airbag off DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 629 of 2627

If the stored DTC information is successfully erased,

go to Step 9.

(9) Turn the ignition switch to the Off position for

about fifteen seconds, and then back to the On posi-

tion. Observe the airbag indicator in the instrument

cluster. It should illuminate for six to eight seconds,

and then go out. This indicates that the supplemen-

tal restraint system is functioning normally and that

the repairs are complete. If the airbag indicator fails

to light, or lights and stays on, there is still an active

supplemental restraint system fault or malfunction.

Refer to the appropriate diagnostic information to

diagnose the problem.

ACM COVER

REMOVAL

The Airbag Control Module (ACM) cover is used

only on models with an automatic transmission. Mod-

els with a manual transmission require that the floor

console be removed to access the ACM for service.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

REMOVAL).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

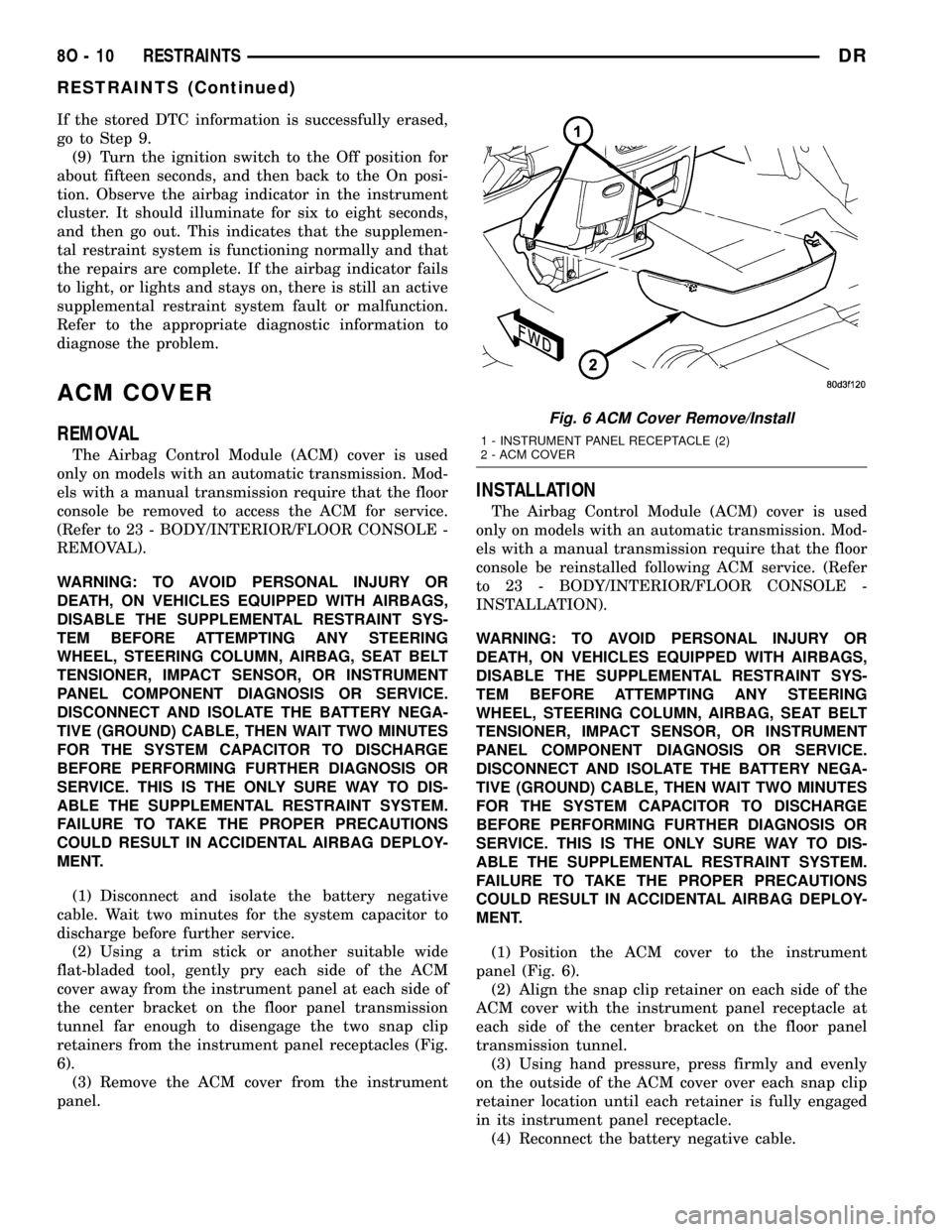

(2) Using a trim stick or another suitable wide

flat-bladed tool, gently pry each side of the ACM

cover away from the instrument panel at each side of

the center bracket on the floor panel transmission

tunnel far enough to disengage the two snap clip

retainers from the instrument panel receptacles (Fig.

6).

(3) Remove the ACM cover from the instrument

panel.

INSTALLATION

The Airbag Control Module (ACM) cover is used

only on models with an automatic transmission. Mod-

els with a manual transmission require that the floor

console be reinstalled following ACM service. (Refer

to 23 - BODY/INTERIOR/FLOOR CONSOLE -

INSTALLATION).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

(1) Position the ACM cover to the instrument

panel (Fig. 6).

(2) Align the snap clip retainer on each side of the

ACM cover with the instrument panel receptacle at

each side of the center bracket on the floor panel

transmission tunnel.

(3) Using hand pressure, press firmly and evenly

on the outside of the ACM cover over each snap clip

retainer location until each retainer is fully engaged

in its instrument panel receptacle.

(4) Reconnect the battery negative cable.

Fig. 6 ACM Cover Remove/Install

1 - INSTRUMENT PANEL RECEPTACLE (2)

2 - ACM COVER

8O - 10 RESTRAINTSDR

RESTRAINTS (Continued)

Page 630 of 2627

AIRBAG CONTROL MODULE

DESCRIPTION

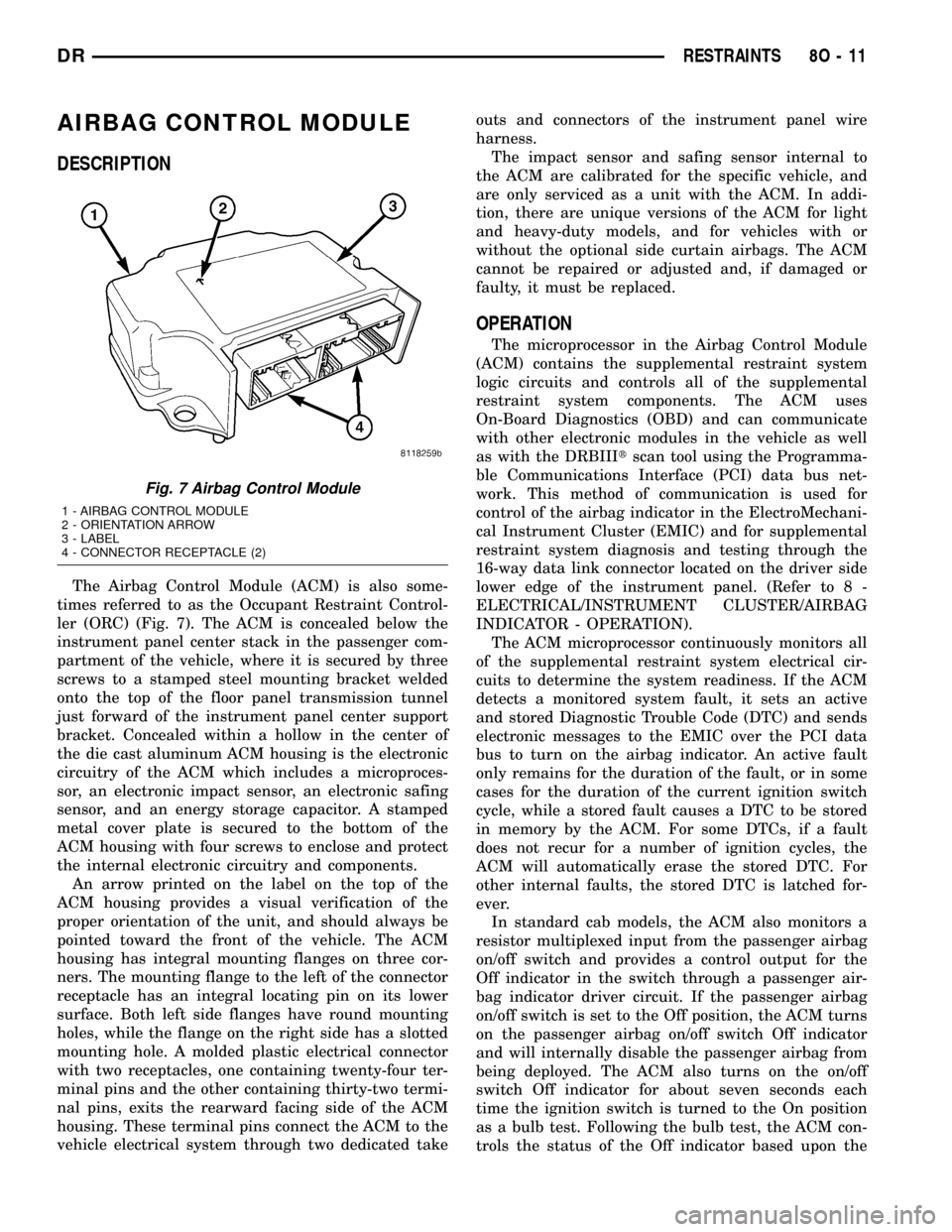

The Airbag Control Module (ACM) is also some-

times referred to as the Occupant Restraint Control-

ler (ORC) (Fig. 7). The ACM is concealed below the

instrument panel center stack in the passenger com-

partment of the vehicle, where it is secured by three

screws to a stamped steel mounting bracket welded

onto the top of the floor panel transmission tunnel

just forward of the instrument panel center support

bracket. Concealed within a hollow in the center of

the die cast aluminum ACM housing is the electronic

circuitry of the ACM which includes a microproces-

sor, an electronic impact sensor, an electronic safing

sensor, and an energy storage capacitor. A stamped

metal cover plate is secured to the bottom of the

ACM housing with four screws to enclose and protect

the internal electronic circuitry and components.

An arrow printed on the label on the top of the

ACM housing provides a visual verification of the

proper orientation of the unit, and should always be

pointed toward the front of the vehicle. The ACM

housing has integral mounting flanges on three cor-

ners. The mounting flange to the left of the connector

receptacle has an integral locating pin on its lower

surface. Both left side flanges have round mounting

holes, while the flange on the right side has a slotted

mounting hole. A molded plastic electrical connector

with two receptacles, one containing twenty-four ter-

minal pins and the other containing thirty-two termi-

nal pins, exits the rearward facing side of the ACM

housing. These terminal pins connect the ACM to the

vehicle electrical system through two dedicated takeouts and connectors of the instrument panel wire

harness.

The impact sensor and safing sensor internal to

the ACM are calibrated for the specific vehicle, and

are only serviced as a unit with the ACM. In addi-

tion, there are unique versions of the ACM for light

and heavy-duty models, and for vehicles with or

without the optional side curtain airbags. The ACM

cannot be repaired or adjusted and, if damaged or

faulty, it must be replaced.

OPERATION

The microprocessor in the Airbag Control Module

(ACM) contains the supplemental restraint system

logic circuits and controls all of the supplemental

restraint system components. The ACM uses

On-Board Diagnostics (OBD) and can communicate

with other electronic modules in the vehicle as well

as with the DRBIIItscan tool using the Programma-

ble Communications Interface (PCI) data bus net-

work. This method of communication is used for

control of the airbag indicator in the ElectroMechani-

cal Instrument Cluster (EMIC) and for supplemental

restraint system diagnosis and testing through the

16-way data link connector located on the driver side

lower edge of the instrument panel. (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER/AIRBAG

INDICATOR - OPERATION).

The ACM microprocessor continuously monitors all

of the supplemental restraint system electrical cir-

cuits to determine the system readiness. If the ACM

detects a monitored system fault, it sets an active

and stored Diagnostic Trouble Code (DTC) and sends

electronic messages to the EMIC over the PCI data

bus to turn on the airbag indicator. An active fault

only remains for the duration of the fault, or in some

cases for the duration of the current ignition switch

cycle, while a stored fault causes a DTC to be stored

in memory by the ACM. For some DTCs, if a fault

does not recur for a number of ignition cycles, the

ACM will automatically erase the stored DTC. For

other internal faults, the stored DTC is latched for-

ever.

In standard cab models, the ACM also monitors a

resistor multiplexed input from the passenger airbag

on/off switch and provides a control output for the

Off indicator in the switch through a passenger air-

bag indicator driver circuit. If the passenger airbag

on/off switch is set to the Off position, the ACM turns

on the passenger airbag on/off switch Off indicator

and will internally disable the passenger airbag from

being deployed. The ACM also turns on the on/off

switch Off indicator for about seven seconds each

time the ignition switch is turned to the On position

as a bulb test. Following the bulb test, the ACM con-

trols the status of the Off indicator based upon the

Fig. 7 Airbag Control Module

1 - AIRBAG CONTROL MODULE

2 - ORIENTATION ARROW

3 - LABEL

4 - CONNECTOR RECEPTACLE (2)

DRRESTRAINTS 8O - 11

Page 631 of 2627

resistance of the input from the on/off switch. The

ACM will also set and/or store a DTC for faults it

detects in the passenger airbag on/off switch circuits,

and will turn on the airbag indicator in the EMIC if

a fault has been detected.

The ACM receives battery current through two cir-

cuits; a fused ignition switch output (run) circuit

through a fuse in the Integrated Power Module

(IPM), and a fused ignition switch output (run-start)

circuit through a second fuse in the IPM. The ACM

receives ground through a ground circuit and take

out of the instrument panel wire harness. This take

out has a single eyelet terminal connector that is

secured by a ground screw to the instrument panel

support structure. These connections allow the ACM

to be operational whenever the ignition switch is in

the Start or On positions.

The ACM also contains an energy-storage capaci-

tor. When the ignition switch is in the Start or On

positions, this capacitor is continually being charged

with enough electrical energy to deploy the supple-

mental restraint components for up to one second fol-

lowing a battery disconnect or failure. The purpose of

the capacitor is to provide backup supplemental

restraint system protection in case there is a loss of

battery current supply to the ACM during an impact.

Two sensors are contained within the ACM, an

electronic impact sensor and a safing sensor. The

electronic impact sensors are accelerometers that

sense the rate of vehicle deceleration, which provide

verification of the direction and severity of an

impact. On models equipped with optional side cur-

tain airbags, the ACM also monitors inputs from two

remote side impact sensors located within both the

left and right B-pillars to control deployment of the

side curtain airbag units.

The safing sensor is an electronic accelerometer

sensor within the ACM that provides an additional

logic input to the ACM microprocessor. The safing

sensor is used to verify the need for a supplemental

restraint deployment by detecting impact energy of a

lesser magnitude than that of the primary electronic

impact sensors, and must exceed a safing threshold

in order for the airbags to deploy. Vehicles equipped

with optional side curtain airbags feature a second

safing sensor within the ACM to provide confirma-

tion to the ACM microprocessor of side impact forces.

This second safing sensor is a bi-directional unit that

detects impact forces from either side of the vehicle.

Pre-programmed decision algorithms in the ACM

microprocessor determine when the deceleration rate

as signaled by the impact sensors and the safing sen-

sors indicate an impact that is severe enough to

require supplemental restraint system protection

and, based upon the severity of the monitored impact

and the status of the passenger airbag on/off switchinput, determines the level of front airbag deploy-

ment force required for each front seating position.

When the programmed conditions are met, the ACM

sends the proper electrical signals to deploy the dual

multistage front airbags at the programmed force

levels, the front seat belt tensioners and, if the vehi-

cle is so equipped, either side curtain airbag unit.

The hard wired inputs and outputs for the ACM

may be diagnosed and tested using conventional

diagnostic tools and procedures. However, conven-

tional diagnostic methods will not prove conclusive in

the diagnosis of the ACM, the PCI data bus network,

or the electronic message inputs to and outputs from

the ACM. The most reliable, efficient, and accurate

means to diagnose the ACM, the PCI data bus net-

work, and the electronic message inputs to and out-

puts from the ACM requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation.

REMOVAL

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, NEVER STRIKE OR DROP THE AIRBAG

CONTROL MODULE, AS IT CAN DAMAGE THE

IMPACT SENSOR OR AFFECT ITS CALIBRATION.

THE AIRBAG CONTROL MODULE CONTAINS THE

IMPACT SENSOR, WHICH ENABLES THE SYSTEM

TO DEPLOY THE SUPPLEMENTAL RESTRAINTS. IF

AN AIRBAG CONTROL MODULE IS ACCIDENTALLY

DROPPED DURING SERVICE, THE MODULE MUST

BE SCRAPPED AND REPLACED WITH A NEW UNIT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN ACCIDENTAL, INCOMPLETE, OR

IMPROPER SUPPLEMENTAL RESTRAINT DEPLOY-

MENT.

8O - 12 RESTRAINTSDR

AIRBAG CONTROL MODULE (Continued)

Page 661 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, THE PASSENGER AIRBAG DOOR MUST

NEVER BE PAINTED. REPLACEMENT PASSENGER

AIRBAG UNITS ARE SERVICED WITH DOORS IN

THE ORIGINAL COLORS. PAINT MAY CHANGE THE

WAY IN WHICH THE MATERIAL OF THE AIRBAG

DOOR RESPONDS TO AN AIRBAG DEPLOYMENT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN OCCUPANT INJURIES UPON AIRBAG

DEPLOYMENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE PAS-

SENGER AIRBAG, OR BECOMING ENTRAPPED

BETWEEN THE PASSENGER AIRBAG CUSHION

AND THE PASSENGER AIRBAG DOOR. FAILURE TO

OBSERVE THIS WARNING COULD RESULT IN

OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

(1) Carefully position the passenger airbag and

airbag door to the instrument panel as a unit.

(2) Reconnect the passenger airbag pigtail wire

connector to the instrument panel wire harness con-

nector for the airbag. This connector is secured to the

inboard side of the airbag housing.Be certain that

the latch on the connector and the red Connec-

tor Position Assurance (CPA) lock are each

fully engaged.

(3) Position the passenger airbag housing and door

unit into the instrument panel.

(4) Using hand pressure, press firmly and evenly

over each of the seven snap features on the upper

and outboard edges of the passenger airbag door

until they snap into their receptacles in the instru-

ment panel base trim.

(5) Reach through and above the glove box opening

to install and tighten the two screws that secure the

passenger airbag front brackets to the instrument

panel structural support (Fig. 37). Tighten the screws

to 6 N´m (55 in. lbs.).

(6) Reach through and above the glove box opening

to install and tighten the two screws that secure the

passenger airbag rear brackets to the upper glove

box opening reinforcement. Tighten the screws to 6

N´m (55 in. lbs.).

(7) Install and tighten the six screws that secure

the inboard and lower flanges of the passenger air-

bag door to the instrument panel (Fig. 36). Tighten

the screws to 2 N´m (20 in. lbs.).

(8) Install and tighten the screw that secures the

mounting tab of the panel outlet housing to the

upper glove box opening reinforcement. Tighten the

screw to 2 N´m (20 in. lbs.).(9) Reinstall the lower surround onto the instru-

ment panel. (Refer to 23 - BODY/INSTRUMENT

PANEL/LOWER SURROUND - INSTALLATION).

(10) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

PASSENGER AIRBAG ON/OFF

SWITCH

DESCRIPTION

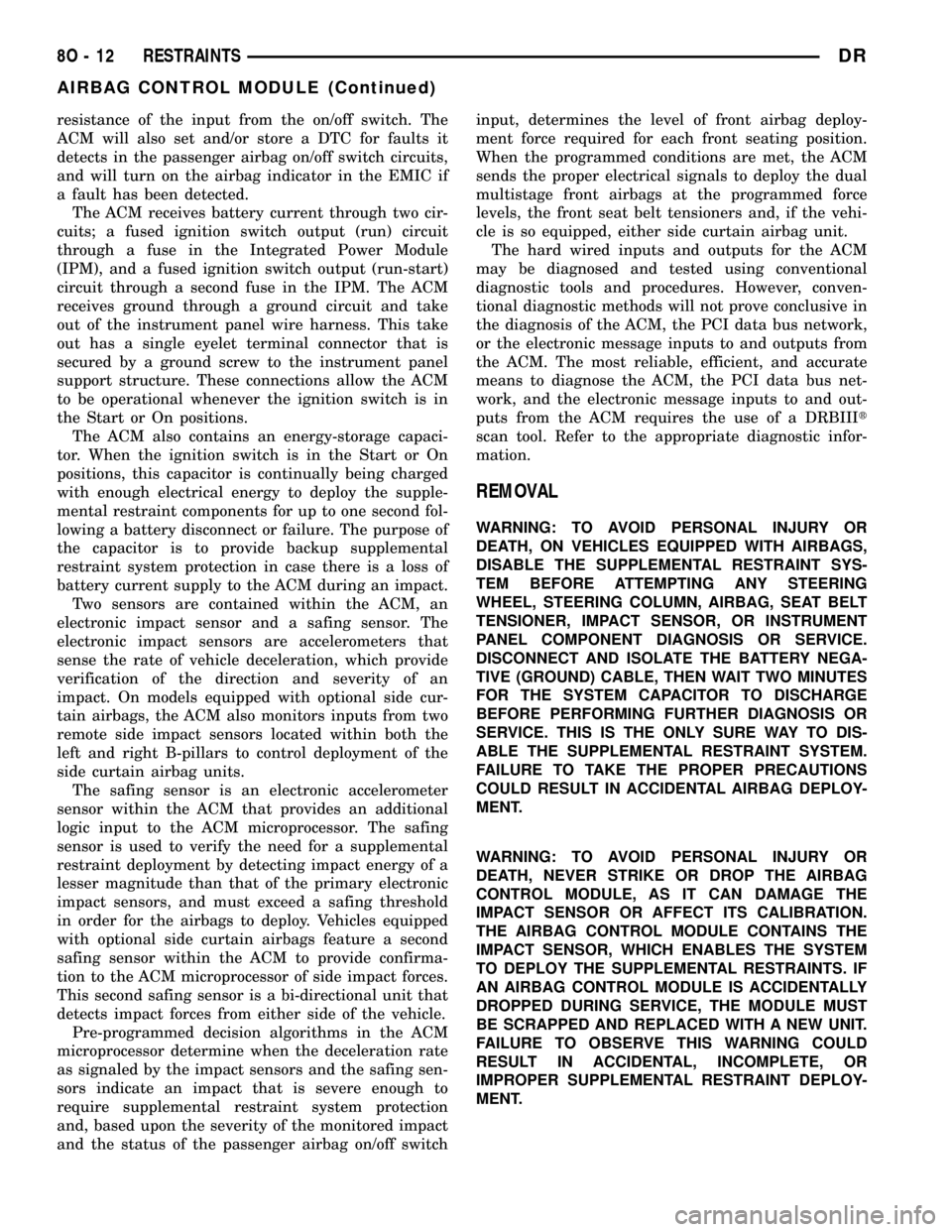

The passenger airbag on/off switch is standard

equipment on all standard cab versions of this model

when they are equipped with the dual front airbag

system (Fig. 39). This switch is a two-position, resis-

tor multiplexed switch with a single integral red

Light-Emitting Diode (LED), and a non-coded key

cylinder-type actuator. The switch is located in the

lower right corner of instrument panel center bezel,

near the center of instrument panel to make the Off

indicator visible to all front seat occupants. When the

switch is in its installed position, the only compo-

nents visible through the dedicated opening of the

cluster bezel are the switch face plate and nomencla-

ture, and the key cylinder actuator. The9Off9position

of the switch is illuminated when this switch position

is selected, while the ªOnº position of the switch is

designated by text imprinted upon the face plate of

the switch, but is not illuminated. The remainder of

the switch is concealed behind the switch face plate

and the instrument panel center bezel.

Fig. 39 Passenger Airbag On/Off Switch

1 - SWITCH

2 - FACE PLATE

3 - OFF INDICATOR

4 - KEY CYLINDER ACTUATOR

8O - 42 RESTRAINTSDR

PASSENGER AIRBAG (Continued)

Page 662 of 2627

The passenger airbag on/off switch housing is con-

structed of molded plastic and has three integral

mounting tabs. These mounting tabs are used to

secure the switch to the back of the molded plastic

switch face plate with three small screws. The

molded plastic face plate also has three integral

mounting tabs that are used to secure the switch and

face plate unit to the instrument panel center bezel

with three additional screws. A molded plastic con-

nector receptacle on the back of the switch housing

connects the switch to the vehicle electrical system

through a dedicated take out and connector of the

instrument panel wire harness. The molded plastic

harness connector insulator is keyed and latched to

ensure proper and secure switch electrical connec-

tions. The passenger airbag on/off switch cannot be

adjusted or repaired and, if faulty or damaged, the

switch must be replaced.

OPERATION

The passenger airbag on/off switch allows the cus-

tomer to turn the passenger airbag function On or

Off to accommodate certain uses of the right front

seating position where airbag protection may not be

desired. See the owner's manual in the vehicle glove

box for specific recommendations on when to enable

or disable the passenger airbag. The Off indicator of

the switch will be illuminated whenever the switch is

turned to the Off position and the ignition switch is

in the On position.

The ignition key is the only key or object that

should ever be inserted into the key cylinder actuator

of the switch. The on/off switch requires only a par-

tial key insertion to fully depress a spring-loaded

locking plunger. The spring-loaded locking plunger

prevents the user from leaving the key in the switch.

The key will be automatically ejected when force is

not applied. To actuate the passenger airbag on/off

switch, insert the ignition key into the switch key

actuator far enough to fully depress the plunger, then

rotate the actuator to the desired switch position.

When the switch key actuator is rotated to its clock-

wise stop (the key actuator slot will be aligned with

the Off indicator), the Off indicator is illuminated

and the passenger airbag is disabled. When the

switch is rotated to its counterclockwise stop (the key

actuator slot will be in a vertical position), the Off

indicator will be extinguished and the passenger air-

bag is enabled.The passenger airbag on/off switch connects one of

two internal resistors in series between the passen-

ger airbag mux switch sense and passenger airbag

mux switch return circuits of the Airbag Control

Module (ACM). The ACM continually monitors the

resistance in these circuits to determine the switch

position that has been selected. When the switch is

in the Off position, the ACM provides a ground input

to the switch through the passenger airbag indicator

driver circuit, which energizes the Light-Emitting

Diode (LED) that illuminates the Off indicator of the

switch.

The ACM will also illuminate the Off indicator of

the switch for about seven seconds each time the

ignition switch is turned to the On position as a bulb

test. The ACM will store a Diagnostic Trouble Code

(DTC) for any fault it detects in the passenger airbag

on/off switch or Off indicator circuits, and will illumi-

nate the airbag indicator in the instrument cluster if

a fault is detected. For proper diagnosis of the pas-

senger airbag on/off switch or the ACM, a DRBIIIt

scan tool is required. Refer to the appropriate diag-

nostic information.

REMOVAL

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) Remove the center bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL).

(3) From the back of the center bezel, remove the

three screws that secure the passenger airbag on/off

switch and face plate unit to the back of the bezel

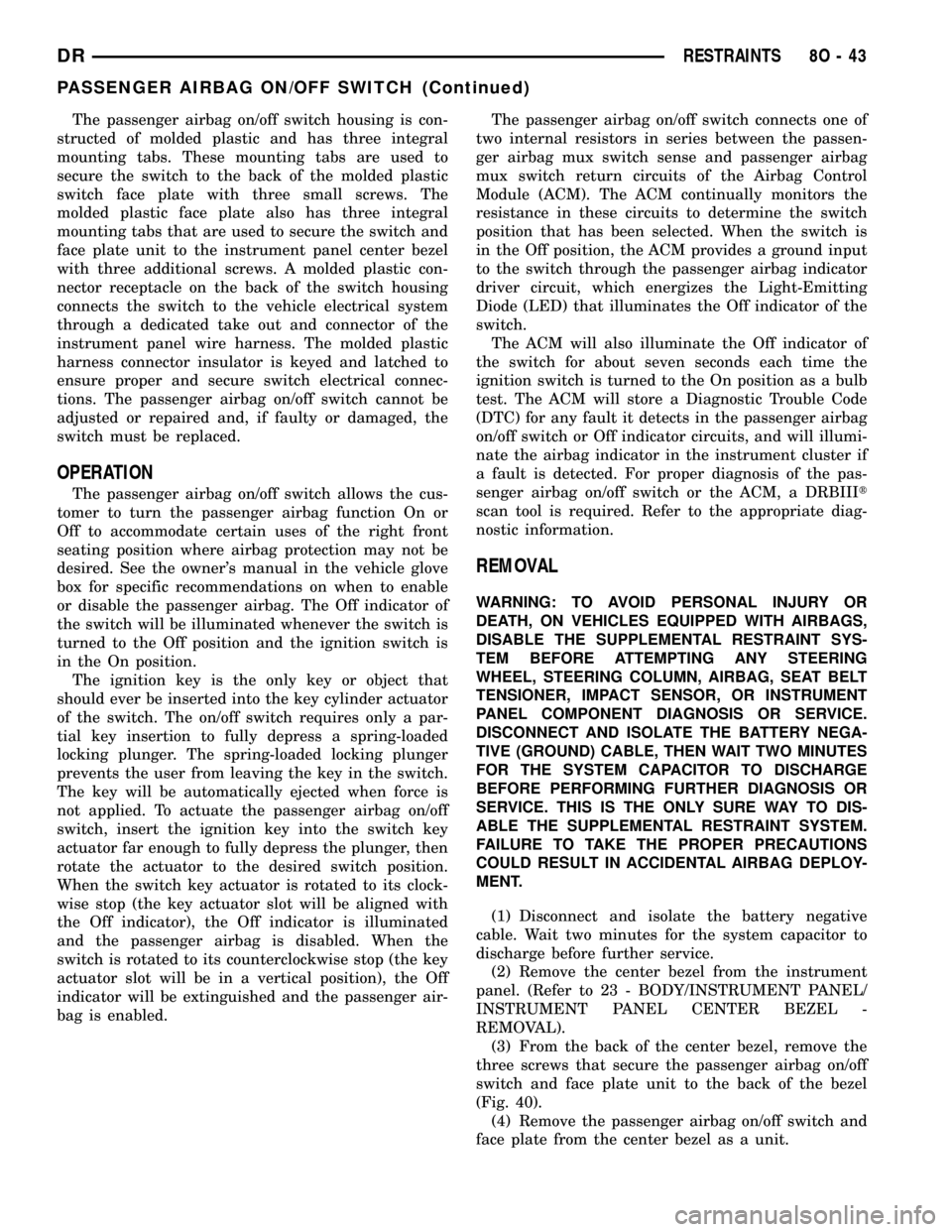

(Fig. 40).

(4) Remove the passenger airbag on/off switch and

face plate from the center bezel as a unit.

DRRESTRAINTS 8O - 43

PASSENGER AIRBAG ON/OFF SWITCH (Continued)

Page 663 of 2627

INSTALLATION

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

(1) Position the passenger airbag on/off switch and

face plate unit to the back of the center bezel (Fig.

40).

(2) Install and tighten the three screws that secure

the passenger airbag on/off switch face plate to the

back of the center bezel. Tighten the screws to 2 N´m

(17 in. lbs.).

(3) Reinstall the center bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(4) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

REAR CENTER SEAT BELT &

RETRACTOR

REMOVAL

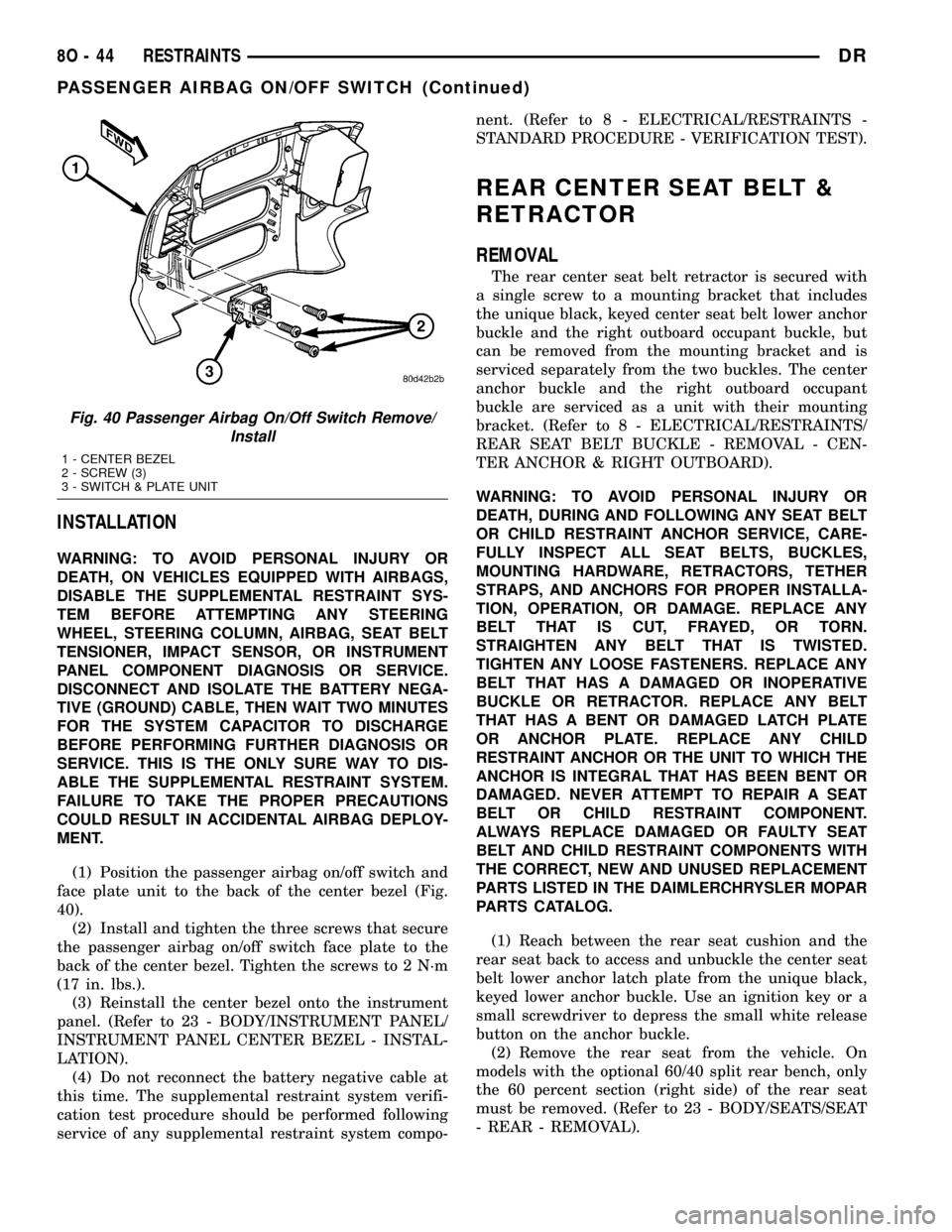

The rear center seat belt retractor is secured with

a single screw to a mounting bracket that includes

the unique black, keyed center seat belt lower anchor

buckle and the right outboard occupant buckle, but

can be removed from the mounting bracket and is

serviced separately from the two buckles. The center

anchor buckle and the right outboard occupant

buckle are serviced as a unit with their mounting

bracket. (Refer to 8 - ELECTRICAL/RESTRAINTS/

REAR SEAT BELT BUCKLE - REMOVAL - CEN-

TER ANCHOR & RIGHT OUTBOARD).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Reach between the rear seat cushion and the

rear seat back to access and unbuckle the center seat

belt lower anchor latch plate from the unique black,

keyed lower anchor buckle. Use an ignition key or a

small screwdriver to depress the small white release

button on the anchor buckle.

(2) Remove the rear seat from the vehicle. On

models with the optional 60/40 split rear bench, only

the 60 percent section (right side) of the rear seat

must be removed. (Refer to 23 - BODY/SEATS/SEAT

- REAR - REMOVAL).

Fig. 40 Passenger Airbag On/Off Switch Remove/

Install

1 - CENTER BEZEL

2 - SCREW (3)

3 - SWITCH & PLATE UNIT

8O - 44 RESTRAINTSDR

PASSENGER AIRBAG ON/OFF SWITCH (Continued)

Page 703 of 2627

interval at which to de-energize the wiper on/off

relay to complete the wipe-after-wash mode cycle.

DIAGNOSIS AND TESTING - WIPER &

WASHER SYSTEM

If the wiper motor operates, but the wipers do not

move on the windshield, replace the faulty wiper

module. If the washer pump/motor operates, but no

washer fluid is dispensed on the glass; or, if the wip-

ers operate, but chatter, lift, or do not clear the glass,

clean and inspect the wiper and washer system com-

ponents as required. (Refer to 8 - ELECTRICAL/

WIPERS/WASHERS - CLEANING) and (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS - INSPECTION).

For diagnosis and testing of the multi-function

switch (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/MULTI-FUNCTION SWITCH -

DIAGNOSIS AND TESTING). Refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

The hard wired circuits and components of the

wiper and washer system may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the

instrument cluster, the Front Control Module (FCM),

or the electronic message inputs to or outputs from

the instrument cluster and the FCM that control the

various wiper and washer system operating modes.

The most reliable, efficient, and accurate means to

diagnose the instrument cluster, the FCM, or the

electronic message inputs and outputs related to the

various wiper and washer system operating modes

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

CLEANING - WIPER & WASHER SYSTEM

WIPER SYSTEM

The squeegees of wiper blades exposed to the ele-

ments for a long time tend to lose their wiping effec-

tiveness. Periodic cleaning of the squeegees is

suggested to remove any deposits of salt or road film.

The wiper blades, arms, and windshield glass should

only be cleaned using a sponge or soft cloth and

windshield washer fluid, a mild detergent, or a non-

abrasive cleaner. If the wiper blades continue to

leave streaks, smears, hazing, or beading on the

glass after thorough cleaning of the squeegees and

the glass, the entire wiper blade assembly must be

replaced.

CAUTION: Protect the rubber squeegees of the

wiper blades from any petroleum-based cleaners,

solvents, or contaminants. These products can rap-

idly deteriorate the rubber squeegees.

WASHER SYSTEM

If the washer system is contaminated with foreign

material, drain the washer reservoir by removing the

washer pump/motor from the reservoir. Clean foreign

material from the inside of the washer pump/motor

inlet filter screen and the washer reservoir using

clean washer fluid, a mild detergent, or a non-abra-

sive cleaner. Flush foreign material from the washer

system plumbing by first disconnecting the washer

hoses from the washer nozzles, then running the

washer pump/motor to run clean washer fluid or

water through the system. Plugged or restricted

washer nozzles should be carefully back-flushed

using compressed air. If the washer nozzle obstruc-

tion cannot be cleared, replace the washer nozzle.

CAUTION: Never introduce petroleum-based clean-

ers, solvents, or contaminants into the washer sys-

tem. These products can rapidly deteriorate the

rubber seals and hoses of the washer system, as

well as the rubber squeegees of the wiper blades.

CAUTION: Never use compressed air to flush the

washer system plumbing. Compressed air pres-

sures are too great for the washer system plumbing

components and will result in further system dam-

age. Never use sharp instruments to clear a

plugged washer nozzle or damage to the nozzle ori-

fice and improper nozzle spray patterns will result.

8R - 6 WIPERS/WASHERSDR

WIPERS/WASHERS (Continued)

Page 744 of 2627

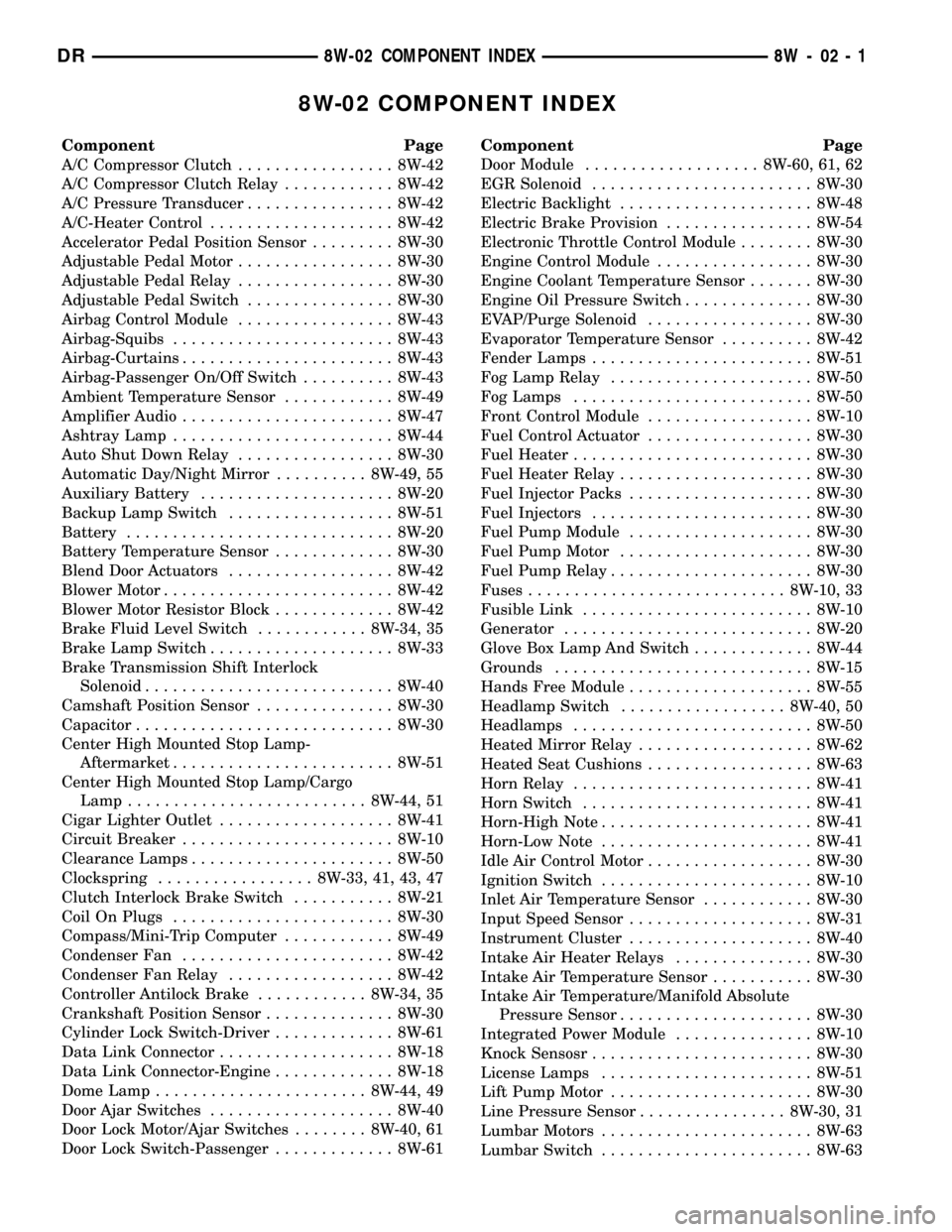

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch................. 8W-42

A/C Compressor Clutch Relay............ 8W-42

A/C Pressure Transducer................ 8W-42

A/C-Heater Control.................... 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Adjustable Pedal Motor................. 8W-30

Adjustable Pedal Relay................. 8W-30

Adjustable Pedal Switch................ 8W-30

Airbag Control Module................. 8W-43

Airbag-Squibs........................ 8W-43

Airbag-Curtains....................... 8W-43

Airbag-Passenger On/Off Switch.......... 8W-43

Ambient Temperature Sensor............ 8W-49

Amplifier Audio....................... 8W-47

Ashtray Lamp........................ 8W-44

Auto Shut Down Relay................. 8W-30

Automatic Day/Night Mirror.......... 8W-49, 55

Auxiliary Battery..................... 8W-20

Backup Lamp Switch.................. 8W-51

Battery............................. 8W-20

Battery Temperature Sensor............. 8W-30

Blend Door Actuators.................. 8W-42

Blower Motor......................... 8W-42

Blower Motor Resistor Block............. 8W-42

Brake Fluid Level Switch............ 8W-34, 35

Brake Lamp Switch.................... 8W-33

Brake Transmission Shift Interlock

Solenoid........................... 8W-40

Camshaft Position Sensor............... 8W-30

Capacitor............................ 8W-30

Center High Mounted Stop Lamp-

Aftermarket........................ 8W-51

Center High Mounted Stop Lamp/Cargo

Lamp.......................... 8W-44, 51

Cigar Lighter Outlet................... 8W-41

Circuit Breaker....................... 8W-10

Clearance Lamps...................... 8W-50

Clockspring................. 8W-33, 41, 43, 47

Clutch Interlock Brake Switch........... 8W-21

Coil On Plugs........................ 8W-30

Compass/Mini-Trip Computer............ 8W-49

Condenser Fan....................... 8W-42

Condenser Fan Relay.................. 8W-42

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cylinder Lock Switch-Driver............. 8W-61

Data Link Connector................... 8W-18

Data Link Connector-Engine............. 8W-18

Dome Lamp....................... 8W-44, 49

Door Ajar Switches.................... 8W-40

Door Lock Motor/Ajar Switches........ 8W-40, 61

Door Lock Switch-Passenger............. 8W-61Component Page

Door Module................... 8W-60, 61, 62

EGR Solenoid........................ 8W-30

Electric Backlight..................... 8W-48

Electric Brake Provision................ 8W-54

Electronic Throttle Control Module........ 8W-30

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Switch.............. 8W-30

EVAP/Purge Solenoid.................. 8W-30

Evaporator Temperature Sensor.......... 8W-42

Fender Lamps........................ 8W-51

Fog Lamp Relay...................... 8W-50

Fog Lamps.......................... 8W-50

Front Control Module.................. 8W-10

Fuel Control Actuator.................. 8W-30

Fuel Heater.......................... 8W-30

Fuel Heater Relay..................... 8W-30

Fuel Injector Packs.................... 8W-30

Fuel Injectors........................ 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Motor..................... 8W-30

Fuel Pump Relay...................... 8W-30

Fuses............................ 8W-10, 33

Fusible Link......................... 8W-10

Generator........................... 8W-20

Glove Box Lamp And Switch............. 8W-44

Grounds............................ 8W-15

Hands Free Module.................... 8W-55

Headlamp Switch.................. 8W-40, 50

Headlamps.......................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Seat Cushions.................. 8W-63

Horn Relay.......................... 8W-41

Horn Switch......................... 8W-41

Horn-High Note....................... 8W-41

Horn-Low Note....................... 8W-41

Idle Air Control Motor.................. 8W-30

Ignition Switch....................... 8W-10

Inlet Air Temperature Sensor............ 8W-30

Input Speed Sensor.................... 8W-31

Instrument Cluster.................... 8W-40

Intake Air Heater Relays............... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intake Air Temperature/Manifold Absolute

Pressure Sensor..................... 8W-30

Integrated Power Module............... 8W-10

Knock Sensosr........................ 8W-30

License Lamps....................... 8W-51

Lift Pump Motor...................... 8W-30

Line Pressure Sensor................ 8W-30, 31

Lumbar Motors....................... 8W-63

Lumbar Switch....................... 8W-63

DR8W-02 COMPONENT INDEX 8W - 02 - 1

Page 746 of 2627

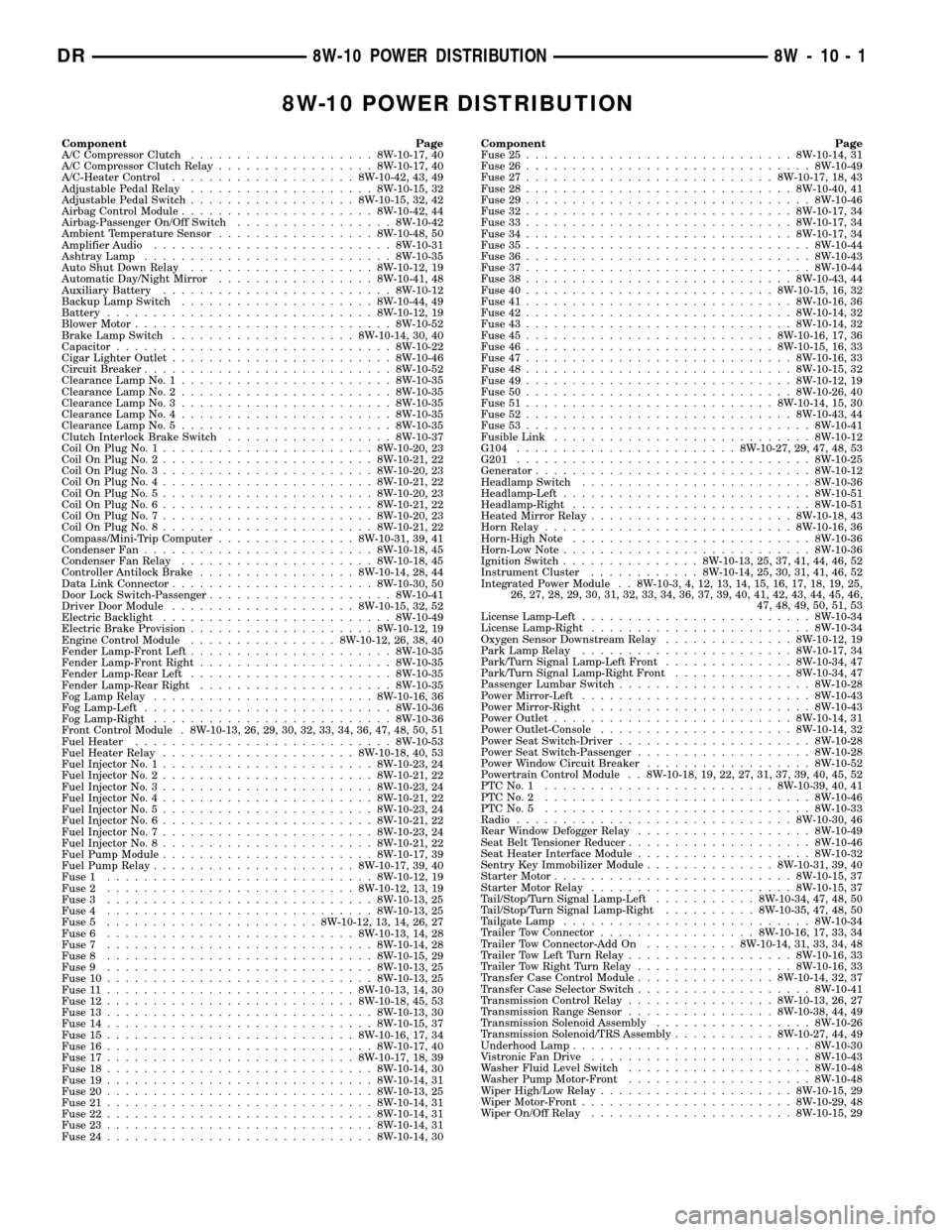

8W-10 POWER DISTRIBUTION

Component Page

A/C Compressor Clutch....................8W-10-17, 40

A/C Compressor Clutch Relay.................8W-10-17, 40

A/C-Heater Control....................8W-10-42, 43, 49

Adjustable Pedal Relay....................8W-10-15, 32

Adjustable Pedal Switch..................8W-10-15, 32, 42

Airbag Control Module.....................8W-10-42, 44

Airbag-Passenger On/Off Switch.................8W-10-42

Ambient Temperature Sensor.................8W-10-48, 50

Amplifier Audio..........................8W-10-31

Ashtray Lamp...........................8W-10-35

Auto Shut Down Relay....................8W-10-12, 19

Automatic Day/Night Mirror.................8W-10-41, 48

Auxiliary Battery.........................8W-10-12

Backup Lamp Switch.....................8W-10-44, 49

Battery.............................8W-10-12, 19

Blower Motor............................8W-10-52

Brake Lamp Switch....................8W-10-14, 30, 40

Capacitor..............................8W-10-22

Cigar Lighter Outlet........................8W-10-46

Circuit Breaker...........................8W-10-52

Clearance Lamp No. 1.......................8W-10-35

Clearance Lamp No. 2.......................8W-10-35

Clearance Lamp No. 3.......................8W-10-35

Clearance Lamp No. 4.......................8W-10-35

Clearance Lamp No. 5.......................8W-10-35

Clutch Interlock Brake Switch..................8W-10-37

Coil On Plug No. 1.......................8W-10-20, 23

Coil On Plug No. 2.......................8W-10-21, 22

Coil On Plug No. 3.......................8W-10-20, 23

Coil On Plug No. 4.......................8W-10-21, 22

Coil On Plug No. 5.......................8W-10-20, 23

Coil On Plug No. 6.......................8W-10-21, 22

Coil On Plug No. 7.......................8W-10-20, 23

Coil On Plug No. 8.......................8W-10-21, 22

Compass/Mini-Trip Computer...............8W-10-31, 39, 41

Condenser Fan.........................8W-10-18, 45

Condenser Fan Relay.....................8W-10-18, 45

Controller Antilock Brake.................8W-10-14, 28, 44

Data Link Connector......................8W-10-30, 50

Door Lock Switch-Passenger....................8W-10-41

Driver Door Module....................8W-10-15, 32, 52

Electric Backlight.........................8W-10-49

Electric Brake Provision....................8W-10-12, 19

Engine Control Module................8W-10-12, 26, 38, 40

Fender Lamp-Front Left......................8W-10-35

Fender Lamp-Front Right.....................8W-10-35

Fender Lamp-Rear Left......................8W-10-35

Fender Lamp-Rear Right.....................8W-10-35

Fog Lamp Relay........................8W-10-16, 36

Fog Lamp-Left...........................8W-10-36

Fog Lamp-Right..........................8W-10-36

Front Control Module . 8W-10-13, 26, 29, 30, 32, 33, 34, 36, 47, 48, 50, 51

Fuel Heater............................8W-10-53

Fuel Heater Relay.....................8W-10-18, 40, 53

Fuel Injector No. 1.......................8W-10-23, 24

Fuel Injector No. 2.......................8W-10-21, 22

Fuel Injector No. 3.......................8W-10-23, 24

Fuel Injector No. 4.......................8W-10-21, 22

Fuel Injector No. 5.......................8W-10-23, 24

Fuel Injector No. 6.......................8W-10-21, 22

Fuel Injector No. 7.......................8W-10-23, 24

Fuel Injector No. 8.......................8W-10-21, 22

Fuel Pump Module.......................8W-10-17, 39

Fuel Pump Relay......................8W-10-17, 39, 40

Fuse 1.............................8W-10-12, 19

Fuse 2...........................8W-10-12, 13, 19

Fuse 3.............................8W-10-13, 25

Fuse 4.............................8W-10-13, 25

Fuse 5.......................8W-10-12, 13, 14, 26, 27

Fuse 6...........................8W-10-13, 14, 28

Fuse 7.............................8W-10-14, 28

Fuse 8.............................8W-10-15, 29

Fuse 9.............................8W-10-13, 25

Fuse 10.............................8W-10-13, 25

Fuse 11...........................8W-10-13, 14, 30

Fuse 12...........................8W-10-18, 45, 53

Fuse 13.............................8W-10-13, 30

Fuse 14.............................8W-10-15, 37

Fuse 15...........................8W-10-16, 17, 34

Fuse 16.............................8W-10-17, 40

Fuse 17...........................8W-10-17, 18, 39

Fuse 18.............................8W-10-14, 30

Fuse 19.............................8W-10-14, 31

Fuse 20.............................8W-10-13, 25

Fuse 21.............................8W-10-14, 31

Fuse 22.............................8W-10-14, 31

Fuse 23.............................8W-10-14, 31

Fuse 24.............................8W-10-14, 30Component Page

Fuse 25.............................8W-10-14, 31

Fuse 26...............................8W-10-49

Fuse 27...........................8W-10-17, 18, 43

Fuse 28.............................8W-10-40, 41

Fuse 29...............................8W-10-46

Fuse 32.............................8W-10-17, 34

Fuse 33.............................8W-10-17, 34

Fuse 34.............................8W-10-17, 34

Fuse 35...............................8W-10-44

Fuse 36...............................8W-10-43

Fuse 37...............................8W-10-44

Fuse 38.............................8W-10-43, 44

Fuse 40...........................8W-10-15, 16, 32

Fuse 41.............................8W-10-16, 36

Fuse 42.............................8W-10-14, 32

Fuse 43.............................8W-10-14, 32

Fuse 45...........................8W-10-16, 17, 36

Fuse 46...........................8W-10-15, 16, 33

Fuse 47.............................8W-10-16, 33

Fuse 48.............................8W-10-15, 32

Fuse 49.............................8W-10-12, 19

Fuse 50.............................8W-10-26, 40

Fuse 51...........................8W-10-14, 15, 30

Fuse 52.............................8W-10-43, 44

Fuse 53...............................8W-10-41

Fusible Link............................8W-10-12

G104........................8W-10-27, 29, 47, 48, 53

G201................................8W-10-25

Generator..............................8W-10-12

Headlamp Switch.........................8W-10-36

Headlamp-Left...........................8W-10-51

Headlamp-Right..........................8W-10-51

Heated Mirror Relay......................8W-10-18, 43

Horn Relay...........................8W-10-16, 36

Horn-High Note..........................8W-10-36

Horn-Low Note...........................8W-10-36

Ignition Switch...............8W-10-13, 25, 37, 41, 44, 46, 52

Instrument Cluster............8W-10-14, 25, 30, 31, 41, 46, 52

Integrated Power Module . . 8W-10-3, 4, 12, 13, 14, 15, 16, 17, 18, 19, 25,

26, 27, 28, 29, 30, 31, 32, 33, 34, 36, 37, 39, 40, 41, 42, 43, 44, 45, 46,

47, 48, 49, 50, 51, 53

License Lamp-Left.........................8W-10-34

License Lamp-Right........................8W-10-34

Oxygen Sensor Downstream Relay..............8W-10-12, 19

Park Lamp Relay.......................8W-10-17, 34

Park/Turn Signal Lamp-Left Front..............8W-10-34, 47

Park/Turn Signal Lamp-Right Front.............8W-10-34, 47

Passenger Lumbar Switch.....................8W-10-28

Power Mirror-Left.........................8W-10-43

Power Mirror-Right........................8W-10-43

Power Outlet..........................8W-10-14, 31

Power Outlet-Console.....................8W-10-14, 32

Power Seat Switch-Driver.....................8W-10-28

Power Seat Switch-Passenger...................8W-10-28

Power Window Circuit Breaker..................8W-10-52

Powertrain Control Module . . 8W-10-18, 19, 22, 27, 31, 37, 39, 40, 45, 52

PTCNo.1 .........................8W-10-39, 40, 41

PTCNo.2 .............................8W-10-46

PTCNo.5 .............................8W-10-33

Radio..............................8W-10-30, 46

Rear Window Defogger Relay...................8W-10-49

Seat Belt Tensioner Reducer....................8W-10-46

Seat Heater Interface Module...................8W-10-32

Sentry Key Immobilizer Module..............8W-10-31, 39, 40

Starter Motor..........................8W-10-15, 37

Starter Motor Relay......................8W-10-15, 37

Tail/Stop/Turn Signal Lamp-Left...........8W-10-34, 47, 48, 50

Tail/Stop/Turn Signal Lamp-Right..........8W-10-35, 47, 48, 50

Tailgate Lamp...........................8W-10-34

Trailer Tow Connector.................8W-10-16, 17, 33, 34

Trailer Tow Connector-Add On..........8W-10-14, 31, 33, 34, 48

Trailer Tow Left Turn Relay..................8W-10-16, 33

Trailer Tow Right Turn Relay.................8W-10-16, 33

Transfer Case Control Module...............8W-10-14, 32, 37

Transfer Case Selector Switch...................8W-10-41

Transmission Control Relay................8W-10-13, 26, 27

Transmission Range Sensor................8W-10-38, 44, 49

Transmission Solenoid Assembly.................8W-10-26

Transmission Solenoid/TRS Assembly...........8W-10-27, 44, 49

Underhood Lamp..........................8W-10-30

Vistronic Fan Drive........................8W-10-43

Washer Fluid Level Switch....................8W-10-48

Washer Pump Motor-Front....................8W-10-48

Wiper High/Low Relay.....................8W-10-15, 29

Wiper Motor-Front.......................8W-10-29, 48

Wiper On/Off Relay......................8W-10-15, 29

DR8W-10 POWER DISTRIBUTION 8W - 10 - 1

Page 964 of 2627

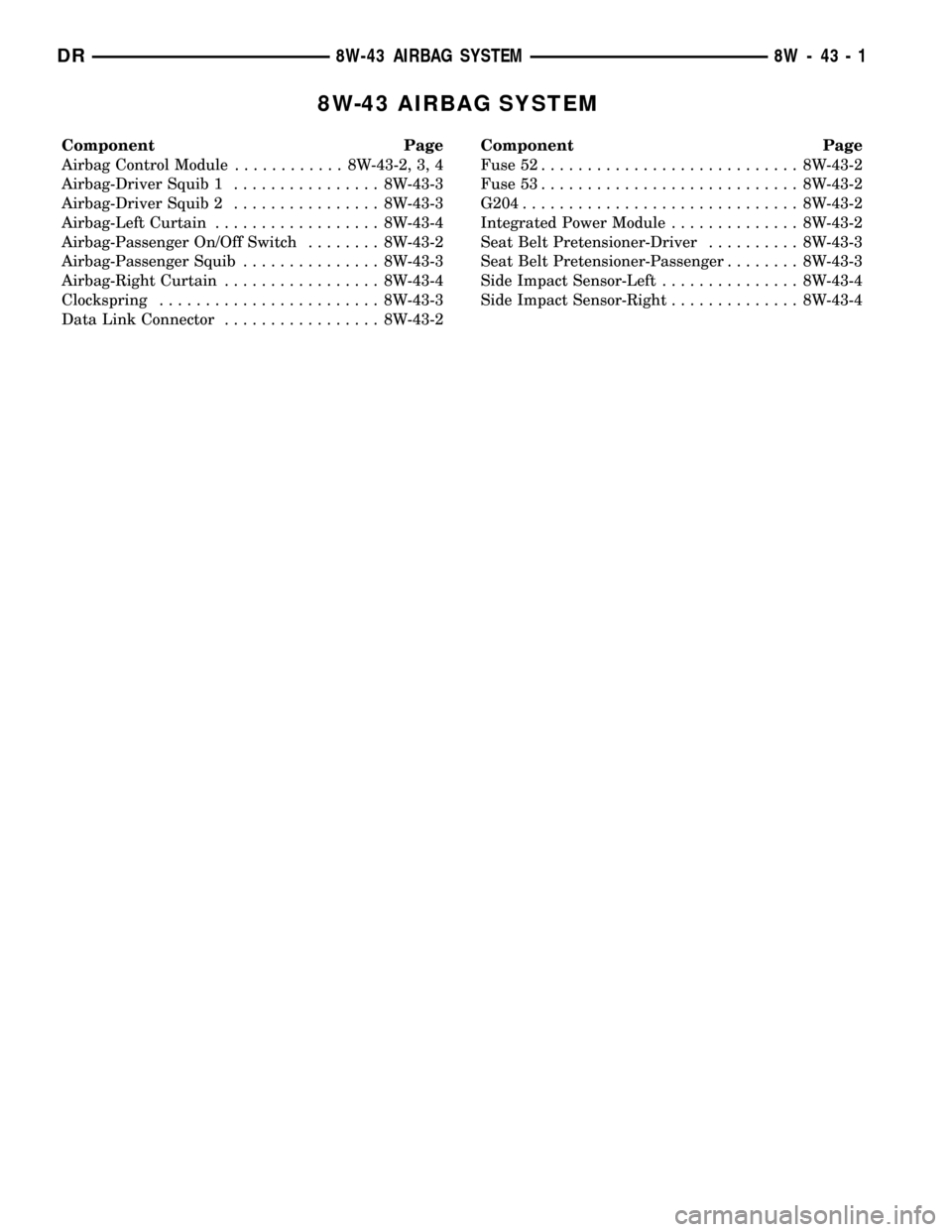

8W-43 AIRBAG SYSTEM

Component Page

Airbag Control Module............ 8W-43-2, 3, 4

Airbag-Driver Squib 1................ 8W-43-3

Airbag-Driver Squib 2................ 8W-43-3

Airbag-Left Curtain.................. 8W-43-4

Airbag-Passenger On/Off Switch........ 8W-43-2

Airbag-Passenger Squib............... 8W-43-3

Airbag-Right Curtain................. 8W-43-4

Clockspring........................ 8W-43-3

Data Link Connector................. 8W-43-2Component Page

Fuse 52............................ 8W-43-2

Fuse 53............................ 8W-43-2

G204.............................. 8W-43-2

Integrated Power Module.............. 8W-43-2

Seat Belt Pretensioner-Driver.......... 8W-43-3

Seat Belt Pretensioner-Passenger........ 8W-43-3

Side Impact Sensor-Left............... 8W-43-4

Side Impact Sensor-Right.............. 8W-43-4

DR8W-43 AIRBAG SYSTEM 8W - 43 - 1