Y case DODGE RAM 1500 1998 2.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 141 of 2627

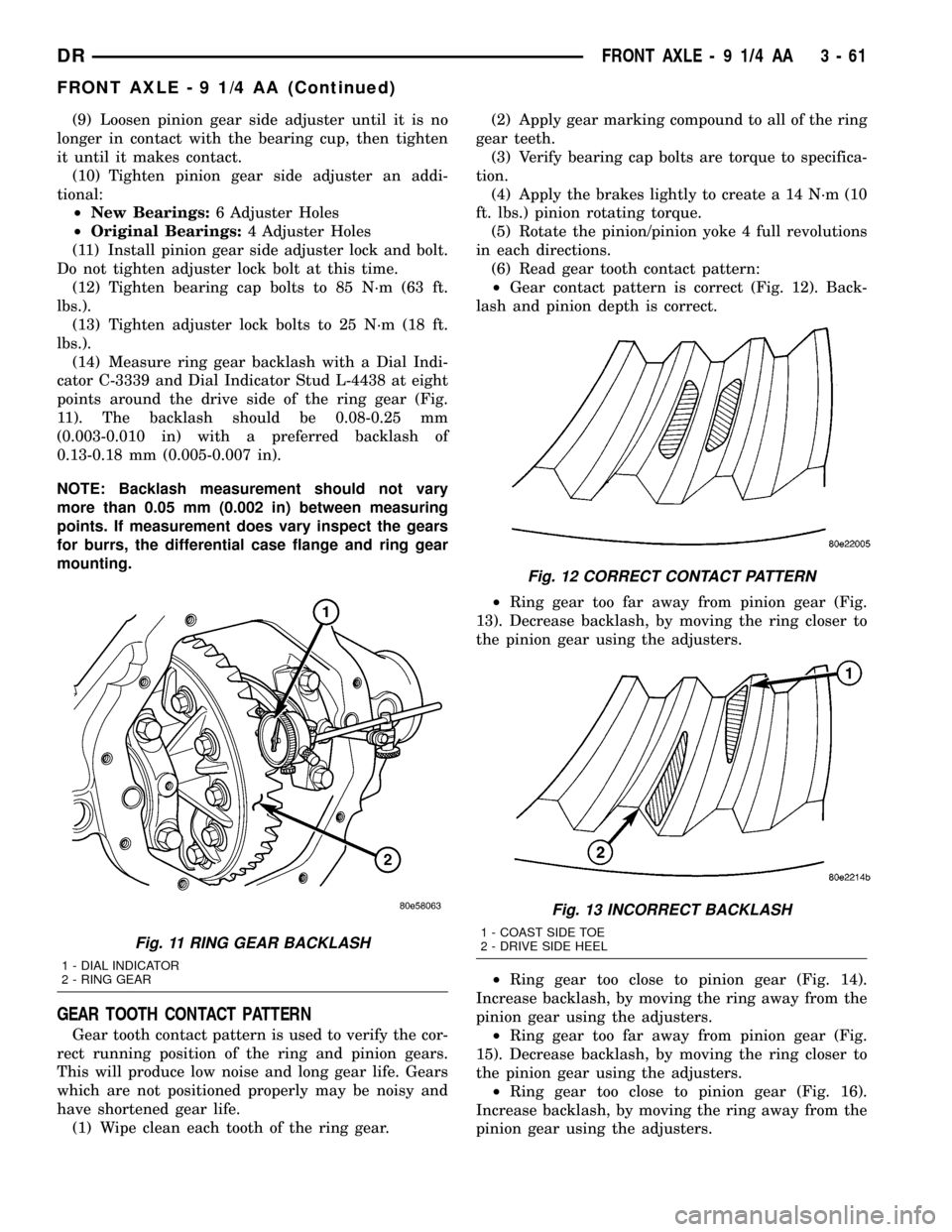

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 9). Move scooter

block till dial indicator crests the arbor, then record

the highest reading.

(9) Select a shim equal to the dial indicator read-

ing.

(10) Install the select shim between the rear pin-

ion bearing and the pinion gear head.

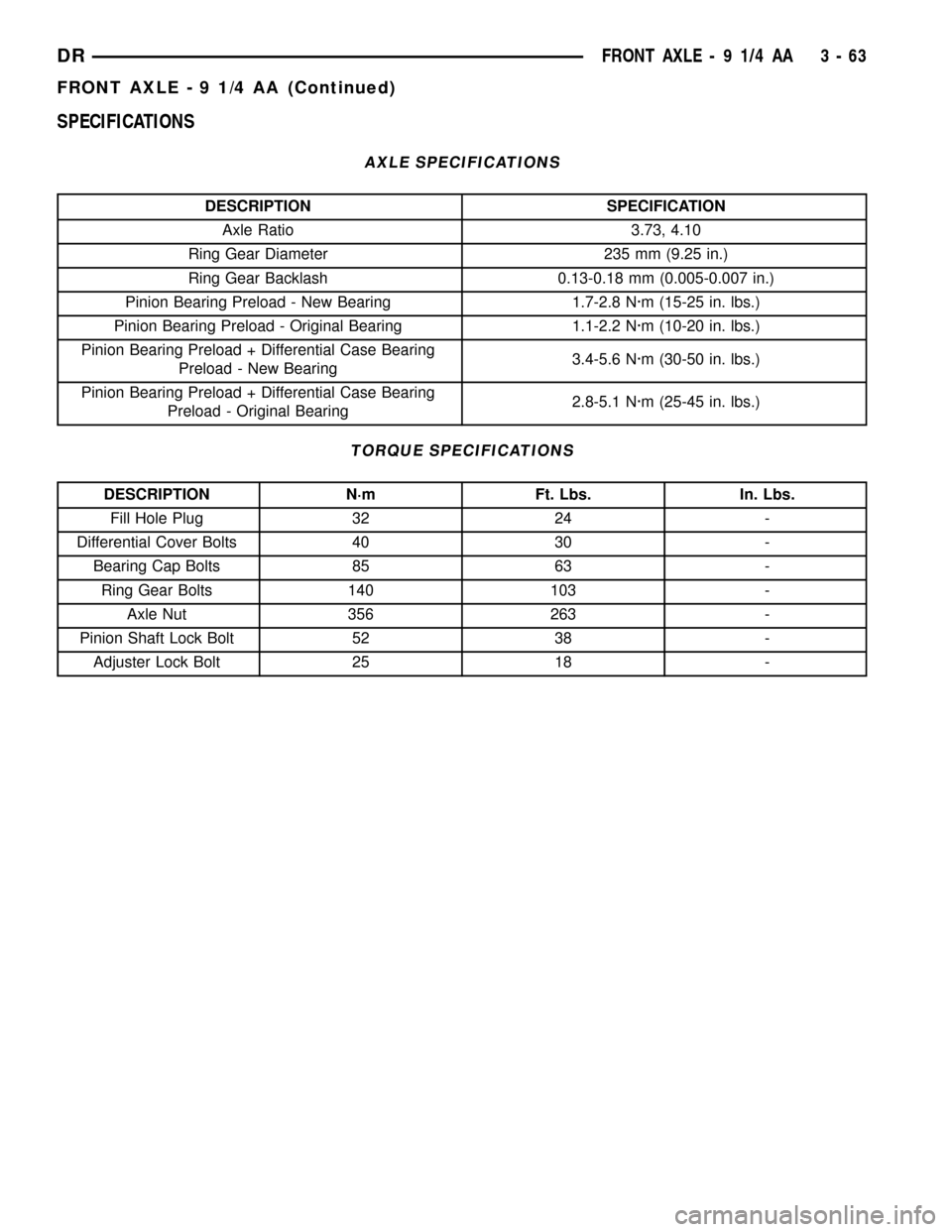

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 10).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(6) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(7) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(8) Rotate the pinion several times to seat the dif-

ferential bearings.

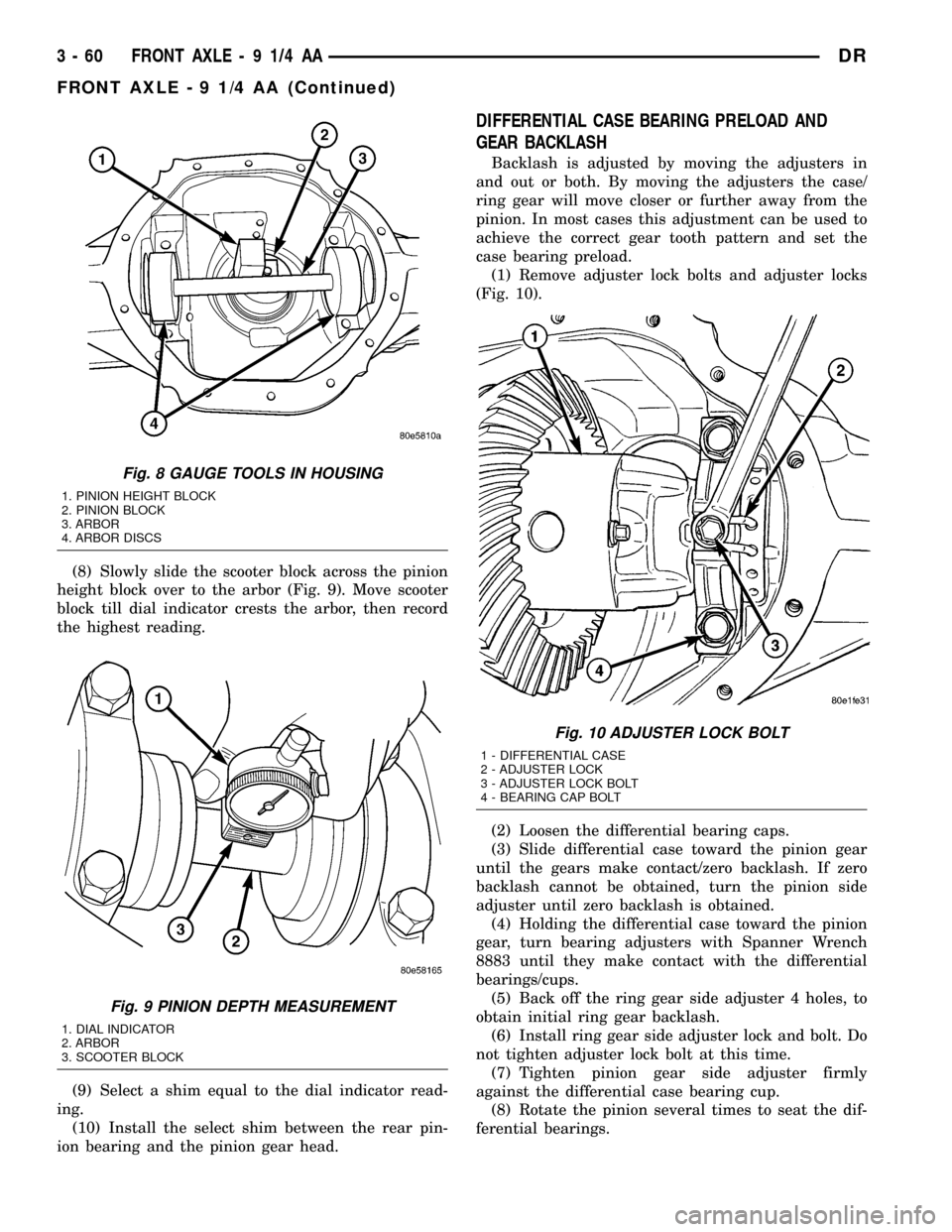

Fig. 8 GAUGE TOOLS IN HOUSING

1. PINION HEIGHT BLOCK

2. PINION BLOCK

3. ARBOR

4. ARBOR DISCS

Fig. 9 PINION DEPTH MEASUREMENT

1. DIAL INDICATOR

2. ARBOR

3. SCOOTER BLOCK

Fig. 10 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 60 FRONT AXLE - 9 1/4 AADR

FRONT AXLE - 9 1/4 AA (Continued)

Page 142 of 2627

(9) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup, then tighten

it until it makes contact.

(10) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings:6 Adjuster Holes

²Original Bearings:4 Adjuster Holes

(11) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(12) Tighten bearing cap bolts to 85 N´m (63 ft.

lbs.).

(13) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.).

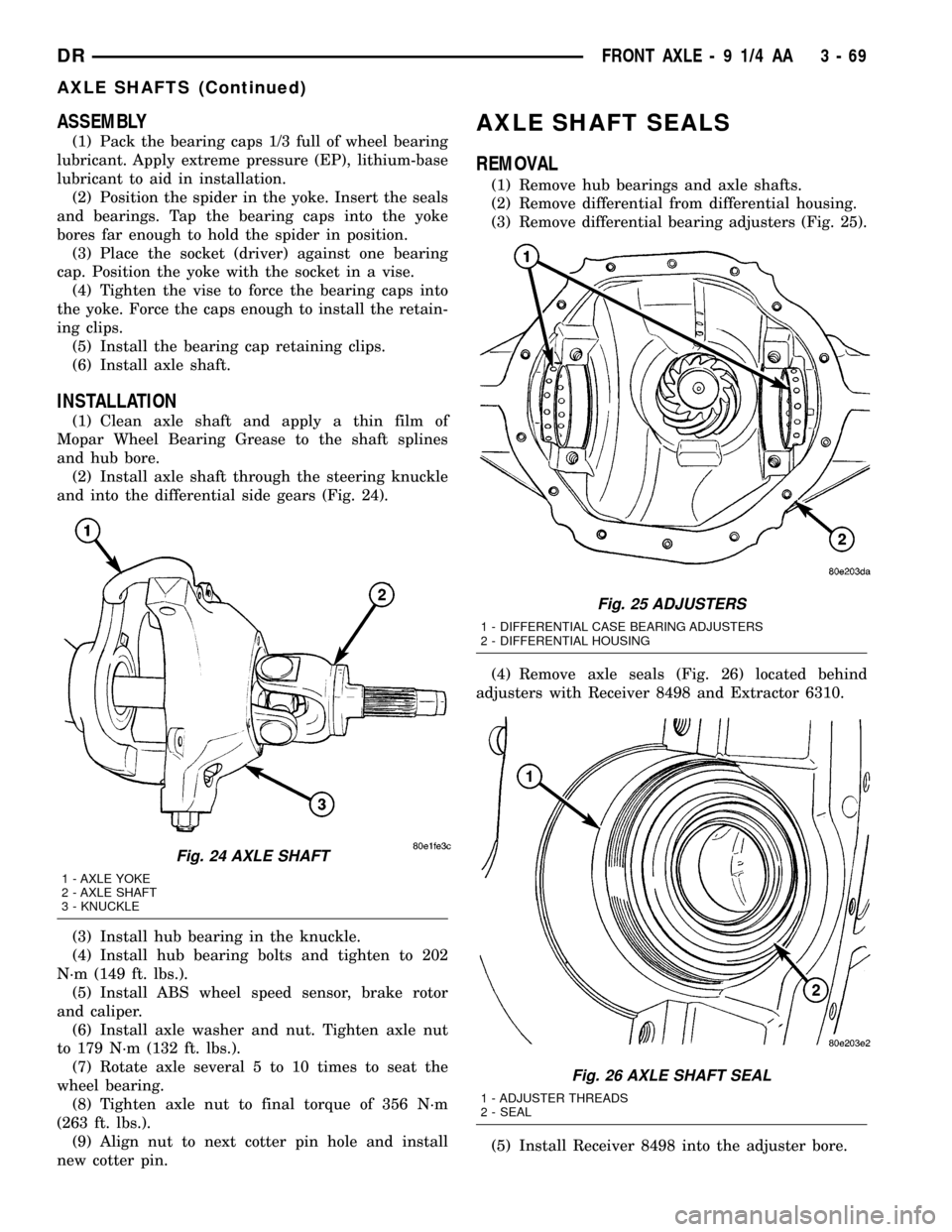

(14) Measure ring gear backlash with a Dial Indi-

cator C-3339 and Dial Indicator Stud L-4438 at eight

points around the drive side of the ring gear (Fig.

11). The backlash should be 0.08-0.25 mm

(0.003-0.010 in) with a preferred backlash of

0.13-0.18 mm (0.005-0.007 in).

NOTE: Backlash measurement should not vary

more than 0.05 mm (0.002 in) between measuring

points. If measurement does vary inspect the gears

for burrs, the differential case flange and ring gear

mounting.

GEAR TOOTH CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shortened gear life.

(1) Wipe clean each tooth of the ring gear.(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque to specifica-

tion.

(4) Apply the brakes lightly to create a 14 N´m (10

ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:

²Gear contact pattern is correct (Fig. 12). Back-

lash and pinion depth is correct.

²Ring gear too far away from pinion gear (Fig.

13). Decrease backlash, by moving the ring closer to

the pinion gear using the adjusters.

²Ring gear too close to pinion gear (Fig. 14).

Increase backlash, by moving the ring away from the

pinion gear using the adjusters.

²Ring gear too far away from pinion gear (Fig.

15). Decrease backlash, by moving the ring closer to

the pinion gear using the adjusters.

²Ring gear too close to pinion gear (Fig. 16).

Increase backlash, by moving the ring away from the

pinion gear using the adjusters.

Fig. 11 RING GEAR BACKLASH

1 - DIAL INDICATOR

2 - RING GEAR

Fig. 12 CORRECT CONTACT PATTERN

Fig. 13 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

DRFRONT AXLE - 9 1/4 AA 3 - 61

FRONT AXLE - 9 1/4 AA (Continued)

Page 144 of 2627

SPECIFICATIONS

AXLE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Axle Ratio 3.73, 4.10

Ring Gear Diameter 235 mm (9.25 in.)

Ring Gear Backlash 0.13-0.18 mm (0.005-0.007 in.)

Pinion Bearing Preload - New Bearing 1.7-2.8 N´m (15-25 in. lbs.)

Pinion Bearing Preload - Original Bearing 1.1-2.2 N´m (10-20 in. lbs.)

Pinion Bearing Preload + Differential Case Bearing

Preload - New Bearing3.4-5.6 N´m (30-50 in. lbs.)

Pinion Bearing Preload + Differential Case Bearing

Preload - Original Bearing2.8-5.1 N´m (25-45 in. lbs.)

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Fill Hole Plug 32 24 -

Differential Cover Bolts 40 30 -

Bearing Cap Bolts 85 63 -

Ring Gear Bolts 140 103 -

Axle Nut 356 263 -

Pinion Shaft Lock Bolt 52 38 -

Adjuster Lock Bolt 25 18 -

DRFRONT AXLE - 9 1/4 AA 3 - 63

FRONT AXLE - 9 1/4 AA (Continued)

Page 150 of 2627

ASSEMBLY

(1) Pack the bearing caps 1/3 full of wheel bearing

lubricant. Apply extreme pressure (EP), lithium-base

lubricant to aid in installation.

(2) Position the spider in the yoke. Insert the seals

and bearings. Tap the bearing caps into the yoke

bores far enough to hold the spider in position.

(3) Place the socket (driver) against one bearing

cap. Position the yoke with the socket in a vise.

(4) Tighten the vise to force the bearing caps into

the yoke. Force the caps enough to install the retain-

ing clips.

(5) Install the bearing cap retaining clips.

(6) Install axle shaft.

INSTALLATION

(1) Clean axle shaft and apply a thin film of

Mopar Wheel Bearing Grease to the shaft splines

and hub bore.

(2) Install axle shaft through the steering knuckle

and into the differential side gears (Fig. 24).

(3) Install hub bearing in the knuckle.

(4) Install hub bearing bolts and tighten to 202

N´m (149 ft. lbs.).

(5) Install ABS wheel speed sensor, brake rotor

and caliper.

(6) Install axle washer and nut. Tighten axle nut

to 179 N´m (132 ft. lbs.).

(7) Rotate axle several 5 to 10 times to seat the

wheel bearing.

(8) Tighten axle nut to final torque of 356 N´m

(263 ft. lbs.).

(9) Align nut to next cotter pin hole and install

new cotter pin.

AXLE SHAFT SEALS

REMOVAL

(1) Remove hub bearings and axle shafts.

(2) Remove differential from differential housing.

(3) Remove differential bearing adjusters (Fig. 25).

(4) Remove axle seals (Fig. 26) located behind

adjusters with Receiver 8498 and Extractor 6310.

(5) Install Receiver 8498 into the adjuster bore.

Fig. 24 AXLE SHAFT

1 - AXLE YOKE

2 - AXLE SHAFT

3 - KNUCKLE

Fig. 25 ADJUSTERS

1 - DIFFERENTIAL CASE BEARING ADJUSTERS

2 - DIFFERENTIAL HOUSING

Fig. 26 AXLE SHAFT SEAL

1 - ADJUSTER THREADS

2 - SEAL

DRFRONT AXLE - 9 1/4 AA 3 - 69

AXLE SHAFTS (Continued)

Page 153 of 2627

DIFFERENTIAL

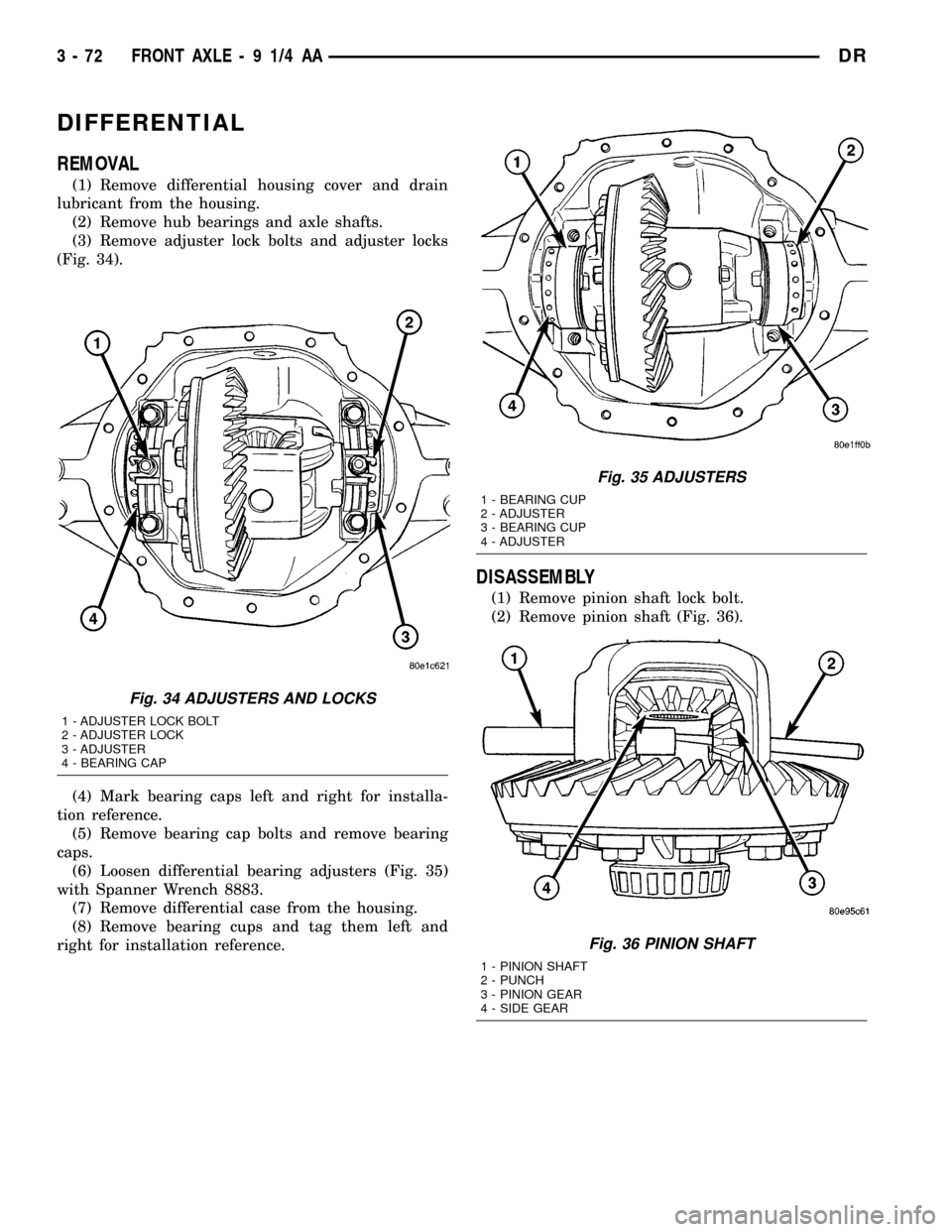

REMOVAL

(1) Remove differential housing cover and drain

lubricant from the housing.

(2) Remove hub bearings and axle shafts.

(3) Remove adjuster lock bolts and adjuster locks

(Fig. 34).

(4) Mark bearing caps left and right for installa-

tion reference.

(5) Remove bearing cap bolts and remove bearing

caps.

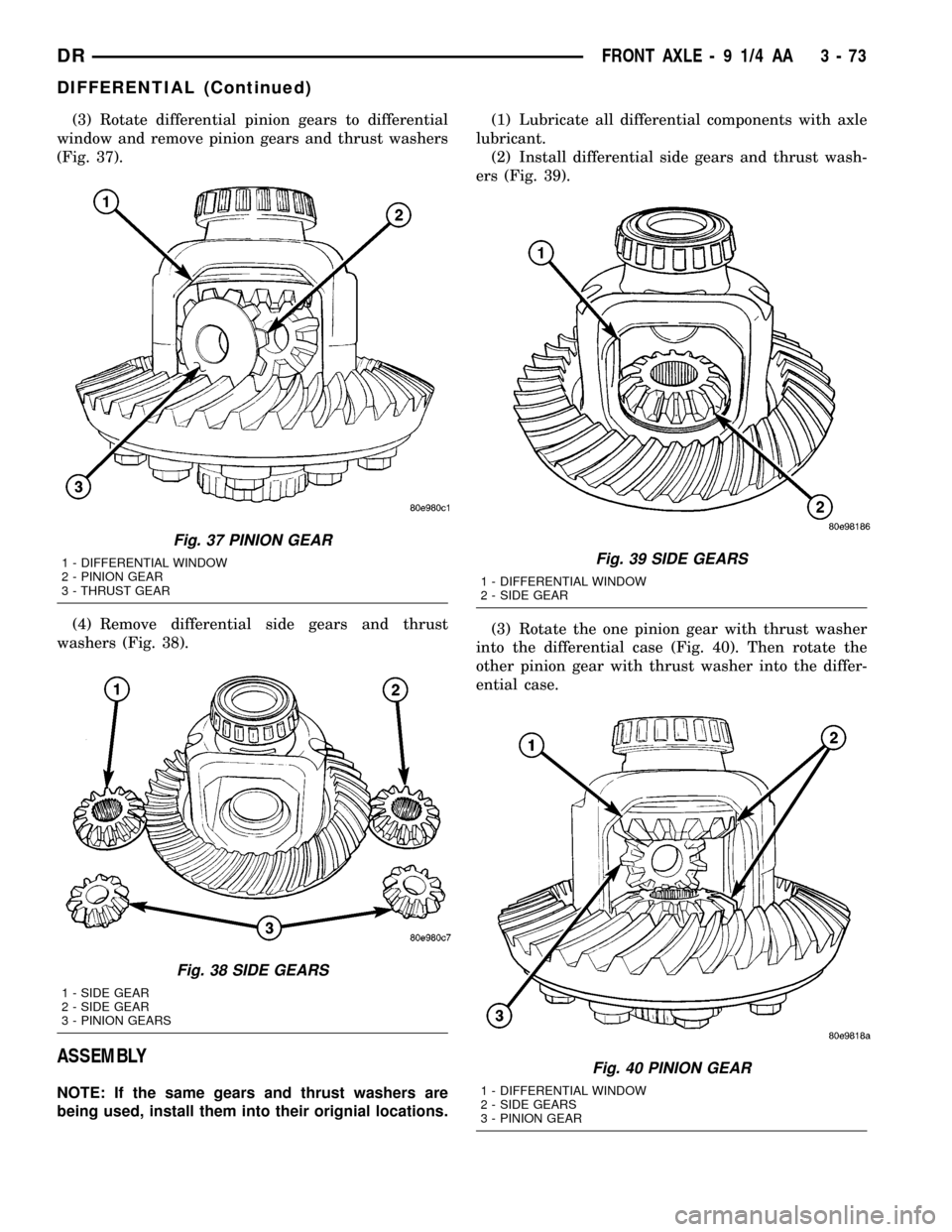

(6) Loosen differential bearing adjusters (Fig. 35)

with Spanner Wrench 8883.

(7) Remove differential case from the housing.

(8) Remove bearing cups and tag them left and

right for installation reference.

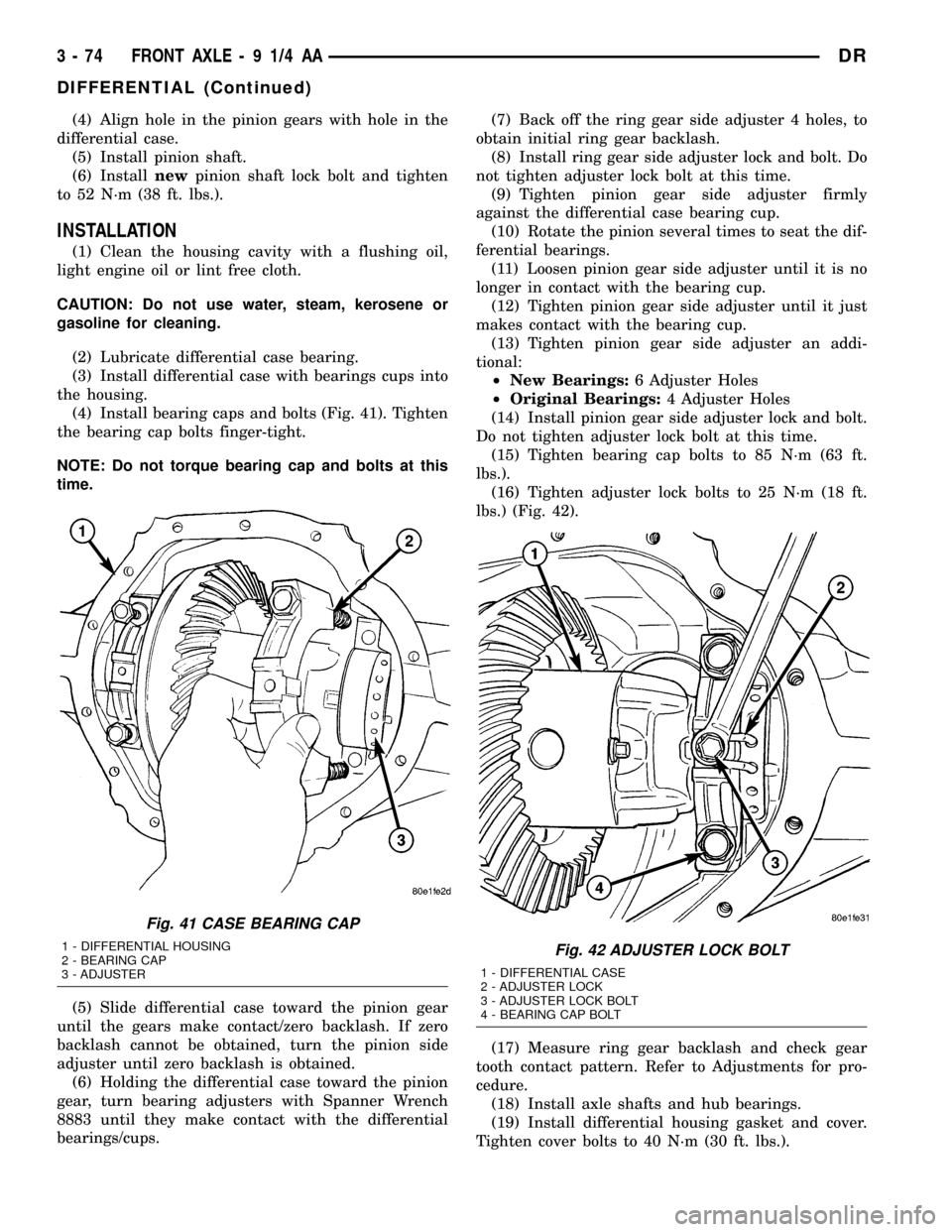

DISASSEMBLY

(1) Remove pinion shaft lock bolt.

(2) Remove pinion shaft (Fig. 36).

Fig. 34 ADJUSTERS AND LOCKS

1 - ADJUSTER LOCK BOLT

2 - ADJUSTER LOCK

3 - ADJUSTER

4 - BEARING CAP

Fig. 35 ADJUSTERS

1 - BEARING CUP

2 - ADJUSTER

3 - BEARING CUP

4 - ADJUSTER

Fig. 36 PINION SHAFT

1 - PINION SHAFT

2 - PUNCH

3 - PINION GEAR

4 - SIDE GEAR

3 - 72 FRONT AXLE - 9 1/4 AADR

Page 154 of 2627

(3) Rotate differential pinion gears to differential

window and remove pinion gears and thrust washers

(Fig. 37).

(4) Remove differential side gears and thrust

washers (Fig. 38).

ASSEMBLY

NOTE: If the same gears and thrust washers are

being used, install them into their orignial locations.(1) Lubricate all differential components with axle

lubricant.

(2) Install differential side gears and thrust wash-

ers (Fig. 39).

(3) Rotate the one pinion gear with thrust washer

into the differential case (Fig. 40). Then rotate the

other pinion gear with thrust washer into the differ-

ential case.

Fig. 37 PINION GEAR

1 - DIFFERENTIAL WINDOW

2 - PINION GEAR

3 - THRUST GEAR

Fig. 38 SIDE GEARS

1 - SIDE GEAR

2 - SIDE GEAR

3 - PINION GEARS

Fig. 39 SIDE GEARS

1 - DIFFERENTIAL WINDOW

2 - SIDE GEAR

Fig. 40 PINION GEAR

1 - DIFFERENTIAL WINDOW

2 - SIDE GEARS

3 - PINION GEAR

DRFRONT AXLE - 9 1/4 AA 3 - 73

DIFFERENTIAL (Continued)

Page 155 of 2627

(4) Align hole in the pinion gears with hole in the

differential case.

(5) Install pinion shaft.

(6) Installnewpinion shaft lock bolt and tighten

to 52 N´m (38 ft. lbs.).

INSTALLATION

(1) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.

CAUTION: Do not use water, steam, kerosene or

gasoline for cleaning.

(2) Lubricate differential case bearing.

(3) Install differential case with bearings cups into

the housing.

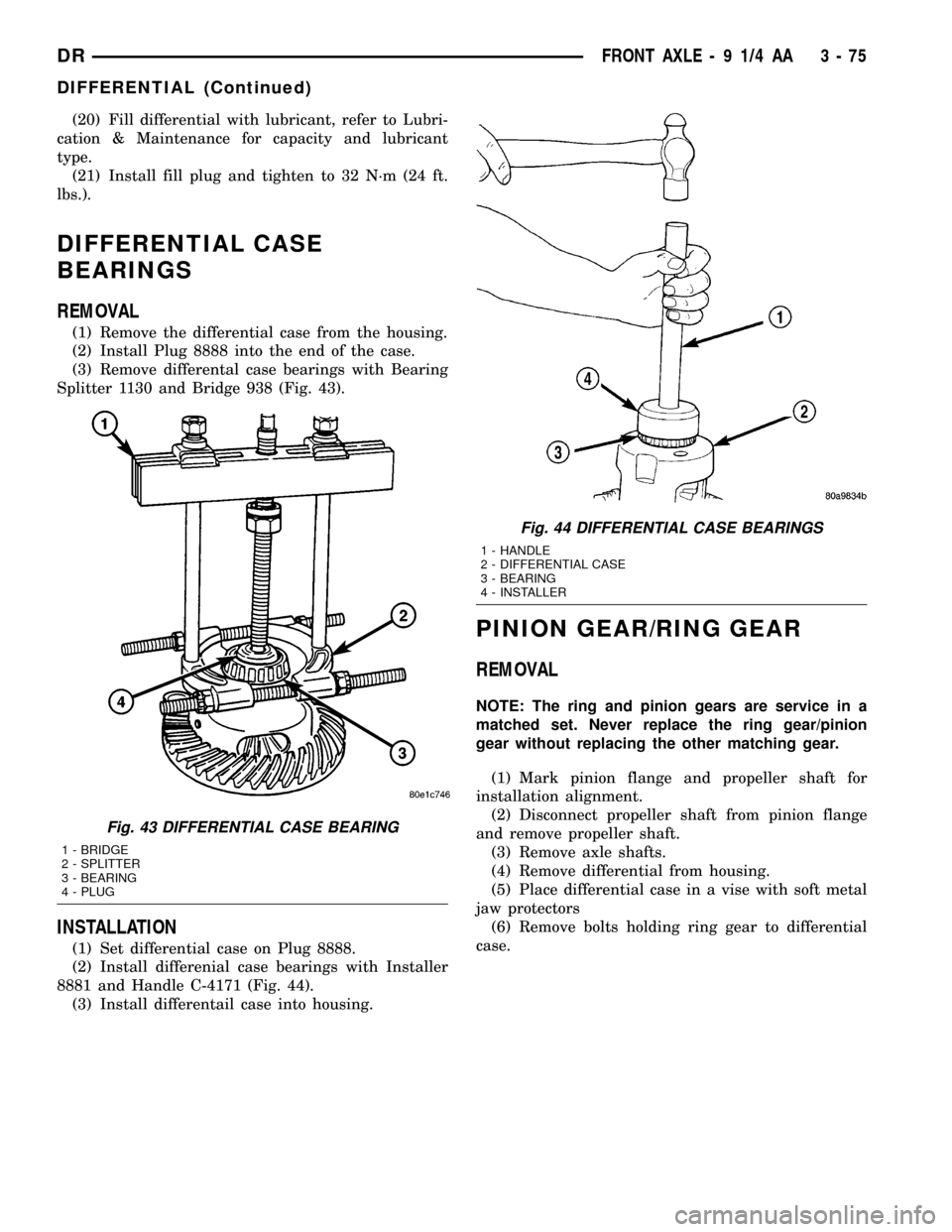

(4) Install bearing caps and bolts (Fig. 41). Tighten

the bearing cap bolts finger-tight.

NOTE: Do not torque bearing cap and bolts at this

time.

(5) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(6) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.(7) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings:6 Adjuster Holes

²Original Bearings:4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 85 N´m (63 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 42).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shafts and hub bearings.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

Fig. 41 CASE BEARING CAP

1 - DIFFERENTIAL HOUSING

2 - BEARING CAP

3 - ADJUSTERFig. 42 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 74 FRONT AXLE - 9 1/4 AADR

DIFFERENTIAL (Continued)

Page 156 of 2627

(20) Fill differential with lubricant, refer to Lubri-

cation & Maintenance for capacity and lubricant

type.

(21) Install fill plug and tighten to 32 N´m (24 ft.

lbs.).

DIFFERENTIAL CASE

BEARINGS

REMOVAL

(1) Remove the differential case from the housing.

(2) Install Plug 8888 into the end of the case.

(3) Remove differental case bearings with Bearing

Splitter 1130 and Bridge 938 (Fig. 43).

INSTALLATION

(1) Set differential case on Plug 8888.

(2) Install differenial case bearings with Installer

8881 and Handle C-4171 (Fig. 44).

(3) Install differentail case into housing.

PINION GEAR/RING GEAR

REMOVAL

NOTE: The ring and pinion gears are service in a

matched set. Never replace the ring gear/pinion

gear without replacing the other matching gear.

(1) Mark pinion flange and propeller shaft for

installation alignment.

(2) Disconnect propeller shaft from pinion flange

and remove propeller shaft.

(3) Remove axle shafts.

(4) Remove differential from housing.

(5) Place differential case in a vise with soft metal

jaw protectors

(6) Remove bolts holding ring gear to differential

case.

Fig. 43 DIFFERENTIAL CASE BEARING

1 - BRIDGE

2 - SPLITTER

3 - BEARING

4 - PLUG

Fig. 44 DIFFERENTIAL CASE BEARINGS

1 - HANDLE

2 - DIFFERENTIAL CASE

3 - BEARING

4 - INSTALLER

DRFRONT AXLE - 9 1/4 AA 3 - 75

DIFFERENTIAL (Continued)

Page 157 of 2627

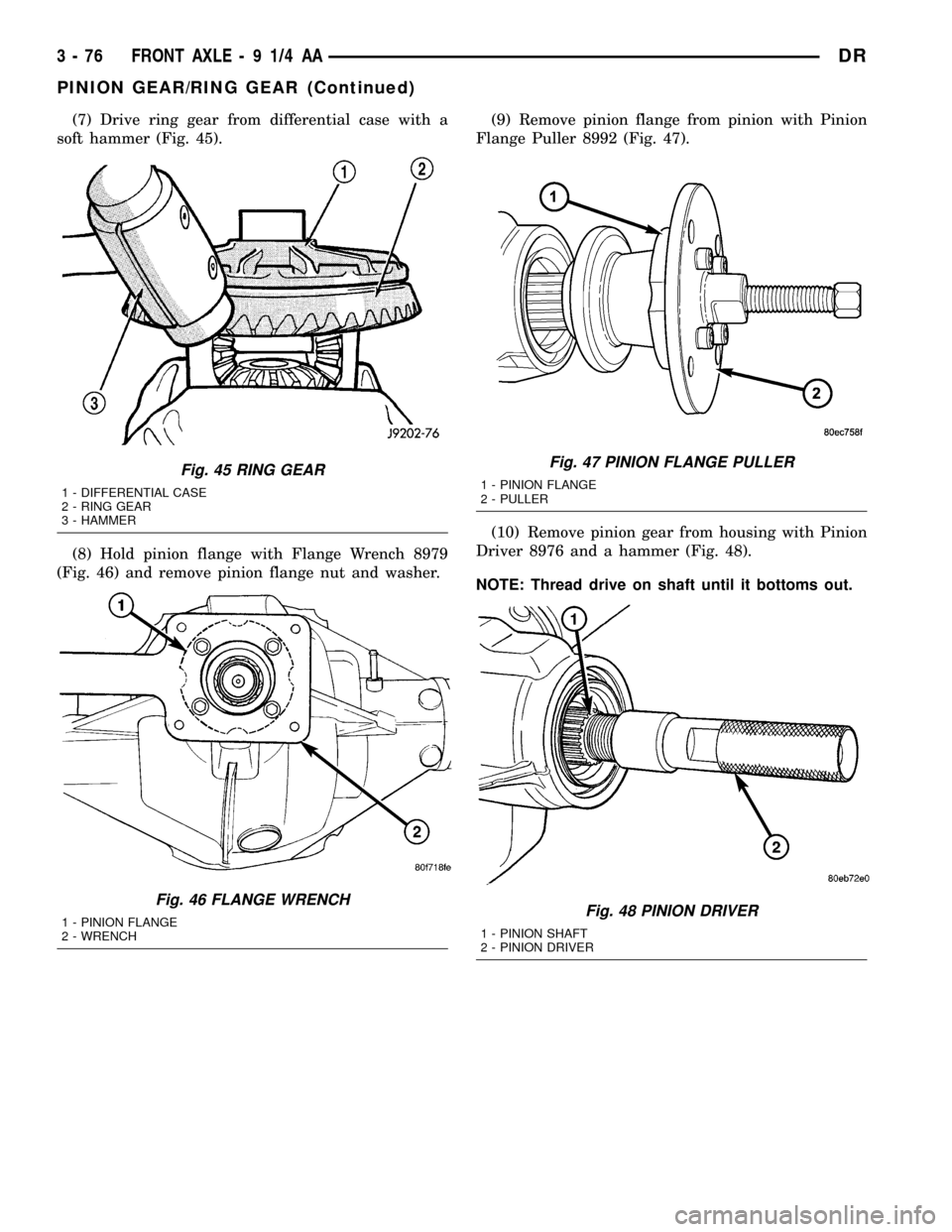

(7) Drive ring gear from differential case with a

soft hammer (Fig. 45).

(8) Hold pinion flange with Flange Wrench 8979

(Fig. 46) and remove pinion flange nut and washer.(9) Remove pinion flange from pinion with Pinion

Flange Puller 8992 (Fig. 47).

(10) Remove pinion gear from housing with Pinion

Driver 8976 and a hammer (Fig. 48).

NOTE: Thread drive on shaft until it bottoms out.

Fig. 45 RING GEAR

1 - DIFFERENTIAL CASE

2 - RING GEAR

3 - HAMMER

Fig. 46 FLANGE WRENCH

1 - PINION FLANGE

2 - WRENCH

Fig. 47 PINION FLANGE PULLER

1 - PINION FLANGE

2 - PULLER

Fig. 48 PINION DRIVER

1 - PINION SHAFT

2 - PINION DRIVER

3 - 76 FRONT AXLE - 9 1/4 AADR

PINION GEAR/RING GEAR (Continued)

Page 160 of 2627

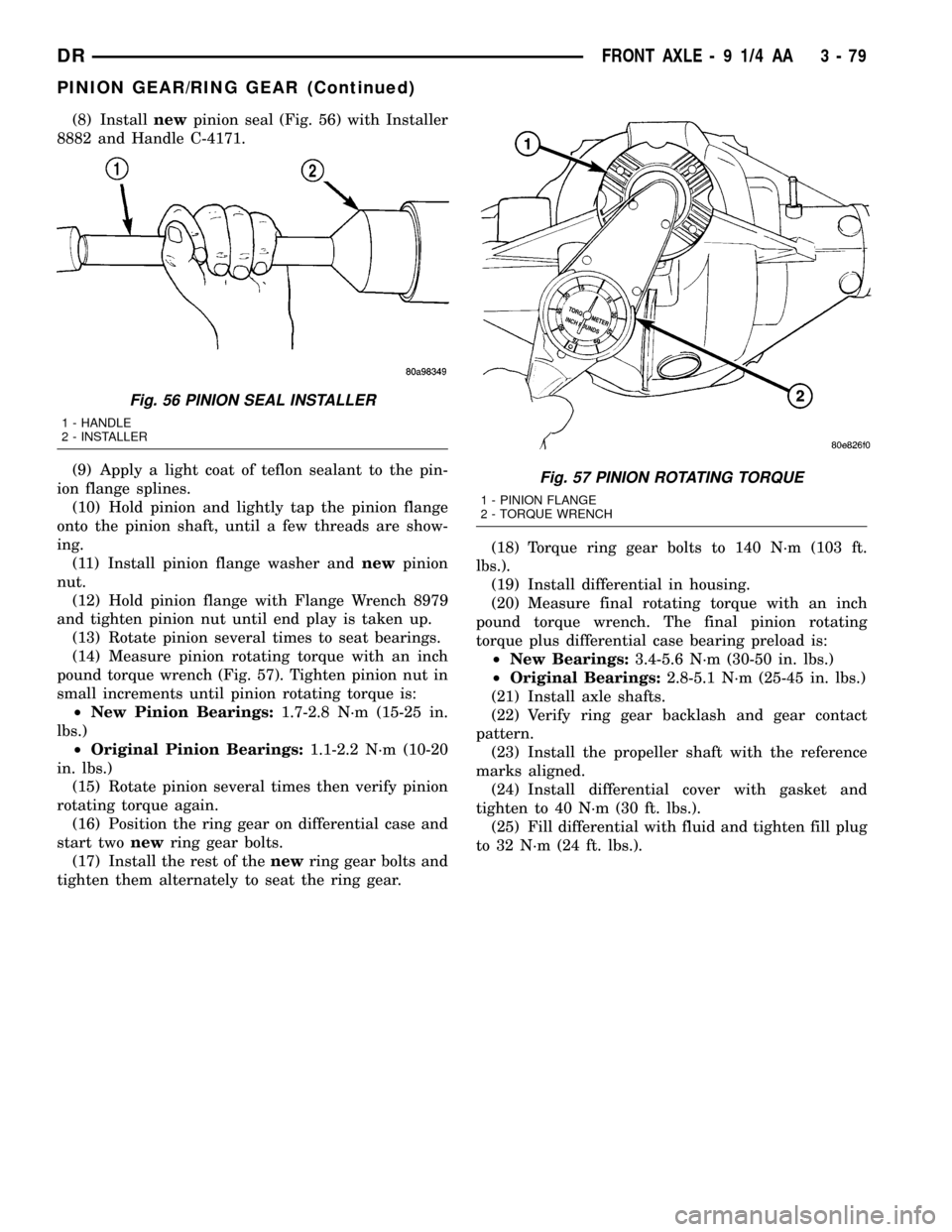

(8) Installnewpinion seal (Fig. 56) with Installer

8882 and Handle C-4171.

(9) Apply a light coat of teflon sealant to the pin-

ion flange splines.

(10) Hold pinion and lightly tap the pinion flange

onto the pinion shaft, until a few threads are show-

ing.

(11) Install pinion flange washer andnewpinion

nut.

(12) Hold pinion flange with Flange Wrench 8979

and tighten pinion nut until end play is taken up.

(13) Rotate pinion several times to seat bearings.

(14) Measure pinion rotating torque with an inch

pound torque wrench (Fig. 57). Tighten pinion nut in

small increments until pinion rotating torque is:

²New Pinion Bearings:1.7-2.8 N´m (15-25 in.

lbs.)

²Original Pinion Bearings:1.1-2.2 N´m (10-20

in. lbs.)

(15) Rotate pinion several times then verify pinion

rotating torque again.

(16) Position the ring gear on differential case and

start twonewring gear bolts.

(17) Install the rest of thenewring gear bolts and

tighten them alternately to seat the ring gear.(18) Torque ring gear bolts to 140 N´m (103 ft.

lbs.).

(19) Install differential in housing.

(20) Measure final rotating torque with an inch

pound torque wrench. The final pinion rotating

torque plus differential case bearing preload is:

²New Bearings:3.4-5.6 N´m (30-50 in. lbs.)

²Original Bearings:2.8-5.1 N´m (25-45 in. lbs.)

(21) Install axle shafts.

(22) Verify ring gear backlash and gear contact

pattern.

(23) Install the propeller shaft with the reference

marks aligned.

(24) Install differential cover with gasket and

tighten to 40 N´m (30 ft. lbs.).

(25) Fill differential with fluid and tighten fill plug

to 32 N´m (24 ft. lbs.).

Fig. 56 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

Fig. 57 PINION ROTATING TORQUE

1 - PINION FLANGE

2 - TORQUE WRENCH

DRFRONT AXLE - 9 1/4 AA 3 - 79

PINION GEAR/RING GEAR (Continued)