bolt pattern DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 164 of 2627

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern. Adjust backlash or

pinion depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lift under axle and secure axle to

lift.

(3) Remove wheels and tires assemblies.

(4) Remove all brake components.

(5) Remove axle vent hose.

(6) Mark propeller shaft and companion flange for

installation alignment reference.

(7) Remove propeller shaft.

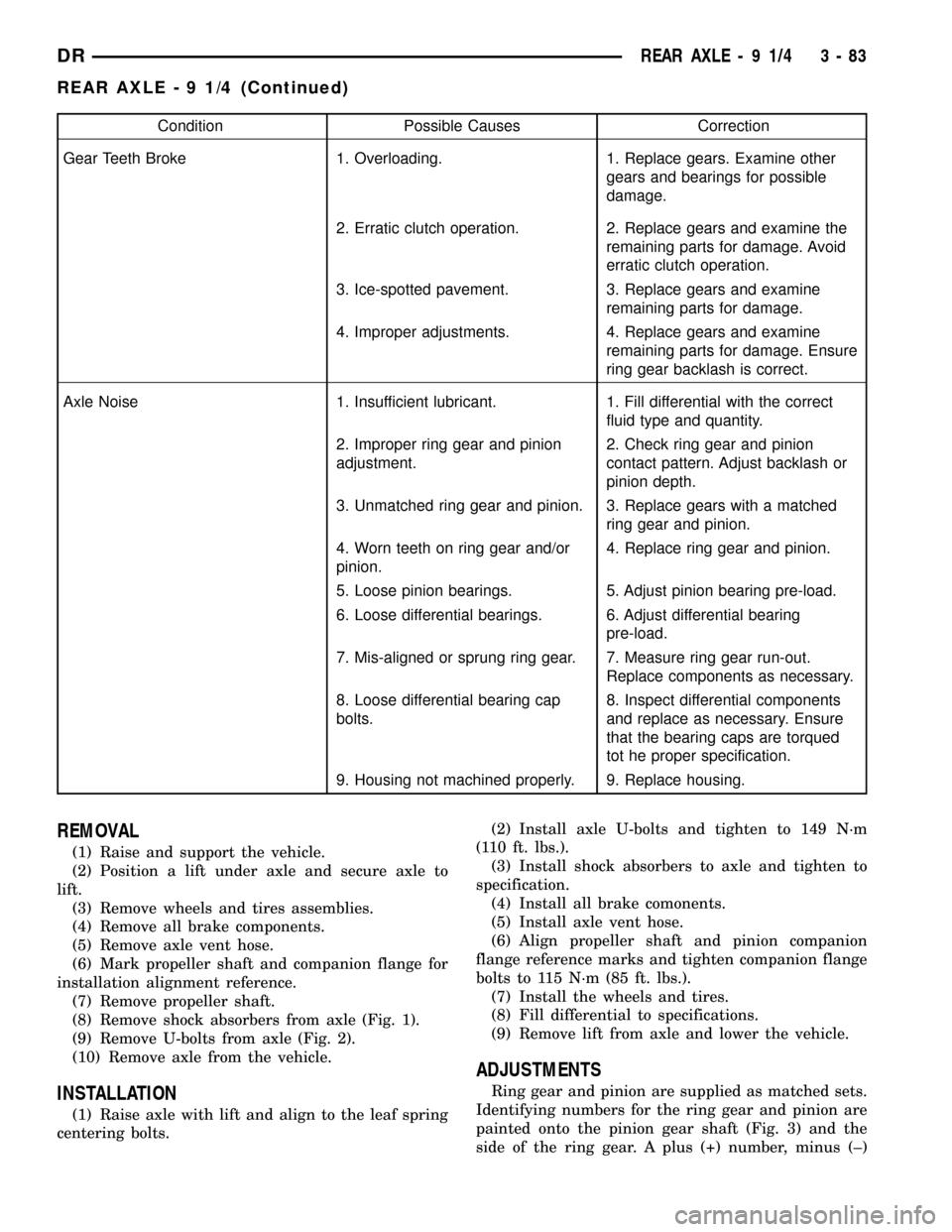

(8) Remove shock absorbers from axle (Fig. 1).

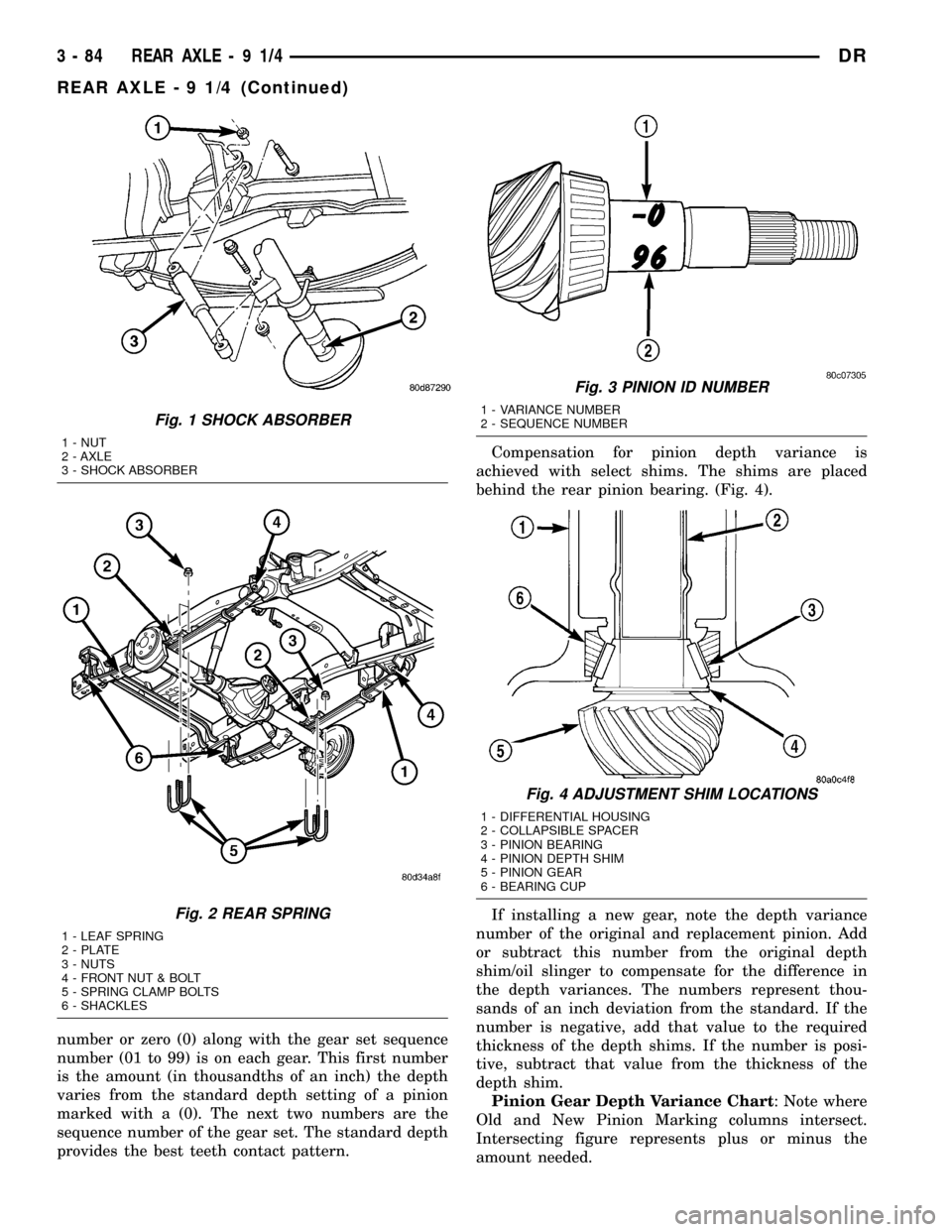

(9) Remove U-bolts from axle (Fig. 2).

(10) Remove axle from the vehicle.

INSTALLATION

(1) Raise axle with lift and align to the leaf spring

centering bolts.(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install all brake comonents.

(5) Install axle vent hose.

(6) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(7) Install the wheels and tires.

(8) Fill differential to specifications.

(9) Remove lift from axle and lower the vehicle.

ADJUSTMENTS

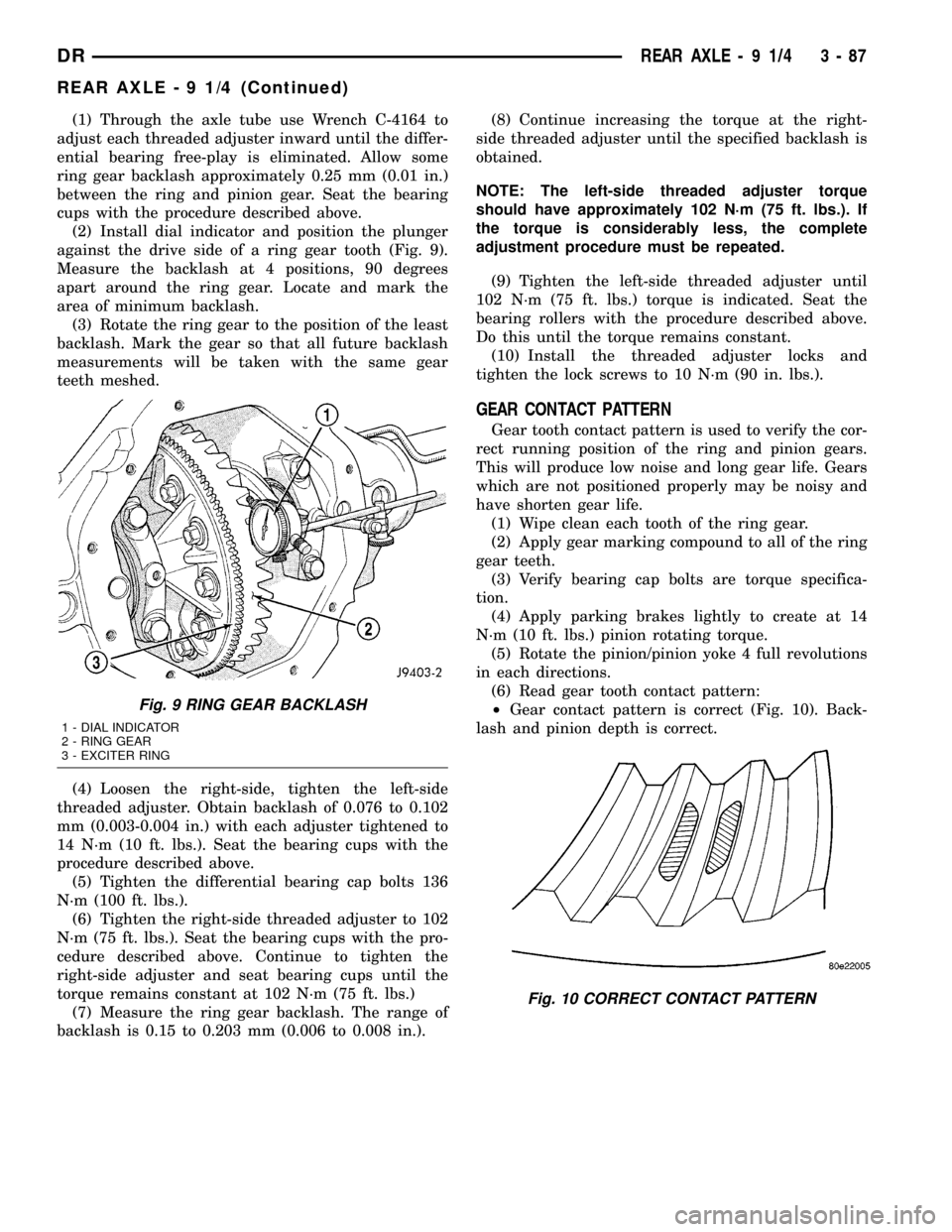

Ring gear and pinion are supplied as matched sets.

Identifying numbers for the ring gear and pinion are

painted onto the pinion gear shaft (Fig. 3) and the

side of the ring gear. A plus (+) number, minus (±)

DRREAR AXLE - 9 1/4 3 - 83

REAR AXLE - 9 1/4 (Continued)

Page 165 of 2627

number or zero (0) along with the gear set sequence

number (01 to 99) is on each gear. This first number

is the amount (in thousandths of an inch) the depth

varies from the standard depth setting of a pinion

marked with a (0). The next two numbers are the

sequence number of the gear set. The standard depth

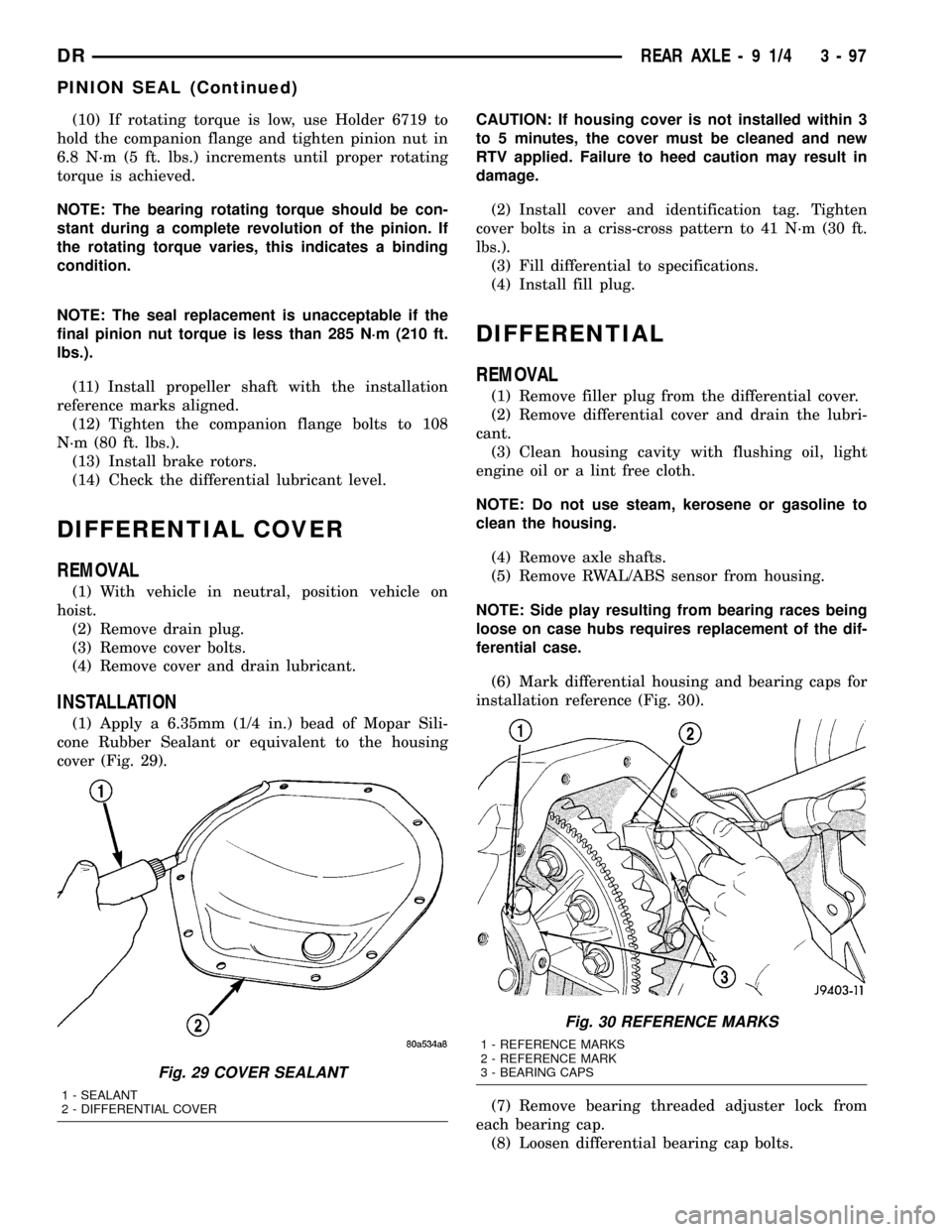

provides the best teeth contact pattern.Compensation for pinion depth variance is

achieved with select shims. The shims are placed

behind the rear pinion bearing. (Fig. 4).

If installing a new gear, note the depth variance

number of the original and replacement pinion. Add

or subtract this number from the original depth

shim/oil slinger to compensate for the difference in

the depth variances. The numbers represent thou-

sands of an inch deviation from the standard. If the

number is negative, add that value to the required

thickness of the depth shims. If the number is posi-

tive, subtract that value from the thickness of the

depth shim.

Pinion Gear Depth Variance Chart: Note where

Old and New Pinion Marking columns intersect.

Intersecting figure represents plus or minus the

amount needed.

Fig. 1 SHOCK ABSORBER

1 - NUT

2 - AXLE

3 - SHOCK ABSORBER

Fig. 2 REAR SPRING

1 - LEAF SPRING

2 - PLATE

3 - NUTS

4 - FRONT NUT & BOLT

5 - SPRING CLAMP BOLTS

6 - SHACKLES

Fig. 3 PINION ID NUMBER

1 - VARIANCE NUMBER

2 - SEQUENCE NUMBER

Fig. 4 ADJUSTMENT SHIM LOCATIONS

1 - DIFFERENTIAL HOUSING

2 - COLLAPSIBLE SPACER

3 - PINION BEARING

4 - PINION DEPTH SHIM

5 - PINION GEAR

6 - BEARING CUP

3 - 84 REAR AXLE-91/4DR

REAR AXLE - 9 1/4 (Continued)

Page 168 of 2627

(1) Through the axle tube use Wrench C-4164 to

adjust each threaded adjuster inward until the differ-

ential bearing free-play is eliminated. Allow some

ring gear backlash approximately 0.25 mm (0.01 in.)

between the ring and pinion gear. Seat the bearing

cups with the procedure described above.

(2) Install dial indicator and position the plunger

against the drive side of a ring gear tooth (Fig. 9).

Measure the backlash at 4 positions, 90 degrees

apart around the ring gear. Locate and mark the

area of minimum backlash.

(3) Rotate the ring gear to the position of the least

backlash. Mark the gear so that all future backlash

measurements will be taken with the same gear

teeth meshed.

(4) Loosen the right-side, tighten the left-side

threaded adjuster. Obtain backlash of 0.076 to 0.102

mm (0.003-0.004 in.) with each adjuster tightened to

14 N´m (10 ft. lbs.). Seat the bearing cups with the

procedure described above.

(5) Tighten the differential bearing cap bolts 136

N´m (100 ft. lbs.).

(6) Tighten the right-side threaded adjuster to 102

N´m (75 ft. lbs.). Seat the bearing cups with the pro-

cedure described above. Continue to tighten the

right-side adjuster and seat bearing cups until the

torque remains constant at 102 N´m (75 ft. lbs.)

(7) Measure the ring gear backlash. The range of

backlash is 0.15 to 0.203 mm (0.006 to 0.008 in.).(8) Continue increasing the torque at the right-

side threaded adjuster until the specified backlash is

obtained.

NOTE: The left-side threaded adjuster torque

should have approximately 102 N´m (75 ft. lbs.). If

the torque is considerably less, the complete

adjustment procedure must be repeated.

(9) Tighten the left-side threaded adjuster until

102 N´m (75 ft. lbs.) torque is indicated. Seat the

bearing rollers with the procedure described above.

Do this until the torque remains constant.

(10) Install the threaded adjuster locks and

tighten the lock screws to 10 N´m (90 in. lbs.).

GEAR CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply parking brakes lightly to create at 14

N´m (10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:

²Gear contact pattern is correct (Fig. 10). Back-

lash and pinion depth is correct.

Fig. 9 RING GEAR BACKLASH

1 - DIAL INDICATOR

2 - RING GEAR

3 - EXCITER RING

Fig. 10 CORRECT CONTACT PATTERN

DRREAR AXLE - 9 1/4 3 - 87

REAR AXLE - 9 1/4 (Continued)

Page 178 of 2627

(10) If rotating torque is low, use Holder 6719 to

hold the companion flange and tighten pinion nut in

6.8 N´m (5 ft. lbs.) increments until proper rotating

torque is achieved.

NOTE: The bearing rotating torque should be con-

stant during a complete revolution of the pinion. If

the rotating torque varies, this indicates a binding

condition.

NOTE: The seal replacement is unacceptable if the

final pinion nut torque is less than 285 N´m (210 ft.

lbs.).

(11) Install propeller shaft with the installation

reference marks aligned.

(12) Tighten the companion flange bolts to 108

N´m (80 ft. lbs.).

(13) Install brake rotors.

(14) Check the differential lubricant level.

DIFFERENTIAL COVER

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove drain plug.

(3) Remove cover bolts.

(4) Remove cover and drain lubricant.

INSTALLATION

(1) Apply a 6.35mm (1/4 in.) bead of Mopar Sili-

cone Rubber Sealant or equivalent to the housing

cover (Fig. 29).CAUTION: If housing cover is not installed within 3

to 5 minutes, the cover must be cleaned and new

RTV applied. Failure to heed caution may result in

damage.

(2) Install cover and identification tag. Tighten

cover bolts in a criss-cross pattern to 41 N´m (30 ft.

lbs.).

(3) Fill differential to specifications.

(4) Install fill plug.

DIFFERENTIAL

REMOVAL

(1) Remove filler plug from the differential cover.

(2) Remove differential cover and drain the lubri-

cant.

(3) Clean housing cavity with flushing oil, light

engine oil or a lint free cloth.

NOTE: Do not use steam, kerosene or gasoline to

clean the housing.

(4) Remove axle shafts.

(5) Remove RWAL/ABS sensor from housing.

NOTE: Side play resulting from bearing races being

loose on case hubs requires replacement of the dif-

ferential case.

(6) Mark differential housing and bearing caps for

installation reference (Fig. 30).

(7) Remove bearing threaded adjuster lock from

each bearing cap.

(8) Loosen differential bearing cap bolts.

Fig. 29 COVER SEALANT

1 - SEALANT

2 - DIFFERENTIAL COVER

Fig. 30 REFERENCE MARKS

1 - REFERENCE MARKS

2 - REFERENCE MARK

3 - BEARING CAPS

DRREAR AXLE - 9 1/4 3 - 97

PINION SEAL (Continued)

Page 192 of 2627

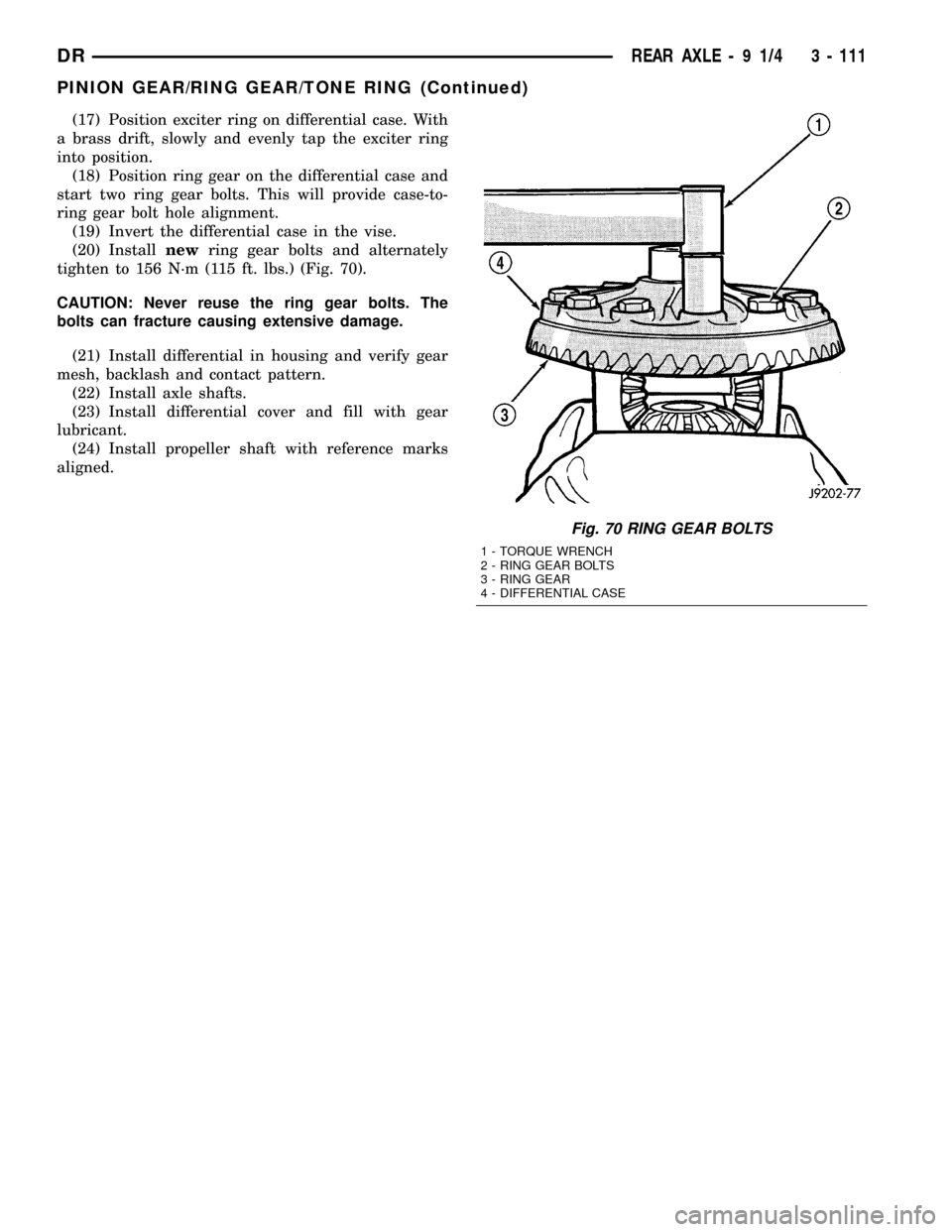

(17) Position exciter ring on differential case. With

a brass drift, slowly and evenly tap the exciter ring

into position.

(18) Position ring gear on the differential case and

start two ring gear bolts. This will provide case-to-

ring gear bolt hole alignment.

(19) Invert the differential case in the vise.

(20) Installnewring gear bolts and alternately

tighten to 156 N´m (115 ft. lbs.) (Fig. 70).

CAUTION: Never reuse the ring gear bolts. The

bolts can fracture causing extensive damage.

(21) Install differential in housing and verify gear

mesh, backlash and contact pattern.

(22) Install axle shafts.

(23) Install differential cover and fill with gear

lubricant.

(24) Install propeller shaft with reference marks

aligned.

Fig. 70 RING GEAR BOLTS

1 - TORQUE WRENCH

2 - RING GEAR BOLTS

3 - RING GEAR

4 - DIFFERENTIAL CASE

DRREAR AXLE - 9 1/4 3 - 111

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 196 of 2627

Condition Possible Causes Correction

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct fluid

type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion contact

pattern. Adjust backlash or pinion

depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched ring

gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out. Replace

components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components and

replace as necessary. Ensure that the

bearing caps are torqued tot he

proper specification.

9. Housing not machined properly. 9. Replace housing.

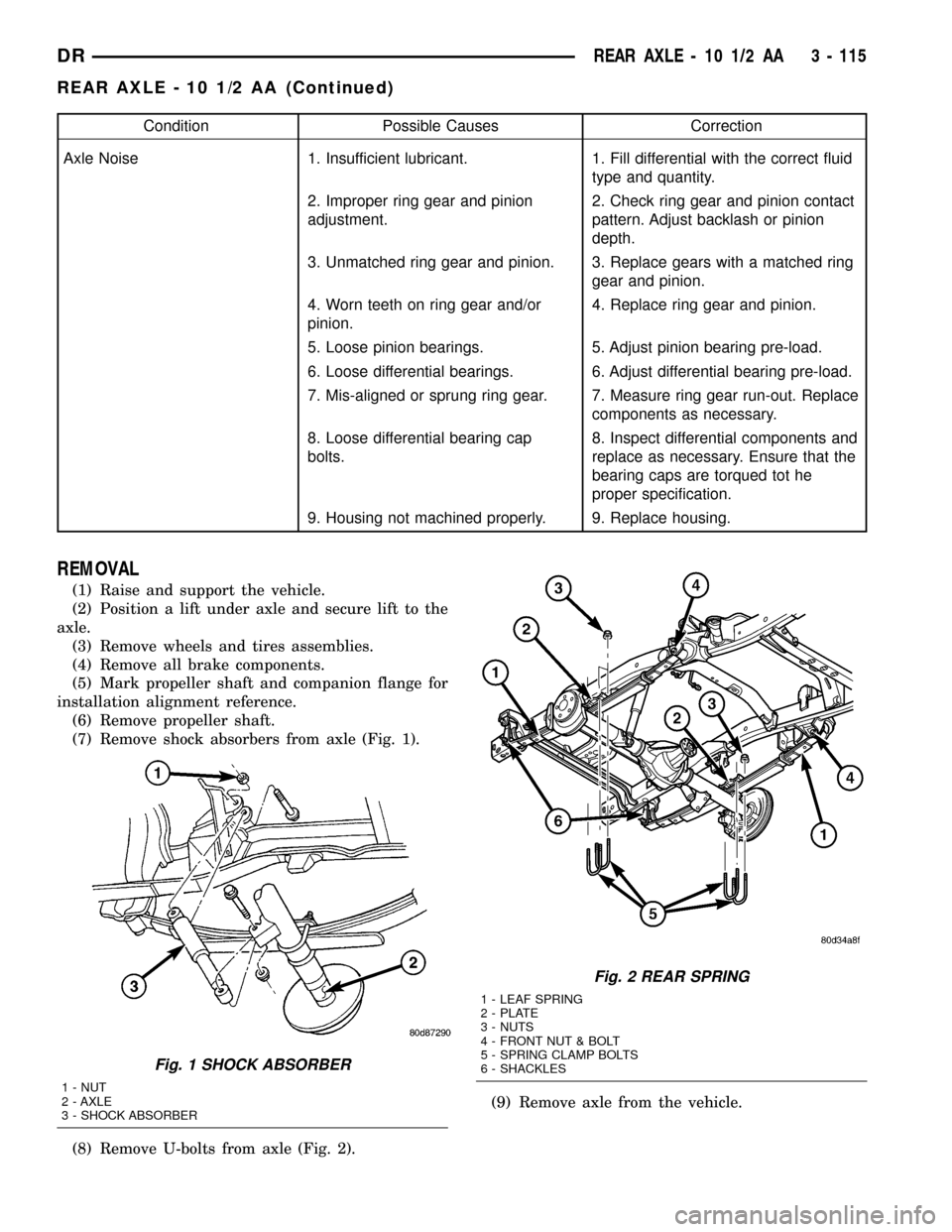

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lift under axle and secure lift to the

axle.

(3) Remove wheels and tires assemblies.

(4) Remove all brake components.

(5) Mark propeller shaft and companion flange for

installation alignment reference.

(6) Remove propeller shaft.

(7) Remove shock absorbers from axle (Fig. 1).

(8) Remove U-bolts from axle (Fig. 2).(9) Remove axle from the vehicle.

Fig. 1 SHOCK ABSORBER

1 - NUT

2 - AXLE

3 - SHOCK ABSORBER

Fig. 2 REAR SPRING

1 - LEAF SPRING

2 - PLATE

3 - NUTS

4 - FRONT NUT & BOLT

5 - SPRING CLAMP BOLTS

6 - SHACKLES

DRREAR AXLE - 10 1/2 AA 3 - 115

REAR AXLE - 10 1/2 AA (Continued)

Page 198 of 2627

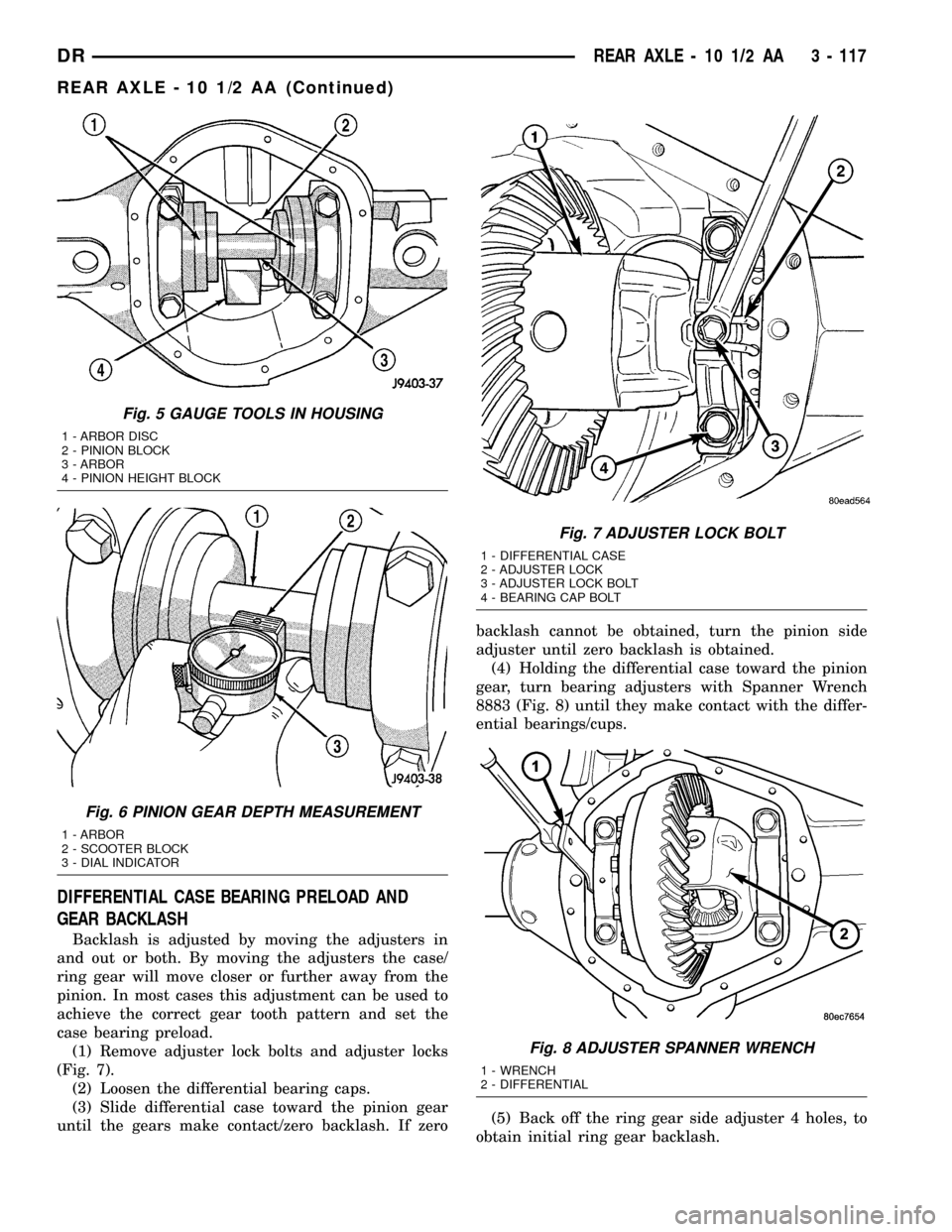

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 7).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zerobacklash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 (Fig. 8) until they make contact with the differ-

ential bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

Fig. 5 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 6 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 7 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 8 ADJUSTER SPANNER WRENCH

1 - WRENCH

2 - DIFFERENTIAL

DRREAR AXLE - 10 1/2 AA 3 - 117

REAR AXLE - 10 1/2 AA (Continued)

Page 199 of 2627

(6) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(7) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(8) Rotate the pinion several times to seat the def-

erential bearings.

(9) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup, then tighten

it until it makes contact.

(10) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings:6 Adjuster Holes

²Original Bearings:4 Adjuster Holes

(11) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(12) Tighten bearing cap bolts to 115 N´m (85 ft.

lbs.).

(13) Tighten adjuster lock bolts to 33 N´m (24 ft.

lbs.).

(14) Measure ring gear backlash with a Dial Indi-

cator C-3339 and Dial Indicator Stud L-4438 at eight

points around the drive side of the ring gear (Fig. 9).

The backlash should be 0.08-0.25 mm (0.003-0.010

in) with a preferred backlash of 0.13-0.18 mm (0.005-

0.007 in).

NOTE: Backlash measurement should not vary

more than 0.05 mm (0.002 in) between measuring

points. If measurement does vary inspect the gears

for burrs, the differential case flange and ring gear

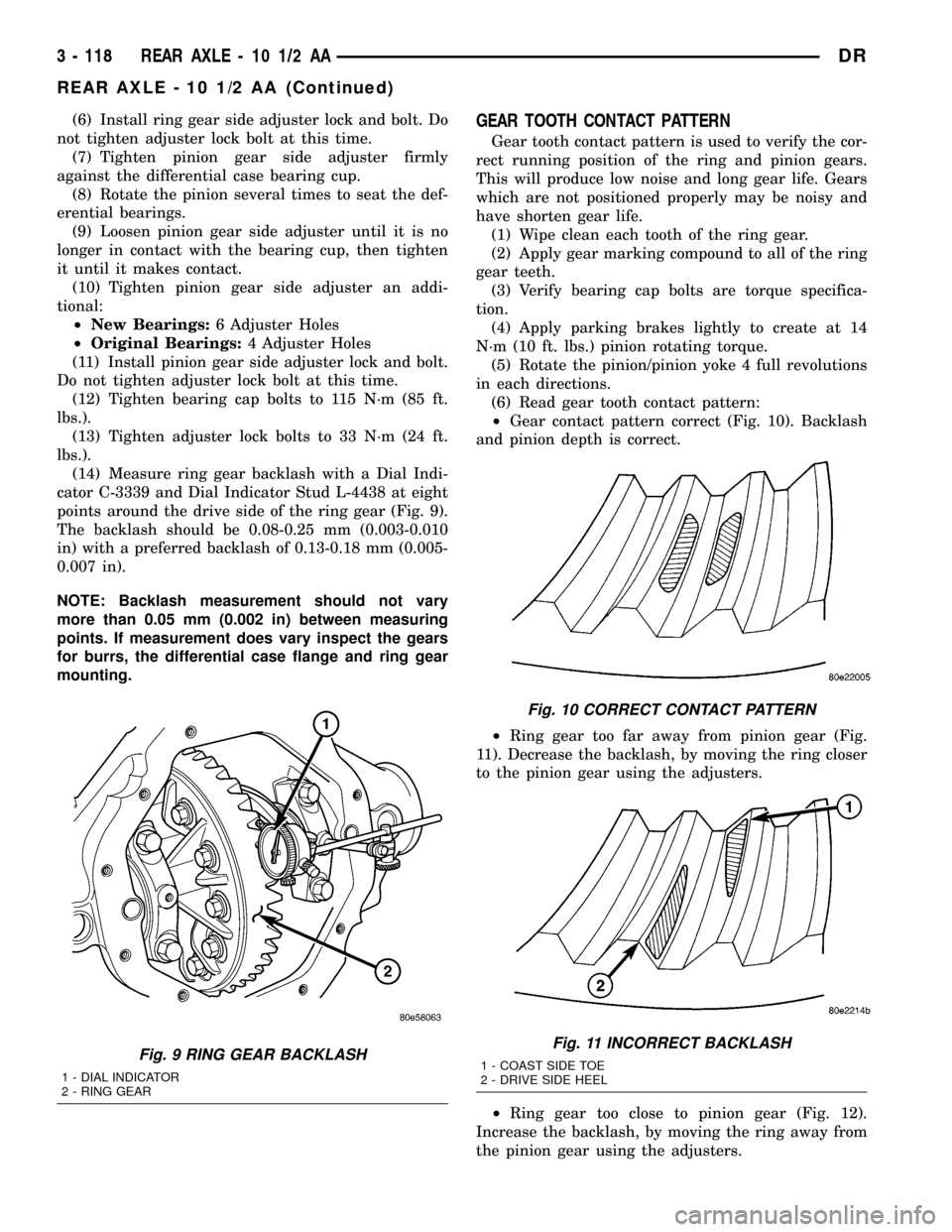

mounting.GEAR TOOTH CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply parking brakes lightly to create at 14

N´m (10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:

²Gear contact pattern correct (Fig. 10). Backlash

and pinion depth is correct.

²Ring gear too far away from pinion gear (Fig.

11). Decrease the backlash, by moving the ring closer

to the pinion gear using the adjusters.

²Ring gear too close to pinion gear (Fig. 12).

Increase the backlash, by moving the ring away from

the pinion gear using the adjusters.

Fig. 9 RING GEAR BACKLASH

1 - DIAL INDICATOR

2 - RING GEAR

Fig. 10 CORRECT CONTACT PATTERN

Fig. 11 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

3 - 118 REAR AXLE - 10 1/2 AADR

REAR AXLE - 10 1/2 AA (Continued)

Page 211 of 2627

INSTALLATION

(1) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.

CAUTION: Do not use water, steam, kerosene or

gasoline for cleaning.

(2) Lubricate differential case bearing.

(3) Install differential case with bearings cups into

the housing.

NOTE: A light coat of grease on the cups will hold

them in place during installation.

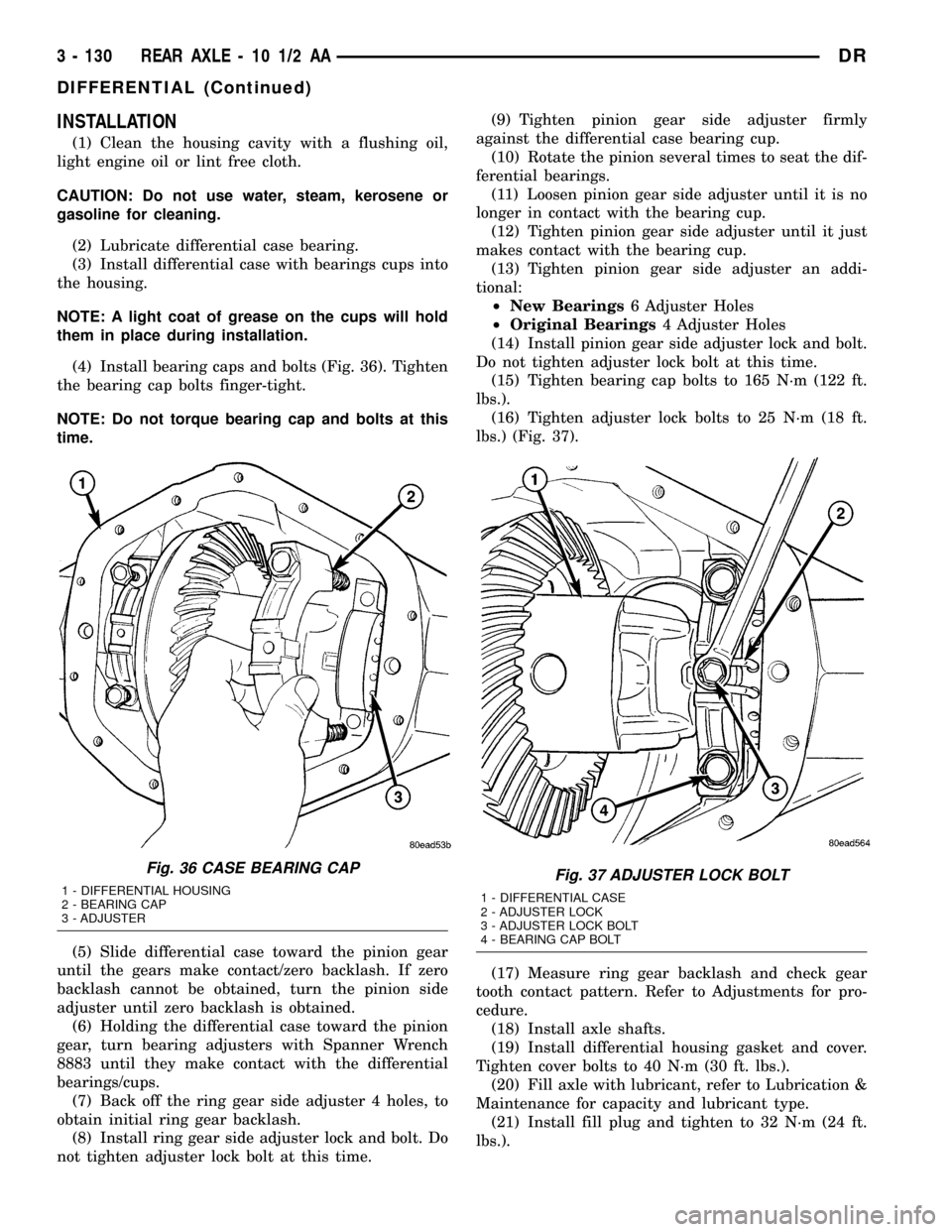

(4) Install bearing caps and bolts (Fig. 36). Tighten

the bearing cap bolts finger-tight.

NOTE: Do not torque bearing cap and bolts at this

time.

(5) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(6) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

(7) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings6 Adjuster Holes

²Original Bearings4 Adjuster Holes

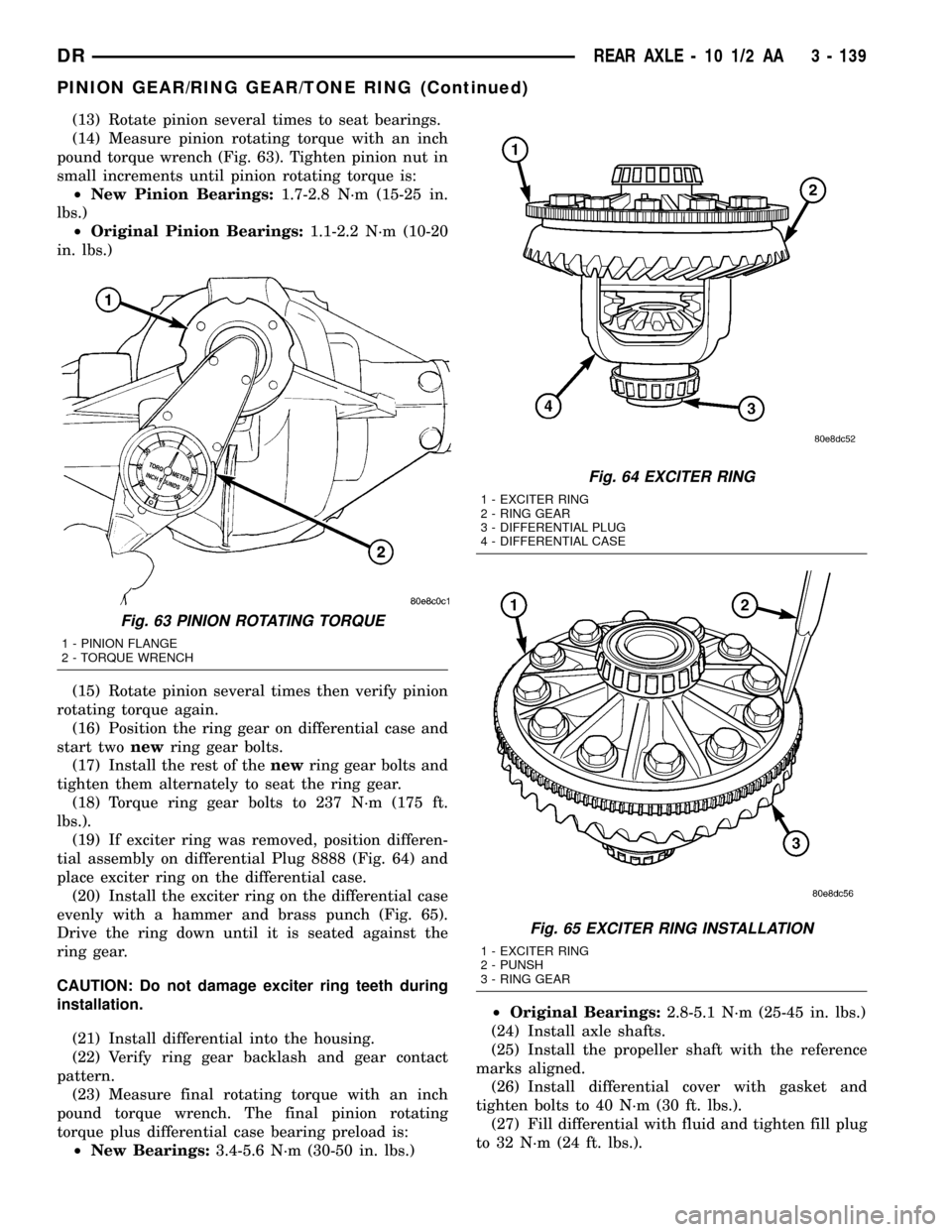

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 165 N´m (122 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 37).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shafts.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

(20) Fill axle with lubricant, refer to Lubrication &

Maintenance for capacity and lubricant type.

(21) Install fill plug and tighten to 32 N´m (24 ft.

lbs.).

Fig. 36 CASE BEARING CAP

1 - DIFFERENTIAL HOUSING

2 - BEARING CAP

3 - ADJUSTERFig. 37 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 130 REAR AXLE - 10 1/2 AADR

DIFFERENTIAL (Continued)

Page 220 of 2627

(13) Rotate pinion several times to seat bearings.

(14) Measure pinion rotating torque with an inch

pound torque wrench (Fig. 63). Tighten pinion nut in

small increments until pinion rotating torque is:

²New Pinion Bearings:1.7-2.8 N´m (15-25 in.

lbs.)

²Original Pinion Bearings:1.1-2.2 N´m (10-20

in. lbs.)

(15) Rotate pinion several times then verify pinion

rotating torque again.

(16) Position the ring gear on differential case and

start twonewring gear bolts.

(17) Install the rest of thenewring gear bolts and

tighten them alternately to seat the ring gear.

(18) Torque ring gear bolts to 237 N´m (175 ft.

lbs.).

(19) If exciter ring was removed, position differen-

tial assembly on differential Plug 8888 (Fig. 64) and

place exciter ring on the differential case.

(20) Install the exciter ring on the differential case

evenly with a hammer and brass punch (Fig. 65).

Drive the ring down until it is seated against the

ring gear.

CAUTION: Do not damage exciter ring teeth during

installation.

(21) Install differential into the housing.

(22) Verify ring gear backlash and gear contact

pattern.

(23) Measure final rotating torque with an inch

pound torque wrench. The final pinion rotating

torque plus differential case bearing preload is:

²New Bearings:3.4-5.6 N´m (30-50 in. lbs.)²Original Bearings:2.8-5.1 N´m (25-45 in. lbs.)

(24) Install axle shafts.

(25) Install the propeller shaft with the reference

marks aligned.

(26) Install differential cover with gasket and

tighten bolts to 40 N´m (30 ft. lbs.).

(27) Fill differential with fluid and tighten fill plug

to 32 N´m (24 ft. lbs.).

Fig. 63 PINION ROTATING TORQUE

1 - PINION FLANGE

2 - TORQUE WRENCH

Fig. 64 EXCITER RING

1 - EXCITER RING

2 - RING GEAR

3 - DIFFERENTIAL PLUG

4 - DIFFERENTIAL CASE

Fig. 65 EXCITER RING INSTALLATION

1 - EXCITER RING

2 - PUNSH

3 - RING GEAR

DRREAR AXLE - 10 1/2 AA 3 - 139

PINION GEAR/RING GEAR/TONE RING (Continued)