Transmission tcc DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2020 of 2627

NOTE: The 45RFE/545RFE utilizes closed loop con-

trol of pump line pressure. The pressure readings

may therefore vary greatly but should always follow

line pressure.

Some common pressures that can be measured to

evaluate pump and clutch performance are the

upshift/downshift pressures, garage shift pressures,

and TCC pressure. The upshift/downshift pressure

for all shifts are shown in UPSHIFT PRESSURES

and DOWNSHIFT PRESSURES. In-gear maximum

pressure for each gear position is shown in IN-GEAR

PRESSURES. The garage shift pressure when per-

forming a N-R shift is 220 psi for 3.7L/4.7L equipped

vehicles and 250 psi for 5.7L equipped vehicles. The

garage shift pressure for the R-N shift is 120 psi. The

garage shift pressure for the N-1 shift is 135 psi for

3.7L/4.7L equipped vehicles and 165 psi for 5.7L

equipped vehicles. Torque converter lock-up pressure

is 120 psi for 3.7L/4.7L equipped vehicles and 125 psi

for 5.7L equipped vehicles.

UPSHIFT PRESSURES

ENGINE 1-2 2-3 2prime-3 3-4 2prime-4 2-5 3-5 4-5

5.7L150 125 125 135 135 135 135 135

3.7L/

4.7L120 120 120 120 120 120 120 130

DOWNSHIFT PRESSURES

ENG-

INE5-

45-3 5-2 4-34-2

prime3-23-2

prime2

prime-

12-

13-1

5.7L135 135 135 135 135 135 135 135 135 135

3.7L/

4.7L120 120 120 120 120 120 120 120 120 120

IN-GEAR PRESSURES

ENGINE 1 22

prime345NEUT-

RALREV-

ERSE

5.7L160 135 135 135 135 135 120 250

3.7L/

4.7L135 120 120 120 120 120 120 220

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH OPERATION

Air-pressure testing can be used to check transmis-

sion clutch operation. The test can be conducted with

the transmission either in the vehicle or on the work

bench, as a final check.

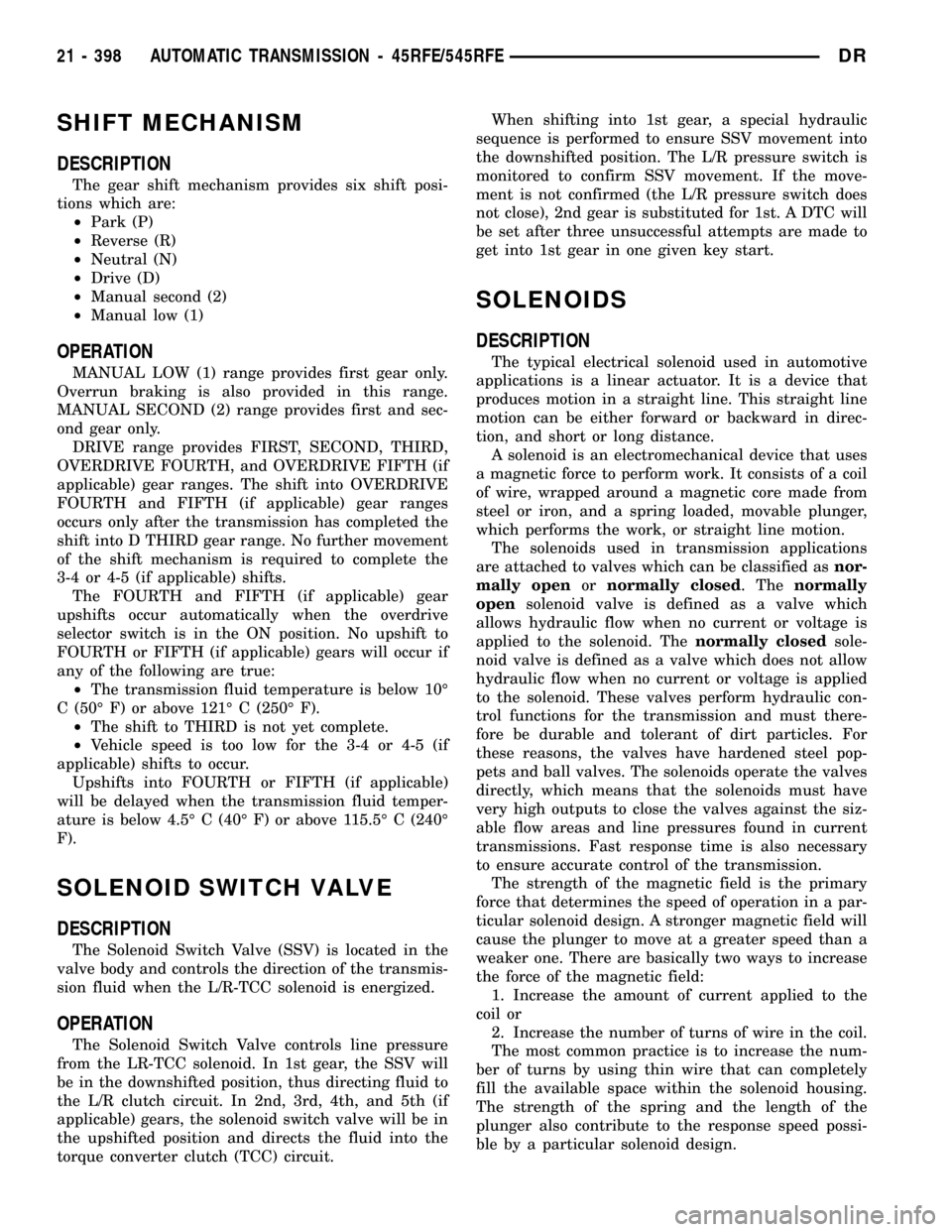

Air-pressure testing requires that the oil pan and

valve body be removed from the transmission. The

clutch apply passages are shown (Fig. 6).

NOTE: The air supply which is used must be free of

moisture and dirt. Use a pressure of 30 psi to test

clutch operation.

Apply air pressure at each port. If the clutch is

functioning, a soft thump will be heard as the clutch

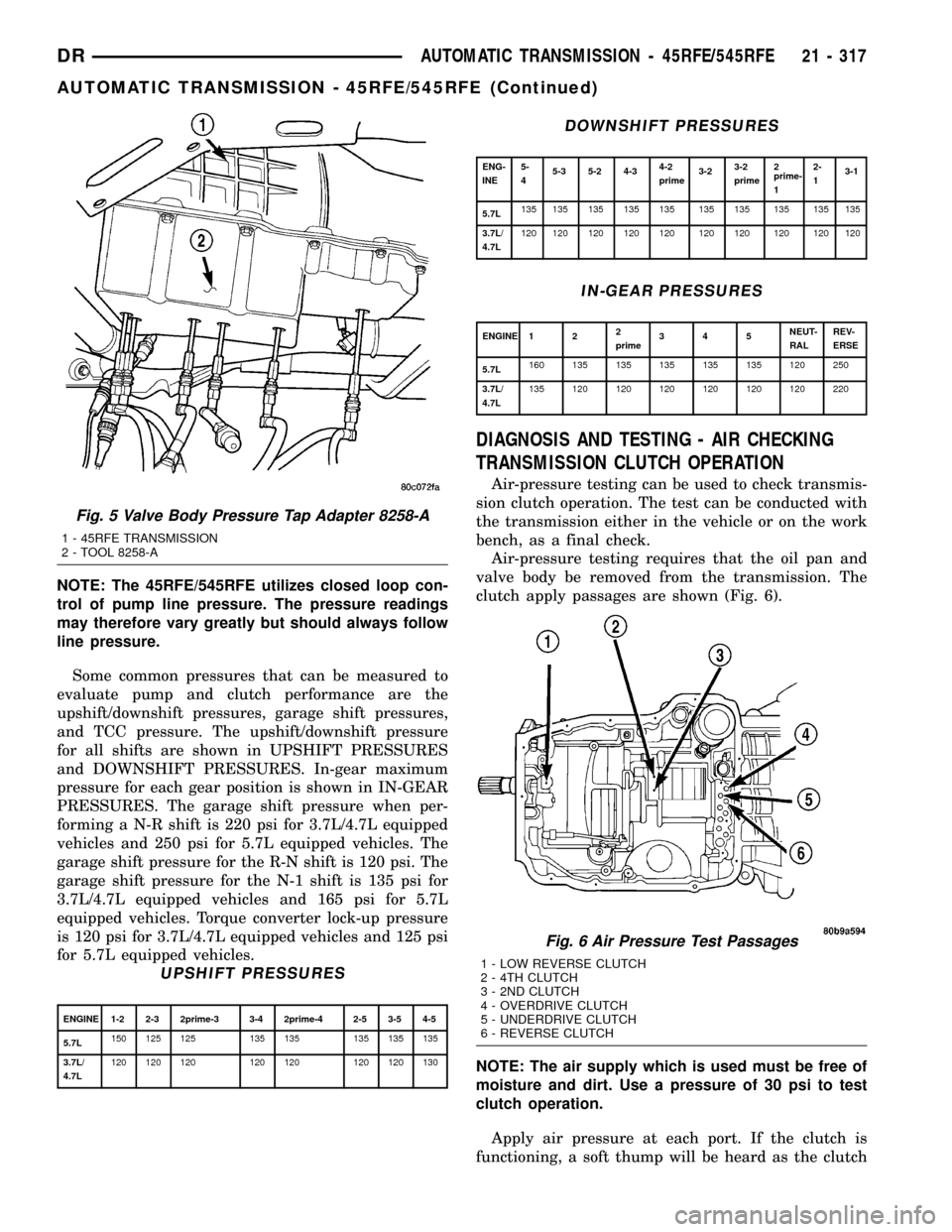

Fig. 5 Valve Body Pressure Tap Adapter 8258-A

1 - 45RFE TRANSMISSION

2 - TOOL 8258-A

Fig. 6 Air Pressure Test Passages

1 - LOW REVERSE CLUTCH

2 - 4TH CLUTCH

3 - 2ND CLUTCH

4 - OVERDRIVE CLUTCH

5 - UNDERDRIVE CLUTCH

6 - REVERSE CLUTCH

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 317

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2101 of 2627

SHIFT MECHANISM

DESCRIPTION

The gear shift mechanism provides six shift posi-

tions which are:

²Park (P)

²Reverse (R)

²Neutral (N)

²Drive (D)

²Manual second (2)

²Manual low (1)

OPERATION

MANUAL LOW (1) range provides first gear only.

Overrun braking is also provided in this range.

MANUAL SECOND (2) range provides first and sec-

ond gear only.

DRIVE range provides FIRST, SECOND, THIRD,

OVERDRIVE FOURTH, and OVERDRIVE FIFTH (if

applicable) gear ranges. The shift into OVERDRIVE

FOURTH and FIFTH (if applicable) gear ranges

occurs only after the transmission has completed the

shift into D THIRD gear range. No further movement

of the shift mechanism is required to complete the

3-4 or 4-5 (if applicable) shifts.

The FOURTH and FIFTH (if applicable) gear

upshifts occur automatically when the overdrive

selector switch is in the ON position. No upshift to

FOURTH or FIFTH (if applicable) gears will occur if

any of the following are true:

²The transmission fluid temperature is below 10É

C (50É F) or above 121É C (250É F).

²The shift to THIRD is not yet complete.

²Vehicle speed is too low for the 3-4 or 4-5 (if

applicable) shifts to occur.

Upshifts into FOURTH or FIFTH (if applicable)

will be delayed when the transmission fluid temper-

ature is below 4.5É C (40É F) or above 115.5É C (240É

F).

SOLENOID SWITCH VALVE

DESCRIPTION

The Solenoid Switch Valve (SSV) is located in the

valve body and controls the direction of the transmis-

sion fluid when the L/R-TCC solenoid is energized.

OPERATION

The Solenoid Switch Valve controls line pressure

from the LR-TCC solenoid. In 1st gear, the SSV will

be in the downshifted position, thus directing fluid to

the L/R clutch circuit. In 2nd, 3rd, 4th, and 5th (if

applicable) gears, the solenoid switch valve will be in

the upshifted position and directs the fluid into the

torque converter clutch (TCC) circuit.When shifting into 1st gear, a special hydraulic

sequence is performed to ensure SSV movement into

the downshifted position. The L/R pressure switch is

monitored to confirm SSV movement. If the move-

ment is not confirmed (the L/R pressure switch does

not close), 2nd gear is substituted for 1st. A DTC will

be set after three unsuccessful attempts are made to

get into 1st gear in one given key start.

SOLENOIDS

DESCRIPTION

The typical electrical solenoid used in automotive

applications is a linear actuator. It is a device that

produces motion in a straight line. This straight line

motion can be either forward or backward in direc-

tion, and short or long distance.

A solenoid is an electromechanical device that uses

a magnetic force to perform work. It consists of a coil

of wire, wrapped around a magnetic core made from

steel or iron, and a spring loaded, movable plunger,

which performs the work, or straight line motion.

The solenoids used in transmission applications

are attached to valves which can be classified asnor-

mally openornormally closed. Thenormally

opensolenoid valve is defined as a valve which

allows hydraulic flow when no current or voltage is

applied to the solenoid. Thenormally closedsole-

noid valve is defined as a valve which does not allow

hydraulic flow when no current or voltage is applied

to the solenoid. These valves perform hydraulic con-

trol functions for the transmission and must there-

fore be durable and tolerant of dirt particles. For

these reasons, the valves have hardened steel pop-

pets and ball valves. The solenoids operate the valves

directly, which means that the solenoids must have

very high outputs to close the valves against the siz-

able flow areas and line pressures found in current

transmissions. Fast response time is also necessary

to ensure accurate control of the transmission.

The strength of the magnetic field is the primary

force that determines the speed of operation in a par-

ticular solenoid design. A stronger magnetic field will

cause the plunger to move at a greater speed than a

weaker one. There are basically two ways to increase

the force of the magnetic field:

1. Increase the amount of current applied to the

coil or

2. Increase the number of turns of wire in the coil.

The most common practice is to increase the num-

ber of turns by using thin wire that can completely

fill the available space within the solenoid housing.

The strength of the spring and the length of the

plunger also contribute to the response speed possi-

ble by a particular solenoid design.

21 - 398 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2105 of 2627

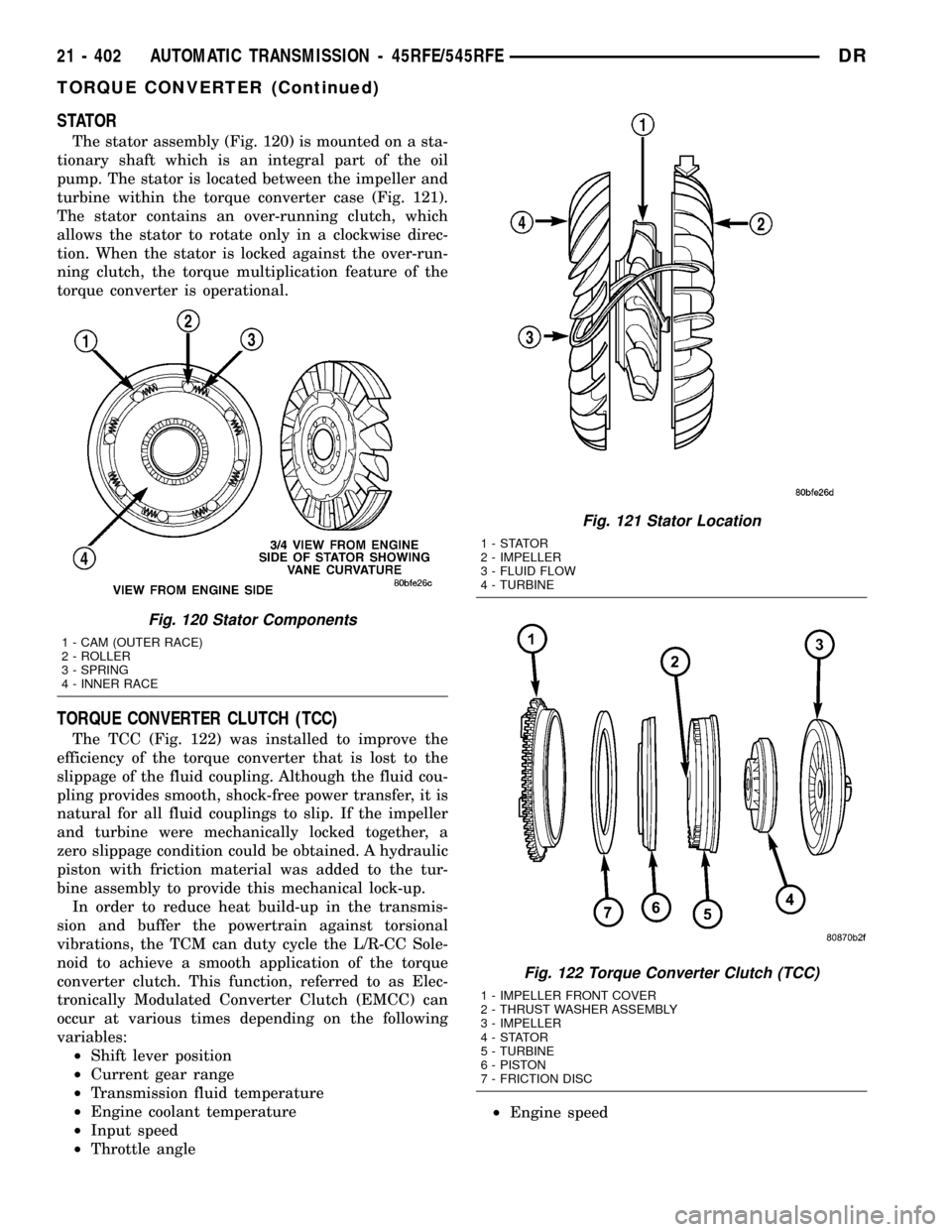

STATOR

The stator assembly (Fig. 120) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 121).

The stator contains an over-running clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the over-run-

ning clutch, the torque multiplication feature of the

torque converter is operational.

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 122) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock-free power transfer, it is

natural for all fluid couplings to slip. If the impeller

and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston with friction material was added to the tur-

bine assembly to provide this mechanical lock-up.

In order to reduce heat build-up in the transmis-

sion and buffer the powertrain against torsional

vibrations, the TCM can duty cycle the L/R-CC Sole-

noid to achieve a smooth application of the torque

converter clutch. This function, referred to as Elec-

tronically Modulated Converter Clutch (EMCC) can

occur at various times depending on the following

variables:

²Shift lever position

²Current gear range

²Transmission fluid temperature

²Engine coolant temperature

²Input speed

²Throttle angle²Engine speed

Fig. 120 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 121 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 122 Torque Converter Clutch (TCC)

1 - IMPELLER FRONT COVER

2 - THRUST WASHER ASSEMBLY

3 - IMPELLER

4-STATOR

5 - TURBINE

6 - PISTON

7 - FRICTION DISC

21 - 402 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

TORQUE CONVERTER (Continued)

Page 2106 of 2627

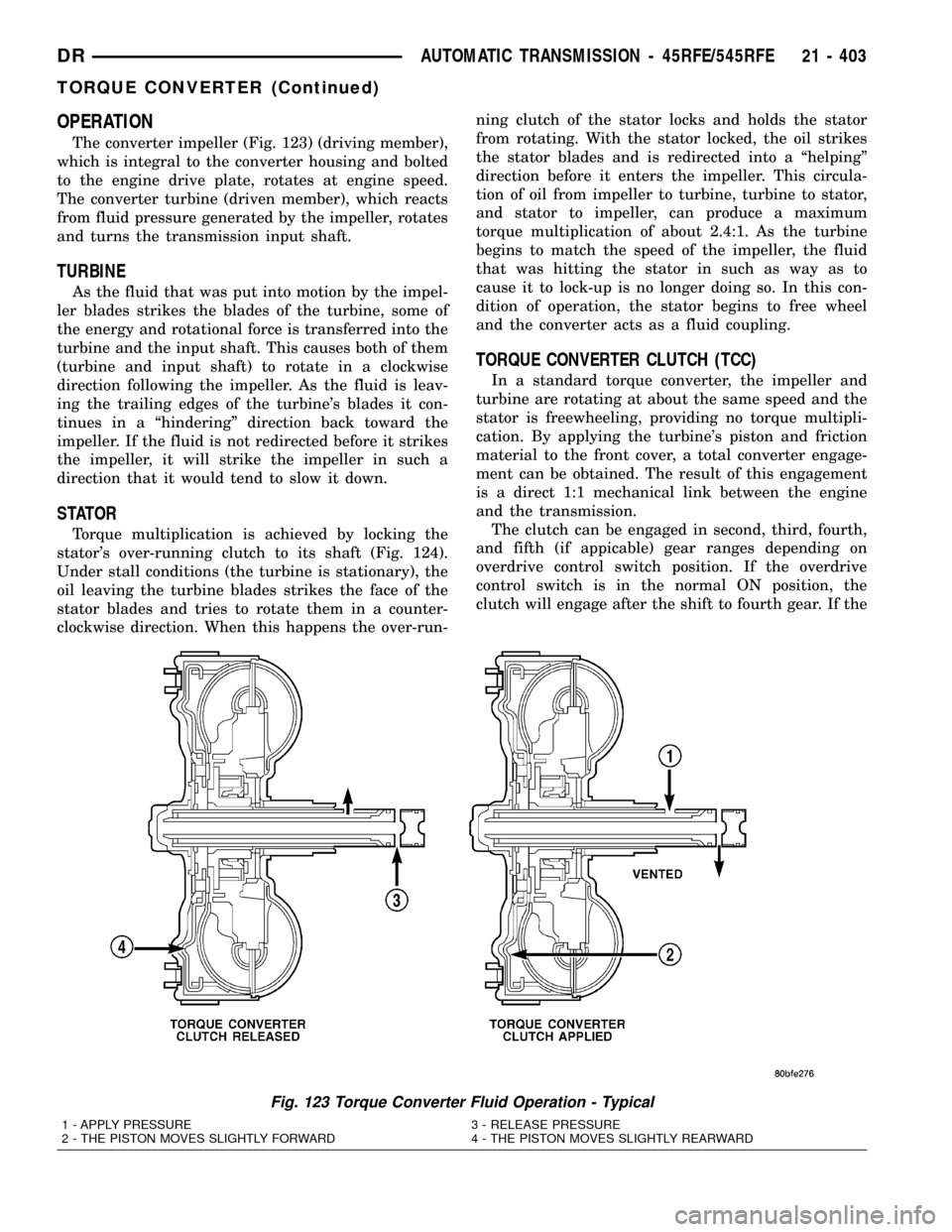

OPERATION

The converter impeller (Fig. 123) (driving member),

which is integral to the converter housing and bolted

to the engine drive plate, rotates at engine speed.

The converter turbine (driven member), which reacts

from fluid pressure generated by the impeller, rotates

and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some of

the energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a

direction that it would tend to slow it down.

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 124).

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-

clockwise direction. When this happens the over-run-ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.4:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock-up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

In a standard torque converter, the impeller and

turbine are rotating at about the same speed and the

stator is freewheeling, providing no torque multipli-

cation. By applying the turbine's piston and friction

material to the front cover, a total converter engage-

ment can be obtained. The result of this engagement

is a direct 1:1 mechanical link between the engine

and the transmission.

The clutch can be engaged in second, third, fourth,

and fifth (if appicable) gear ranges depending on

overdrive control switch position. If the overdrive

control switch is in the normal ON position, the

clutch will engage after the shift to fourth gear. If the

Fig. 123 Torque Converter Fluid Operation - Typical

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 403

TORQUE CONVERTER (Continued)

Page 2111 of 2627

INSTALLATION

(1) Place TRS selector plate in the PARK position.

(2) Position the transmission solenoid/TRS assem-

bly onto the valve body. Be sure that both alignment

dowels are fully seated in the valve body and that

the TRS switch contacts are properly positioned in

the selector plate

(3) Install the screws to hold the transmission

solenoid/TRS assembly onto the valve body.

(4) Tighten the solenoid assembly screws adjacent

to the arrows cast into the bottom of the valve body

first. Tighten the screws to 5.7 N´m (50 in.lbs.).

(5) Tighten the remainder of the solenoid assembly

screws to 5.7 N´m (50 in.lbs.).

(6) Install the valve body into the transmission.

TRANSMISSION

TEMPERATURE SENSOR

DESCRIPTION

The transmission temperature sensor is a ther-

mistor that is integral to the Transmission Range

Sensor (TRS).

OPERATION

The transmission temperature sensor is used by

the TCM to sense the temperature of the fluid in the

sump. Since fluid temperature can affect transmis-

sion shift quality and convertor lock up, the TCM

requires this information to determine which shift

schedule to operate in.

Calculated Temperature

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-

dicted fluid temperature which is calculated from a

combination of inputs:

²Battery (ambient) temperature

²Engine coolant temperature

²In-gear run time since start-up

VALVE BODY

DESCRIPTION

The valve body consists of a cast aluminum valve

body, a separator plate, and a transfer plate. The

valve body contains valves and check balls that con-

trol fluid delivery to the torque converter clutch,

bands, and frictional clutches. The valve body con-

tains the following components (Fig. 129) and (Fig.

130):

²Solenoid switch valve

²Manual valve

²Low/reverse switch valve

²5 Accumulators

²7 check balls

OPERATION

NOTE: Refer to the Hydraulic Schematics for a

visual aid in determining valve location, operation

and design.

SOLENOID SWITCH VALVE

The Solenoid Switch Valve (SSV) controls the direc-

tion of the transmission fluid when the L/R-TCC sole-

noid is energized.

When shifting into 1st gear, a special hydraulic

sequence is performed to ensure SSV movement into

the downshifted position. The L/R pressure switch is

monitored to confirm SSV movement. If the move-

ment is not confirmed (the L/R pressure switch does

not close), 2nd gear is substituted for 1st. A DTC will

be set after three unsuccessful attempts are made to

get into 1st gear in one given key start.

MANUAL VALVE

The manual valve is a relay valve. The purpose of

the manual valve is to direct fluid to the correct cir-

cuit needed for a specific gear or driving range. The

manual valve, as the name implies, is manually oper-

ated by the driver with a lever located on the top of

the valve body. The valve is connected mechanically

by a cable to the gearshift mechanism. The valve is

held in each of its positions by a roller detent spring

(Fig. 131) that engages the ªroostercombº of the TRS

selector plate.

21 - 408 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

TRANSMISSION SOLENOID/TRS ASSEMBLY (Continued)

Page 2214 of 2627

²A flashing operating mode LED for the desired

gear indicates that a shift to that position has been

requested, but all of the driver controllable conditions

have not been met. This is in an attempt to notify the

driver that the transmission needs to be put into NEU-

TRAL, the vehicle speed is too great, or some other con-

dition outlined (other than a diagnostic failure that

would prevent this shift) elsewhere (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/TRANS-

FER CASE CONTROL MODULE - OPERATION) is not

met. Note that this flashing will continue indefinitely

until the conditions are eventually met, or the selector

switch position is changed, or if diagnostic routines no

longer allow the requested shift.

²If the driver attempts to make a shift into transfer

case NEUTRAL, and any of the driver controllable con-

ditions are not met, the request will be ignored until all

of the conditions are met or until the NEUTRAL select

button is released. Additionally the neutral lamp will

flash, or begin to flash while the button is depressed

and operator controllable conditions are not being met.

All of the LED's except the Neutral will flash if any of

the operator controllable conditions for shifting are not

met while the Neutral button is depressed. This9toggle9

type of feature is necessary because the TCCM would

interpret another request immediately after the shift

into transfer case NEUTRAL has completed.

²No LED's illuminated indicate a fault in the

transfer case control system.

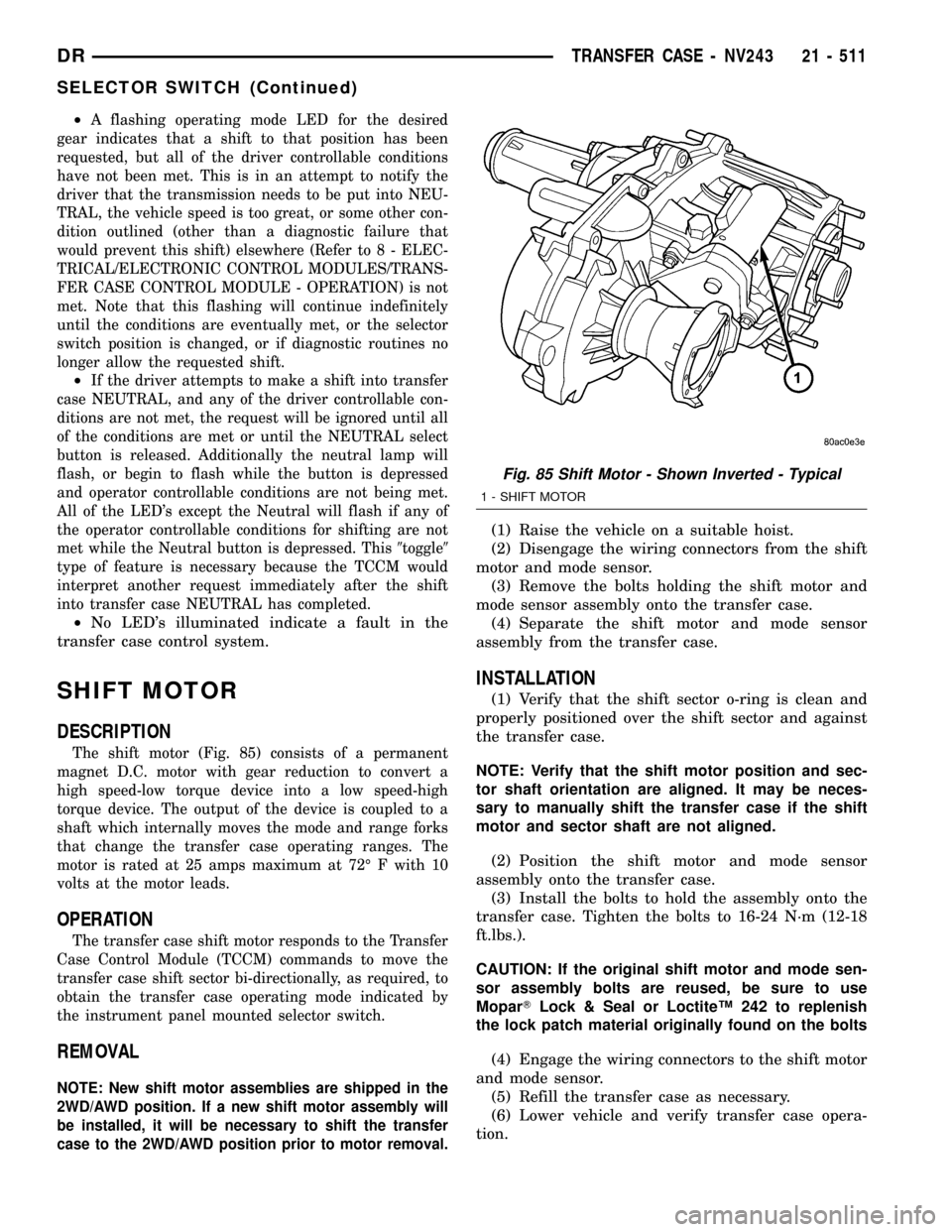

SHIFT MOTOR

DESCRIPTION

The shift motor (Fig. 85) consists of a permanent

magnet D.C. motor with gear reduction to convert a

high speed-low torque device into a low speed-high

torque device. The output of the device is coupled to a

shaft which internally moves the mode and range forks

that change the transfer case operating ranges. The

motor is rated at 25 amps maximum at 72É F with 10

volts at the motor leads.

OPERATION

The transfer case shift motor responds to the Transfer

Case Control Module (TCCM) commands to move the

transfer case shift sector bi-directionally, as required, to

obtain the transfer case operating mode indicated by

the instrument panel mounted selector switch.

REMOVAL

NOTE: New shift motor assemblies are shipped in the

2WD/AWD position. If a new shift motor assembly will

be installed, it will be necessary to shift the transfer

case to the 2WD/AWD position prior to motor removal.

(1) Raise the vehicle on a suitable hoist.

(2) Disengage the wiring connectors from the shift

motor and mode sensor.

(3) Remove the bolts holding the shift motor and

mode sensor assembly onto the transfer case.

(4) Separate the shift motor and mode sensor

assembly from the transfer case.

INSTALLATION

(1) Verify that the shift sector o-ring is clean and

properly positioned over the shift sector and against

the transfer case.

NOTE: Verify that the shift motor position and sec-

tor shaft orientation are aligned. It may be neces-

sary to manually shift the transfer case if the shift

motor and sector shaft are not aligned.

(2) Position the shift motor and mode sensor

assembly onto the transfer case.

(3) Install the bolts to hold the assembly onto the

transfer case. Tighten the bolts to 16-24 N´m (12-18

ft.lbs.).

CAUTION: If the original shift motor and mode sen-

sor assembly bolts are reused, be sure to use

MoparTLock & Seal or LoctiteŸ 242 to replenish

the lock patch material originally found on the bolts

(4) Engage the wiring connectors to the shift motor

and mode sensor.

(5) Refill the transfer case as necessary.

(6) Lower vehicle and verify transfer case opera-

tion.

Fig. 85 Shift Motor - Shown Inverted - Typical

1 - SHIFT MOTOR

DRTRANSFER CASE - NV243 21 - 511

SELECTOR SWITCH (Continued)

Page 2243 of 2627

OPERATION

As the position of the selector switch varies, the

resistance between the Mode Sensor supply voltage

pin and the Mode Sensor output will vary. Hardware,

software, and calibrations within the Transfer Case

Control Module (TCCM) are provided that interpret

the selector switch resistance as given in the table

below: SELECTOR SWITCH INTERPRETATION

SELECTOR SWITCH INTERPRETATION

Step Resistance

Range (ohms)Required

Interpretation

A <200 Shorted

B 400-700 NEUTRAL

C 1050-1450 4LO

D 1850-2300 4H

E 3050-5950 AWD (Default)

F 9.5-12.5K In between

positions

G >15.5K Open

For resistances between the ranges B-E shown for

each valid position (T-Case NEUTRAL, 4LO, 4HI,

AWD), the TCCM may interpret the resistance as:

²either of the neighboring valid positions.

²as an invalid fault position.

For resistances between the ranges E and F shown

for AWD and in-between positions, the TCCM may

interpret the resistance as:

²the AWD position.

²an invalid fault position.

²a valid in-between position.

For resistances between the ranges F and G shown

for in-between positions and fault condition (open),

the TCCM may interpret the resistance as:

²a valid in-between position.

²an invalid fault position.

For resistances between the ranges A and B shown

for the fault condition (short) and , T-Case NEU-

TRAL, the TCCM may interpret the resistance as:²the T-Case NEUTRAL position.

²an invalid fault position.

The LED's in the selector assembly are illuminat-

ed/flashed in the following manner to indicate a par-

ticular condition or state.

²A solidly illuminated LED indicates a success-

fully completed shift and the current operating mode

of the transfer case. While a shift has been requested

but not yet completed, the LED for the desired trans-

fer case position is flashed.

²A flashing operating mode LED for the desired

gear indicates that a shift to that position has been

requested, but all of the driver controllable conditions

have not been met. This is in an attempt to notify

the driver that the transmission needs to be put into

NEUTRAL, the vehicle speed is too great, or some

other condition outlined (other than a diagnostic fail-

ure that would prevent this shift) elsewhere (Refer to

8 - ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/TRANSFER CASE CONTROL MODULE -

OPERATION) is not met. Note that this flashing will

continue indefinitely until the conditions are eventu-

ally met, or the selector switch position is changed,

or if diagnostic routines no longer allow the

requested shift.

²If the driver attempts to make a shift into trans-

fer case NEUTRAL, and any of the driver controlla-

ble conditions are not met, the request will be

ignored until all of the conditions are met or until

the NEUTRAL select button is released. Additionally

the neutral lamp will flash, or begin to flash while

the button is depressed and operator controllable

conditions are not being met. All of the LED's except

the Neutral will flash if any of the operator control-

lable conditions for shifting are not met while the

Neutral button is depressed. This9toggle9type of fea-

ture is necessary because the TCCM would interpret

another request immediately after the shift into

transfer case NEUTRAL has completed.

²No LED's illuminated indicate a fault in the

transfer case control system.

21 - 540 TRANSFER CASE - NV244 GENIIDR

SELECTOR SWITCH (Continued)

Page 2278 of 2627

have not been met. This is in an attempt to notify

the driver that the transmission needs to be put into

NEUTRAL, the vehicle speed is too great, or some

other condition outlined (other than a diagnostic fail-

ure that would prevent this shift) elsewhere (Refer to

8 - ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/TRANSFER CASE CONTROL MODULE -

OPERATION) is not met. Note that this flashing will

continue indefinitely until the conditions are eventu-

ally met, or the selector switch position is changed,

or if diagnostic routines no longer allow the

requested shift.

²

If the driver attempts to make a shift into transfer

case NEUTRAL, and any of the driver controllable con-

ditions are not met, the request will be ignored until all

of the conditions are met or until the NEUTRAL select

button is released. Additionally the neutral lamp will

flash, or begin to flash while the button is depressed

and operator controllable conditions are not being met.

All of the LED's except the Neutral will flash if any of

the operator controllable conditions for shifting are not

met while the Neutral button is depressed. This9toggle9

type of feature is necessary because the TCCM would

interpret another request immediately after the shift

into transfer case NEUTRAL has completed.

²No LED's illuminated indicate a fault in the

transfer case control system.

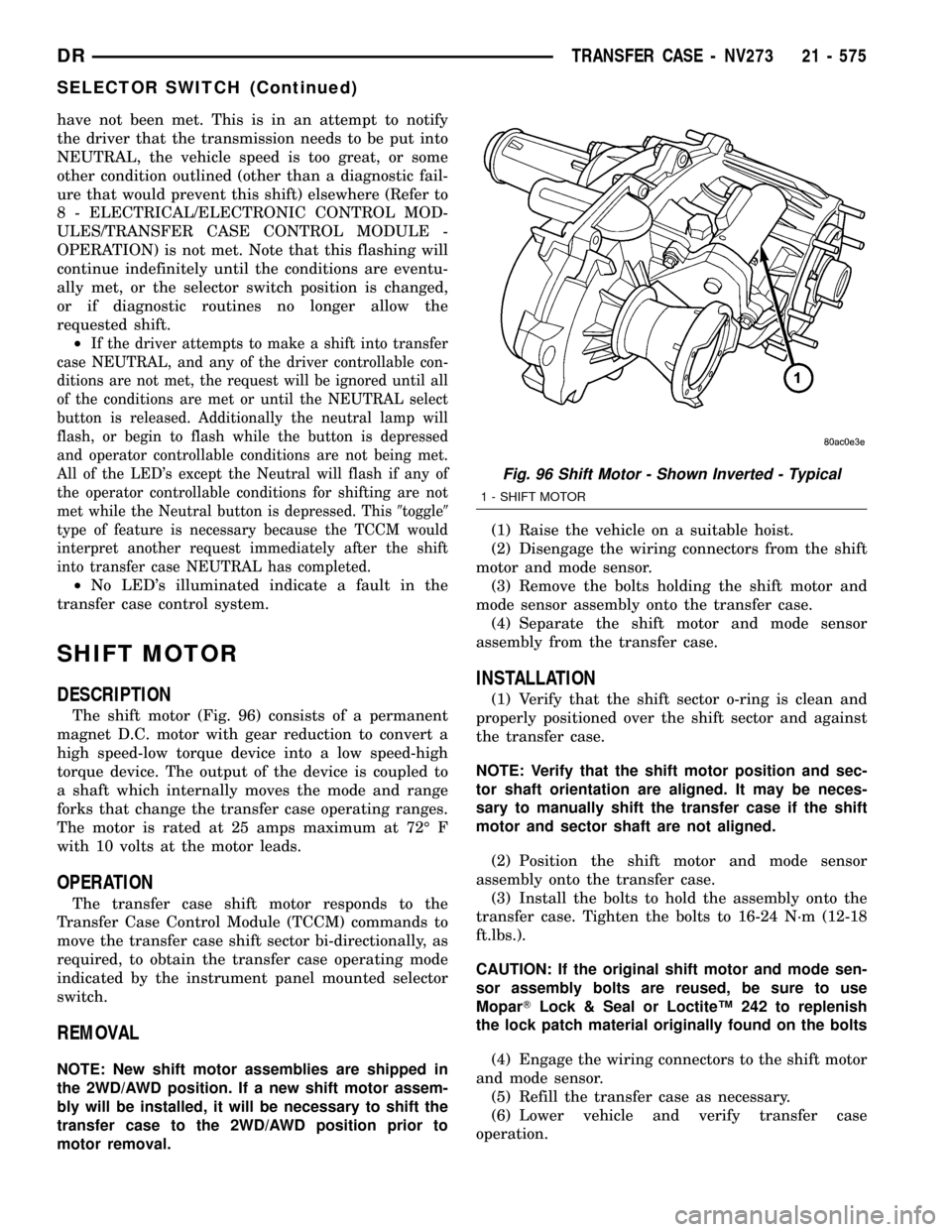

SHIFT MOTOR

DESCRIPTION

The shift motor (Fig. 96) consists of a permanent

magnet D.C. motor with gear reduction to convert a

high speed-low torque device into a low speed-high

torque device. The output of the device is coupled to

a shaft which internally moves the mode and range

forks that change the transfer case operating ranges.

The motor is rated at 25 amps maximum at 72É F

with 10 volts at the motor leads.

OPERATION

The transfer case shift motor responds to the

Transfer Case Control Module (TCCM) commands to

move the transfer case shift sector bi-directionally, as

required, to obtain the transfer case operating mode

indicated by the instrument panel mounted selector

switch.

REMOVAL

NOTE: New shift motor assemblies are shipped in

the 2WD/AWD position. If a new shift motor assem-

bly will be installed, it will be necessary to shift the

transfer case to the 2WD/AWD position prior to

motor removal.(1) Raise the vehicle on a suitable hoist.

(2) Disengage the wiring connectors from the shift

motor and mode sensor.

(3) Remove the bolts holding the shift motor and

mode sensor assembly onto the transfer case.

(4) Separate the shift motor and mode sensor

assembly from the transfer case.

INSTALLATION

(1) Verify that the shift sector o-ring is clean and

properly positioned over the shift sector and against

the transfer case.

NOTE: Verify that the shift motor position and sec-

tor shaft orientation are aligned. It may be neces-

sary to manually shift the transfer case if the shift

motor and sector shaft are not aligned.

(2) Position the shift motor and mode sensor

assembly onto the transfer case.

(3) Install the bolts to hold the assembly onto the

transfer case. Tighten the bolts to 16-24 N´m (12-18

ft.lbs.).

CAUTION: If the original shift motor and mode sen-

sor assembly bolts are reused, be sure to use

MoparTLock & Seal or LoctiteŸ 242 to replenish

the lock patch material originally found on the bolts

(4) Engage the wiring connectors to the shift motor

and mode sensor.

(5) Refill the transfer case as necessary.

(6) Lower vehicle and verify transfer case

operation.

Fig. 96 Shift Motor - Shown Inverted - Typical

1 - SHIFT MOTOR

DRTRANSFER CASE - NV273 21 - 575

SELECTOR SWITCH (Continued)