DODGE RAM 1500 1998 2.G Workshop Manual

Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2221 of 2627

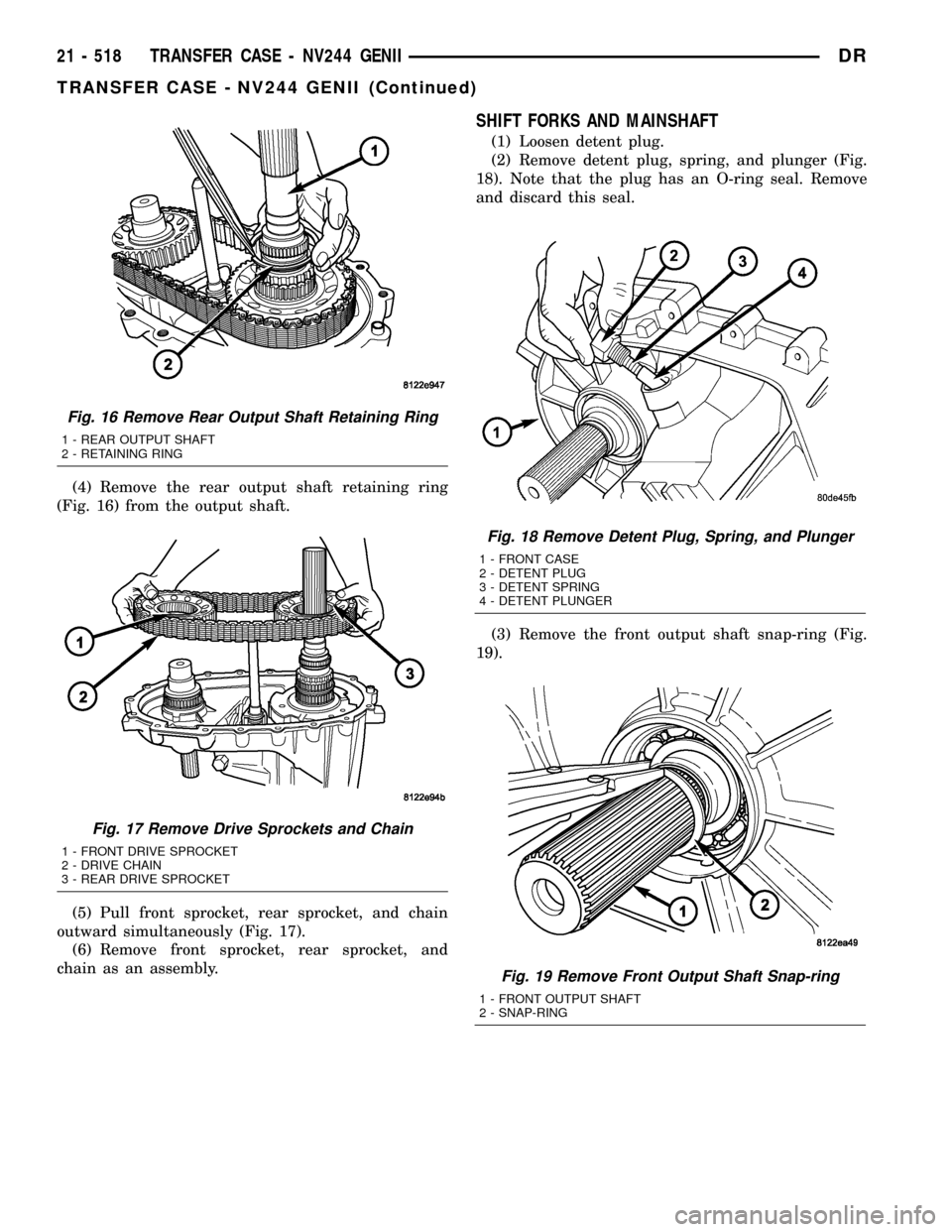

(4) Remove the rear output shaft retaining ring

(Fig. 16) from the output shaft.

(5) Pull front sprocket, rear sprocket, and chain

outward simultaneously (Fig. 17).

(6) Remove front sprocket, rear sprocket, and

chain as an assembly.

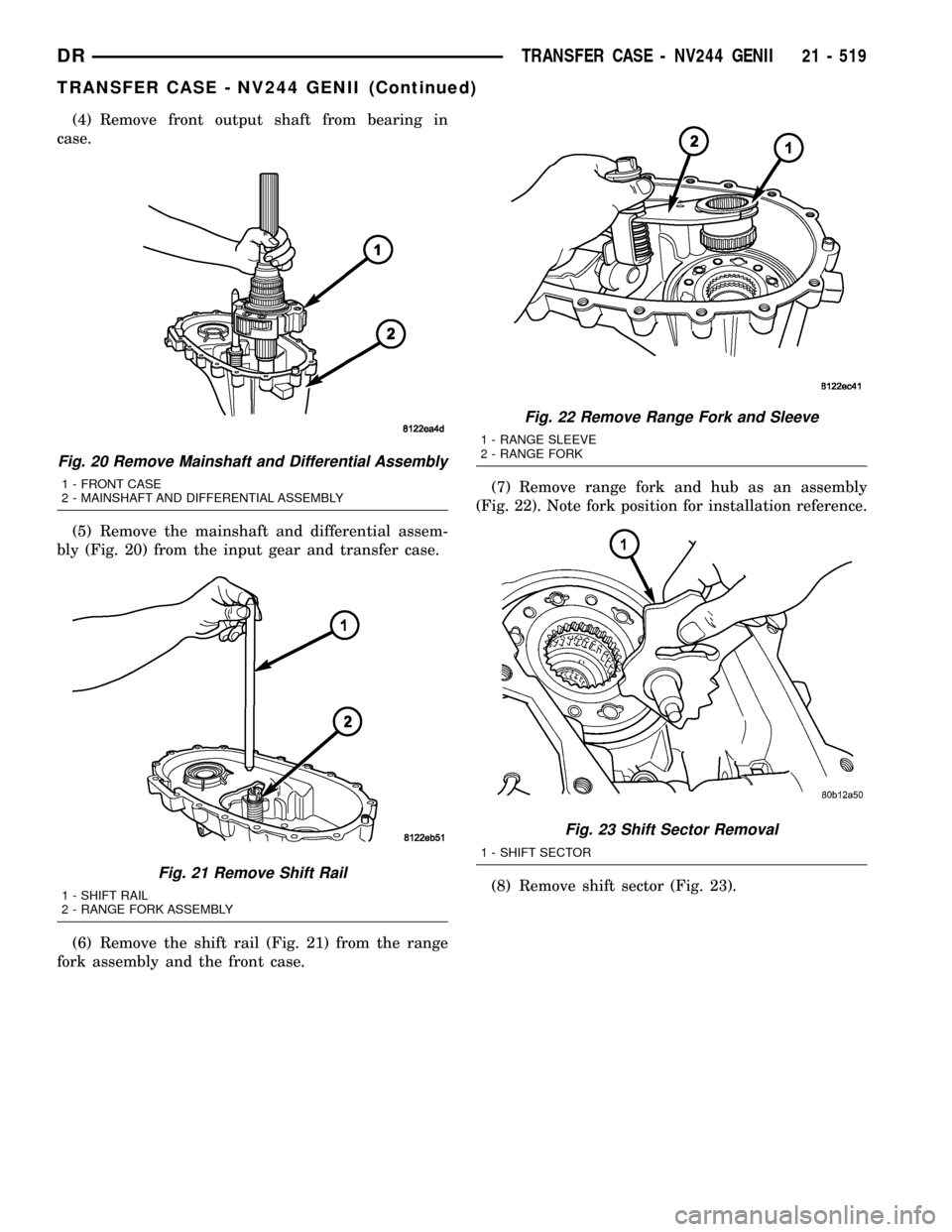

SHIFT FORKS AND MAINSHAFT

(1) Loosen detent plug.

(2) Remove detent plug, spring, and plunger (Fig.

18). Note that the plug has an O-ring seal. Remove

and discard this seal.

(3) Remove the front output shaft snap-ring (Fig.

19).

Fig. 18 Remove Detent Plug, Spring, and Plunger

1 - FRONT CASE

2 - DETENT PLUG

3 - DETENT SPRING

4 - DETENT PLUNGER

Fig. 19 Remove Front Output Shaft Snap-ring

1 - FRONT OUTPUT SHAFT

2 - SNAP-RING

Fig. 16 Remove Rear Output Shaft Retaining Ring

1 - REAR OUTPUT SHAFT

2 - RETAINING RING

Fig. 17 Remove Drive Sprockets and Chain

1 - FRONT DRIVE SPROCKET

2 - DRIVE CHAIN

3 - REAR DRIVE SPROCKET

21 - 518 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2222 of 2627

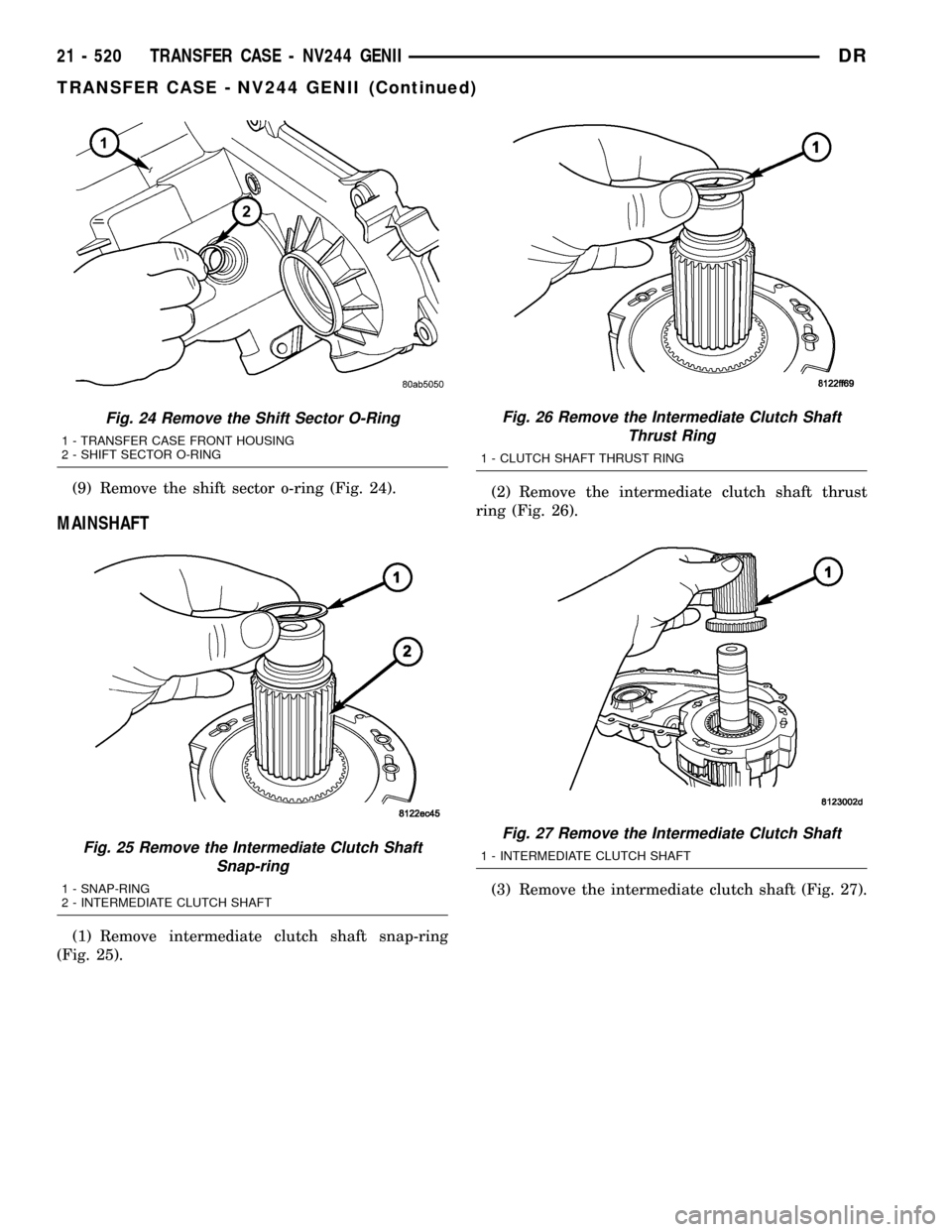

(4) Remove front output shaft from bearing in

case.

(5) Remove the mainshaft and differential assem-

bly (Fig. 20) from the input gear and transfer case.

(6) Remove the shift rail (Fig. 21) from the range

fork assembly and the front case.(7) Remove range fork and hub as an assembly

(Fig. 22). Note fork position for installation reference.

(8) Remove shift sector (Fig. 23).

Fig. 20 Remove Mainshaft and Differential Assembly

1 - FRONT CASE

2 - MAINSHAFT AND DIFFERENTIAL ASSEMBLY

Fig. 21 Remove Shift Rail

1 - SHIFT RAIL

2 - RANGE FORK ASSEMBLY

Fig. 22 Remove Range Fork and Sleeve

1 - RANGE SLEEVE

2 - RANGE FORK

Fig. 23 Shift Sector Removal

1 - SHIFT SECTOR

DRTRANSFER CASE - NV244 GENII 21 - 519

TRANSFER CASE - NV244 GENII (Continued)

Page 2223 of 2627

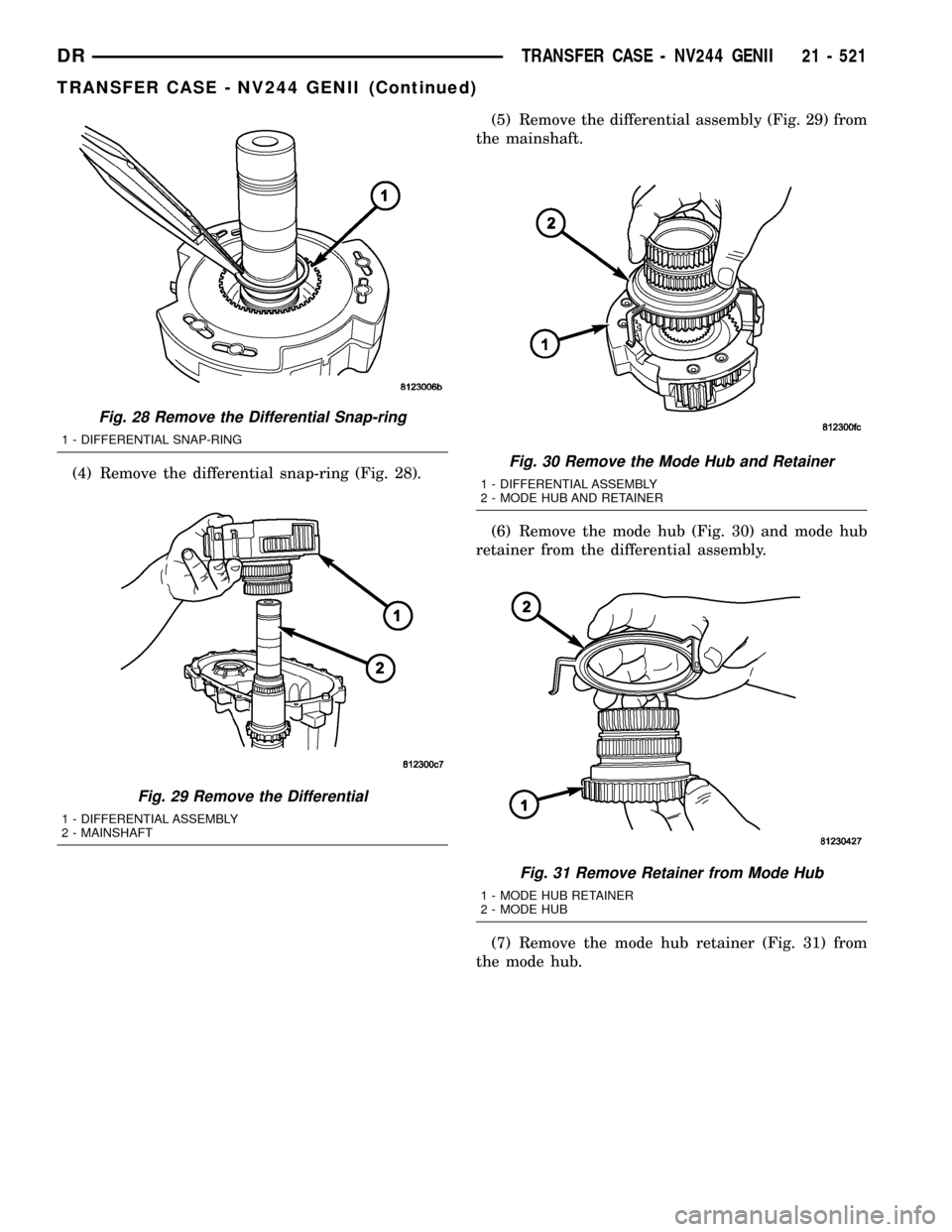

(9) Remove the shift sector o-ring (Fig. 24).

MAINSHAFT

(1) Remove intermediate clutch shaft snap-ring

(Fig. 25).(2) Remove the intermediate clutch shaft thrust

ring (Fig. 26).

(3) Remove the intermediate clutch shaft (Fig. 27).

Fig. 24 Remove the Shift Sector O-Ring

1 - TRANSFER CASE FRONT HOUSING

2 - SHIFT SECTOR O-RING

Fig. 25 Remove the Intermediate Clutch Shaft

Snap-ring

1 - SNAP-RING

2 - INTERMEDIATE CLUTCH SHAFT

Fig. 26 Remove the Intermediate Clutch Shaft

Thrust Ring

1 - CLUTCH SHAFT THRUST RING

Fig. 27 Remove the Intermediate Clutch Shaft

1 - INTERMEDIATE CLUTCH SHAFT

21 - 520 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2224 of 2627

(4) Remove the differential snap-ring (Fig. 28).(5) Remove the differential assembly (Fig. 29) from

the mainshaft.

(6) Remove the mode hub (Fig. 30) and mode hub

retainer from the differential assembly.

(7) Remove the mode hub retainer (Fig. 31) from

the mode hub.

Fig. 28 Remove the Differential Snap-ring

1 - DIFFERENTIAL SNAP-RING

Fig. 29 Remove the Differential

1 - DIFFERENTIAL ASSEMBLY

2 - MAINSHAFT

Fig. 30 Remove the Mode Hub and Retainer

1 - DIFFERENTIAL ASSEMBLY

2 - MODE HUB AND RETAINER

Fig. 31 Remove Retainer from Mode Hub

1 - MODE HUB RETAINER

2 - MODE HUB

DRTRANSFER CASE - NV244 GENII 21 - 521

TRANSFER CASE - NV244 GENII (Continued)

Page 2225 of 2627

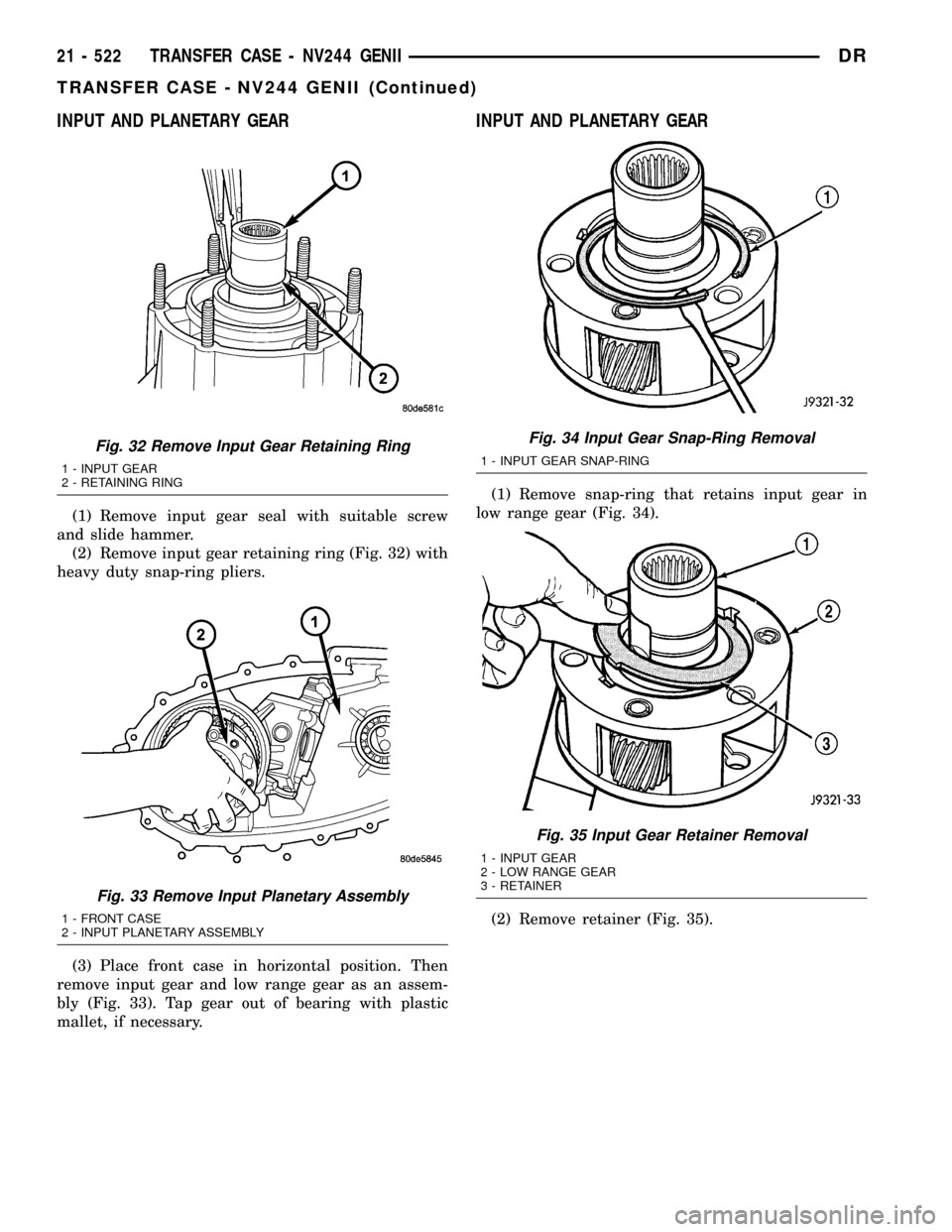

INPUT AND PLANETARY GEAR

(1) Remove input gear seal with suitable screw

and slide hammer.

(2) Remove input gear retaining ring (Fig. 32) with

heavy duty snap-ring pliers.

(3) Place front case in horizontal position. Then

remove input gear and low range gear as an assem-

bly (Fig. 33). Tap gear out of bearing with plastic

mallet, if necessary.

INPUT AND PLANETARY GEAR

(1) Remove snap-ring that retains input gear in

low range gear (Fig. 34).

(2) Remove retainer (Fig. 35).

Fig. 32 Remove Input Gear Retaining Ring

1 - INPUT GEAR

2 - RETAINING RING

Fig. 33 Remove Input Planetary Assembly

1 - FRONT CASE

2 - INPUT PLANETARY ASSEMBLY

Fig. 34 Input Gear Snap-Ring Removal

1 - INPUT GEAR SNAP-RING

Fig. 35 Input Gear Retainer Removal

1 - INPUT GEAR

2 - LOW RANGE GEAR

3 - RETAINER

21 - 522 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2226 of 2627

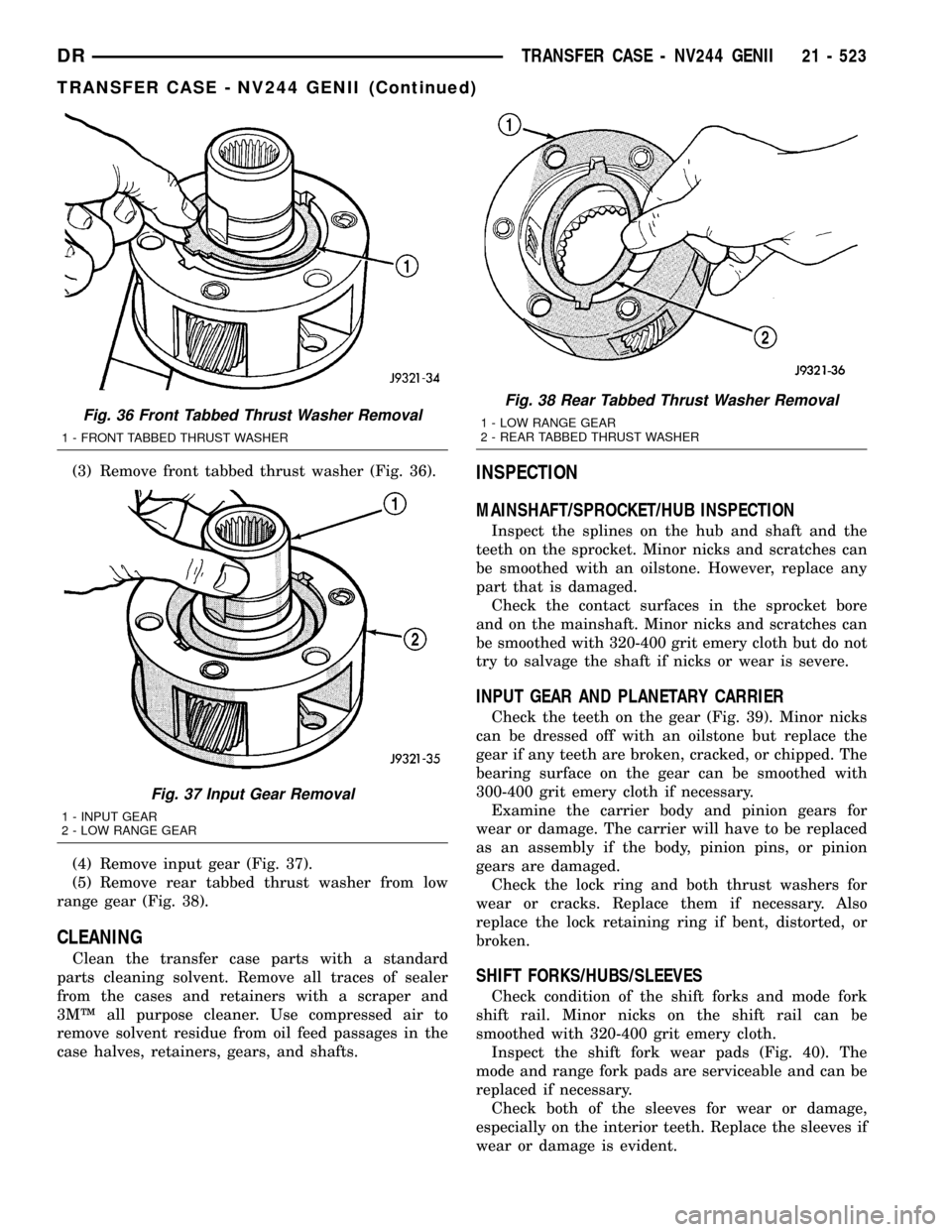

(3) Remove front tabbed thrust washer (Fig. 36).

(4) Remove input gear (Fig. 37).

(5) Remove rear tabbed thrust washer from low

range gear (Fig. 38).

CLEANING

Clean the transfer case parts with a standard

parts cleaning solvent. Remove all traces of sealer

from the cases and retainers with a scraper and

3MŸ all purpose cleaner. Use compressed air to

remove solvent residue from oil feed passages in the

case halves, retainers, gears, and shafts.

INSPECTION

MAINSHAFT/SPROCKET/HUB INSPECTION

Inspect the splines on the hub and shaft and the

teeth on the sprocket. Minor nicks and scratches can

be smoothed with an oilstone. However, replace any

part that is damaged.

Check the contact surfaces in the sprocket bore

and on the mainshaft. Minor nicks and scratches can

be smoothed with 320-400 grit emery cloth but do not

try to salvage the shaft if nicks or wear is severe.

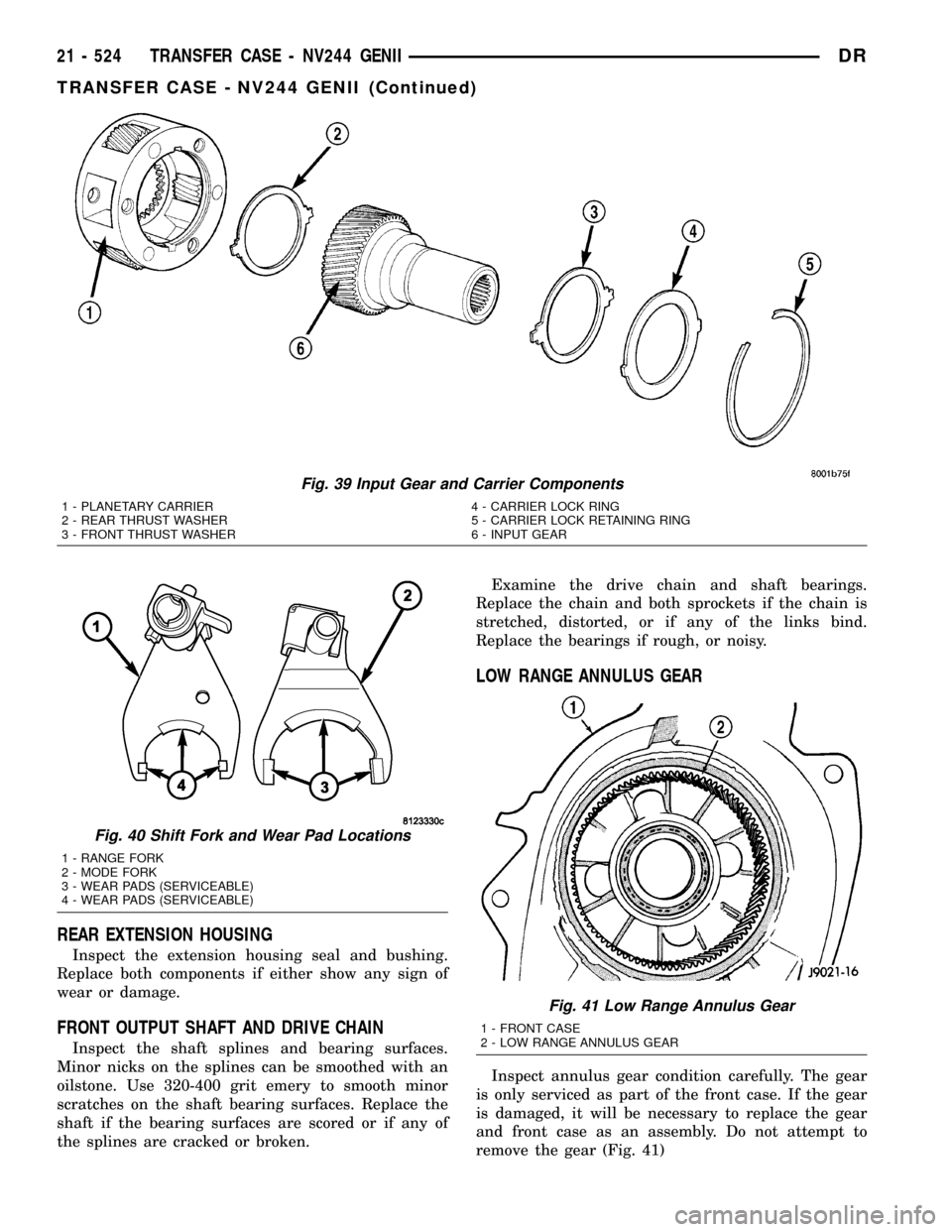

INPUT GEAR AND PLANETARY CARRIER

Check the teeth on the gear (Fig. 39). Minor nicks

can be dressed off with an oilstone but replace the

gear if any teeth are broken, cracked, or chipped. The

bearing surface on the gear can be smoothed with

300-400 grit emery cloth if necessary.

Examine the carrier body and pinion gears for

wear or damage. The carrier will have to be replaced

as an assembly if the body, pinion pins, or pinion

gears are damaged.

Check the lock ring and both thrust washers for

wear or cracks. Replace them if necessary. Also

replace the lock retaining ring if bent, distorted, or

broken.

SHIFT FORKS/HUBS/SLEEVES

Check condition of the shift forks and mode fork

shift rail. Minor nicks on the shift rail can be

smoothed with 320-400 grit emery cloth.

Inspect the shift fork wear pads (Fig. 40). The

mode and range fork pads are serviceable and can be

replaced if necessary.

Check both of the sleeves for wear or damage,

especially on the interior teeth. Replace the sleeves if

wear or damage is evident.

Fig. 36 Front Tabbed Thrust Washer Removal

1 - FRONT TABBED THRUST WASHER

Fig. 37 Input Gear Removal

1 - INPUT GEAR

2 - LOW RANGE GEAR

Fig. 38 Rear Tabbed Thrust Washer Removal

1 - LOW RANGE GEAR

2 - REAR TABBED THRUST WASHER

DRTRANSFER CASE - NV244 GENII 21 - 523

TRANSFER CASE - NV244 GENII (Continued)

Page 2227 of 2627

REAR EXTENSION HOUSING

Inspect the extension housing seal and bushing.

Replace both components if either show any sign of

wear or damage.

FRONT OUTPUT SHAFT AND DRIVE CHAIN

Inspect the shaft splines and bearing surfaces.

Minor nicks on the splines can be smoothed with an

oilstone. Use 320-400 grit emery to smooth minor

scratches on the shaft bearing surfaces. Replace the

shaft if the bearing surfaces are scored or if any of

the splines are cracked or broken.Examine the drive chain and shaft bearings.

Replace the chain and both sprockets if the chain is

stretched, distorted, or if any of the links bind.

Replace the bearings if rough, or noisy.

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 41)

Fig. 39 Input Gear and Carrier Components

1 - PLANETARY CARRIER 4 - CARRIER LOCK RING

2 - REAR THRUST WASHER 5 - CARRIER LOCK RETAINING RING

3 - FRONT THRUST WASHER 6 - INPUT GEAR

Fig. 40 Shift Fork and Wear Pad Locations

1 - RANGE FORK

2 - MODE FORK

3 - WEAR PADS (SERVICEABLE)

4 - WEAR PADS (SERVICEABLE)

Fig. 41 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEAR

21 - 524 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2228 of 2627

FRONT AND REAR CASES

Inspect the cases for wear and damage.

Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with Helicoiltstain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

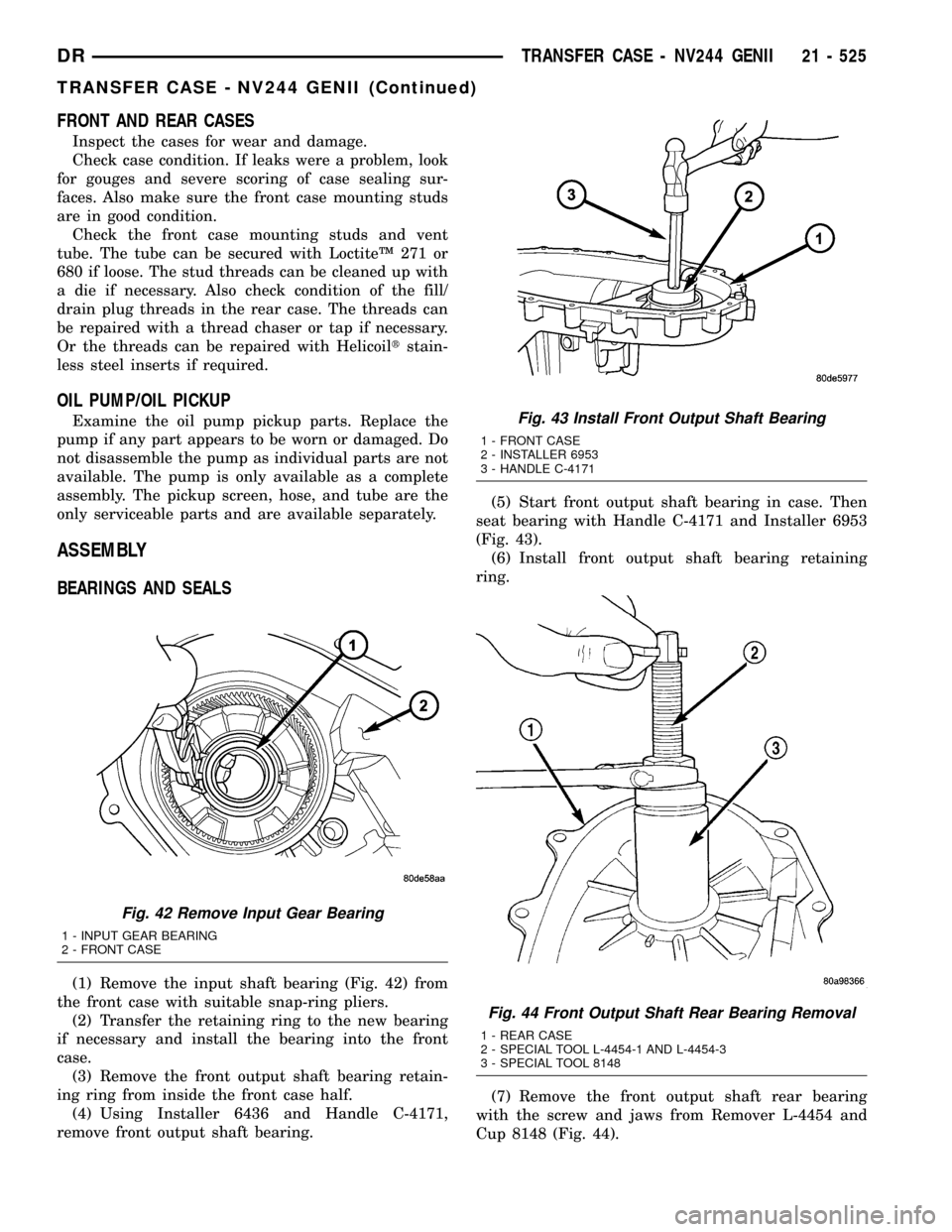

ASSEMBLY

BEARINGS AND SEALS

(1) Remove the input shaft bearing (Fig. 42) from

the front case with suitable snap-ring pliers.

(2) Transfer the retaining ring to the new bearing

if necessary and install the bearing into the front

case.

(3) Remove the front output shaft bearing retain-

ing ring from inside the front case half.

(4) Using Installer 6436 and Handle C-4171,

remove front output shaft bearing.(5) Start front output shaft bearing in case. Then

seat bearing with Handle C-4171 and Installer 6953

(Fig. 43).

(6) Install front output shaft bearing retaining

ring.

(7) Remove the front output shaft rear bearing

with the screw and jaws from Remover L-4454 and

Cup 8148 (Fig. 44).

Fig. 42 Remove Input Gear Bearing

1 - INPUT GEAR BEARING

2 - FRONT CASE

Fig. 43 Install Front Output Shaft Bearing

1 - FRONT CASE

2 - INSTALLER 6953

3 - HANDLE C-4171

Fig. 44 Front Output Shaft Rear Bearing Removal

1 - REAR CASE

2 - SPECIAL TOOL L-4454-1 AND L-4454-3

3 - SPECIAL TOOL 8148

DRTRANSFER CASE - NV244 GENII 21 - 525

TRANSFER CASE - NV244 GENII (Continued)

Page 2229 of 2627

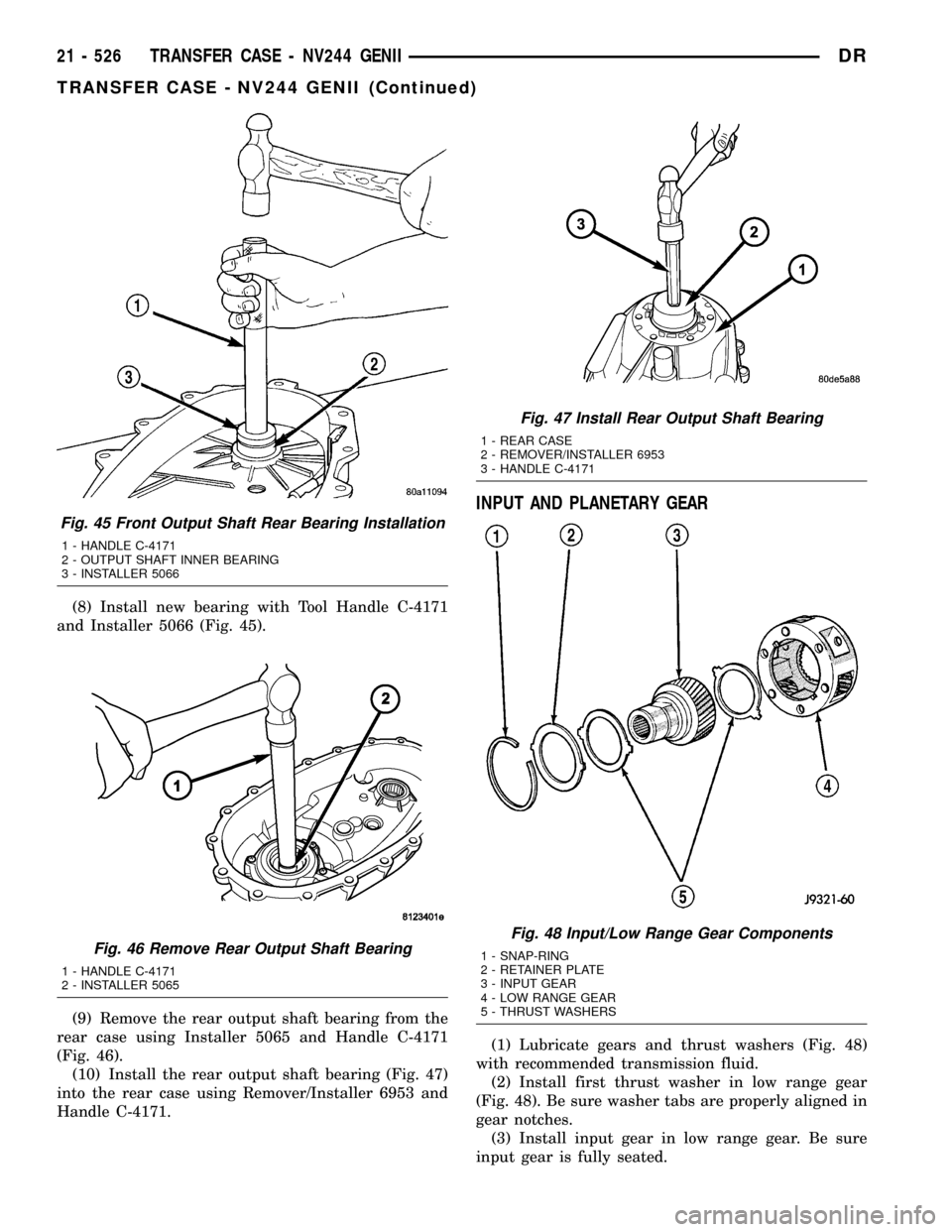

(8) Install new bearing with Tool Handle C-4171

and Installer 5066 (Fig. 45).

(9) Remove the rear output shaft bearing from the

rear case using Installer 5065 and Handle C-4171

(Fig. 46).

(10) Install the rear output shaft bearing (Fig. 47)

into the rear case using Remover/Installer 6953 and

Handle C-4171.

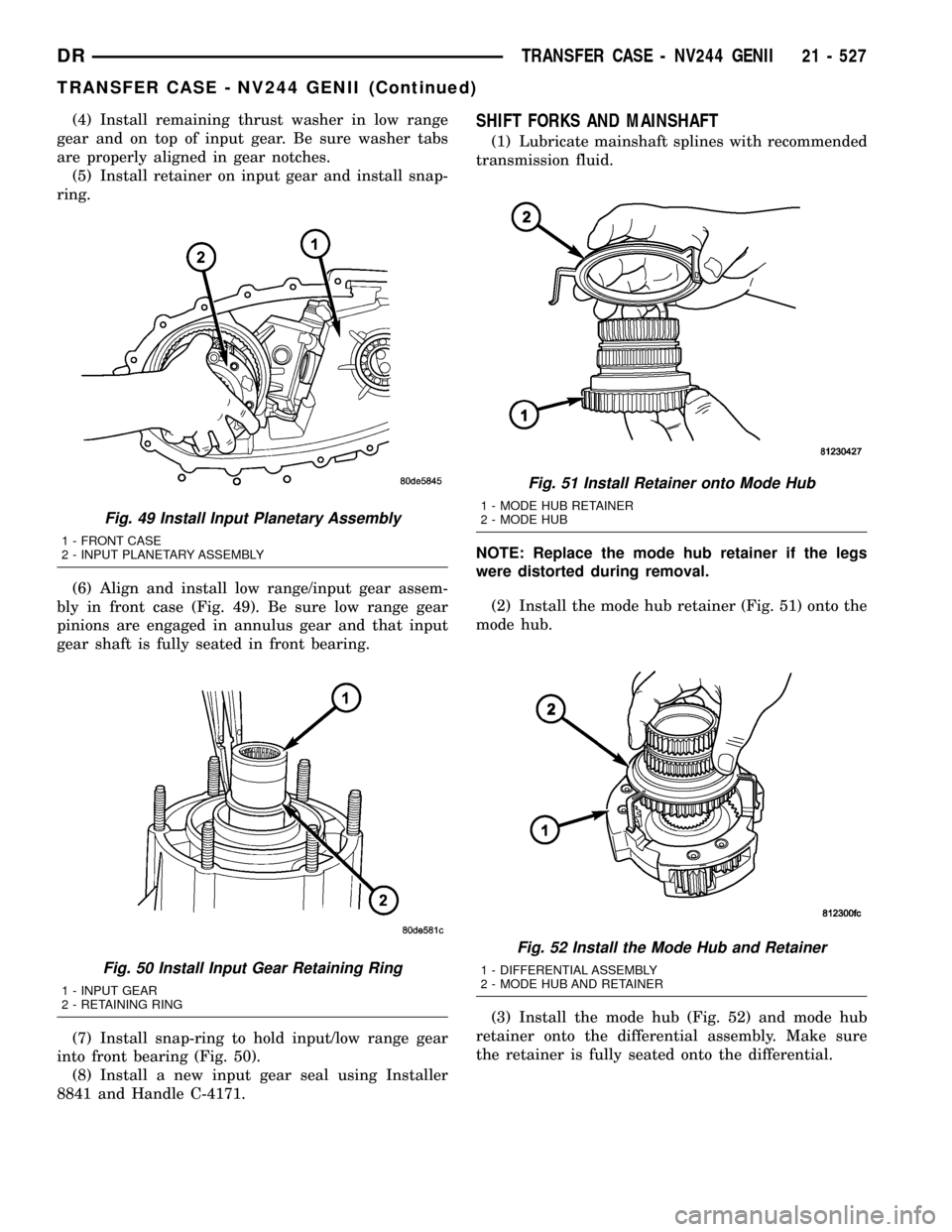

INPUT AND PLANETARY GEAR

(1) Lubricate gears and thrust washers (Fig. 48)

with recommended transmission fluid.

(2) Install first thrust washer in low range gear

(Fig. 48). Be sure washer tabs are properly aligned in

gear notches.

(3) Install input gear in low range gear. Be sure

input gear is fully seated.

Fig. 45 Front Output Shaft Rear Bearing Installation

1 - HANDLE C-4171

2 - OUTPUT SHAFT INNER BEARING

3 - INSTALLER 5066

Fig. 46 Remove Rear Output Shaft Bearing

1 - HANDLE C-4171

2 - INSTALLER 5065

Fig. 47 Install Rear Output Shaft Bearing

1 - REAR CASE

2 - REMOVER/INSTALLER 6953

3 - HANDLE C-4171

Fig. 48 Input/Low Range Gear Components

1 - SNAP-RING

2 - RETAINER PLATE

3 - INPUT GEAR

4 - LOW RANGE GEAR

5 - THRUST WASHERS

21 - 526 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2230 of 2627

(4) Install remaining thrust washer in low range

gear and on top of input gear. Be sure washer tabs

are properly aligned in gear notches.

(5) Install retainer on input gear and install snap-

ring.

(6) Align and install low range/input gear assem-

bly in front case (Fig. 49). Be sure low range gear

pinions are engaged in annulus gear and that input

gear shaft is fully seated in front bearing.

(7) Install snap-ring to hold input/low range gear

into front bearing (Fig. 50).

(8) Install a new input gear seal using Installer

8841 and Handle C-4171.SHIFT FORKS AND MAINSHAFT

(1) Lubricate mainshaft splines with recommended

transmission fluid.

NOTE: Replace the mode hub retainer if the legs

were distorted during removal.

(2) Install the mode hub retainer (Fig. 51) onto the

mode hub.

(3) Install the mode hub (Fig. 52) and mode hub

retainer onto the differential assembly. Make sure

the retainer is fully seated onto the differential.

Fig. 49 Install Input Planetary Assembly

1 - FRONT CASE

2 - INPUT PLANETARY ASSEMBLY

Fig. 50 Install Input Gear Retaining Ring

1 - INPUT GEAR

2 - RETAINING RING

Fig. 51 Install Retainer onto Mode Hub

1 - MODE HUB RETAINER

2 - MODE HUB

Fig. 52 Install the Mode Hub and Retainer

1 - DIFFERENTIAL ASSEMBLY

2 - MODE HUB AND RETAINER

DRTRANSFER CASE - NV244 GENII 21 - 527

TRANSFER CASE - NV244 GENII (Continued)