Drive shaft DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2152 of 2627

DIAGNOSIS CHART

Condition Possible Cause Correction

Transfer Case difficult to shift or will not

shift into desired range.1) Vehicle speed too great to permit

shifting.1) Stop vehicle and shift into desired

range. Or, reduce speed to below 3-4

km/h (2-3 mph) before attempting the

shift.

2) If vehicle was operated for an

extended period in 4H on a dry paved

surface, the driveline torque load may

be causing a bind.2) Stop vehicle and shift the

transmission into neutral. Shift the

transfer case to 2H and operate vehicle

in 2H on dry paved surfaces.

3) Transfer case external shift linkage

binding.3) Lubricate, repair, or replace linkage

bushings, or tighten loose components

as necessary.

4) Insufficient or incorrect lubricant. 4) Drain and refill to edge of fill hole

with MoparTATF +4, Automatic

Transmission fluid.

5) Internal components binding, worn,

or damaged.5) Disassemble the transfer case and

replace worn or damaged components

as necessary.

Transfer Case noisy in all operating

ranges.1) Insufficient or incorrect lubricant. 1) Drain and refill to edge of fill hole

with MoparTATF +4, Automatic

Transmission fluid.

Noisy in, or jumps out of, four wheel

drive low range.1) Transfer case not completely

engaged in 4L position.1) With the transmission in NEUTRAL,

or the clutch depressed in the case of a

manual transmission and the vehicle

moving under 3-4 km/h (2-3 mph), shift

the transfer case to NEUTRAL and then

shift into the 4L position.

2) Shift linkage out of adjustment. 2) Adjust linkage.

3) Shift linkage loose or binding. 3) Tighten, lubricate, or repair linkage as

necessary.

4) Range fork damaged, inserts worn,

or fork is binding on the shift rail.4) Disassemble unit and repair as

necessary.

5) Low range gear worn or damaged. 5) Disassemble unit and repair as

necessary.

Lubricant leaking from output shaft seal

or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct level.

2) Vent closed or restricted. 2) Clear or replace vent as necessary.

3) Output shaft seals damaged or

installed incorrectly.3) Replace seal as necessary. Check to

ensure that another component, the

propeller shaft slip yoke for example, is

not causing damage to seal.

Abnormal tire wear. 1) Extended operation on hard, dry

surfaces in the 4H position.1) Operate vehicle in the 2H position on

hard, dry surfaces.

DRTRANSFER CASE - NV271 21 - 449

TRANSFER CASE - NV271 (Continued)

Page 2153 of 2627

REMOVAL

(1) Raise and support vehicle.

(2) Remove skid plate, if equipped. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - REMOVAL)

(3) Position drain oil container under transfer

case.

(4) Remove transfer case drain plug and drain

lubricant into container.

(5) Disconnect vent hose and transfer case position

sensor connector.

(6) Disconnect shift rod from grommet in transfer

case shift lever, or from floor shift arm whichever

provides easy access. Use channel lock style pliers to

press rod out of lever grommet.

(7) Support transmission with jack stand.

(8) Mark front and rear propeller shafts for assem-

bly reference.

(9) Remove front and rear propeller shafts. (Refer

to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL)

(10) Support transfer case with suitable jack.

Secure transfer case to jack with safety chains.

(11) Remove nuts attaching transfer case to trans-

mission.

(12) Move transfer case assembly rearward until

free of transmission output shaft.

(13) Lower jack and move transfer case from

under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan.

Remove drain plug and drain any remaining lubri-

cant remaining in case.

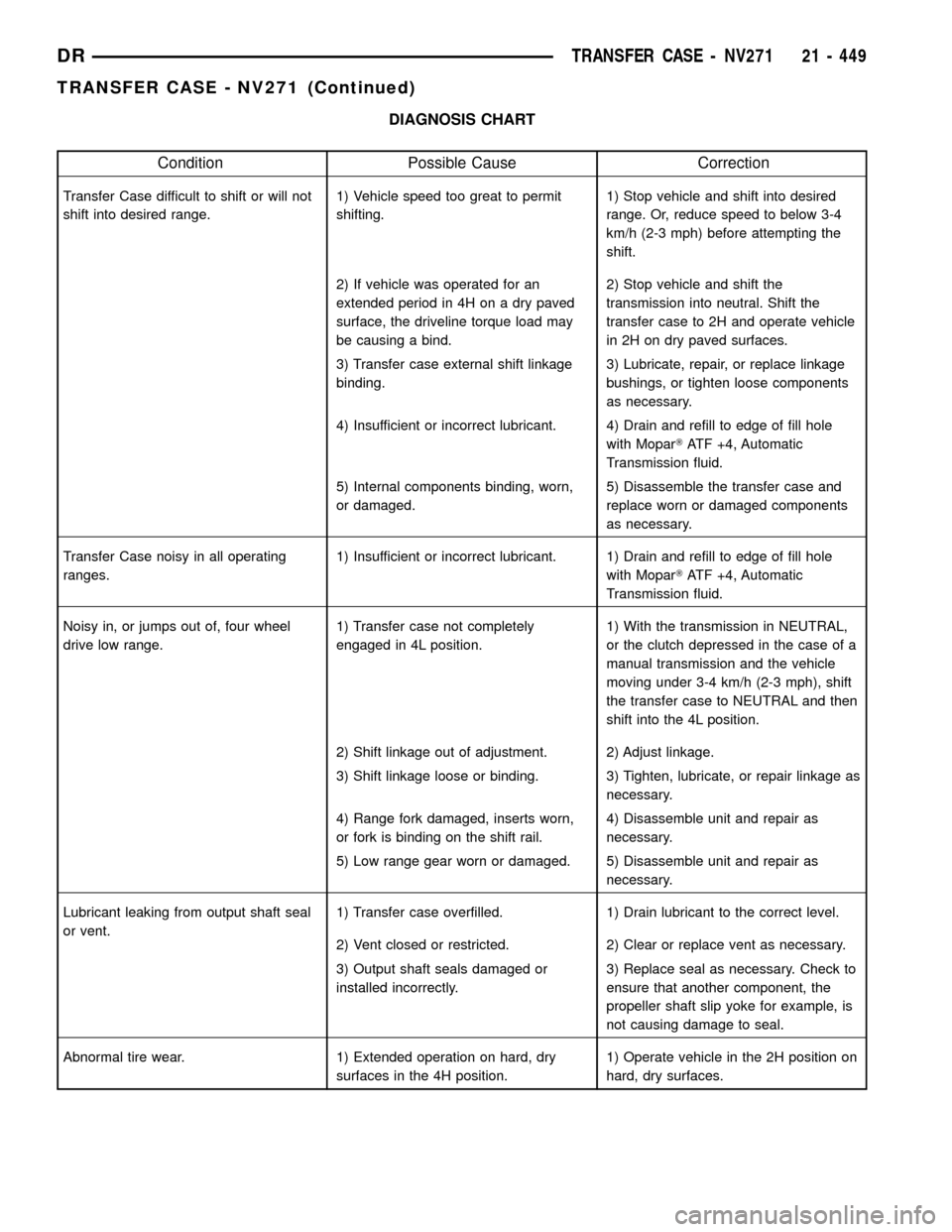

COMPANION FLANGE AND EXTENSION HOUSING

(1) Install two bolts 180É apart into the front out-

put shaft companion flange.

(2) Place holder over the bolts and against the

companion flange (Fig. 3).

(3) Remove and discard the front companion flange

nut.

(4) Remove the companion flange from the front

output shaft. It may be necessary to use Flange

puller 8992 to remove the companion flange.

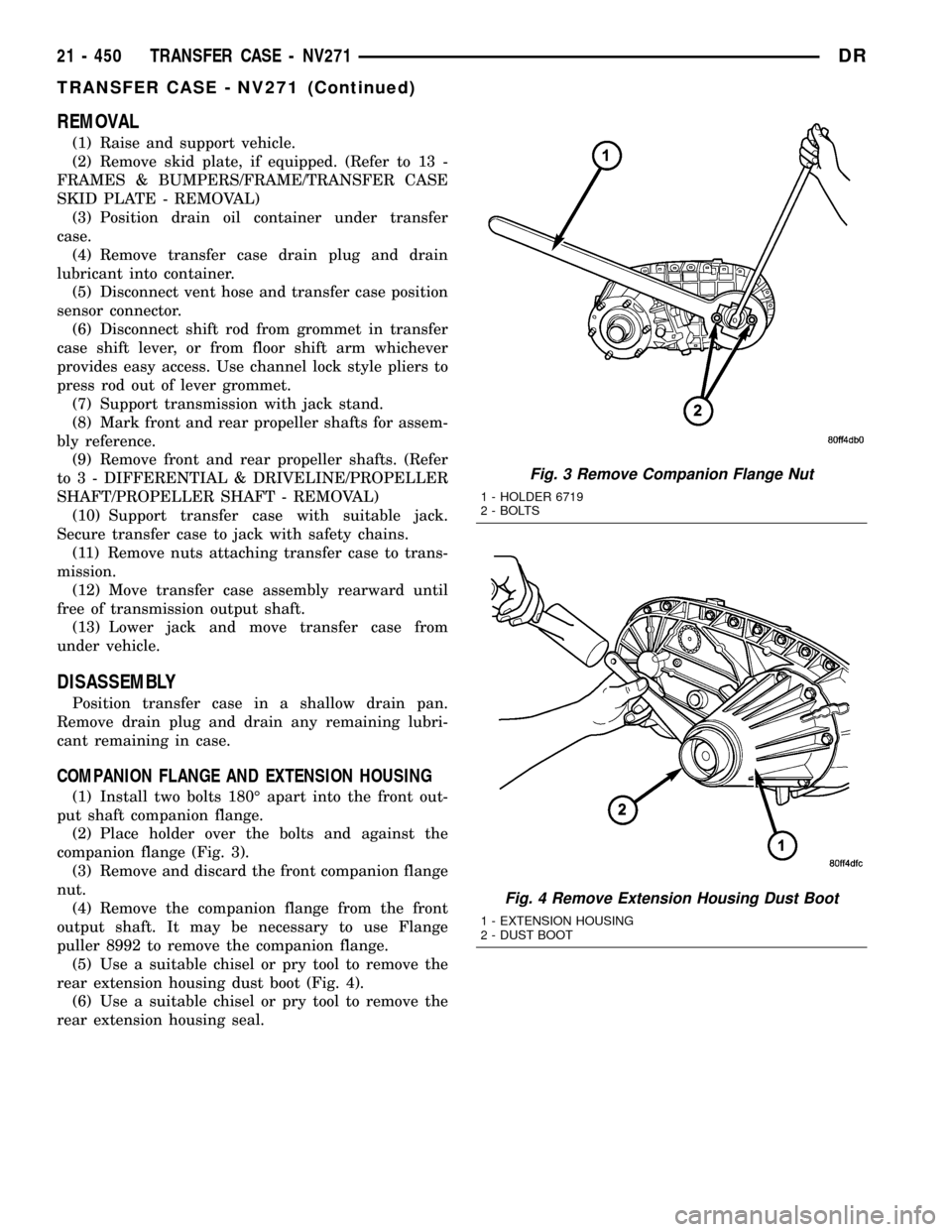

(5) Use a suitable chisel or pry tool to remove the

rear extension housing dust boot (Fig. 4).

(6) Use a suitable chisel or pry tool to remove the

rear extension housing seal.

Fig. 3 Remove Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

Fig. 4 Remove Extension Housing Dust Boot

1 - EXTENSION HOUSING

2 - DUST BOOT

21 - 450 TRANSFER CASE - NV271DR

TRANSFER CASE - NV271 (Continued)

Page 2156 of 2627

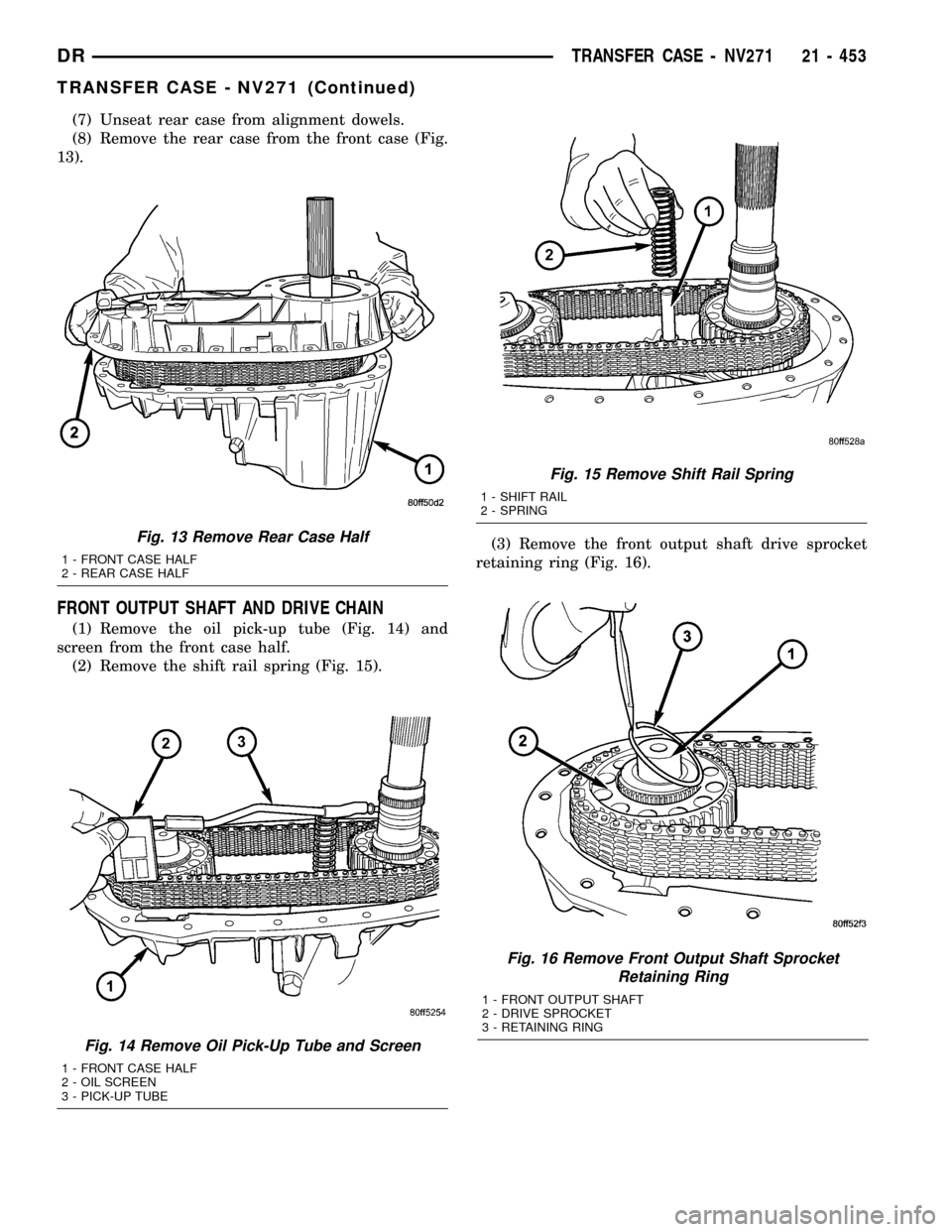

(7) Unseat rear case from alignment dowels.

(8) Remove the rear case from the front case (Fig.

13).

FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Remove the oil pick-up tube (Fig. 14) and

screen from the front case half.

(2) Remove the shift rail spring (Fig. 15).(3) Remove the front output shaft drive sprocket

retaining ring (Fig. 16).

Fig. 16 Remove Front Output Shaft Sprocket

Retaining Ring

1 - FRONT OUTPUT SHAFT

2 - DRIVE SPROCKET

3 - RETAINING RING

Fig. 13 Remove Rear Case Half

1 - FRONT CASE HALF

2 - REAR CASE HALF

Fig. 14 Remove Oil Pick-Up Tube and Screen

1 - FRONT CASE HALF

2 - OIL SCREEN

3 - PICK-UP TUBE

Fig. 15 Remove Shift Rail Spring

1 - SHIFT RAIL

2 - SPRING

DRTRANSFER CASE - NV271 21 - 453

TRANSFER CASE - NV271 (Continued)

Page 2157 of 2627

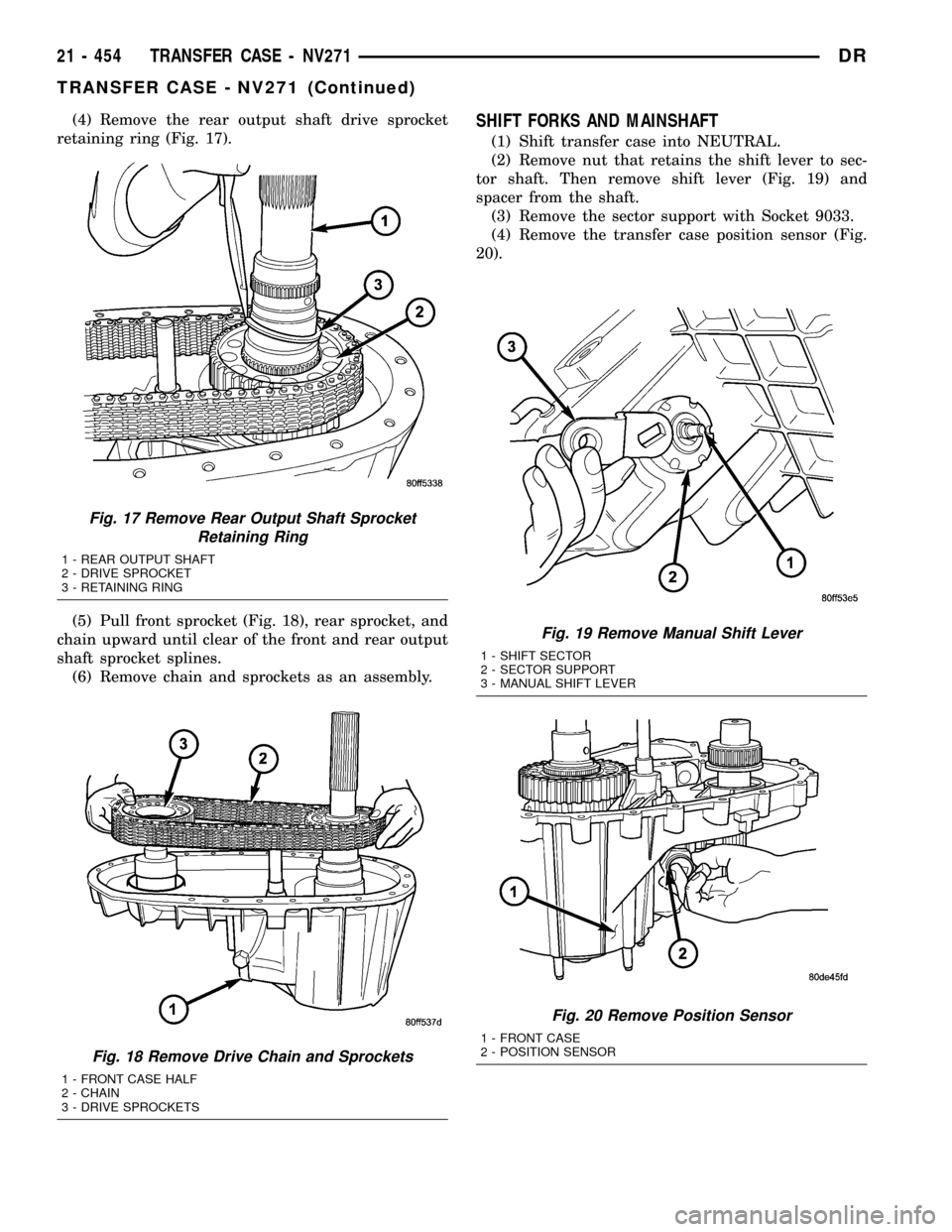

(4) Remove the rear output shaft drive sprocket

retaining ring (Fig. 17).

(5) Pull front sprocket (Fig. 18), rear sprocket, and

chain upward until clear of the front and rear output

shaft sprocket splines.

(6) Remove chain and sprockets as an assembly.SHIFT FORKS AND MAINSHAFT

(1) Shift transfer case into NEUTRAL.

(2) Remove nut that retains the shift lever to sec-

tor shaft. Then remove shift lever (Fig. 19) and

spacer from the shaft.

(3) Remove the sector support with Socket 9033.

(4) Remove the transfer case position sensor (Fig.

20).

Fig. 17 Remove Rear Output Shaft Sprocket

Retaining Ring

1 - REAR OUTPUT SHAFT

2 - DRIVE SPROCKET

3 - RETAINING RING

Fig. 18 Remove Drive Chain and Sprockets

1 - FRONT CASE HALF

2 - CHAIN

3 - DRIVE SPROCKETS

Fig. 19 Remove Manual Shift Lever

1 - SHIFT SECTOR

2 - SECTOR SUPPORT

3 - MANUAL SHIFT LEVER

Fig. 20 Remove Position Sensor

1 - FRONT CASE

2 - POSITION SENSOR

21 - 454 TRANSFER CASE - NV271DR

TRANSFER CASE - NV271 (Continued)

Page 2160 of 2627

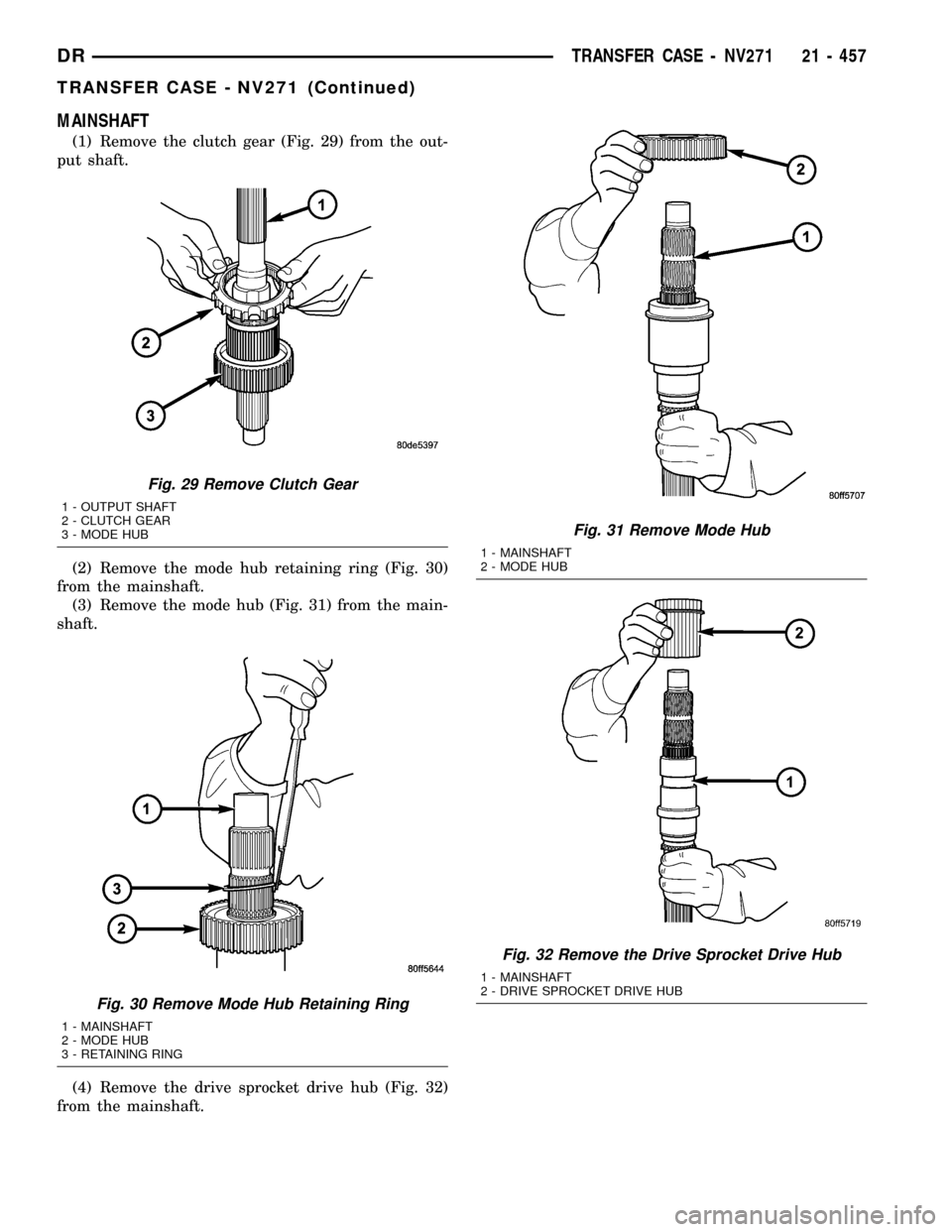

MAINSHAFT

(1) Remove the clutch gear (Fig. 29) from the out-

put shaft.

(2) Remove the mode hub retaining ring (Fig. 30)

from the mainshaft.

(3) Remove the mode hub (Fig. 31) from the main-

shaft.

(4) Remove the drive sprocket drive hub (Fig. 32)

from the mainshaft.

Fig. 29 Remove Clutch Gear

1 - OUTPUT SHAFT

2 - CLUTCH GEAR

3 - MODE HUB

Fig. 30 Remove Mode Hub Retaining Ring

1 - MAINSHAFT

2 - MODE HUB

3 - RETAINING RING

Fig. 31 Remove Mode Hub

1 - MAINSHAFT

2 - MODE HUB

Fig. 32 Remove the Drive Sprocket Drive Hub

1 - MAINSHAFT

2 - DRIVE SPROCKET DRIVE HUB

DRTRANSFER CASE - NV271 21 - 457

TRANSFER CASE - NV271 (Continued)

Page 2164 of 2627

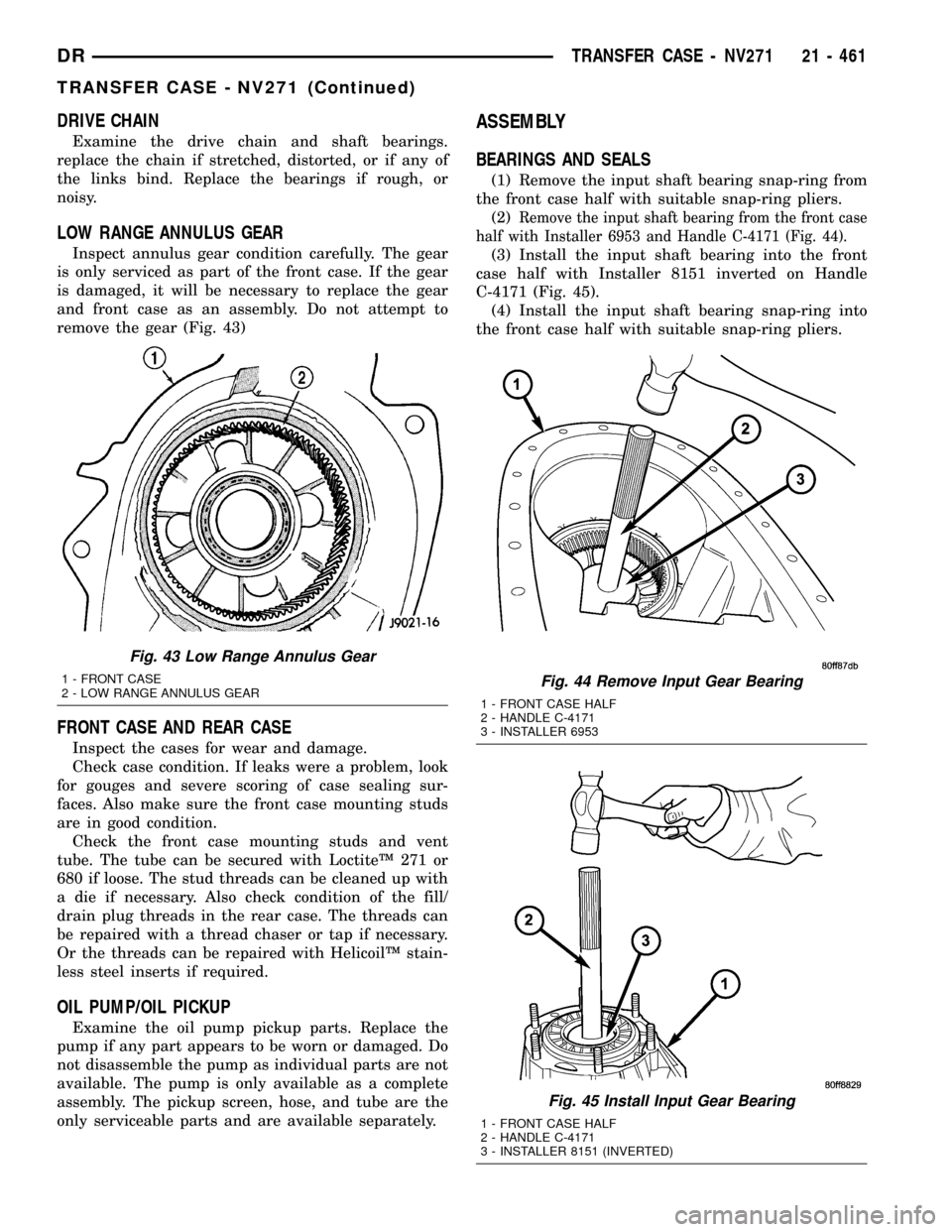

DRIVE CHAIN

Examine the drive chain and shaft bearings.

replace the chain if stretched, distorted, or if any of

the links bind. Replace the bearings if rough, or

noisy.

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 43)

FRONT CASE AND REAR CASE

Inspect the cases for wear and damage.

Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with HelicoilŸ stain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

ASSEMBLY

BEARINGS AND SEALS

(1) Remove the input shaft bearing snap-ring from

the front case half with suitable snap-ring pliers.

(2)

Remove the input shaft bearing from the front case

half with Installer 6953 and Handle C-4171 (Fig. 44).

(3) Install the input shaft bearing into the front

case half with Installer 8151 inverted on Handle

C-4171 (Fig. 45).

(4) Install the input shaft bearing snap-ring into

the front case half with suitable snap-ring pliers.

Fig. 43 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEARFig. 44 Remove Input Gear Bearing

1 - FRONT CASE HALF

2 - HANDLE C-4171

3 - INSTALLER 6953

Fig. 45 Install Input Gear Bearing

1 - FRONT CASE HALF

2 - HANDLE C-4171

3 - INSTALLER 8151 (INVERTED)

DRTRANSFER CASE - NV271 21 - 461

TRANSFER CASE - NV271 (Continued)

Page 2169 of 2627

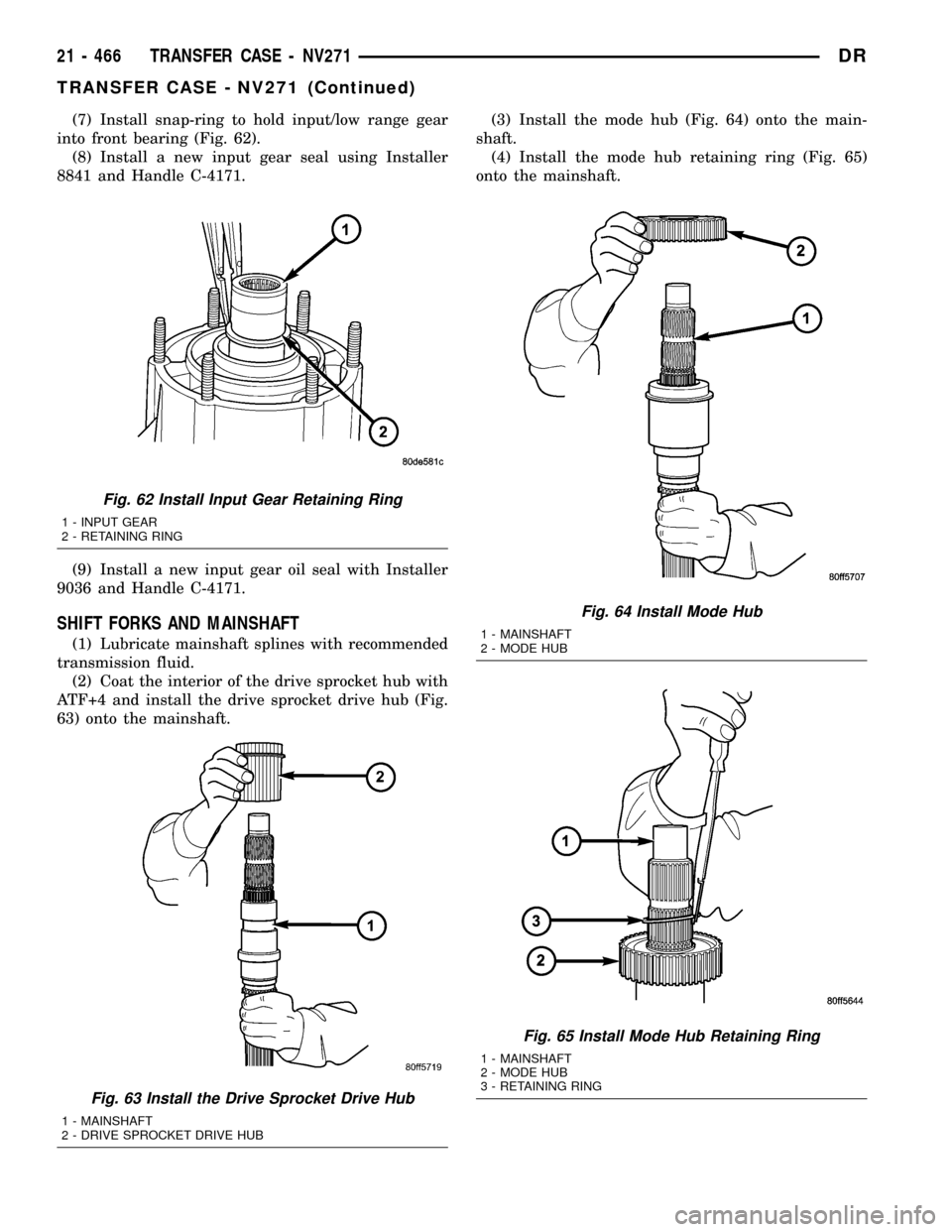

(7) Install snap-ring to hold input/low range gear

into front bearing (Fig. 62).

(8) Install a new input gear seal using Installer

8841 and Handle C-4171.

(9) Install a new input gear oil seal with Installer

9036 and Handle C-4171.

SHIFT FORKS AND MAINSHAFT

(1) Lubricate mainshaft splines with recommended

transmission fluid.

(2) Coat the interior of the drive sprocket hub with

ATF+4 and install the drive sprocket drive hub (Fig.

63) onto the mainshaft.(3) Install the mode hub (Fig. 64) onto the main-

shaft.

(4) Install the mode hub retaining ring (Fig. 65)

onto the mainshaft.

Fig. 62 Install Input Gear Retaining Ring

1 - INPUT GEAR

2 - RETAINING RING

Fig. 63 Install the Drive Sprocket Drive Hub

1 - MAINSHAFT

2 - DRIVE SPROCKET DRIVE HUB

Fig. 64 Install Mode Hub

1 - MAINSHAFT

2 - MODE HUB

Fig. 65 Install Mode Hub Retaining Ring

1 - MAINSHAFT

2 - MODE HUB

3 - RETAINING RING

21 - 466 TRANSFER CASE - NV271DR

TRANSFER CASE - NV271 (Continued)

Page 2172 of 2627

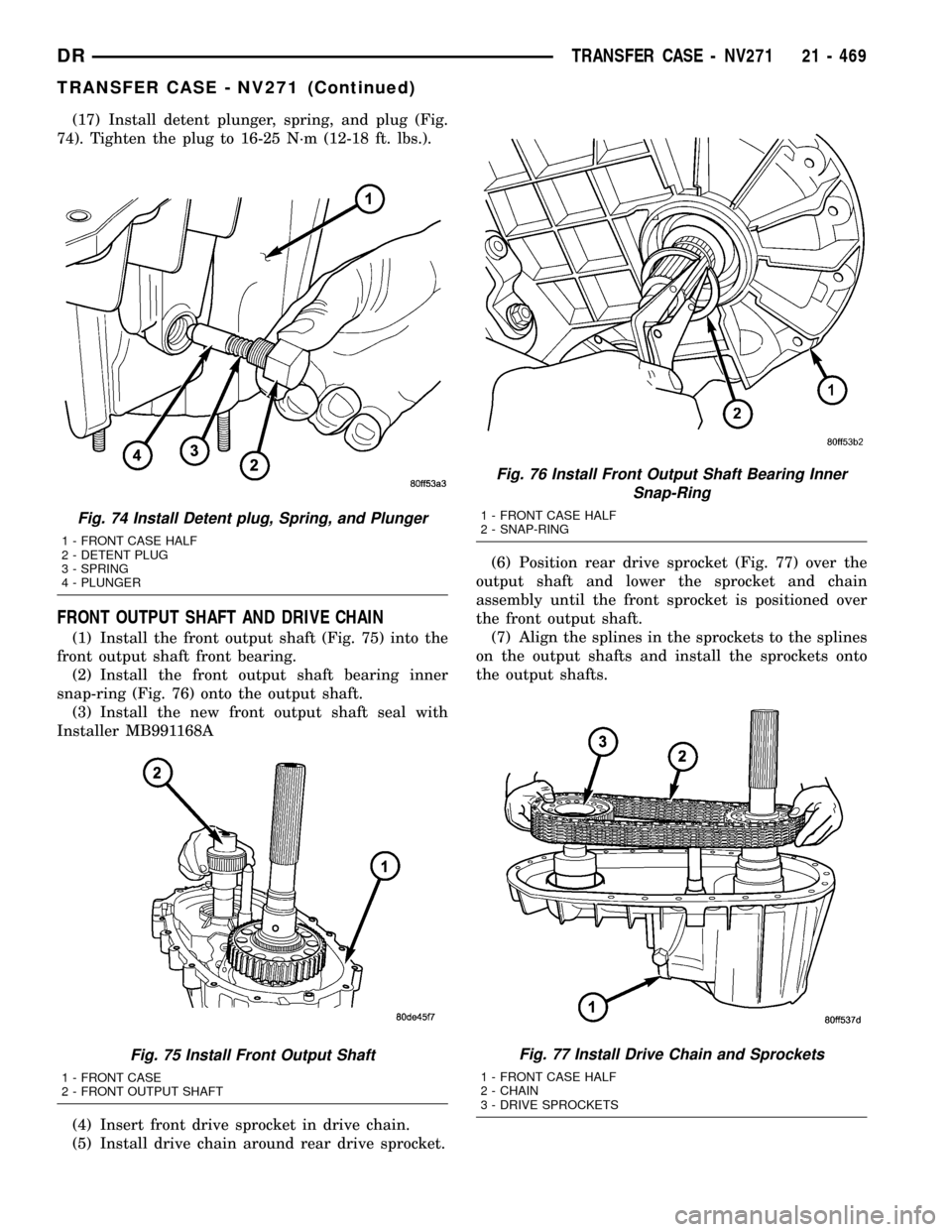

(17) Install detent plunger, spring, and plug (Fig.

74). Tighten the plug to 16-25 N´m (12-18 ft. lbs.).

FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Install the front output shaft (Fig. 75) into the

front output shaft front bearing.

(2) Install the front output shaft bearing inner

snap-ring (Fig. 76) onto the output shaft.

(3) Install the new front output shaft seal with

Installer MB991168A

(4) Insert front drive sprocket in drive chain.

(5) Install drive chain around rear drive sprocket.(6) Position rear drive sprocket (Fig. 77) over the

output shaft and lower the sprocket and chain

assembly until the front sprocket is positioned over

the front output shaft.

(7) Align the splines in the sprockets to the splines

on the output shafts and install the sprockets onto

the output shafts.

Fig. 74 Install Detent plug, Spring, and Plunger

1 - FRONT CASE HALF

2 - DETENT PLUG

3 - SPRING

4 - PLUNGER

Fig. 75 Install Front Output Shaft

1 - FRONT CASE

2 - FRONT OUTPUT SHAFT

Fig. 76 Install Front Output Shaft Bearing Inner

Snap-Ring

1 - FRONT CASE HALF

2 - SNAP-RING

Fig. 77 Install Drive Chain and Sprockets

1 - FRONT CASE HALF

2 - CHAIN

3 - DRIVE SPROCKETS

DRTRANSFER CASE - NV271 21 - 469

TRANSFER CASE - NV271 (Continued)

Page 2173 of 2627

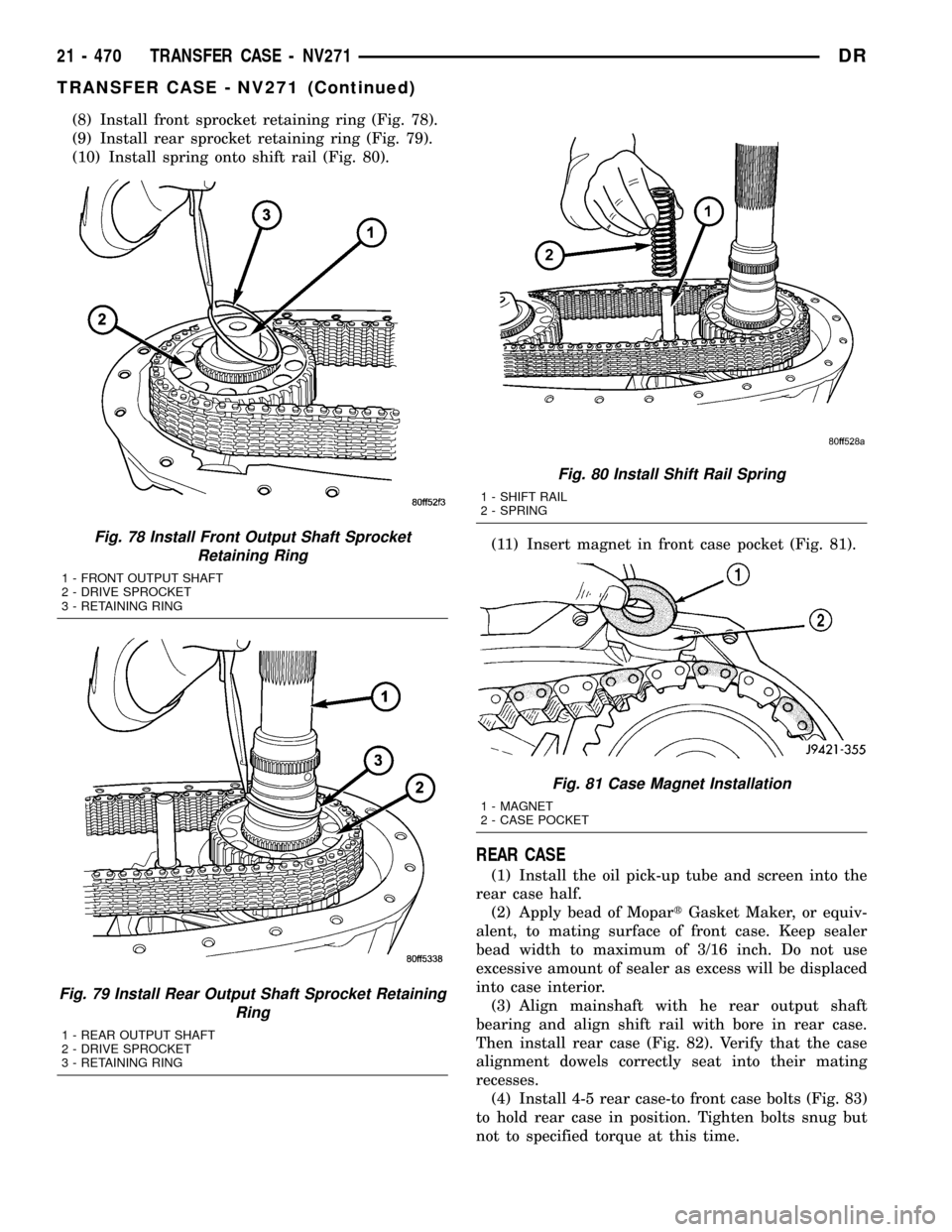

(8) Install front sprocket retaining ring (Fig. 78).

(9) Install rear sprocket retaining ring (Fig. 79).

(10) Install spring onto shift rail (Fig. 80).

(11) Insert magnet in front case pocket (Fig. 81).

REAR CASE

(1) Install the oil pick-up tube and screen into the

rear case half.

(2) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of front case. Keep sealer

bead width to maximum of 3/16 inch. Do not use

excessive amount of sealer as excess will be displaced

into case interior.

(3) Align mainshaft with he rear output shaft

bearing and align shift rail with bore in rear case.

Then install rear case (Fig. 82). Verify that the case

alignment dowels correctly seat into their mating

recesses.

(4) Install 4-5 rear case-to front case bolts (Fig. 83)

to hold rear case in position. Tighten bolts snug but

not to specified torque at this time.

Fig. 78 Install Front Output Shaft Sprocket

Retaining Ring

1 - FRONT OUTPUT SHAFT

2 - DRIVE SPROCKET

3 - RETAINING RING

Fig. 79 Install Rear Output Shaft Sprocket Retaining

Ring

1 - REAR OUTPUT SHAFT

2 - DRIVE SPROCKET

3 - RETAINING RING

Fig. 80 Install Shift Rail Spring

1 - SHIFT RAIL

2 - SPRING

Fig. 81 Case Magnet Installation

1 - MAGNET

2 - CASE POCKET

21 - 470 TRANSFER CASE - NV271DR

TRANSFER CASE - NV271 (Continued)

Page 2176 of 2627

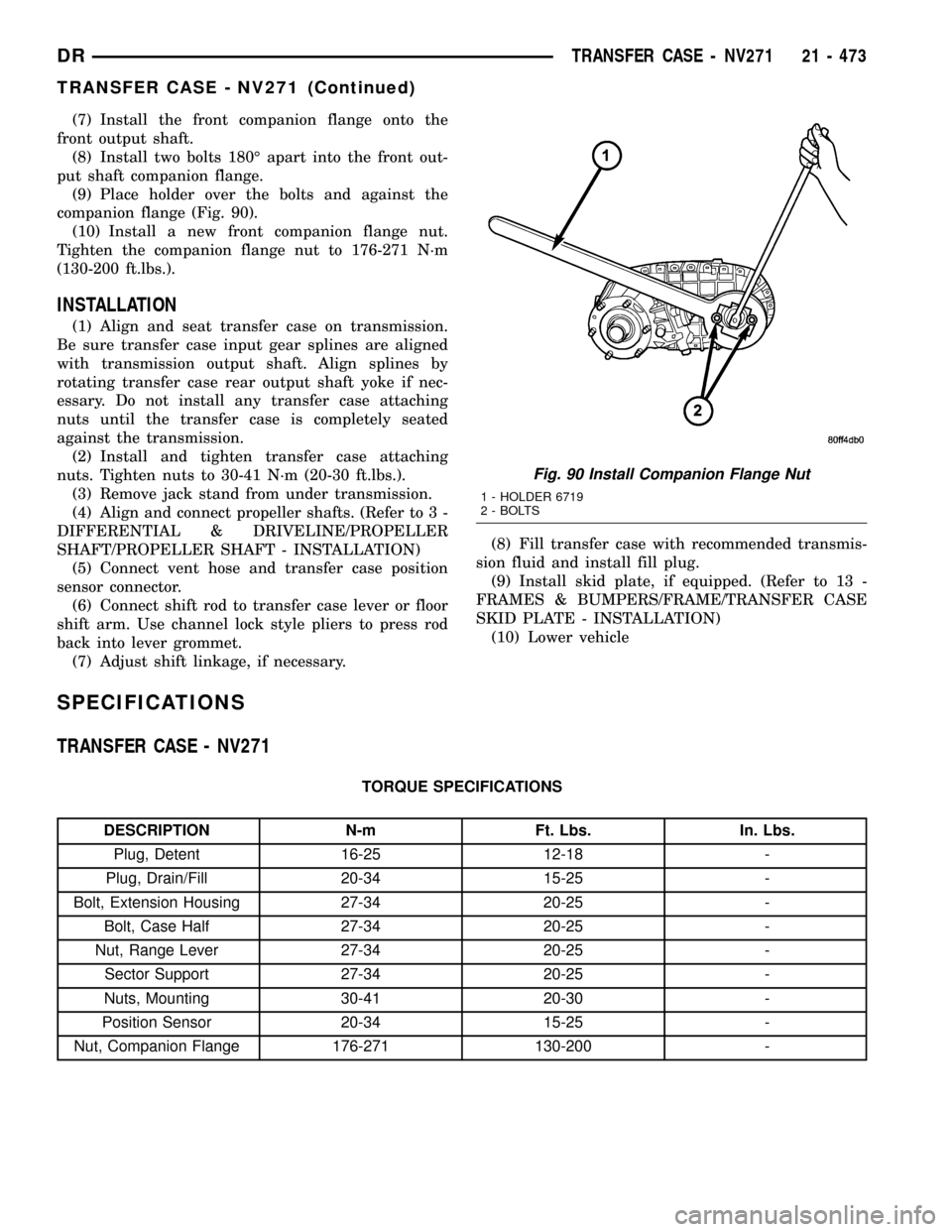

(7) Install the front companion flange onto the

front output shaft.

(8) Install two bolts 180É apart into the front out-

put shaft companion flange.

(9) Place holder over the bolts and against the

companion flange (Fig. 90).

(10) Install a new front companion flange nut.

Tighten the companion flange nut to 176-271 N´m

(130-200 ft.lbs.).

INSTALLATION

(1) Align and seat transfer case on transmission.

Be sure transfer case input gear splines are aligned

with transmission output shaft. Align splines by

rotating transfer case rear output shaft yoke if nec-

essary. Do not install any transfer case attaching

nuts until the transfer case is completely seated

against the transmission.

(2) Install and tighten transfer case attaching

nuts. Tighten nuts to 30-41 N´m (20-30 ft.lbs.).

(3) Remove jack stand from under transmission.

(4) Align and connect propeller shafts. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(5) Connect vent hose and transfer case position

sensor connector.

(6) Connect shift rod to transfer case lever or floor

shift arm. Use channel lock style pliers to press rod

back into lever grommet.

(7) Adjust shift linkage, if necessary.(8) Fill transfer case with recommended transmis-

sion fluid and install fill plug.

(9) Install skid plate, if equipped. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION)

(10) Lower vehicle

SPECIFICATIONS

TRANSFER CASE - NV271

TORQUE SPECIFICATIONS

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-25 12-18 -

Plug, Drain/Fill 20-34 15-25 -

Bolt, Extension Housing 27-34 20-25 -

Bolt, Case Half 27-34 20-25 -

Nut, Range Lever 27-34 20-25 -

Sector Support 27-34 20-25 -

Nuts, Mounting 30-41 20-30 -

Position Sensor 20-34 15-25 -

Nut, Companion Flange 176-271 130-200 -

Fig. 90 Install Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

DRTRANSFER CASE - NV271 21 - 473

TRANSFER CASE - NV271 (Continued)