Crankshaft position sensor DODGE RAM 1500 1998 2.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1590 of 2627

FUEL INJECTION - GAS

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL

REMOVAL.............................21

INSTALLATION.........................21

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................22

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................24

INSTALLATION.........................25

FUEL INJECTOR

DESCRIPTION.........................26

OPERATION

OPERATION - FUEL INJECTOR..........26

OPERATION - PCM OUTPUT............27

REMOVAL.............................27

INSTALLATION.........................27

FUEL PUMP RELAY

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................28

INSTALLATION.........................28

IDLE AIR CONTROL MOTOR

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................29

INSTALLATION.........................29INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION.........................30

OPERATION...........................30

REMOVAL.............................30

INSTALLATION.........................31

MAP SENSOR

DESCRIPTION.........................32

OPERATION...........................32

REMOVAL.............................33

INSTALLATION.........................34

OXYGEN SENSOR

DESCRIPTION.........................35

REMOVAL.............................35

INSTALLATION.........................36

PTO SWITCH

DESCRIPTION.........................36

OPERATION...........................36

THROTTLE BODY

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................37

THROTTLE CONTROL CABLE

REMOVAL.............................38

INSTALLATION.........................40

THROTTLE POSITION SENSOR

DESCRIPTION.........................41

OPERATION...........................41

REMOVAL.............................41

INSTALLATION.........................43

ACCELERATOR PEDAL

REMOVAL

The following procedure applies only to vehicles

without the Adjustable Pedal Package (code XAP).

The accelerator pedal is serviced as a complete

assembly including the bracket.

The accelerator cable is connected to the upper

part of the accelerator pedal arm by a plastic

retainer (clip) (Fig. 1). This plastic retainer snaps

into the top of the accelerator pedal arm.

(1) From inside the vehicle, hold up accelerator

pedal. Remove plastic cable retainer (clip) and throt-

tle cable core wire from upper end of accelerator

pedal arm (Fig. 1). Plastic cable retainer (clip) snaps

into pedal arm.(2) Remove 2 accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.INSTALLATION

(1) Place accelerator pedal assembly over 2 studs.

(2) Install and tighten 2 mounting nuts. Refer to

Torque Specifications.

(3) Slide throttle cable into opening slot in top of

pedal arm.

(4) Push plastic cable retainer (clip) into accelera-

tor pedal arm opening until it snaps into place.

(5) Before starting engine, operate accelerator

pedal to check for any binding.

DRFUEL INJECTION - GAS 14 - 21

Page 1592 of 2627

(5) Position APPS assembly to bottom of battery

tray and install 3 bolts. Refer to Torque Specifica-

tions.

(6) Install wheelhouse liner. Refer to Body.

(7)The 5.7L V-8 engine is equipped with a

fully electronic accelerator pedal position sen-

sor. If equipped with a 5.7L, also perform the

following 3 steps:

(a) Connect negative battery cable to battery.

(b) Turn ignition switch ON, but do not crank

engine.

(c) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn electrical

parameters.

(d) The DRB IIItScan Tool may also be used to

learn electrical parameters. Go to the Miscella-

neous menu, and then select ETC Learn.

(8) If the previous step is not performed, a Diag-

nostic Trouble Code (DTC) will be set.

(9) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from PCM.

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

4.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

5.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

OPERATION

3.7L V-6

Engine speed and crankshaft position are provided

through the CKP (Crankshaft Position) sensor. The

sensor generates pulses that are the input sent to the

Powertrain Control Module (PCM). The PCM inter-

prets the sensor input to determine the crankshaft

position. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

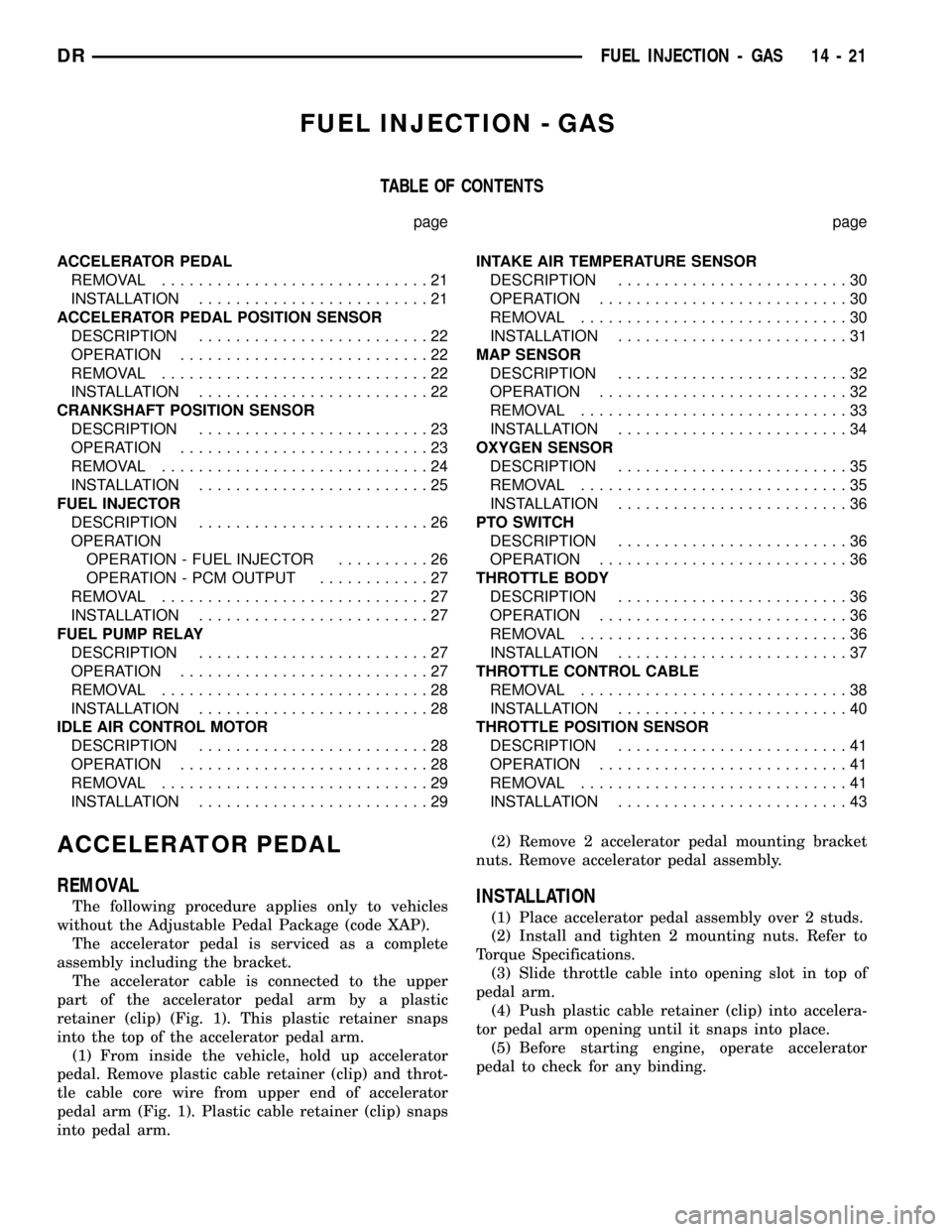

Fig. 3 APPS REMOVE / INSTALL

1 - BOTTOM OF BATTERY TRAY

2 - ELECTRICAL CONNECTOR

3 - APPS

4 - SWING-DOWN DOOR

5 - CABLE (TO PEDAL)

6 - CABLE RELEASE TAB

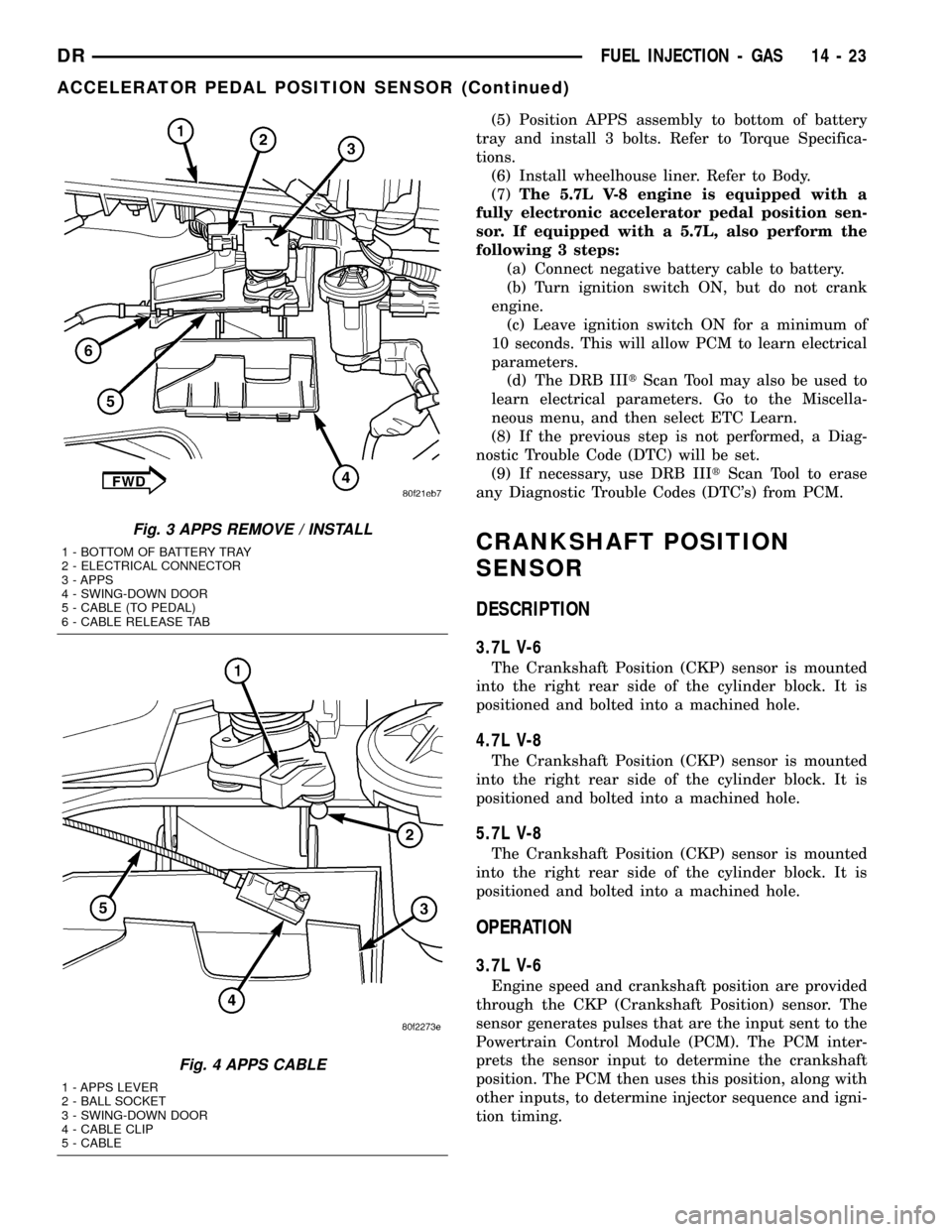

Fig. 4 APPS CABLE

1 - APPS LEVER

2 - BALL SOCKET

3 - SWING-DOWN DOOR

4 - CABLE CLIP

5 - CABLE

DRFUEL INJECTION - GAS 14 - 23

ACCELERATOR PEDAL POSITION SENSOR (Continued)

Page 1593 of 2627

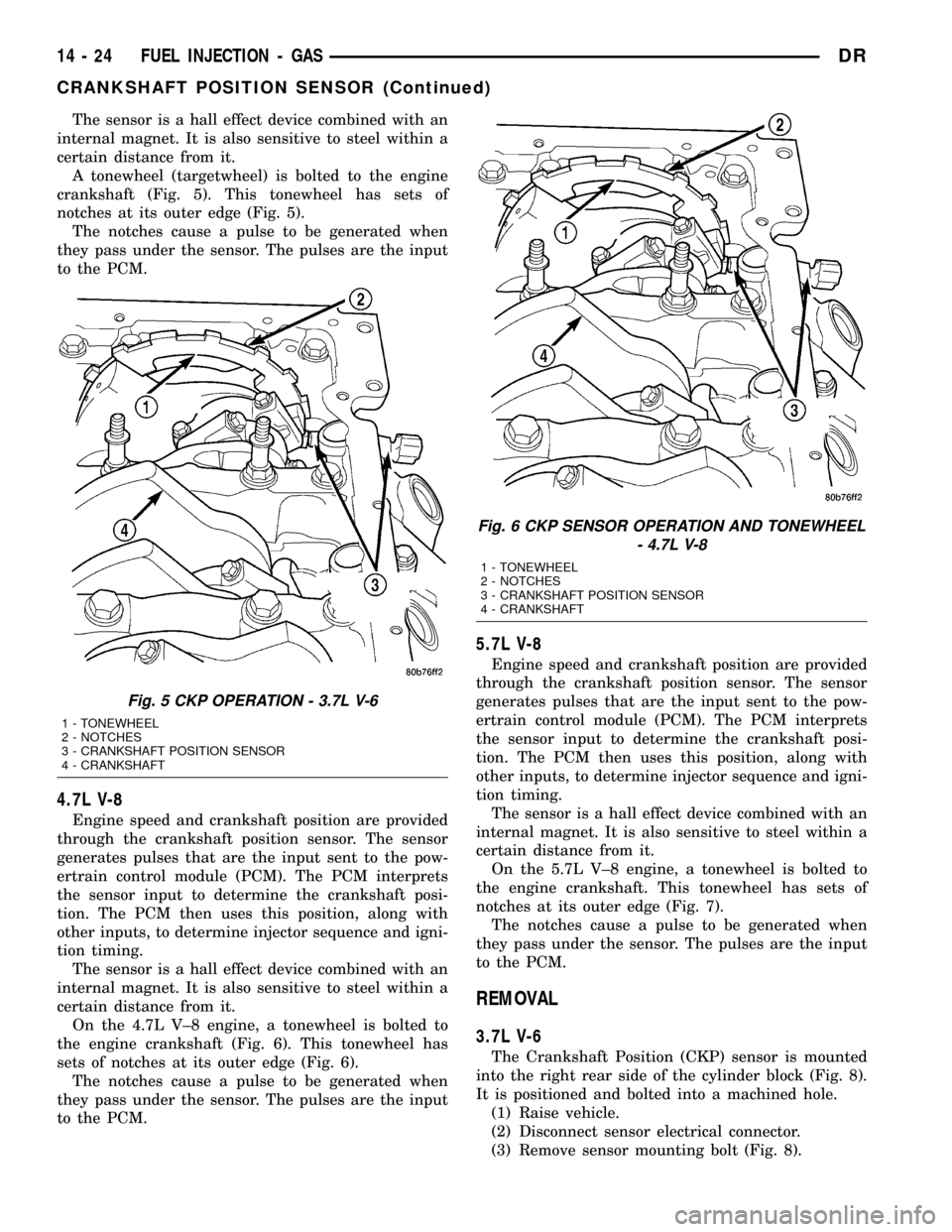

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

A tonewheel (targetwheel) is bolted to the engine

crankshaft (Fig. 5). This tonewheel has sets of

notches at its outer edge (Fig. 5).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

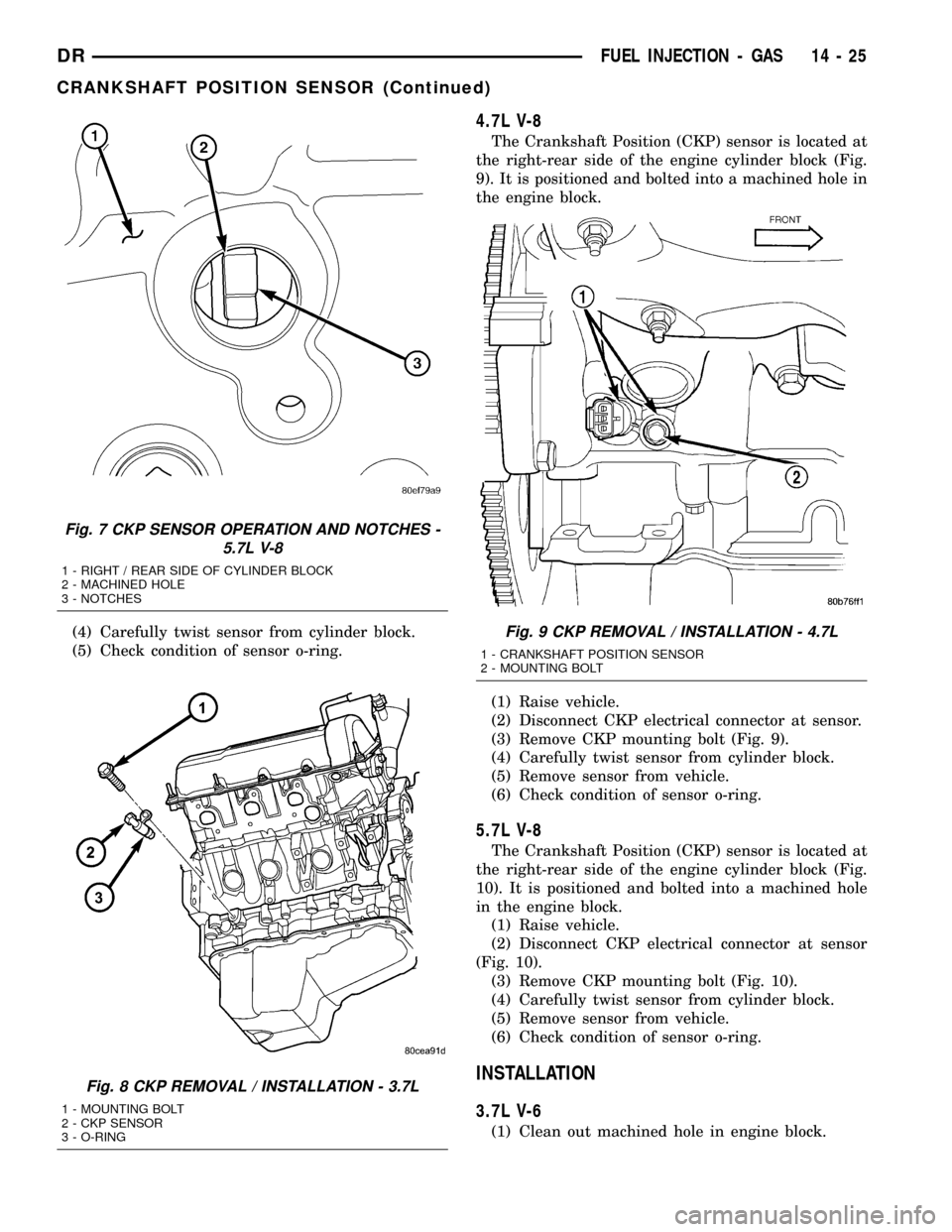

4.7L V-8

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the pow-

ertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft posi-

tion. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On the 4.7L V±8 engine, a tonewheel is bolted to

the engine crankshaft (Fig. 6). This tonewheel has

sets of notches at its outer edge (Fig. 6).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

5.7L V-8

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the pow-

ertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft posi-

tion. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On the 5.7L V±8 engine, a tonewheel is bolted to

the engine crankshaft. This tonewheel has sets of

notches at its outer edge (Fig. 7).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

REMOVAL

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block (Fig. 8).

It is positioned and bolted into a machined hole.

(1) Raise vehicle.

(2) Disconnect sensor electrical connector.

(3) Remove sensor mounting bolt (Fig. 8).

Fig. 5 CKP OPERATION - 3.7L V-6

1 - TONEWHEEL

2 - NOTCHES

3 - CRANKSHAFT POSITION SENSOR

4 - CRANKSHAFT

Fig. 6 CKP SENSOR OPERATION AND TONEWHEEL

- 4.7L V-8

1 - TONEWHEEL

2 - NOTCHES

3 - CRANKSHAFT POSITION SENSOR

4 - CRANKSHAFT

14 - 24 FUEL INJECTION - GASDR

CRANKSHAFT POSITION SENSOR (Continued)

Page 1594 of 2627

(4) Carefully twist sensor from cylinder block.

(5) Check condition of sensor o-ring.

4.7L V-8

The Crankshaft Position (CKP) sensor is located at

the right-rear side of the engine cylinder block (Fig.

9). It is positioned and bolted into a machined hole in

the engine block.

(1) Raise vehicle.

(2) Disconnect CKP electrical connector at sensor.

(3) Remove CKP mounting bolt (Fig. 9).

(4) Carefully twist sensor from cylinder block.

(5) Remove sensor from vehicle.

(6) Check condition of sensor o-ring.

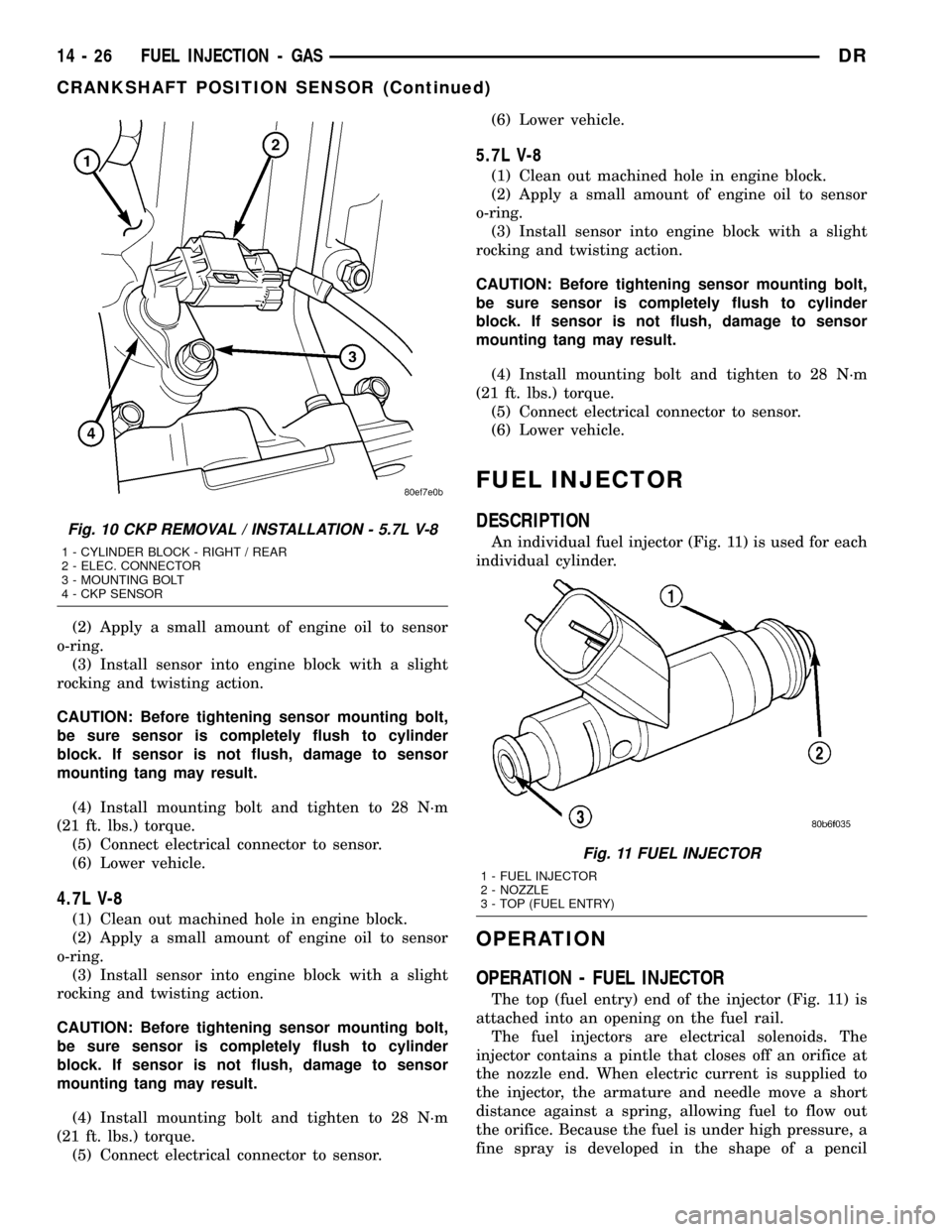

5.7L V-8

The Crankshaft Position (CKP) sensor is located at

the right-rear side of the engine cylinder block (Fig.

10). It is positioned and bolted into a machined hole

in the engine block.

(1) Raise vehicle.

(2) Disconnect CKP electrical connector at sensor

(Fig. 10).

(3) Remove CKP mounting bolt (Fig. 10).

(4) Carefully twist sensor from cylinder block.

(5) Remove sensor from vehicle.

(6) Check condition of sensor o-ring.

INSTALLATION

3.7L V-6

(1) Clean out machined hole in engine block.

Fig. 7 CKP SENSOR OPERATION AND NOTCHES -

5.7L V-8

1 - RIGHT / REAR SIDE OF CYLINDER BLOCK

2 - MACHINED HOLE

3 - NOTCHES

Fig. 8 CKP REMOVAL / INSTALLATION - 3.7L

1 - MOUNTING BOLT

2 - CKP SENSOR

3 - O-RING

Fig. 9 CKP REMOVAL / INSTALLATION - 4.7L

1 - CRANKSHAFT POSITION SENSOR

2 - MOUNTING BOLT

DRFUEL INJECTION - GAS 14 - 25

CRANKSHAFT POSITION SENSOR (Continued)

Page 1595 of 2627

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.

(6) Lower vehicle.

4.7L V-8

(1) Clean out machined hole in engine block.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.(6) Lower vehicle.

5.7L V-8

(1) Clean out machined hole in engine block.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.

(6) Lower vehicle.

FUEL INJECTOR

DESCRIPTION

An individual fuel injector (Fig. 11) is used for each

individual cylinder.

OPERATION

OPERATION - FUEL INJECTOR

The top (fuel entry) end of the injector (Fig. 11) is

attached into an opening on the fuel rail.

The fuel injectors are electrical solenoids. The

injector contains a pintle that closes off an orifice at

the nozzle end. When electric current is supplied to

the injector, the armature and needle move a short

distance against a spring, allowing fuel to flow out

the orifice. Because the fuel is under high pressure, a

fine spray is developed in the shape of a pencil

Fig. 10 CKP REMOVAL / INSTALLATION - 5.7L V-8

1 - CYLINDER BLOCK - RIGHT / REAR

2 - ELEC. CONNECTOR

3 - MOUNTING BOLT

4 - CKP SENSOR

Fig. 11 FUEL INJECTOR

1 - FUEL INJECTOR

2 - NOZZLE

3 - TOP (FUEL ENTRY)

14 - 26 FUEL INJECTION - GASDR

CRANKSHAFT POSITION SENSOR (Continued)

Page 1615 of 2627

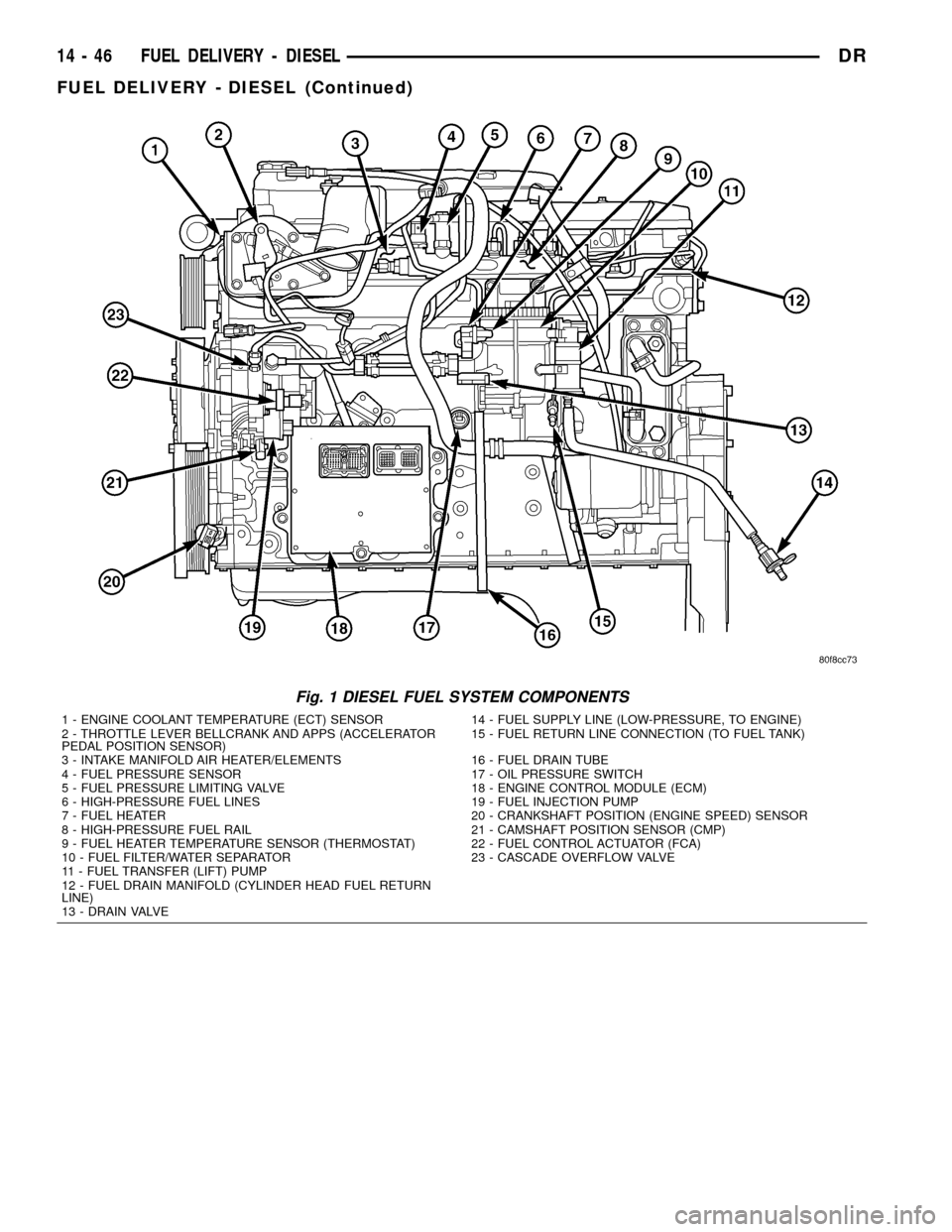

Fig. 1 DIESEL FUEL SYSTEM COMPONENTS

1 - ENGINE COOLANT TEMPERATURE (ECT) SENSOR 14 - FUEL SUPPLY LINE (LOW-PRESSURE, TO ENGINE)

2 - THROTTLE LEVER BELLCRANK AND APPS (ACCELERATOR

PEDAL POSITION SENSOR)15 - FUEL RETURN LINE CONNECTION (TO FUEL TANK)

3 - INTAKE MANIFOLD AIR HEATER/ELEMENTS 16 - FUEL DRAIN TUBE

4 - FUEL PRESSURE SENSOR 17 - OIL PRESSURE SWITCH

5 - FUEL PRESSURE LIMITING VALVE 18 - ENGINE CONTROL MODULE (ECM)

6 - HIGH-PRESSURE FUEL LINES 19 - FUEL INJECTION PUMP

7 - FUEL HEATER 20 - CRANKSHAFT POSITION (ENGINE SPEED) SENSOR

8 - HIGH-PRESSURE FUEL RAIL 21 - CAMSHAFT POSITION SENSOR (CMP)

9 - FUEL HEATER TEMPERATURE SENSOR (THERMOSTAT) 22 - FUEL CONTROL ACTUATOR (FCA)

10 - FUEL FILTER/WATER SEPARATOR 23 - CASCADE OVERFLOW VALVE

11 - FUEL TRANSFER (LIFT) PUMP

12 - FUEL DRAIN MANIFOLD (CYLINDER HEAD FUEL RETURN

LINE)

13 - DRAIN VALVE

14 - 46 FUEL DELIVERY - DIESELDR

FUEL DELIVERY - DIESEL (Continued)

Page 1617 of 2627

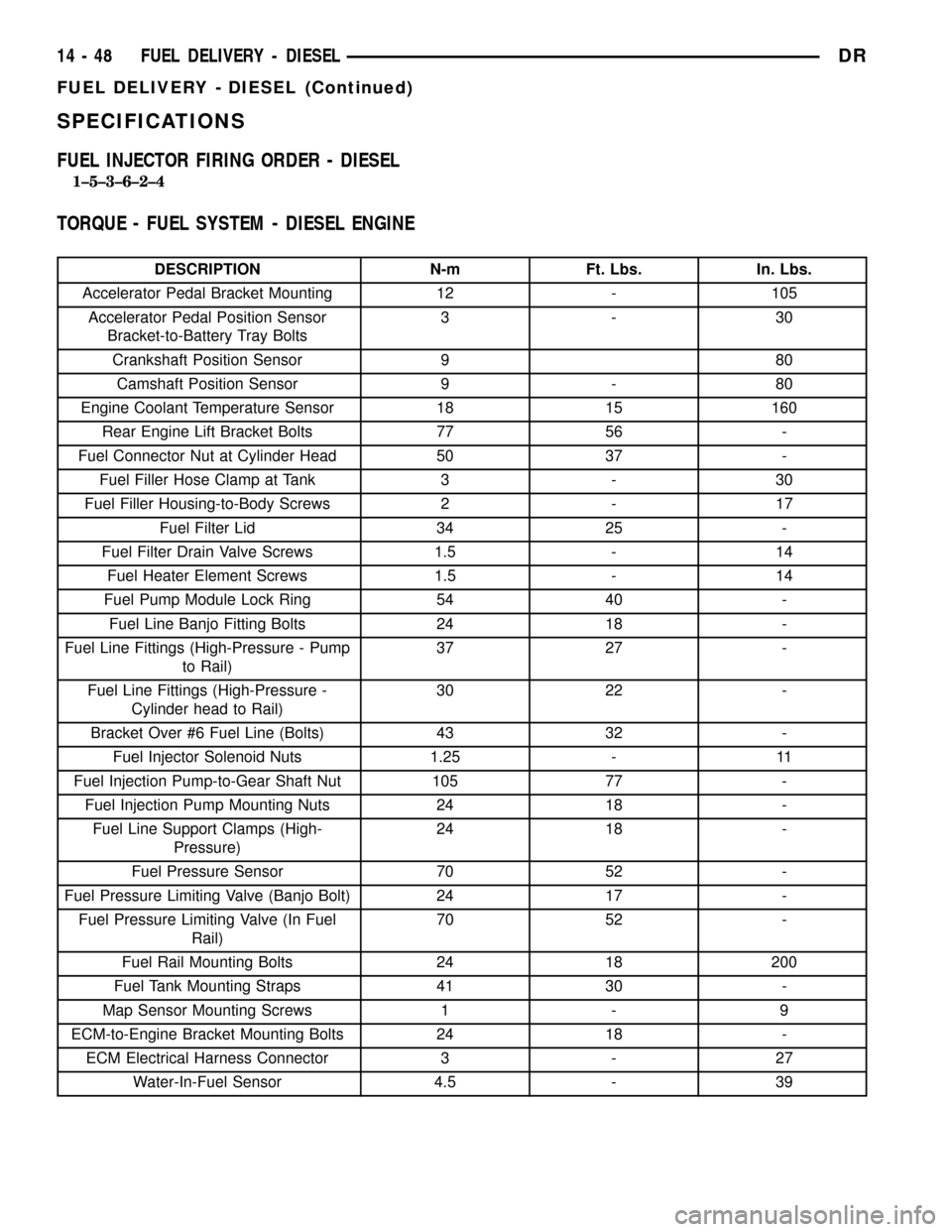

SPECIFICATIONS

FUEL INJECTOR FIRING ORDER - DIESEL

1±5±3±6±2±4

TORQUE - FUEL SYSTEM - DIESEL ENGINE

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket Mounting 12 - 105

Accelerator Pedal Position Sensor

Bracket-to-Battery Tray Bolts3-30

Crankshaft Position Sensor 9 80

Camshaft Position Sensor 9 - 80

Engine Coolant Temperature Sensor 18 15 160

Rear Engine Lift Bracket Bolts 77 56 -

Fuel Connector Nut at Cylinder Head 50 37 -

Fuel Filler Hose Clamp at Tank 3 - 30

Fuel Filler Housing-to-Body Screws 2 - 17

Fuel Filter Lid 34 25 -

Fuel Filter Drain Valve Screws 1.5 - 14

Fuel Heater Element Screws 1.5 - 14

Fuel Pump Module Lock Ring 54 40 -

Fuel Line Banjo Fitting Bolts 24 18 -

Fuel Line Fittings (High-Pressure - Pump

to Rail)37 27 -

Fuel Line Fittings (High-Pressure -

Cylinder head to Rail)30 22 -

Bracket Over #6 Fuel Line (Bolts) 43 32 -

Fuel Injector Solenoid Nuts 1.25 - 11

Fuel Injection Pump-to-Gear Shaft Nut 105 77 -

Fuel Injection Pump Mounting Nuts 24 18 -

Fuel Line Support Clamps (High-

Pressure)24 18 -

Fuel Pressure Sensor 70 52 -

Fuel Pressure Limiting Valve (Banjo Bolt) 24 17 -

Fuel Pressure Limiting Valve (In Fuel

Rail)70 52 -

Fuel Rail Mounting Bolts 24 18 200

Fuel Tank Mounting Straps 41 30 -

Map Sensor Mounting Screws 1 - 9

ECM-to-Engine Bracket Mounting Bolts 24 18 -

ECM Electrical Harness Connector 3 - 27

Water-In-Fuel Sensor 4.5 - 39

14 - 48 FUEL DELIVERY - DIESELDR

FUEL DELIVERY - DIESEL (Continued)

Page 1637 of 2627

FUEL INJECTION - DIESEL

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................68

OPERATION...........................68

REMOVAL.............................68

INSTALLATION.........................71

CAMSHAFT POSITION SENSOR

DESCRIPTION.........................71

OPERATION...........................71

REMOVAL.............................72

INSTALLATION.........................72

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................72

OPERATION...........................72

REMOVAL.............................73

INSTALLATION.........................73

FUEL CONTROL ACTUATOR

DESCRIPTION.........................74

OPERATION...........................74

REMOVAL.............................74

FUEL INJECTOR

DESCRIPTION.........................74

OPERATION...........................74

REMOVAL.............................75

INSTALLATION.........................77

FUEL INJECTOR RAIL

DESCRIPTION.........................78

OPERATION...........................78

REMOVAL.............................78

INSTALLATION.........................78INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR

DESCRIPTION.........................79

OPERATION...........................79

REMOVAL.............................79

INSTALLATION.........................79

INTAKE AIR HEATER

DESCRIPTION.........................80

OPERATION...........................80

REMOVAL.............................80

INSTALLATION.........................80

INTAKE AIR HEATER RELAY

DESCRIPTION.........................82

OPERATION...........................82

REMOVAL.............................82

INSTALLATION.........................82

INTAKE AIR TEMPERATURE SENSOR/MAP

SENSOR

DESCRIPTION.........................82

OPERATION...........................82

REMOVAL.............................82

INSTALLATION.........................82

MAP SENSOR

DESCRIPTION.........................83

THROTTLE CONTROL CABLE

REMOVAL.............................83

INSTALLATION.........................84

PTO SWITCH

DESCRIPTION.........................85

OPERATION...........................85

ACCELERATOR PEDAL

POSITION SENSOR

DESCRIPTION

Engine Mounted Sensor:The APPS assembly is

located at the top-left-front of the engine. A plastic

cover is used to cover the assembly. The actual sen-

sor is located behind its mounting bracket.

Battery Tray Mounted Sensor:The Accelerator

Pedal Position Sensor (APPS) assembly is located

under the vehicle battery tray. A cable connects the

assembly to the accelerator pedal. A plastic cover

with a movable door is used to cover the assembly.

OPERATION

Engine Mounted Sensor:The Accelerator Pedal

Position Sensor (APPS) is a linear potentiometer. Itprovides the Engine Control Module (ECM) with a

DC voltage signal proportional to the angle, or posi-

tion of the accelerator pedal.

Battery Tray Mounted Sensor:The APPS pro-

vides the ECM with two DC voltage signals which

change as the position of the accelerator changes.

One of the DC voltage signals will be half the voltage

of the other signal.

REMOVAL

Engine Mounted Sensor :

The APPS is serviced (replaced) as one assembly

including the lever, brackets and sensor. The APPS is

calibrated to its mounting bracket. The APPS assem-

bly is located at left-front of engine below plastic

cable/lever/linkage cover (Fig. 1).

14 - 68 FUEL INJECTION - DIESELDR

Page 1640 of 2627

INSTALLATION

Engine Mounted Sensor :

The APPS is serviced (replaced) as one assembly

including the lever, brackets and sensor. The APPS is

calibrated to its mounting bracket.

(1) Snap electrical connector into bottom of sensor.

(2) Position APPS assembly to engine and install 6

bolts. Tighten bolts to 24 N´m (18 ft. lbs.) torque.

(3) Connect wiring harness clip at bottom of

bracket.

(4) Refer to Group 21, Transmission for transmis-

sion control cable installation procedures.

(5) Install speed control cable into mounting

bracket. Be sure pinch tabs have secured cable.

(6) Install throttle cable into mounting bracket. Be

sure pinch tabs have secured cable.

(7) Connect throttle cable at lever (snaps on).

(8) Connect speed control cable to lever by pushing

cable connector rearward onto lever pin while hold-

ing lever forward.

(9) Install cable cover.

(10) Connect both negative battery cables to both

batteries.

(11) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from ECM.Battery Tray Mounted Sensor :

(1) Install Accelerator Pedal Position Sensor

(APPS) cable to accelerator pedal. Refer to Accelera-

tor Pedal Removal / Installation.

(2) Connect electrical connector to APPS.

(3) If necessary, connect cable to APPS lever ball

socket (snaps on).

(4) Snap APPS cable cover closed.

(5) Position APPS assembly to bottom of battery

tray and install 3 bolts. Refer to Torque Specifica-

tions.

(6) Install wheelhouse liner. Refer to Body.

(7) Perform the following procedure:

(a) Connect negative battery cables to both bat-

teries.

(b) Turn key switch ON, but do not crank

engine.

(c) Leave key switch ON for a minimum of 10

seconds. This will allow ECM to learn electrical

parameters.

(8) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from ECM.

CAMSHAFT POSITION

SENSOR

DESCRIPTION

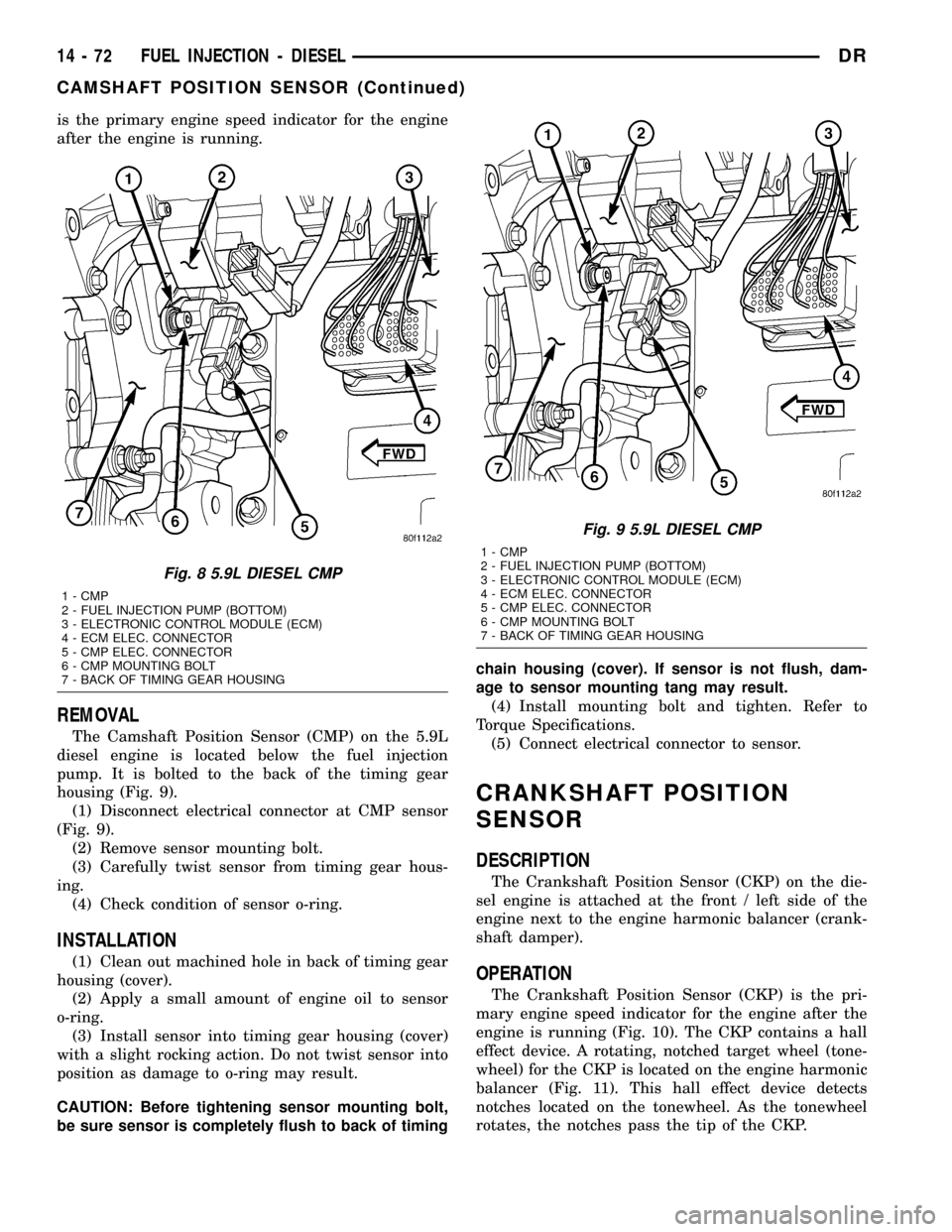

The Camshaft Position Sensor (CMP) on the 5.9L

diesel engine is located below the fuel injection

pump. It is bolted to the back of the timing gear

housing.

OPERATION

The diesel Camshaft Position Sensor (CMP) con-

tains a hall effect device. A rotating target wheel

(tonewheel) for the CMP is located on the camshaft

gear. This hall effect device detects notches located

on the back side of the camshaft gear. As the cam-

shaft gear rotates, the notches pass the tip of the

CMP.

When the leading edge of the notch passes the tip

of the CMP, the following occurs: The interruption of

magnetic field causes the voltage to switch high

resulting in a signal of approximately 5 volts.

When the trailing edge of the notch passes the tip

of the CMP, the following occurs: The change of the

magnetic field causes the signal voltage to switch low

to 0 volts.

The CMP (Fig. 8) provides a signal to the Engine

Control Module (ECM) at all times when the engine

is running. The ECM uses the CMP information pri-

marily on engine start-up. Once the engine is run-

ning, the ECM uses the CMP as a backup sensor for

engine speed. The Crankshaft Position Sensor (CKP)

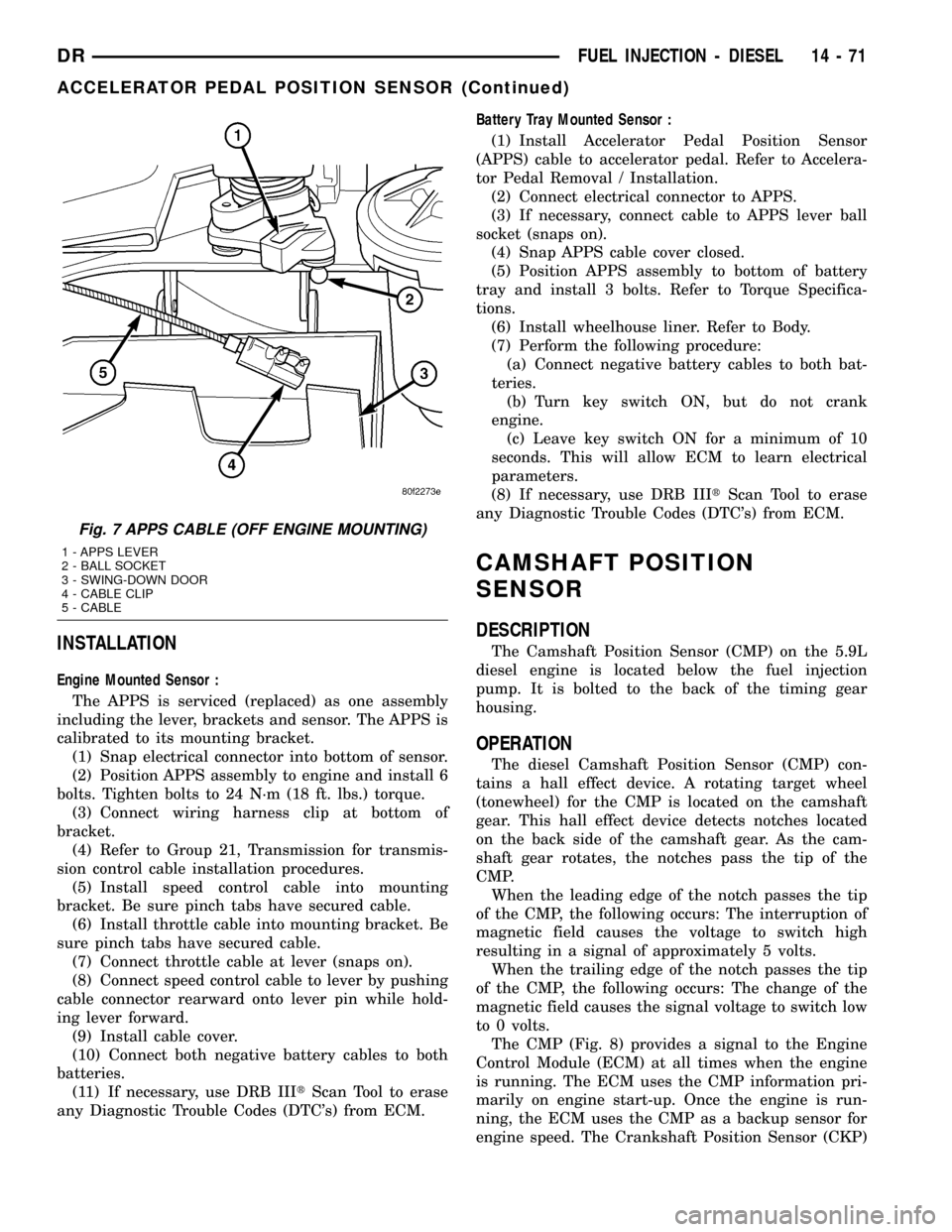

Fig. 7 APPS CABLE (OFF ENGINE MOUNTING)

1 - APPS LEVER

2 - BALL SOCKET

3 - SWING-DOWN DOOR

4 - CABLE CLIP

5 - CABLE

DRFUEL INJECTION - DIESEL 14 - 71

ACCELERATOR PEDAL POSITION SENSOR (Continued)

Page 1641 of 2627

is the primary engine speed indicator for the engine

after the engine is running.

REMOVAL

The Camshaft Position Sensor (CMP) on the 5.9L

diesel engine is located below the fuel injection

pump. It is bolted to the back of the timing gear

housing (Fig. 9).

(1) Disconnect electrical connector at CMP sensor

(Fig. 9).

(2) Remove sensor mounting bolt.

(3) Carefully twist sensor from timing gear hous-

ing.

(4) Check condition of sensor o-ring.

INSTALLATION

(1) Clean out machined hole in back of timing gear

housing (cover).

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into timing gear housing (cover)

with a slight rocking action. Do not twist sensor into

position as damage to o-ring may result.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to back of timingchain housing (cover). If sensor is not flush, dam-

age to sensor mounting tang may result.

(4) Install mounting bolt and tighten. Refer to

Torque Specifications.

(5) Connect electrical connector to sensor.

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

The Crankshaft Position Sensor (CKP) on the die-

sel engine is attached at the front / left side of the

engine next to the engine harmonic balancer (crank-

shaft damper).

OPERATION

The Crankshaft Position Sensor (CKP) is the pri-

mary engine speed indicator for the engine after the

engine is running (Fig. 10). The CKP contains a hall

effect device. A rotating, notched target wheel (tone-

wheel) for the CKP is located on the engine harmonic

balancer (Fig. 11). This hall effect device detects

notches located on the tonewheel. As the tonewheel

rotates, the notches pass the tip of the CKP.

Fig. 8 5.9L DIESEL CMP

1 - CMP

2 - FUEL INJECTION PUMP (BOTTOM)

3 - ELECTRONIC CONTROL MODULE (ECM)

4 - ECM ELEC. CONNECTOR

5 - CMP ELEC. CONNECTOR

6 - CMP MOUNTING BOLT

7 - BACK OF TIMING GEAR HOUSING

Fig. 9 5.9L DIESEL CMP

1 - CMP

2 - FUEL INJECTION PUMP (BOTTOM)

3 - ELECTRONIC CONTROL MODULE (ECM)

4 - ECM ELEC. CONNECTOR

5 - CMP ELEC. CONNECTOR

6 - CMP MOUNTING BOLT

7 - BACK OF TIMING GEAR HOUSING

14 - 72 FUEL INJECTION - DIESELDR

CAMSHAFT POSITION SENSOR (Continued)