Power control DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 368 of 2627

LEAKS

Viscous fan drive operation is not affected by small

oil stains near the drive bearing. If leakage appears

excessive, replace the fan drive unit.

ELECTRONICALLY CONTROLLED VISCOUS DRIVE

If the fan assembly free-wheels without drag (the

fan blades will revolve more than five turns when

spun by hand), do not replace the fan drive. This

spin test must be performed when the engine is cool.

If the fan assembly does not free-wheel and a

metallic grinding sound exists, replace the electroni-

cally controlled fan drive (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - REMOVAL).

NOTE: The following test may take up to 15 minutes

to perform.

The engine should be at normal operating temper-

ature.

(1) Set the parking brake and verify the transmis-

sion is in park or neutral.

(2) Set air conditioner (if equipped) and blower fan

to OFF.

(3) Start and allow engine to reach normal operat-

ing temperatures.

(4) Stop engine, connect the DRB III and select

appropriate model year and engine option.

(5) Check for and correct existing DTC's

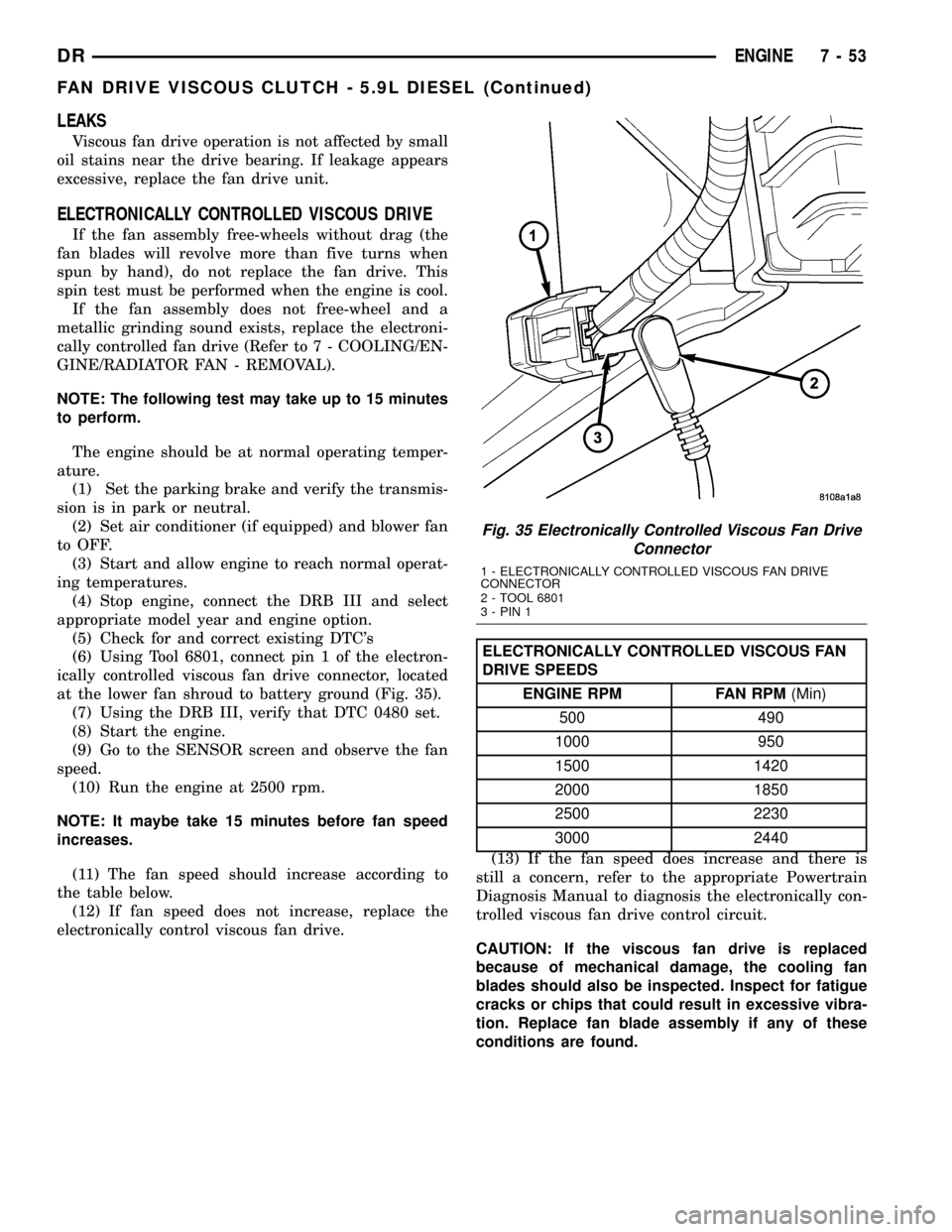

(6) Using Tool 6801, connect pin 1 of the electron-

ically controlled viscous fan drive connector, located

at the lower fan shroud to battery ground (Fig. 35).

(7) Using the DRB III, verify that DTC 0480 set.

(8) Start the engine.

(9) Go to the SENSOR screen and observe the fan

speed.

(10) Run the engine at 2500 rpm.

NOTE: It maybe take 15 minutes before fan speed

increases.

(11) The fan speed should increase according to

the table below.

(12) If fan speed does not increase, replace the

electronically control viscous fan drive.

ELECTRONICALLY CONTROLLED VISCOUS FAN

DRIVE SPEEDS

ENGINE RPM FAN RPM(Min)

500 490

1000 950

1500 1420

2000 1850

2500 2230

3000 2440

(13) If the fan speed does increase and there is

still a concern, refer to the appropriate Powertrain

Diagnosis Manual to diagnosis the electronically con-

trolled viscous fan drive control circuit.

CAUTION: If the viscous fan drive is replaced

because of mechanical damage, the cooling fan

blades should also be inspected. Inspect for fatigue

cracks or chips that could result in excessive vibra-

tion. Replace fan blade assembly if any of these

conditions are found.

Fig. 35 Electronically Controlled Viscous Fan Drive

Connector

1 - ELECTRONICALLY CONTROLLED VISCOUS FAN DRIVE

CONNECTOR

2 - TOOL 6801

3 - PIN 1

DRENGINE 7 - 53

FAN DRIVE VISCOUS CLUTCH - 5.9L DIESEL (Continued)

Page 372 of 2627

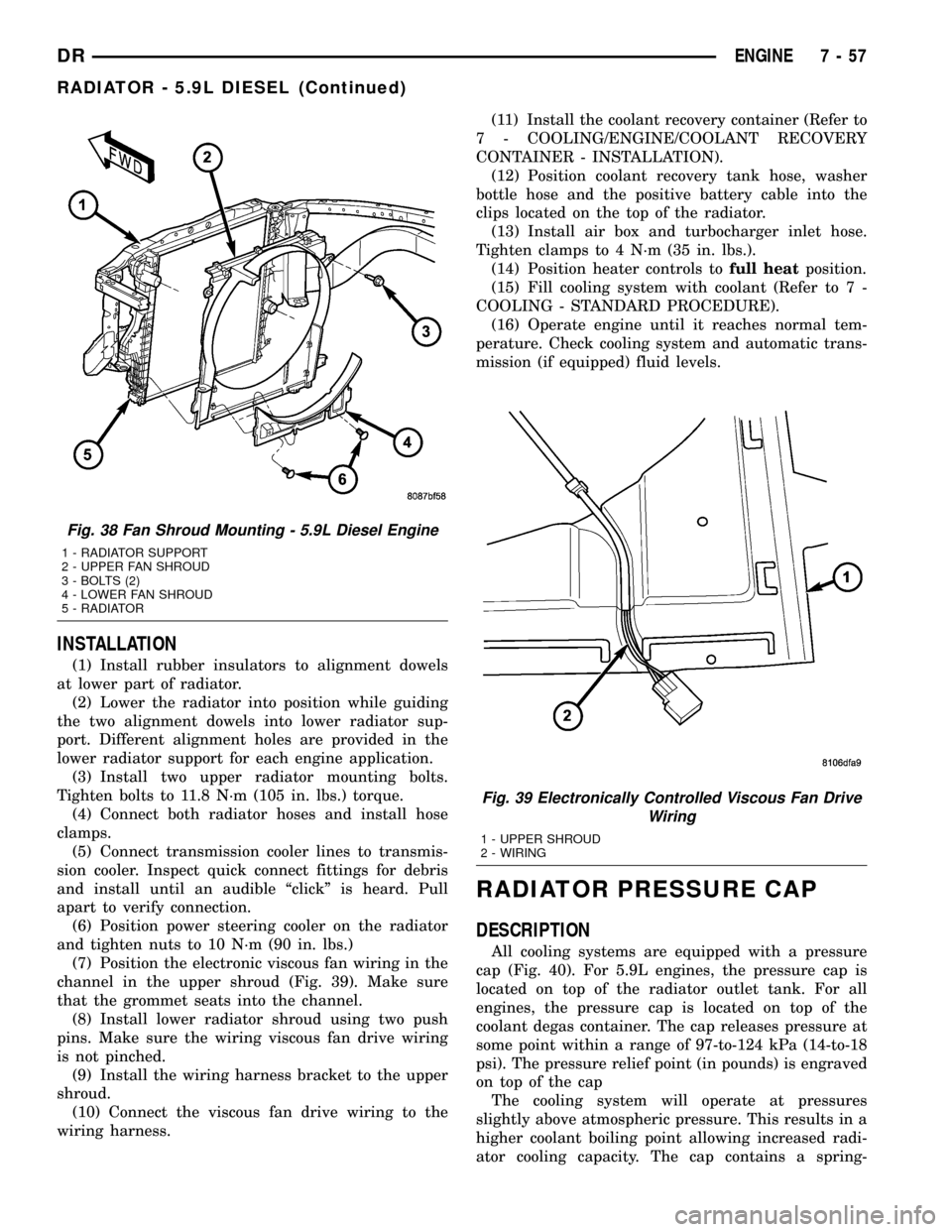

INSTALLATION

(1) Install rubber insulators to alignment dowels

at lower part of radiator.

(2) Lower the radiator into position while guiding

the two alignment dowels into lower radiator sup-

port. Different alignment holes are provided in the

lower radiator support for each engine application.

(3) Install two upper radiator mounting bolts.

Tighten bolts to 11.8 N´m (105 in. lbs.) torque.

(4) Connect both radiator hoses and install hose

clamps.

(5) Connect transmission cooler lines to transmis-

sion cooler. Inspect quick connect fittings for debris

and install until an audible ªclickº is heard. Pull

apart to verify connection.

(6) Position power steering cooler on the radiator

and tighten nuts to 10 N´m (90 in. lbs.)

(7) Position the electronic viscous fan wiring in the

channel in the upper shroud (Fig. 39). Make sure

that the grommet seats into the channel.

(8) Install lower radiator shroud using two push

pins. Make sure the wiring viscous fan drive wiring

is not pinched.

(9) Install the wiring harness bracket to the upper

shroud.

(10) Connect the viscous fan drive wiring to the

wiring harness.(11) Install the coolant recovery container (Refer to

7 - COOLING/ENGINE/COOLANT RECOVERY

CONTAINER - INSTALLATION).

(12) Position coolant recovery tank hose, washer

bottle hose and the positive battery cable into the

clips located on the top of the radiator.

(13) Install air box and turbocharger inlet hose.

Tighten clamps to 4 N´m (35 in. lbs.).

(14) Position heater controls tofull heatposition.

(15) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(16) Operate engine until it reaches normal tem-

perature. Check cooling system and automatic trans-

mission (if equipped) fluid levels.

RADIATOR PRESSURE CAP

DESCRIPTION

All cooling systems are equipped with a pressure

cap (Fig. 40). For 5.9L engines, the pressure cap is

located on top of the radiator outlet tank. For all

engines, the pressure cap is located on top of the

coolant degas container. The cap releases pressure at

some point within a range of 97-to-124 kPa (14-to-18

psi). The pressure relief point (in pounds) is engraved

on top of the cap

The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi-

ator cooling capacity. The cap contains a spring-

Fig. 38 Fan Shroud Mounting - 5.9L Diesel Engine

1 - RADIATOR SUPPORT

2 - UPPER FAN SHROUD

3 - BOLTS (2)

4 - LOWER FAN SHROUD

5 - RADIATOR

Fig. 39 Electronically Controlled Viscous Fan Drive

Wiring

1 - UPPER SHROUD

2 - WIRING

DRENGINE 7 - 57

RADIATOR - 5.9L DIESEL (Continued)

Page 379 of 2627

REMOVAL

NOTE:

The water pump on all models can be removed

without discharging the air conditioning system (if

equipped).

The water pump on all gas powered engines is

bolted directly to the engine timing chain case/

cover.

On the 8.0L V-10 engine, a rubber o-ring (instead of

a gasket) is used as a seal between the water pump

and timing chain case/cover.

If water pump is replaced because of bearing/shaft

damage or leaking shaft seal, the mechanical cooling

fan assembly should also be inspected. Inspect for

fatigue cracks, loose blades or loose rivets that could

have resulted from excessive vibration. Replace fan if

any of these conditions are found. Also check condi-

tion of the thermal viscous fan drive (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - DIAGNOSIS AND TESTING).

(1) Disconnect negative battery cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

(3) Remove windshield washer reservoir tank from

radiator fan shroud.

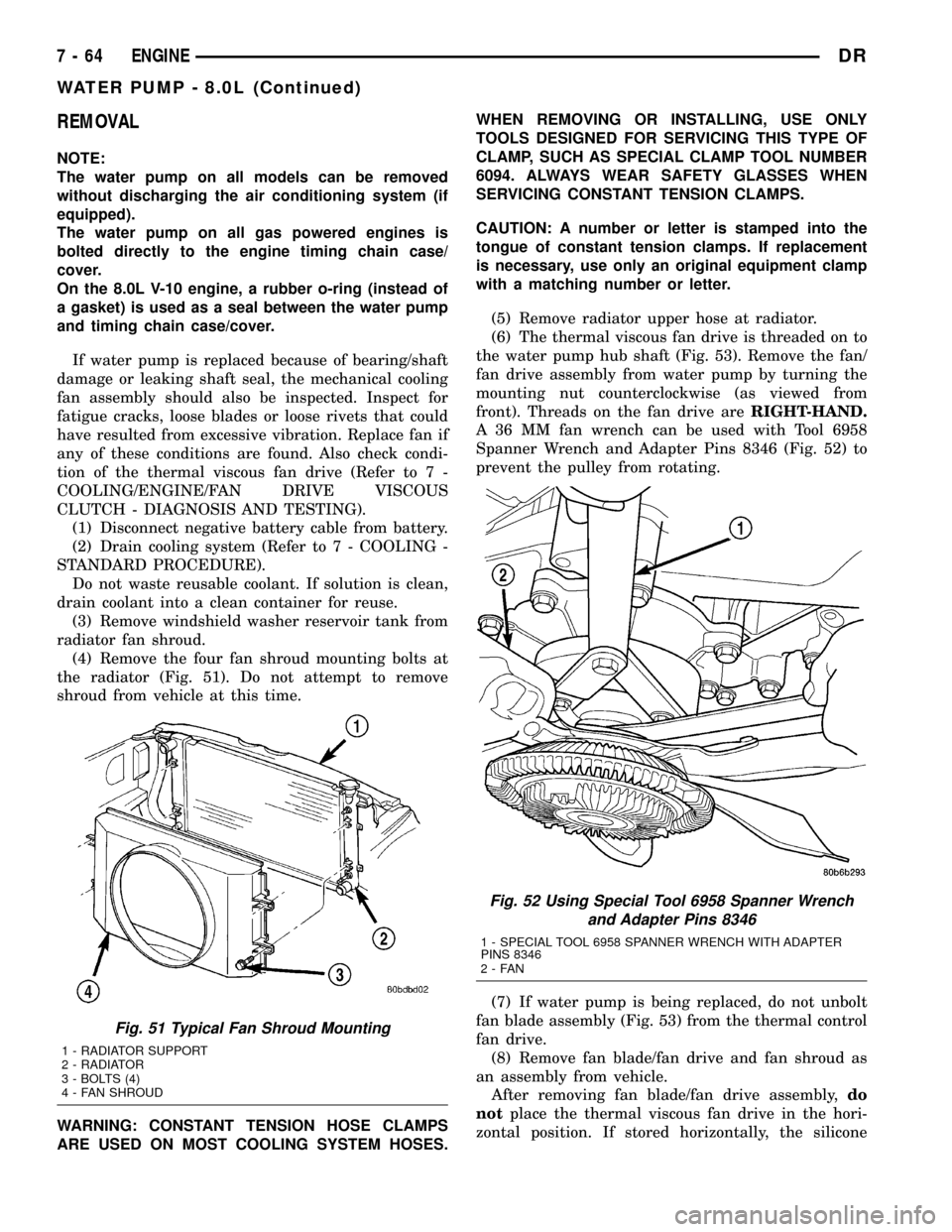

(4) Remove the four fan shroud mounting bolts at

the radiator (Fig. 51). Do not attempt to remove

shroud from vehicle at this time.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL NUMBER

6094. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(5) Remove radiator upper hose at radiator.

(6) The thermal viscous fan drive is threaded on to

the water pump hub shaft (Fig. 53). Remove the fan/

fan drive assembly from water pump by turning the

mounting nut counterclockwise (as viewed from

front). Threads on the fan drive areRIGHT-HAND.

A 36 MM fan wrench can be used with Tool 6958

Spanner Wrench and Adapter Pins 8346 (Fig. 52) to

prevent the pulley from rotating.

(7) If water pump is being replaced, do not unbolt

fan blade assembly (Fig. 53) from the thermal control

fan drive.

(8) Remove fan blade/fan drive and fan shroud as

an assembly from vehicle.

After removing fan blade/fan drive assembly,do

notplace the thermal viscous fan drive in the hori-

zontal position. If stored horizontally, the silicone

Fig. 51 Typical Fan Shroud Mounting

1 - RADIATOR SUPPORT

2 - RADIATOR

3 - BOLTS (4)

4 - FAN SHROUD

Fig. 52 Using Special Tool 6958 Spanner Wrench

and Adapter Pins 8346

1 - SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2-FAN

7 - 64 ENGINEDR

WATER PUMP - 8.0L (Continued)

Page 387 of 2627

The optional navigation radio system receives GPS

signals from up to eight satellites to display the posi-

tion and direction of the vehicle. Map information is

supplied through a DVD-ROM. An electronic gyro-

sensor and the vehicle's speed sensor enable the sys-

tem to display the present vehicle position even in

locations where GPS signals may be blocked.

When a destination is selected, the navigation sys-

tem uses information from the map to quickly calcu-

late a route. As the vehicle is driven along the chosen

route, the operator is guided with pictorial displays

and voice prompts. For complete operating instruc-

tions, refer to the manual included with the vehicle.

On vehicles that are equipped with the optional

remote radio switches, the Instrument Cluster

receives hard wired resistor multiplexed inputs from

the remote radio switches. The programming in the

Instrument Cluster allows it to process those inputs

and send the proper messages to the radio receiver

over the Programmable Communication Interface

(PCI) bus network to control the radio volume up or

down, station seek up or down, preset station

advance, and mode advance functions.DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the

DRB IIIt, refer to the appropriate Diagnostic

Service Manual.

Refer to the appropriate wiring information.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

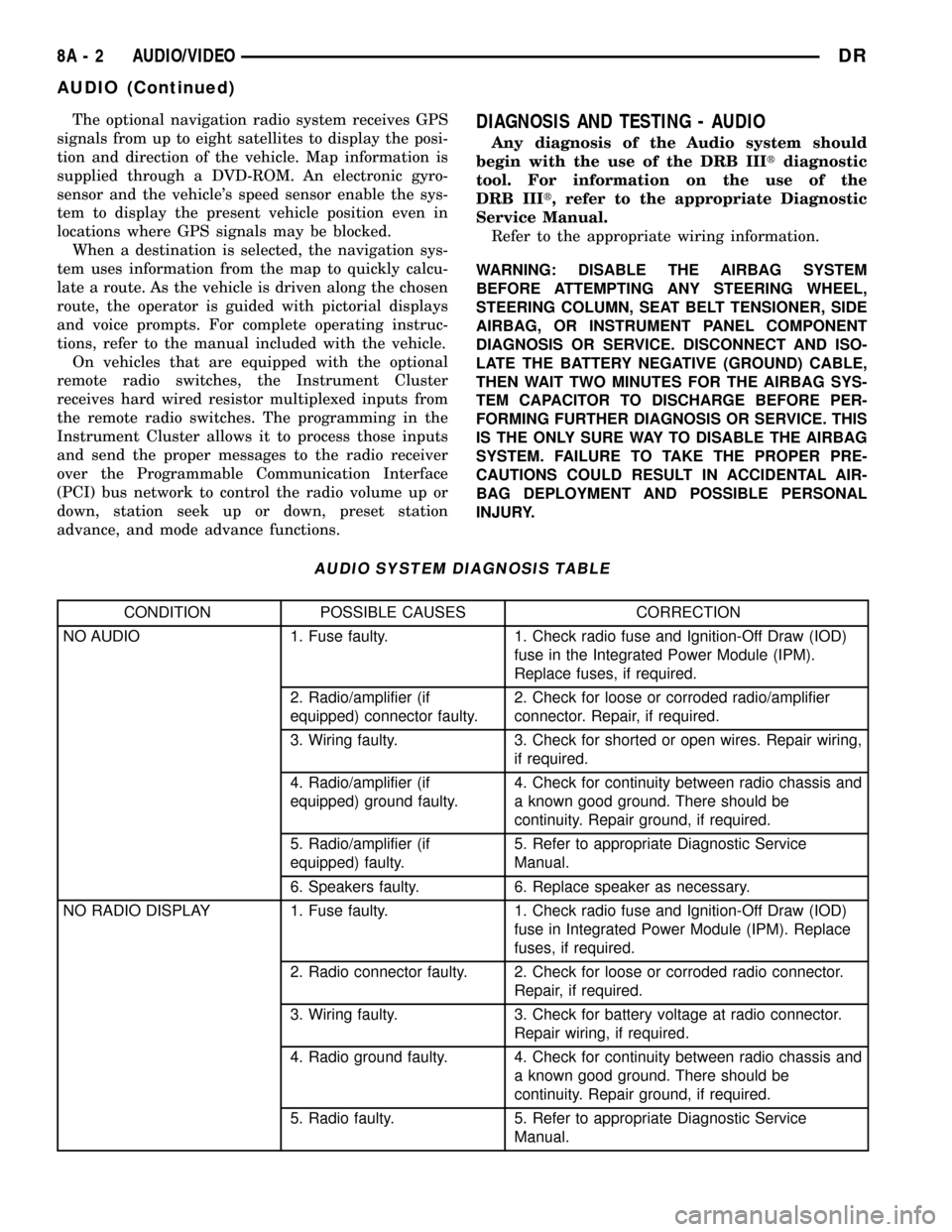

AUDIO SYSTEM DIAGNOSIS TABLE

CONDITION POSSIBLE CAUSES CORRECTION

NO AUDIO 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in the Integrated Power Module (IPM).

Replace fuses, if required.

2. Radio/amplifier (if

equipped) connector faulty.2. Check for loose or corroded radio/amplifier

connector. Repair, if required.

3. Wiring faulty. 3. Check for shorted or open wires. Repair wiring,

if required.

4. Radio/amplifier (if

equipped) ground faulty.4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio/amplifier (if

equipped) faulty.5. Refer to appropriate Diagnostic Service

Manual.

6. Speakers faulty. 6. Replace speaker as necessary.

NO RADIO DISPLAY 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in Integrated Power Module (IPM). Replace

fuses, if required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for battery voltage at radio connector.

Repair wiring, if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

8A - 2 AUDIO/VIDEODR

AUDIO (Continued)

Page 394 of 2627

RADIO NOISE SUPPRESSION

GROUND STRAP

DESCRIPTION

Radio noise suppression devices are factory-in-

stalled standard equipment on this vehicle. Radio

Frequency Interference (RFI) and ElectroMagnetic

Interference (EMI) can be produced by any on-board

or external source of electromagnetic energy. These

electromagnetic energy sources can radiate electro-

magnetic signals through the air, or conduct them

through the vehicle electrical system.

When the audio system converts RFI or EMI to an

audible acoustic wave form, it is referred to as radio

noise. This undesirable radio noise is generally man-

ifested in the form of ªbuzzing,º ªhissing,º ªpopping,º

ªclicking,º ªcrackling,º and/or ªwhirringº sounds. In

most cases, RFI and EMI radio noise can be sup-

pressed using a combination of vehicle and compo-

nent grounding, filtering and shielding techniques.

This vehicle is equipped with factory-installed radio

noise suppression devices that were designed to min-

imize exposure to typical sources of RFI and EMI;

thereby, minimizing radio noise complaints.

Factory-installed radio noise suppression is accom-

plished primarily through circuitry or devices that

are integral to the factory-installed radios, audio

power amplifiers and other on-board electrical com-

ponents such as generators, wiper motors, blower

motors, and fuel pumps that have been found to be

potential sources of RFI or EMI. External radio noise

suppression devices that are used on this vehicle to

control RFI or EMI, and can be serviced, include the

following:

²Engine-to-body ground strap- This length of

braided ground strap has an eyelet terminal connec-

tor crimped to each end. One end is secured to the

engine cylinder head(s). The other is secured to the

plenum at the exhaust heat shield forward/outer

attaching stud.

²Resistor-type spark plugs- This type of spark

plug has an internal resistor connected in series

between the spark plug terminal and the center elec-

trode to help reduce the production of electromag-

netic radiation that can result in radio noise.

OPERATION

There are two common strategies that can be used

to suppress Radio Frequency Interference (RFI) and

ElectroMagnetic Interference (EMI) radio noise. The

first suppression strategy involves preventing the

production of RFI and EMI electromagnetic signals

at their sources. The second suppression strategy

involves preventing the reception of RFI and EMIelectromagnetic signals by the audio system compo-

nents.

The use of braided ground straps in key locations

is part of the RFI and EMI prevention strategy.

These ground straps ensure adequate ground paths,

particularly for high current components such as

many of those found in the starting, charging, igni-

tion, engine control and transmission control sys-

tems. An insufficient ground path for any of these

high current components may result in radio noise

caused by induced voltages created as the high cur-

rent seeks alternative ground paths through compo-

nents or circuits intended for use by, or in close

proximity to the audio system components or circuits.

Preventing the reception of RFI and EMI is accom-

plished by ensuring that the audio system compo-

nents are correctly installed in the vehicle. Loose,

corroded or improperly soldered wire harness connec-

tions, improperly routed wiring and inadequate audio

system component grounding can all contribute to

the reception of RFI and EMI. A properly grounded

antenna body and radio chassis, as well as a shielded

antenna coaxial cable with clean and tight connec-

tions will each help reduce the potential for reception

of RFI and EMI.

REMOVAL

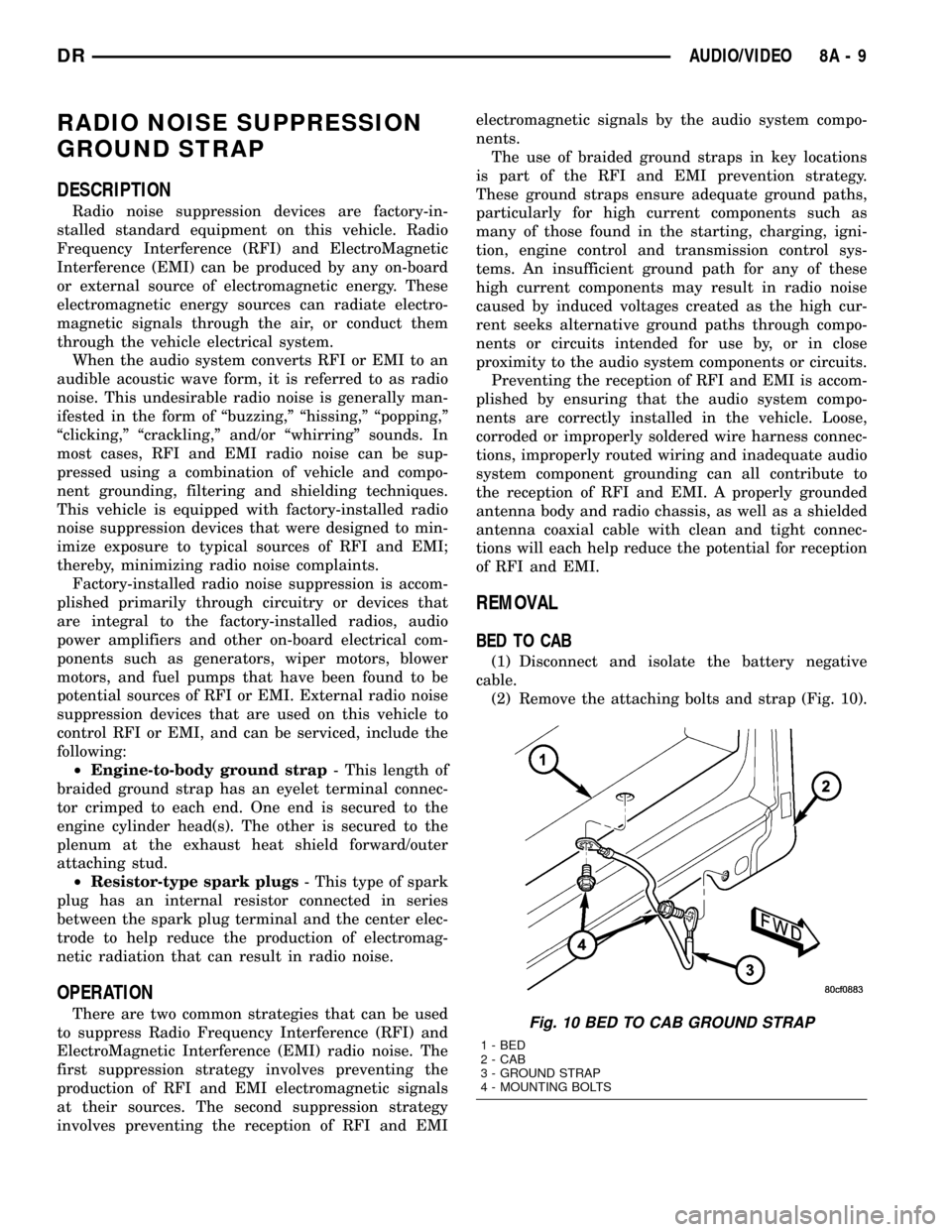

BED TO CAB

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the attaching bolts and strap (Fig. 10).

Fig. 10 BED TO CAB GROUND STRAP

1 - BED

2 - CAB

3 - GROUND STRAP

4 - MOUNTING BOLTS

DRAUDIO/VIDEO 8A - 9

Page 397 of 2627

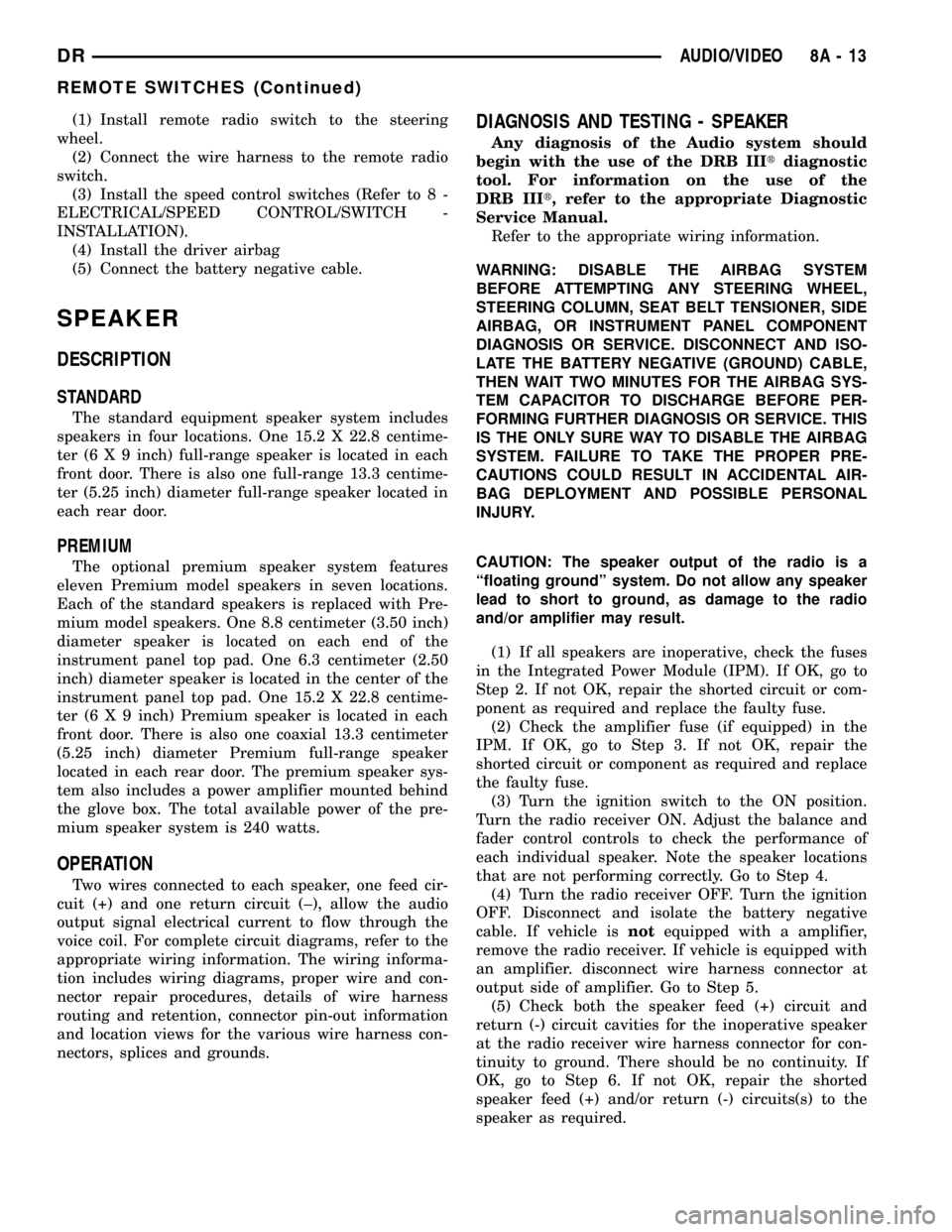

REMOTE RADIO SWITCH TEST TABLE

Switch Switch Position Resistance

Right

(White)Volume Up1.210 Kilohms

1%

Right

(White)Volume Down3.010 Kilohms

1%

Right

(White)Mode Advance0.0511 Kilohms

1%

Left

(Black)Seek Up0.261 Kilohms

1%

Left

(Black)Seek Down0.681 Kilohms

1%

Left

(Black)Pre-Set Station

Advance0.162 Kilohms

1%

(3) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for 5 volts

at the radio control mux circuit cavities of the steer-

ing wheel wire harness connectors for both remote

radio switches. If OK, go to Step 4. If not OK, repair

the open or shorted radio control mux circuit to the

Integrated Power Module (IPM) as required.

(4) Disconnect and isolate the battery negative

cable. Disconnect the 22-way instrument panel wire

harness connector from the IPM. Check for continu-

ity between the remote radio switch ground circuit

cavities of the steering wheel wire harness connec-

tors for both remote radio switches and a good

ground. There should be no continuity. If OK, go to

Step 5. If not OK, repair the shorted remote radio

switch ground circuit to the IPM as required.

(5) Check for continuity between the remote radio

switch ground circuit cavities of the steering wheel

wire harness connectors for both remote radio

switches and the 22-way instrument panel wire har-

ness connector for the IPM. There should be continu-

ity. If OK, refer to the proper Diagnostic Procedures

manual to test the IPM and the PCI data bus. If not

OK, repair the open remote radio switch ground cir-

cuit as required.

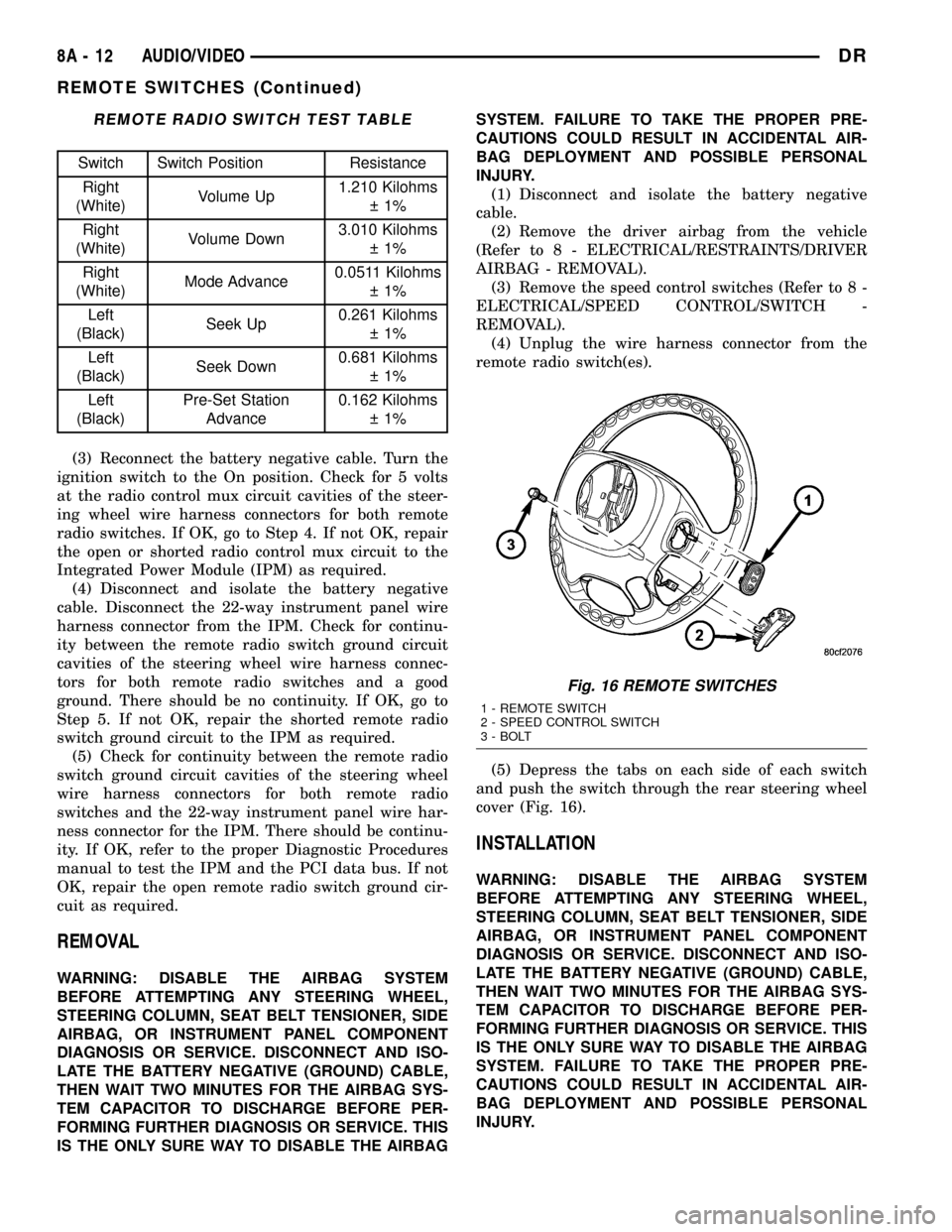

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAGSYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver airbag from the vehicle

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - REMOVAL).

(3) Remove the speed control switches (Refer to 8 -

ELECTRICAL/SPEED CONTROL/SWITCH -

REMOVAL).

(4) Unplug the wire harness connector from the

remote radio switch(es).

(5) Depress the tabs on each side of each switch

and push the switch through the rear steering wheel

cover (Fig. 16).

INSTALLATION

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Fig. 16 REMOTE SWITCHES

1 - REMOTE SWITCH

2 - SPEED CONTROL SWITCH

3 - BOLT

8A - 12 AUDIO/VIDEODR

REMOTE SWITCHES (Continued)

Page 398 of 2627

(1) Install remote radio switch to the steering

wheel.

(2) Connect the wire harness to the remote radio

switch.

(3) Install the speed control switches (Refer to 8 -

ELECTRICAL/SPEED CONTROL/SWITCH -

INSTALLATION).

(4) Install the driver airbag

(5) Connect the battery negative cable.

SPEAKER

DESCRIPTION

STANDARD

The standard equipment speaker system includes

speakers in four locations. One 15.2 X 22.8 centime-

ter (6 X 9 inch) full-range speaker is located in each

front door. There is also one full-range 13.3 centime-

ter (5.25 inch) diameter full-range speaker located in

each rear door.

PREMIUM

The optional premium speaker system features

eleven Premium model speakers in seven locations.

Each of the standard speakers is replaced with Pre-

mium model speakers. One 8.8 centimeter (3.50 inch)

diameter speaker is located on each end of the

instrument panel top pad. One 6.3 centimeter (2.50

inch) diameter speaker is located in the center of the

instrument panel top pad. One 15.2 X 22.8 centime-

ter (6 X 9 inch) Premium speaker is located in each

front door. There is also one coaxial 13.3 centimeter

(5.25 inch) diameter Premium full-range speaker

located in each rear door. The premium speaker sys-

tem also includes a power amplifier mounted behind

the glove box. The total available power of the pre-

mium speaker system is 240 watts.

OPERATION

Two wires connected to each speaker, one feed cir-

cuit (+) and one return circuit (±), allow the audio

output signal electrical current to flow through the

voice coil. For complete circuit diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

DIAGNOSIS AND TESTING - SPEAKER

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the

DRB IIIt, refer to the appropriate Diagnostic

Service Manual.

Refer to the appropriate wiring information.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

and/or amplifier may result.

(1) If all speakers are inoperative, check the fuses

in the Integrated Power Module (IPM). If OK, go to

Step 2. If not OK, repair the shorted circuit or com-

ponent as required and replace the faulty fuse.

(2) Check the amplifier fuse (if equipped) in the

IPM. If OK, go to Step 3. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(3) Turn the ignition switch to the ON position.

Turn the radio receiver ON. Adjust the balance and

fader control controls to check the performance of

each individual speaker. Note the speaker locations

that are not performing correctly. Go to Step 4.

(4) Turn the radio receiver OFF. Turn the ignition

OFF. Disconnect and isolate the battery negative

cable. If vehicle isnotequipped with a amplifier,

remove the radio receiver. If vehicle is equipped with

an amplifier. disconnect wire harness connector at

output side of amplifier. Go to Step 5.

(5) Check both the speaker feed (+) circuit and

return (-) circuit cavities for the inoperative speaker

at the radio receiver wire harness connector for con-

tinuity to ground. There should be no continuity. If

OK, go to Step 6. If not OK, repair the shorted

speaker feed (+) and/or return (-) circuits(s) to the

speaker as required.

DRAUDIO/VIDEO 8A - 13

REMOTE SWITCHES (Continued)

Page 402 of 2627

CHIME/BUZZER

TABLE OF CONTENTS

page page

CHIME WARNING SYSTEM

DESCRIPTION..........................1

OPERATION............................1DIAGNOSIS AND TESTING - CHIME

WARNING SYSTEM.....................3

CHIME WARNING SYSTEM

DESCRIPTION

A chime warning system is standard factory-in-

stalled equipment on this model. The chime warning

system uses a single chime tone generator that is

integral to the instrument cluster to provide an audi-

ble indication of various vehicle conditions that may

require the attention of the vehicle operator. The

chime warning system includes the following major

components, which are described in further detail

elsewhere in this service information:

²Door Ajar Switch- A door ajar switch is inte-

gral to each door latch. This switch provides an input

to the chime warning system indicating whether the

front doors are open or closed.

²Ignition Switch- A key-in ignition switch is

integral to the ignition switch. The key-in ignition

switch provides an input to the chime warning sys-

tem indicating whether a key is present in the igni-

tion lock cylinder.

²Instrument Cluster- The instrument cluster

contains an integral chime tone generator, integrated

circuitry, a central processing unit and the program-

ming to provide all of the proper chime warning sys-

tem features based upon the monitored inputs. The

instrument cluster circuitry monitors hard-wired

switch inputs, as well as message inputs received

from other vehicle electronic modules on the Pro-

grammable Communications Interface (PCI) data bus

network.

²Headlamp Switch- The headlamp switch pro-

vides an input to the chime warning system indicat-

ing when the exterior lamps are turned On or Off.

²Seat Belt Switch- A seat belt switch is inte-

gral to the driver seat belt buckle-half unit. The seat

belt switch provides an input to the chime warning

system indicating whether the driver seat belt is fas-

tened.

Hard wired circuitry connects many of the chime

warning system components to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained bymany different methods. Refer to the appropriate

wiring information.

The instrument cluster chime warning system cir-

cuitry and the integral chime tone generator cannot

be adjusted or repaired. If the instrument cluster or

the chime tone generator are damaged or faulty, the

instrument cluster must be replaced.

OPERATION

The chime warning system is designed to provide

an audible output as an indication of various condi-

tions that may require the attention or awareness of

the vehicle operator. The chime warning system com-

ponents operate on battery voltage received through

the Ignition-Off Draw (IOD) fuse in the Power Distri-

bution Center (PDC) so that the system may operate

regardless of the ignition switch position.

The chime warning system provides an audible

warning to the vehicle operator under the following

conditions:

²Air Bag Warning- The instrument cluster

chime tone generator will generate a single chime

tone when the airbag indicator is illuminated for an

airbag system fault condition. The instrument cluster

uses airbag indicator lamp-on and lamp-off message

inputs received from the Airbag Control Module

(ACM) over the Programmable Communications

Interface (PCI) data bus indicating that the airbag

indicator should be illuminated for an airbag system

fault condition.

²Door Ajar Warning- The instrument cluster

chime tone generator will generate a single chimes to

announce that the hard wired inputs from the door

ajar switches and the ignition switch as well as an

engine speed message input received from the PCM

over the PCI data bus indicate that a driver or pas-

senger door is opened with the ignition switch in the

On position and vehicle speed present.

²Engine Coolant Temperature High Warning

(Diesel Engine Only)- The instrument cluster

chime tone generator will generate a single chime

tone when the check gauges indicator is illuminated

for a high or critical engine coolant temperature con-

dition. The instrument cluster uses engine coolant

temperature message inputs received from the diesel

DRCHIME/BUZZER 8B - 1

Page 408 of 2627

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

COMMUNICATION

DESCRIPTION..........................1

OPERATION............................2

CONTROLLER ANTILOCK BRAKE

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................3

INSTALLATION..........................3

DATA LINK CONNECTOR

DESCRIPTION - DATA LINK CONNECTOR.....3

OPERATION - DATA LINK CONNECTOR......3

ENGINE CONTROL MODULE

DESCRIPTION - ECM.....................3

OPERATION - ECM......................3

REMOVAL.............................4

INSTALLATION..........................4

FRONT CONTROL MODULE

DESCRIPTION..........................5

OPERATION............................5

DIAGNOSIS AND TESTING - FRONT

CONTROL MODULE....................5

REMOVAL.............................5

INSTALLATION..........................5

HEATED SEAT MODULE

DESCRIPTION..........................6

OPERATION............................6

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE.............................6

REMOVAL.............................7

INSTALLATION..........................7

POWERTRAIN CONTROL MODULE

DESCRIPTION

DESCRIPTION - PCM...................7DESCRIPTION - MODES OF OPERATION....7

DESCRIPTION - 5 VOLT SUPPLIES.......10

DESCRIPTION - IGNITION CIRCUIT SENSE . 10

DESCRIPTION - POWER GROUNDS......10

DESCRIPTION - SENSOR RETURN.......10

OPERATION

OPERATION - PCM....................10

OPERATION - 5 VOLT SUPPLIES.........11

OPERATION - IGNITION CIRCUIT SENSE . . . 11

REMOVAL.............................12

INSTALLATION.........................12

SENTRY KEY IMMOBILIZER MODULE

DESCRIPTION.........................13

OPERATION...........................13

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING......................14

REMOVAL.............................15

INSTALLATION.........................15

TRANSFER CASE CONTROL MODULE

DESCRIPTION.........................16

OPERATION...........................16

TRANSMISSION CONTROL MODULE

DESCRIPTION.........................20

OPERATION...........................20

STANDARD PROCEDURE

STANDARD PROCEDURE - TCM QUICK

LEARN..............................23

STANDARD PROCEDURE - DRIVE LEARN . . 23

COMMUNICATION

DESCRIPTION

The DaimlerChrysler Programmable Communica-

tion Interface (PCI) data bus system is a single wire

multiplex system used for vehicle communications on

many DaimlerChrysler Corporation vehicles. Multi-

plexing is a system that enables the transmission of

several messages over a single channel or circuit. All

DaimlerChrysler vehicles use this principle for com-

munication between various microprocessor-based

electronic control modules. The PCI data bus exceeds

the Society of Automotive Engineers (SAE) J1850

Standard for Class B Multiplexing.Many of the electronic control modules in a vehicle

require information from the same sensing device. In

the past, if information from one sensing device was

required by several controllers, a wire from each con-

troller needed to be connected in parallel to that sen-

sor. In addition, each controller utilizing analog

sensors required an Analog/Digital (A/D) converter in

order to9read9these sensor inputs. Multiplexing

reduces wire harness complexity, sensor current

loads and controller hardware because each sensing

device is connected to only one controller, which

reads and distributes the sensor information to the

other controllers over the data bus. Also, because

each controller on the data bus can access the con-

troller sensor inputs to every other controller on the

DRELECTRONIC CONTROL MODULES 8E - 1

Page 409 of 2627

data bus, more function and feature capabilities are

possible.

In addition to reducing wire harness complexity,

component sensor current loads and controller hard-

ware, multiplexing offers a diagnostic advantage. A

multiplex system allows the information flowing

between controllers to be monitored using a diagnos-

tic scan tool. The DaimlerChrysler system allows an

electronic control module to broadcast message data

out onto the bus where all other electronic control

modules can9hear9the messages that are being sent.

When a module hears a message on the data bus

that it requires, it relays that message to its micro-

processor. Each module ignores the messages on the

data bus that are being sent to other electronic con-

trol modules.

OPERATION

Data exchange between modules is achieved by serial

transmission of encoded data over a single wire broad-

cast network. The wire colors used for the PCI data bus

circuits are yellow with a violet tracer, or violet with a

yellow tracer, depending upon the application. The PCI

data bus messages are carried over the bus in the form

of Variable Pulse Width Modulated (VPWM) signals.

The PCI data bus speed is an average 10.4 Kilo-bits per

second (Kbps). By comparison, the prior two-wire

Chrysler Collision Detection (CCD) data bus system is

designed to run at 7.8125 Kbps.

The voltage network used to transmit messages

requires biasing and termination. Each module on

the PCI data bus system provides its own biasing

and termination. Each module (also referred to as a

node) terminates the bus through a terminating

resistor and a terminating capacitor. There are two

types of nodes on the bus. The dominant node termi-

nates the bus througha1KWresistor and a 3300 pF

capacitor. The Powertrain Control Module (PCM) is

the only dominant node for the PCI data bus system.

A standard node terminates the bus through an 11

KW resistor and a 330 pF capacitor.

The modules bias the bus when transmitting a

message. The PCI bus uses low and high voltage lev-

els to generate signals. Low voltage is around zero

volts and the high voltage is about seven and one-

half volts. The low and high voltage levels are gener-

ated by means of variable-pulse width modulation to

form signals of varying length. The Variable Pulse

Width Modulation (VPWM) used in PCI bus messag-

ing is a method in which both the state of the bus

and the width of the pulse are used to encode bit

information. A9zero9bit is defined as a short low

pulse or a long high pulse. A9one9bit is defined as a

long low pulse or a short high pulse. A low (passive)

state on the bus does not necessarily mean a zero bit.

It also depends upon pulse width. If the width isshort, it stands for a zero bit. If the width is long, it

stands for a one bit. Similarly, a high (active) state

does not necessarily mean a one bit. This too depends

upon pulse width. If the width is short, it stands for

a one bit. If the width is long, it stands for a zero bit.

In the case where there are successive zero or one

data bits, both the state of the bus and the width of

the pulse are changed alternately. This encoding

scheme is used for two reasons. First, this ensures

that only one symbol per transition and one transi-

tion per symbol exists. On each transition, every

transmitting module must decode the symbol on the

bus and begin timing of the next symbol. Since tim-

ing of the next symbol begins with the last transition

detected on the bus, all of the modules are re-syn-

chronized with each symbol. This ensures that there

are no accumulated timing errors during PCI data

bus communication.

The second reason for this encoding scheme is to

guarantee that the zero bit is the dominant bit on

the bus. When two modules are transmitting simul-

taneously on the bus, there must be some form of

arbitration to determine which module will gain con-

trol. A data collision occurs when two modules are

transmitting different messages at the same time.

When a module is transmitting on the bus, it is read-

ing the bus at the same time to ensure message

integrity. When a collision is detected, the module

that transmitted the one bit stops sending messages

over the bus until the bus becomes idle.

Each module is capable of transmitting and receiv-

ing data simultaneously. The typical PCI bus mes-

sage has the following four components:

²Message Header- One to three bytes in length.

The header contains information identifying the mes-

sage type and length, message priority, target mod-

ule(s) and sending module.

²Data Byte(s)- This is the actual message that

is being sent.

²Cyclic Redundancy Check (CRC) Byte- This

byte is used to detect errors during a message trans-

mission.

²In-Frame Response (IFR) byte(s)-Ifa

response is required from the target module(s), it can

be sent during this frame. This function is described

in greater detail in the following paragraph.

The IFR consists of one or more bytes, which are

transmitted during a message. If the sending module

requires information to be received immediately, the

target module(s) can send data over the bus during

the original message. This allows the sending module

to receive time-critical information without having to

wait for the target module to access the bus. After

the IFR is received, the sending module broadcasts

an End of Frame (EOF) message and releases control

of the bus.

8E - 2 ELECTRONIC CONTROL MODULESDR

COMMUNICATION (Continued)