Drive shaft DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2255 of 2627

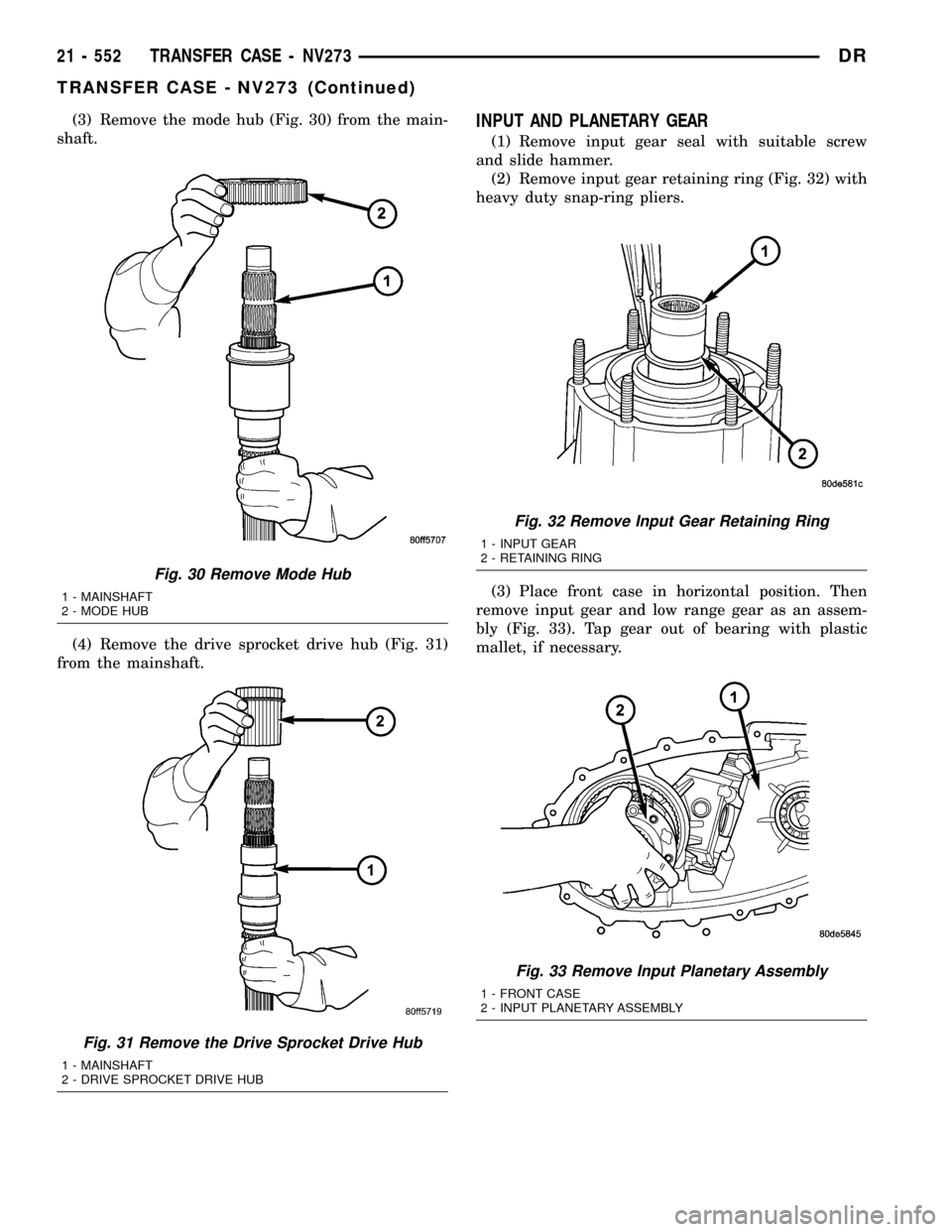

(3) Remove the mode hub (Fig. 30) from the main-

shaft.

(4) Remove the drive sprocket drive hub (Fig. 31)

from the mainshaft.INPUT AND PLANETARY GEAR

(1) Remove input gear seal with suitable screw

and slide hammer.

(2) Remove input gear retaining ring (Fig. 32) with

heavy duty snap-ring pliers.

(3) Place front case in horizontal position. Then

remove input gear and low range gear as an assem-

bly (Fig. 33). Tap gear out of bearing with plastic

mallet, if necessary.

Fig. 30 Remove Mode Hub

1 - MAINSHAFT

2 - MODE HUB

Fig. 31 Remove the Drive Sprocket Drive Hub

1 - MAINSHAFT

2 - DRIVE SPROCKET DRIVE HUB

Fig. 32 Remove Input Gear Retaining Ring

1 - INPUT GEAR

2 - RETAINING RING

Fig. 33 Remove Input Planetary Assembly

1 - FRONT CASE

2 - INPUT PLANETARY ASSEMBLY

21 - 552 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2258 of 2627

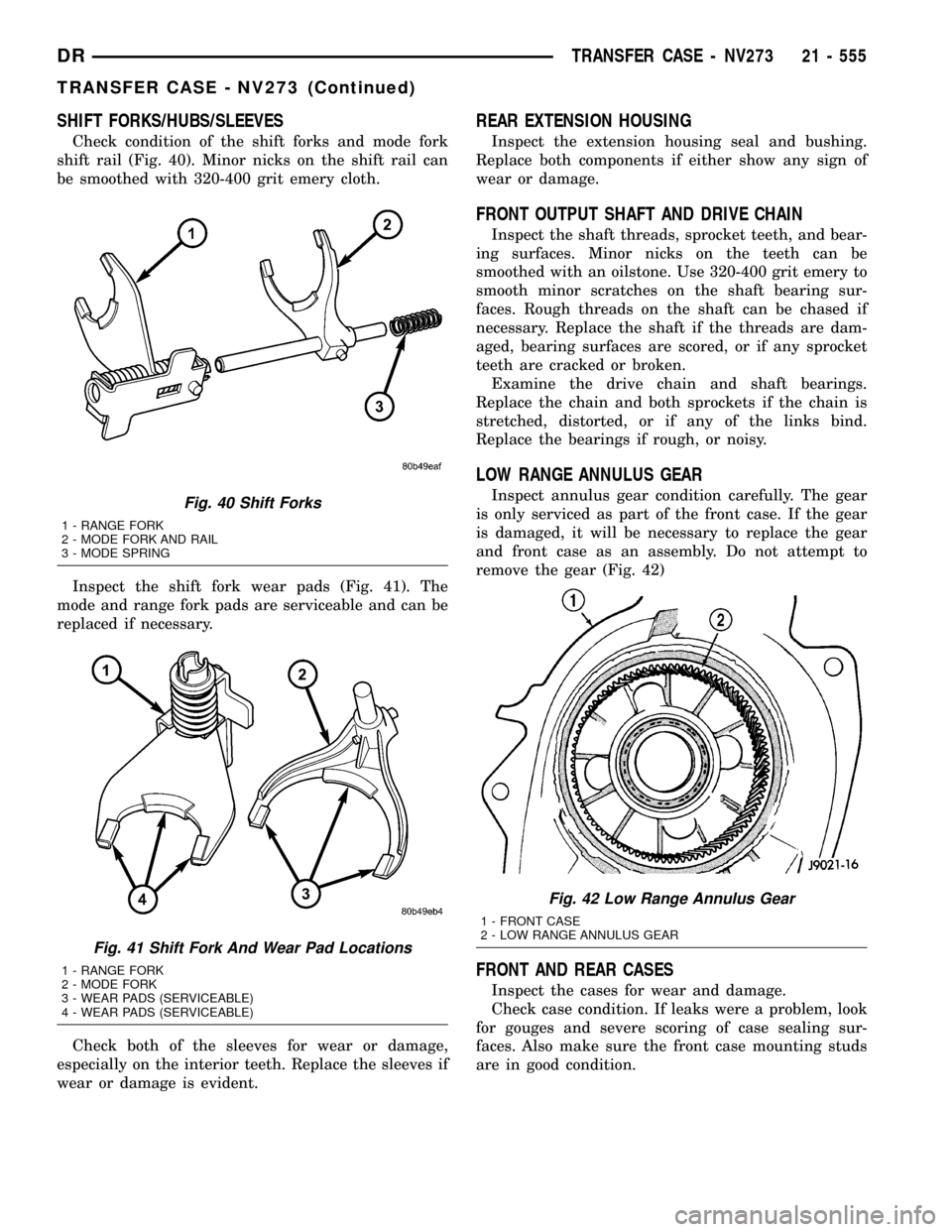

SHIFT FORKS/HUBS/SLEEVES

Check condition of the shift forks and mode fork

shift rail (Fig. 40). Minor nicks on the shift rail can

be smoothed with 320-400 grit emery cloth.

Inspect the shift fork wear pads (Fig. 41). The

mode and range fork pads are serviceable and can be

replaced if necessary.

Check both of the sleeves for wear or damage,

especially on the interior teeth. Replace the sleeves if

wear or damage is evident.

REAR EXTENSION HOUSING

Inspect the extension housing seal and bushing.

Replace both components if either show any sign of

wear or damage.

FRONT OUTPUT SHAFT AND DRIVE CHAIN

Inspect the shaft threads, sprocket teeth, and bear-

ing surfaces. Minor nicks on the teeth can be

smoothed with an oilstone. Use 320-400 grit emery to

smooth minor scratches on the shaft bearing sur-

faces. Rough threads on the shaft can be chased if

necessary. Replace the shaft if the threads are dam-

aged, bearing surfaces are scored, or if any sprocket

teeth are cracked or broken.

Examine the drive chain and shaft bearings.

Replace the chain and both sprockets if the chain is

stretched, distorted, or if any of the links bind.

Replace the bearings if rough, or noisy.

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 42)

FRONT AND REAR CASES

Inspect the cases for wear and damage.

Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Fig. 40 Shift Forks

1 - RANGE FORK

2 - MODE FORK AND RAIL

3 - MODE SPRING

Fig. 41 Shift Fork And Wear Pad Locations

1 - RANGE FORK

2 - MODE FORK

3 - WEAR PADS (SERVICEABLE)

4 - WEAR PADS (SERVICEABLE)

Fig. 42 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEAR

DRTRANSFER CASE - NV273 21 - 555

TRANSFER CASE - NV273 (Continued)

Page 2264 of 2627

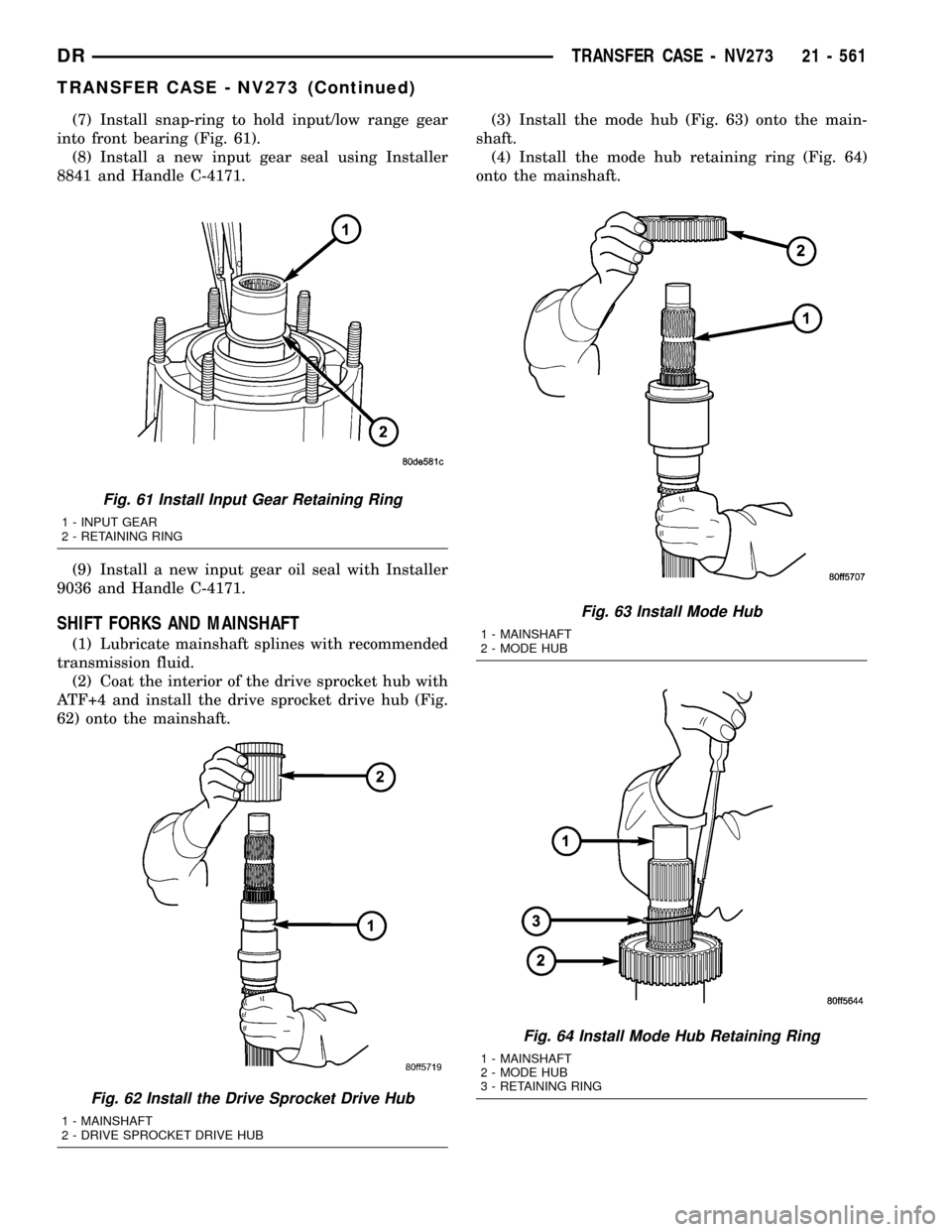

(7) Install snap-ring to hold input/low range gear

into front bearing (Fig. 61).

(8) Install a new input gear seal using Installer

8841 and Handle C-4171.

(9) Install a new input gear oil seal with Installer

9036 and Handle C-4171.

SHIFT FORKS AND MAINSHAFT

(1) Lubricate mainshaft splines with recommended

transmission fluid.

(2) Coat the interior of the drive sprocket hub with

ATF+4 and install the drive sprocket drive hub (Fig.

62) onto the mainshaft.(3) Install the mode hub (Fig. 63) onto the main-

shaft.

(4) Install the mode hub retaining ring (Fig. 64)

onto the mainshaft.

Fig. 61 Install Input Gear Retaining Ring

1 - INPUT GEAR

2 - RETAINING RING

Fig. 62 Install the Drive Sprocket Drive Hub

1 - MAINSHAFT

2 - DRIVE SPROCKET DRIVE HUB

Fig. 63 Install Mode Hub

1 - MAINSHAFT

2 - MODE HUB

Fig. 64 Install Mode Hub Retaining Ring

1 - MAINSHAFT

2 - MODE HUB

3 - RETAINING RING

DRTRANSFER CASE - NV273 21 - 561

TRANSFER CASE - NV273 (Continued)

Page 2267 of 2627

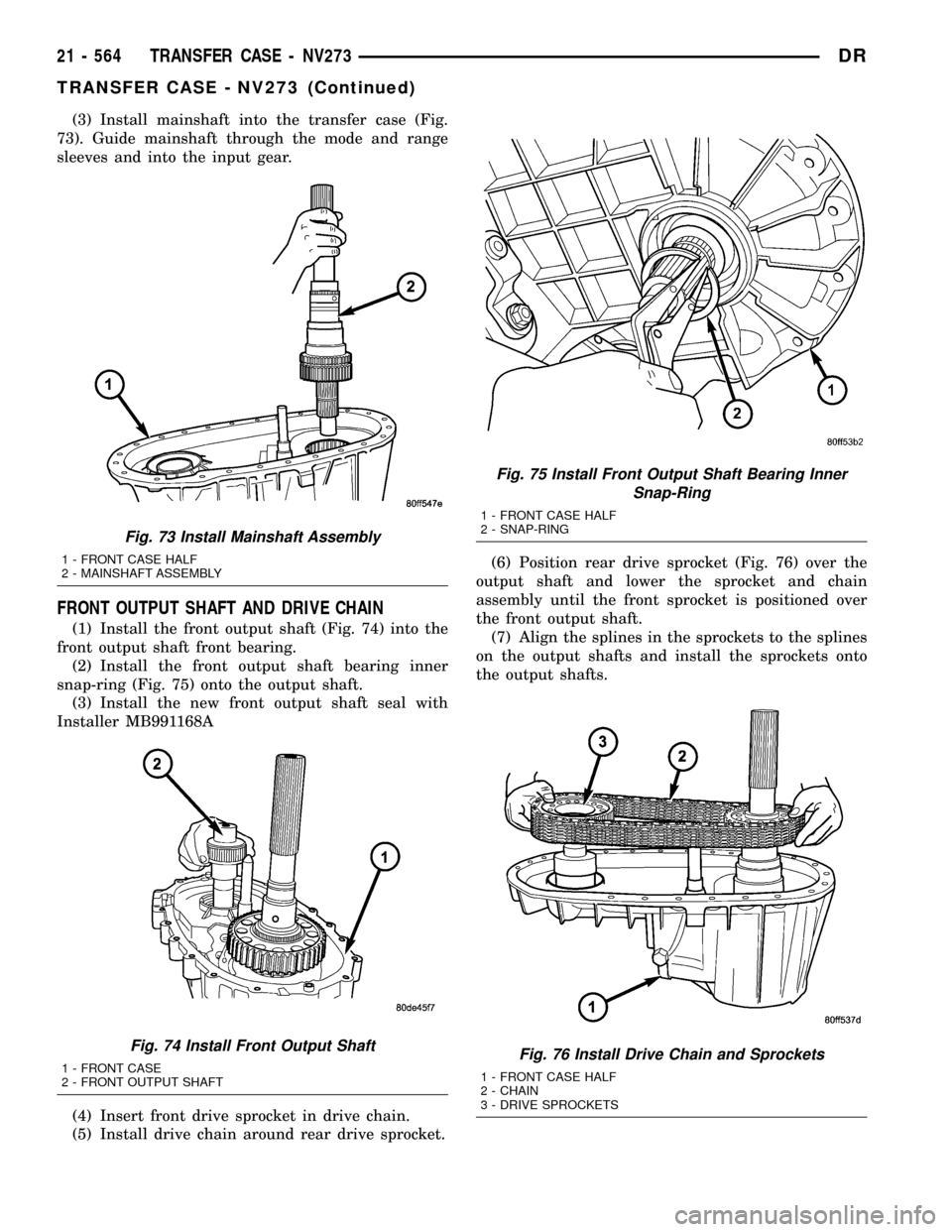

(3) Install mainshaft into the transfer case (Fig.

73). Guide mainshaft through the mode and range

sleeves and into the input gear.

FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Install the front output shaft (Fig. 74) into the

front output shaft front bearing.

(2) Install the front output shaft bearing inner

snap-ring (Fig. 75) onto the output shaft.

(3) Install the new front output shaft seal with

Installer MB991168A

(4) Insert front drive sprocket in drive chain.

(5) Install drive chain around rear drive sprocket.(6) Position rear drive sprocket (Fig. 76) over the

output shaft and lower the sprocket and chain

assembly until the front sprocket is positioned over

the front output shaft.

(7) Align the splines in the sprockets to the splines

on the output shafts and install the sprockets onto

the output shafts.

Fig. 73 Install Mainshaft Assembly

1 - FRONT CASE HALF

2 - MAINSHAFT ASSEMBLY

Fig. 74 Install Front Output Shaft

1 - FRONT CASE

2 - FRONT OUTPUT SHAFT

Fig. 75 Install Front Output Shaft Bearing Inner

Snap-Ring

1 - FRONT CASE HALF

2 - SNAP-RING

Fig. 76 Install Drive Chain and Sprockets

1 - FRONT CASE HALF

2 - CHAIN

3 - DRIVE SPROCKETS

21 - 564 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2268 of 2627

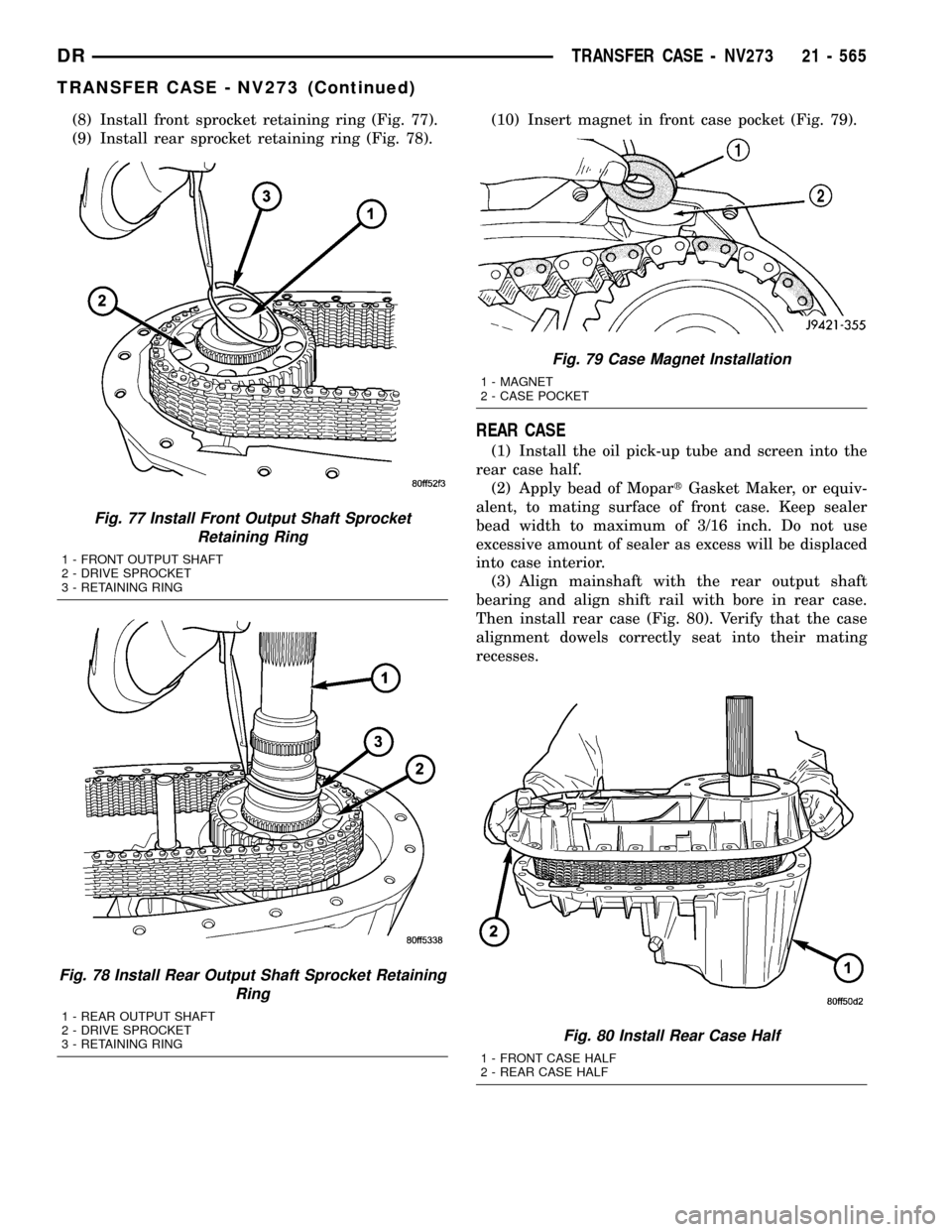

(8) Install front sprocket retaining ring (Fig. 77).

(9) Install rear sprocket retaining ring (Fig. 78).(10) Insert magnet in front case pocket (Fig. 79).

REAR CASE

(1) Install the oil pick-up tube and screen into the

rear case half.

(2) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of front case. Keep sealer

bead width to maximum of 3/16 inch. Do not use

excessive amount of sealer as excess will be displaced

into case interior.

(3) Align mainshaft with the rear output shaft

bearing and align shift rail with bore in rear case.

Then install rear case (Fig. 80). Verify that the case

alignment dowels correctly seat into their mating

recesses.

Fig. 77 Install Front Output Shaft Sprocket

Retaining Ring

1 - FRONT OUTPUT SHAFT

2 - DRIVE SPROCKET

3 - RETAINING RING

Fig. 78 Install Rear Output Shaft Sprocket Retaining

Ring

1 - REAR OUTPUT SHAFT

2 - DRIVE SPROCKET

3 - RETAINING RING

Fig. 79 Case Magnet Installation

1 - MAGNET

2 - CASE POCKET

Fig. 80 Install Rear Case Half

1 - FRONT CASE HALF

2 - REAR CASE HALF

DRTRANSFER CASE - NV273 21 - 565

TRANSFER CASE - NV273 (Continued)

Page 2274 of 2627

EXTENSION HOUSING SEAL

AND DUST BOOT

REMOVAL

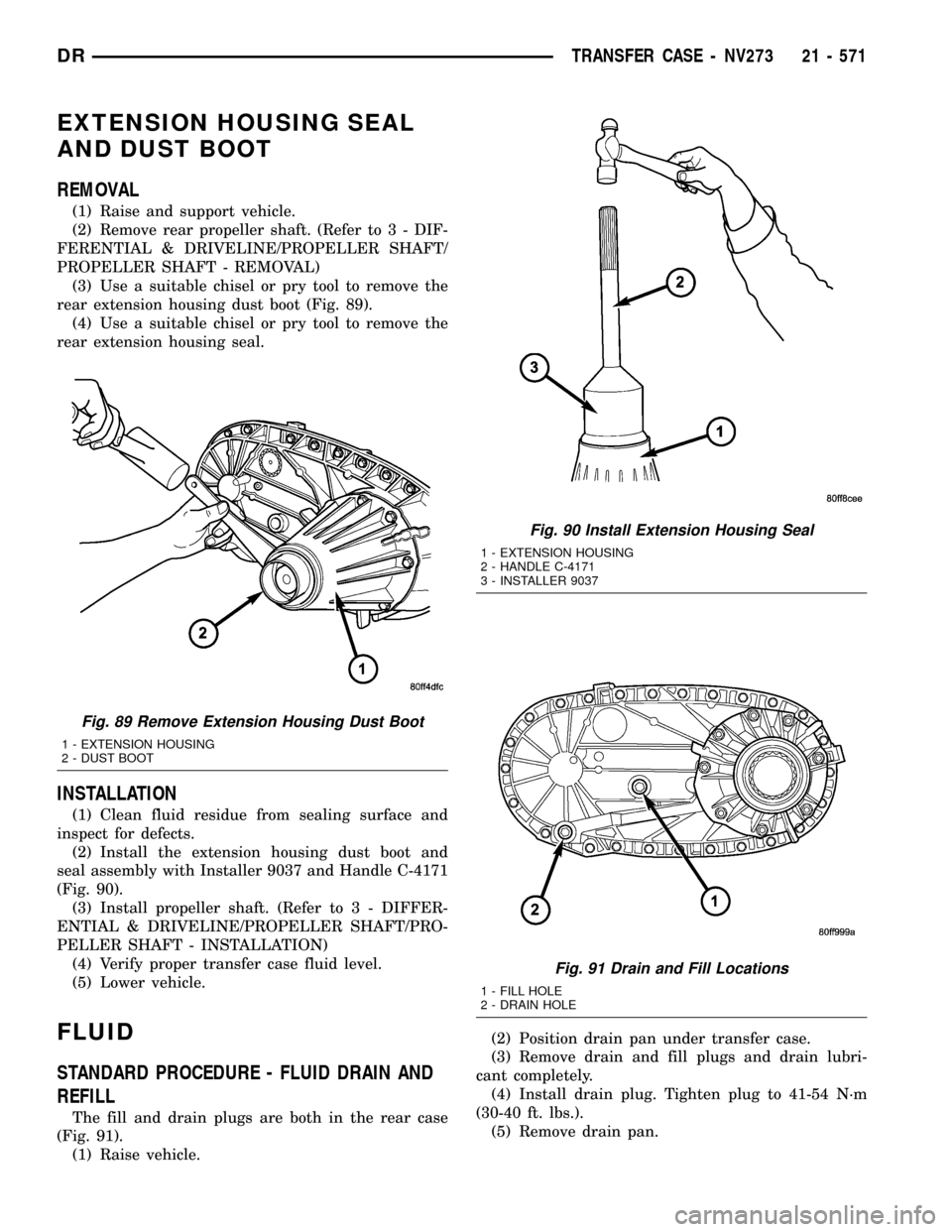

(1) Raise and support vehicle.

(2) Remove rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Use a suitable chisel or pry tool to remove the

rear extension housing dust boot (Fig. 89).

(4) Use a suitable chisel or pry tool to remove the

rear extension housing seal.

INSTALLATION

(1) Clean fluid residue from sealing surface and

inspect for defects.

(2) Install the extension housing dust boot and

seal assembly with Installer 9037 and Handle C-4171

(Fig. 90).

(3) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)

(4) Verify proper transfer case fluid level.

(5) Lower vehicle.

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL

The fill and drain plugs are both in the rear case

(Fig. 91).

(1) Raise vehicle.(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 41-54 N´m

(30-40 ft. lbs.).

(5) Remove drain pan.

Fig. 89 Remove Extension Housing Dust Boot

1 - EXTENSION HOUSING

2 - DUST BOOT

Fig. 90 Install Extension Housing Seal

1 - EXTENSION HOUSING

2 - HANDLE C-4171

3 - INSTALLER 9037

Fig. 91 Drain and Fill Locations

1 - FILL HOLE

2 - DRAIN HOLE

DRTRANSFER CASE - NV273 21 - 571

Page 2275 of 2627

(6) Fill transfer case to bottom edge of fill plug

opening with MopartATF +4, Automatic Transmis-

sion fluid.

(7) Install and tighten fill plug to 41-54 N´m

(30-40 ft. lbs.).

(8) Lower vehicle.

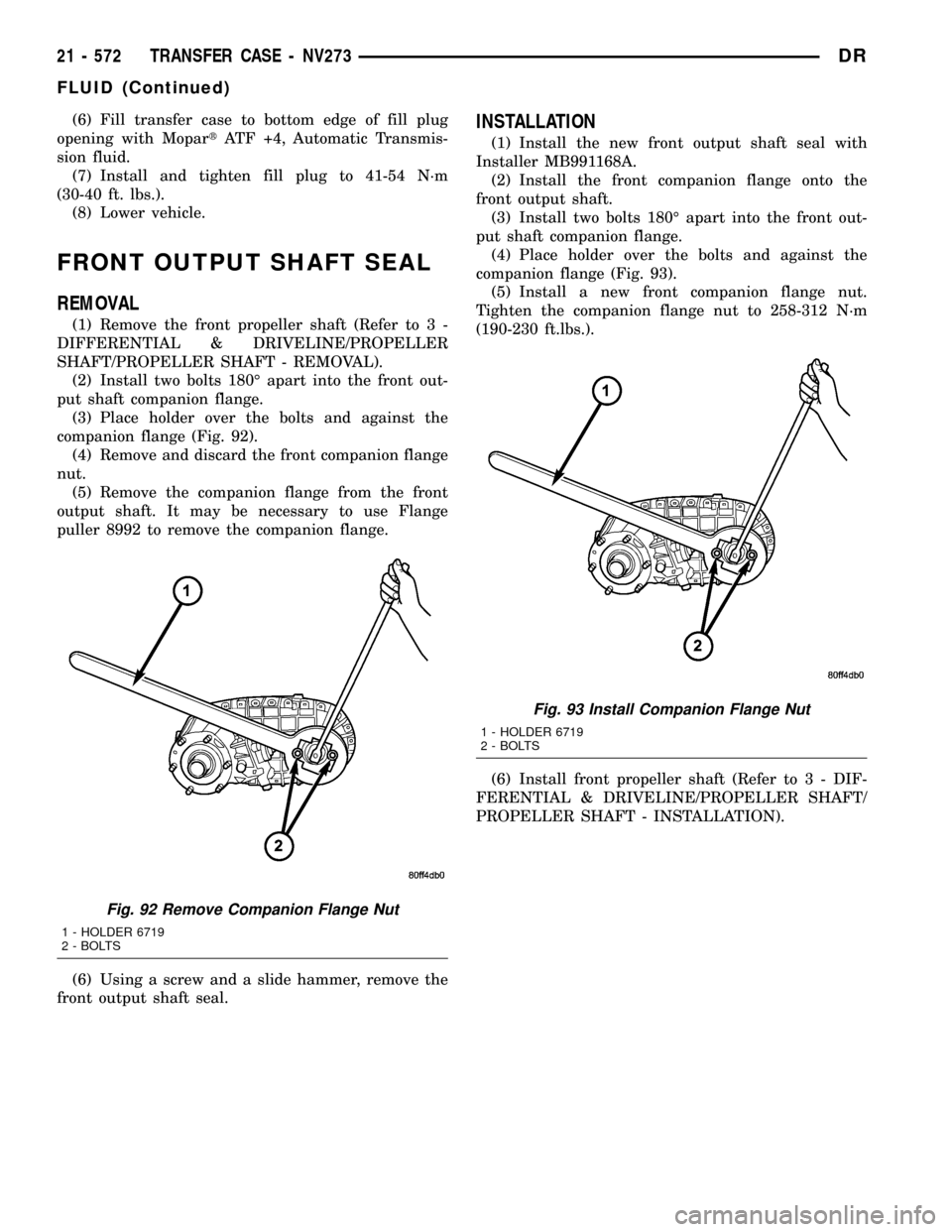

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Remove the front propeller shaft (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL).

(2) Install two bolts 180É apart into the front out-

put shaft companion flange.

(3) Place holder over the bolts and against the

companion flange (Fig. 92).

(4) Remove and discard the front companion flange

nut.

(5) Remove the companion flange from the front

output shaft. It may be necessary to use Flange

puller 8992 to remove the companion flange.

(6) Using a screw and a slide hammer, remove the

front output shaft seal.

INSTALLATION

(1) Install the new front output shaft seal with

Installer MB991168A.

(2) Install the front companion flange onto the

front output shaft.

(3) Install two bolts 180É apart into the front out-

put shaft companion flange.

(4) Place holder over the bolts and against the

companion flange (Fig. 93).

(5) Install a new front companion flange nut.

Tighten the companion flange nut to 258-312 N´m

(190-230 ft.lbs.).

(6) Install front propeller shaft (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION).

Fig. 92 Remove Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

Fig. 93 Install Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

21 - 572 TRANSFER CASE - NV273DR

FLUID (Continued)

Page 2278 of 2627

have not been met. This is in an attempt to notify

the driver that the transmission needs to be put into

NEUTRAL, the vehicle speed is too great, or some

other condition outlined (other than a diagnostic fail-

ure that would prevent this shift) elsewhere (Refer to

8 - ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/TRANSFER CASE CONTROL MODULE -

OPERATION) is not met. Note that this flashing will

continue indefinitely until the conditions are eventu-

ally met, or the selector switch position is changed,

or if diagnostic routines no longer allow the

requested shift.

²

If the driver attempts to make a shift into transfer

case NEUTRAL, and any of the driver controllable con-

ditions are not met, the request will be ignored until all

of the conditions are met or until the NEUTRAL select

button is released. Additionally the neutral lamp will

flash, or begin to flash while the button is depressed

and operator controllable conditions are not being met.

All of the LED's except the Neutral will flash if any of

the operator controllable conditions for shifting are not

met while the Neutral button is depressed. This9toggle9

type of feature is necessary because the TCCM would

interpret another request immediately after the shift

into transfer case NEUTRAL has completed.

²No LED's illuminated indicate a fault in the

transfer case control system.

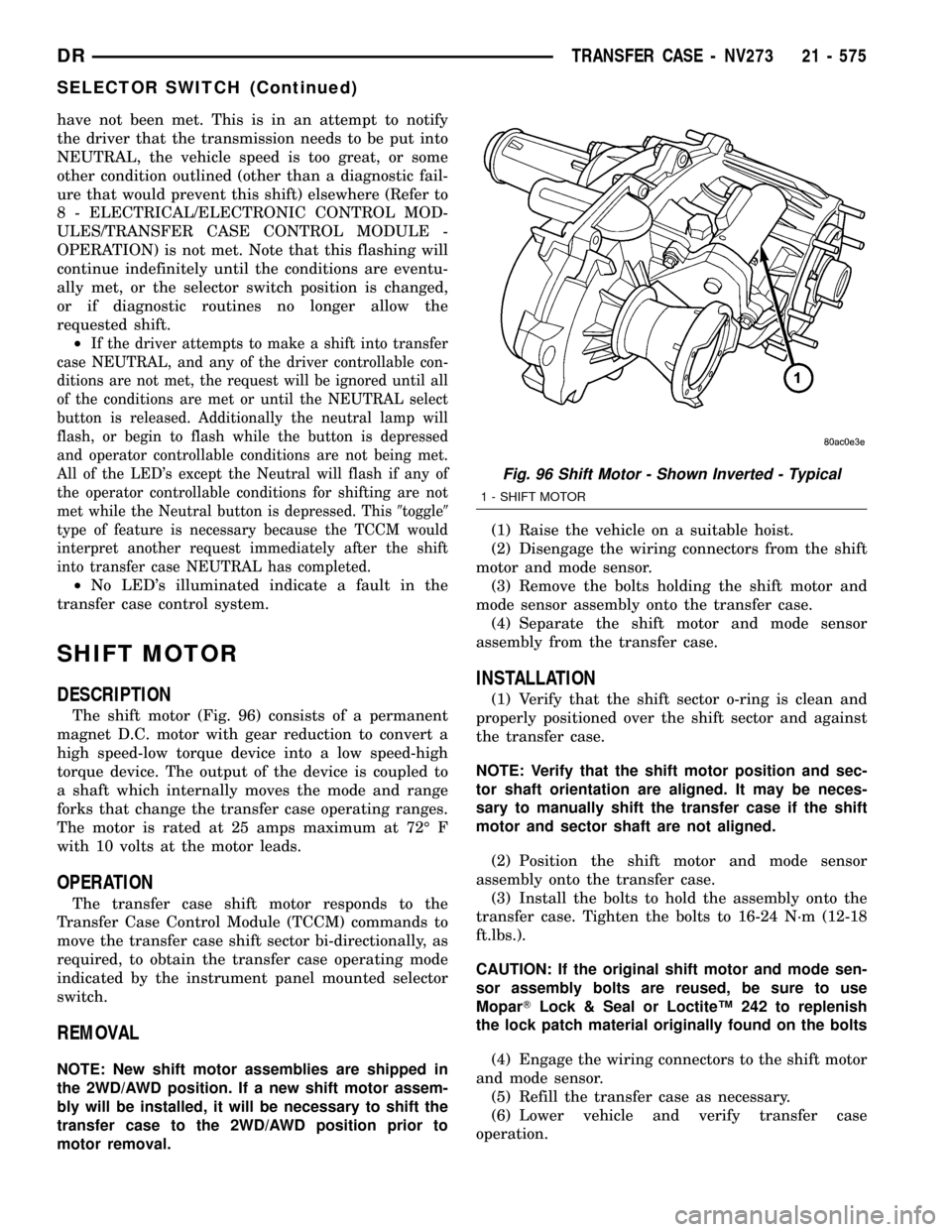

SHIFT MOTOR

DESCRIPTION

The shift motor (Fig. 96) consists of a permanent

magnet D.C. motor with gear reduction to convert a

high speed-low torque device into a low speed-high

torque device. The output of the device is coupled to

a shaft which internally moves the mode and range

forks that change the transfer case operating ranges.

The motor is rated at 25 amps maximum at 72É F

with 10 volts at the motor leads.

OPERATION

The transfer case shift motor responds to the

Transfer Case Control Module (TCCM) commands to

move the transfer case shift sector bi-directionally, as

required, to obtain the transfer case operating mode

indicated by the instrument panel mounted selector

switch.

REMOVAL

NOTE: New shift motor assemblies are shipped in

the 2WD/AWD position. If a new shift motor assem-

bly will be installed, it will be necessary to shift the

transfer case to the 2WD/AWD position prior to

motor removal.(1) Raise the vehicle on a suitable hoist.

(2) Disengage the wiring connectors from the shift

motor and mode sensor.

(3) Remove the bolts holding the shift motor and

mode sensor assembly onto the transfer case.

(4) Separate the shift motor and mode sensor

assembly from the transfer case.

INSTALLATION

(1) Verify that the shift sector o-ring is clean and

properly positioned over the shift sector and against

the transfer case.

NOTE: Verify that the shift motor position and sec-

tor shaft orientation are aligned. It may be neces-

sary to manually shift the transfer case if the shift

motor and sector shaft are not aligned.

(2) Position the shift motor and mode sensor

assembly onto the transfer case.

(3) Install the bolts to hold the assembly onto the

transfer case. Tighten the bolts to 16-24 N´m (12-18

ft.lbs.).

CAUTION: If the original shift motor and mode sen-

sor assembly bolts are reused, be sure to use

MoparTLock & Seal or LoctiteŸ 242 to replenish

the lock patch material originally found on the bolts

(4) Engage the wiring connectors to the shift motor

and mode sensor.

(5) Refill the transfer case as necessary.

(6) Lower vehicle and verify transfer case

operation.

Fig. 96 Shift Motor - Shown Inverted - Typical

1 - SHIFT MOTOR

DRTRANSFER CASE - NV273 21 - 575

SELECTOR SWITCH (Continued)

Page 2281 of 2627

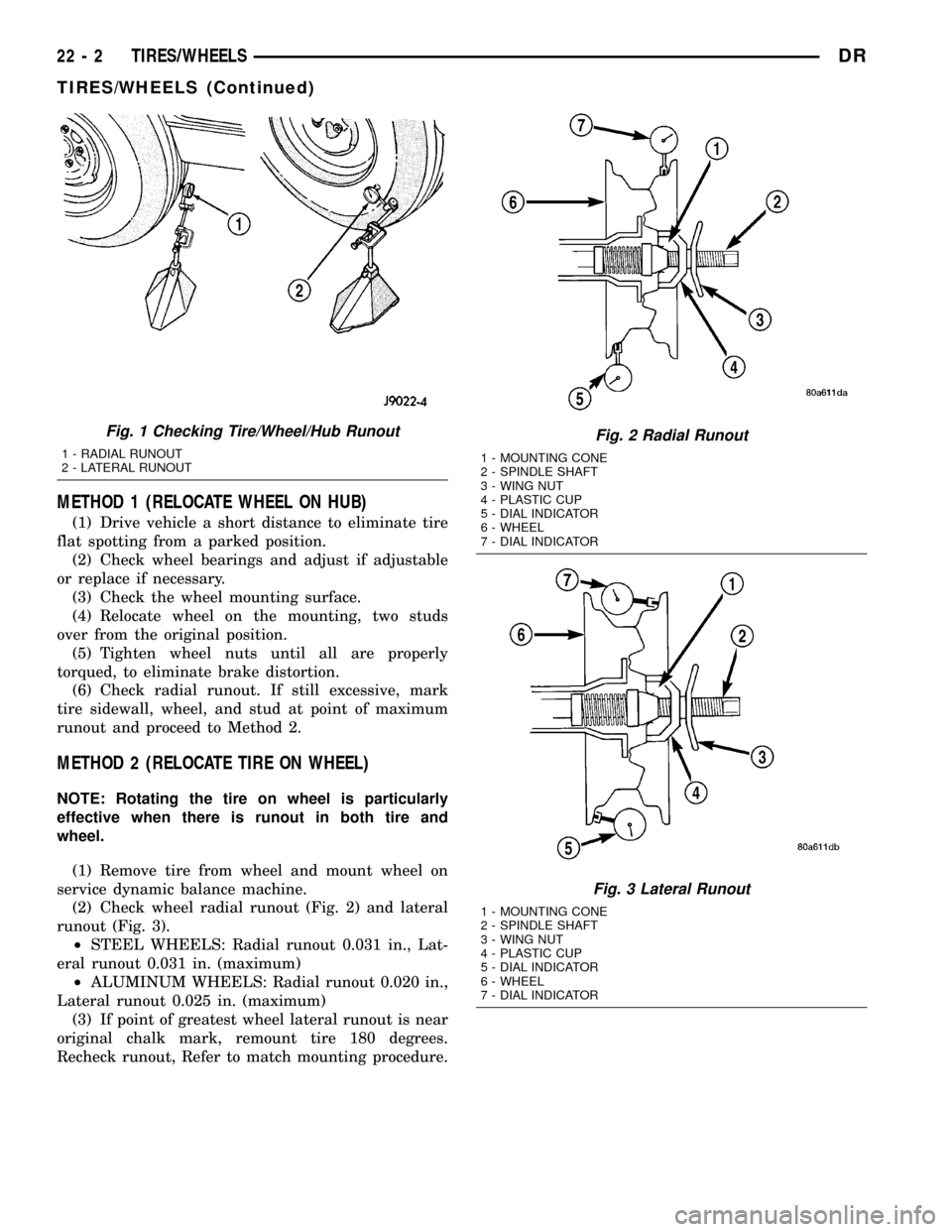

METHOD 1 (RELOCATE WHEEL ON HUB)

(1) Drive vehicle a short distance to eliminate tire

flat spotting from a parked position.

(2) Check wheel bearings and adjust if adjustable

or replace if necessary.

(3) Check the wheel mounting surface.

(4) Relocate wheel on the mounting, two studs

over from the original position.

(5) Tighten wheel nuts until all are properly

torqued, to eliminate brake distortion.

(6) Check radial runout. If still excessive, mark

tire sidewall, wheel, and stud at point of maximum

runout and proceed to Method 2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

NOTE: Rotating the tire on wheel is particularly

effective when there is runout in both tire and

wheel.

(1) Remove tire from wheel and mount wheel on

service dynamic balance machine.

(2) Check wheel radial runout (Fig. 2) and lateral

runout (Fig. 3).

²STEEL WHEELS: Radial runout 0.031 in., Lat-

eral runout 0.031 in. (maximum)

²ALUMINUM WHEELS: Radial runout 0.020 in.,

Lateral runout 0.025 in. (maximum)

(3) If point of greatest wheel lateral runout is near

original chalk mark, remount tire 180 degrees.

Recheck runout, Refer to match mounting procedure.

Fig. 1 Checking Tire/Wheel/Hub Runout

1 - RADIAL RUNOUT

2 - LATERAL RUNOUT

Fig. 2 Radial Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

Fig. 3 Lateral Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

22 - 2 TIRES/WHEELSDR

TIRES/WHEELS (Continued)

Page 2377 of 2627

(2) Install the three nuts attaching the center seat

section to the other seat, and tighten to 25 N´m (18

ft. lbs.).

(3) Roll the seat assembly forward and install new

rear bolts.

(4) Connect the 12v power supply electrical con-

nector.

(5) Tighten the rear bolts to 40 N´m (30 ft. lbs.).

(6) Fold the seat backs up and slide the seats to

the rear.

(7) Install new front bolts and tighten to 28 N´m

(21 ft. lbs.).

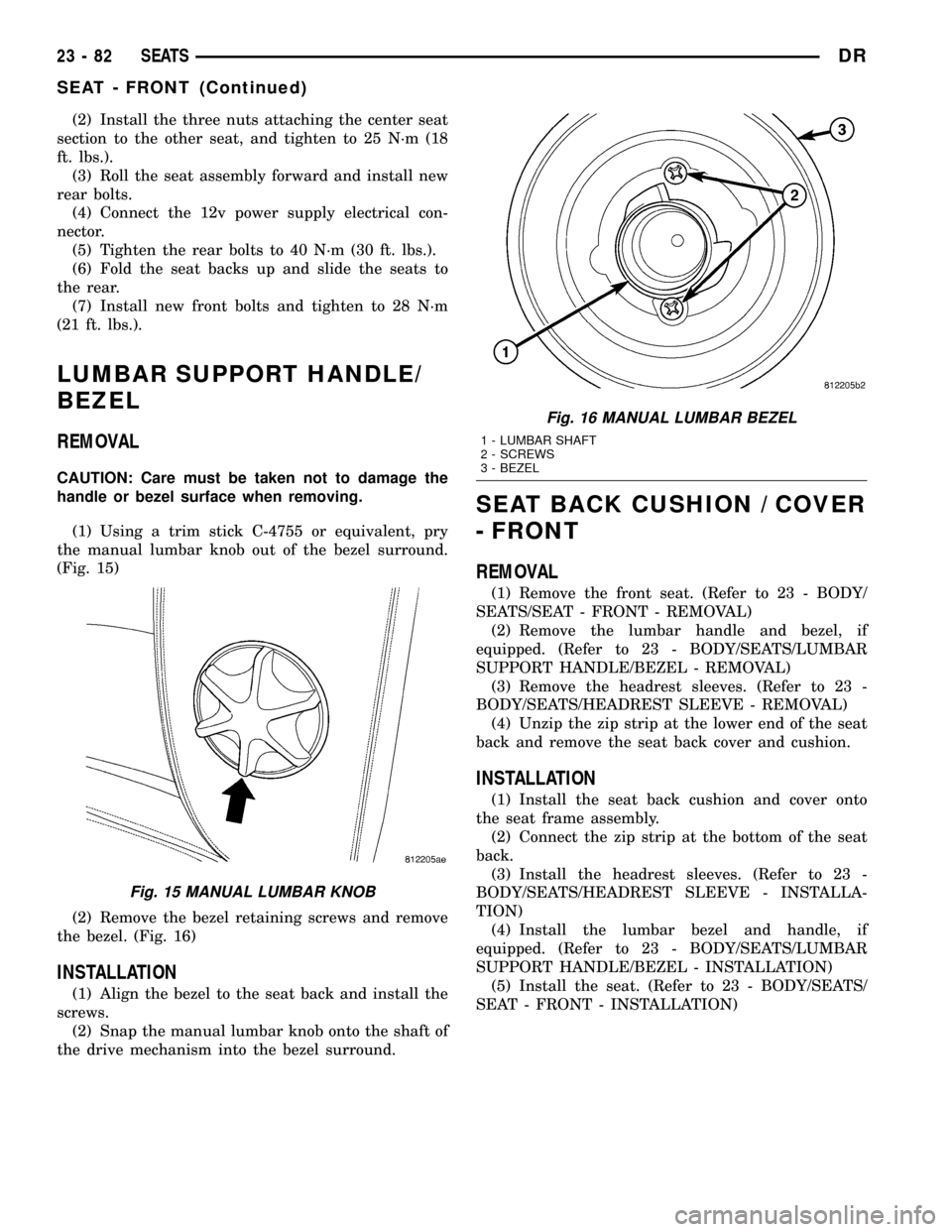

LUMBAR SUPPORT HANDLE/

BEZEL

REMOVAL

CAUTION: Care must be taken not to damage the

handle or bezel surface when removing.

(1) Using a trim stick C-4755 or equivalent, pry

the manual lumbar knob out of the bezel surround.

(Fig. 15)

(2) Remove the bezel retaining screws and remove

the bezel. (Fig. 16)

INSTALLATION

(1) Align the bezel to the seat back and install the

screws.

(2) Snap the manual lumbar knob onto the shaft of

the drive mechanism into the bezel surround.

SEAT BACK CUSHION / COVER

- FRONT

REMOVAL

(1) Remove the front seat. (Refer to 23 - BODY/

SEATS/SEAT - FRONT - REMOVAL)

(2) Remove the lumbar handle and bezel, if

equipped. (Refer to 23 - BODY/SEATS/LUMBAR

SUPPORT HANDLE/BEZEL - REMOVAL)

(3) Remove the headrest sleeves. (Refer to 23 -

BODY/SEATS/HEADREST SLEEVE - REMOVAL)

(4) Unzip the zip strip at the lower end of the seat

back and remove the seat back cover and cushion.

INSTALLATION

(1) Install the seat back cushion and cover onto

the seat frame assembly.

(2) Connect the zip strip at the bottom of the seat

back.

(3) Install the headrest sleeves. (Refer to 23 -

BODY/SEATS/HEADREST SLEEVE - INSTALLA-

TION)

(4) Install the lumbar bezel and handle, if

equipped. (Refer to 23 - BODY/SEATS/LUMBAR

SUPPORT HANDLE/BEZEL - INSTALLATION)

(5) Install the seat. (Refer to 23 - BODY/SEATS/

SEAT - FRONT - INSTALLATION)

Fig. 15 MANUAL LUMBAR KNOB

Fig. 16 MANUAL LUMBAR BEZEL

1 - LUMBAR SHAFT

2 - SCREWS

3 - BEZEL

23 - 82 SEATSDR

SEAT - FRONT (Continued)