DODGE RAM 1500 1998 2.G Workshop Manual

Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2031 of 2627

specification, the reaction plate, all the friction discs,

and steels must be replaced.

(16) Remove the 4C retainer/bulkhead and all of

the 2C clutch components from the transmission

case.

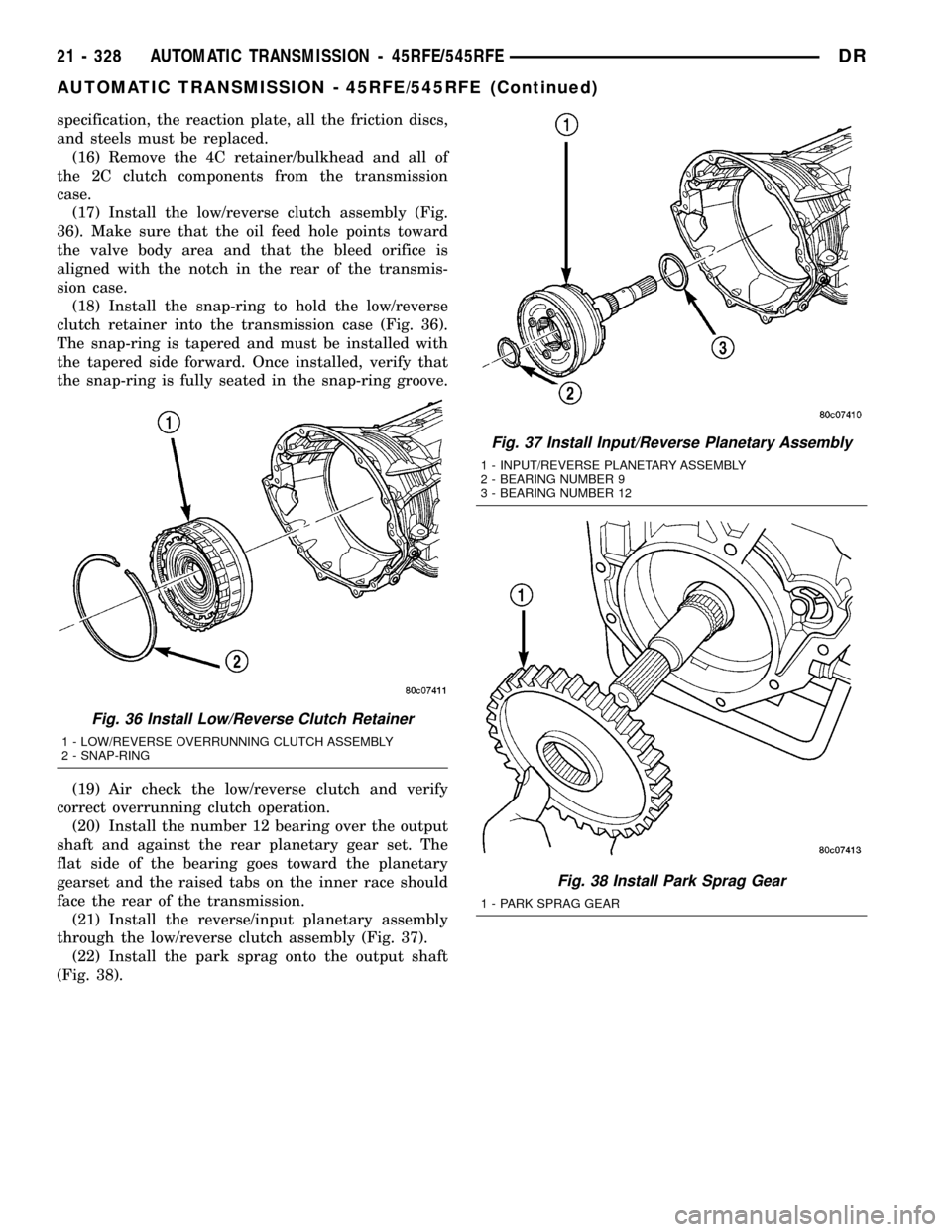

(17) Install the low/reverse clutch assembly (Fig.

36). Make sure that the oil feed hole points toward

the valve body area and that the bleed orifice is

aligned with the notch in the rear of the transmis-

sion case.

(18) Install the snap-ring to hold the low/reverse

clutch retainer into the transmission case (Fig. 36).

The snap-ring is tapered and must be installed with

the tapered side forward. Once installed, verify that

the snap-ring is fully seated in the snap-ring groove.

(19) Air check the low/reverse clutch and verify

correct overrunning clutch operation.

(20) Install the number 12 bearing over the output

shaft and against the rear planetary gear set. The

flat side of the bearing goes toward the planetary

gearset and the raised tabs on the inner race should

face the rear of the transmission.

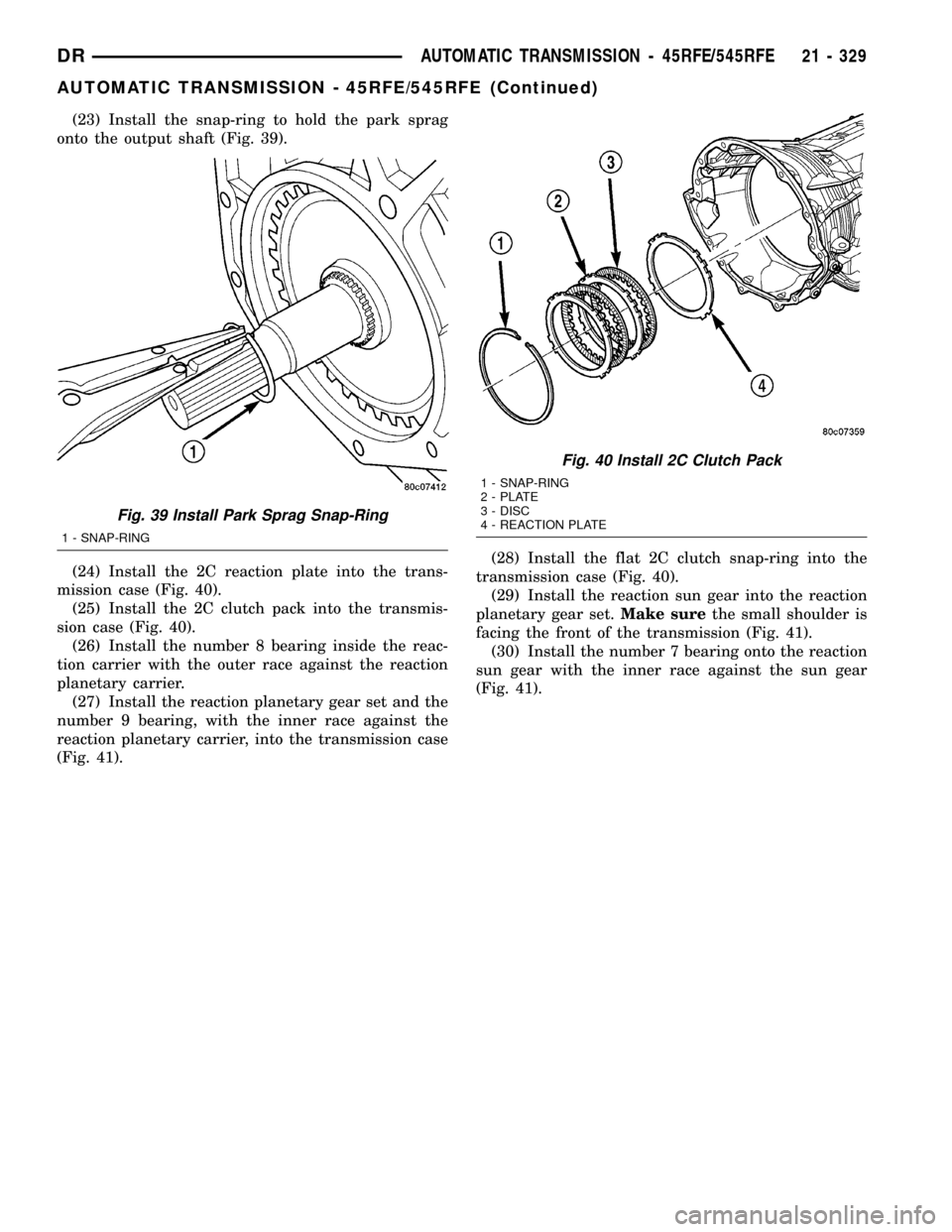

(21) Install the reverse/input planetary assembly

through the low/reverse clutch assembly (Fig. 37).

(22) Install the park sprag onto the output shaft

(Fig. 38).

Fig. 38 Install Park Sprag Gear

1 - PARK SPRAG GEAR

Fig. 36 Install Low/Reverse Clutch Retainer

1 - LOW/REVERSE OVERRUNNING CLUTCH ASSEMBLY

2 - SNAP-RING

Fig. 37 Install Input/Reverse Planetary Assembly

1 - INPUT/REVERSE PLANETARY ASSEMBLY

2 - BEARING NUMBER 9

3 - BEARING NUMBER 12

21 - 328 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2032 of 2627

(23) Install the snap-ring to hold the park sprag

onto the output shaft (Fig. 39).

(24) Install the 2C reaction plate into the trans-

mission case (Fig. 40).

(25) Install the 2C clutch pack into the transmis-

sion case (Fig. 40).

(26) Install the number 8 bearing inside the reac-

tion carrier with the outer race against the reaction

planetary carrier.

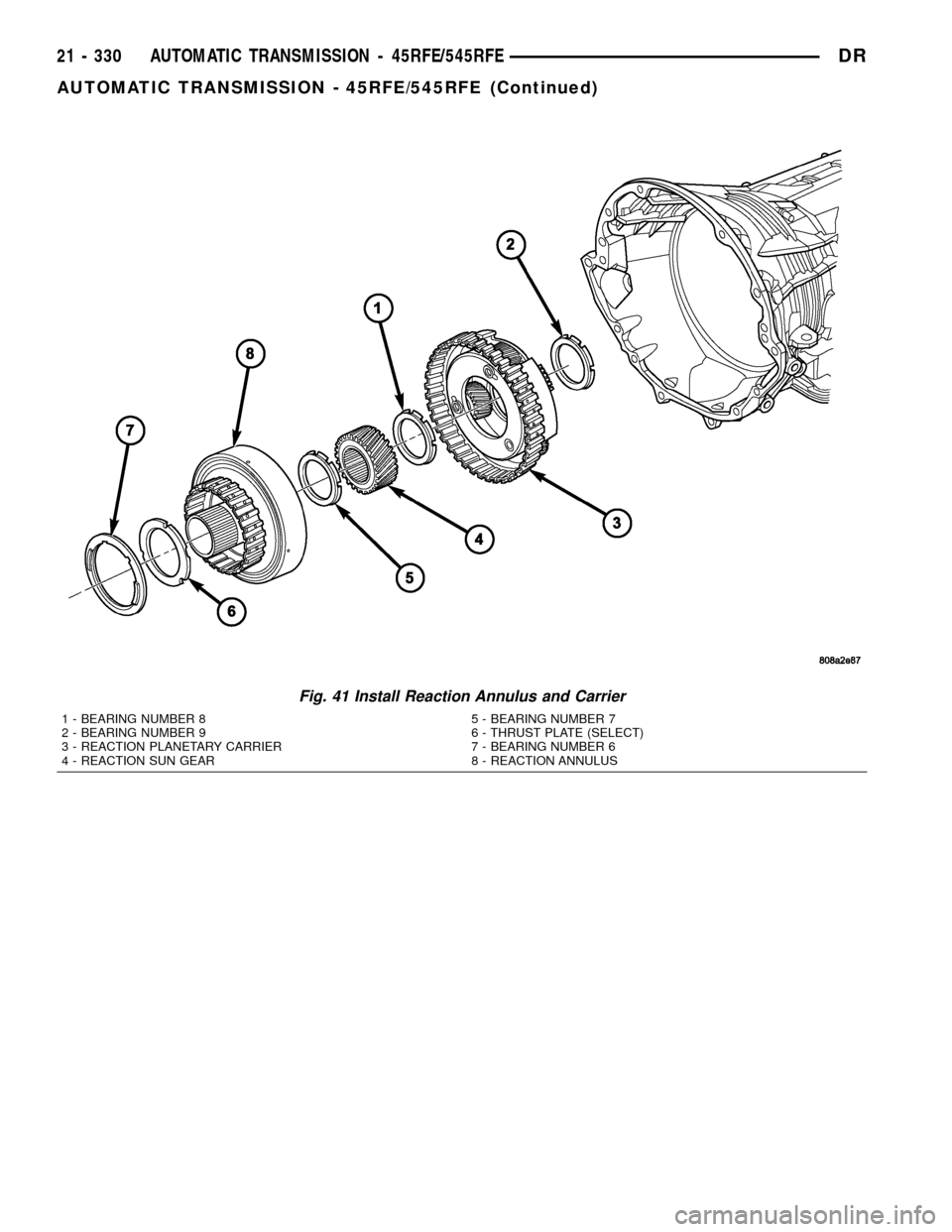

(27) Install the reaction planetary gear set and the

number 9 bearing, with the inner race against the

reaction planetary carrier, into the transmission case

(Fig. 41).(28) Install the flat 2C clutch snap-ring into the

transmission case (Fig. 40).

(29) Install the reaction sun gear into the reaction

planetary gear set.Make surethe small shoulder is

facing the front of the transmission (Fig. 41).

(30) Install the number 7 bearing onto the reaction

sun gear with the inner race against the sun gear

(Fig. 41).

Fig. 39 Install Park Sprag Snap-Ring

1 - SNAP-RING

Fig. 40 Install 2C Clutch Pack

1 - SNAP-RING

2 - PLATE

3 - DISC

4 - REACTION PLATE

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 329

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2033 of 2627

Fig. 41 Install Reaction Annulus and Carrier

1 - BEARING NUMBER 8 5 - BEARING NUMBER 7

2 - BEARING NUMBER 9 6 - THRUST PLATE (SELECT)

3 - REACTION PLANETARY CARRIER 7 - BEARING NUMBER 6

4 - REACTION SUN GEAR 8 - REACTION ANNULUS

21 - 330 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2034 of 2627

(31) Install the output shaft selective thrust plate

onto the reaction annulus with the oil grooves facing

the annulus gear and the tabs and notches aligned as

shown in (Fig. 42).

(32) Install the number 6 bearing against the out-

put shaft selective thrust plate with the flat side

against the thrust plate (Fig. 41) and the raised tabs

on the inner race facing the front of the transmis-

sion.

(33) Install the reaction annulus into the reaction

planetary gear set (Fig. 41).

(34) Install the 4C retainer/bulkhead into the

transmission case. Make sure that the oil feed holes

are pointing toward the valve body area. Rotate the

reaction annulus during the installation of the 4C

retainer/bulkhead to ease installation.

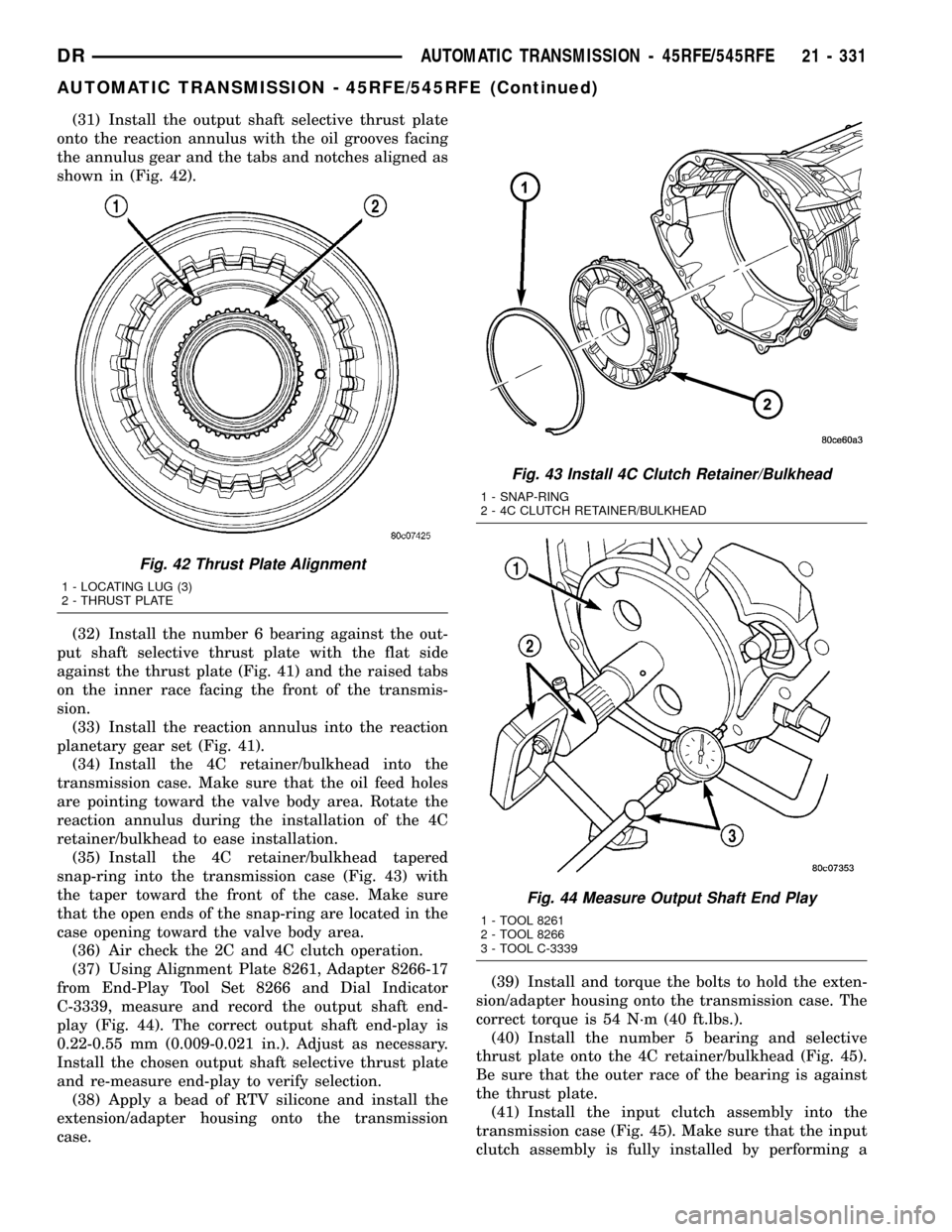

(35) Install the 4C retainer/bulkhead tapered

snap-ring into the transmission case (Fig. 43) with

the taper toward the front of the case. Make sure

that the open ends of the snap-ring are located in the

case opening toward the valve body area.

(36) Air check the 2C and 4C clutch operation.

(37) Using Alignment Plate 8261, Adapter 8266-17

from End-Play Tool Set 8266 and Dial Indicator

C-3339, measure and record the output shaft end-

play (Fig. 44). The correct output shaft end-play is

0.22-0.55 mm (0.009-0.021 in.). Adjust as necessary.

Install the chosen output shaft selective thrust plate

and re-measure end-play to verify selection.

(38) Apply a bead of RTV silicone and install the

extension/adapter housing onto the transmission

case.(39) Install and torque the bolts to hold the exten-

sion/adapter housing onto the transmission case. The

correct torque is 54 N´m (40 ft.lbs.).

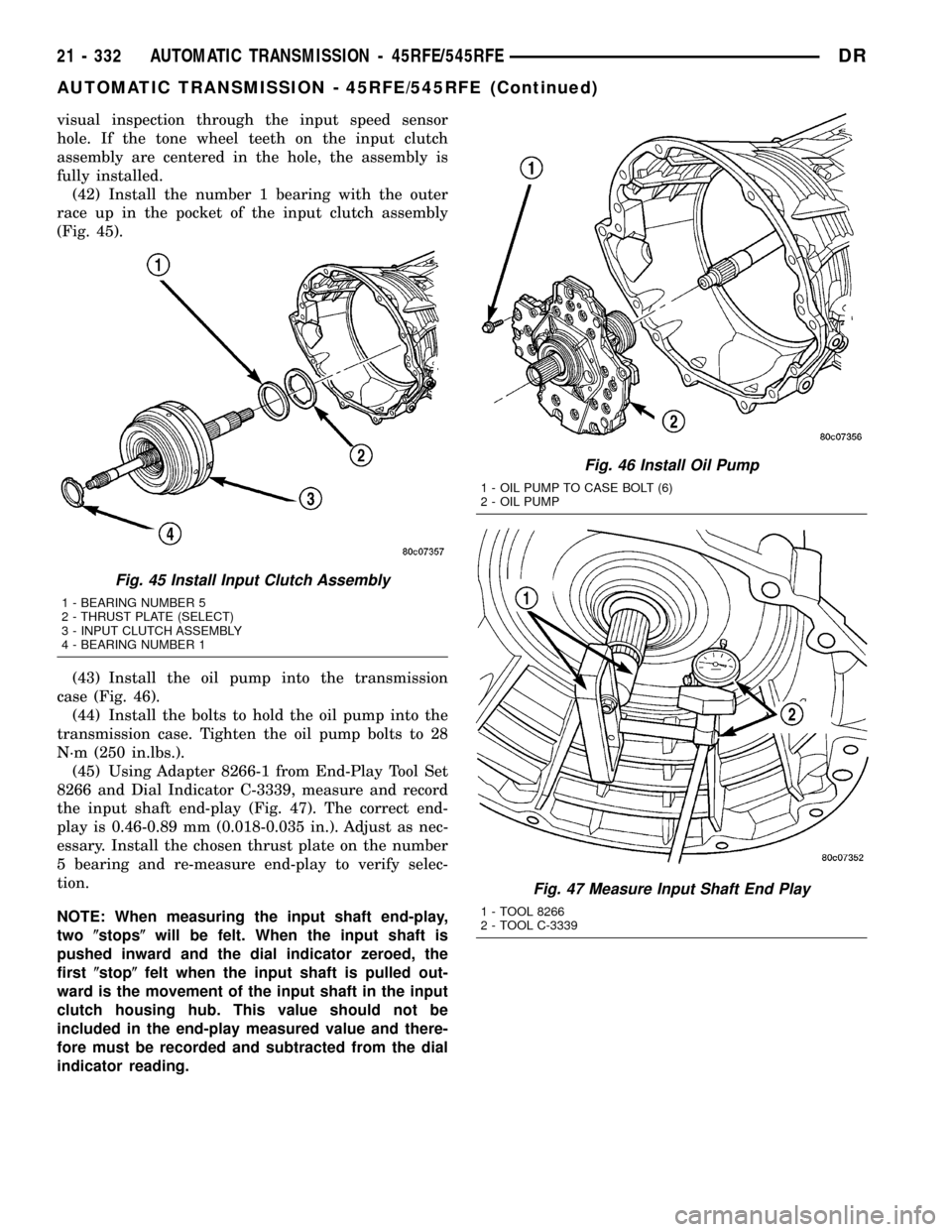

(40) Install the number 5 bearing and selective

thrust plate onto the 4C retainer/bulkhead (Fig. 45).

Be sure that the outer race of the bearing is against

the thrust plate.

(41) Install the input clutch assembly into the

transmission case (Fig. 45). Make sure that the input

clutch assembly is fully installed by performing a

Fig. 42 Thrust Plate Alignment

1 - LOCATING LUG (3)

2 - THRUST PLATE

Fig. 43 Install 4C Clutch Retainer/Bulkhead

1 - SNAP-RING

2 - 4C CLUTCH RETAINER/BULKHEAD

Fig. 44 Measure Output Shaft End Play

1 - TOOL 8261

2 - TOOL 8266

3 - TOOL C-3339

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 331

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2035 of 2627

visual inspection through the input speed sensor

hole. If the tone wheel teeth on the input clutch

assembly are centered in the hole, the assembly is

fully installed.

(42) Install the number 1 bearing with the outer

race up in the pocket of the input clutch assembly

(Fig. 45).

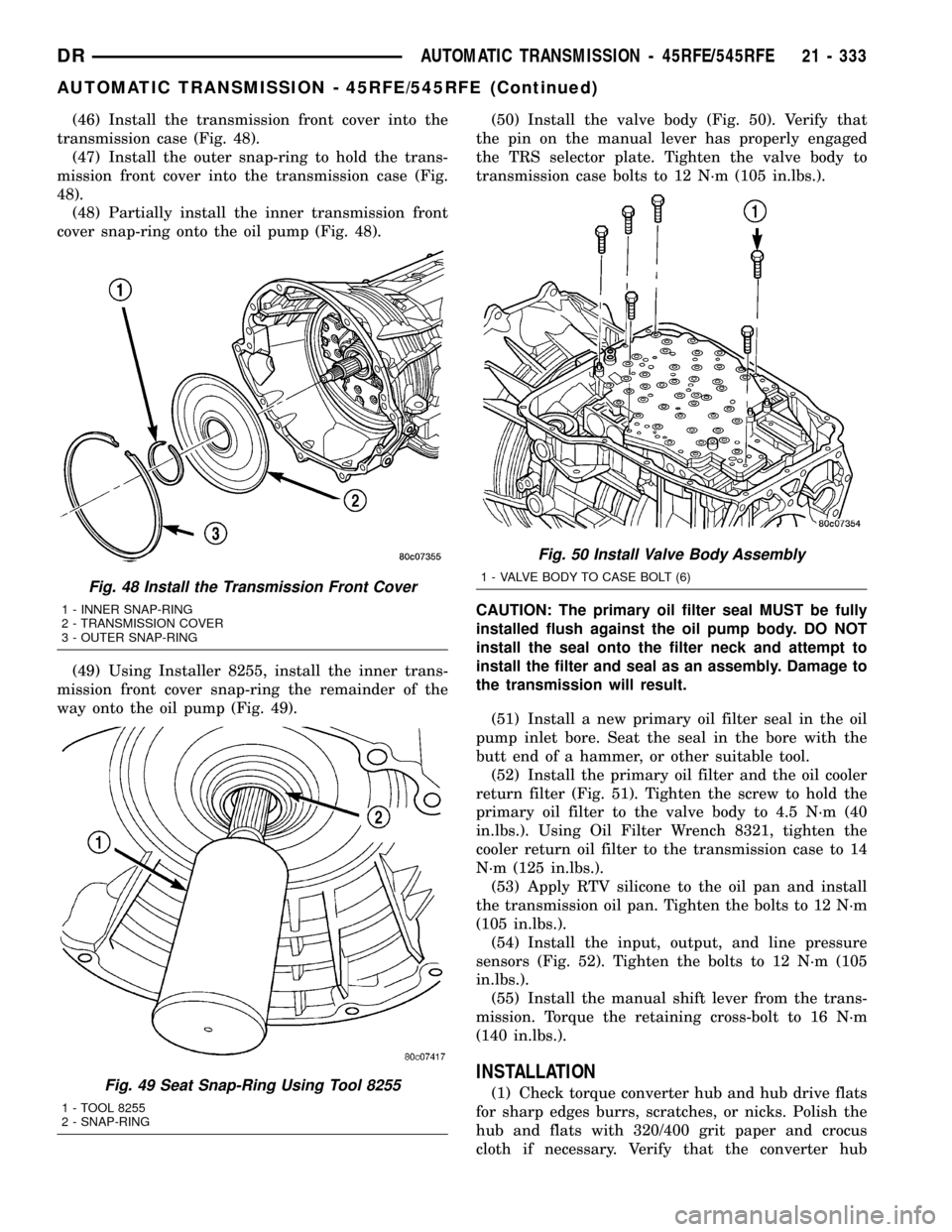

(43) Install the oil pump into the transmission

case (Fig. 46).

(44) Install the bolts to hold the oil pump into the

transmission case. Tighten the oil pump bolts to 28

N´m (250 in.lbs.).

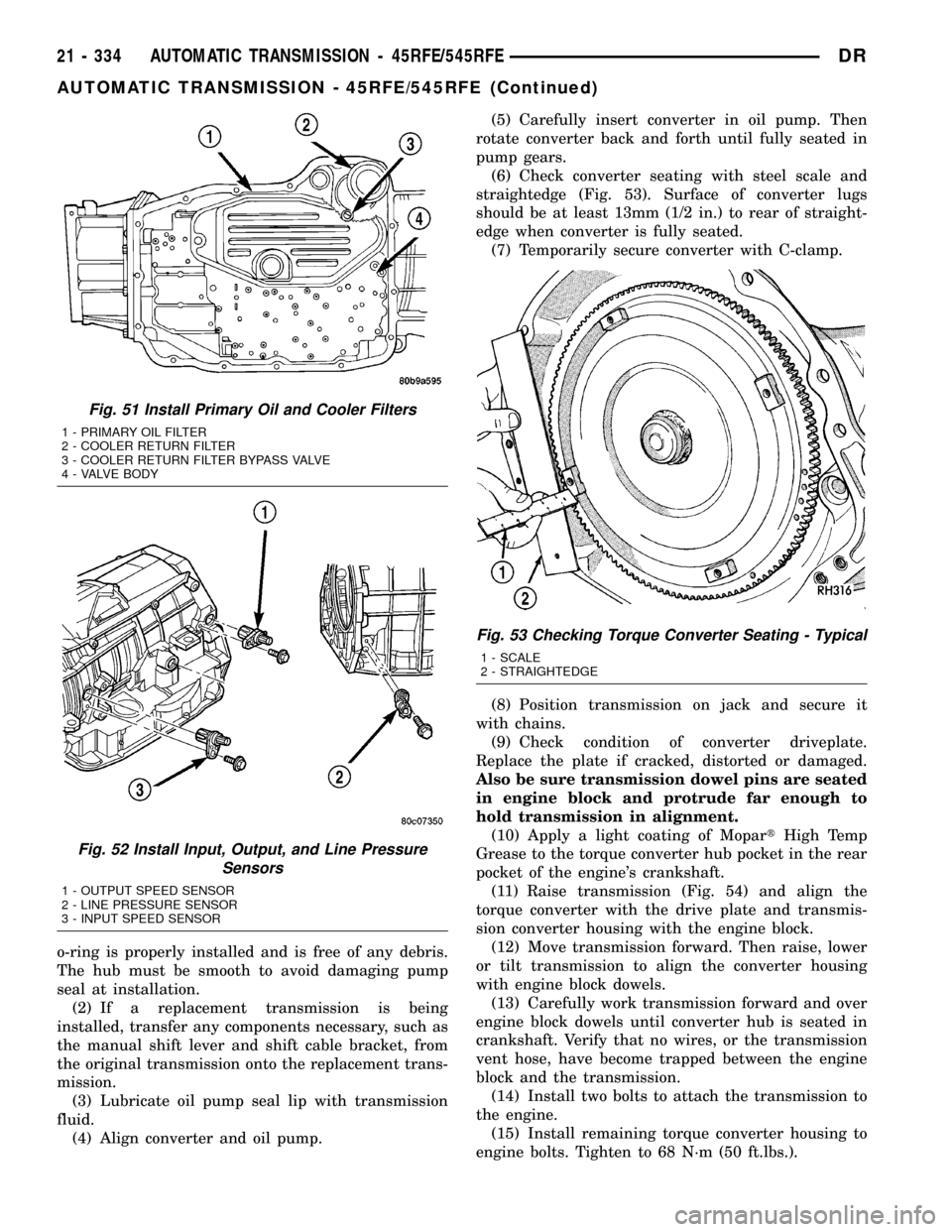

(45) Using Adapter 8266-1 from End-Play Tool Set

8266 and Dial Indicator C-3339, measure and record

the input shaft end-play (Fig. 47). The correct end-

play is 0.46-0.89 mm (0.018-0.035 in.). Adjust as nec-

essary. Install the chosen thrust plate on the number

5 bearing and re-measure end-play to verify selec-

tion.

NOTE: When measuring the input shaft end-play,

two(stops(will be felt. When the input shaft is

pushed inward and the dial indicator zeroed, the

first(stop(felt when the input shaft is pulled out-

ward is the movement of the input shaft in the input

clutch housing hub. This value should not be

included in the end-play measured value and there-

fore must be recorded and subtracted from the dial

indicator reading.

Fig. 45 Install Input Clutch Assembly

1 - BEARING NUMBER 5

2 - THRUST PLATE (SELECT)

3 - INPUT CLUTCH ASSEMBLY

4 - BEARING NUMBER 1

Fig. 46 Install Oil Pump

1 - OIL PUMP TO CASE BOLT (6)

2 - OIL PUMP

Fig. 47 Measure Input Shaft End Play

1 - TOOL 8266

2 - TOOL C-3339

21 - 332 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2036 of 2627

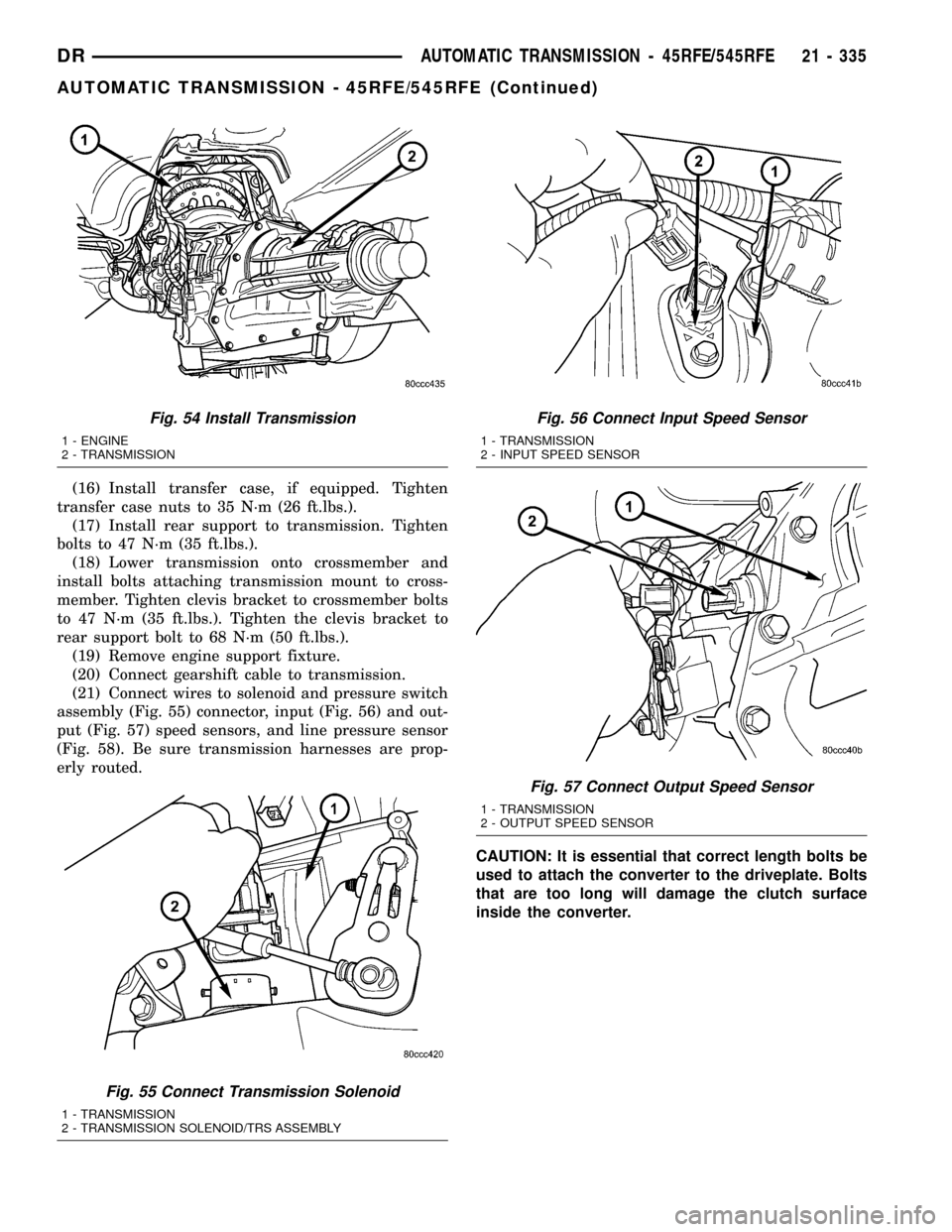

(46) Install the transmission front cover into the

transmission case (Fig. 48).

(47) Install the outer snap-ring to hold the trans-

mission front cover into the transmission case (Fig.

48).

(48) Partially install the inner transmission front

cover snap-ring onto the oil pump (Fig. 48).

(49) Using Installer 8255, install the inner trans-

mission front cover snap-ring the remainder of the

way onto the oil pump (Fig. 49).(50) Install the valve body (Fig. 50). Verify that

the pin on the manual lever has properly engaged

the TRS selector plate. Tighten the valve body to

transmission case bolts to 12 N´m (105 in.lbs.).

CAUTION: The primary oil filter seal MUST be fully

installed flush against the oil pump body. DO NOT

install the seal onto the filter neck and attempt to

install the filter and seal as an assembly. Damage to

the transmission will result.

(51) Install a new primary oil filter seal in the oil

pump inlet bore. Seat the seal in the bore with the

butt end of a hammer, or other suitable tool.

(52) Install the primary oil filter and the oil cooler

return filter (Fig. 51). Tighten the screw to hold the

primary oil filter to the valve body to 4.5 N´m (40

in.lbs.). Using Oil Filter Wrench 8321, tighten the

cooler return oil filter to the transmission case to 14

N´m (125 in.lbs.).

(53) Apply RTV silicone to the oil pan and install

the transmission oil pan. Tighten the bolts to 12 N´m

(105 in.lbs.).

(54) Install the input, output, and line pressure

sensors (Fig. 52). Tighten the bolts to 12 N´m (105

in.lbs.).

(55) Install the manual shift lever from the trans-

mission. Torque the retaining cross-bolt to 16 N´m

(140 in.lbs.).

INSTALLATION

(1) Check torque converter hub and hub drive flats

for sharp edges burrs, scratches, or nicks. Polish the

hub and flats with 320/400 grit paper and crocus

cloth if necessary. Verify that the converter hub

Fig. 48 Install the Transmission Front Cover

1 - INNER SNAP-RING

2 - TRANSMISSION COVER

3 - OUTER SNAP-RING

Fig. 49 Seat Snap-Ring Using Tool 8255

1 - TOOL 8255

2 - SNAP-RING

Fig. 50 Install Valve Body Assembly

1 - VALVE BODY TO CASE BOLT (6)

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 333

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2037 of 2627

o-ring is properly installed and is free of any debris.

The hub must be smooth to avoid damaging pump

seal at installation.

(2) If a replacement transmission is being

installed, transfer any components necessary, such as

the manual shift lever and shift cable bracket, from

the original transmission onto the replacement trans-

mission.

(3) Lubricate oil pump seal lip with transmission

fluid.

(4) Align converter and oil pump.(5) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

(6) Check converter seating with steel scale and

straightedge (Fig. 53). Surface of converter lugs

should be at least 13mm (1/2 in.) to rear of straight-

edge when converter is fully seated.

(7) Temporarily secure converter with C-clamp.

(8) Position transmission on jack and secure it

with chains.

(9) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated

in engine block and protrude far enough to

hold transmission in alignment.

(10) Apply a light coating of MopartHigh Temp

Grease to the torque converter hub pocket in the rear

pocket of the engine's crankshaft.

(11) Raise transmission (Fig. 54) and align the

torque converter with the drive plate and transmis-

sion converter housing with the engine block.

(12) Move transmission forward. Then raise, lower

or tilt transmission to align the converter housing

with engine block dowels.

(13) Carefully work transmission forward and over

engine block dowels until converter hub is seated in

crankshaft. Verify that no wires, or the transmission

vent hose, have become trapped between the engine

block and the transmission.

(14) Install two bolts to attach the transmission to

the engine.

(15) Install remaining torque converter housing to

engine bolts. Tighten to 68 N´m (50 ft.lbs.).

Fig. 51 Install Primary Oil and Cooler Filters

1 - PRIMARY OIL FILTER

2 - COOLER RETURN FILTER

3 - COOLER RETURN FILTER BYPASS VALVE

4 - VALVE BODY

Fig. 52 Install Input, Output, and Line Pressure

Sensors

1 - OUTPUT SPEED SENSOR

2 - LINE PRESSURE SENSOR

3 - INPUT SPEED SENSOR

Fig. 53 Checking Torque Converter Seating - Typical

1 - SCALE

2 - STRAIGHTEDGE

21 - 334 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2038 of 2627

(16) Install transfer case, if equipped. Tighten

transfer case nuts to 35 N´m (26 ft.lbs.).

(17) Install rear support to transmission. Tighten

bolts to 47 N´m (35 ft.lbs.).

(18) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member. Tighten clevis bracket to crossmember bolts

to 47 N´m (35 ft.lbs.). Tighten the clevis bracket to

rear support bolt to 68 N´m (50 ft.lbs.).

(19) Remove engine support fixture.

(20) Connect gearshift cable to transmission.

(21) Connect wires to solenoid and pressure switch

assembly (Fig. 55) connector, input (Fig. 56) and out-

put (Fig. 57) speed sensors, and line pressure sensor

(Fig. 58). Be sure transmission harnesses are prop-

erly routed.

CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.

Fig. 54 Install Transmission

1 - ENGINE

2 - TRANSMISSION

Fig. 55 Connect Transmission Solenoid

1 - TRANSMISSION

2 - TRANSMISSION SOLENOID/TRS ASSEMBLY

Fig. 56 Connect Input Speed Sensor

1 - TRANSMISSION

2 - INPUT SPEED SENSOR

Fig. 57 Connect Output Speed Sensor

1 - TRANSMISSION

2 - OUTPUT SPEED SENSOR

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 335

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2039 of 2627

(22) Install torque converter-to-driveplate bolts.

Tighten bolts to 31 N´m (270 in. lbs.).

(23) Install starter motor and cooler line bracket.

(24) Connect cooler lines to transmission.

(25) Install transmission fill tube.

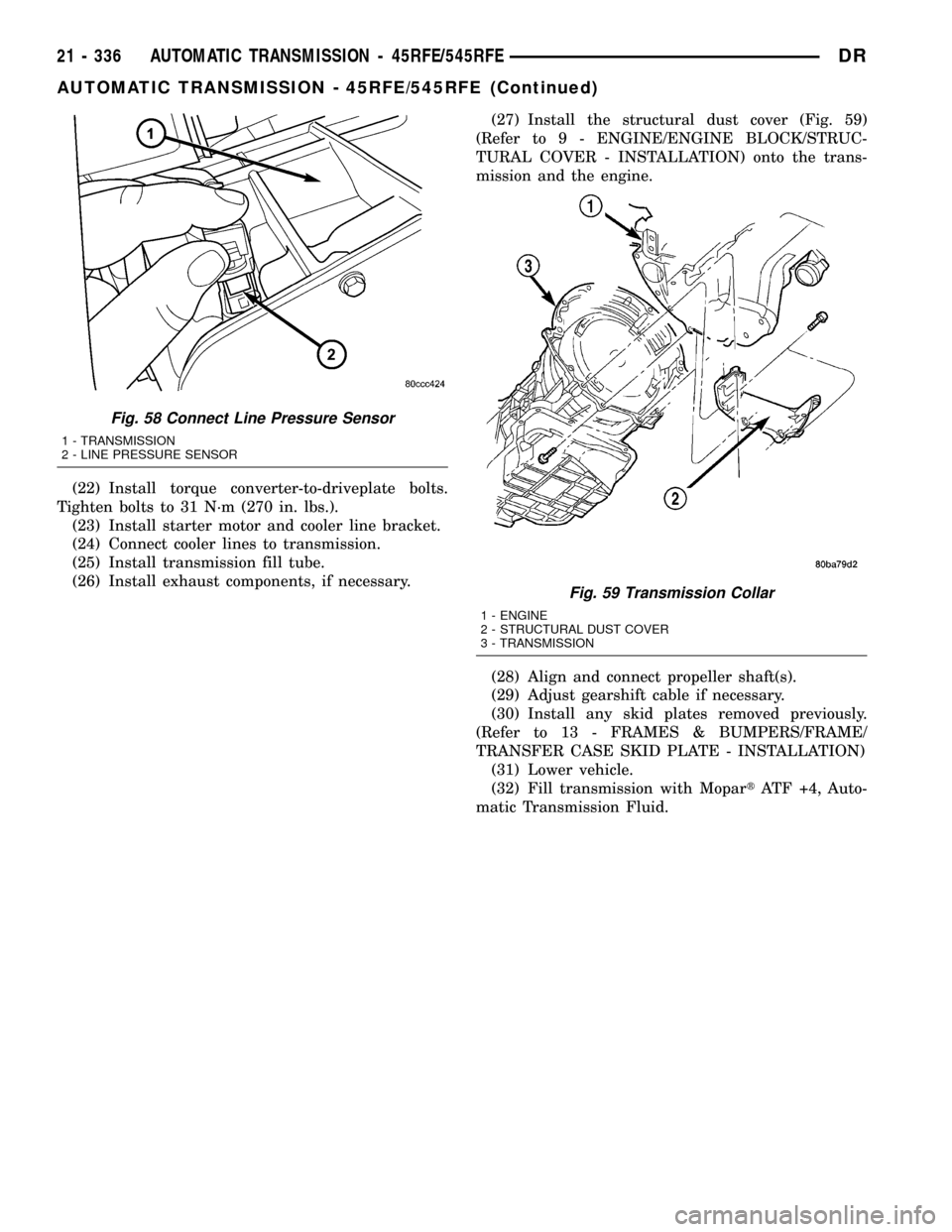

(26) Install exhaust components, if necessary.(27) Install the structural dust cover (Fig. 59)

(Refer to 9 - ENGINE/ENGINE BLOCK/STRUC-

TURAL COVER - INSTALLATION) onto the trans-

mission and the engine.

(28) Align and connect propeller shaft(s).

(29) Adjust gearshift cable if necessary.

(30) Install any skid plates removed previously.

(Refer to 13 - FRAMES & BUMPERS/FRAME/

TRANSFER CASE SKID PLATE - INSTALLATION)

(31) Lower vehicle.

(32) Fill transmission with MopartATF +4, Auto-

matic Transmission Fluid.

Fig. 58 Connect Line Pressure Sensor

1 - TRANSMISSION

2 - LINE PRESSURE SENSOR

Fig. 59 Transmission Collar

1 - ENGINE

2 - STRUCTURAL DUST COVER

3 - TRANSMISSION

21 - 336 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2040 of 2627

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS

HYDRAULIC FLOW IN PARK/NEUTRAL

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 337

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)