 2627

DIAGNOSIS AND TESTING - THERMOSTAT

The cooling system used with the diesel engine

provides the extra coolant capacity and extra cooling

protection needed for higher GVWR (Gross Vehicle

Weight Rating) and GCWR (Gross Combined Weight

Rating) vehicles.

This system capacity will not effect warm up or

cold weather operating characteristics if the thermo-

stat is operating properly. This is because coolant

will be held in the engine until it reaches the ther-

mostat ªsetº temperature.

Diesel engines, due to their inherent efficiency are

slower to warm up than gasoline powered engines,

and will operate at lower temperatures when the

vehicle is unloaded. Because of this, lower tempera-

ture gauge readings for diesel versus gasoline

engines may, at times be normal.

Typically, complaints of low engine coolant temper-

ature are observed as low heater output when com-

bined with cool or cold outside temperatures.

To help promote faster engine warm-up, the elec-

tric engine block heater must be used with cool or

cold outside temperatures. This will help keep the

engine coolant warm when the vehicle is parked.

A ªCold Weather Coverº is available from the parts

department through the Mopar Accessories product

line. This accessory cover is designed to block airflow

entering the radiator and engine compartment to

promote faster engine warm-up. It attaches to the

front of the vehicle at the grill opening.The cover is

to be used with cool or cold temperatures only.

If used with high outside temperatures, serious

engine damage could result.Refer to the litera-

ture supplied with the cover for additional informa-

tion.

(1) To determine if the thermostat is defective, it

must be removed from the vehicle (Refer to 7 -

COOLING/ENGINE/ENGINE COOLANT THERMO-

STAT - REMOVAL).

(2) After the thermostat has been removed, exam-

ine the thermostat and inside of thermostat housing

for contaminants. If contaminants are found, the

thermostat may already be in a ªstuck openº position.

Flush the cooling system before replacing thermostat

(Refer to 7 - COOLING - STANDARD PROCE-

DURE).

(3) Place the thermostat into a container filled

with water.

(4) Place the container on a hot plate or other suit-

able heating device.

(5) Place a commercially available radiator ther-

mometer into the water.

(6) Apply heat to the water while observing the

thermostat and thermometer.

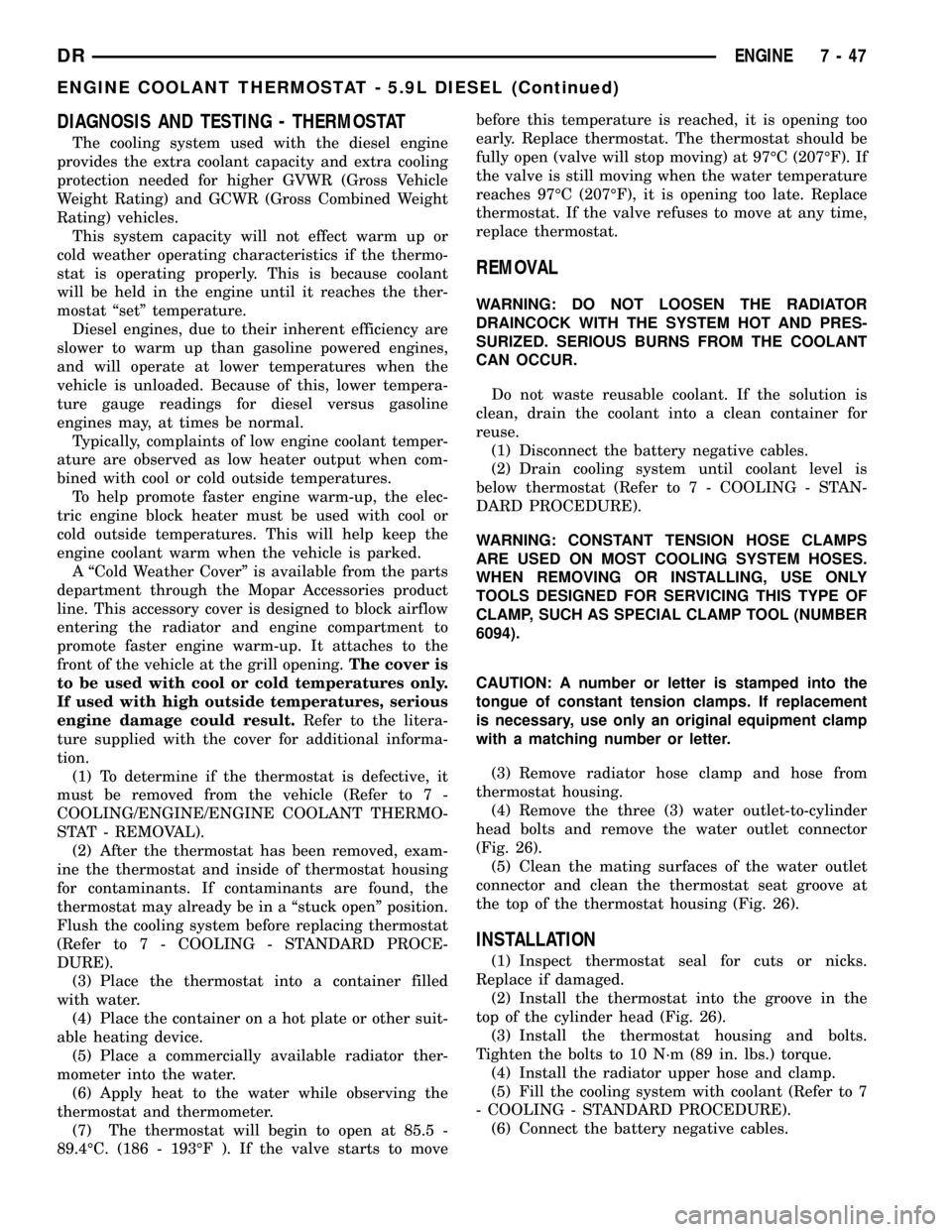

(7) The thermostat will begin to open at 85.5 -

89.4ÉC. (186 - 193ÉF ). If the valve starts to movebefore this temperature is reached, it is opening too

early. Replace thermostat. The thermostat should be

fully open (valve will stop moving) at 97ÉC (207ÉF). If

the valve is still moving when the water temperature

reaches 97ÉC (207ÉF), it is opening too late. Replace

thermostat. If the valve refuses to move at any time,

replace thermostat.

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND PRES-

SURIZED. SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for

reuse.

(1) Disconnect the battery negative cables.

(2) Drain cooling system until coolant level is

below thermostat (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094).

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

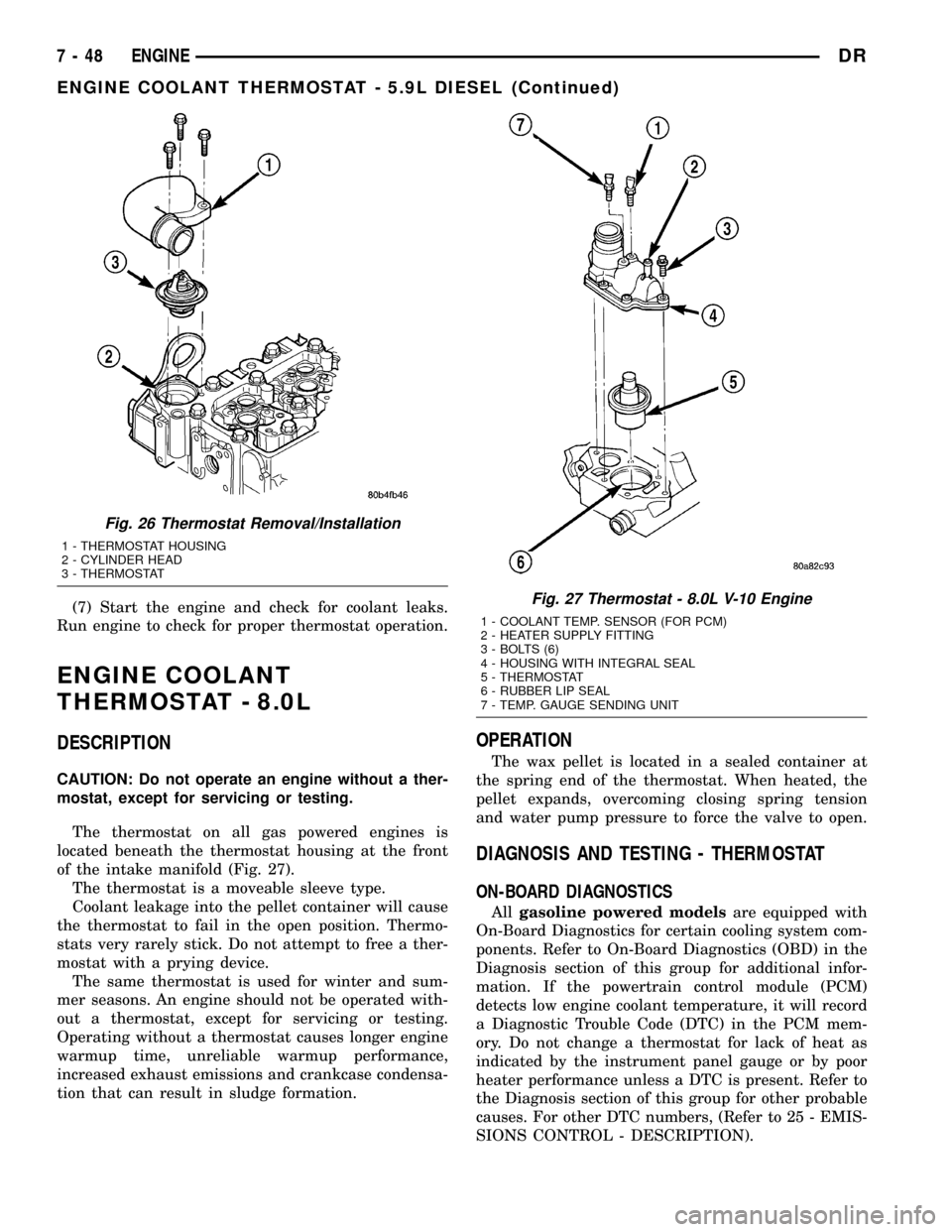

(3) Remove radiator hose clamp and hose from

thermostat housing.

(4) Remove the three (3) water outlet-to-cylinder

head bolts and remove the water outlet connector

(Fig. 26).

(5) Clean the mating surfaces of the water outlet

connector and clean the thermostat seat groove at

the top of the thermostat housing (Fig. 26).

INSTALLATION

(1) Inspect thermostat seal for cuts or nicks.

Replace if damaged.

(2) Install the thermostat into the groove in the

top of the cylinder head (Fig. 26).

(3) Install the thermostat housing and bolts.

Tighten the bolts to 10 N´m (89 in. lbs.) torque.

(4) Install the radiator upper hose and clamp.

(5) Fill the cooling system with coolant (Refer to 7

- COOLING - STANDARD PROCEDURE).

(6) Connect the battery negative cables.

DRENGINE 7 - 47

ENGINE COOLANT THERMOSTAT - 5.9L DIESEL (Continued)

Page 363 of 2627

(7) Start the engine and check for coolant leaks.

Run engine to check for proper thermostat operation.

ENGINE COOLANT

THERMOSTAT - 8.0L

DESCRIPTION

CAUTION: Do not operate an engine without a ther-

mostat, except for servicing or testing.

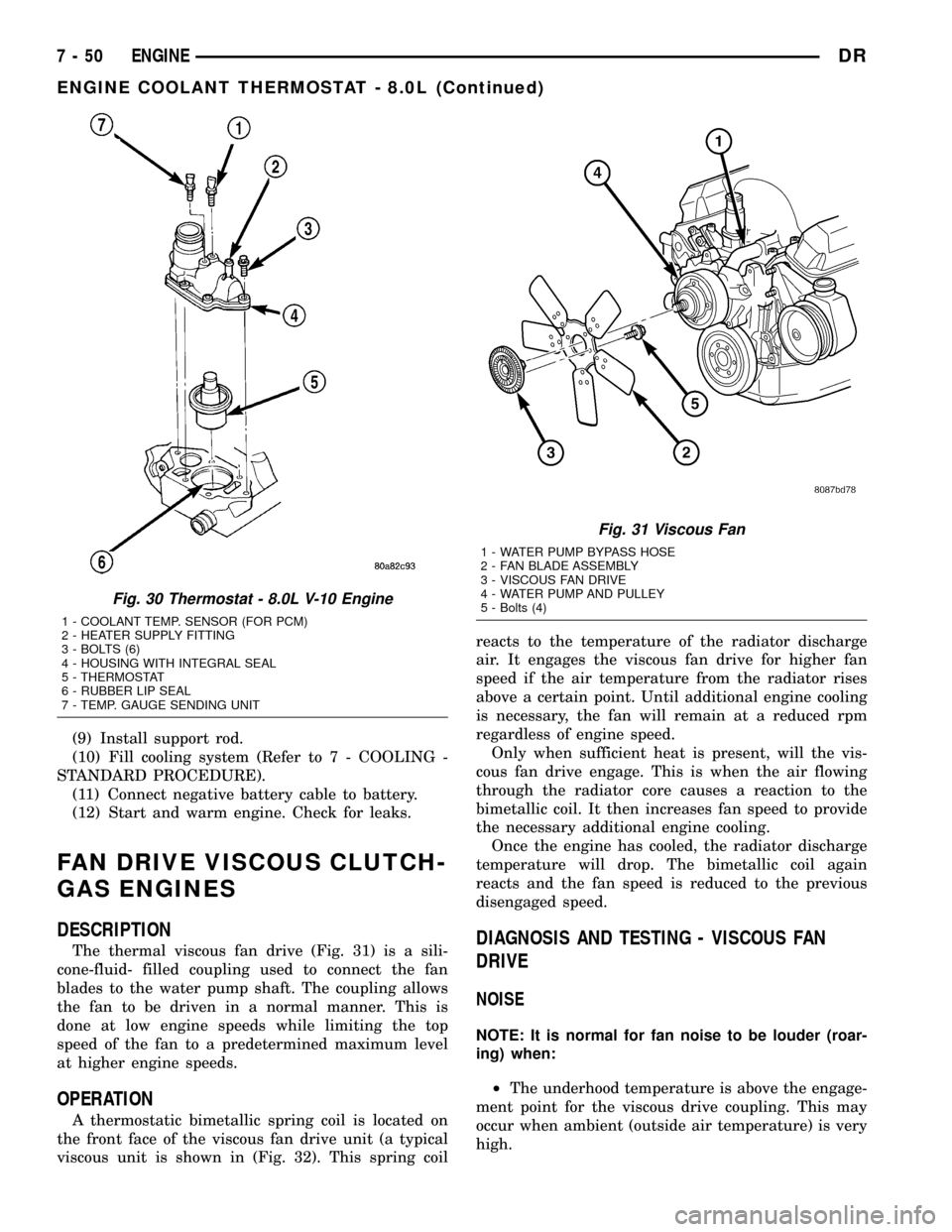

The thermostat on all gas powered engines is

located beneath the thermostat housing at the front

of the intake manifold (Fig. 27).

The thermostat is a moveable sleeve type.

Coolant leakage into the pellet container will cause

the thermostat to fail in the open position. Thermo-

stats very rarely stick. Do not attempt to free a ther-

mostat with a prying device.

The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes longer engine

warmup time, unreliable warmup performance,

increased exhaust emissions and crankcase condensa-

tion that can result in sludge formation.

OPERATION

The wax pellet is located in a sealed container at

the spring end of the thermostat. When heated, the

pellet expands, overcoming closing spring tension

and water pump pressure to force the valve to open.

DIAGNOSIS AND TESTING - THERMOSTAT

ON-BOARD DIAGNOSTICS

Allgasoline powered modelsare equipped with

On-Board Diagnostics for certain cooling system com-

ponents. Refer to On-Board Diagnostics (OBD) in the

Diagnosis section of this group for additional infor-

mation. If the powertrain control module (PCM)

detects low engine coolant temperature, it will record

a Diagnostic Trouble Code (DTC) in the PCM mem-

ory. Do not change a thermostat for lack of heat as

indicated by the instrument panel gauge or by poor

heater performance unless a DTC is present. Refer to

the Diagnosis section of this group for other probable

causes. For other DTC numbers, (Refer to 25 - EMIS-

SIONS CONTROL - DESCRIPTION).

Fig. 26 Thermostat Removal/Installation

1 - THERMOSTAT HOUSING

2 - CYLINDER HEAD

3 - THERMOSTAT

Fig. 27 Thermostat - 8.0L V-10 Engine

1 - COOLANT TEMP. SENSOR (FOR PCM)

2 - HEATER SUPPLY FITTING

3 - BOLTS (6)

4 - HOUSING WITH INTEGRAL SEAL

5 - THERMOSTAT

6 - RUBBER LIP SEAL

7 - TEMP. GAUGE SENDING UNIT

7 - 48 ENGINEDR

ENGINE COOLANT THERMOSTAT - 5.9L DIESEL (Continued)

Page 365 of 2627

(9) Install support rod.

(10) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(11) Connect negative battery cable to battery.

(12) Start and warm engine. Check for leaks.

FAN DRIVE VISCOUS CLUTCH-

GAS ENGINES

DESCRIPTION

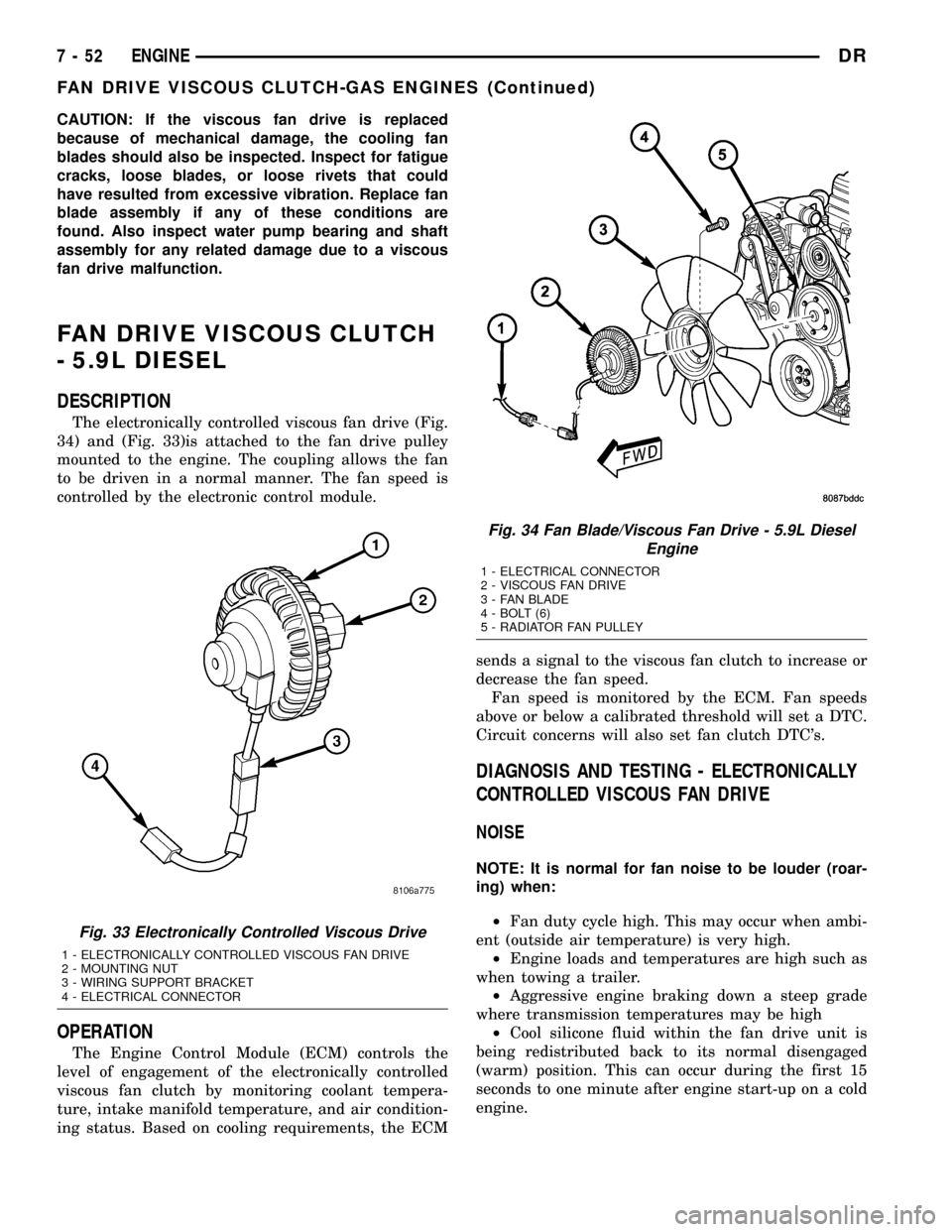

The thermal viscous fan drive (Fig. 31) is a sili-

cone-fluid- filled coupling used to connect the fan

blades to the water pump shaft. The coupling allows

the fan to be driven in a normal manner. This is

done at low engine speeds while limiting the top

speed of the fan to a predetermined maximum level

at higher engine speeds.

OPERATION

A thermostatic bimetallic spring coil is located on

the front face of the viscous fan drive unit (a typical

viscous unit is shown in (Fig. 32). This spring coilreacts to the temperature of the radiator discharge

air. It engages the viscous fan drive for higher fan

speed if the air temperature from the radiator rises

above a certain point. Until additional engine cooling

is necessary, the fan will remain at a reduced rpm

regardless of engine speed.

Only when sufficient heat is present, will the vis-

cous fan drive engage. This is when the air flowing

through the radiator core causes a reaction to the

bimetallic coil. It then increases fan speed to provide

the necessary additional engine cooling.

Once the engine has cooled, the radiator discharge

temperature will drop. The bimetallic coil again

reacts and the fan speed is reduced to the previous

disengaged speed.

DIAGNOSIS AND TESTING - VISCOUS FAN

DRIVE

NOISE

NOTE: It is normal for fan noise to be louder (roar-

ing) when:

²The underhood temperature is above the engage-

ment point for the viscous drive coupling. This may

occur when ambient (outside air temperature) is very

high.

Fig. 30 Thermostat - 8.0L V-10 Engine

1 - COOLANT TEMP. SENSOR (FOR PCM)

2 - HEATER SUPPLY FITTING

3 - BOLTS (6)

4 - HOUSING WITH INTEGRAL SEAL

5 - THERMOSTAT

6 - RUBBER LIP SEAL

7 - TEMP. GAUGE SENDING UNIT

Fig. 31 Viscous Fan

1 - WATER PUMP BYPASS HOSE

2 - FAN BLADE ASSEMBLY

3 - VISCOUS FAN DRIVE

4 - WATER PUMP AND PULLEY

5 - Bolts (4)

7 - 50 ENGINEDR

ENGINE COOLANT THERMOSTAT - 8.0L (Continued)

Page 367 of 2627

CAUTION: If the viscous fan drive is replaced

because of mechanical damage, the cooling fan

blades should also be inspected. Inspect for fatigue

cracks, loose blades, or loose rivets that could

have resulted from excessive vibration. Replace fan

blade assembly if any of these conditions are

found. Also inspect water pump bearing and shaft

assembly for any related damage due to a viscous

fan drive malfunction.

FAN DRIVE VISCOUS CLUTCH

- 5.9L DIESEL

DESCRIPTION

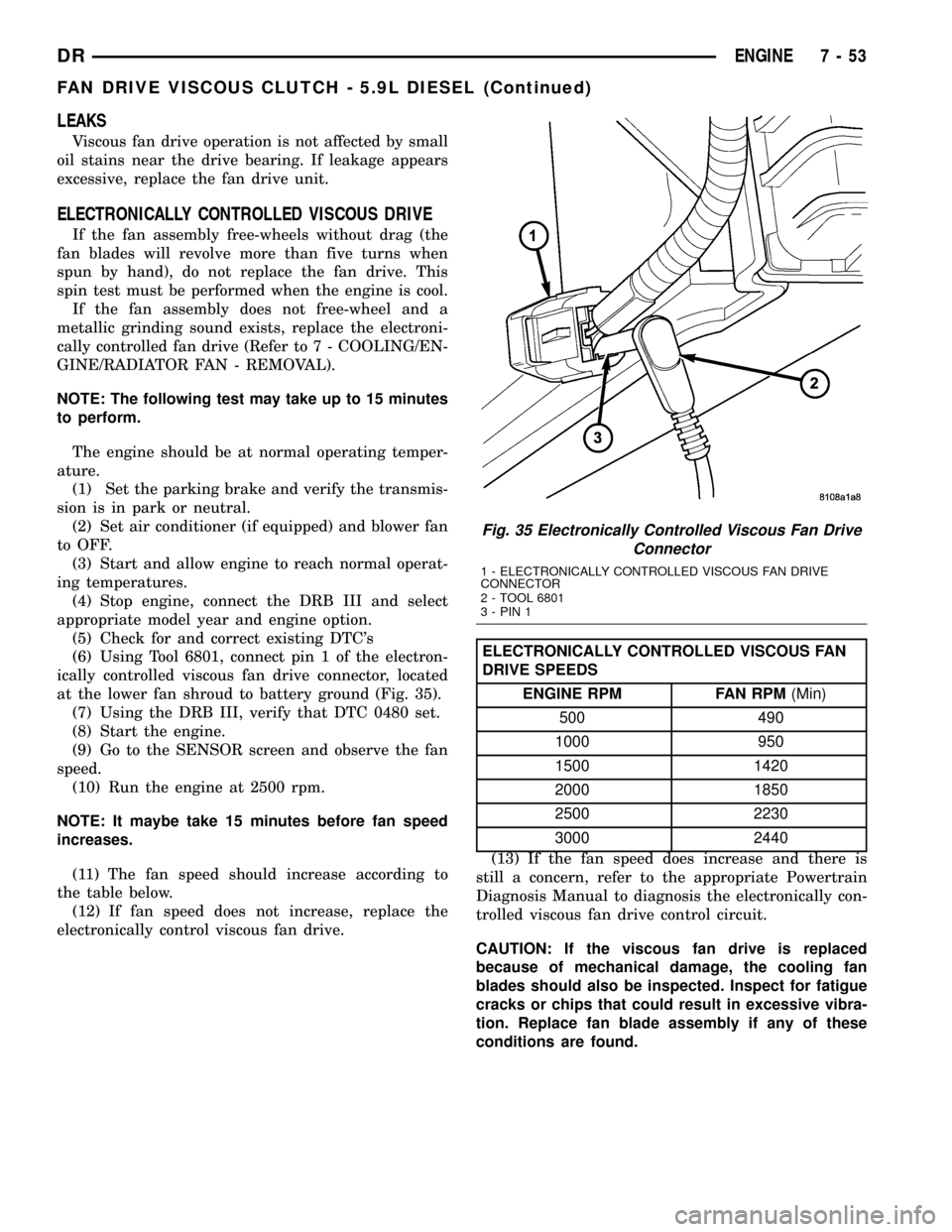

The electronically controlled viscous fan drive (Fig.

34) and (Fig. 33)is attached to the fan drive pulley

mounted to the engine. The coupling allows the fan

to be driven in a normal manner. The fan speed is

controlled by the electronic control module.

OPERATION

The Engine Control Module (ECM) controls the

level of engagement of the electronically controlled

viscous fan clutch by monitoring coolant tempera-

ture, intake manifold temperature, and air condition-

ing status. Based on cooling requirements, the ECMsends a signal to the viscous fan clutch to increase or

decrease the fan speed.

Fan speed is monitored by the ECM. Fan speeds

above or below a calibrated threshold will set a DTC.

Circuit concerns will also set fan clutch DTC's.

DIAGNOSIS AND TESTING - ELECTRONICALLY

CONTROLLED VISCOUS FAN DRIVE

NOISE

NOTE: It is normal for fan noise to be louder (roar-

ing) when:

²Fan duty cycle high. This may occur when ambi-

ent (outside air temperature) is very high.

²Engine loads and temperatures are high such as

when towing a trailer.

²Aggressive engine braking down a steep grade

where transmission temperatures may be high

²Cool silicone fluid within the fan drive unit is

being redistributed back to its normal disengaged

(warm) position. This can occur during the first 15

seconds to one minute after engine start-up on a cold

engine.

Fig. 33 Electronically Controlled Viscous Drive

1 - ELECTRONICALLY CONTROLLED VISCOUS FAN DRIVE

2 - MOUNTING NUT

3 - WIRING SUPPORT BRACKET

4 - ELECTRICAL CONNECTOR

Fig. 34 Fan Blade/Viscous Fan Drive - 5.9L Diesel

Engine

1 - ELECTRICAL CONNECTOR

2 - VISCOUS FAN DRIVE

3 - FAN BLADE

4 - BOLT (6)

5 - RADIATOR FAN PULLEY

7 - 52 ENGINEDR

FAN DRIVE VISCOUS CLUTCH-GAS ENGINES (Continued)

Page 368 of 2627

LEAKS

Viscous fan drive operation is not affected by small

oil stains near the drive bearing. If leakage appears

excessive, replace the fan drive unit.

ELECTRONICALLY CONTROLLED VISCOUS DRIVE

If the fan assembly free-wheels without drag (the

fan blades will revolve more than five turns when

spun by hand), do not replace the fan drive. This

spin test must be performed when the engine is cool.

If the fan assembly does not free-wheel and a

metallic grinding sound exists, replace the electroni-

cally controlled fan drive (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - REMOVAL).

NOTE: The following test may take up to 15 minutes

to perform.

The engine should be at normal operating temper-

ature.

(1) Set the parking brake and verify the transmis-

sion is in park or neutral.

(2) Set air conditioner (if equipped) and blower fan

to OFF.

(3) Start and allow engine to reach normal operat-

ing temperatures.

(4) Stop engine, connect the DRB III and select

appropriate model year and engine option.

(5) Check for and correct existing DTC's

(6) Using Tool 6801, connect pin 1 of the electron-

ically controlled viscous fan drive connector, located

at the lower fan shroud to battery ground (Fig. 35).

(7) Using the DRB III, verify that DTC 0480 set.

(8) Start the engine.

(9) Go to the SENSOR screen and observe the fan

speed.

(10) Run the engine at 2500 rpm.

NOTE: It maybe take 15 minutes before fan speed

increases.

(11) The fan speed should increase according to

the table below.

(12) If fan speed does not increase, replace the

electronically control viscous fan drive.

ELECTRONICALLY CONTROLLED VISCOUS FAN

DRIVE SPEEDS

ENGINE RPM FAN RPM(Min)

500 490

1000 950

1500 1420

2000 1850

2500 2230

3000 2440

(13) If the fan speed does increase and there is

still a concern, refer to the appropriate Powertrain

Diagnosis Manual to diagnosis the electronically con-

trolled viscous fan drive control circuit.

CAUTION: If the viscous fan drive is replaced

because of mechanical damage, the cooling fan

blades should also be inspected. Inspect for fatigue

cracks or chips that could result in excessive vibra-

tion. Replace fan blade assembly if any of these

conditions are found.

Fig. 35 Electronically Controlled Viscous Fan Drive

Connector

1 - ELECTRONICALLY CONTROLLED VISCOUS FAN DRIVE

CONNECTOR

2 - TOOL 6801

3 - PIN 1

DRENGINE 7 - 53

FAN DRIVE VISCOUS CLUTCH - 5.9L DIESEL (Continued)

Page 377 of 2627

(3) Spin the water pump to be sure that the pump

impeller does not rub against the timing chain case/

cover.

(4) Connect the radiator lower hose to the water

pump.

(5) Relax the tension from the belt tensioner (Fig.

46). Install the drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

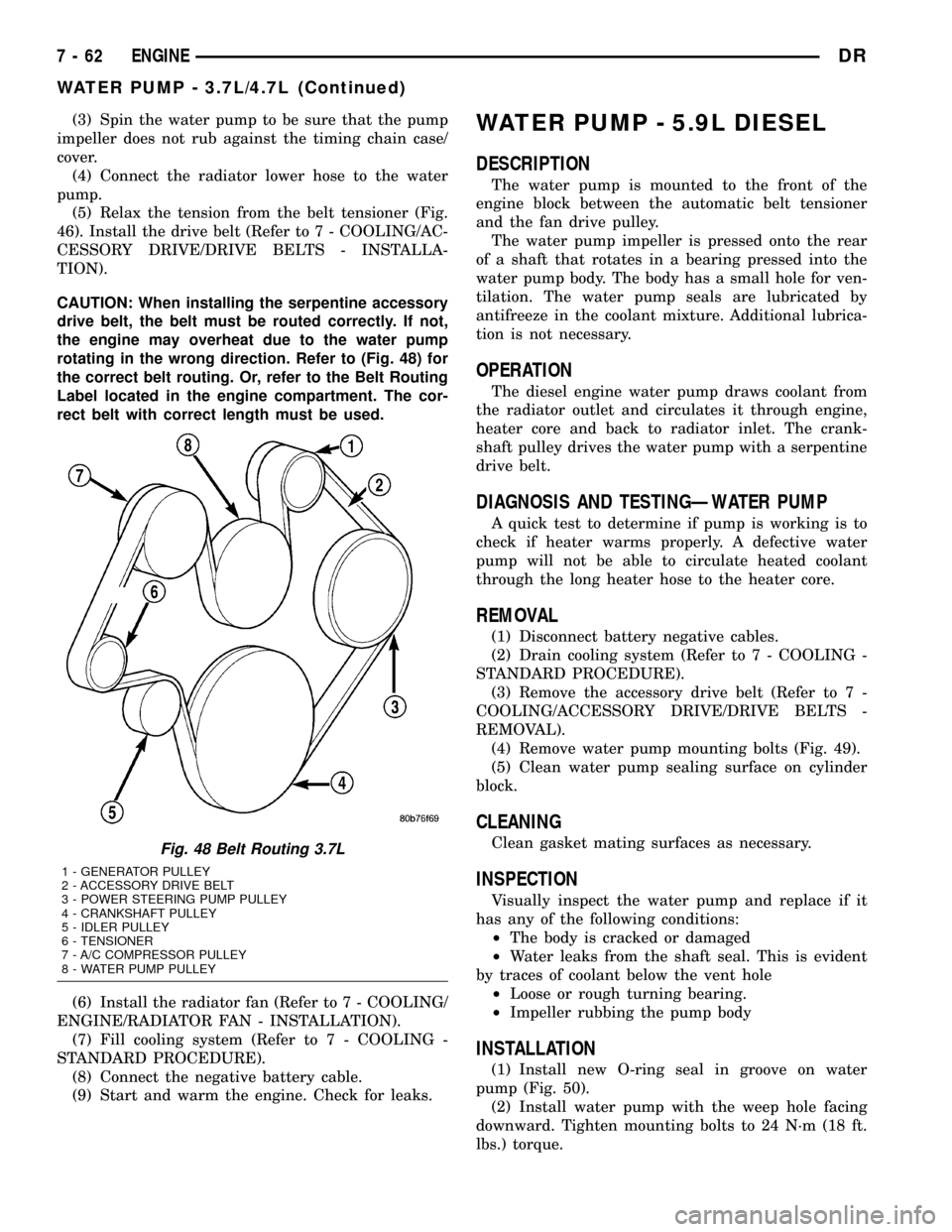

CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction. Refer to (Fig. 48) for

the correct belt routing. Or, refer to the Belt Routing

Label located in the engine compartment. The cor-

rect belt with correct length must be used.

(6) Install the radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(7) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(8) Connect the negative battery cable.

(9) Start and warm the engine. Check for leaks.WATER PUMP - 5.9L DIESEL

DESCRIPTION

The water pump is mounted to the front of the

engine block between the automatic belt tensioner

and the fan drive pulley.

The water pump impeller is pressed onto the rear

of a shaft that rotates in a bearing pressed into the

water pump body. The body has a small hole for ven-

tilation. The water pump seals are lubricated by

antifreeze in the coolant mixture. Additional lubrica-

tion is not necessary.

OPERATION

The diesel engine water pump draws coolant from

the radiator outlet and circulates it through engine,

heater core and back to radiator inlet. The crank-

shaft pulley drives the water pump with a serpentine

drive belt.

DIAGNOSIS AND TESTINGÐWATER PUMP

A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

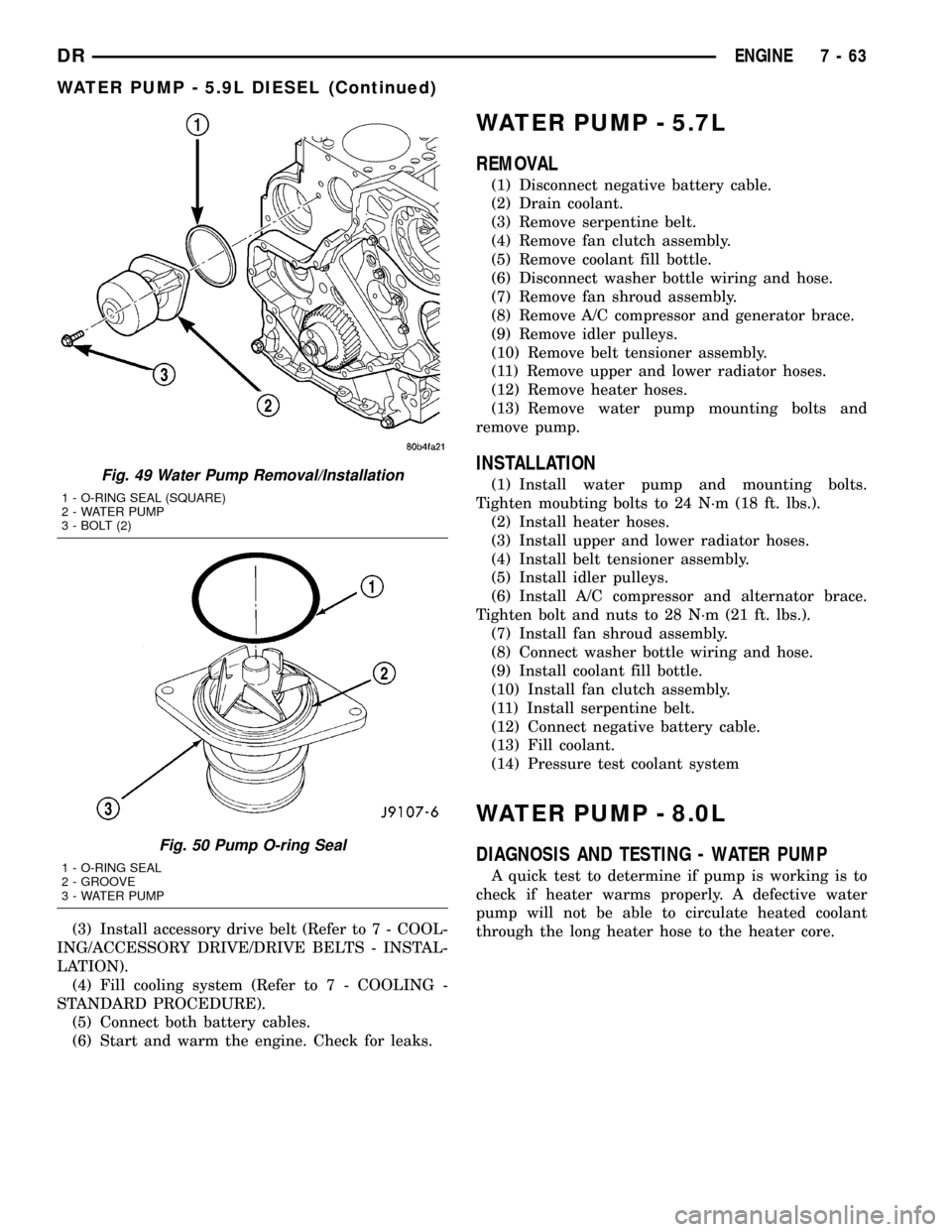

REMOVAL

(1) Disconnect battery negative cables.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove water pump mounting bolts (Fig. 49).

(5) Clean water pump sealing surface on cylinder

block.

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Visually inspect the water pump and replace if it

has any of the following conditions:

²The body is cracked or damaged

²Water leaks from the shaft seal. This is evident

by traces of coolant below the vent hole

²Loose or rough turning bearing.

²Impeller rubbing the pump body

INSTALLATION

(1) Install new O-ring seal in groove on water

pump (Fig. 50).

(2) Install water pump with the weep hole facing

downward. Tighten mounting bolts to 24 N´m (18 ft.

lbs.) torque.

Fig. 48 Belt Routing 3.7L

1 - GENERATOR PULLEY

2 - ACCESSORY DRIVE BELT

3 - POWER STEERING PUMP PULLEY

4 - CRANKSHAFT PULLEY

5 - IDLER PULLEY

6 - TENSIONER

7 - A/C COMPRESSOR PULLEY

8 - WATER PUMP PULLEY

7 - 62 ENGINEDR

WATER PUMP - 3.7L/4.7L (Continued)

Page 378 of 2627

(3) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(4) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(5) Connect both battery cables.

(6) Start and warm the engine. Check for leaks.

WATER PUMP - 5.7L

REMOVAL

(1) Disconnect negative battery cable.

(2) Drain coolant.

(3) Remove serpentine belt.

(4) Remove fan clutch assembly.

(5) Remove coolant fill bottle.

(6) Disconnect washer bottle wiring and hose.

(7) Remove fan shroud assembly.

(8) Remove A/C compressor and generator brace.

(9) Remove idler pulleys.

(10) Remove belt tensioner assembly.

(11) Remove upper and lower radiator hoses.

(12) Remove heater hoses.

(13) Remove water pump mounting bolts and

remove pump.

INSTALLATION

(1) Install water pump and mounting bolts.

Tighten moubting bolts to 24 N´m (18 ft. lbs.).

(2) Install heater hoses.

(3) Install upper and lower radiator hoses.

(4) Install belt tensioner assembly.

(5) Install idler pulleys.

(6) Install A/C compressor and alternator brace.

Tighten bolt and nuts to 28 N´m (21 ft. lbs.).

(7) Install fan shroud assembly.

(8) Connect washer bottle wiring and hose.

(9) Install coolant fill bottle.

(10) Install fan clutch assembly.

(11) Install serpentine belt.

(12) Connect negative battery cable.

(13) Fill coolant.

(14) Pressure test coolant system

WATER PUMP - 8.0L

DIAGNOSIS AND TESTING - WATER PUMP

A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

Fig. 49 Water Pump Removal/Installation

1 - O-RING SEAL (SQUARE)

2 - WATER PUMP

3 - BOLT (2)

Fig. 50 Pump O-ring Seal

1 - O-RING SEAL

2 - GROOVE

3 - WATER PUMP

DRENGINE 7 - 63

WATER PUMP - 5.9L DIESEL (Continued)