Removal DODGE RAM 1500 1998 2.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 112 of 2627

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove axle half shafts.

(3) Remove exhaust crossover.

(4) Mark front propeller shaft and remove shaft.

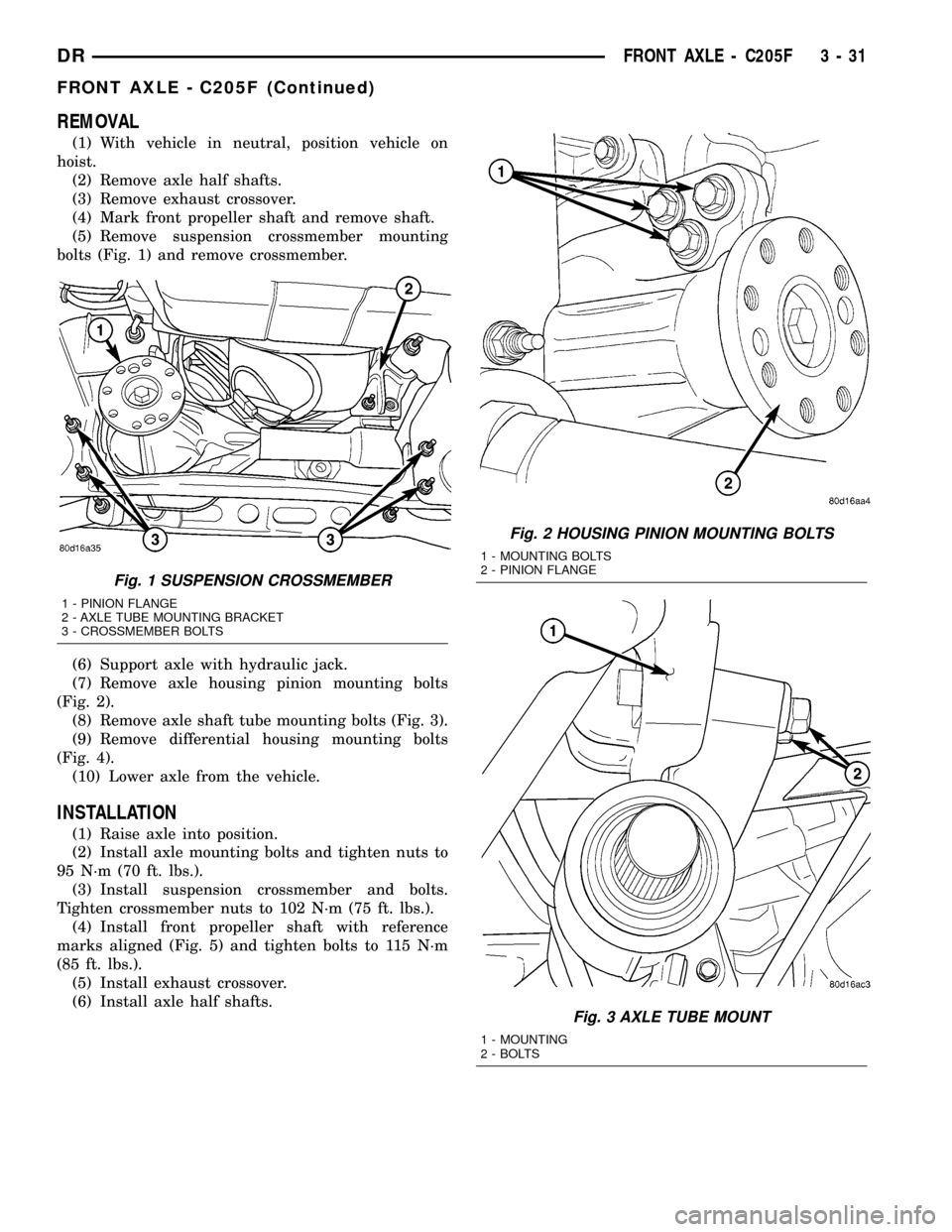

(5) Remove suspension crossmember mounting

bolts (Fig. 1) and remove crossmember.

(6) Support axle with hydraulic jack.

(7) Remove axle housing pinion mounting bolts

(Fig. 2).

(8) Remove axle shaft tube mounting bolts (Fig. 3).

(9) Remove differential housing mounting bolts

(Fig. 4).

(10) Lower axle from the vehicle.

INSTALLATION

(1) Raise axle into position.

(2) Install axle mounting bolts and tighten nuts to

95 N´m (70 ft. lbs.).

(3) Install suspension crossmember and bolts.

Tighten crossmember nuts to 102 N´m (75 ft. lbs.).

(4) Install front propeller shaft with reference

marks aligned (Fig. 5) and tighten bolts to 115 N´m

(85 ft. lbs.).

(5) Install exhaust crossover.

(6) Install axle half shafts.

Fig. 1 SUSPENSION CROSSMEMBER

1 - PINION FLANGE

2 - AXLE TUBE MOUNTING BRACKET

3 - CROSSMEMBER BOLTS

Fig. 2 HOUSING PINION MOUNTING BOLTS

1 - MOUNTING BOLTS

2 - PINION FLANGE

Fig. 3 AXLE TUBE MOUNT

1 - MOUNTING

2 - BOLTS

DRFRONT AXLE - C205F 3 - 31

FRONT AXLE - C205F (Continued)

Page 116 of 2627

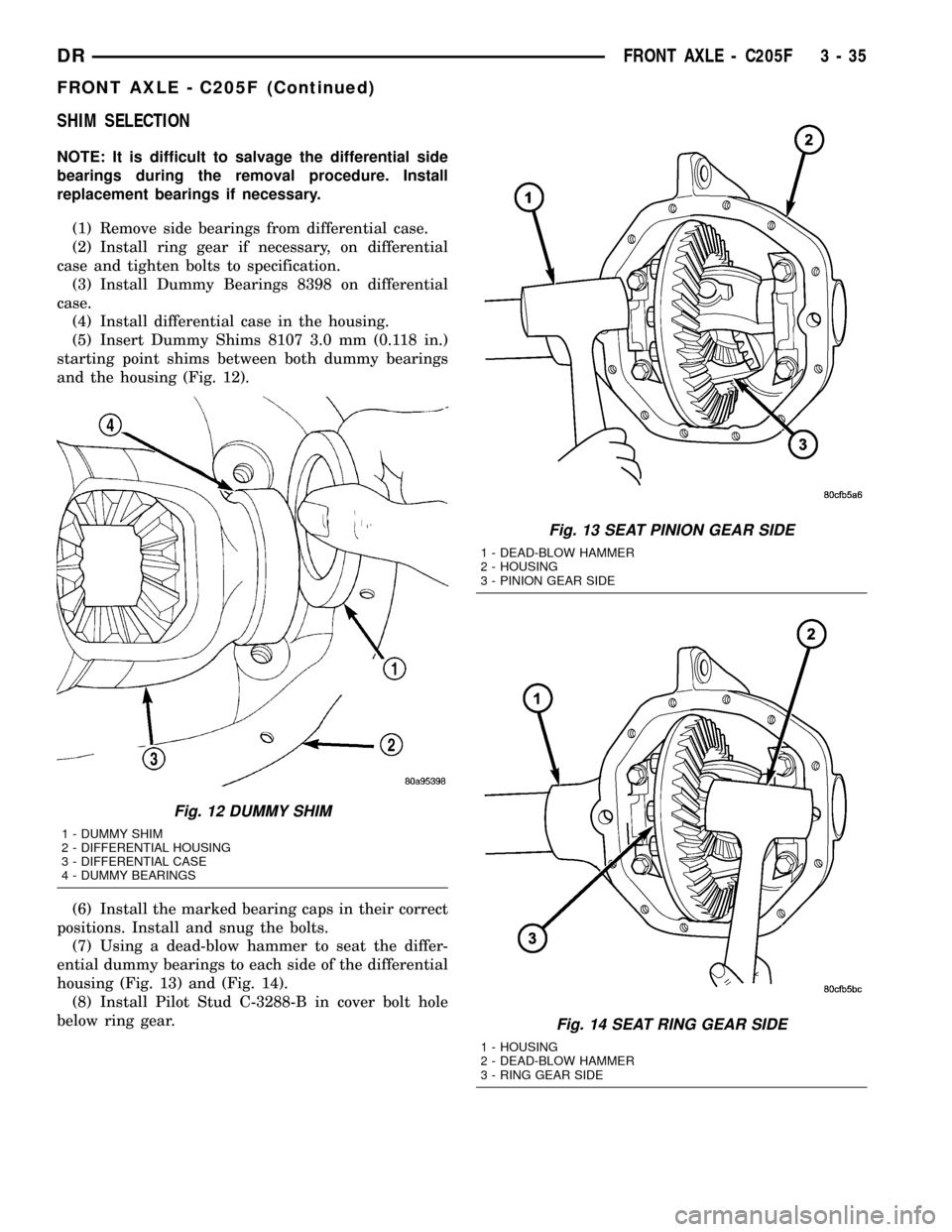

SHIM SELECTION

NOTE: It is difficult to salvage the differential side

bearings during the removal procedure. Install

replacement bearings if necessary.

(1) Remove side bearings from differential case.

(2) Install ring gear if necessary, on differential

case and tighten bolts to specification.

(3) Install Dummy Bearings 8398 on differential

case.

(4) Install differential case in the housing.

(5) Insert Dummy Shims 8107 3.0 mm (0.118 in.)

starting point shims between both dummy bearings

and the housing (Fig. 12).

(6) Install the marked bearing caps in their correct

positions. Install and snug the bolts.

(7) Using a dead-blow hammer to seat the differ-

ential dummy bearings to each side of the differential

housing (Fig. 13) and (Fig. 14).

(8) Install Pilot Stud C-3288-B in cover bolt hole

below ring gear.

Fig. 12 DUMMY SHIM

1 - DUMMY SHIM

2 - DIFFERENTIAL HOUSING

3 - DIFFERENTIAL CASE

4 - DUMMY BEARINGS

Fig. 13 SEAT PINION GEAR SIDE

1 - DEAD-BLOW HAMMER

2 - HOUSING

3 - PINION GEAR SIDE

Fig. 14 SEAT RING GEAR SIDE

1 - HOUSING

2 - DEAD-BLOW HAMMER

3 - RING GEAR SIDE

DRFRONT AXLE - C205F 3 - 35

FRONT AXLE - C205F (Continued)

Page 124 of 2627

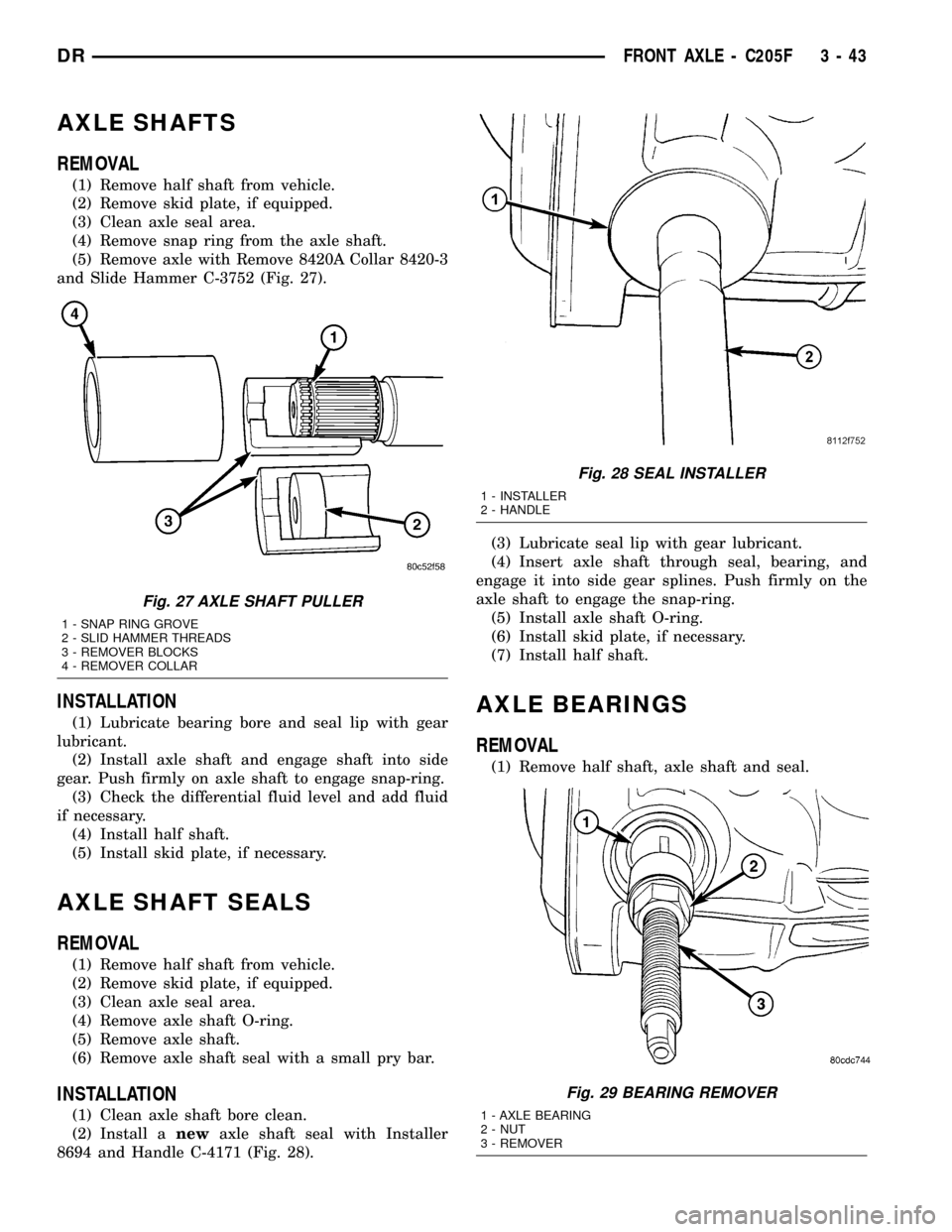

AXLE SHAFTS

REMOVAL

(1) Remove half shaft from vehicle.

(2) Remove skid plate, if equipped.

(3) Clean axle seal area.

(4) Remove snap ring from the axle shaft.

(5) Remove axle with Remove 8420A Collar 8420-3

and Slide Hammer C-3752 (Fig. 27).

INSTALLATION

(1) Lubricate bearing bore and seal lip with gear

lubricant.

(2) Install axle shaft and engage shaft into side

gear. Push firmly on axle shaft to engage snap-ring.

(3) Check the differential fluid level and add fluid

if necessary.

(4) Install half shaft.

(5) Install skid plate, if necessary.

AXLE SHAFT SEALS

REMOVAL

(1) Remove half shaft from vehicle.

(2) Remove skid plate, if equipped.

(3) Clean axle seal area.

(4) Remove axle shaft O-ring.

(5) Remove axle shaft.

(6) Remove axle shaft seal with a small pry bar.

INSTALLATION

(1) Clean axle shaft bore clean.

(2) Install anewaxle shaft seal with Installer

8694 and Handle C-4171 (Fig. 28).(3) Lubricate seal lip with gear lubricant.

(4) Insert axle shaft through seal, bearing, and

engage it into side gear splines. Push firmly on the

axle shaft to engage the snap-ring.

(5) Install axle shaft O-ring.

(6) Install skid plate, if necessary.

(7) Install half shaft.

AXLE BEARINGS

REMOVAL

(1) Remove half shaft, axle shaft and seal.

Fig. 27 AXLE SHAFT PULLER

1 - SNAP RING GROVE

2 - SLID HAMMER THREADS

3 - REMOVER BLOCKS

4 - REMOVER COLLAR

Fig. 28 SEAL INSTALLER

1 - INSTALLER

2 - HANDLE

Fig. 29 BEARING REMOVER

1 - AXLE BEARING

2 - NUT

3 - REMOVER

DRFRONT AXLE - C205F 3 - 43

Page 125 of 2627

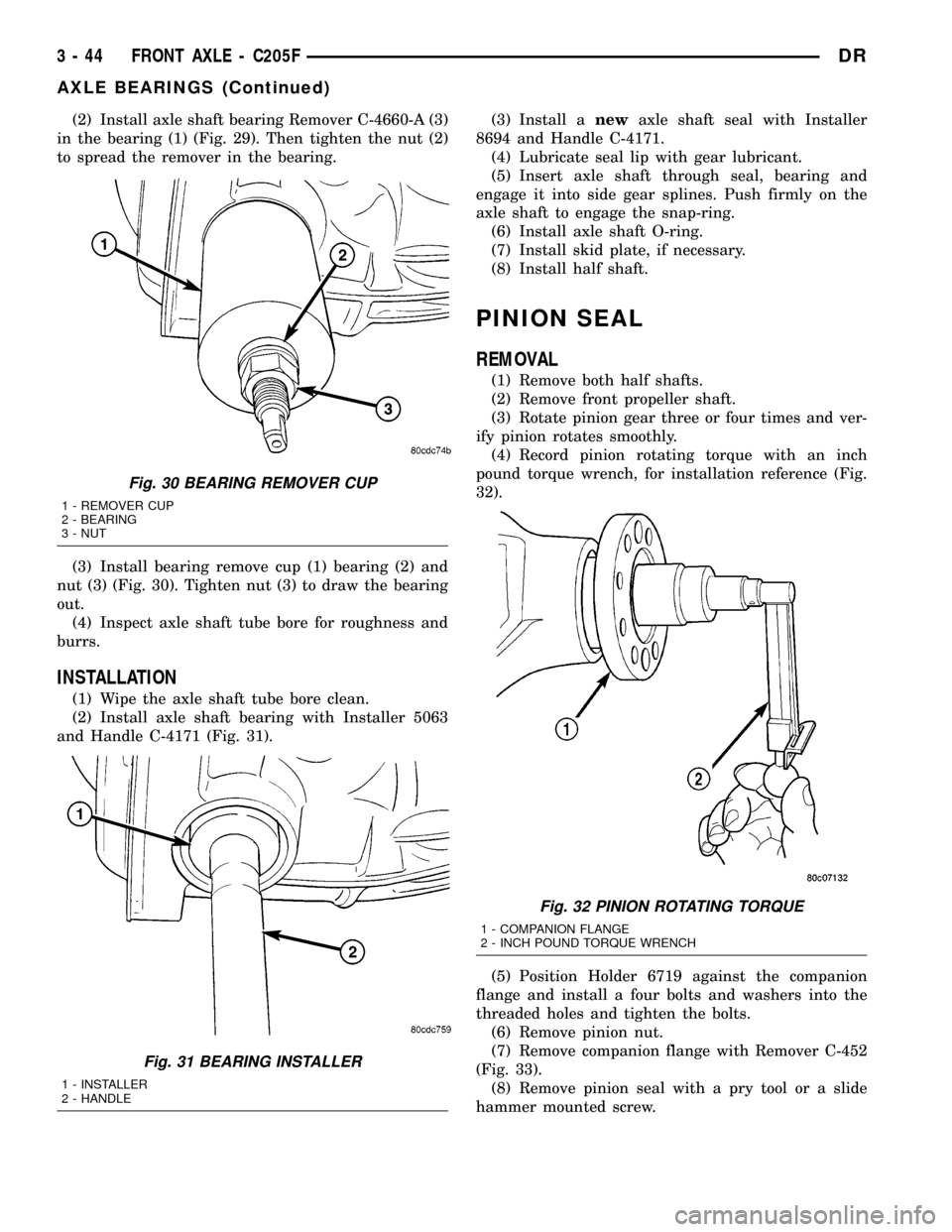

(2) Install axle shaft bearing Remover C-4660-A (3)

in the bearing (1) (Fig. 29). Then tighten the nut (2)

to spread the remover in the bearing.

(3) Install bearing remove cup (1) bearing (2) and

nut (3) (Fig. 30). Tighten nut (3) to draw the bearing

out.

(4) Inspect axle shaft tube bore for roughness and

burrs.

INSTALLATION

(1) Wipe the axle shaft tube bore clean.

(2) Install axle shaft bearing with Installer 5063

and Handle C-4171 (Fig. 31).(3) Install anewaxle shaft seal with Installer

8694 and Handle C-4171.

(4) Lubricate seal lip with gear lubricant.

(5) Insert axle shaft through seal, bearing and

engage it into side gear splines. Push firmly on the

axle shaft to engage the snap-ring.

(6) Install axle shaft O-ring.

(7) Install skid plate, if necessary.

(8) Install half shaft.

PINION SEAL

REMOVAL

(1) Remove both half shafts.

(2) Remove front propeller shaft.

(3) Rotate pinion gear three or four times and ver-

ify pinion rotates smoothly.

(4) Record pinion rotating torque with an inch

pound torque wrench, for installation reference (Fig.

32).

(5) Position Holder 6719 against the companion

flange and install a four bolts and washers into the

threaded holes and tighten the bolts.

(6) Remove pinion nut.

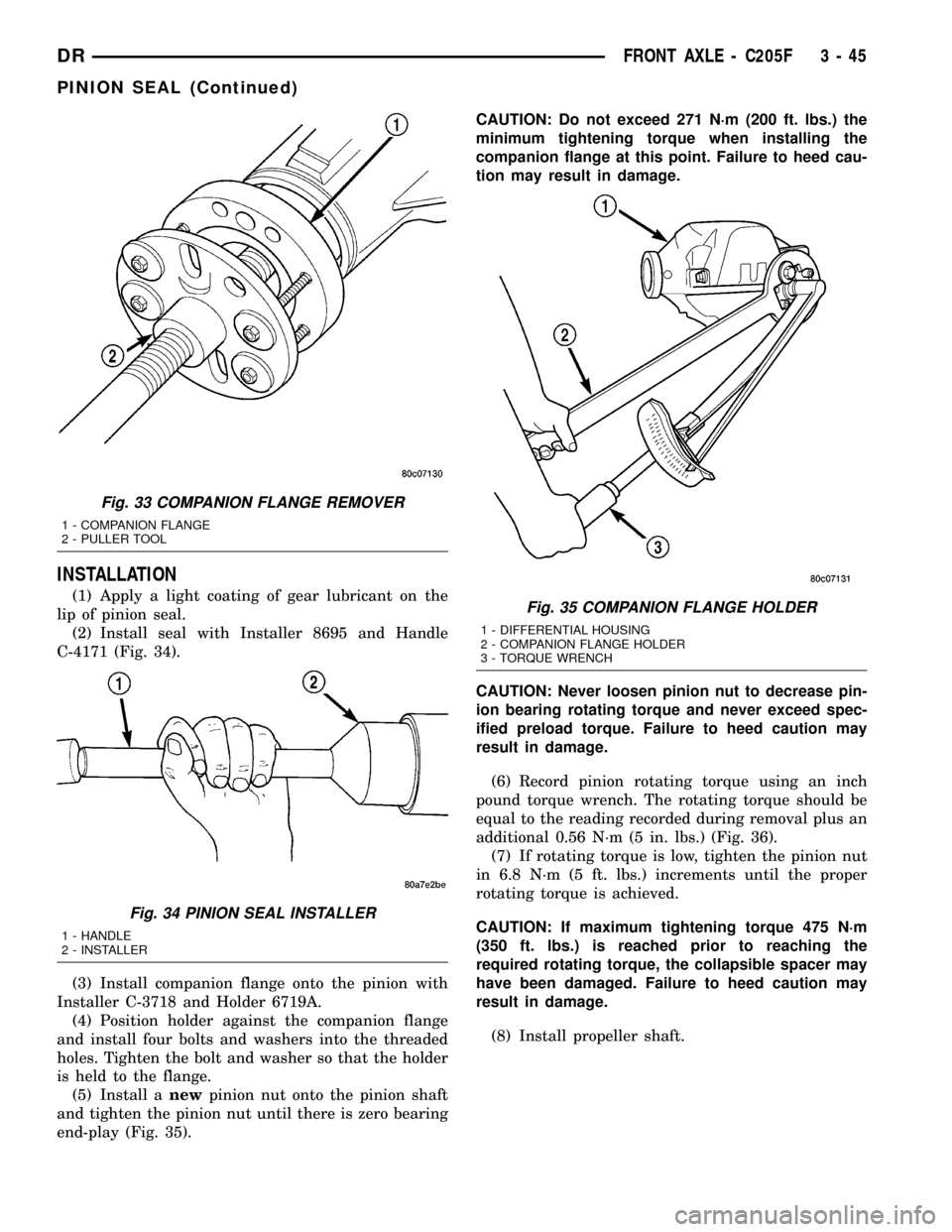

(7) Remove companion flange with Remover C-452

(Fig. 33).

(8) Remove pinion seal with a pry tool or a slide

hammer mounted screw.

Fig. 30 BEARING REMOVER CUP

1 - REMOVER CUP

2 - BEARING

3 - NUT

Fig. 31 BEARING INSTALLER

1 - INSTALLER

2 - HANDLE

Fig. 32 PINION ROTATING TORQUE

1 - COMPANION FLANGE

2 - INCH POUND TORQUE WRENCH

3 - 44 FRONT AXLE - C205FDR

AXLE BEARINGS (Continued)

Page 126 of 2627

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal.

(2) Install seal with Installer 8695 and Handle

C-4171 (Fig. 34).

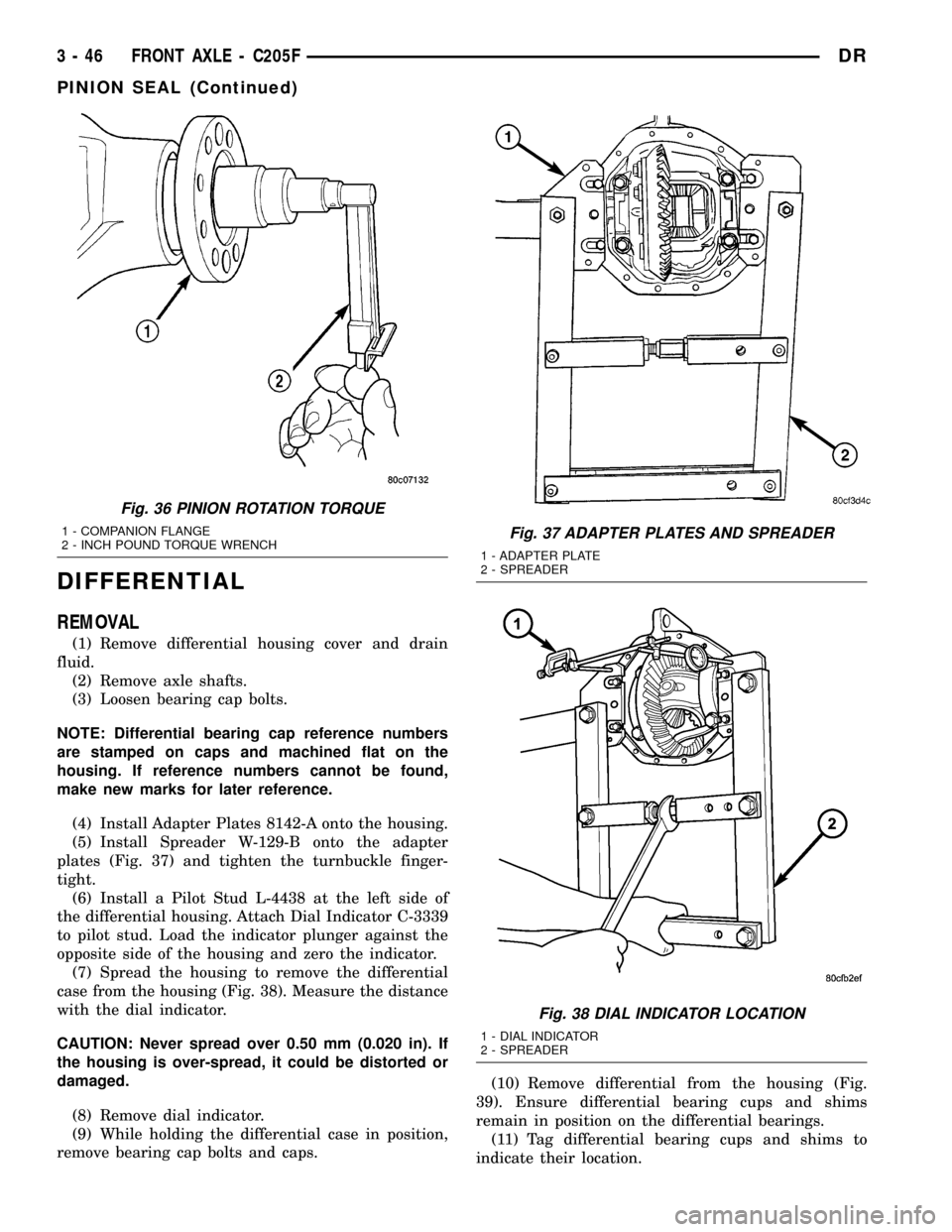

(3) Install companion flange onto the pinion with

Installer C-3718 and Holder 6719A.

(4) Position holder against the companion flange

and install four bolts and washers into the threaded

holes. Tighten the bolt and washer so that the holder

is held to the flange.

(5) Install anewpinion nut onto the pinion shaft

and tighten the pinion nut until there is zero bearing

end-play (Fig. 35).CAUTION: Do not exceed 271 N´m (200 ft. lbs.) the

minimum tightening torque when installing the

companion flange at this point. Failure to heed cau-

tion may result in damage.

CAUTION: Never loosen pinion nut to decrease pin-

ion bearing rotating torque and never exceed spec-

ified preload torque. Failure to heed caution may

result in damage.

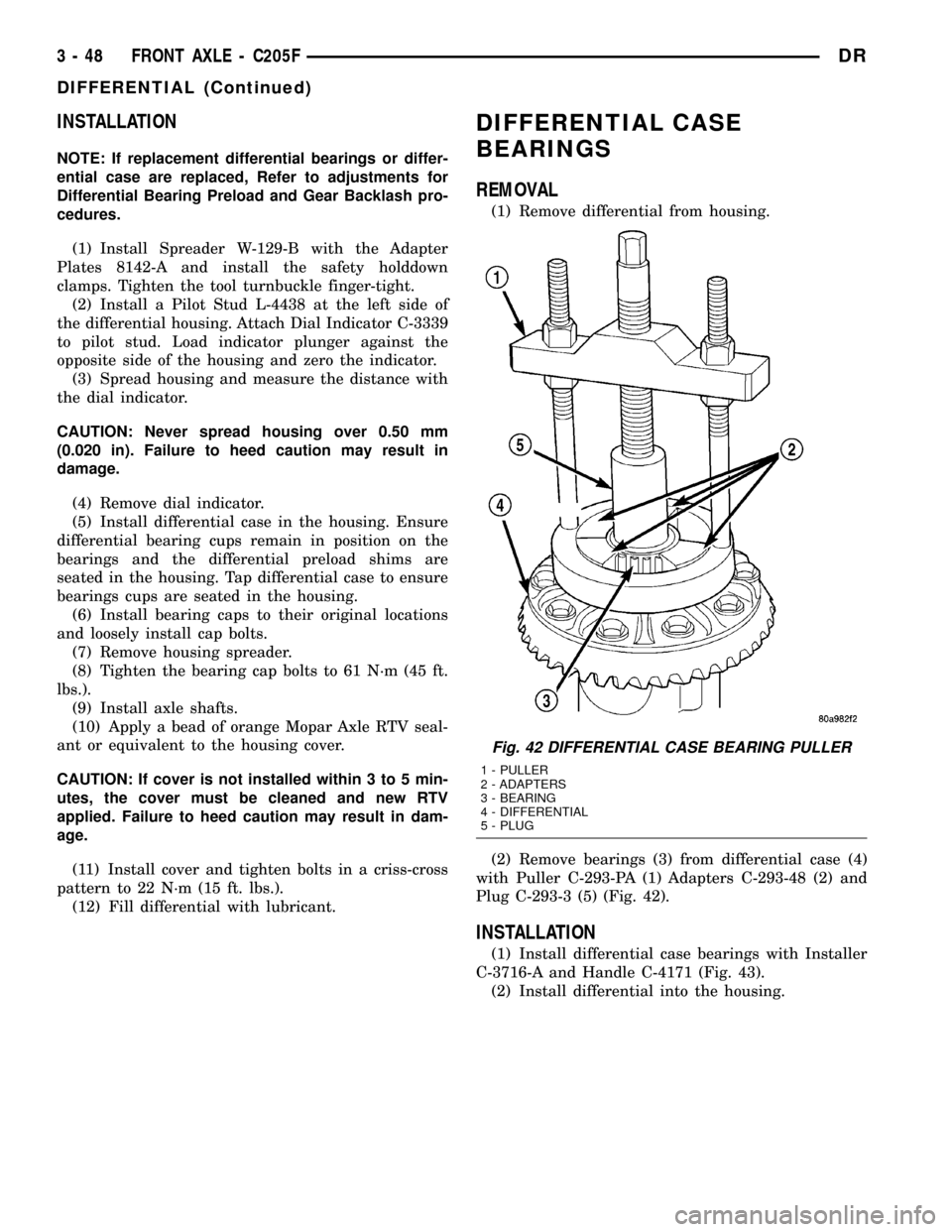

(6) Record pinion rotating torque using an inch

pound torque wrench. The rotating torque should be

equal to the reading recorded during removal plus an

additional 0.56 N´m (5 in. lbs.) (Fig. 36).

(7) If rotating torque is low, tighten the pinion nut

in 6.8 N´m (5 ft. lbs.) increments until the proper

rotating torque is achieved.

CAUTION: If maximum tightening torque 475 N´m

(350 ft. lbs.) is reached prior to reaching the

required rotating torque, the collapsible spacer may

have been damaged. Failure to heed caution may

result in damage.

(8) Install propeller shaft.

Fig. 33 COMPANION FLANGE REMOVER

1 - COMPANION FLANGE

2 - PULLER TOOL

Fig. 34 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

Fig. 35 COMPANION FLANGE HOLDER

1 - DIFFERENTIAL HOUSING

2 - COMPANION FLANGE HOLDER

3 - TORQUE WRENCH

DRFRONT AXLE - C205F 3 - 45

PINION SEAL (Continued)

Page 127 of 2627

DIFFERENTIAL

REMOVAL

(1) Remove differential housing cover and drain

fluid.

(2) Remove axle shafts.

(3) Loosen bearing cap bolts.

NOTE: Differential bearing cap reference numbers

are stamped on caps and machined flat on the

housing. If reference numbers cannot be found,

make new marks for later reference.

(4) Install Adapter Plates 8142-A onto the housing.

(5) Install Spreader W-129-B onto the adapter

plates (Fig. 37) and tighten the turnbuckle finger-

tight.

(6) Install a Pilot Stud L-4438 at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the indicator.

(7) Spread the housing to remove the differential

case from the housing (Fig. 38). Measure the distance

with the dial indicator.

CAUTION: Never spread over 0.50 mm (0.020 in). If

the housing is over-spread, it could be distorted or

damaged.

(8) Remove dial indicator.

(9) While holding the differential case in position,

remove bearing cap bolts and caps.(10) Remove differential from the housing (Fig.

39). Ensure differential bearing cups and shims

remain in position on the differential bearings.

(11) Tag differential bearing cups and shims to

indicate their location.

Fig. 36 PINION ROTATION TORQUE

1 - COMPANION FLANGE

2 - INCH POUND TORQUE WRENCHFig. 37 ADAPTER PLATES AND SPREADER

1 - ADAPTER PLATE

2 - SPREADER

Fig. 38 DIAL INDICATOR LOCATION

1 - DIAL INDICATOR

2 - SPREADER

3 - 46 FRONT AXLE - C205FDR

PINION SEAL (Continued)

Page 129 of 2627

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are replaced, Refer to adjustments for

Differential Bearing Preload and Gear Backlash pro-

cedures.

(1) Install Spreader W-129-B with the Adapter

Plates 8142-A and install the safety holddown

clamps. Tighten the tool turnbuckle finger-tight.

(2) Install a Pilot Stud L-4438 at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load indicator plunger against the

opposite side of the housing and zero the indicator.

(3) Spread housing and measure the distance with

the dial indicator.

CAUTION: Never spread housing over 0.50 mm

(0.020 in). Failure to heed caution may result in

damage.

(4) Remove dial indicator.

(5) Install differential case in the housing. Ensure

differential bearing cups remain in position on the

bearings and the differential preload shims are

seated in the housing. Tap differential case to ensure

bearings cups are seated in the housing.

(6) Install bearing caps to their original locations

and loosely install cap bolts.

(7) Remove housing spreader.

(8) Tighten the bearing cap bolts to 61 N´m (45 ft.

lbs.).

(9) Install axle shafts.

(10) Apply a bead of orange Mopar Axle RTV seal-

ant or equivalent to the housing cover.

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied. Failure to heed caution may result in dam-

age.

(11) Install cover and tighten bolts in a criss-cross

pattern to 22 N´m (15 ft. lbs.).

(12) Fill differential with lubricant.

DIFFERENTIAL CASE

BEARINGS

REMOVAL

(1) Remove differential from housing.

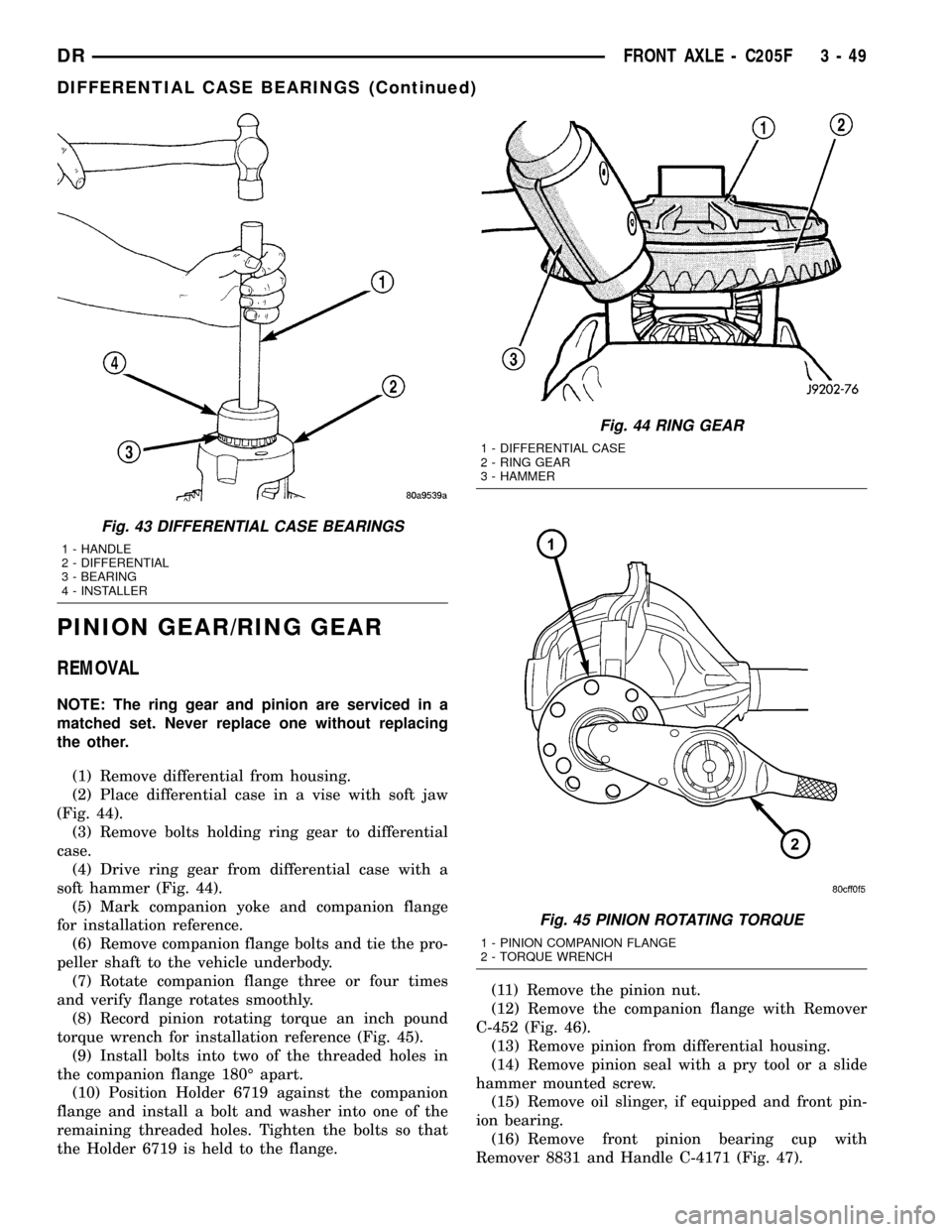

(2) Remove bearings (3) from differential case (4)

with Puller C-293-PA (1) Adapters C-293-48 (2) and

Plug C-293-3 (5) (Fig. 42).

INSTALLATION

(1) Install differential case bearings with Installer

C-3716-A and Handle C-4171 (Fig. 43).

(2) Install differential into the housing.

Fig. 42 DIFFERENTIAL CASE BEARING PULLER

1 - PULLER

2 - ADAPTERS

3 - BEARING

4 - DIFFERENTIAL

5 - PLUG

3 - 48 FRONT AXLE - C205FDR

DIFFERENTIAL (Continued)

Page 130 of 2627

PINION GEAR/RING GEAR

REMOVAL

NOTE: The ring gear and pinion are serviced in a

matched set. Never replace one without replacing

the other.

(1) Remove differential from housing.

(2) Place differential case in a vise with soft jaw

(Fig. 44).

(3) Remove bolts holding ring gear to differential

case.

(4) Drive ring gear from differential case with a

soft hammer (Fig. 44).

(5) Mark companion yoke and companion flange

for installation reference.

(6) Remove companion flange bolts and tie the pro-

peller shaft to the vehicle underbody.

(7) Rotate companion flange three or four times

and verify flange rotates smoothly.

(8) Record pinion rotating torque an inch pound

torque wrench for installation reference (Fig. 45).

(9) Install bolts into two of the threaded holes in

the companion flange 180É apart.

(10) Position Holder 6719 against the companion

flange and install a bolt and washer into one of the

remaining threaded holes. Tighten the bolts so that

the Holder 6719 is held to the flange.(11) Remove the pinion nut.

(12) Remove the companion flange with Remover

C-452 (Fig. 46).

(13) Remove pinion from differential housing.

(14) Remove pinion seal with a pry tool or a slide

hammer mounted screw.

(15) Remove oil slinger, if equipped and front pin-

ion bearing.

(16) Remove front pinion bearing cup with

Remover 8831 and Handle C-4171 (Fig. 47).

Fig. 43 DIFFERENTIAL CASE BEARINGS

1 - HANDLE

2 - DIFFERENTIAL

3 - BEARING

4 - INSTALLER

Fig. 44 RING GEAR

1 - DIFFERENTIAL CASE

2 - RING GEAR

3 - HAMMER

Fig. 45 PINION ROTATING TORQUE

1 - PINION COMPANION FLANGE

2 - TORQUE WRENCH

DRFRONT AXLE - C205F 3 - 49

DIFFERENTIAL CASE BEARINGS (Continued)

Page 135 of 2627

FRONT AXLE - 9 1/4 AA

TABLE OF CONTENTS

page page

FRONT AXLE - 9 1/4 AA

DIAGNOSIS AND TESTING................54

REMOVAL.............................57

INSTALLATION.........................58

ADJUSTMENTS........................59

SPECIFICATIONS.......................63

SPECIAL TOOLS.......................64

AXLE SHAFTS

REMOVAL.............................67

DISASSEMBLY.........................68

ASSEMBLY............................69

INSTALLATION.........................69

AXLE SHAFT SEALS

REMOVAL.............................69

INSTALLATION.........................70PINION SEAL

REMOVAL.............................70

INSTALLATION.........................71

DIFFERENTIAL

REMOVAL.............................72

DISASSEMBLY.........................72

ASSEMBLY............................73

INSTALLATION.........................74

DIFFERENTIAL CASE BEARINGS

REMOVAL.............................75

INSTALLATION.........................75

PINION GEAR/RING GEAR

REMOVAL.............................75

INSTALLATION.........................77

FRONT AXLE - 9 1/4 AA

DIAGNOSIS AND TESTING

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, tooth contact, worn/damaged

gears or the carrier housing not having the proper

offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly check for:

²Insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. The side gears are loaded dur-

ing turns. They usually do not cause noise during

straight-ahead driving when the gears are unloaded.

A worn pinion mate shaft can also cause a snapping

or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearingshave a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Differential bearingsusually produce a low pitch

noise. Differential bearing noise is similar to pinion

bearing noise. The pitch of differential bearing noise

is also constant and varies only with vehicle speed.

Axle shaft bearingsproduce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 m.p.h.

LOW SPEED KNOCK

Low speed knock is generally caused by:

²Worn U-joint(s).

²Worn side-gear thrust washers.

²Worn pinion shaft bore.

3 - 54 FRONT AXLE - 9 1/4 AADR

Page 138 of 2627

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

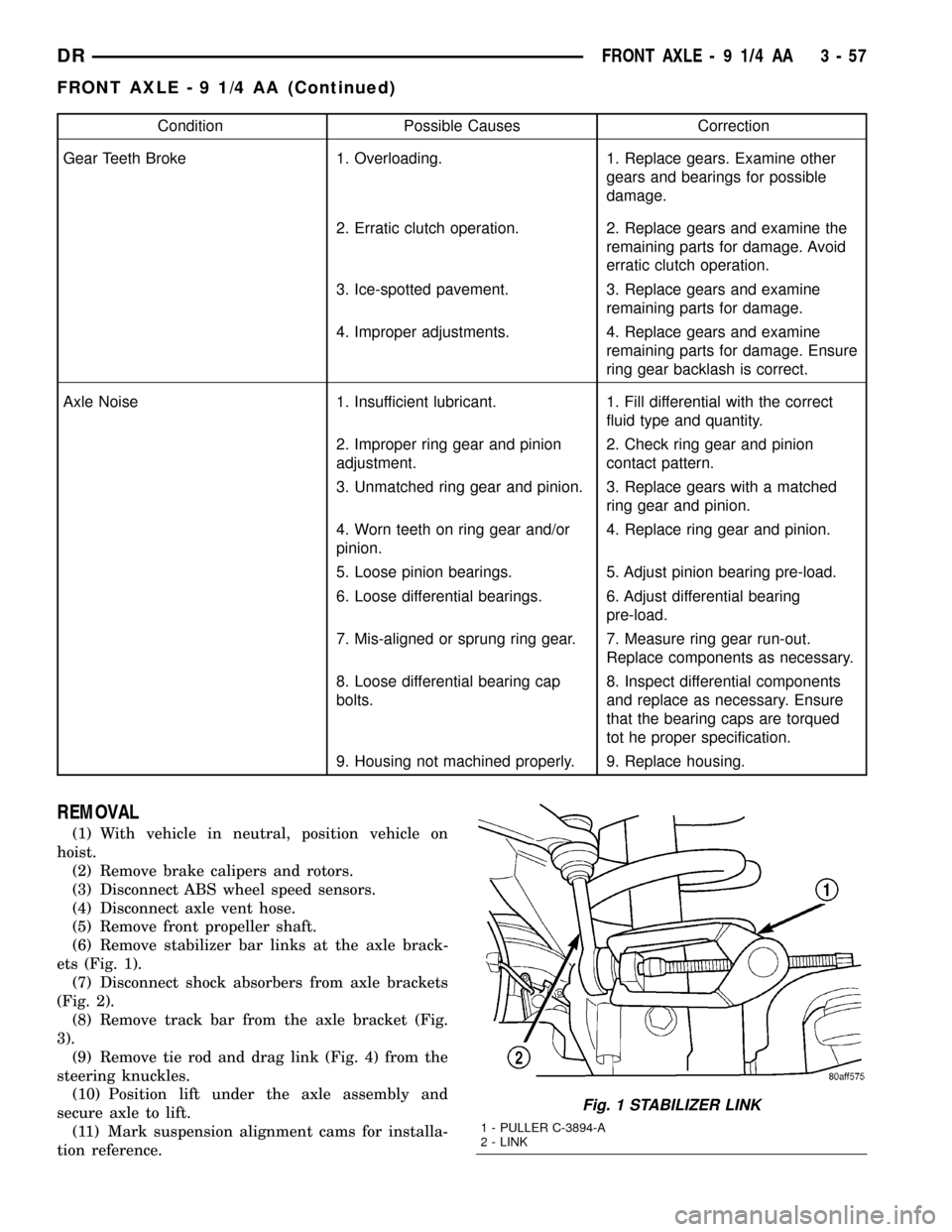

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove brake calipers and rotors.

(3) Disconnect ABS wheel speed sensors.

(4) Disconnect axle vent hose.

(5) Remove front propeller shaft.

(6) Remove stabilizer bar links at the axle brack-

ets (Fig. 1).

(7) Disconnect shock absorbers from axle brackets

(Fig. 2).

(8) Remove track bar from the axle bracket (Fig.

3).

(9) Remove tie rod and drag link (Fig. 4) from the

steering knuckles.

(10) Position lift under the axle assembly and

secure axle to lift.

(11) Mark suspension alignment cams for installa-

tion reference.

Fig. 1 STABILIZER LINK

1 - PULLER C-3894-A

2 - LINK

DRFRONT AXLE - 9 1/4 AA 3 - 57

FRONT AXLE - 9 1/4 AA (Continued)