engine DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 548 of 2627

tioned at the relative engine speed position on the

gauge scale until the engine stops running, or until

the ignition switch is turned to the Off position,

whichever occurs first.

²Communication Error- If the cluster fails to

receive an engine speed message, it will hold the

gauge needle at the last indication for about three

seconds, or until the ignition switch is turned to the

Off position, whichever occurs first. After three sec-

onds, the gauge needle will return to the left end of

the gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the tachometer needle will

be swept to several calibration points on the gauge

scale in a prescribed sequence in order to confirm the

functionality of the gauge and the cluster control cir-

cuitry.

On vehicles with a gasoline engine, the PCM con-

tinually monitors the crankshaft position sensor to

determine the engine speed. On vehicles with a die-

sel engine, the ECM continually monitors the engine

speed sensor to determine the engine speed. The

PCM or ECM then sends the proper engine speed

messages to the instrument cluster. For further diag-

nosis of the tachometer or the instrument cluster cir-

cuitry that controls the gauge, (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - DIAGNO-

SIS AND TESTING). For proper diagnosis of the

crankshaft position sensor, the engine speed sensor,

the PCM, the ECM, the PCI data bus, or the elec-

tronic message inputs to the instrument cluster that

control the tachometer, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

TOW/HAUL INDICATOR

DESCRIPTION

A tow/haul indicator is standard equipment on all

instrument clusters (Fig. 30). However, on vehicles

not equipped with the optional overdrive automatic

transmission, this indicator is electronically disabled.

The tow/haul indicator consists of the text ªTOW/

HAULº, which appears in the lower portion of the

odometer/trip odometer indicator Vacuum Fluores-

cent Display (VFD) unit. The VFD is soldered onto

the cluster electronic circuit board and is visible

through a window with a smoked clear lens located

on the lower edge of the tachometer gauge dial face

of the cluster overlay. The dark lens over the VFDprevents the indicator from being clearly visible

when it is not illuminated. The text ªTOW/HAULº

appear in an amber color and at the same lighting

level as the odometer/trip odometer information

when they are illuminated by the instrument cluster

electronic circuit board. The tow/haul indicator is ser-

viced as a unit with the VFD in the instrument clus-

ter.

OPERATION

The tow/haul indicator gives an indication to the

vehicle operator when the Off position of the tow/

haul switch has been selected, disabling the electron-

ically controlled overdrive feature of the automatic

transmission. This indicator is controlled by the

instrument cluster circuit board based upon cluster

programming and electronic messages received by

the cluster from the Powertrain Control Module

(PCM) over the Programmable Communications

Interface (PCI) data bus. The tow/haul indicator is

completely controlled by the instrument cluster logic

circuit, and that logic will only allow this indicator to

operate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the indicator will

always be off when the ignition switch is in any posi-

tion except On or Start. The indicator only illumi-

nates when it is switched to ground by the

instrument cluster circuitry. The instrument cluster

will turn on the tow/haul off indicator for the follow-

ing reasons:

²Tow/Haul Lamp-On Message- Each time the

cluster receives a tow/haul lamp-on message from the

PCM indicating that the Off position of the tow/haul

switch has been selected, the tow/haul indicator will

be illuminated. The indicator remains illuminated

until the cluster receives a tow/haul lamp-off mes-

sage from the PCM, or until the ignition switch is

turned to the Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the tow/haul indicator will

be turned on, then off again during the VFD portion

of the test to confirm the functionality of the VFD

and the cluster control circuitry.

The PCM continually monitors the tow/haul switch

to determine the proper outputs to the automatic

transmission. The PCM then sends the proper tow/

haul lamp-on and lamp-off messages to the instru-

ment cluster. For further diagnosis of the tow/haul

indicator or the instrument cluster circuitry that con-

trols the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the overdrive con-

trol system, the PCM, the PCI data bus, or the elec-

tronic message inputs to the instrument cluster that

control the tow/haul indicator, a DRBIIItscan tool is

Fig. 30 Tow/Haul Indicator

DRINSTRUMENT CLUSTER 8J - 39

TACHOMETER (Continued)

Page 551 of 2627

cator is electronically disabled. The upshift indicator

consists of an upward pointed arrow icon, which

appears on the right side of the electronic gear selec-

tor indicator Vacuum Fluorescent Display (VFD)

unit. The VFD is soldered onto the cluster electronic

circuit board and is visible through a window with a

smoked clear lens located on the lower edge of the

speedometer gauge dial face of the cluster overlay.

The dark lens over the VFD prevents the indicator

from being clearly visible when it is not illuminated.

The icon appears in a blue-green color and at the

same lighting level as the odometer/trip odometer

information when it is illuminated by the instrument

cluster electronic circuit board. The upshift indicator

is serviced as a unit with the instrument cluster.

OPERATION

The upshift indicator gives an indication to the

vehicle operator when the manual transmission

should be shifted to the next highest gear in order to

achieve the best fuel economy. This indicator is con-

trolled by the instrument cluster circuit board based

upon cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) on vehicles with a gasoline engine, or

from the Engine Control Module (ECM) on vehicles

with a diesel engine over the Programmable Commu-

nications Interface (PCI) data bus. The upshift indi-

cator is completely controlled by the instrument

cluster logic circuit, and that logic will only allow

this indicator to operate when the instrument cluster

receives a battery current input on the fused ignition

switch output (run-start) circuit. Therefore, the indi-

cator will always be off when the ignition switch is in

any position except On or Start. The indicator only

illuminates when it is switched to ground by the

instrument cluster circuitry. The instrument cluster

will turn on the upshift indicator for the following

reasons:

²Upshift Lamp-On Message- Each time the

cluster receives an upshift lamp-on message from the

PCM or ECM indicating the engine speed and load

conditions are right for a transmission upshift to

occur, the upshift indicator is illuminated. The indi-

cator remains illuminated until the cluster receives

an upshift lamp-off message from the PCM or ECM,

or until the ignition switch is turned to the Off posi-

tion, whichever occurs first. The PCM or ECM will

normally send an upshift lamp-off message three to

five seconds after a lamp-on message, if an upshift is

not performed. The indicator will then remain off

until the vehicle stops accelerating and is brought

back into the range of indicator operation, or until

the transmission is shifted into another gear.

²Actuator Test- Each time the cluster is put

through the actuator test, the upshift indicator willbe turned on, then off again during the VFD portion

of the test to confirm the functionality of the VFD

and the cluster control circuitry.

On vehicles with a gasoline engine, the PCM con-

tinually monitors the engine speed and load condi-

tions to determine the proper fuel and ignition

requirements. On vehicles with a diesel engine, the

ECM continually monitors the engine speed and load

conditions to determine the proper fuel requirements.

The PCM or ECM then sends the proper upshift indi-

cator lamp-on and lamp-off messages to the instru-

ment cluster. For further diagnosis of the upshift

indicator or the instrument cluster circuitry that con-

trols the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the PCM, the

ECM, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the

upshift indicator, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

VOLTAGE GAUGE

DESCRIPTION

A voltage gauge is standard equipment on all

instrument clusters. The voltage gauge is located in

the upper left quadrant of the instrument cluster,

above the fuel gauge. The voltage gauge consists of a

movable gauge needle or pointer controlled by the

instrument cluster circuitry and a fixed 90 degree

scale on the cluster overlay that reads left-to-right

from ªLº (or Low) to ªHº (or High) for gasoline

engines. On vehicles with a diesel engine, the scale

reads from ª8º to ª18º volts. An International Control

and Display Symbol icon for ªBattery Charging Con-

ditionº is located on the cluster overlay, directly

below the right end of the gauge scale (Fig. 34). The

voltage gauge graphics are black against a white

field except for a single red graduation at each end of

the gauge scale, making them clearly visible within

the instrument cluster in daylight. When illuminated

from behind by the panel lamps dimmer controlled

cluster illumination lighting with the exterior lamps

turned On, the black graphics appear blue and the

red graphics still appear red. The orange gauge nee-

dle is internally illuminated. Gauge illumination is

provided by replaceable incandescent bulb and bulb

holder units located on the instrument cluster elec-

tronic circuit board. The voltage gauge is serviced as

a unit with the instrument cluster.

Fig. 34 Battery Charging Condition Icon

8J - 42 INSTRUMENT CLUSTERDR

UPSHIFT INDICATOR (Continued)

Page 552 of 2627

OPERATION

The voltage gauge gives an indication to the vehi-

cle operator of the electrical system voltage. This

gauge is controlled by the instrument cluster circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) on vehicles

equipped with a gasoline engine, or from the Engine

Control Module (ECM) on vehicles equipped with a

diesel engine over the Programmable Communica-

tions Interface (PCI) data bus. The voltage gauge is

an air core magnetic unit that receives battery cur-

rent on the instrument cluster electronic circuit

board through the fused ignition switch output (run-

start) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed to

move the gauge needle back to the left end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²System Voltage Message- Each time the clus-

ter receives a system voltage message from the PCM

or ECM indicating the system voltage is between

about 9.5 volts and about 15 volts, the gauge needle

is moved to the relative voltage position on the gauge

scale.

²System Voltage Low (Charge Fail) Message

- Each time the cluster receives three consecutive

messages from the PCM or ECM indicating the elec-

trical system voltage is less than about 9 volts

(charge fail condition), the gauge needle is moved to

the graduation on the far left end of the gauge scale

and the check gauges indicator is illuminated. The

gauge needle remains at the far left end of the gauge

scale and the check gauges indicator remains illumi-

nated until the cluster receives a single message

from the PCM or ECM indicating the electrical sys-

tem voltage is greater than about 9.5 volts (but less

than about 15.5 volts), or until the ignition switch is

turned to the Off position, whichever occurs first. On

vehicles equipped with the optional diesel engine, the

ECM is programmed to restrict the voltage gauge

needle to a position above the graduation on the far

left end of the gauge scale and suppress the check

engine indicator operation until after the engine

intake manifold air heater has completed a pre-heat

or post-heat cycle.²System Voltage High Message- Each time

the cluster receives three consecutive messages from

the PCM or ECM indicating the electrical system

voltage is greater than about 15.5 volts, the gauge

needle is moved to the graduation on the far right

end of the gauge scale and the check gauges indica-

tor is illuminated. The gauge needle remains at the

right end of the gauge scale and the check gauges

indicator remains illuminated until the cluster

receives a message from the PCM or ECM indicating

the electrical system voltage is less than about 15.0

volts (but greater than about 9.5 volts), or until the

ignition switch is turned to the Off position, which-

ever occurs first.

²Communication Error- If the cluster fails to

receive a system voltage message, it will hold the

gauge needle at the last indication for about five sec-

onds or until the ignition switch is turned to the Off

position, whichever occurs first. After five seconds,

the cluster will move the gauge needle to the far left

end of the gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the voltage gauge needle

will be swept to several calibration points on the

gauge scale in a prescribed sequence in order to con-

firm the functionality of the gauge and the cluster

control circuitry.

On vehicles with a gasoline engine, the PCM con-

tinually monitors the system voltage to control the

generator output. On vehicles with a diesel engine,

the ECM continually monitors the system voltage to

control the generator output. The PCM or ECM then

sends the proper system voltage messages to the

instrument cluster. For further diagnosis of the volt-

age gauge or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). If the instrument cluster turns on the check

gauges indicator due to a charge fail or voltage high

condition, it may indicate that the charging system

requires service. For proper diagnosis of the charging

system, the PCM, the ECM, the PCI data bus, or the

electronic message inputs to the instrument cluster

that control the voltage gauge, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

DRINSTRUMENT CLUSTER 8J - 43

VOLTAGE GAUGE (Continued)

Page 553 of 2627

WAIT-TO-START INDICATOR

DESCRIPTION

A wait-to-start indicator is only found in the

instrument clusters for vehicles equipped with an

optional diesel engine (Fig. 35). The wait-to-start

indicator is located near the lower edge of the instru-

ment cluster, between the tachometer and the speed-

ometer. The wait-to-start indicator consists of stencil-

like cutout of the International Control and Display

Symbol icon for ªDiesel Preheatº in the opaque layer

of the instrument cluster overlay. The dark outer

layer of the overlay prevents the indicator from being

clearly visible when it is not illuminated. An amber

Light Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the icon to appear

in amber through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by the LED, which is soldered onto the

instrument cluster electronic circuit board. The wait-

to-start indicator is serviced as a unit with the

instrument cluster.

OPERATION

The wait-to-start indicator gives an indication to

the vehicle operator when the air temperature within

the diesel engine intake manifold is too cool for effi-

cient and reliable engine starting, and that the

intake air heater grids are energized in their pre-

heat operating mode. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Engine Control

Module (ECM) over the Programmable Communica-

tions Interface (PCI) data bus. The wait-to-start indi-

cator Light Emitting Diode (LED) is completely

controlled by the instrument cluster logic circuit, and

that logic will only allow this indicator to operate

when the instrument cluster receives a battery cur-

rent input on the fused ignition switch output (run-

start) circuit. Therefore, the LED will always be off

when the ignition switch is in any position except On

or Start. The LED only illuminates when it is pro-

vided a path to ground by the instrument cluster

transistor. The instrument cluster will turn on the

wait-to-start indicator for the following reasons:

²Wait-To-Start Lamp-On Message- Each time

the cluster receives a wait-to-start lamp-on message

from the ECM indicating that the air temperature

within the intake manifold is too cool for efficient

and reliable engine starting, the wait-to-start indica-

tor will be illuminated. The indicator remains illumi-nated until the cluster receives a wait-to-start lamp-

off message, until the ECM detects that the engine is

running or until the ignition switch is turned to the

Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the wait-to-start indicator

will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

The ECM continually monitors the engine intake

air temperature sensor to determine when the intake

air heater grids should be energized in their pre-heat

operating mode. The ECM then sends the proper

wait-to-start lamp-on and lamp-off messages to the

instrument cluster. For further diagnosis of the wait-

to-start indicator or the instrument cluster circuitry

that controls the indicator, (Refer to 8 - ELECTRI-

CAL/INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the engine intake

air temperature sensor, the intake air heater grid

control circuits, the ECM, the PCI data bus, or the

electronic message inputs to the instrument cluster

that control the wait-to-start indicator, a DRBIIIt

scan tool is required. Refer to the appropriate diag-

nostic information.

WASHER FLUID INDICATOR

DESCRIPTION

A washer fluid indicator is standard equipment on

all instrument clusters. The washer fluid indicator

consists of the words ªLOW WASHº, which appear in

the lower portion of the odometer/trip odometer Vac-

uum-Fluorescent Display (VFD) unit (Fig. 36). The

VFD is soldered onto the cluster electronic circuit

board and is visible through a window with a smoked

clear lens located on the lower edge of the tachome-

ter gauge dial face of the cluster overlay. The dark

lens over the VFD prevents the indicator from being

clearly visible when it is not illuminated. The ªLOW

WASHº text appears in an amber color and at the

same lighting level as the odometer/trip odometer

information when it is illuminated by the instrument

cluster electronic circuit board. The washer fluid

indicator is serviced as a unit with the VFD in the

instrument cluster.

OPERATION

The washer fluid indicator gives an indication to

the vehicle operator that the fluid level in the washer

Fig. 35 Wait-To-Start Indicator

Fig. 36 Washer Fluid Indicator

8J - 44 INSTRUMENT CLUSTERDR

Page 554 of 2627

reservoir is low. This indicator is controlled by the

instrument cluster circuit board based upon cluster

programming and electronic messages received by

the cluster from the Front Control Module (FCM)

over the Programmable Communications Interface

(PCI) data bus. The washer fluid indicator is com-

pletely controlled by the instrument cluster logic cir-

cuit, and that logic will only allow this indicator to

operate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the indicator will

always be off when the ignition switch is in any posi-

tion except On or Start. The indicator only illumi-

nates when it is switched to ground by the

instrument cluster circuitry. The instrument cluster

will turn on the washer fluid indicator for the follow-

ing reasons:

²Washer Fluid Indicator Lamp-On Message-

Each time the cluster receives a washer fluid indica-

tor lamp-on message from the FCM indicating that a

low washer condition has been detected for sixty con-

secutive seconds, the washer fluid indicator is illumi-

nated and a single chime tone is sounded. The

indicator remains illuminated until the cluster

receives a washer fluid indicator lamp-off message

for sixty consecutive seconds from the FCM or until

the ignition switch is turned to the Off position,

whichever occurs first. The chime tone feature will

only repeat during the same ignition cycle if the

washer fluid indicator is cycled off and then on again

by the appropriate washer fluid lamp messages from

the FCM.

²Actuator Test- Each time the cluster is put

through the actuator test, the washer fluid indicator

will be turned on, then off again during the VFD por-

tion of the test to confirm the functionality of the

VFD and the cluster control circuitry.

The FCM continually monitors the washer fluid

level switch in the washer reservoir to determine the

level of the washer fluid. The FCM then sends the

proper washer fluid indicator lamp-on and lamp-off

messages to the instrument cluster. For further diag-

nosis of the washer fluid indicator or the instrument

cluster circuitry that controls the indicator, (Refer to

8 - ELECTRICAL/INSTRUMENT CLUSTER - DIAG-

NOSIS AND TESTING). For proper diagnosis of the

washer fluid level switch, the FCM, the PCI data

bus, or the electronic message inputs to the instru-

ment cluster that control the washer fluid indicator,

a DRBIIItscan tool is required. Refer to the appro-

priate diagnostic information.WATER-IN-FUEL INDICATOR

DESCRIPTION

A water-in-fuel indicator is only found in the

instrument clusters for vehicles equipped with an

optional diesel engine (Fig. 37). The water-in-fuel

indicator is located near the lower edge of the instru-

ment cluster, between the tachometer and the speed-

ometer. The water-in-fuel indicator consists of stencil-

like cutout of the International Control and Display

Symbol icon for ªWater In Fuelº in the opaque layer

of the instrument cluster overlay. The dark outer

layer of the overlay prevents the indicator from being

clearly visible when it is not illuminated. A red Light

Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the icon to appear

in red through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by the LED, which is soldered onto the

instrument cluster electronic circuit board. The

water-in-fuel indicator is serviced as a unit with the

instrument cluster.

OPERATION

The water-in-fuel indicator gives an indication to

the vehicle operator when there is excessive water in

the fuel system. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon the cluster programming and electronic

messages received by the cluster from the Engine

Control Module (ECM) over the Programmable Com-

munications Interface (PCI) data bus. The water-in-

fuel indicator Light Emitting Diode (LED) is

completely controlled by the instrument cluster logic

circuit, and that logic will only allow this indicator to

operate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the LED will

always be off when the ignition switch is in any posi-

tion except On or Start. The LED only illuminates

when it is provided a path to ground by the instru-

ment cluster transistor. The instrument cluster will

turn on the water-in-fuel indicator for the following

reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the water-in-fuel indicator

is illuminated for about two seconds as a bulb test.

²Water-In-Fuel Lamp-On Message- Each time

the cluster receives a water-in-fuel lamp-on message

from the ECM indicating that there is excessive

Fig. 37 Water-In-Fuel Indicator

DRINSTRUMENT CLUSTER 8J - 45

WASHER FLUID INDICATOR (Continued)

Page 558 of 2627

Instrument Cluster transmits a message via J1850

informing the the FCM. The FCM will then turn off

the headlamps, park lamps and fog lamps. This fea-

ture (load shed) prevents the vehicle battery from

being discharged when the vehicle lights have been

left ON.

HEADLAMP TIME DELAY SYSTEM

The headlamp time delay system is activated by

turning the headlamps ON (high or low beam) while

the engine is running, turning the ignition switch

OFF, and then turning the headlamp switch OFF

within 45 seconds. The system will not activate if

more than 45 seconds elapse between ignition switch

OFF and headlamp switch OFF. The FCM will allow

the headlamps to remain ON for 60 seconds (config-

urable) before they automatically turn off (If the key

is in the ignition during the headlamp time delay

mode, then the headlamps including panel dimming

will be ON).

LAMP OUTAGE

If one or more of the following lamps (Low and/or

High beams, Brake and/or Turn Signal) are out, then

a ªlamps outº indicator located in the cluster will

illuminate.

OPTICAL HORN/HIGH BEAMS

When the multiplexed multifunction switch is

pulled to the first detent (optical horn) signal, the

headlamps are ON, the Instrument Cluster shall

send a message via J1850 to the FCM to turn on the

headlamps drivers to illuminate all four filaments

(Low and High beams). When the multifunction

switch is pulled to the second detent (high beam) sig-

nal and the headlamps are ON, the Instrument Clus-

ter shall send a message via J1850 to the FCM to

turn on the headlamps drivers. The High Beams are

illuminated and the Low Beams and Fog Lamps (if

ON) are extinguished. If the headlamps were in the

high beam configuration when power was removedfrom the headlamps, the headlamps will return to

their last state prior to being shut off.

DIAGNOSIS AND TESTING - LAMPS/LIGHTING

- EXTERIOR

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result. Do not use bulbs other than

those indicated in the Bulb Application table. Dam-

age to lamp and/or Daytime Running Lamp Module

can result. Do not use fuses, circuit breakers or

relays having greater amperage value than indi-

cated on the fuse panel or in the Owners Manual.

When a vehicle experiences problems with the

headlamp system, verify the condition of the battery

connections, fuses, charging system, headlamp bulbs,

wire connectors, relay, multifunction switch, and

headlamp switch. Refer to the appropriate wiring

information.

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

loose pin connections and corrosion. Repair as neces-

sary.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.

DRLAMPS/LIGHTING - EXTERIOR 8L - 3

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 559 of 2627

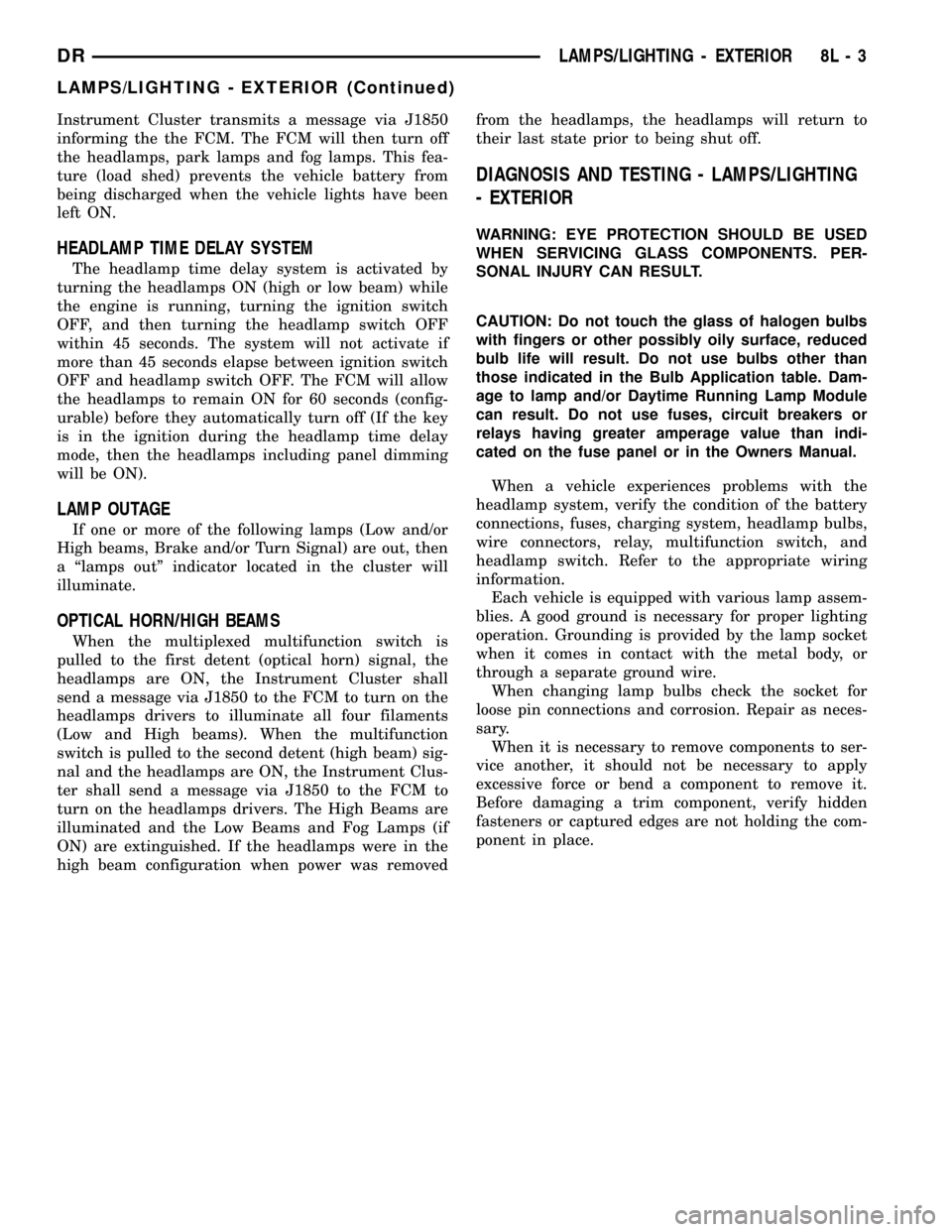

HEADLAMP DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS ARE DIM

WITH ENGINE IDLING

OR IGNITION TURNED

OFF1. Loose or corroded battery

cables.1. Clean and secure battery cable clamps and

posts.

2. Loose or worn generator drive

belt.2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system, refer to

Electrical, Charging

4. Battery has insufficient charge. 4. Test battery state-of-charge, refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery, refer to Electrical, Battery

System.

6. Poor lighting circuit ground. 6. Test for voltage drop across ground circuits,

refer to Electrical, Wiring Diagram Information.

HEADLAMP BULBS

BURN OUT

FREQUENTLY1. Integrated Control Module (ICM)

not controlling voltage.1. Test and repair Integrated Control Module.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and splices.

Refer to Electrical, Wiring Information.

HEADLAMPS ARE DIM

WITH ENGINE

RUNNING ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system, refer to

Electrical, Wiring Information.

2. Poor lighting circuit ground. 2. Test for voltage drop across ground circuits,

refer to Electrical, Wiring Information.

3. High resistance in headlamp

circuit.3. Test amperage draw of headlamp circuit.

HEADLAMPS FLASH

RANDOMLY1. Poor lighting circuit ground. 1. Test for voltage drop across ground

locations, refer to Electrical, Wiring Information.

2. Variable resistance in headlamp

circuit.2. Test amperage draw of headlamp circuit.

3. Loose or corroded terminals or

splices in circuit.3. Inspect and repair all connectors and splices,

refer to Electrical, Wiring Information.

4. Faulty headlamp switch. 4. Replace headlamp switch.

5. Front Control Module

Malfunction.5. Refer to appropriate ICM/FCM diagnostics.

8L - 4 LAMPS/LIGHTING - EXTERIORDR

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 560 of 2627

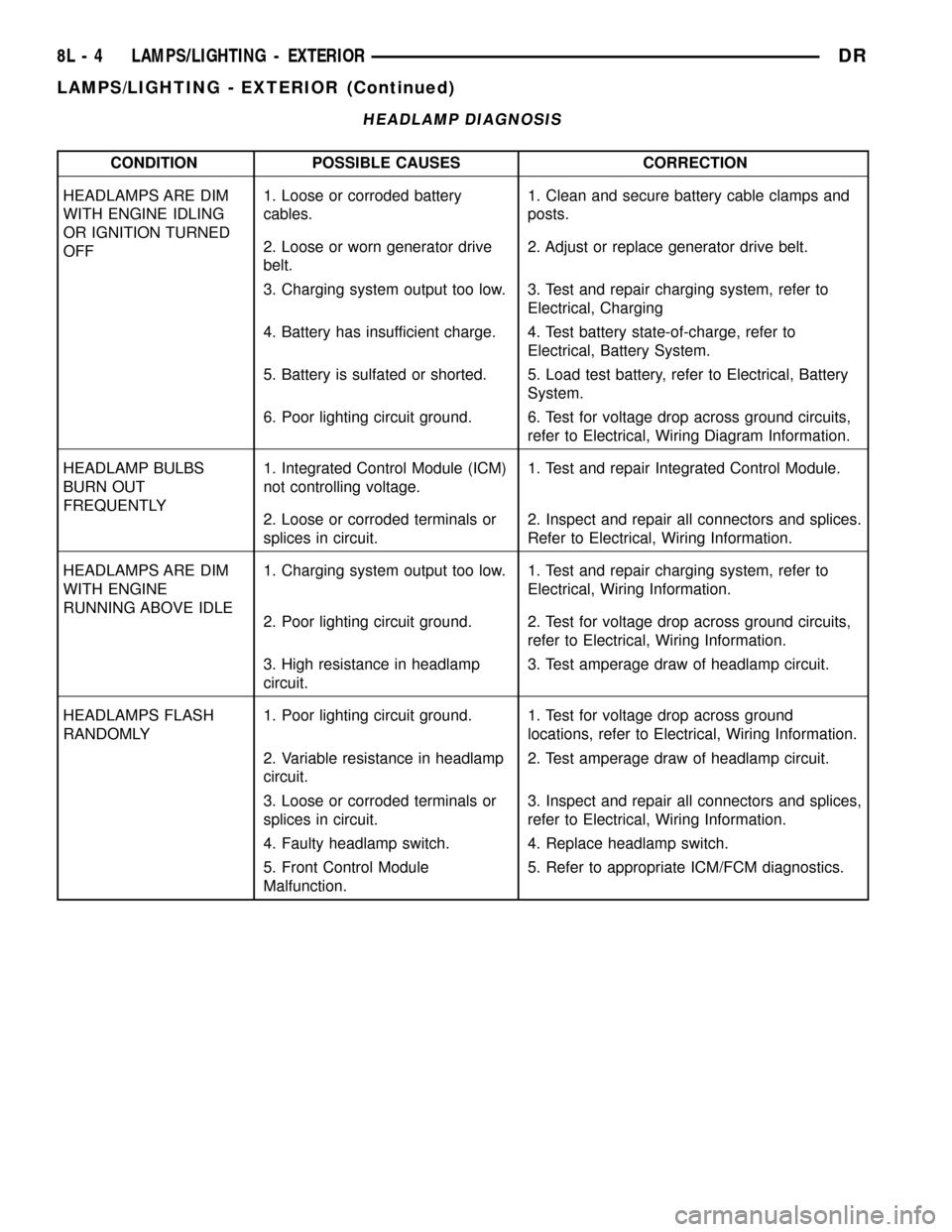

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS DO NOT

ILLUMINATE1. No voltage to headlamps. 1. Repair open headlamp circuit, refer to

Electrical, Wiring Information.

2. No ground at headlamps. 2. Repair circuit ground, refer to Electrical,

Wiring Information.

3. Broken connector terminal or

wire splice in headlamp circuit.3. Repair connector terminal or wire splice.

4. Faulty or burned out bulb. 4. Replace headlamp bulb(s).

5. Integrated Control Module

malfunction.5. Refer to appropriate Body Control Module

diagnostics.

6. J1850 Bus Communication 6. Verify messages being transmitted by

Instrument Cluster and received by FCM.

7. Front Control Module

Malfunction.7. Refer to appropriate ICM/FCM diagnostics.

HEADLAMPS ON WITH

IGNITION IN RUN, WITH

HEADLAMP SWITCH

OFF1. Faulty headlamp switch. 1. Replace headlamp switch (review Instrument

Cluster logged faults).

2. Diagnostic tool indicates (4.7 -

5.0V) on headlamp switch input to

Instrument Cluster.2. Inspect and repair terminals, connectors and

open circuits.

3. J1850 Bus Communication. 3. Verify messages being transmitted by

Instrument Cluster and received by FCM.

4. Front Control Module

Malfunction.4. Refer to appropriate ICM/FCM diagnostics.

FOG LAMP DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM

WITH ENGINE IDLING

OR IGNITION TURNED

OFF.1. Loose or corroded battery

cables.1. Clean and secure battery cable clamps and

posts.

2. Loose or worn generator drive

belt.2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system. Refer to

Electrical, Charging,

4. Battery has insufficient charge. 4. Test battery state-of-charge. Refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery. Refer to Electrical, Battery

System.

6. Poor lighting circuit ground. 6. Test for voltage drop across ground

locations. Refer to Electrical, Wiring

Information.

FOG LAMP BULBS

BURN OUT

FREQUENTLY1. Charging system output too

high.1. Test and repair charging system. Refer to

Electrical, Charging.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and splices.

Refer to Electrical, Wiring Information.

DRLAMPS/LIGHTING - EXTERIOR 8L - 5

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 561 of 2627

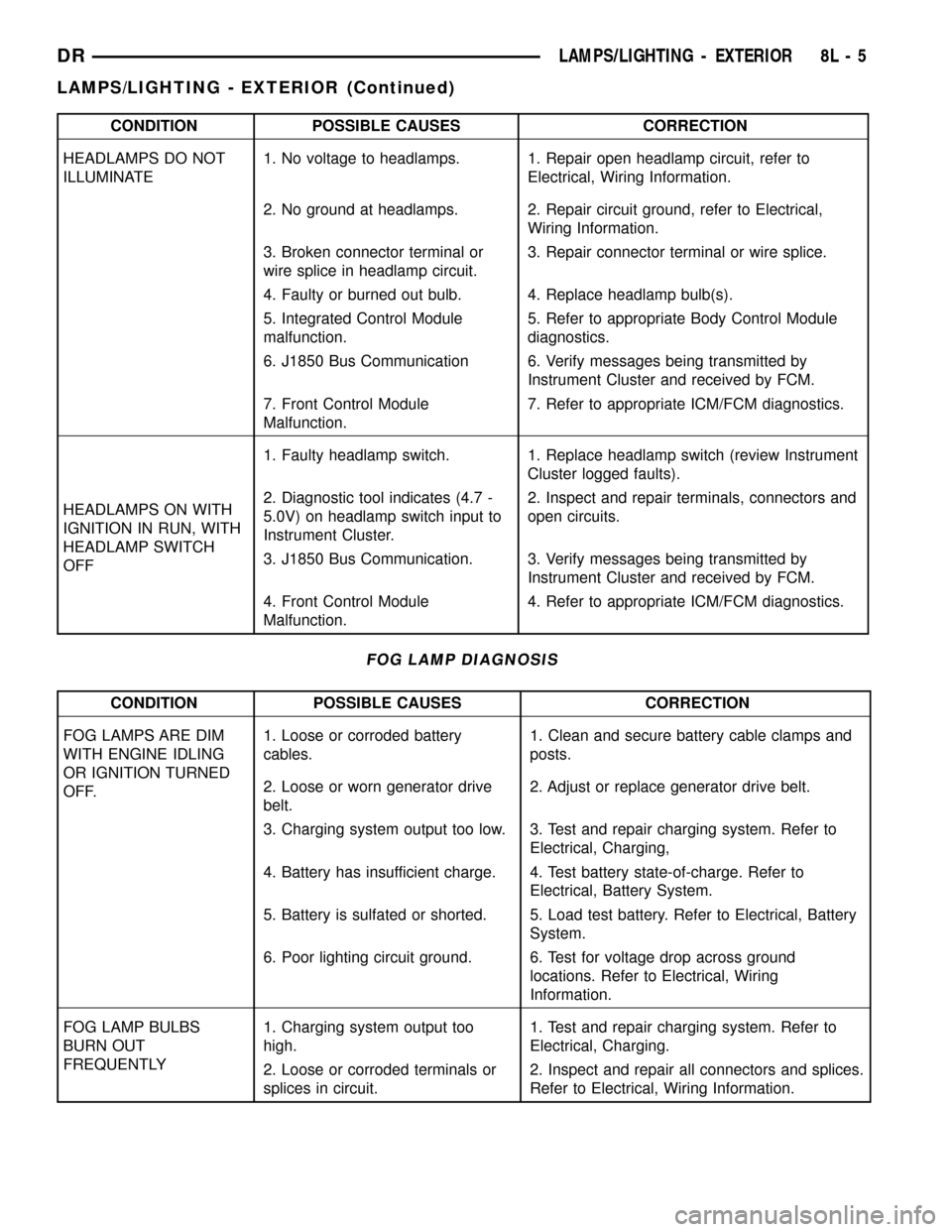

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM

WITH ENGINE

RUNNING ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Poor lighting circuit ground. 2. Test for voltage drop across ground

locations. Refer to Electrical, Wiring

Information.

3. High resistance in fog lamp

circuit.3. Test amperage draw of fog lamp circuit.

FOG LAMPS FLASH

RANDOMLY1. Poor lighting circuit ground. 1. Test for voltage drop across ground

locations. Refer to Electrical, Wiring

Information.

2. Variable resistance in fog lamp

circuit.2. Test amperage draw of fog lamp circuit.

3. Faulty fog lamp switch (part of

headlamp switch).3. Replace headlamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and splices.

Refer to Electrical, Wiring Information.

5. Is relay engaging properly? 5. Verify function of fog lamp relay in IPM.

6. J1850 Bus Communication. 6. Verify J1850 message (fog lamp info)

transmitted from Instrument Cluster and

received by FCM.

FOG LAMPS DO NOT

ILLUMINATE1. Blown fuse for fog lamp. 1. Replace fuse. Refer to Electrical, Wiring

Information.

2. No ground at fog lamps. 2. Repair circuit ground. Refer to Electrical,

Wiring Information.

3. Faulty fog lamp switch (part of

headlamp switch).3. Replace headlamp switch.

4. Broken connector terminal or

wire splice in fog lamp circuit.4. Repair connector terminal or wire splice.

5. Faulty or burned out bulb. 5. Replace bulb.

6. Is relay engaging? 6. Verify function of fog lamp relay in IPM.

7. J1850 Bus Communication. 7. Verify J1850 message (fog lamp info)

transmitted from Instrument Cluster and

received by FCM.

DAYTIME RUNNING LAMP (CANADA ONLY) DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

DAYTIME RUNNING

LAMPS DO NOT

OPERATE1. Parking brake engaged. 1. Disengage parking brake.

2. Parking brake circuit shorted

to ground.2. Check cluster telltale, refer to the appropriate

wiring information.

3. Headlamp circuit shorted to

ground.3. Refer to the appropriate wiring information.

4. FCM, Instrument Cluster not

programed with Canadian

country code.4. Check country code.

8L - 6 LAMPS/LIGHTING - EXTERIORDR

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 563 of 2627

(2) Install the lamp back plate onto the tail lamp

unit.

(3) Install the tail lamp unit (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - INSTALLATION).

(4) Reconnect the negative battery cable.

INSTALLATION - WITHOUT CARGO BOX

(1) Install the backup lamp bulb into the backup

lamp socket by pushing inward and rotating it clock-

wise.

NOTE: Install the tail lamp lens with the clear por-

tion (back-up lens) at the top of the housing. Make

sure that the gasket is correctly in place and not

twisted or torn.

(2) Position the tail lamp lens and gasket onto the

tail lamp unit.

NOTE: Do not overtighten the tail lamp lens screws

or damage to the tail lamp lens may result.

(3) Install the four screws that secure the tail

lamp lens to the tail lamp unit. Tighten the screws

securely.

(4) Reconnect the negative battery cable.

BACKUP LAMP SWITCH

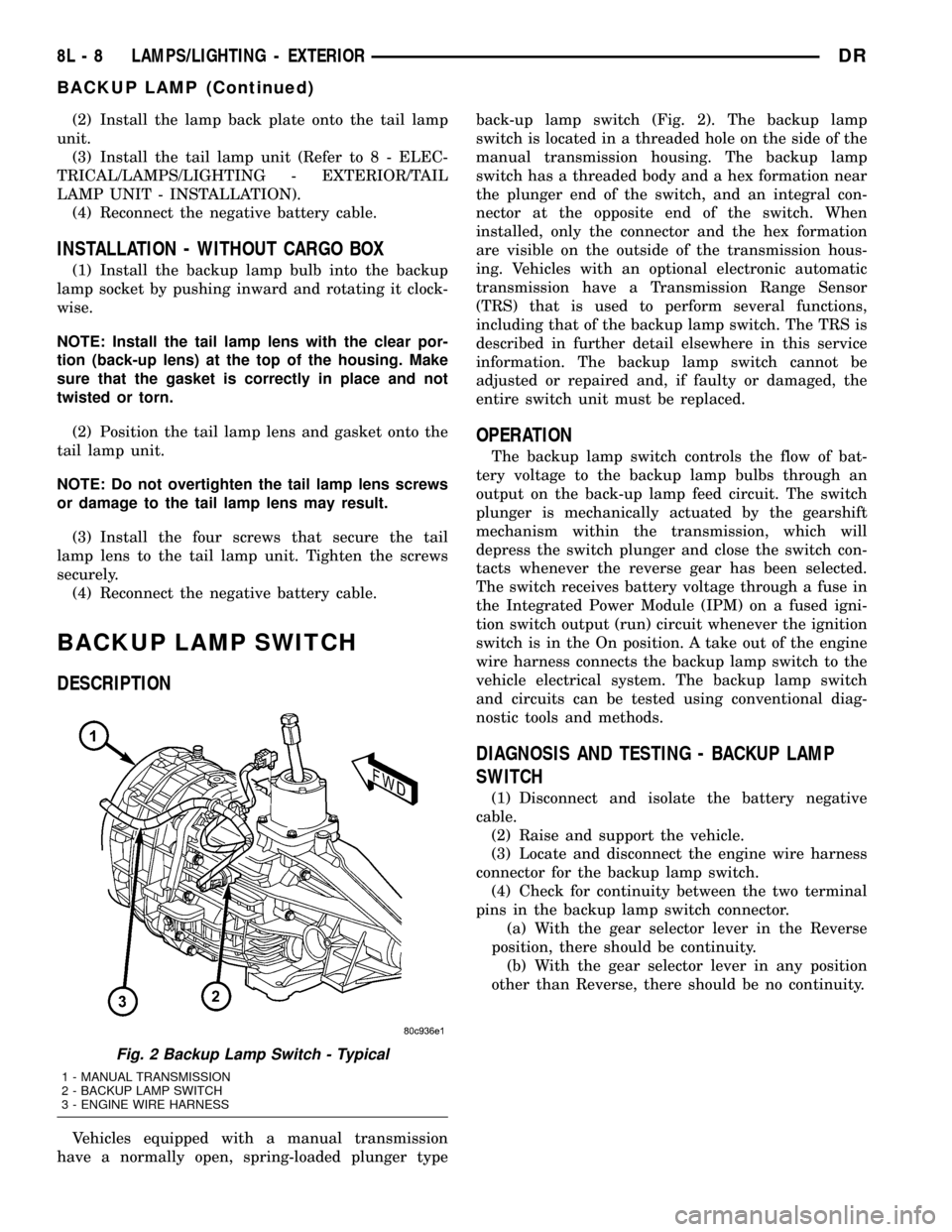

DESCRIPTION

Vehicles equipped with a manual transmission

have a normally open, spring-loaded plunger typeback-up lamp switch (Fig. 2). The backup lamp

switch is located in a threaded hole on the side of the

manual transmission housing. The backup lamp

switch has a threaded body and a hex formation near

the plunger end of the switch, and an integral con-

nector at the opposite end of the switch. When

installed, only the connector and the hex formation

are visible on the outside of the transmission hous-

ing. Vehicles with an optional electronic automatic

transmission have a Transmission Range Sensor

(TRS) that is used to perform several functions,

including that of the backup lamp switch. The TRS is

described in further detail elsewhere in this service

information. The backup lamp switch cannot be

adjusted or repaired and, if faulty or damaged, the

entire switch unit must be replaced.

OPERATION

The backup lamp switch controls the flow of bat-

tery voltage to the backup lamp bulbs through an

output on the back-up lamp feed circuit. The switch

plunger is mechanically actuated by the gearshift

mechanism within the transmission, which will

depress the switch plunger and close the switch con-

tacts whenever the reverse gear has been selected.

The switch receives battery voltage through a fuse in

the Integrated Power Module (IPM) on a fused igni-

tion switch output (run) circuit whenever the ignition

switch is in the On position. A take out of the engine

wire harness connects the backup lamp switch to the

vehicle electrical system. The backup lamp switch

and circuits can be tested using conventional diag-

nostic tools and methods.

DIAGNOSIS AND TESTING - BACKUP LAMP

SWITCH

(1) Disconnect and isolate the battery negative

cable.

(2) Raise and support the vehicle.

(3) Locate and disconnect the engine wire harness

connector for the backup lamp switch.

(4) Check for continuity between the two terminal

pins in the backup lamp switch connector.

(a) With the gear selector lever in the Reverse

position, there should be continuity.

(b) With the gear selector lever in any position

other than Reverse, there should be no continuity.

Fig. 2 Backup Lamp Switch - Typical

1 - MANUAL TRANSMISSION

2 - BACKUP LAMP SWITCH

3 - ENGINE WIRE HARNESS

8L - 8 LAMPS/LIGHTING - EXTERIORDR

BACKUP LAMP (Continued)