DODGE RAM 1500 1998 2.G Workshop Manual

Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2201 of 2627

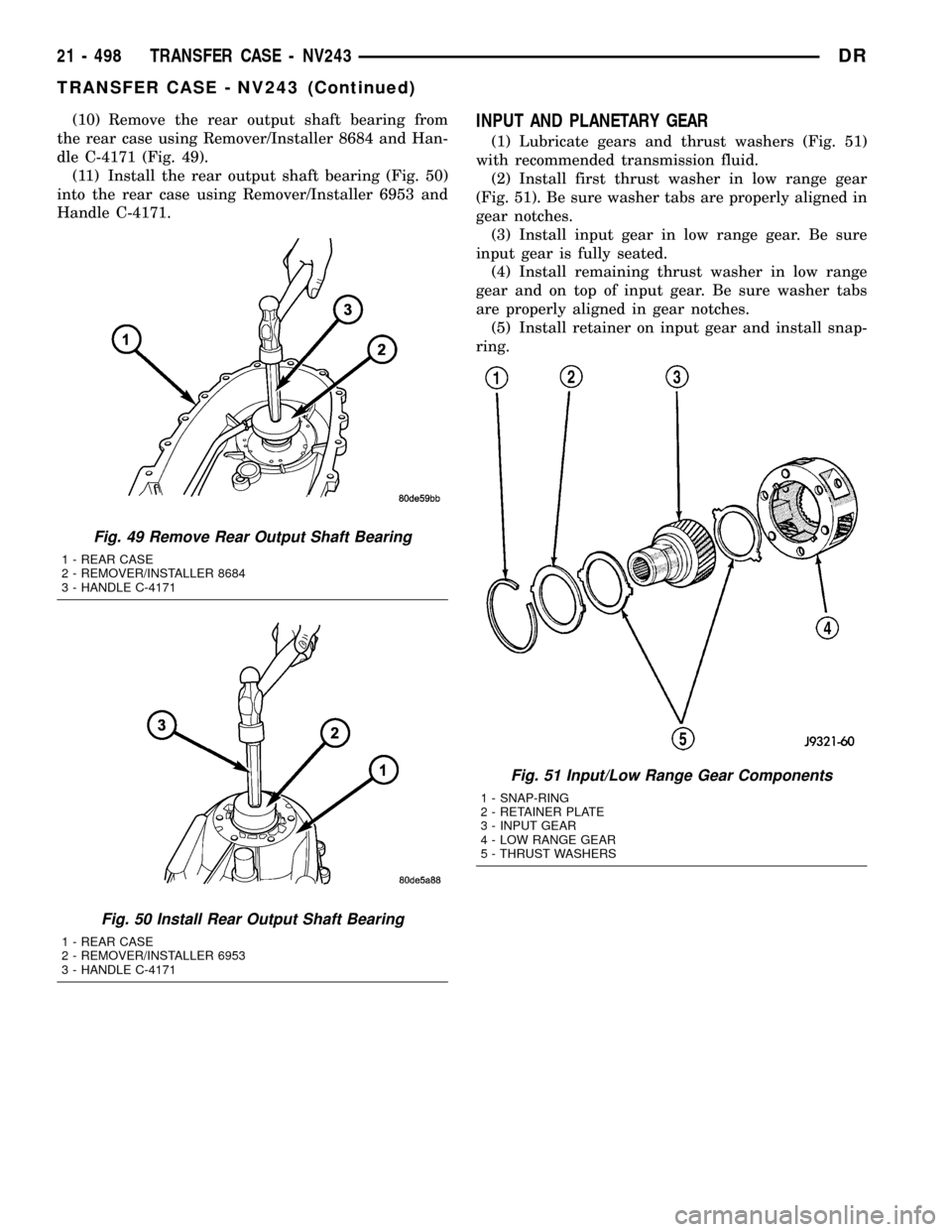

(10) Remove the rear output shaft bearing from

the rear case using Remover/Installer 8684 and Han-

dle C-4171 (Fig. 49).

(11) Install the rear output shaft bearing (Fig. 50)

into the rear case using Remover/Installer 6953 and

Handle C-4171.INPUT AND PLANETARY GEAR

(1) Lubricate gears and thrust washers (Fig. 51)

with recommended transmission fluid.

(2) Install first thrust washer in low range gear

(Fig. 51). Be sure washer tabs are properly aligned in

gear notches.

(3) Install input gear in low range gear. Be sure

input gear is fully seated.

(4) Install remaining thrust washer in low range

gear and on top of input gear. Be sure washer tabs

are properly aligned in gear notches.

(5) Install retainer on input gear and install snap-

ring.

Fig. 49 Remove Rear Output Shaft Bearing

1 - REAR CASE

2 - REMOVER/INSTALLER 8684

3 - HANDLE C-4171

Fig. 50 Install Rear Output Shaft Bearing

1 - REAR CASE

2 - REMOVER/INSTALLER 6953

3 - HANDLE C-4171

Fig. 51 Input/Low Range Gear Components

1 - SNAP-RING

2 - RETAINER PLATE

3 - INPUT GEAR

4 - LOW RANGE GEAR

5 - THRUST WASHERS

21 - 498 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2202 of 2627

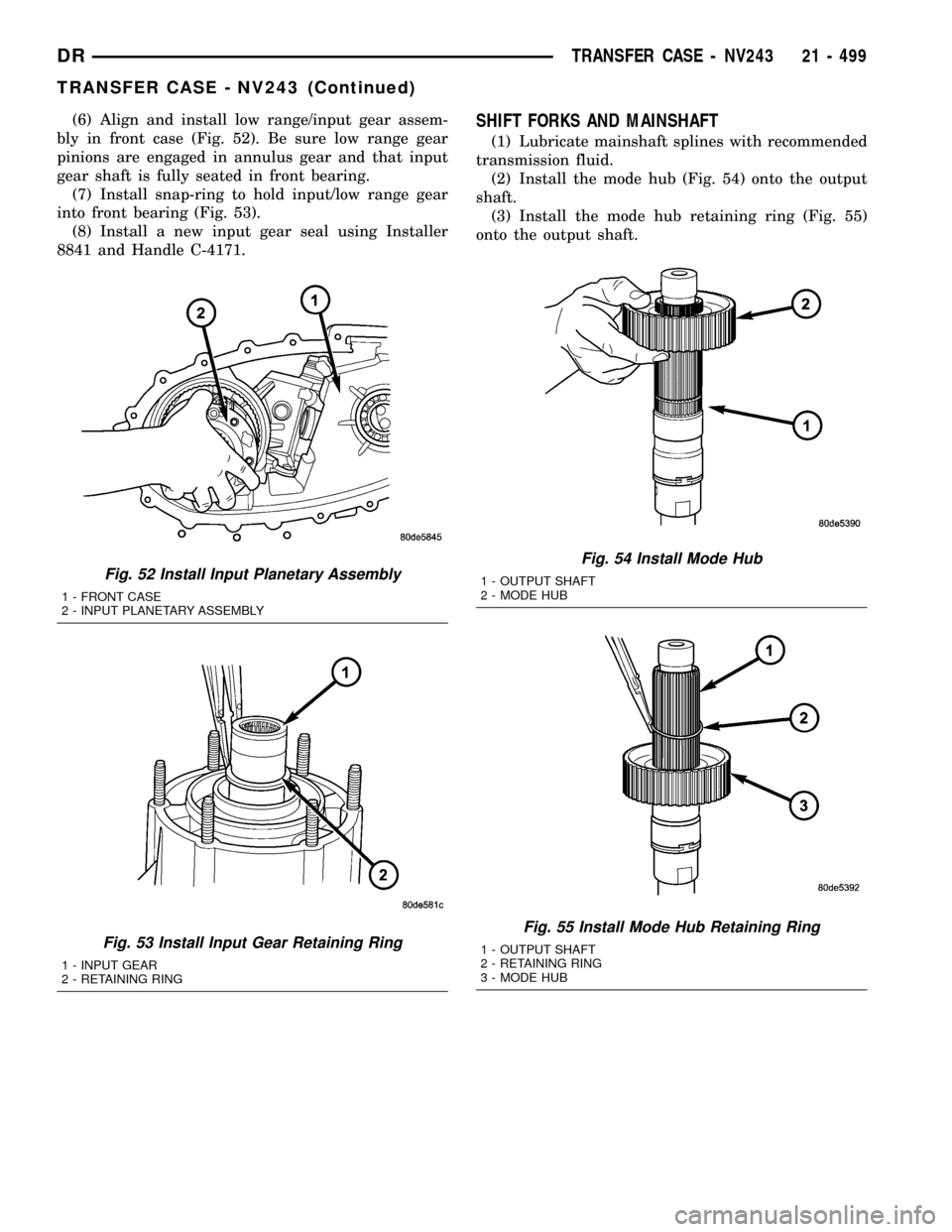

(6) Align and install low range/input gear assem-

bly in front case (Fig. 52). Be sure low range gear

pinions are engaged in annulus gear and that input

gear shaft is fully seated in front bearing.

(7) Install snap-ring to hold input/low range gear

into front bearing (Fig. 53).

(8) Install a new input gear seal using Installer

8841 and Handle C-4171.SHIFT FORKS AND MAINSHAFT

(1) Lubricate mainshaft splines with recommended

transmission fluid.

(2) Install the mode hub (Fig. 54) onto the output

shaft.

(3) Install the mode hub retaining ring (Fig. 55)

onto the output shaft.

Fig. 52 Install Input Planetary Assembly

1 - FRONT CASE

2 - INPUT PLANETARY ASSEMBLY

Fig. 53 Install Input Gear Retaining Ring

1 - INPUT GEAR

2 - RETAINING RING

Fig. 54 Install Mode Hub

1 - OUTPUT SHAFT

2 - MODE HUB

Fig. 55 Install Mode Hub Retaining Ring

1 - OUTPUT SHAFT

2 - RETAINING RING

3 - MODE HUB

DRTRANSFER CASE - NV243 21 - 499

TRANSFER CASE - NV243 (Continued)

Page 2203 of 2627

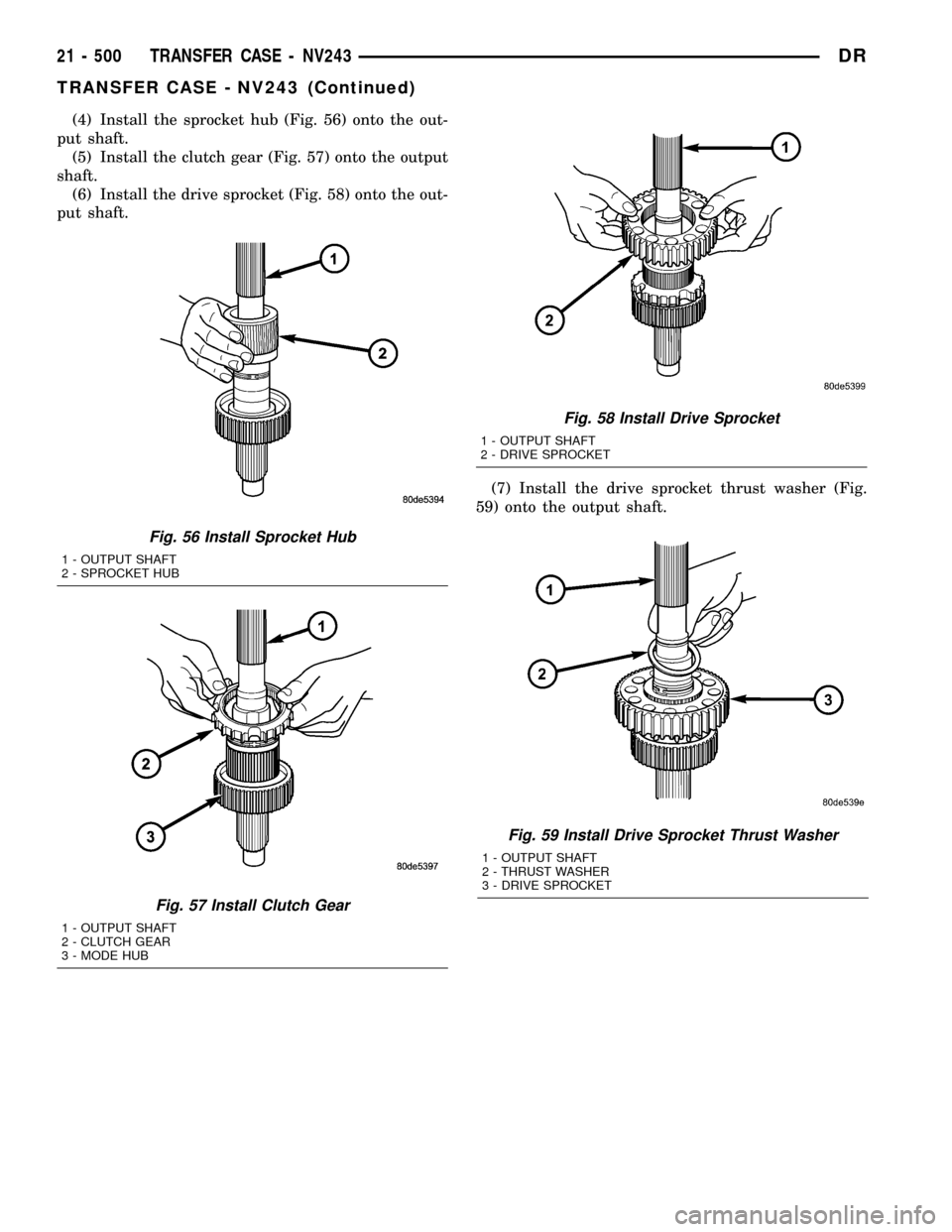

(4) Install the sprocket hub (Fig. 56) onto the out-

put shaft.

(5) Install the clutch gear (Fig. 57) onto the output

shaft.

(6) Install the drive sprocket (Fig. 58) onto the out-

put shaft.

(7) Install the drive sprocket thrust washer (Fig.

59) onto the output shaft.

Fig. 59 Install Drive Sprocket Thrust Washer

1 - OUTPUT SHAFT

2 - THRUST WASHER

3 - DRIVE SPROCKET

Fig. 56 Install Sprocket Hub

1 - OUTPUT SHAFT

2 - SPROCKET HUB

Fig. 57 Install Clutch Gear

1 - OUTPUT SHAFT

2 - CLUTCH GEAR

3 - MODE HUB

Fig. 58 Install Drive Sprocket

1 - OUTPUT SHAFT

2 - DRIVE SPROCKET

21 - 500 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2204 of 2627

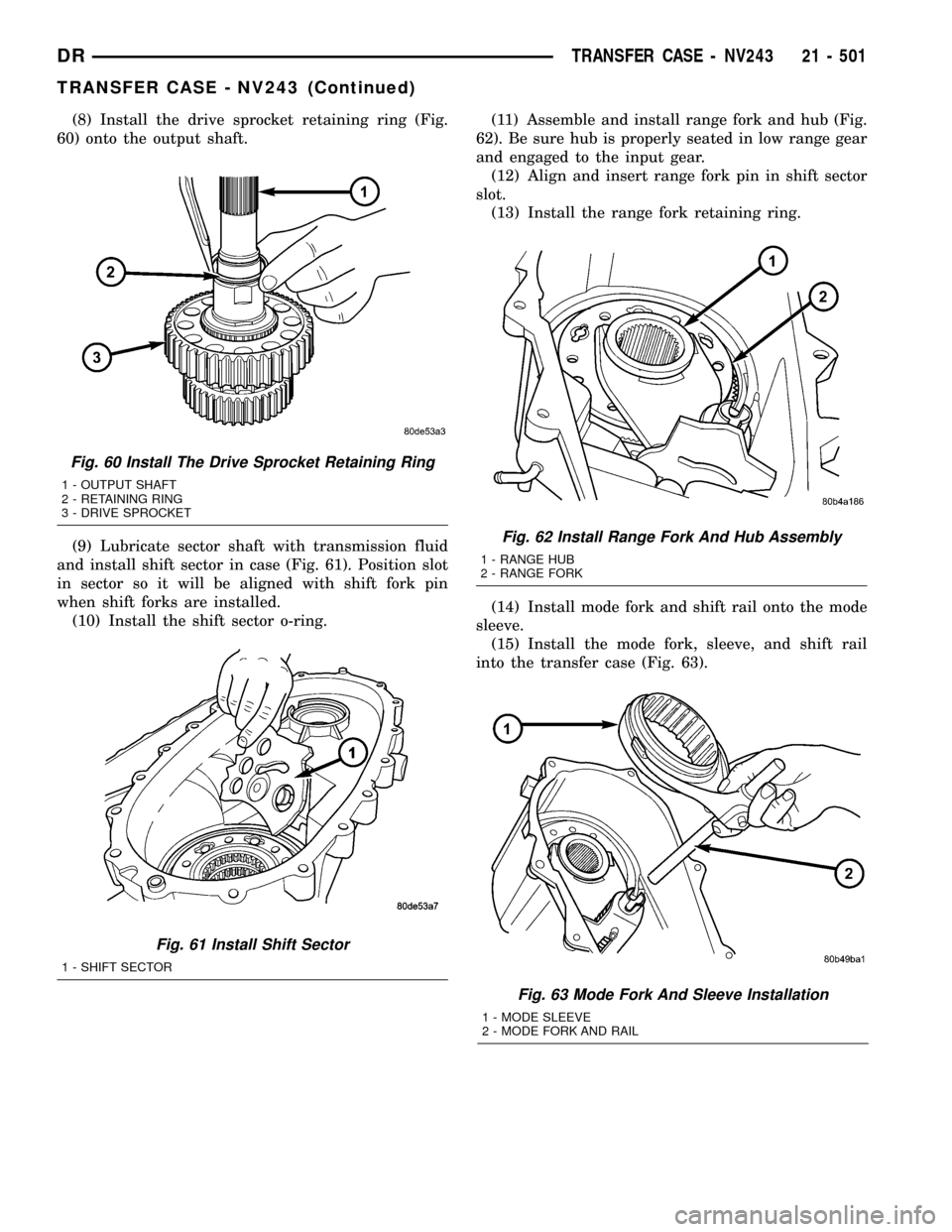

(8) Install the drive sprocket retaining ring (Fig.

60) onto the output shaft.

(9) Lubricate sector shaft with transmission fluid

and install shift sector in case (Fig. 61). Position slot

in sector so it will be aligned with shift fork pin

when shift forks are installed.

(10) Install the shift sector o-ring.(11) Assemble and install range fork and hub (Fig.

62). Be sure hub is properly seated in low range gear

and engaged to the input gear.

(12) Align and insert range fork pin in shift sector

slot.

(13) Install the range fork retaining ring.

(14) Install mode fork and shift rail onto the mode

sleeve.

(15) Install the mode fork, sleeve, and shift rail

into the transfer case (Fig. 63).

Fig. 63 Mode Fork And Sleeve Installation

1 - MODE SLEEVE

2 - MODE FORK AND RAIL

Fig. 60 Install The Drive Sprocket Retaining Ring

1 - OUTPUT SHAFT

2 - RETAINING RING

3 - DRIVE SPROCKET

Fig. 61 Install Shift Sector

1 - SHIFT SECTOR

Fig. 62 Install Range Fork And Hub Assembly

1 - RANGE HUB

2 - RANGE FORK

DRTRANSFER CASE - NV243 21 - 501

TRANSFER CASE - NV243 (Continued)

Page 2205 of 2627

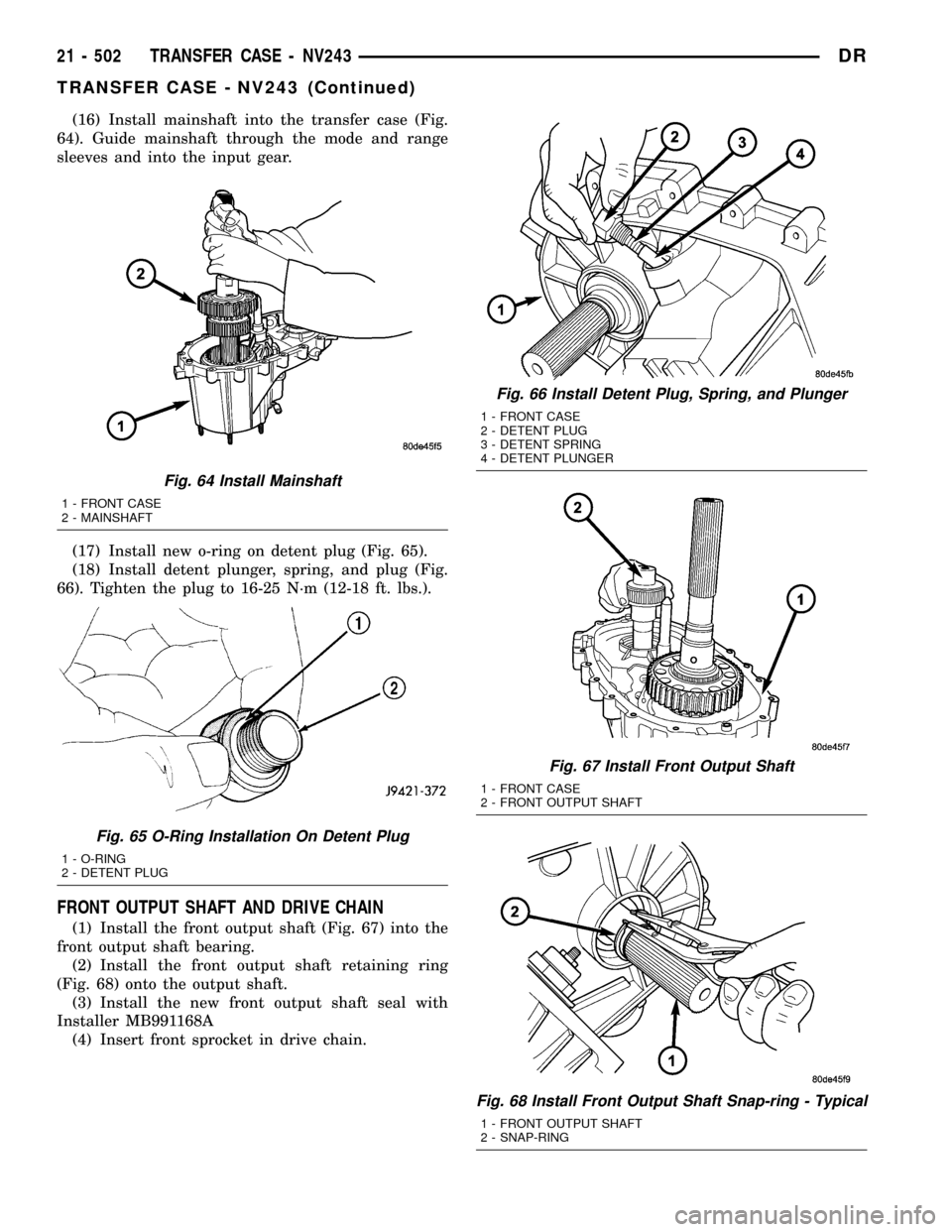

(16) Install mainshaft into the transfer case (Fig.

64). Guide mainshaft through the mode and range

sleeves and into the input gear.

(17) Install new o-ring on detent plug (Fig. 65).

(18) Install detent plunger, spring, and plug (Fig.

66). Tighten the plug to 16-25 N´m (12-18 ft. lbs.).

FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Install the front output shaft (Fig. 67) into the

front output shaft bearing.

(2) Install the front output shaft retaining ring

(Fig. 68) onto the output shaft.

(3) Install the new front output shaft seal with

Installer MB991168A

(4) Insert front sprocket in drive chain.

Fig. 64 Install Mainshaft

1 - FRONT CASE

2 - MAINSHAFT

Fig. 65 O-Ring Installation On Detent Plug

1 - O-RING

2 - DETENT PLUG

Fig. 66 Install Detent Plug, Spring, and Plunger

1 - FRONT CASE

2 - DETENT PLUG

3 - DETENT SPRING

4 - DETENT PLUNGER

Fig. 67 Install Front Output Shaft

1 - FRONT CASE

2 - FRONT OUTPUT SHAFT

Fig. 68 Install Front Output Shaft Snap-ring - Typical

1 - FRONT OUTPUT SHAFT

2 - SNAP-RING

21 - 502 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2206 of 2627

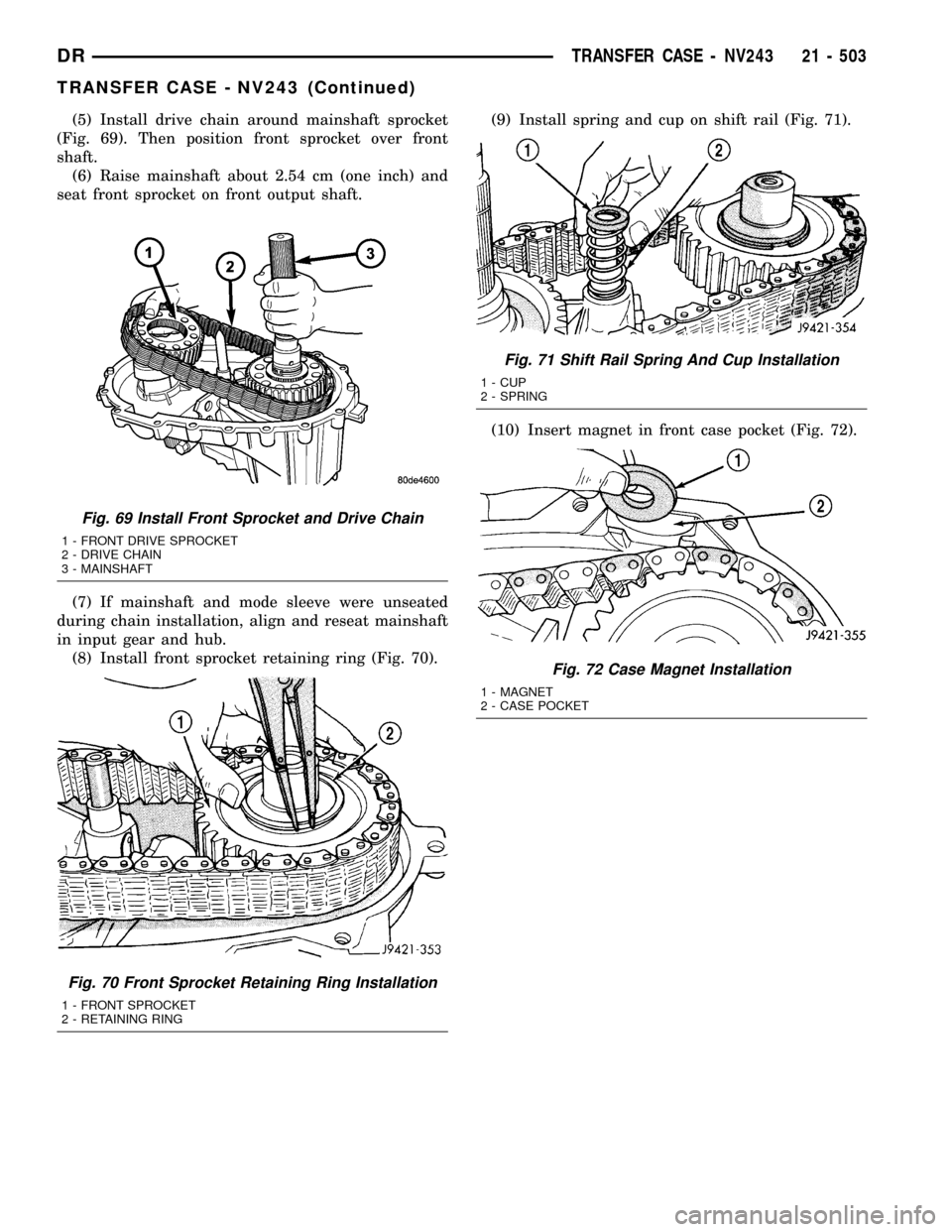

(5) Install drive chain around mainshaft sprocket

(Fig. 69). Then position front sprocket over front

shaft.

(6) Raise mainshaft about 2.54 cm (one inch) and

seat front sprocket on front output shaft.

(7) If mainshaft and mode sleeve were unseated

during chain installation, align and reseat mainshaft

in input gear and hub.

(8) Install front sprocket retaining ring (Fig. 70).(9) Install spring and cup on shift rail (Fig. 71).

(10) Insert magnet in front case pocket (Fig. 72).

Fig. 69 Install Front Sprocket and Drive Chain

1 - FRONT DRIVE SPROCKET

2 - DRIVE CHAIN

3 - MAINSHAFT

Fig. 70 Front Sprocket Retaining Ring Installation

1 - FRONT SPROCKET

2 - RETAINING RING

Fig. 71 Shift Rail Spring And Cup Installation

1 - CUP

2 - SPRING

Fig. 72 Case Magnet Installation

1 - MAGNET

2 - CASE POCKET

DRTRANSFER CASE - NV243 21 - 503

TRANSFER CASE - NV243 (Continued)

Page 2207 of 2627

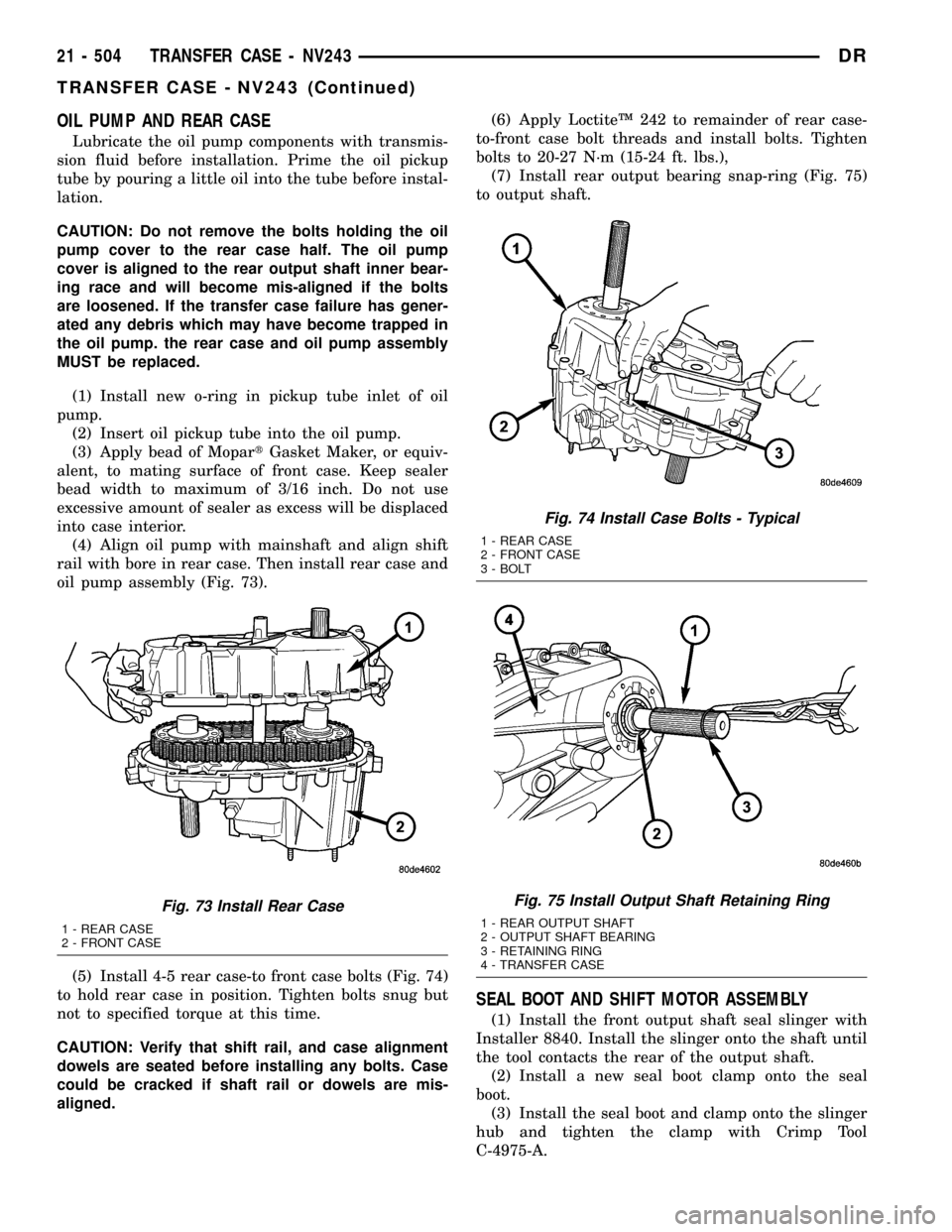

OIL PUMP AND REAR CASE

Lubricate the oil pump components with transmis-

sion fluid before installation. Prime the oil pickup

tube by pouring a little oil into the tube before instal-

lation.

CAUTION: Do not remove the bolts holding the oil

pump cover to the rear case half. The oil pump

cover is aligned to the rear output shaft inner bear-

ing race and will become mis-aligned if the bolts

are loosened. If the transfer case failure has gener-

ated any debris which may have become trapped in

the oil pump. the rear case and oil pump assembly

MUST be replaced.

(1) Install new o-ring in pickup tube inlet of oil

pump.

(2) Insert oil pickup tube into the oil pump.

(3) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of front case. Keep sealer

bead width to maximum of 3/16 inch. Do not use

excessive amount of sealer as excess will be displaced

into case interior.

(4) Align oil pump with mainshaft and align shift

rail with bore in rear case. Then install rear case and

oil pump assembly (Fig. 73).

(5) Install 4-5 rear case-to front case bolts (Fig. 74)

to hold rear case in position. Tighten bolts snug but

not to specified torque at this time.

CAUTION: Verify that shift rail, and case alignment

dowels are seated before installing any bolts. Case

could be cracked if shaft rail or dowels are mis-

aligned.(6) Apply LoctiteŸ 242 to remainder of rear case-

to-front case bolt threads and install bolts. Tighten

bolts to 20-27 N´m (15-24 ft. lbs.),

(7) Install rear output bearing snap-ring (Fig. 75)

to output shaft.

SEAL BOOT AND SHIFT MOTOR ASSEMBLY

(1) Install the front output shaft seal slinger with

Installer 8840. Install the slinger onto the shaft until

the tool contacts the rear of the output shaft.

(2) Install a new seal boot clamp onto the seal

boot.

(3) Install the seal boot and clamp onto the slinger

hub and tighten the clamp with Crimp Tool

C-4975-A.

Fig. 73 Install Rear Case

1 - REAR CASE

2 - FRONT CASE

Fig. 74 Install Case Bolts - Typical

1 - REAR CASE

2 - FRONT CASE

3 - BOLT

Fig. 75 Install Output Shaft Retaining Ring

1 - REAR OUTPUT SHAFT

2 - OUTPUT SHAFT BEARING

3 - RETAINING RING

4 - TRANSFER CASE

21 - 504 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2208 of 2627

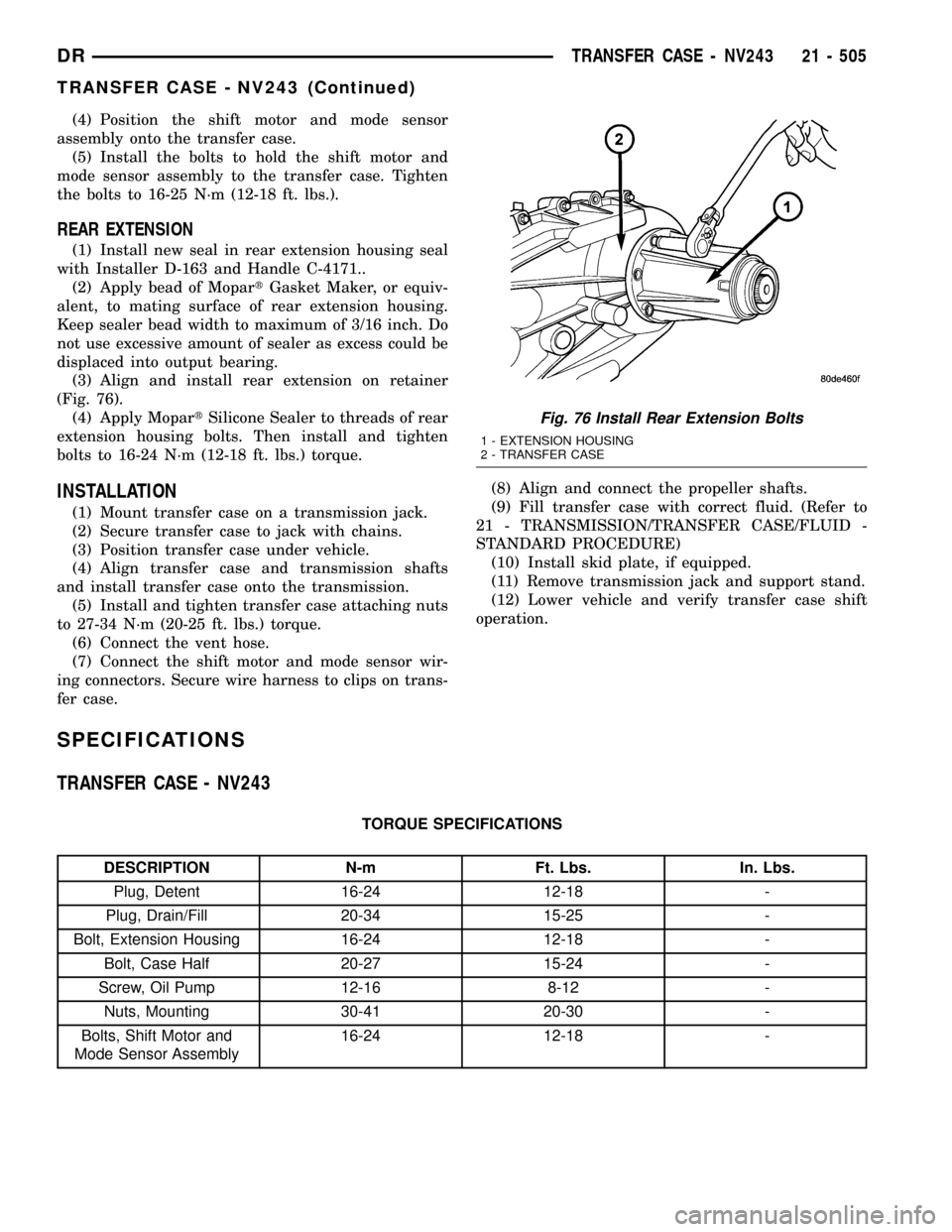

(4) Position the shift motor and mode sensor

assembly onto the transfer case.

(5) Install the bolts to hold the shift motor and

mode sensor assembly to the transfer case. Tighten

the bolts to 16-25 N´m (12-18 ft. lbs.).

REAR EXTENSION

(1) Install new seal in rear extension housing seal

with Installer D-163 and Handle C-4171..

(2) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of rear extension housing.

Keep sealer bead width to maximum of 3/16 inch. Do

not use excessive amount of sealer as excess could be

displaced into output bearing.

(3) Align and install rear extension on retainer

(Fig. 76).

(4) Apply MopartSilicone Sealer to threads of rear

extension housing bolts. Then install and tighten

bolts to 16-24 N´m (12-18 ft. lbs.) torque.

INSTALLATION

(1) Mount transfer case on a transmission jack.

(2) Secure transfer case to jack with chains.

(3) Position transfer case under vehicle.

(4) Align transfer case and transmission shafts

and install transfer case onto the transmission.

(5) Install and tighten transfer case attaching nuts

to 27-34 N´m (20-25 ft. lbs.) torque.

(6) Connect the vent hose.

(7) Connect the shift motor and mode sensor wir-

ing connectors. Secure wire harness to clips on trans-

fer case.(8) Align and connect the propeller shafts.

(9) Fill transfer case with correct fluid. (Refer to

21 - TRANSMISSION/TRANSFER CASE/FLUID -

STANDARD PROCEDURE)

(10) Install skid plate, if equipped.

(11) Remove transmission jack and support stand.

(12) Lower vehicle and verify transfer case shift

operation.

SPECIFICATIONS

TRANSFER CASE - NV243

TORQUE SPECIFICATIONS

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-24 12-18 -

Plug, Drain/Fill 20-34 15-25 -

Bolt, Extension Housing 16-24 12-18 -

Bolt, Case Half 20-27 15-24 -

Screw, Oil Pump 12-16 8-12 -

Nuts, Mounting 30-41 20-30 -

Bolts, Shift Motor and

Mode Sensor Assembly16-24 12-18 -

Fig. 76 Install Rear Extension Bolts

1 - EXTENSION HOUSING

2 - TRANSFER CASE

DRTRANSFER CASE - NV243 21 - 505

TRANSFER CASE - NV243 (Continued)

Page 2209 of 2627

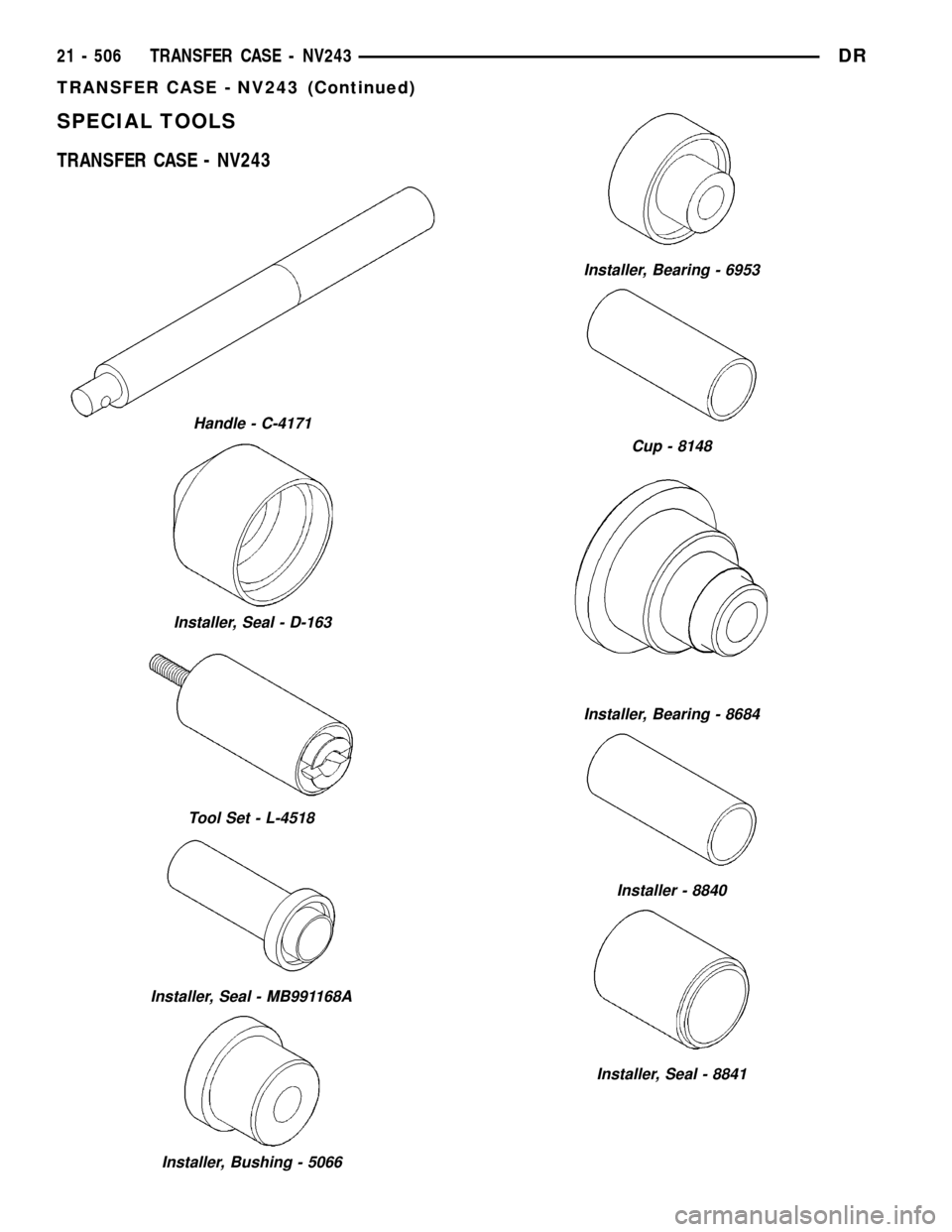

SPECIAL TOOLS

TRANSFER CASE - NV243

Handle - C-4171

Installer, Seal - D-163

Tool Set - L-4518

Installer, Seal - MB991168A

Installer, Bushing - 5066

Installer, Bearing - 6953

Cup - 8148

Installer, Bearing - 8684

Installer - 8840

Installer, Seal - 8841

21 - 506 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2210 of 2627

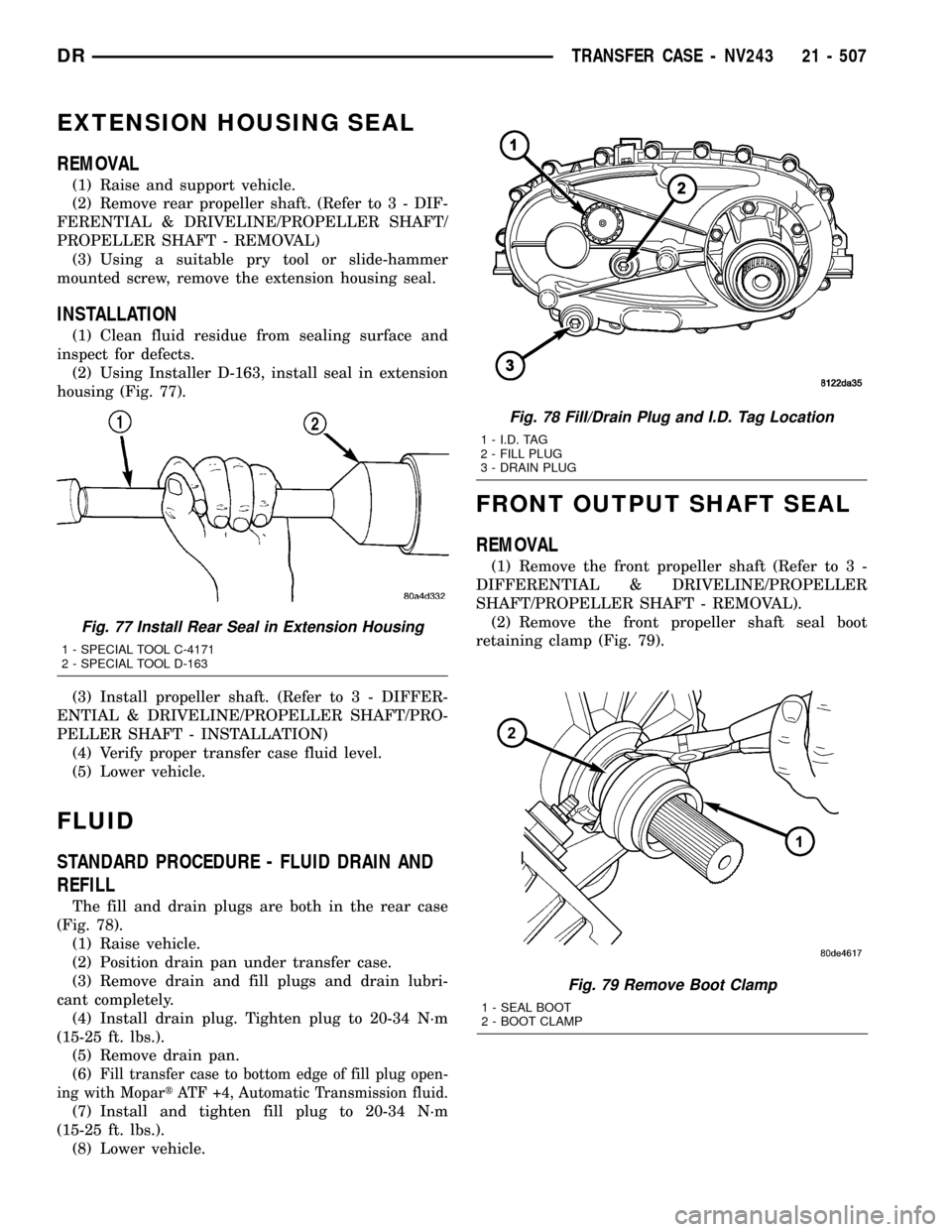

EXTENSION HOUSING SEAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Using a suitable pry tool or slide-hammer

mounted screw, remove the extension housing seal.

INSTALLATION

(1) Clean fluid residue from sealing surface and

inspect for defects.

(2) Using Installer D-163, install seal in extension

housing (Fig. 77).

(3) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)

(4) Verify proper transfer case fluid level.

(5) Lower vehicle.

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL

The fill and drain plugs are both in the rear case

(Fig. 78).

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 20-34 N´m

(15-25 ft. lbs.).

(5) Remove drain pan.

(6)

Fill transfer case to bottom edge of fill plug open-

ing with MopartATF +4, Automatic Transmission fluid.

(7) Install and tighten fill plug to 20-34 N´m

(15-25 ft. lbs.).

(8) Lower vehicle.

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Remove the front propeller shaft (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL).

(2) Remove the front propeller shaft seal boot

retaining clamp (Fig. 79).

Fig. 79 Remove Boot Clamp

1 - SEAL BOOT

2 - BOOT CLAMP

Fig. 77 Install Rear Seal in Extension Housing

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL D-163

Fig. 78 Fill/Drain Plug and I.D. Tag Location

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

DRTRANSFER CASE - NV243 21 - 507