Drive shaft DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2221 of 2627

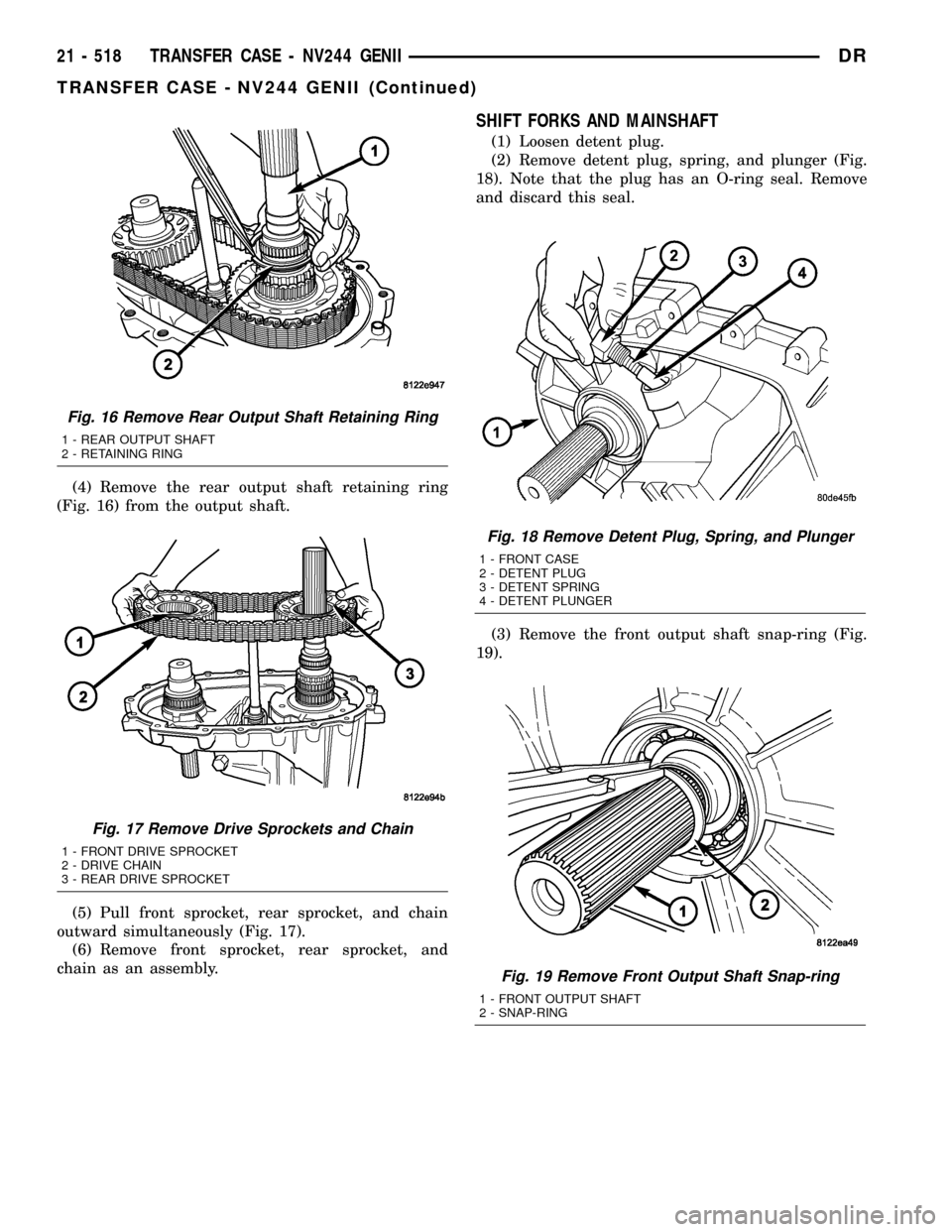

(4) Remove the rear output shaft retaining ring

(Fig. 16) from the output shaft.

(5) Pull front sprocket, rear sprocket, and chain

outward simultaneously (Fig. 17).

(6) Remove front sprocket, rear sprocket, and

chain as an assembly.

SHIFT FORKS AND MAINSHAFT

(1) Loosen detent plug.

(2) Remove detent plug, spring, and plunger (Fig.

18). Note that the plug has an O-ring seal. Remove

and discard this seal.

(3) Remove the front output shaft snap-ring (Fig.

19).

Fig. 18 Remove Detent Plug, Spring, and Plunger

1 - FRONT CASE

2 - DETENT PLUG

3 - DETENT SPRING

4 - DETENT PLUNGER

Fig. 19 Remove Front Output Shaft Snap-ring

1 - FRONT OUTPUT SHAFT

2 - SNAP-RING

Fig. 16 Remove Rear Output Shaft Retaining Ring

1 - REAR OUTPUT SHAFT

2 - RETAINING RING

Fig. 17 Remove Drive Sprockets and Chain

1 - FRONT DRIVE SPROCKET

2 - DRIVE CHAIN

3 - REAR DRIVE SPROCKET

21 - 518 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2227 of 2627

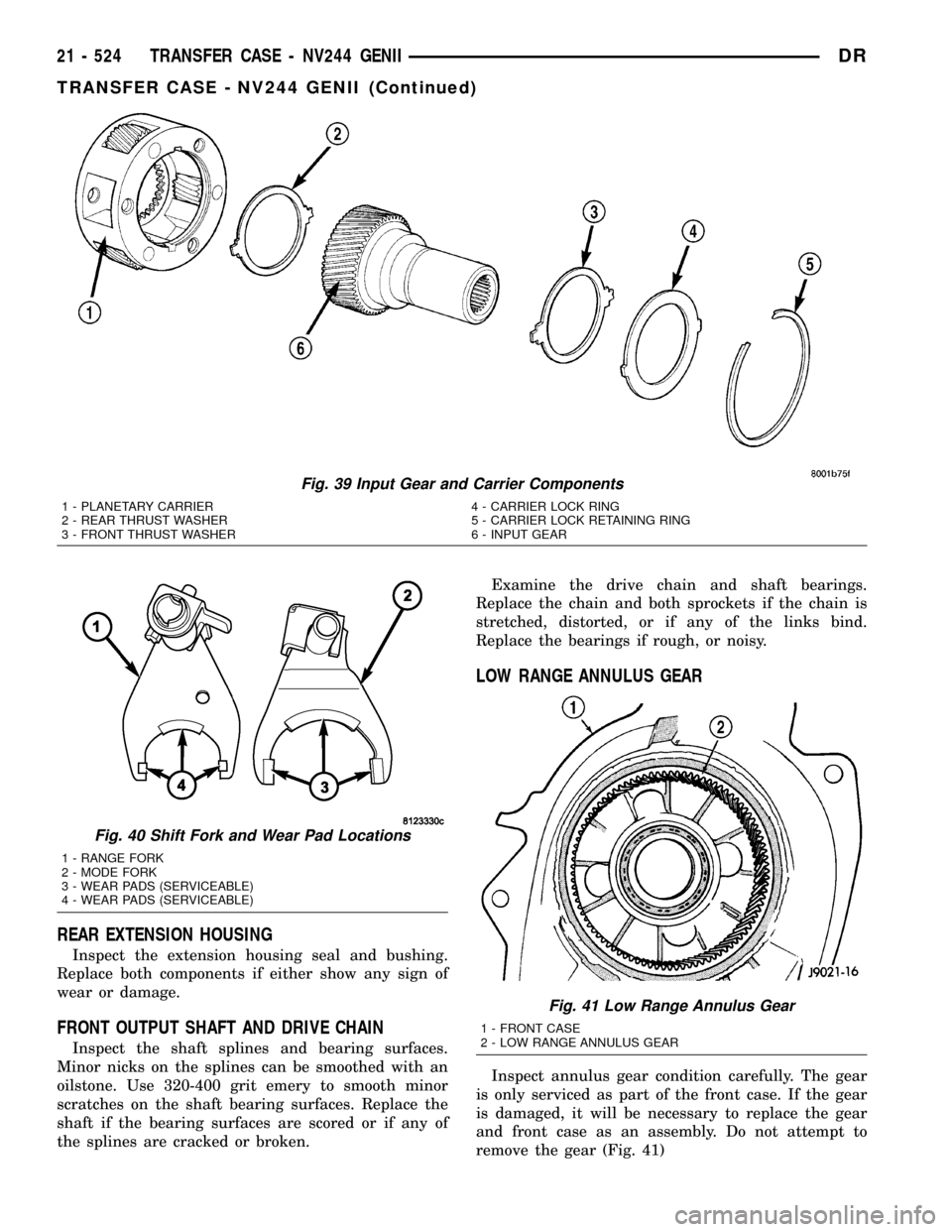

REAR EXTENSION HOUSING

Inspect the extension housing seal and bushing.

Replace both components if either show any sign of

wear or damage.

FRONT OUTPUT SHAFT AND DRIVE CHAIN

Inspect the shaft splines and bearing surfaces.

Minor nicks on the splines can be smoothed with an

oilstone. Use 320-400 grit emery to smooth minor

scratches on the shaft bearing surfaces. Replace the

shaft if the bearing surfaces are scored or if any of

the splines are cracked or broken.Examine the drive chain and shaft bearings.

Replace the chain and both sprockets if the chain is

stretched, distorted, or if any of the links bind.

Replace the bearings if rough, or noisy.

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 41)

Fig. 39 Input Gear and Carrier Components

1 - PLANETARY CARRIER 4 - CARRIER LOCK RING

2 - REAR THRUST WASHER 5 - CARRIER LOCK RETAINING RING

3 - FRONT THRUST WASHER 6 - INPUT GEAR

Fig. 40 Shift Fork and Wear Pad Locations

1 - RANGE FORK

2 - MODE FORK

3 - WEAR PADS (SERVICEABLE)

4 - WEAR PADS (SERVICEABLE)

Fig. 41 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEAR

21 - 524 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2233 of 2627

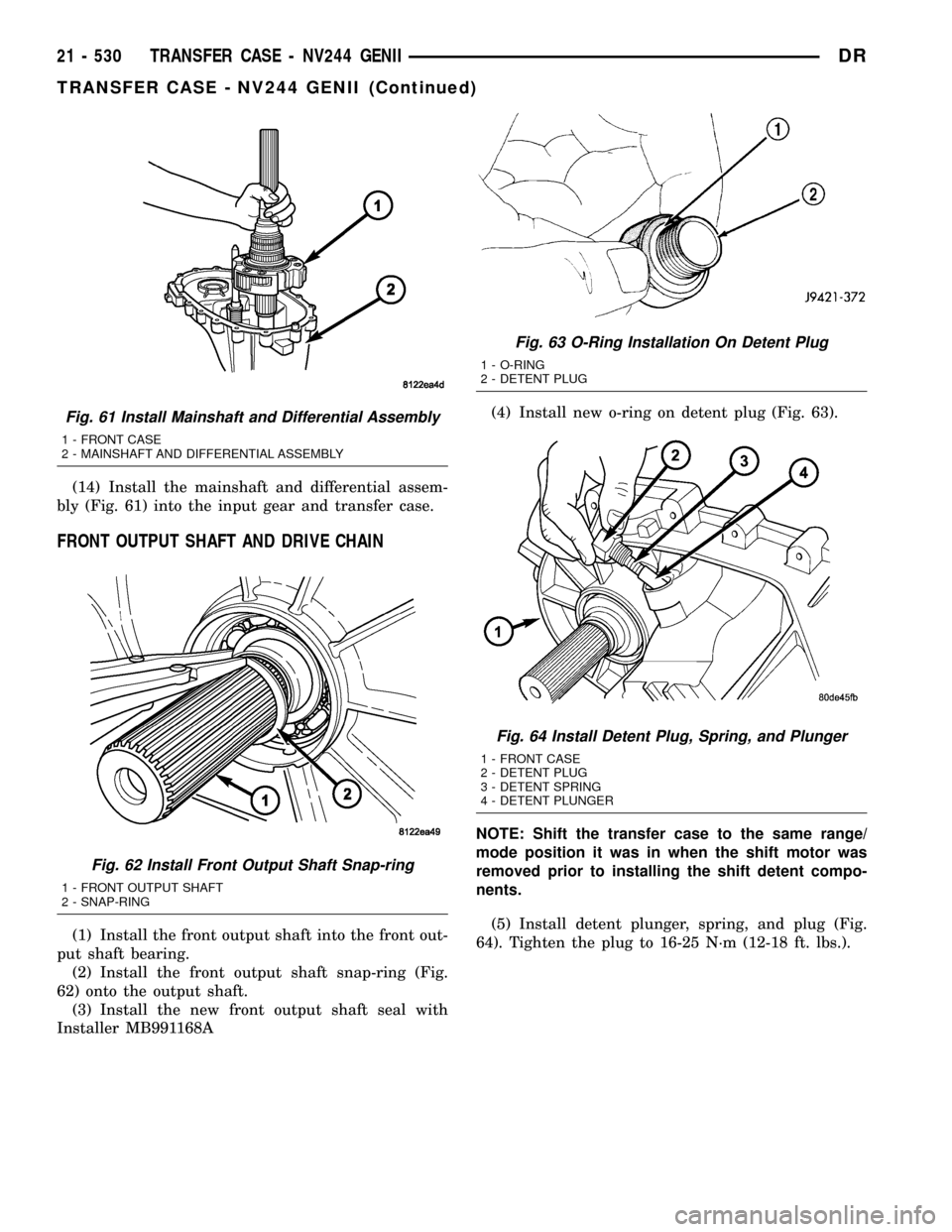

(14) Install the mainshaft and differential assem-

bly (Fig. 61) into the input gear and transfer case.

FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Install the front output shaft into the front out-

put shaft bearing.

(2) Install the front output shaft snap-ring (Fig.

62) onto the output shaft.

(3) Install the new front output shaft seal with

Installer MB991168A(4) Install new o-ring on detent plug (Fig. 63).

NOTE: Shift the transfer case to the same range/

mode position it was in when the shift motor was

removed prior to installing the shift detent compo-

nents.

(5) Install detent plunger, spring, and plug (Fig.

64). Tighten the plug to 16-25 N´m (12-18 ft. lbs.).

Fig. 61 Install Mainshaft and Differential Assembly

1 - FRONT CASE

2 - MAINSHAFT AND DIFFERENTIAL ASSEMBLY

Fig. 62 Install Front Output Shaft Snap-ring

1 - FRONT OUTPUT SHAFT

2 - SNAP-RING

Fig. 63 O-Ring Installation On Detent Plug

1 - O-RING

2 - DETENT PLUG

Fig. 64 Install Detent Plug, Spring, and Plunger

1 - FRONT CASE

2 - DETENT PLUG

3 - DETENT SPRING

4 - DETENT PLUNGER

21 - 530 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2234 of 2627

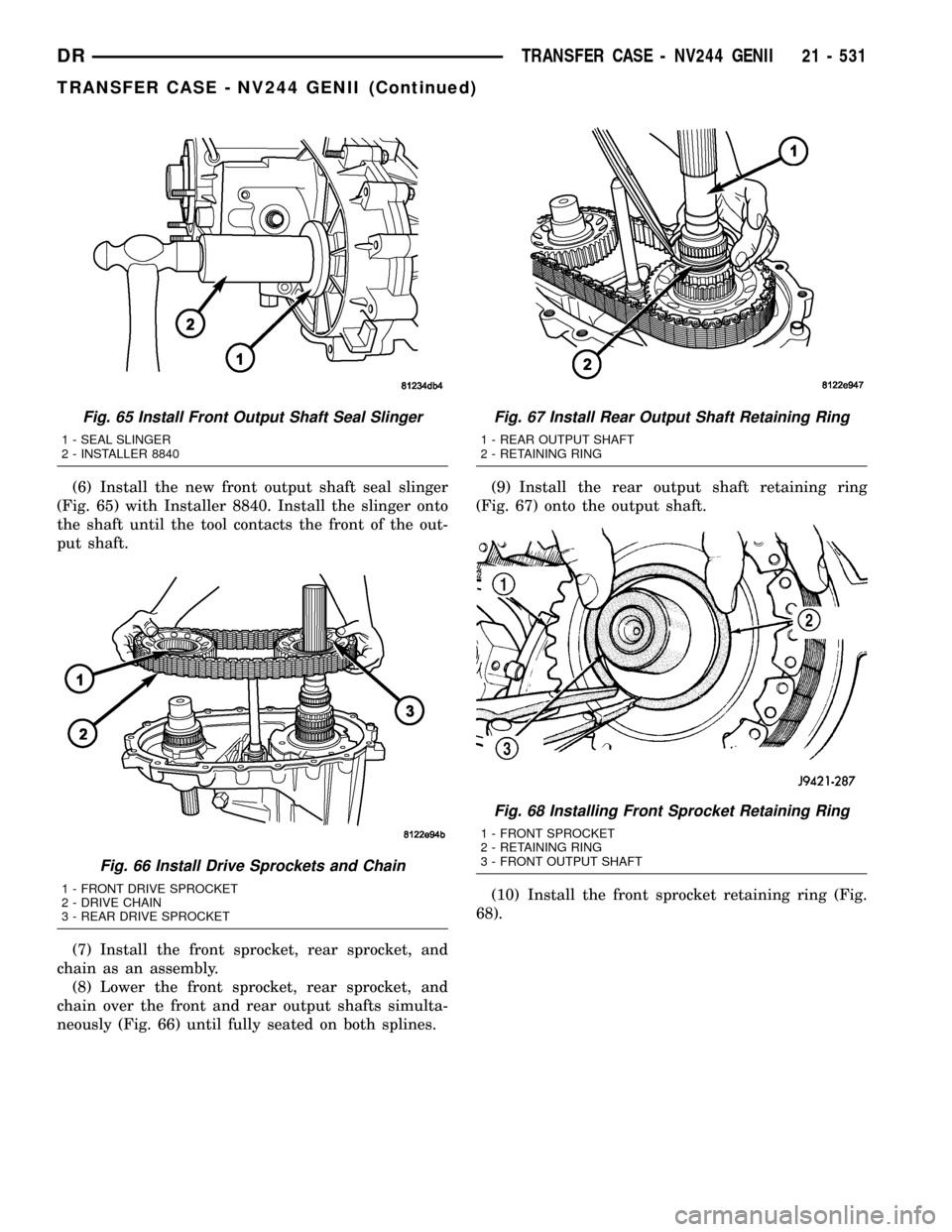

(6) Install the new front output shaft seal slinger

(Fig. 65) with Installer 8840. Install the slinger onto

the shaft until the tool contacts the front of the out-

put shaft.

(7) Install the front sprocket, rear sprocket, and

chain as an assembly.

(8) Lower the front sprocket, rear sprocket, and

chain over the front and rear output shafts simulta-

neously (Fig. 66) until fully seated on both splines.(9) Install the rear output shaft retaining ring

(Fig. 67) onto the output shaft.

(10) Install the front sprocket retaining ring (Fig.

68).

Fig. 65 Install Front Output Shaft Seal Slinger

1 - SEAL SLINGER

2 - INSTALLER 8840

Fig. 66 Install Drive Sprockets and Chain

1 - FRONT DRIVE SPROCKET

2 - DRIVE CHAIN

3 - REAR DRIVE SPROCKET

Fig. 67 Install Rear Output Shaft Retaining Ring

1 - REAR OUTPUT SHAFT

2 - RETAINING RING

Fig. 68 Installing Front Sprocket Retaining Ring

1 - FRONT SPROCKET

2 - RETAINING RING

3 - FRONT OUTPUT SHAFT

DRTRANSFER CASE - NV244 GENII 21 - 531

TRANSFER CASE - NV244 GENII (Continued)

Page 2239 of 2627

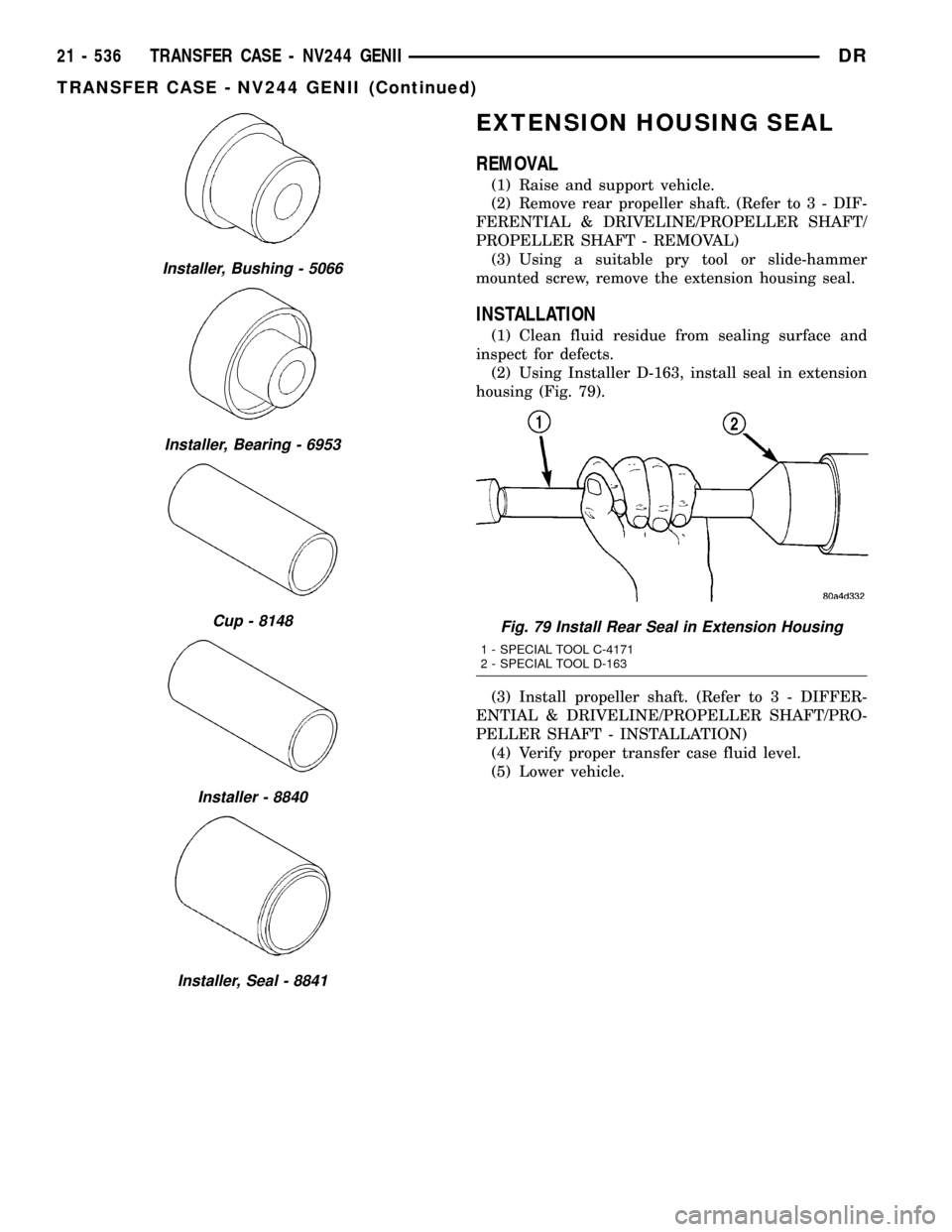

EXTENSION HOUSING SEAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Using a suitable pry tool or slide-hammer

mounted screw, remove the extension housing seal.

INSTALLATION

(1) Clean fluid residue from sealing surface and

inspect for defects.

(2) Using Installer D-163, install seal in extension

housing (Fig. 79).

(3) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)

(4) Verify proper transfer case fluid level.

(5) Lower vehicle.

Installer, Bushing - 5066

Installer, Bearing - 6953

Cup - 8148

Installer - 8840

Installer, Seal - 8841

Fig. 79 Install Rear Seal in Extension Housing

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL D-163

21 - 536 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2240 of 2627

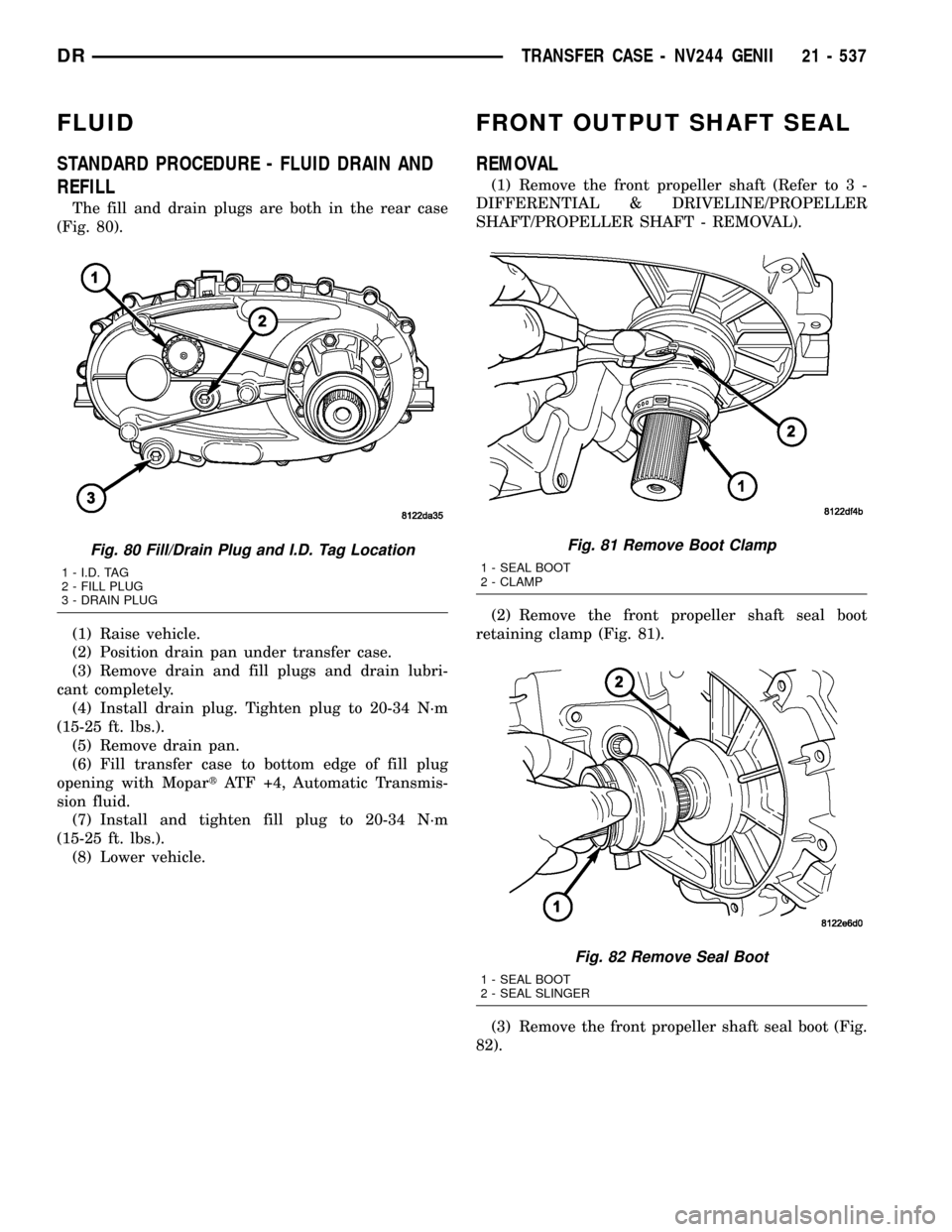

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL

The fill and drain plugs are both in the rear case

(Fig. 80).

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 20-34 N´m

(15-25 ft. lbs.).

(5) Remove drain pan.

(6) Fill transfer case to bottom edge of fill plug

opening with MopartATF +4, Automatic Transmis-

sion fluid.

(7) Install and tighten fill plug to 20-34 N´m

(15-25 ft. lbs.).

(8) Lower vehicle.

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Remove the front propeller shaft (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL).

(2) Remove the front propeller shaft seal boot

retaining clamp (Fig. 81).

(3) Remove the front propeller shaft seal boot (Fig.

82).

Fig. 80 Fill/Drain Plug and I.D. Tag Location

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

Fig. 81 Remove Boot Clamp

1 - SEAL BOOT

2 - CLAMP

Fig. 82 Remove Seal Boot

1 - SEAL BOOT

2 - SEAL SLINGER

DRTRANSFER CASE - NV244 GENII 21 - 537

Page 2241 of 2627

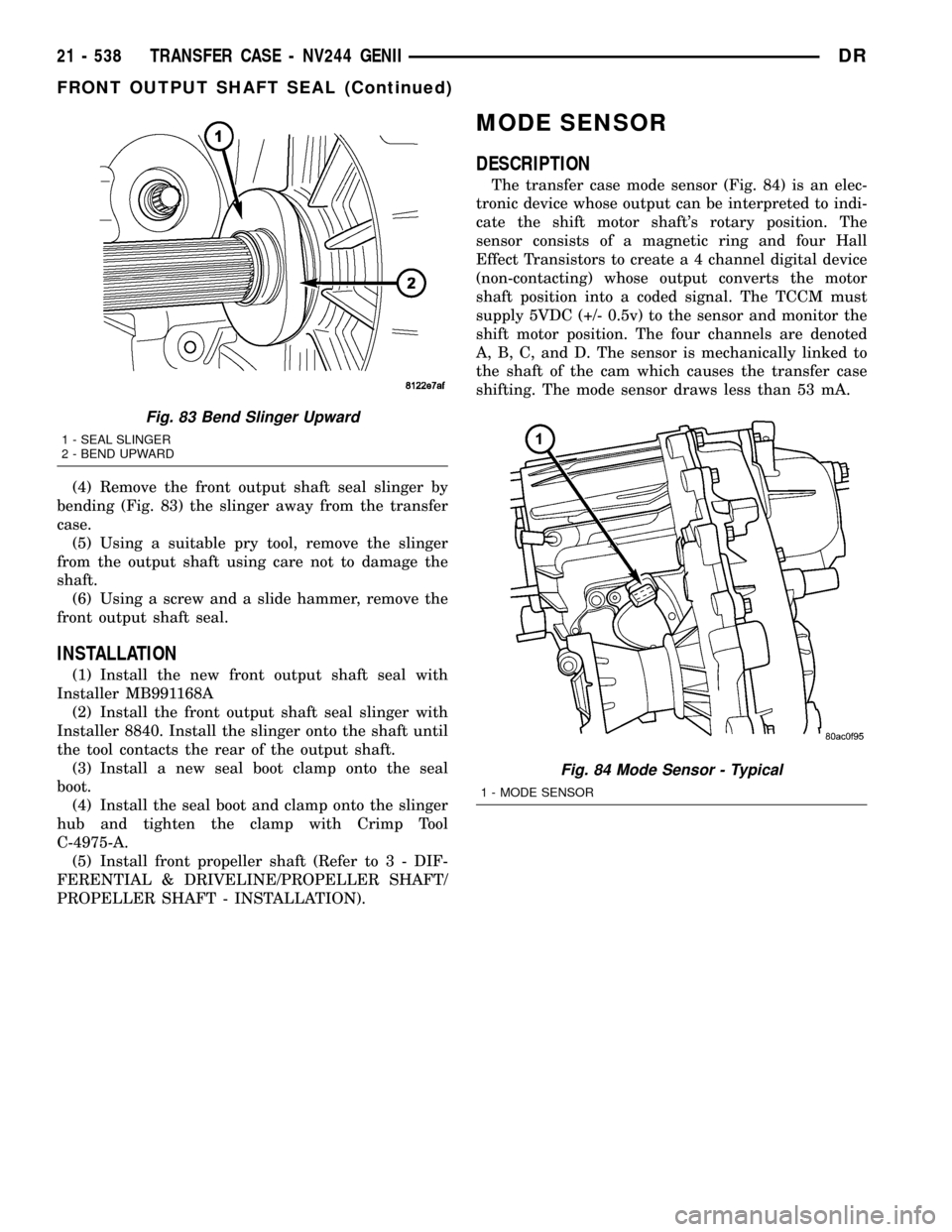

(4) Remove the front output shaft seal slinger by

bending (Fig. 83) the slinger away from the transfer

case.

(5) Using a suitable pry tool, remove the slinger

from the output shaft using care not to damage the

shaft.

(6) Using a screw and a slide hammer, remove the

front output shaft seal.

INSTALLATION

(1) Install the new front output shaft seal with

Installer MB991168A

(2) Install the front output shaft seal slinger with

Installer 8840. Install the slinger onto the shaft until

the tool contacts the rear of the output shaft.

(3) Install a new seal boot clamp onto the seal

boot.

(4) Install the seal boot and clamp onto the slinger

hub and tighten the clamp with Crimp Tool

C-4975-A.

(5) Install front propeller shaft (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION).

MODE SENSOR

DESCRIPTION

The transfer case mode sensor (Fig. 84) is an elec-

tronic device whose output can be interpreted to indi-

cate the shift motor shaft's rotary position. The

sensor consists of a magnetic ring and four Hall

Effect Transistors to create a 4 channel digital device

(non-contacting) whose output converts the motor

shaft position into a coded signal. The TCCM must

supply 5VDC (+/- 0.5v) to the sensor and monitor the

shift motor position. The four channels are denoted

A, B, C, and D. The sensor is mechanically linked to

the shaft of the cam which causes the transfer case

shifting. The mode sensor draws less than 53 mA.

Fig. 83 Bend Slinger Upward

1 - SEAL SLINGER

2 - BEND UPWARD

Fig. 84 Mode Sensor - Typical

1 - MODE SENSOR

21 - 538 TRANSFER CASE - NV244 GENIIDR

FRONT OUTPUT SHAFT SEAL (Continued)

Page 2245 of 2627

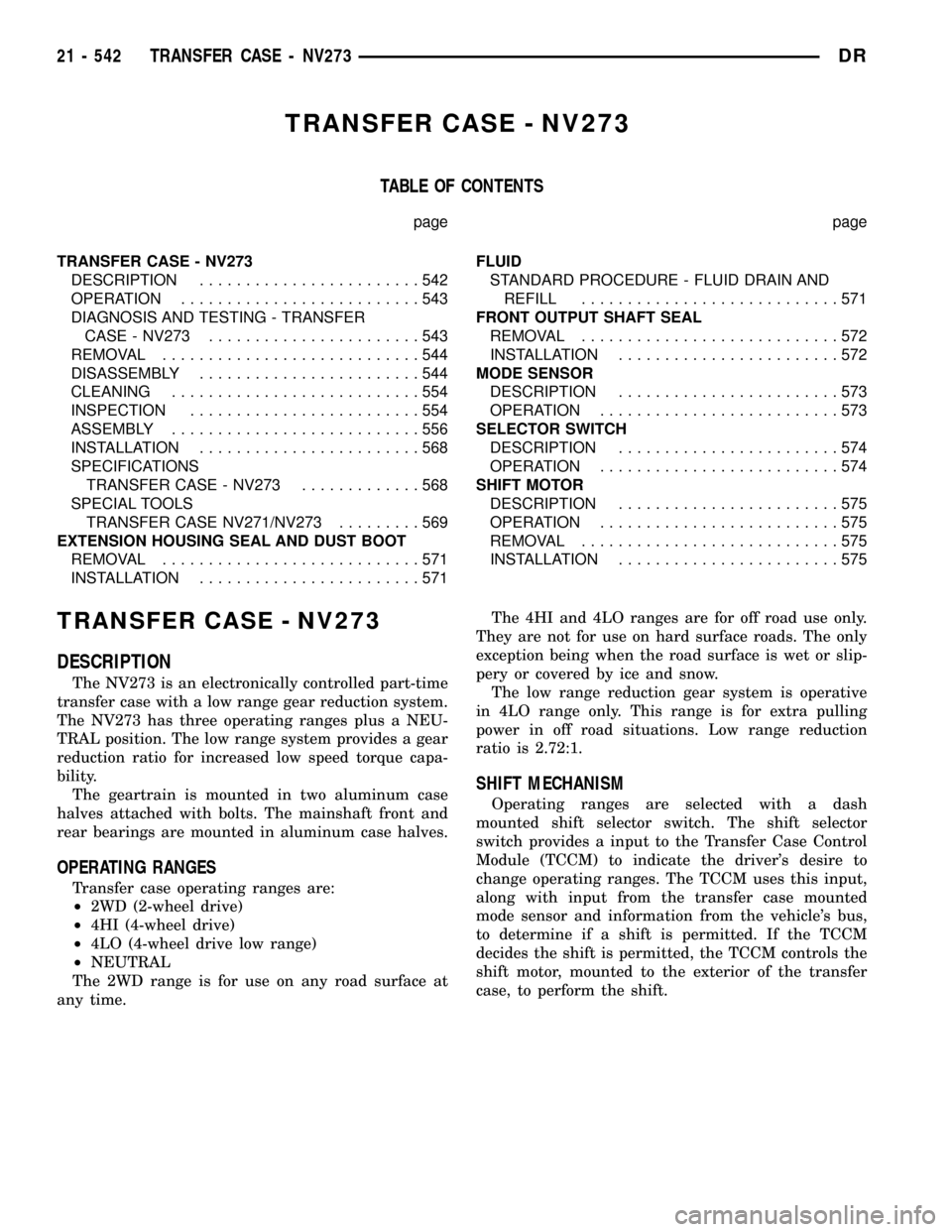

TRANSFER CASE - NV273

TABLE OF CONTENTS

page page

TRANSFER CASE - NV273

DESCRIPTION........................542

OPERATION..........................543

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV273.......................543

REMOVAL............................544

DISASSEMBLY........................544

CLEANING...........................554

INSPECTION.........................554

ASSEMBLY...........................556

INSTALLATION........................568

SPECIFICATIONS

TRANSFER CASE - NV273.............568

SPECIAL TOOLS

TRANSFER CASE NV271/NV273.........569

EXTENSION HOUSING SEAL AND DUST BOOT

REMOVAL............................571

INSTALLATION........................571FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL............................571

FRONT OUTPUT SHAFT SEAL

REMOVAL............................572

INSTALLATION........................572

MODE SENSOR

DESCRIPTION........................573

OPERATION..........................573

SELECTOR SWITCH

DESCRIPTION........................574

OPERATION..........................574

SHIFT MOTOR

DESCRIPTION........................575

OPERATION..........................575

REMOVAL............................575

INSTALLATION........................575

TRANSFER CASE - NV273

DESCRIPTION

The NV273 is an electronically controlled part-time

transfer case with a low range gear reduction system.

The NV273 has three operating ranges plus a NEU-

TRAL position. The low range system provides a gear

reduction ratio for increased low speed torque capa-

bility.

The geartrain is mounted in two aluminum case

halves attached with bolts. The mainshaft front and

rear bearings are mounted in aluminum case halves.

OPERATING RANGES

Transfer case operating ranges are:

²2WD (2-wheel drive)

²4HI (4-wheel drive)

²4LO (4-wheel drive low range)

²NEUTRAL

The 2WD range is for use on any road surface at

any time.The 4HI and 4LO ranges are for off road use only.

They are not for use on hard surface roads. The only

exception being when the road surface is wet or slip-

pery or covered by ice and snow.

The low range reduction gear system is operative

in 4LO range only. This range is for extra pulling

power in off road situations. Low range reduction

ratio is 2.72:1.

SHIFT MECHANISM

Operating ranges are selected with a dash

mounted shift selector switch. The shift selector

switch provides a input to the Transfer Case Control

Module (TCCM) to indicate the driver's desire to

change operating ranges. The TCCM uses this input,

along with input from the transfer case mounted

mode sensor and information from the vehicle's bus,

to determine if a shift is permitted. If the TCCM

decides the shift is permitted, the TCCM controls the

shift motor, mounted to the exterior of the transfer

case, to perform the shift.

21 - 542 TRANSFER CASE - NV273DR

Page 2246 of 2627

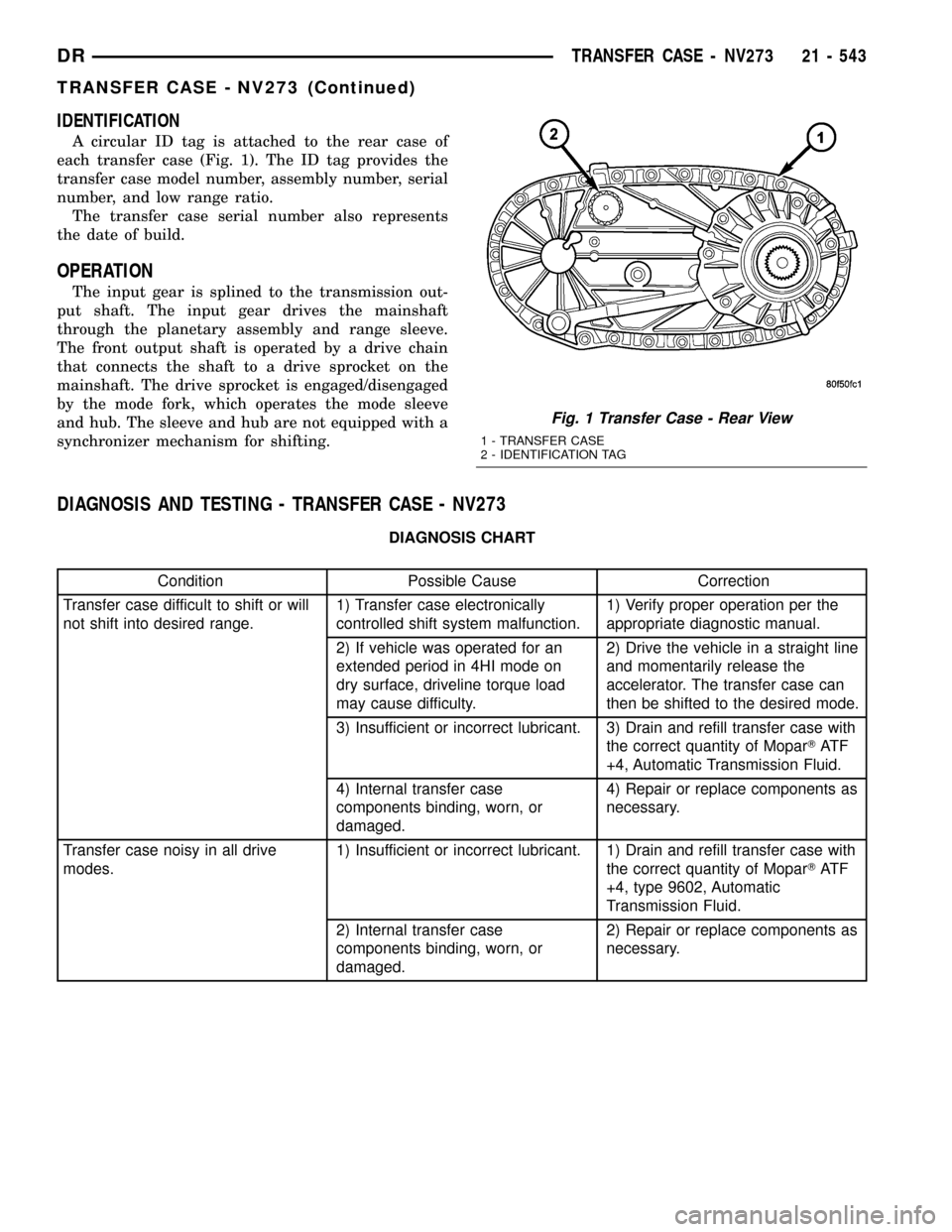

IDENTIFICATION

A circular ID tag is attached to the rear case of

each transfer case (Fig. 1). The ID tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.

The transfer case serial number also represents

the date of build.

OPERATION

The input gear is splined to the transmission out-

put shaft. The input gear drives the mainshaft

through the planetary assembly and range sleeve.

The front output shaft is operated by a drive chain

that connects the shaft to a drive sprocket on the

mainshaft. The drive sprocket is engaged/disengaged

by the mode fork, which operates the mode sleeve

and hub. The sleeve and hub are not equipped with a

synchronizer mechanism for shifting.

DIAGNOSIS AND TESTING - TRANSFER CASE - NV273

DIAGNOSIS CHART

Condition Possible Cause Correction

Transfer case difficult to shift or will

not shift into desired range.1) Transfer case electronically

controlled shift system malfunction.1) Verify proper operation per the

appropriate diagnostic manual.

2) If vehicle was operated for an

extended period in 4HI mode on

dry surface, driveline torque load

may cause difficulty.2) Drive the vehicle in a straight line

and momentarily release the

accelerator. The transfer case can

then be shifted to the desired mode.

3) Insufficient or incorrect lubricant. 3) Drain and refill transfer case with

the correct quantity of MoparTAT F

+4, Automatic Transmission Fluid.

4) Internal transfer case

components binding, worn, or

damaged.4) Repair or replace components as

necessary.

Transfer case noisy in all drive

modes.1) Insufficient or incorrect lubricant. 1) Drain and refill transfer case with

the correct quantity of MoparTAT F

+4, type 9602, Automatic

Transmission Fluid.

2) Internal transfer case

components binding, worn, or

damaged.2) Repair or replace components as

necessary.

Fig. 1 Transfer Case - Rear View

1 - TRANSFER CASE

2 - IDENTIFICATION TAG

DRTRANSFER CASE - NV273 21 - 543

TRANSFER CASE - NV273 (Continued)

Page 2251 of 2627

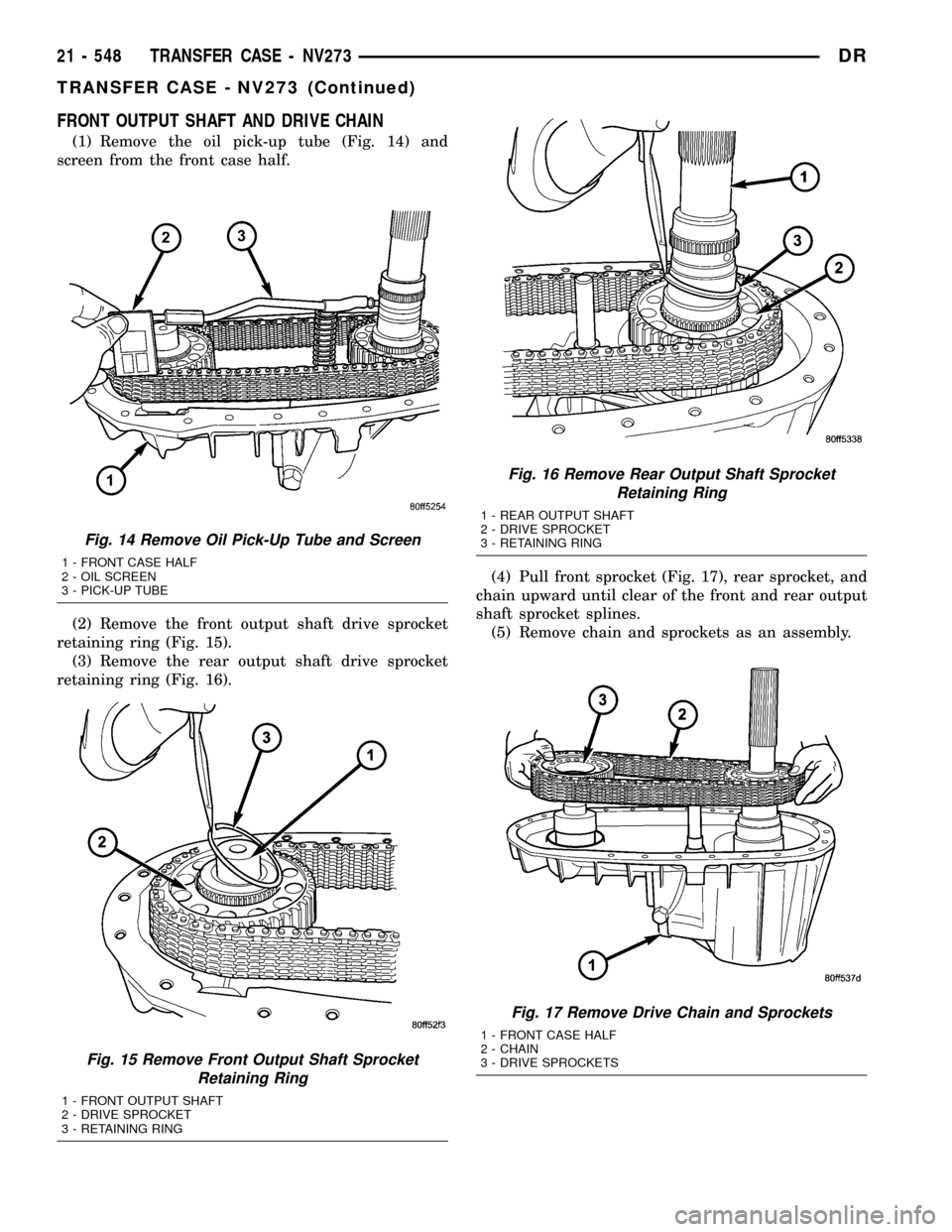

FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Remove the oil pick-up tube (Fig. 14) and

screen from the front case half.

(2) Remove the front output shaft drive sprocket

retaining ring (Fig. 15).

(3) Remove the rear output shaft drive sprocket

retaining ring (Fig. 16).(4) Pull front sprocket (Fig. 17), rear sprocket, and

chain upward until clear of the front and rear output

shaft sprocket splines.

(5) Remove chain and sprockets as an assembly.

Fig. 14 Remove Oil Pick-Up Tube and Screen

1 - FRONT CASE HALF

2 - OIL SCREEN

3 - PICK-UP TUBE

Fig. 15 Remove Front Output Shaft Sprocket

Retaining Ring

1 - FRONT OUTPUT SHAFT

2 - DRIVE SPROCKET

3 - RETAINING RING

Fig. 16 Remove Rear Output Shaft Sprocket

Retaining Ring

1 - REAR OUTPUT SHAFT

2 - DRIVE SPROCKET

3 - RETAINING RING

Fig. 17 Remove Drive Chain and Sprockets

1 - FRONT CASE HALF

2 - CHAIN

3 - DRIVE SPROCKETS

21 - 548 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)