loose steering DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 369 of 2627

RADIATOR-3.7L/4.7L/5.7L

DESCRIPTION

The radiator is a aluminum cross-flow design with

horizontal tubes through the radiator core and verti-

cal plastic side tanks (Fig. 38).

This radiator does not contain an internal trans-

mission oil cooler.

OPERATION

The radiator supplies sufficient heat transfer using

the cooling fins interlaced between the horizontal

tubes in the radiator core to cool the engine.

DIAGNOSIS AND TESTING - RADIATOR

COOLANT FLOW

Use the following procedure to determine if coolant

is flowing through the cooling system.

(1) Idle engine until operating temperature is

reached. If the upper radiator hose is warm to the

touch, the thermostat is opening and coolant is flow-

ing to the radiator.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. USING A RAG TO

COVER THE RADIATOR PRESSURE CAP, OPEN

RADIATOR CAP SLOWLY TO THE FIRST STOP. THIS

WILL ALLOW ANY BUILT-UP PRESSURE TO VENT

TO THE RESERVE/OVERFLOW TANK. AFTER PRES-

SURE BUILD-UP HAS BEEN RELEASED, REMOVE

CAP FROM FILLER NECK.

(2) Drain a small amount of coolant from the radi-

ator until the ends of the radiator tubes are visible

through the filler neck. Idle the engine at normal

operating temperature. If coolant is flowing past the

exposed tubes, the coolant is circulating.

REMOVAL

(1) Disconnect battery negative cables.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM THE COOL-

ANT CAN OCCUR.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter and the correct

width.

(3) Remove the hose clamps and hoses from radia-

tor.

(4) Remove the coolant reserve/overflow tank hose

from the radiator filler neck.

(5) Remove the coolant reserve/overflow tank from

the fan shroud (pull straight up). The tank slips into

slots on the fan shroud.

(6) Unclip the power steering hoses from the fan

shroud.

(7) Disconnect the electrical connectors at the

windshield washer reservoir tank and remove the

tank.

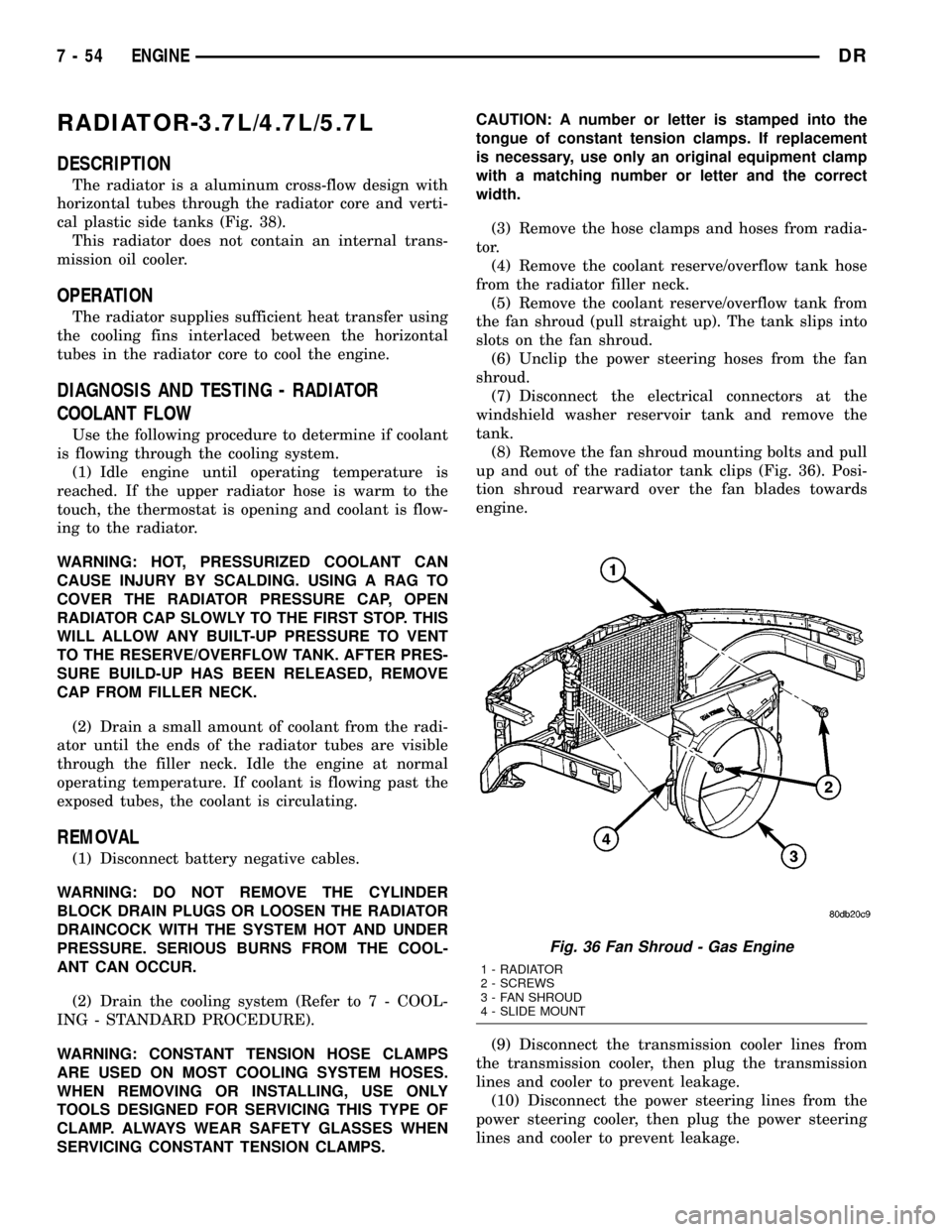

(8) Remove the fan shroud mounting bolts and pull

up and out of the radiator tank clips (Fig. 36). Posi-

tion shroud rearward over the fan blades towards

engine.

(9) Disconnect the transmission cooler lines from

the transmission cooler, then plug the transmission

lines and cooler to prevent leakage.

(10) Disconnect the power steering lines from the

power steering cooler, then plug the power steering

lines and cooler to prevent leakage.

Fig. 36 Fan Shroud - Gas Engine

1 - RADIATOR

2 - SCREWS

3 - FAN SHROUD

4 - SLIDE MOUNT

7 - 54 ENGINEDR

Page 371 of 2627

RADIATOR - 5.9L DIESEL

DESCRIPTION

The radiator is a aluminum cross-flow design with

horizontal tubes through the radiator core and verti-

cal plastic side tanks (Fig. 38).

This radiator does not contain an internal trans-

mission oil cooler.

OPERATION

The radiator supplies sufficient heat transfer using

the cooling fins interlaced between the horizontal

tubes in the radiator core to cool the engine.

DIAGNOSIS AND TESTING - RADIATOR

COOLANT FLOW

Use the following procedure to determine if coolant

is flowing through the cooling system.

(1) Idle engine until operating temperature is

reached. If the upper radiator hose is warm to the

touch, the thermostat is opening and coolant is flow-

ing to the radiator.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. USING A RAG TO

COVER THE RADIATOR PRESSURE CAP, OPEN

RADIATOR CAP SLOWLY TO THE FIRST STOP. THIS

WILL ALLOW ANY BUILT-UP PRESSURE TO VENT

TO THE RESERVE/OVERFLOW TANK. AFTER PRES-

SURE BUILD-UP HAS BEEN RELEASED, REMOVE

CAP FROM FILLER NECK.

(2) Drain a small amount of coolant from the radi-

ator until the ends of the radiator tubes are visible

through the filler neck. Idle the engine at normal

operating temperature. If coolant is flowing past the

exposed tubes, the coolant is circulating.

REMOVAL

(1) Disconnect both battery negative cables.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER6094). ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(3) Remove air box and turbocharger inlet tube.

(4) Remove coolant tank hose, washer bottle hose

and the positive battery cable from the fastening

clips located on top of the radiator.

(5) Remove hose clamps and hoses from radiator.

(6) Remove the power steering cooler mounting

bolts and position the power steering cooler out of

the way.

(7) Disconnect the transmission cooler lines at the

transmission cooler. The transmission cooler will

remain on the radiator and can be removed as an

assembly.

(8) Disconnect the electronic viscous fan drive elec-

trical connector.

(9) Using a fastener removal tool, remove the two

push pins and the lower shroud assembly and elec-

tronic viscous fan drive wiring from the upper shroud

assembly. Position wiring out of the way. Do not

impact or damage the electronic viscous fan drive or

pull it's wiring.

(10) Using a fastener tool, remove the wiring har-

ness bracket from the upper fan shroud.

(11) Remove the two radiator upper mounting

bolts (Fig. 38).

(12) Lift radiator straight up and out of engine

compartment. The bottom of the radiator is equipped

with two alignment dowels that fit into holes in the

lower radiator support panel. Rubber biscuits (insu-

lators) are installed to these dowels. Take care not to

damage cooling fins or tubes on the radiator and air

conditioning condenser or the electronic viscous fan

connector when removing.

CLEANING

Clean radiator fins are necessary for good heat

transfer. The radiator and oil cooler fins should be

cleaned when an accumulation of debris has

occurred. With the engine cold, apply cold water and

compressed air to the back (engine side) of the radi-

ator to flush the radiator and/or oil coolers of debris.

INSPECTION

Inspect the radiator side tanks for cracks, and bro-

ken or missing fittings. Inspect the joint where the

tanks seam up to the radiator core for signs of leak-

age and/or deteriorating seals.

Inspect radiator core for corroded, bent or missing

cooling fins. Inspect the core for bent or damaged

cooling tubes.

7 - 56 ENGINEDR

Page 377 of 2627

(3) Spin the water pump to be sure that the pump

impeller does not rub against the timing chain case/

cover.

(4) Connect the radiator lower hose to the water

pump.

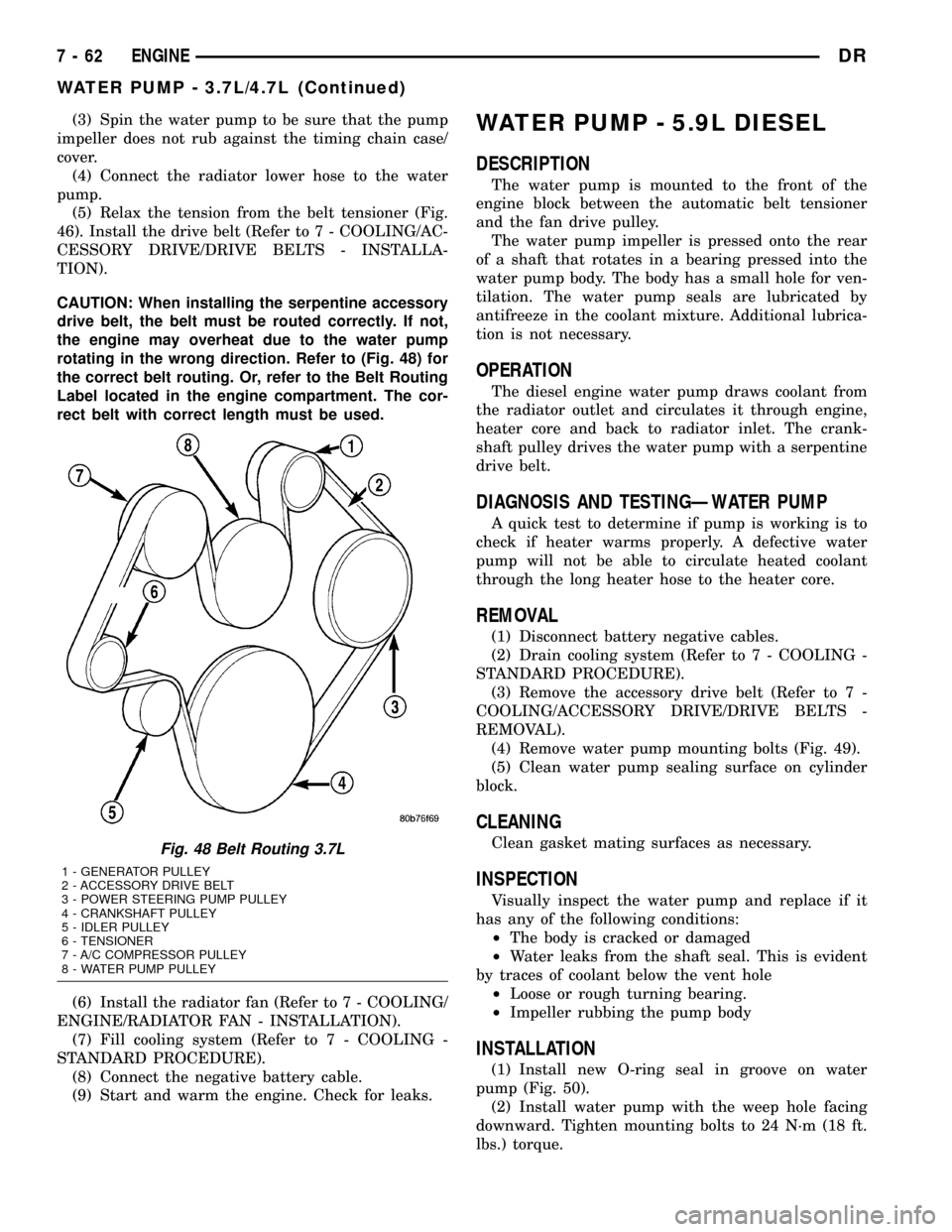

(5) Relax the tension from the belt tensioner (Fig.

46). Install the drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction. Refer to (Fig. 48) for

the correct belt routing. Or, refer to the Belt Routing

Label located in the engine compartment. The cor-

rect belt with correct length must be used.

(6) Install the radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(7) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(8) Connect the negative battery cable.

(9) Start and warm the engine. Check for leaks.WATER PUMP - 5.9L DIESEL

DESCRIPTION

The water pump is mounted to the front of the

engine block between the automatic belt tensioner

and the fan drive pulley.

The water pump impeller is pressed onto the rear

of a shaft that rotates in a bearing pressed into the

water pump body. The body has a small hole for ven-

tilation. The water pump seals are lubricated by

antifreeze in the coolant mixture. Additional lubrica-

tion is not necessary.

OPERATION

The diesel engine water pump draws coolant from

the radiator outlet and circulates it through engine,

heater core and back to radiator inlet. The crank-

shaft pulley drives the water pump with a serpentine

drive belt.

DIAGNOSIS AND TESTINGÐWATER PUMP

A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

REMOVAL

(1) Disconnect battery negative cables.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove water pump mounting bolts (Fig. 49).

(5) Clean water pump sealing surface on cylinder

block.

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Visually inspect the water pump and replace if it

has any of the following conditions:

²The body is cracked or damaged

²Water leaks from the shaft seal. This is evident

by traces of coolant below the vent hole

²Loose or rough turning bearing.

²Impeller rubbing the pump body

INSTALLATION

(1) Install new O-ring seal in groove on water

pump (Fig. 50).

(2) Install water pump with the weep hole facing

downward. Tighten mounting bolts to 24 N´m (18 ft.

lbs.) torque.

Fig. 48 Belt Routing 3.7L

1 - GENERATOR PULLEY

2 - ACCESSORY DRIVE BELT

3 - POWER STEERING PUMP PULLEY

4 - CRANKSHAFT PULLEY

5 - IDLER PULLEY

6 - TENSIONER

7 - A/C COMPRESSOR PULLEY

8 - WATER PUMP PULLEY

7 - 62 ENGINEDR

WATER PUMP - 3.7L/4.7L (Continued)

Page 387 of 2627

The optional navigation radio system receives GPS

signals from up to eight satellites to display the posi-

tion and direction of the vehicle. Map information is

supplied through a DVD-ROM. An electronic gyro-

sensor and the vehicle's speed sensor enable the sys-

tem to display the present vehicle position even in

locations where GPS signals may be blocked.

When a destination is selected, the navigation sys-

tem uses information from the map to quickly calcu-

late a route. As the vehicle is driven along the chosen

route, the operator is guided with pictorial displays

and voice prompts. For complete operating instruc-

tions, refer to the manual included with the vehicle.

On vehicles that are equipped with the optional

remote radio switches, the Instrument Cluster

receives hard wired resistor multiplexed inputs from

the remote radio switches. The programming in the

Instrument Cluster allows it to process those inputs

and send the proper messages to the radio receiver

over the Programmable Communication Interface

(PCI) bus network to control the radio volume up or

down, station seek up or down, preset station

advance, and mode advance functions.DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the

DRB IIIt, refer to the appropriate Diagnostic

Service Manual.

Refer to the appropriate wiring information.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

AUDIO SYSTEM DIAGNOSIS TABLE

CONDITION POSSIBLE CAUSES CORRECTION

NO AUDIO 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in the Integrated Power Module (IPM).

Replace fuses, if required.

2. Radio/amplifier (if

equipped) connector faulty.2. Check for loose or corroded radio/amplifier

connector. Repair, if required.

3. Wiring faulty. 3. Check for shorted or open wires. Repair wiring,

if required.

4. Radio/amplifier (if

equipped) ground faulty.4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio/amplifier (if

equipped) faulty.5. Refer to appropriate Diagnostic Service

Manual.

6. Speakers faulty. 6. Replace speaker as necessary.

NO RADIO DISPLAY 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in Integrated Power Module (IPM). Replace

fuses, if required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for battery voltage at radio connector.

Repair wiring, if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

8A - 2 AUDIO/VIDEODR

AUDIO (Continued)

Page 459 of 2627

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER ENGAGES,

FAILS TO TURN

ENGINE.1. Battery discharged or

faulty.1. Refer to Battery. Charge or replace battery if required.

2. Starting circuit wiring

faulty.2. Refer to 8, Wiring Diagrams. Test and repair starter

feed and/or control circuits if required.

3. Starter motor faulty. 3. If all other starting system components and circuits test

OK, replace starter motor assembly.

4. Engine seized. 4. Refer to Engine Diagnosis in the Diagnosis and Testing

section of 9, Engine.

STARTER ENGAGES,

SPINS OUT BEFORE

ENGINE STARTS.1. Starter ring gear faulty. 1. Refer to Starter Motor Removal and Installation.

Remove starter motor to inspect starter ring gear.

Replace starter ring gear if required.

2. Starter motor faulty. 2. If all other starting system components and circuits test

OK, replace starter motor assembly.

STARTER DOES NOT

DISENGAGE.1. Starter motor

improperly installed.1. Refer to Starter Motor Removal and Installation.

Tighten starter mounting hardware to correct torque

specifications.

2. Starter relay faulty. 2. Refer to Starter Relay Diagnosis and Testing. Replace

starter relay if required.

3. Ignition switch faulty. 3. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch if required.

4. Starter motor faulty. 4. If all other starting system components and circuits test

OK, replace starter motor.

INSPECTION

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. Before removing any unit

from starting system for repair or diagnosis, perform

the following inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO 8, PASSIVE RESTRAINT SYS-

TEMS, BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY.

²Battery- Visually inspect battery for indica-

tions of physical damage and loose or corroded cable

connections. Determine state-of-charge and cranking

capacity of battery. Charge or replace battery if

required. Refer toBatteryin 8, Battery.Note: If

equipped with diesel engine, a dual battery sys-

tem may be used, and both batteries must be

inspected.

²Ignition Switch- Visually inspect ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer toIgni-

tion Switch and Key Lock Cylinder.²Clutch Pedal Position Switch- If equipped

with manual transmission, visually inspect clutch

pedal position switch for indications of physical dam-

age and loose or corroded wire harness connections.

Refer toClutch Pedal Position Switchin 6,

Clutch.

²Park/Neutral Position Switch- If equipped

with automatic transmission, visually inspect park/

neutral position switch for indications of physical

damage and loose or corroded wire harness connec-

tions. Refer toPark/Neutral Position Switchin

21, Transmission.

²Starter Relay- Visually inspect starter relay

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Motor- Visually inspect starter motor

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Solenoid- Visually inspect starter sole-

noid for indications of physical damage and loose or

corroded wire harness connections.

²Wiring- Visually inspect wire harnesses for

damage. Repair or replace any faulty wiring, as

required. Refer to 8, Wiring Diagrams.

8F - 28 STARTINGDR

STARTING (Continued)

Page 624 of 2627

Airbag Control Module (ACM). An airbag indicator in

the ElectroMechanical Instrument Cluster (EMIC)

illuminates for about six seconds as a bulb test each

time the ignition switch is turned to the On or Start

positions. Following the bulb test, the airbag indica-

tor is turned on or off by the ACM to indicate the

status of the supplemental restraint system. If the

airbag indicator comes on at any time other than

during the bulb test, it indicates that there is a prob-

lem in the supplemental restraint system electrical

circuits. Such a problem may cause airbags not to

deploy when required, or to deploy when not

required.

Deployment of the supplemental restraints

depends upon the angle and severity of an impact.

Deployment is not based upon vehicle speed; rather,

deployment is based upon the rate of deceleration as

measured by the forces of gravity (G force) upon the

impact sensors. When an impact is severe enough,

the microprocessor in the ACM signals the inflator of

the appropriate airbag units to deploy their airbag

cushions. The outboard front seat belt tensioners are

provided with a deployment signal by the ACM in

conjunction with the driver and passenger front air-

bags. During a frontal vehicle impact, the knee block-

ers work in concert with properly fastened and

adjusted seat belts to restrain both the driver and

the front seat passenger in the proper position for an

airbag deployment. The knee blockers also absorb

and distribute the crash energy from the driver and

the front seat passenger to the structure of the

instrument panel. The seat belt tensioner removes

the slack from the outboard front seat belts to pro-

vide further assurance that the driver and front seat

passenger are properly positioned and restrained for

an airbag deployment.

Typically, the vehicle occupants recall more about

the events preceding and following a collision than

they do of an airbag deployment itself. This is

because the airbag deployment and deflation occur

very rapidly. In a typical 48 kilometer-per-hour (30

mile-per-hour) barrier impact, from the moment of

impact until the airbags are fully inflated takes

about 40 milliseconds. Within one to two seconds

from the moment of impact, the airbags are almost

entirely deflated. The times cited for these events are

approximations, which apply only to a barrier impact

at the given speed. Actual times will vary somewhat,

depending upon the vehicle speed, impact angle,

severity of the impact, and the type of collision.

When the ACM monitors a problem in any of the

supplemental restraint system circuits or compo-

nents, including the seat belt tensioners, it stores a

fault code or Diagnostic Trouble Code (DTC) in its

memory circuit and sends an electronic message to

the EMIC to turn on the airbag indicator. Propertesting of the supplemental restraint system compo-

nents, the Programmable Communications Interface

(PCI) data bus, the electronic message inputs to and

outputs from the EMIC or the ACM, as well as the

retrieval or erasure of a DTC from the ACM or EMIC

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the factory-installed passive restraints.

WARNING

WARNINGS - RESTRAINT SYSTEM

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

DRRESTRAINTS 8O - 5

RESTRAINTS (Continued)

Page 632 of 2627

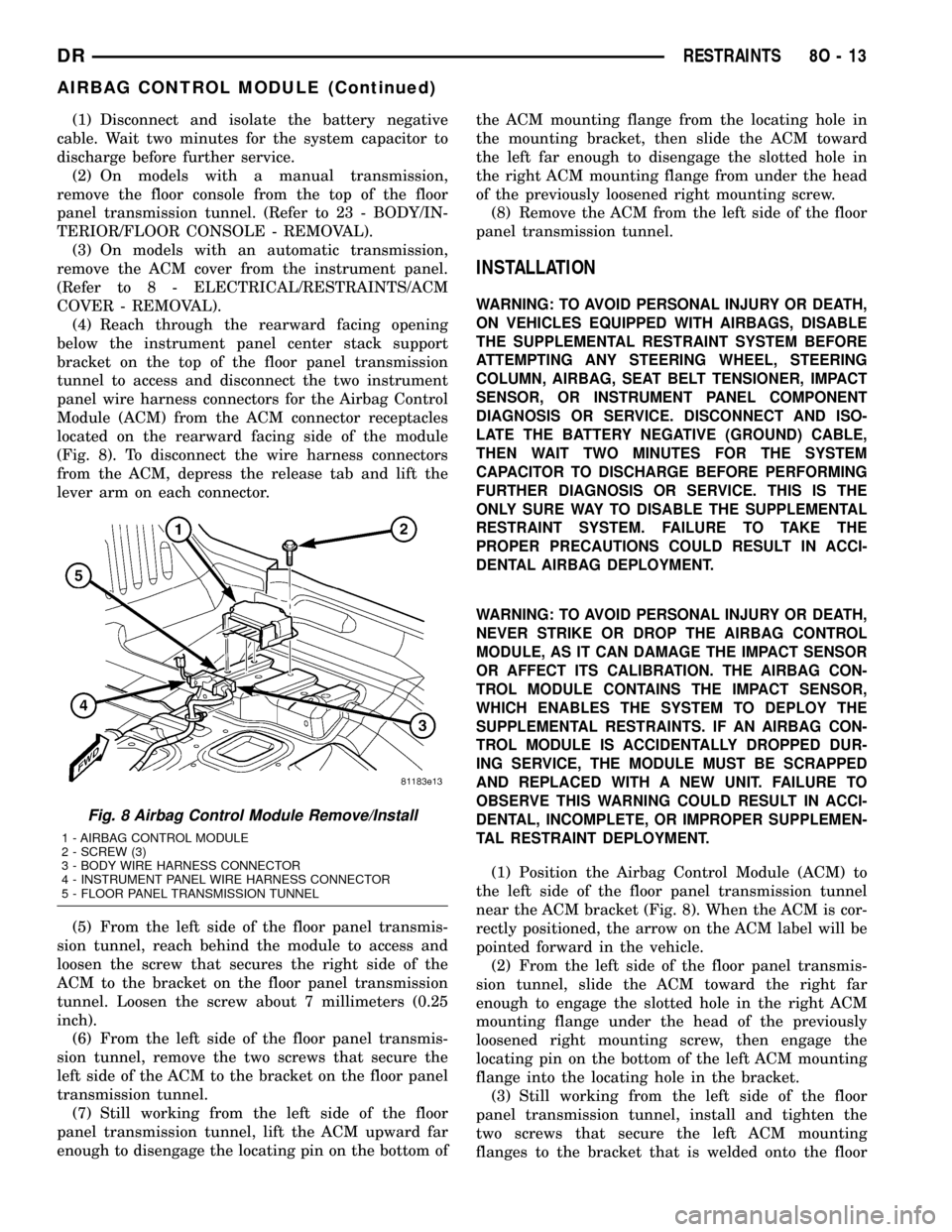

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) On models with a manual transmission,

remove the floor console from the top of the floor

panel transmission tunnel. (Refer to 23 - BODY/IN-

TERIOR/FLOOR CONSOLE - REMOVAL).

(3) On models with an automatic transmission,

remove the ACM cover from the instrument panel.

(Refer to 8 - ELECTRICAL/RESTRAINTS/ACM

COVER - REMOVAL).

(4) Reach through the rearward facing opening

below the instrument panel center stack support

bracket on the top of the floor panel transmission

tunnel to access and disconnect the two instrument

panel wire harness connectors for the Airbag Control

Module (ACM) from the ACM connector receptacles

located on the rearward facing side of the module

(Fig. 8). To disconnect the wire harness connectors

from the ACM, depress the release tab and lift the

lever arm on each connector.

(5) From the left side of the floor panel transmis-

sion tunnel, reach behind the module to access and

loosen the screw that secures the right side of the

ACM to the bracket on the floor panel transmission

tunnel. Loosen the screw about 7 millimeters (0.25

inch).

(6) From the left side of the floor panel transmis-

sion tunnel, remove the two screws that secure the

left side of the ACM to the bracket on the floor panel

transmission tunnel.

(7) Still working from the left side of the floor

panel transmission tunnel, lift the ACM upward far

enough to disengage the locating pin on the bottom ofthe ACM mounting flange from the locating hole in

the mounting bracket, then slide the ACM toward

the left far enough to disengage the slotted hole in

the right ACM mounting flange from under the head

of the previously loosened right mounting screw.

(8) Remove the ACM from the left side of the floor

panel transmission tunnel.

INSTALLATION

WARNING: TO AVOID PERSONAL INJURY OR DEATH,

ON VEHICLES EQUIPPED WITH AIRBAGS, DISABLE

THE SUPPLEMENTAL RESTRAINT SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, AIRBAG, SEAT BELT TENSIONER, IMPACT

SENSOR, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE SYSTEM

CAPACITOR TO DISCHARGE BEFORE PERFORMING

FURTHER DIAGNOSIS OR SERVICE. THIS IS THE

ONLY SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT.

WARNING: TO AVOID PERSONAL INJURY OR DEATH,

NEVER STRIKE OR DROP THE AIRBAG CONTROL

MODULE, AS IT CAN DAMAGE THE IMPACT SENSOR

OR AFFECT ITS CALIBRATION. THE AIRBAG CON-

TROL MODULE CONTAINS THE IMPACT SENSOR,

WHICH ENABLES THE SYSTEM TO DEPLOY THE

SUPPLEMENTAL RESTRAINTS. IF AN AIRBAG CON-

TROL MODULE IS ACCIDENTALLY DROPPED DUR-

ING SERVICE, THE MODULE MUST BE SCRAPPED

AND REPLACED WITH A NEW UNIT. FAILURE TO

OBSERVE THIS WARNING COULD RESULT IN ACCI-

DENTAL, INCOMPLETE, OR IMPROPER SUPPLEMEN-

TAL RESTRAINT DEPLOYMENT.

(1) Position the Airbag Control Module (ACM) to

the left side of the floor panel transmission tunnel

near the ACM bracket (Fig. 8). When the ACM is cor-

rectly positioned, the arrow on the ACM label will be

pointed forward in the vehicle.

(2) From the left side of the floor panel transmis-

sion tunnel, slide the ACM toward the right far

enough to engage the slotted hole in the right ACM

mounting flange under the head of the previously

loosened right mounting screw, then engage the

locating pin on the bottom of the left ACM mounting

flange into the locating hole in the bracket.

(3) Still working from the left side of the floor

panel transmission tunnel, install and tighten the

two screws that secure the left ACM mounting

flanges to the bracket that is welded onto the floor

Fig. 8 Airbag Control Module Remove/Install

1 - AIRBAG CONTROL MODULE

2 - SCREW (3)

3 - BODY WIRE HARNESS CONNECTOR

4 - INSTRUMENT PANEL WIRE HARNESS CONNECTOR

5 - FLOOR PANEL TRANSMISSION TUNNEL

DRRESTRAINTS 8O - 13

AIRBAG CONTROL MODULE (Continued)

Page 637 of 2627

INSTALLATION

The following procedure applies only to the rear

seat upper child tether straps used on quad cab mod-

els. The child restraint anchors used in other models

and locations are integral to other components and

cannot be serviced separately.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

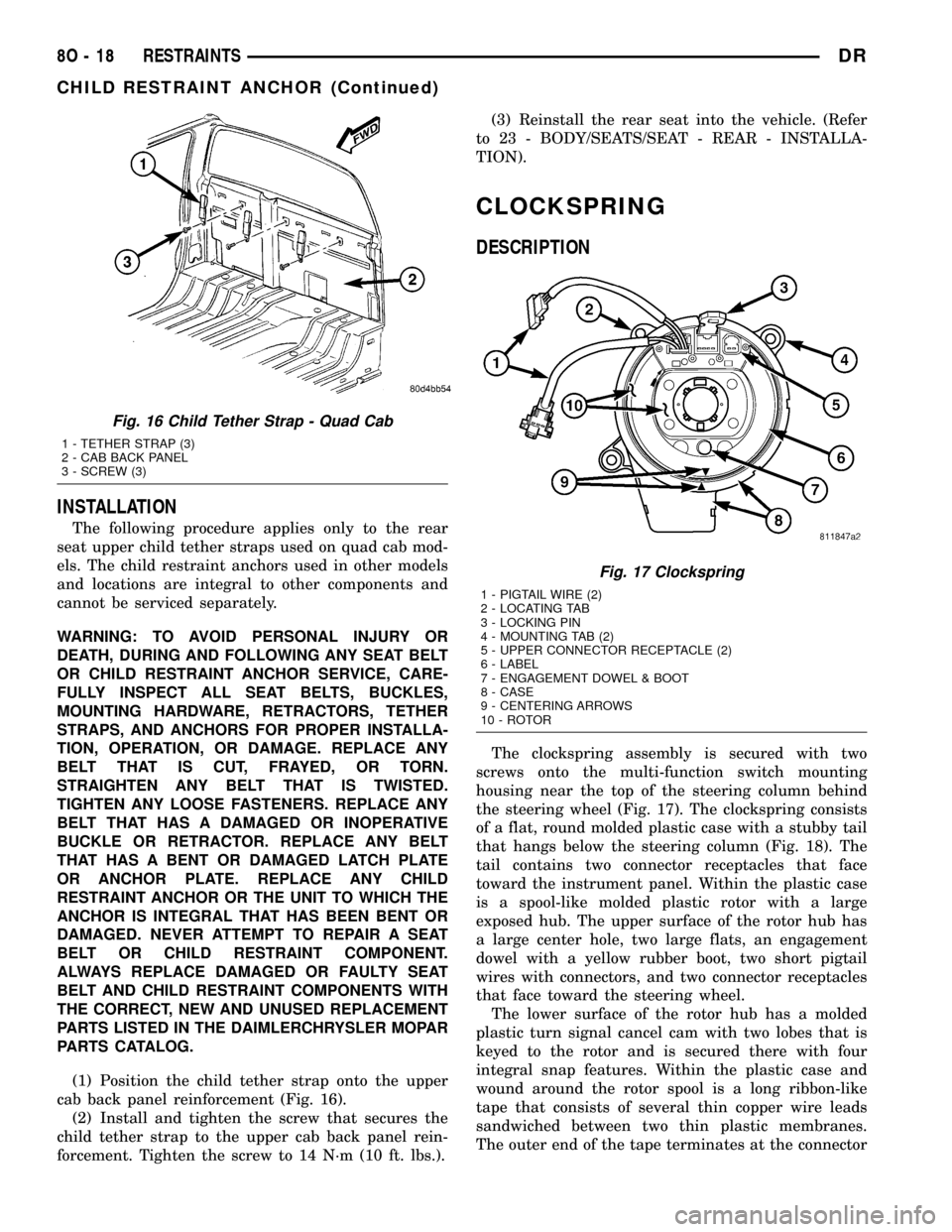

(1) Position the child tether strap onto the upper

cab back panel reinforcement (Fig. 16).

(2) Install and tighten the screw that secures the

child tether strap to the upper cab back panel rein-

forcement. Tighten the screw to 14 N´m (10 ft. lbs.).(3) Reinstall the rear seat into the vehicle. (Refer

to 23 - BODY/SEATS/SEAT - REAR - INSTALLA-

TION).

CLOCKSPRING

DESCRIPTION

The clockspring assembly is secured with two

screws onto the multi-function switch mounting

housing near the top of the steering column behind

the steering wheel (Fig. 17). The clockspring consists

of a flat, round molded plastic case with a stubby tail

that hangs below the steering column (Fig. 18). The

tail contains two connector receptacles that face

toward the instrument panel. Within the plastic case

is a spool-like molded plastic rotor with a large

exposed hub. The upper surface of the rotor hub has

a large center hole, two large flats, an engagement

dowel with a yellow rubber boot, two short pigtail

wires with connectors, and two connector receptacles

that face toward the steering wheel.

The lower surface of the rotor hub has a molded

plastic turn signal cancel cam with two lobes that is

keyed to the rotor and is secured there with four

integral snap features. Within the plastic case and

wound around the rotor spool is a long ribbon-like

tape that consists of several thin copper wire leads

sandwiched between two thin plastic membranes.

The outer end of the tape terminates at the connector

Fig. 16 Child Tether Strap - Quad Cab

1 - TETHER STRAP (3)

2 - CAB BACK PANEL

3 - SCREW (3)

Fig. 17 Clockspring

1 - PIGTAIL WIRE (2)

2 - LOCATING TAB

3 - LOCKING PIN

4 - MOUNTING TAB (2)

5 - UPPER CONNECTOR RECEPTACLE (2)

6 - LABEL

7 - ENGAGEMENT DOWEL & BOOT

8 - CASE

9 - CENTERING ARROWS

10 - ROTOR

8O - 18 RESTRAINTSDR

CHILD RESTRAINT ANCHOR (Continued)

Page 651 of 2627

(1) From the front of the front seat, position the

front center seat belt buckle, lap belt unit, or unique

black, keyed front center seat belt lower anchor

buckle between the center seat cushion and the adja-

cent right or left front outboard seat cushion.

(2) From the front of the front seat, reach between

the center seat cushion and the adjacent right or left

front outboard seat cushion to route the front center

seat belt buckle, lap belt unit lower anchor, or unique

black, keyed front center seat belt lower anchor

buckle through the elastic strap on the side of the

center seat cushion (Fig. 30).

(3) From behind the front seat, position the front

center seat belt buckle, lap belt lower anchor, or

unique black, keyed front center seat belt lower

anchor buckle to the center seat support bracket.

(4) Install and tighten the screw that secures the

front center seat belt buckle, lap belt lower anchor, or

unique black, keyed front center seat belt lower

anchor buckle to the center seat support bracket.

Tighten the screw to 40 N´m (29 ft. lbs.).

(5) Move the adjacent right or left front outboard

seat section (40 percent) back to its rearward posi-

tion.

FRONT OUTBOARD SEAT

BELT & RETRACTOR

REMOVAL

REMOVAL - STANDARD CAB

The following procedure is for replacement of a

faulty or damaged front outboard seat belt and

retractor unit, which includes a seat belt tensioner

for this model.(Refer to 8 - ELECTRICAL/RE-

STRAINTS/SEAT BELT TENSIONER - DESCRIP-

TION). The only component of this seat belt and

retractor unit that is available for individual service

replacement is the plastic web stop button that pre-

vents the latch plate from falling to the floor while in

the stored position. Refer to the instructions supplied

with the service kit for the proper web stop button

replacement procedures.

The seat belt retractor on the driver's side of stan-

dard cab models only also includes a tension reducer.

(Refer to 8 - ELECTRICAL/RESTRAINTS/TENSION

REDUCER - DESCRIPTION). The seat belt retractor

on the passenger's side of all models includes a swit-

chable automatic locking mechanism. (Refer to 8 -

ELECTRICAL/RESTRAINTS/AUTOMATIC LOCK-

ING RETRACTOR - DESCRIPTION).

If the seat belt or retractor is faulty or damaged,

but the seat belt tensioner is not deployed, review

the recommended procedures for handling non-de-ployed supplemental restraints. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS - STANDARD PROCEDURE

- HANDLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the seat belt tensioner has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the front outboard seat belt and

retractor from the vehicle. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - STANDARD PROCEDURE -

SERVICE AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Move the front seat to its most forward position

for easiest access to the lower seat belt anchor and

the B-pillar trim.

8O - 32 RESTRAINTSDR

FRONT CENTER SEAT BELT (Continued)

Page 653 of 2627

before removing the front outboard seat belt and

retractor from the vehicle. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - STANDARD PROCEDURE -

SERVICE AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

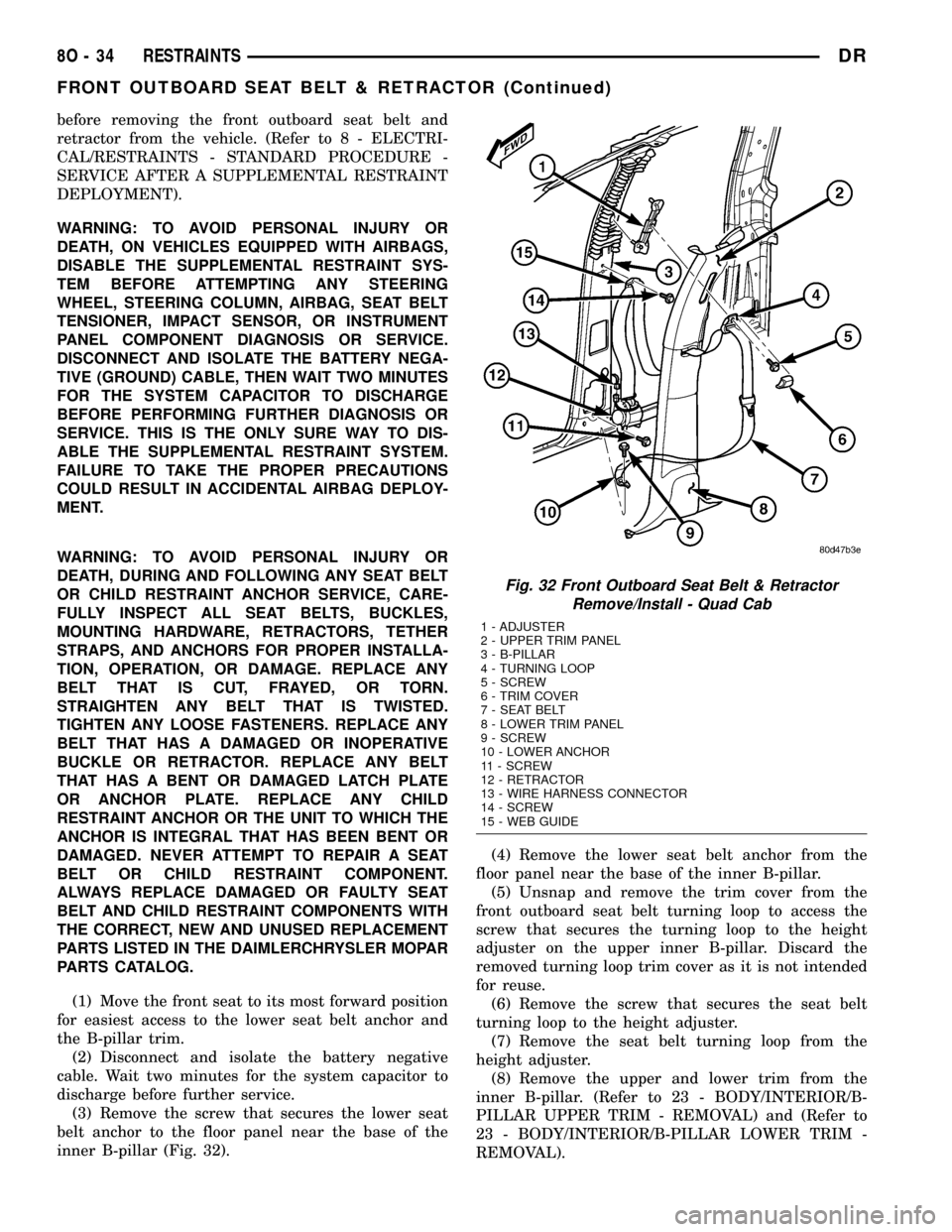

(1) Move the front seat to its most forward position

for easiest access to the lower seat belt anchor and

the B-pillar trim.

(2) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(3) Remove the screw that secures the lower seat

belt anchor to the floor panel near the base of the

inner B-pillar (Fig. 32).(4) Remove the lower seat belt anchor from the

floor panel near the base of the inner B-pillar.

(5) Unsnap and remove the trim cover from the

front outboard seat belt turning loop to access the

screw that secures the turning loop to the height

adjuster on the upper inner B-pillar. Discard the

removed turning loop trim cover as it is not intended

for reuse.

(6) Remove the screw that secures the seat belt

turning loop to the height adjuster.

(7) Remove the seat belt turning loop from the

height adjuster.

(8) Remove the upper and lower trim from the

inner B-pillar. (Refer to 23 - BODY/INTERIOR/B-

PILLAR UPPER TRIM - REMOVAL) and (Refer to

23 - BODY/INTERIOR/B-PILLAR LOWER TRIM -

REMOVAL).

Fig. 32 Front Outboard Seat Belt & Retractor

Remove/Install - Quad Cab

1 - ADJUSTER

2 - UPPER TRIM PANEL

3 - B-PILLAR

4 - TURNING LOOP

5 - SCREW

6 - TRIM COVER

7 - SEAT BELT

8 - LOWER TRIM PANEL

9 - SCREW

10 - LOWER ANCHOR

11 - SCREW

12 - RETRACTOR

13 - WIRE HARNESS CONNECTOR

14 - SCREW

15 - WEB GUIDE

8O - 34 RESTRAINTSDR

FRONT OUTBOARD SEAT BELT & RETRACTOR (Continued)