brake rotor DODGE RAM 1500 1998 2.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 288 of 2627

INSTALLATION - LEFT REAR CABLE

(1) Install the brake cable to the brake lever (Fig.

72).

(2) Install the brake cable to the frame bracket.

(3) Install the left brake cable to the equalizer.

(4) Adjust the brake cable at the equalizer and

adjuster nut.

SHOES

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper,(Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the disc brake rotor, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(5) Lockout the parking brake cable (Fig. 74).

(6) Disengage the park brake cable from behind

the rotor assembly to allow easier disassembly of the

park brake shoes (Fig. 75).

(7) Remove the axleshaft (Fig. 76) (Refer to 3 -

DIFFERENTIAL & DRIVELINE/REAR AXLE - 9 1/4/

AXLE SHAFTS - REMOVAL).

(8) Disassemble the rear park brake shoes (Fig.

67).

CLEANING - REAR DRUM IN HAT BRAKE

Clean the individual brake components, including

the support plate exterior, with a water dampened

cloth or with brake cleaner. Do not use any other

cleaning agents. Remove light rust and scale fromthe brake shoe contact pads on the support plate

with fine sandpaper.

INSPECTION - REAR DRUM IN HAT BRAKE

As a general rule, riveted brake shoes should be

replaced when worn to within 0.78 mm (1/32 in.) of

the rivet heads. Bonded lining should be replaced

when worn to a thickness of 1.6 mm (1/16 in.).

Examine the lining contact pattern to determine if

the shoes are bent or the drum is tapered. The lining

should exhibit contact across its entire width. Shoes

exhibiting contact only on one side should be

replaced and the drum checked for runout or taper

(Fig. 77).

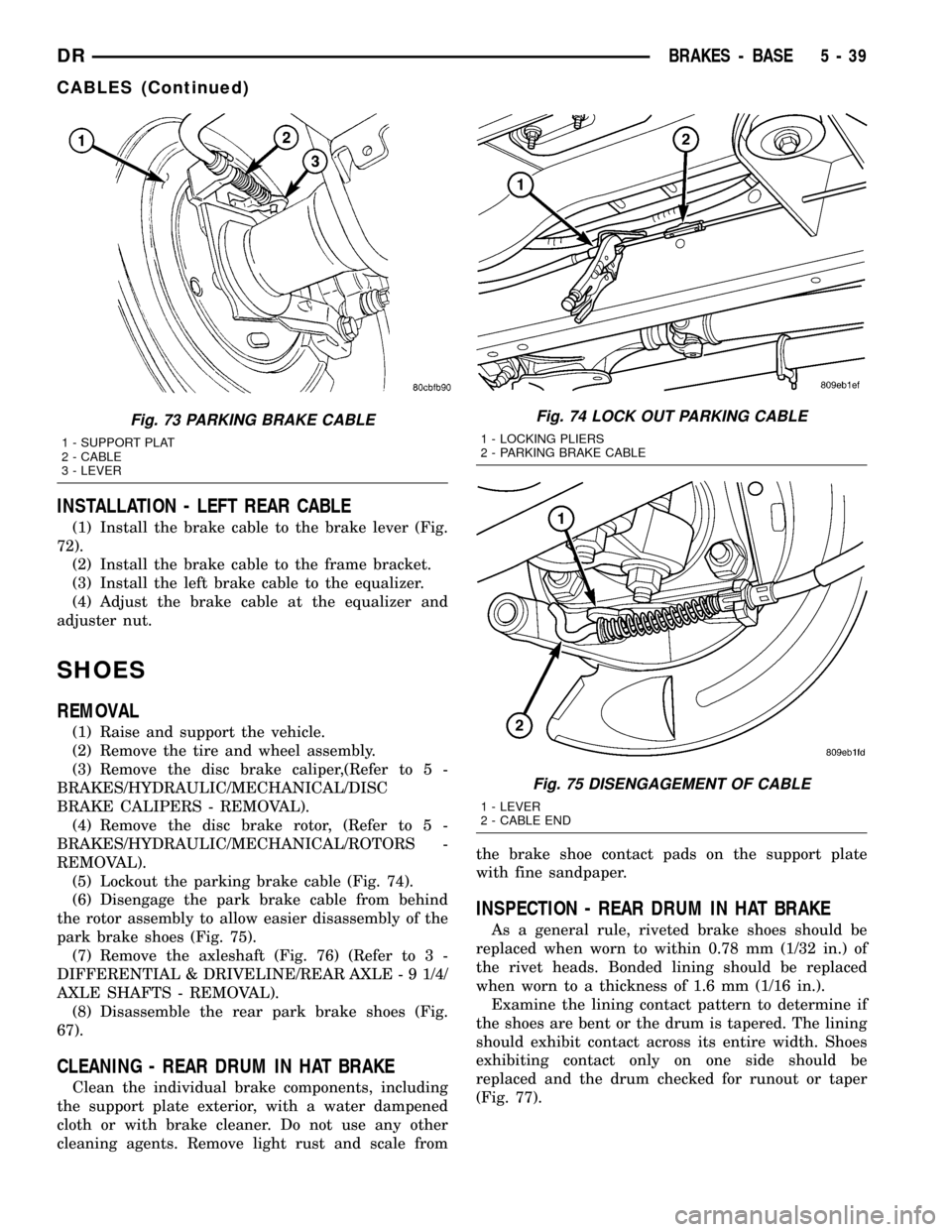

Fig. 73 PARKING BRAKE CABLE

1 - SUPPORT PLAT

2 - CABLE

3 - LEVER

Fig. 74 LOCK OUT PARKING CABLE

1 - LOCKING PLIERS

2 - PARKING BRAKE CABLE

Fig. 75 DISENGAGEMENT OF CABLE

1 - LEVER

2 - CABLE END

DRBRAKES - BASE 5 - 39

CABLES (Continued)

Page 289 of 2627

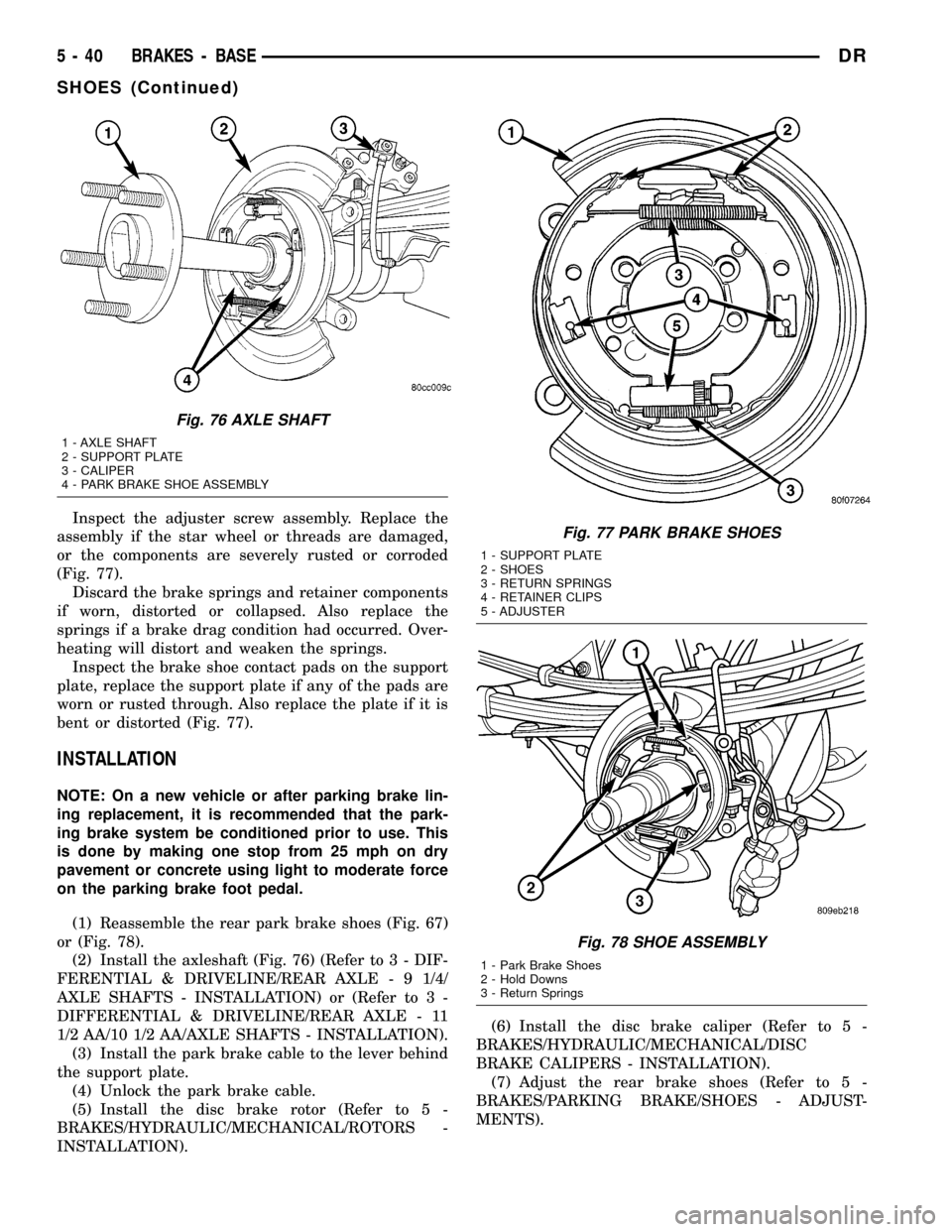

Inspect the adjuster screw assembly. Replace the

assembly if the star wheel or threads are damaged,

or the components are severely rusted or corroded

(Fig. 77).

Discard the brake springs and retainer components

if worn, distorted or collapsed. Also replace the

springs if a brake drag condition had occurred. Over-

heating will distort and weaken the springs.

Inspect the brake shoe contact pads on the support

plate, replace the support plate if any of the pads are

worn or rusted through. Also replace the plate if it is

bent or distorted (Fig. 77).

INSTALLATION

NOTE: On a new vehicle or after parking brake lin-

ing replacement, it is recommended that the park-

ing brake system be conditioned prior to use. This

is done by making one stop from 25 mph on dry

pavement or concrete using light to moderate force

on the parking brake foot pedal.

(1) Reassemble the rear park brake shoes (Fig. 67)

or (Fig. 78).

(2) Install the axleshaft (Fig. 76) (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/REAR AXLE - 9 1/4/

AXLE SHAFTS - INSTALLATION) or (Refer to 3 -

DIFFERENTIAL & DRIVELINE/REAR AXLE - 11

1/2 AA/10 1/2 AA/AXLE SHAFTS - INSTALLATION).

(3) Install the park brake cable to the lever behind

the support plate.

(4) Unlock the park brake cable.

(5) Install the disc brake rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).(6) Install the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(7) Adjust the rear brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - ADJUST-

MENTS).

Fig. 76 AXLE SHAFT

1 - AXLE SHAFT

2 - SUPPORT PLATE

3 - CALIPER

4 - PARK BRAKE SHOE ASSEMBLY

Fig. 77 PARK BRAKE SHOES

1 - SUPPORT PLATE

2 - SHOES

3 - RETURN SPRINGS

4 - RETAINER CLIPS

5 - ADJUSTER

Fig. 78 SHOE ASSEMBLY

1 - Park Brake Shoes

2 - Hold Downs

3 - Return Springs

5 - 40 BRAKES - BASEDR

SHOES (Continued)

Page 290 of 2627

(8) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(9) Lower the vehicle.

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE SHOES

CAUTION: Before adjusting the park brake shoes be

sure that the park brake pedal is in the fully

released position. If park brake pedal is not in the

fully released position, the park brake shoes can

not be accurately adjusted.

(1) Raise vehicle.

(2) Remove tire and wheel.

(3) Remove disc brake caliper from caliper adapter

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

DISC BRAKE CALIPERS - REMOVAL).

(4) Remove rotor from the axleshaft (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

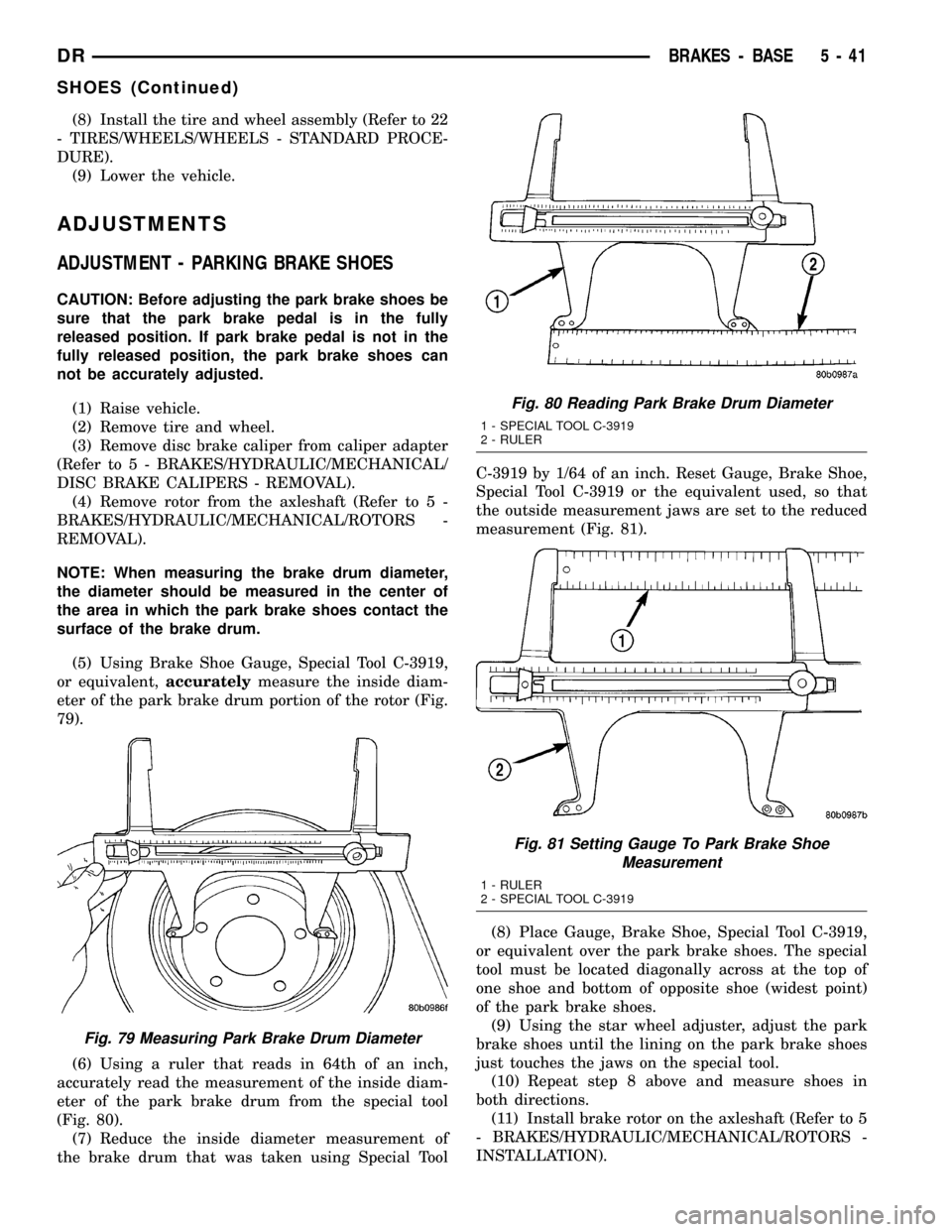

NOTE: When measuring the brake drum diameter,

the diameter should be measured in the center of

the area in which the park brake shoes contact the

surface of the brake drum.

(5) Using Brake Shoe Gauge, Special Tool C-3919,

or equivalent,accuratelymeasure the inside diam-

eter of the park brake drum portion of the rotor (Fig.

79).

(6) Using a ruler that reads in 64th of an inch,

accurately read the measurement of the inside diam-

eter of the park brake drum from the special tool

(Fig. 80).

(7) Reduce the inside diameter measurement of

the brake drum that was taken using Special ToolC-3919 by 1/64 of an inch. Reset Gauge, Brake Shoe,

Special Tool C-3919 or the equivalent used, so that

the outside measurement jaws are set to the reduced

measurement (Fig. 81).

(8) Place Gauge, Brake Shoe, Special Tool C-3919,

or equivalent over the park brake shoes. The special

tool must be located diagonally across at the top of

one shoe and bottom of opposite shoe (widest point)

of the park brake shoes.

(9) Using the star wheel adjuster, adjust the park

brake shoes until the lining on the park brake shoes

just touches the jaws on the special tool.

(10) Repeat step 8 above and measure shoes in

both directions.

(11) Install brake rotor on the axleshaft (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).

Fig. 79 Measuring Park Brake Drum Diameter

Fig. 80 Reading Park Brake Drum Diameter

1 - SPECIAL TOOL C-3919

2 - RULER

Fig. 81 Setting Gauge To Park Brake Shoe

Measurement

1 - RULER

2 - SPECIAL TOOL C-3919

DRBRAKES - BASE 5 - 41

SHOES (Continued)

Page 291 of 2627

(12) Rotate rotor to verify that the park brake

shoes are not dragging on the brake drum. If park

brake shoes are dragging, remove rotor and back off

star wheel adjuster one notch and recheck for brake

shoe drag against drum. Continue with the previous

step until brake shoes are not dragging on brake

drum.

(13) Install disc brake caliper on caliper adapter

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

DISC BRAKE CALIPERS - INSTALLATION).

(14) Install wheel and tire.

(15) Tighten the wheel mounting nuts in the

proper sequence until all nuts are torqued to half the

specified torque. Then repeat the tightening sequence

to the full specified torque of 180 N´m (135 ft. lbs.)

1500 & 2500 Series or 195 N´m (145 ft. lbs.) 3500

Series.

(16) Lower vehicle.

(17) Apply and release the park brake pedal one

time. This will seat and correctly adjust the park

brake cables.

CAUTION: Before moving vehicle, pump brake

pedal several times to ensure the vehicle has a firm

enough pedal to stop the vehicle.

NOTE: On a new vehicle or after parking brake lin-

ing replacement, it is recommended that the park-

ing brake system be conditioned prior to use. This

is done by making one stop from 25 mph on dry

pavement or concrete using light to moderate force

on the parking brake foot pedal.

(18) Road test the vehicle to ensure proper func-

tion of the vehicle's brake system.

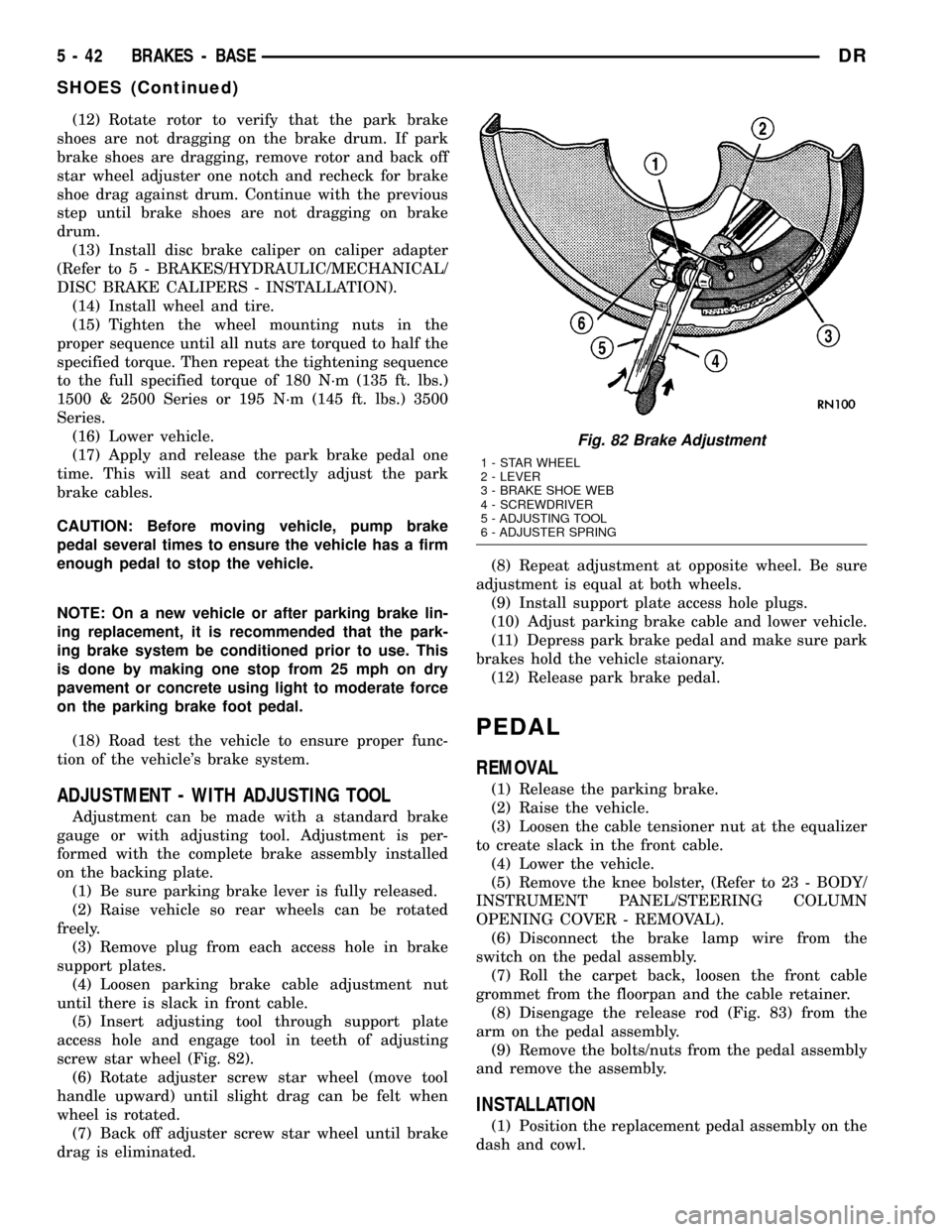

ADJUSTMENT - WITH ADJUSTING TOOL

Adjustment can be made with a standard brake

gauge or with adjusting tool. Adjustment is per-

formed with the complete brake assembly installed

on the backing plate.

(1) Be sure parking brake lever is fully released.

(2) Raise vehicle so rear wheels can be rotated

freely.

(3) Remove plug from each access hole in brake

support plates.

(4) Loosen parking brake cable adjustment nut

until there is slack in front cable.

(5) Insert adjusting tool through support plate

access hole and engage tool in teeth of adjusting

screw star wheel (Fig. 82).

(6) Rotate adjuster screw star wheel (move tool

handle upward) until slight drag can be felt when

wheel is rotated.

(7) Back off adjuster screw star wheel until brake

drag is eliminated.(8) Repeat adjustment at opposite wheel. Be sure

adjustment is equal at both wheels.

(9) Install support plate access hole plugs.

(10) Adjust parking brake cable and lower vehicle.

(11) Depress park brake pedal and make sure park

brakes hold the vehicle staionary.

(12) Release park brake pedal.

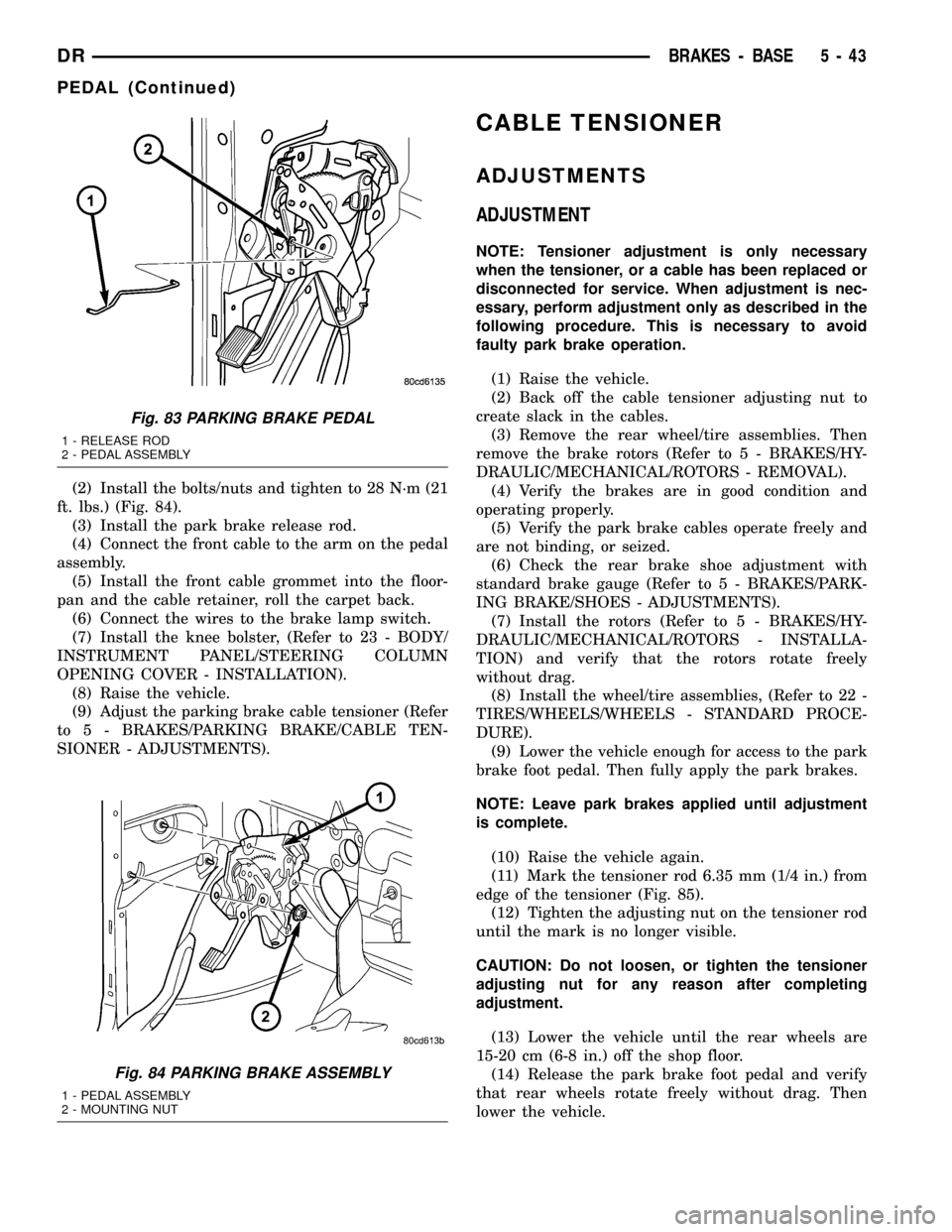

PEDAL

REMOVAL

(1) Release the parking brake.

(2) Raise the vehicle.

(3) Loosen the cable tensioner nut at the equalizer

to create slack in the front cable.

(4) Lower the vehicle.

(5) Remove the knee bolster, (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(6) Disconnect the brake lamp wire from the

switch on the pedal assembly.

(7) Roll the carpet back, loosen the front cable

grommet from the floorpan and the cable retainer.

(8) Disengage the release rod (Fig. 83) from the

arm on the pedal assembly.

(9) Remove the bolts/nuts from the pedal assembly

and remove the assembly.

INSTALLATION

(1) Position the replacement pedal assembly on the

dash and cowl.

Fig. 82 Brake Adjustment

1 - STAR WHEEL

2 - LEVER

3 - BRAKE SHOE WEB

4 - SCREWDRIVER

5 - ADJUSTING TOOL

6 - ADJUSTER SPRING

5 - 42 BRAKES - BASEDR

SHOES (Continued)

Page 292 of 2627

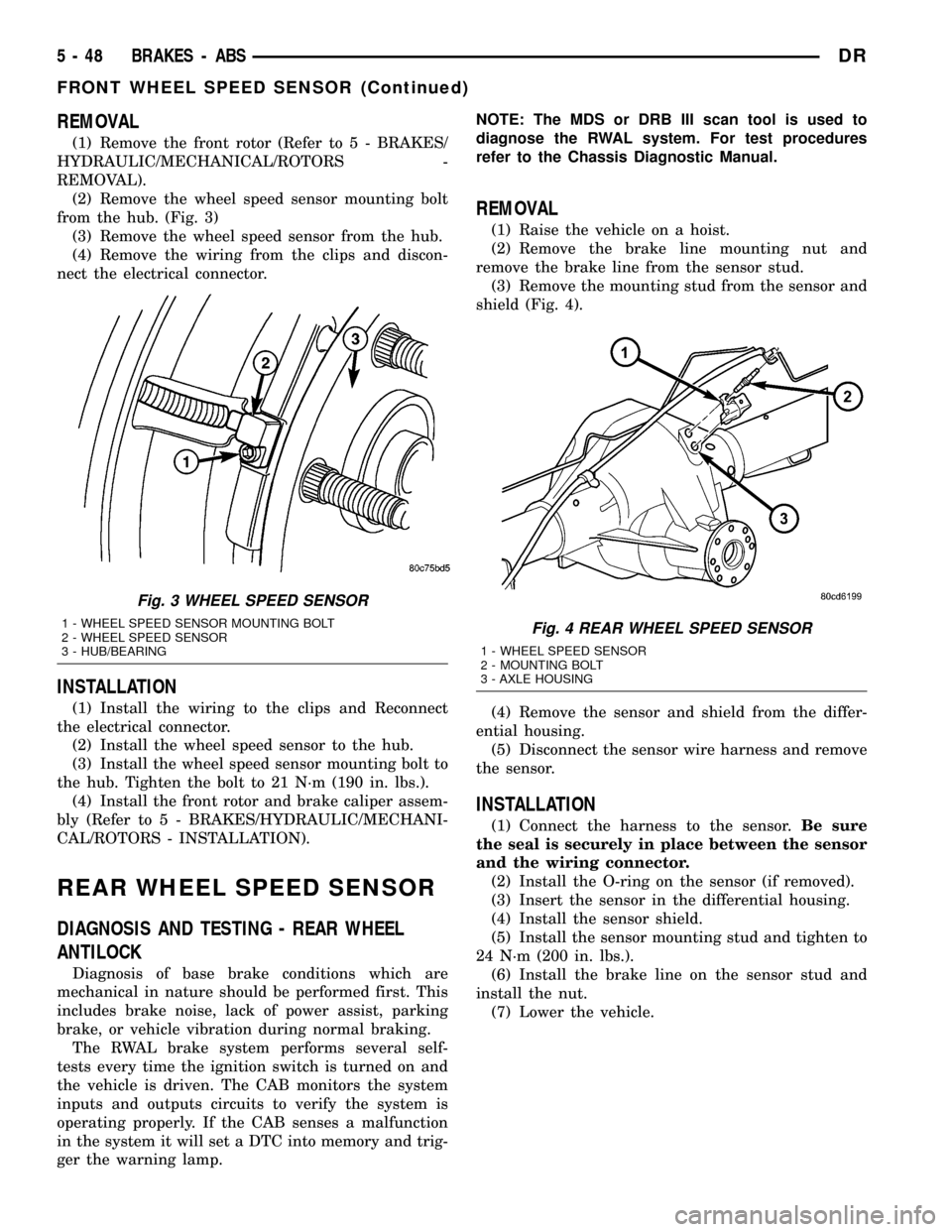

(2) Install the bolts/nuts and tighten to 28 N´m (21

ft. lbs.) (Fig. 84).

(3) Install the park brake release rod.

(4) Connect the front cable to the arm on the pedal

assembly.

(5) Install the front cable grommet into the floor-

pan and the cable retainer, roll the carpet back.

(6) Connect the wires to the brake lamp switch.

(7) Install the knee bolster, (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - INSTALLATION).

(8) Raise the vehicle.

(9) Adjust the parking brake cable tensioner (Refer

to 5 - BRAKES/PARKING BRAKE/CABLE TEN-

SIONER - ADJUSTMENTS).

CABLE TENSIONER

ADJUSTMENTS

ADJUSTMENT

NOTE: Tensioner adjustment is only necessary

when the tensioner, or a cable has been replaced or

disconnected for service. When adjustment is nec-

essary, perform adjustment only as described in the

following procedure. This is necessary to avoid

faulty park brake operation.

(1) Raise the vehicle.

(2) Back off the cable tensioner adjusting nut to

create slack in the cables.

(3) Remove the rear wheel/tire assemblies. Then

remove the brake rotors (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - REMOVAL).

(4) Verify the brakes are in good condition and

operating properly.

(5) Verify the park brake cables operate freely and

are not binding, or seized.

(6) Check the rear brake shoe adjustment with

standard brake gauge (Refer to 5 - BRAKES/PARK-

ING BRAKE/SHOES - ADJUSTMENTS).

(7) Install the rotors (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION) and verify that the rotors rotate freely

without drag.

(8) Install the wheel/tire assemblies, (Refer to 22 -

TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(9) Lower the vehicle enough for access to the park

brake foot pedal. Then fully apply the park brakes.

NOTE: Leave park brakes applied until adjustment

is complete.

(10) Raise the vehicle again.

(11) Mark the tensioner rod 6.35 mm (1/4 in.) from

edge of the tensioner (Fig. 85).

(12) Tighten the adjusting nut on the tensioner rod

until the mark is no longer visible.

CAUTION: Do not loosen, or tighten the tensioner

adjusting nut for any reason after completing

adjustment.

(13) Lower the vehicle until the rear wheels are

15-20 cm (6-8 in.) off the shop floor.

(14) Release the park brake foot pedal and verify

that rear wheels rotate freely without drag. Then

lower the vehicle.

Fig. 83 PARKING BRAKE PEDAL

1 - RELEASE ROD

2 - PEDAL ASSEMBLY

Fig. 84 PARKING BRAKE ASSEMBLY

1 - PEDAL ASSEMBLY

2 - MOUNTING NUT

DRBRAKES - BASE 5 - 43

PEDAL (Continued)

Page 297 of 2627

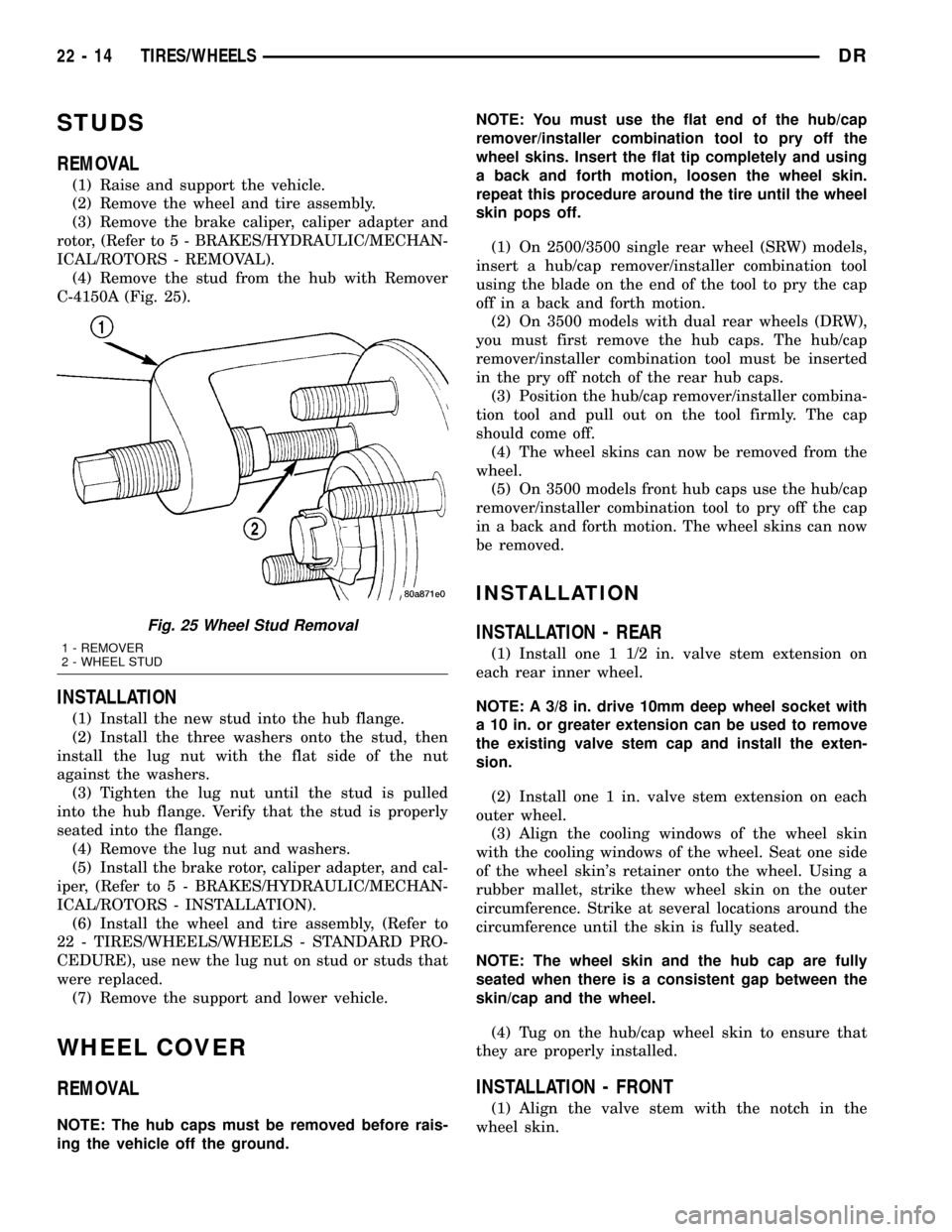

REMOVAL

(1) Remove the front rotor (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(2) Remove the wheel speed sensor mounting bolt

from the hub. (Fig. 3)

(3) Remove the wheel speed sensor from the hub.

(4) Remove the wiring from the clips and discon-

nect the electrical connector.

INSTALLATION

(1) Install the wiring to the clips and Reconnect

the electrical connector.

(2) Install the wheel speed sensor to the hub.

(3) Install the wheel speed sensor mounting bolt to

the hub. Tighten the bolt to 21 N´m (190 in. lbs.).

(4) Install the front rotor and brake caliper assem-

bly (Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/ROTORS - INSTALLATION).

REAR WHEEL SPEED SENSOR

DIAGNOSIS AND TESTING - REAR WHEEL

ANTILOCK

Diagnosis of base brake conditions which are

mechanical in nature should be performed first. This

includes brake noise, lack of power assist, parking

brake, or vehicle vibration during normal braking.

The RWAL brake system performs several self-

tests every time the ignition switch is turned on and

the vehicle is driven. The CAB monitors the system

inputs and outputs circuits to verify the system is

operating properly. If the CAB senses a malfunction

in the system it will set a DTC into memory and trig-

ger the warning lamp.NOTE: The MDS or DRB III scan tool is used to

diagnose the RWAL system. For test procedures

refer to the Chassis Diagnostic Manual.

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Remove the brake line mounting nut and

remove the brake line from the sensor stud.

(3) Remove the mounting stud from the sensor and

shield (Fig. 4).

(4) Remove the sensor and shield from the differ-

ential housing.

(5) Disconnect the sensor wire harness and remove

the sensor.

INSTALLATION

(1) Connect the harness to the sensor.Be sure

the seal is securely in place between the sensor

and the wiring connector.

(2) Install the O-ring on the sensor (if removed).

(3) Insert the sensor in the differential housing.

(4) Install the sensor shield.

(5) Install the sensor mounting stud and tighten to

24 N´m (200 in. lbs.).

(6) Install the brake line on the sensor stud and

install the nut.

(7) Lower the vehicle.

Fig. 3 WHEEL SPEED SENSOR

1 - WHEEL SPEED SENSOR MOUNTING BOLT

2 - WHEEL SPEED SENSOR

3 - HUB/BEARINGFig. 4 REAR WHEEL SPEED SENSOR

1 - WHEEL SPEED SENSOR

2 - MOUNTING BOLT

3 - AXLE HOUSING

5 - 48 BRAKES - ABSDR

FRONT WHEEL SPEED SENSOR (Continued)

Page 2293 of 2627

STUDS

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the brake caliper, caliper adapter and

rotor, (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - REMOVAL).

(4) Remove the stud from the hub with Remover

C-4150A (Fig. 25).

INSTALLATION

(1) Install the new stud into the hub flange.

(2) Install the three washers onto the stud, then

install the lug nut with the flat side of the nut

against the washers.

(3) Tighten the lug nut until the stud is pulled

into the hub flange. Verify that the stud is properly

seated into the flange.

(4) Remove the lug nut and washers.

(5) Install the brake rotor, caliper adapter, and cal-

iper, (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - INSTALLATION).

(6) Install the wheel and tire assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE), use new the lug nut on stud or studs that

were replaced.

(7) Remove the support and lower vehicle.

WHEEL COVER

REMOVAL

NOTE: The hub caps must be removed before rais-

ing the vehicle off the ground.NOTE: You must use the flat end of the hub/cap

remover/installer combination tool to pry off the

wheel skins. Insert the flat tip completely and using

a back and forth motion, loosen the wheel skin.

repeat this procedure around the tire until the wheel

skin pops off.

(1) On 2500/3500 single rear wheel (SRW) models,

insert a hub/cap remover/installer combination tool

using the blade on the end of the tool to pry the cap

off in a back and forth motion.

(2) On 3500 models with dual rear wheels (DRW),

you must first remove the hub caps. The hub/cap

remover/installer combination tool must be inserted

in the pry off notch of the rear hub caps.

(3) Position the hub/cap remover/installer combina-

tion tool and pull out on the tool firmly. The cap

should come off.

(4) The wheel skins can now be removed from the

wheel.

(5) On 3500 models front hub caps use the hub/cap

remover/installer combination tool to pry off the cap

in a back and forth motion. The wheel skins can now

be removed.

INSTALLATION

INSTALLATION - REAR

(1) Install one 1 1/2 in. valve stem extension on

each rear inner wheel.

NOTE: A 3/8 in. drive 10mm deep wheel socket with

a 10 in. or greater extension can be used to remove

the existing valve stem cap and install the exten-

sion.

(2) Install one 1 in. valve stem extension on each

outer wheel.

(3) Align the cooling windows of the wheel skin

with the cooling windows of the wheel. Seat one side

of the wheel skin's retainer onto the wheel. Using a

rubber mallet, strike thew wheel skin on the outer

circumference. Strike at several locations around the

circumference until the skin is fully seated.

NOTE: The wheel skin and the hub cap are fully

seated when there is a consistent gap between the

skin/cap and the wheel.

(4) Tug on the hub/cap wheel skin to ensure that

they are properly installed.

INSTALLATION - FRONT

(1) Align the valve stem with the notch in the

wheel skin.

Fig. 25 Wheel Stud Removal

1 - REMOVER

2 - WHEEL STUD

22 - 14 TIRES/WHEELSDR

Page 2591 of 2627

BLOCK - DIAGNOSIS AND TESTING,

BLOWER MOTOR RESISTOR............24-19

BLOCK - INSPECTION, ENGINE . 9-128,9-205,9-39

BLOCK - INSTALLATION, BLOWER

MOTOR RESISTOR...................24-19

BLOCK - INSTALLATION, BRAKE

JUNCTION...........................5-24

BLOCK - OPERATION, BLOWER MOTOR

RESISTOR..........................24-18

BLOCK - REMOVAL, BLOWER MOTOR

RESISTOR..........................24-19

BLOCK - REMOVAL, BRAKE JUNCTION....5-24

BLOCK HEATER - 5.9L DIESEL -

DESCRIPTION, ENGINE.................7-37

BLOCK HEATER - 5.9L DIESEL -

INSTALLATION, ENGINE................7-38

BLOCK HEATER - 5.9L DIESEL -

OPERATION, ENGINE...................7-38

BLOCK HEATER - 5.9L DIESEL -

REMOVAL, ENGINE....................7-38

BLOCK HEATER - DESCRIPTION, ENGINE . . . 7-36

BLOCK HEATER - DIAGNOSIS AND

TESTING, ENGINE.....................7-36

BLOCK HEATER - INSTALLATION,

ENGINE.............................7-37

BLOCK HEATER - OPERATION, ENGINE....7-36

BLOCK HEATER - REMOVAL, ENGINE......7-37

BLOCK REFACING - STANDARD

PROCEDURE, CYLINDER...............9-264

BLOWER MOTOR - DESCRIPTION.......24-28

BLOWER MOTOR - DIAGNOSIS AND

TESTING.............................24-28

BLOWER MOTOR - INSTALLATION.......24-31

BLOWER MOTOR - OPERATION.........24-28

BLOWER MOTOR - REMOVAL...........24-31

BLOWER MOTOR RESISTOR BLOCK -

DESCRIPTION.......................24-18

BLOWER MOTOR RESISTOR BLOCK -

DIAGNOSIS AND TESTING.............24-19

BLOWER MOTOR RESISTOR BLOCK -

INSTALLATION.......................24-19

BLOWER MOTOR RESISTOR BLOCK -

OPERATION.........................24-18

BLOWER MOTOR RESISTOR BLOCK -

REMOVAL..........................24-19

BLOWER MOTOR SWITCH -

DESCRIPTION.......................24-20

BLOWER MOTOR SWITCH - DIAGNOSIS

AND TESTING.......................24-20

BLOWER MOTOR SWITCH - OPERATION . . 24-20

BODY - ADJUSTMENTS, VALVE........21-310

BODY - ASSEMBLY, VALVE......21-299,21-414

BODY & CABLE - DESCRIPTION,

ANTENNA...........................8A-4

BODY & CABLE - INSTALLATION,

ANTENNA...........................8A-6

BODY & CABLE - OPERATION, ANTENNA . . . 8A-4

BODY & CABLE - REMOVAL, ANTENNA....8A-6

BODY - CLEANING, VALVE......21-298,21-412

BODY - DESCRIPTION, THROTTLE.......14-36

BODY - DESCRIPTION, VALVE....21-267,21-408

BODY - DISASSEMBLY, VALVE . . . 21-287,21-410

BODY - INSPECTION, VALVE.....21-298,21-413

BODY - INSTALLATION, THROTTLE.......14-37

BODY - INSTALLATION, VALVE . . . 21-309,21-414

BODY - OPERATION, THROTTLE.........14-36

BODY - OPERATION, VALVE.....21-272,21-408

BODY - REMOVAL, THROTTLE..........14-36

BODY - REMOVAL, VALVE.......21-286,21-410

BODY AND CABLE - DIAGNOSIS AND

TESTING, ANTENNA

...................8A-4

BODY CODE PLATE - DESCRIPTION

.....Intro.-3

BODY ISOLATORS - INSTALLATION

......23-37

BODY ISOLATORS - REMOVAL

..........23-36

BODY LUBRICATION - STANDARD

PROCEDURE

.........................23-3

BODY OPENING DIMENSIONS -

SPECIFICATIONS

.....................23-99

BODY PANEL REPAIR - STANDARD

PROCEDURE, PLASTIC

.................23-3

BODY SIDE MOLDINGS - INSTALLATION

. . 23-36

BODY SIDE MOLDINGS - REMOVAL

......23-36

BODY, SPECIAL TOOLS

................23-14

BODY VENT - INSTALLATION

...........23-71

BODY VENT - REMOVAL

...............23-71

BOOST PRESSURE - DIAGNOSIS AND

TESTING, TURBOCHARGER

.............11-11BOOSTER - DESCRIPTION, POWER

BRAKE..............................5-29

BOOSTER - DIAGNOSIS AND TESTING,

HYDRAULIC..........................5-30

BOOSTER - DIAGNOSIS AND TESTING,

MASTER CYLINDER/POWER.............5-25

BOOSTER - INSTALLATION, HYDRO-

BOOST BRAKE........................5-32

BOOSTER - INSTALLATION, POWER

BRAKE..............................5-29

BOOSTER - OPERATION, POWER BRAKE . . . 5-29

BOOSTER - REMOVAL, HYDRO-BOOST

BRAKE..............................5-31

BOOSTER - REMOVAL, POWER BRAKE....5-29

BOOT - INSTALLATION, 4WD FLOOR

SHIFT..............................23-62

BOOT - INSTALLATION, EXTENSION

HOUSING SEAL AND DUST......21-476,21-571

BOOT - REMOVAL, 4WD FLOOR SHIFT....23-62

BOOT - REMOVAL, EXTENSION HOUSING

SEAL AND DUST..............21-476,21-571

BORE - DE-GLAZE - STANDARD

PROCEDURE, CYLINDER...............9-264

BORE HONING - STANDARD

PROCEDURE, CYLINDER...........9-128,9-38

BORE REPAIR - STANDARD

PROCEDURE, CAM...................9-267

BORE REPAIR - STANDARD

PROCEDURE, CYLINDER...............9-265

BOX - INSTALLATION, CARGO..........23-37

BOX - INSTALLATION, GLOVE...........23-52

BOX - INSTALLATION, WITH CARGO . 8L-22,8L-23,

8L-24,8L-7,8L-9

BOX - INSTALLATION, WITHOUT CARGO . . 8L-22,

8L-23,8L-24,8L-8,8L-9

BOX - REMOVAL, CARGO..............23-37

BOX - REMOVAL, GLOVE..............23-52

BOX - REMOVAL, WITH CARGO....8L-22,8L-24,

8L-7,8L-9

BOX - REMOVAL, WITHOUT CARGO.....8L-22,

8L-23,8L-24,8L-7,8L-9

BOX - TIE DOWN - INSTALLATION,

CARGO............................23-38

BOX - TIE DOWN - REMOVAL, CARGO....23-38

BOX LAMP/SWITCH - INSTALLATION,

GLOVE.............................8L-28

BOX LAMP/SWITCH - REMOVAL, GLOVE . . 8L-27

BOX LATCH - INSTALLATION, GLOVE.....23-52

BOX LATCH - REMOVAL, GLOVE.........23-52

B-PILLAR GRAB HANDLE -

INSTALLATION.......................23-68

B-PILLAR GRAB HANDLE - REMOVAL....23-68

B-PILLAR LOWER TRIM - INSTALLATION . . 23-64

B-PILLAR LOWER TRIM - REMOVAL.....23-63

B-PILLAR UPPER TRIM - INSTALLATION . . 23-64

B-PILLAR UPPER TRIM - REMOVAL......23-64

BRACKET - INSTALLATION, REAR VIEW

MIRROR SUPPORT...................23-70

BRACKET - INSTALLATION, STEERING

COLUMN OPENING SUPPORT...........23-60

BRACKET - REMOVAL, STEERING

COLUMN OPENING SUPPORT...........23-60

BRACKETS - INSTALLATION, SEAT BACK

REAR - FOOTMANS LOOP..............23-85

BRACKETS - REMOVAL, SEAT BACK

REAR - FOOTMANS LOOP..............23-85

BRAKE - CLEANING, REAR DRUM IN

HAT ................................5-39

BRAKE - DESCRIPTION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - DESCRIPTION, PARKING........5-36

BRAKE - INSPECTION, REAR DRUM IN

HAT ................................5-39

BRAKE - INSTALLATION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - OPERATION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - OPERATION, PARKING..........5-36

BRAKE - REMOVAL, CONTROLLER

ANTILOCK

...........................8E-3

BRAKE BLEEDING - STANDARD

PROCEDURE, ABS

.....................5-46

BRAKE BOOSTER - DESCRIPTION,

POWER

.............................5-29

BRAKE BOOSTER - INSTALLATION,

HYDRO-BOOST

.......................5-32

BRAKE BOOSTER - INSTALLATION,

POWER

.............................5-29BRAKE BOOSTER - OPERATION, POWER . . . 5-29

BRAKE BOOSTER - REMOVAL,

HYDRO-BOOST.......................5-31

BRAKE BOOSTER - REMOVAL, POWER....5-29

BRAKE CABLE - INSTALLATION, FRONT

PARKING............................5-38

BRAKE CABLE - INSTALLATION, REAR

PARK...............................5-38

BRAKE CABLE - REMOVAL, FRONT

PARKING............................5-36

BRAKE CABLE - REMOVAL, REAR PARK . . . 5-37

BRAKE CALIPER ADAPTER MOUNT -

INSTALLATION, DISC...................5-22

BRAKE CALIPERS - DESCRIPTION, DISC . . . 5-16

BRAKE CALIPERS - OPERATION, DISC.....5-16

BRAKE FLUID CONTAMINATION -

DIAGNOSIS AND TESTING..............5-23

BRAKE FLUID LEVEL - STANDARD

PROCEDURE.........................5-23

BRAKE FLUID, SPECIFICATIONS..........5-23

BRAKE HOSE - INSTALLATION, FRONT.....5-13

BRAKE HOSE - INSTALLATION, REAR......5-12

BRAKE HOSE - REMOVAL, REAR.........5-11

BRAKE INDICATOR - DESCRIPTION,

BRAKE/PARK........................8J-19

BRAKE INDICATOR - DIAGNOSIS AND

TESTING...........................8J-20

BRAKE INDICATOR - OPERATION,

BRAKE/PARK........................8J-19

BRAKE JUNCTION BLOCK -

INSTALLATION.........................5-24

BRAKE JUNCTION BLOCK - REMOVAL.....5-24

BRAKE LAMP SWITCH - DESCRIPTION....8L-9

BRAKE LAMP SWITCH - DIAGNOSIS

AND TESTING.......................8L-10

BRAKE LAMP SWITCH - INSTALLATION . . . 8L-11

BRAKE LAMP SWITCH - OPERATION......8L-9

BRAKE LAMP SWITCH - REMOVAL......8L-10

BRAKE PROPORTIONING -

DESCRIPTION, ELECTRONIC VARIABLE....5-49

BRAKE PROPORTIONING - OPERATION,

ELECTRONIC VARIABLE................5-49

BRAKE ROTOR, DIAGNOSIS AND

TESTING - DISC......................5-32

BRAKE SHOES - ADJUSTMENT, PARKING . . 5-41

BRAKE, SPECIFICATIONS - BASE.........5-10

BRAKE SYSTEM - DIAGNOSIS AND

TESTING, BASE........................5-2

BRAKE TRANSMISSION SHIFT

INTERLOCK - ADJUSTMENTS....21-196,21-365

BRAKE TRANSMISSION SHIFT

INTERLOCK - DIAGNOSIS AND

TESTING....................21-196,21-364

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - DESCRIPTION . . . 21-196,

21-364

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - OPERATION.....21-196,

21-364

BRAKE/PARK BRAKE INDICATOR -

DESCRIPTION.......................8J-19

BRAKE/PARK BRAKE INDICATOR -

OPERATION.........................8J-19

BRAKES - ABS - DESCRIPTION...........5-45

BRAKES - ABS - OPERATION............5-45

BRAKES, SPECIAL TOOLS - BASE.........5-5

BREAK-IN - STANDARD PROCEDURE,

A/C COMPRESSOR CLUTCH............24-10

BREATHER - INSTALLATION,

CRANKCASE

........................9-243

BREATHER - REMOVAL, CRANKCASE

.....9-242

BUCKLE - INSTALLATION, FRONT

OUTBOARD SEAT BELT

................8O-38

BUCKLE - REMOVAL, FRONT OUTBOARD

SEAT BELT

.........................8O-37

BUILT-IN INDICATOR TEST - STANDARD

PROCEDURE

........................8F-10

BUMPER - INSTALLATION, FRONT

........13-2

BUMPER - INSTALLATION, JOUNCE

.......2-43

BUMPER - INSTALLATION, REAR

.........13-4

BUMPER - REMOVAL, FRONT

............13-2

BUMPER - REMOVAL, JOUNCE

...........2-43

BUMPER - REMOVAL, REAR

.............13-3

BUMPERS (3500) - INSTALLATION,

AUXILIARY SPRING

....................2-43

BUMPERS (3500) - REMOVAL,

AUXILIARY SPRING

....................2-43

4 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2597 of 2627

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL RESTRAINT............8O-7

DETECTION ASSY - DESCRIPTION,

NATURAL VAC LEAK..................25-23

DETECTION ASSY - INSTALLATION,

NATURAL VAC LEAK..................25-25

DETECTION ASSY - OPERATION,

NATURAL VAC LEAK..................25-23

DETECTION ASSY - REMOVAL, NATURAL

VAC LEAK..........................25-24

DETECTION PUMP - DESCRIPTION, LEAK . 25-13

DETECTION PUMP - INSTALLATION,

LEAK..............................25-16

DETECTION PUMP - OPERATION, LEAK . . . 25-14

DETECTION PUMP - REMOVAL, LEAK....25-16

DEVICES - STANDARD PROCEDURE,

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE........................8W-01-8

DIAGNOSTIC TROUBLE CODES -

DESCRIPTION........................25-1

DIAGNOSTICS (OBD) - DIAGNOSIS AND

TESTING, ON-BOARD...................7-5

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING......................8W-01-1

DIAGRAMS - HYDRAULIC SCHEMATICS,

SCHEMATICS.................21-176,21-337

DIESEL - CLEANING, RADIATOR - 5.9L....7-56

DIESEL - CLEANING, RADIATOR FAN -

5.9L................................7-35

DIESEL - CLEANING, WATER PUMP -

5.9L................................7-62

DIESEL - DESCRIPTION.................14-62

DIESEL - DESCRIPTION, 5.9L............11-3

DIESEL - DESCRIPTION, BELT

TENSIONER - 5.9L.....................7-23

DIESEL - DESCRIPTION, COOLING

SYSTEM FLOW - 5.9L...................7-3

DIESEL - DESCRIPTION, ENGINE 5.9L....9-232

DIESEL - DESCRIPTION, ENGINE BLOCK

HEATER - 5.9L........................7-37

DIESEL - DESCRIPTION, ENGINE

COOLANT THERMOSTAT - 5.9L...........7-46

DIESEL - DESCRIPTION, FAN DRIVE

VISCOUS CLUTCH - 5.9L...............7-52

DIESEL - DESCRIPTION, RADIATOR -

5.9L................................7-56

DIESEL - DESCRIPTION, TRANS COOLER

- 5.9L..............................7-68

DIESEL - DESCRIPTION, WATER PUMP -

5.9L................................7-62

DIESEL - FUEL INJECTOR FIRING ORDER . 14-48

DIESEL - INSPECTION, RADIATOR - 5.9L . . . 7-56

DIESEL - INSPECTION, RADIATOR FAN -

5.9L................................7-35

DIESEL - INSPECTION, TAILPIPE - 5.9L . . . 11-10

DIESEL - INSPECTION, WATER PUMP -

5.9L................................7-62

DIESEL - INSTALLATION................11-8

DIESEL - INSTALLATION...............14-62

DIESEL - INSTALLATION.....19-26,19-31,19-42

DIESEL - INSTALLATION, BELT

TENSIONER - 5.9L.....................7-24

DIESEL - INSTALLATION, DRIVE BELT -

5.9L

................................7-29

DIESEL - INSTALLATION, ENGINE BLOCK

HEATER - 5.9L

........................7-38

DIESEL - INSTALLATION, ENGINE

COOLANT THERMOSTAT - 5.9L

...........7-47

DIESEL - INSTALLATION, EXCEPT

........14-19

DIESEL - INSTALLATION, MUFFLER -

5.9L

...............................11-10

DIESEL - INSTALLATION, RADIATOR -

5.9L

................................7-57

DIESEL - INSTALLATION, RADIATOR FAN

- 5.9L

..............................7-36

DIESEL - INSTALLATION, TAILPIPE - 5.9L

. 11-11

DIESEL - INSTALLATION, WATER PUMP -

5.9L

................................7-62

DIESEL - MAINTENANCE SCHEDULES,

24-VALVE CUMMINS TURBO

.............0-12

DIESEL - OPERATION, BELT TENSIONER

- 5.9L

..............................7-23

DIESEL - OPERATION, ENGINE BLOCK

HEATER - 5.9L

........................7-38

DIESEL - OPERATION, ENGINE COOLANT

THERMOSTAT - 5.9L

...................7-46DIESEL - OPERATION, FAN DRIVE

VISCOUS CLUTCH - 5.9L...............7-52

DIESEL - OPERATION, RADIATOR - 5.9L . . . 7-56

DIESEL - OPERATION, TRANS COOLER -

5.9L................................7-69

DIESEL - OPERATION, WATER PUMP -

5.9L................................7-62

DIESEL - REMOVAL....................11-7

DIESEL - REMOVAL...................14-62

DIESEL - REMOVAL.........19-25,19-30,19-41

DIESEL - REMOVAL, BELT TENSIONER -

5.9L................................7-23

DIESEL - REMOVAL, DRIVE BELT - 5.9L....7-29

DIESEL - REMOVAL, ENGINE BLOCK

HEATER - 5.9L........................7-38

DIESEL - REMOVAL, ENGINE COOLANT

THERMOSTAT - 5.9L...................7-47

DIESEL - REMOVAL, EXCEPT...........14-17

DIESEL - REMOVAL, MUFFLER - 5.9L.....11-10

DIESEL - REMOVAL, RADIATOR - 5.9L.....7-56

DIESEL - REMOVAL, RADIATOR FAN -

5.9L................................7-35

DIESEL - REMOVAL, TAILPIPE - 5.9L.....11-10

DIESEL - REMOVAL, WATER PUMP -

5.9L................................7-62

DIESEL - SPECIFICATIONS, 5.9L.........9-244

DIESEL - TORQUE, FUEL SYSTEM -

EXCEPT.............................14-3

DIESEL ENGINE - DESCRIPTION, FUEL

REQUIREMENTS.......................0-1

DIESEL ENGINE - DIAGNOSIS AND

TESTING............................11-5

DIESEL ENGINE - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-7

DIESEL ENGINE - INSTALLATION........8R-17

DIESEL ENGINE - INSTALLATION, 5.9L . . . 24-54,

24-58,24-72

DIESEL ENGINE - INSTALLATION,

EXCEPT............................8R-17

DIESEL ENGINE - REMOVAL............8R-16

DIESEL ENGINE - REMOVAL, 5.9L . . 24-53,24-56,

24-70

DIESEL ENGINE - REMOVAL, EXCEPT....8R-15

DIESEL ENGINE - STANDARD

PROCEDURE, DRAINING COOLING

SYSTEM 5.9L........................7-18

DIESEL ENGINE - STANDARD

PROCEDURE, REFILLING COOLING

SYSTEM 5.9L........................7-19

DIESEL ENGINE - TORQUE, FUEL

SYSTEM............................14-48

DIESEL ENGINE, SPECIAL TOOLS - 5.9L . . 9-246

DIESEL ENGINES - DESCRIPTION,

ENGINE OIL...........................0-2

DIESEL FUEL SYSTEM - DESCRIPTION . . . 14-45

DIESEL FUEL SYSTEM, SPECIAL TOOLS . . 14-49

DIESEL ONLY - ASSEMBLY, 5.9L..........7-70

DIESEL ONLY - DISASSEMBLY, 5.9L.......7-70

DIFFERENTIAL - ASSEMBLY . . . 3-129,3-156,3-47,

3-73,3-99

DIFFERENTIAL - DISASSEMBLY....3-128,3-155,

3-47,3-72,3-98

DIFFERENTIAL - INSTALLATION....3-130,3-157,

3-48,3-74,3-99

DIFFERENTIAL - REMOVAL

. . . 3-127,3-155,3-46,

3-72,3-97

DIFFERENTIAL CASE BEARINGS -

INSTALLATION

....3-106,3-134,3-161,3-48,3-75

DIFFERENTIAL CASE BEARINGS -

REMOVAL

........3-105,3-134,3-161,3-48,3-75

DIFFERENTIAL COVER - INSTALLATION

....3-97

DIFFERENTIAL COVER - REMOVAL

........3-97

DIFFERENTIAL TRAC-RITE - ASSEMBLY

. . 3-133,

3-161

DIFFERENTIAL TRAC-RITE - CLEANING

. . . 3-132,

3-160

DIFFERENTIAL TRAC-RITE -

DESCRIPTION

..................3-131,3-158

DIFFERENTIAL TRAC-RITE -

DISASSEMBLY

..................3-131,3-158

DIFFERENTIAL TRAC-RITE - INSPECTION

. 3-132,

3-160

DIFFERENTIAL TRAC-RITE - OPERATION

. . 3-131,

3-158

DIFFERENTIAL-TRAC-LOK - ASSEMBLY

. . . 3-103

DIFFERENTIAL-TRAC-LOK -

DESCRIPTION

.......................3-100DIFFERENTIAL-TRAC-LOK - DIAGNOSIS

AND TESTING.......................3-100

DIFFERENTIAL-TRAC-LOK -

DISASSEMBLY.......................3-101

DIFFERENTIAL-TRAC-LOK - OPERATION . . . 3-100

DIMENSIONS - SPECIFICATIONS, BODY

OPENING...........................23-99

DIMENSIONS - SPECIFICATIONS, FRAME . . 13-16

DIODE - INSTALLATION............8W-01-14

DIODE - REMOVAL................8W-01-14

DIODE REPLACEMENT - STANDARD

PROCEDURE........................24-45

DISC - INSTALLATION, CLUTCH...........6-5

DISC - REMOVAL, CLUTCH...............6-5

DISC BRAKE CALIPER ADAPTER MOUNT

- INSTALLATION......................5-22

DISC BRAKE CALIPERS - DESCRIPTION....5-16

DISC BRAKE CALIPERS - OPERATION.....5-16

DISC BRAKE ROTOR, DIAGNOSIS AND

TESTING............................5-32

DISCHARGE (ESD) SENSITIVE DEVICES -

STANDARD PROCEDURE,

ELECTROSTATIC...................8W-01-8

DISCHARGE LINE - DESCRIPTION, A/C....24-56

DISPLAY TEST MODE - DESCRIPTION,

STATE ..............................25-1

DISTRIBUTION - DESCRIPTION, POWER . 8W-97-1

DISTRIBUTION - OPERATION, POWER . . 8W-97-1

DISTRIBUTION DUCT - INSTALLATION,

FLOOR.............................24-34

DISTRIBUTION DUCT - REMOVAL,

FLOOR.............................24-33

DISTRIBUTION SYSTEMS, SPECIAL

TOOLS - POWER...................8W-97-2

DOME LAMP - DESCRIPTION...........8L-26

DOME LAMP - INSTALLATION..........8L-26

DOME LAMP - OPERATION.............8L-26

DOME LAMP - REMOVAL..............8L-26

DOOR - INSTALLATION...........23-18,23-28

DOOR - INSTALLATION, BLEND.........24-27

DOOR - INSTALLATION, DEFROST.......24-31

DOOR - INSTALLATION, FUEL FILL.......23-39

DOOR - INSTALLATION, MODE..........24-38

DOOR - INSTALLATION, RECIRCULATION . . 24-40

DOOR - REMOVAL...............23-18,23-28

DOOR - REMOVAL, BLEND.............24-27

DOOR - REMOVAL, DEFROST...........24-31

DOOR - REMOVAL, FUEL FILL..........23-39

DOOR - REMOVAL, MODE..............24-38

DOOR - REMOVAL, RECIRCULATION.....24-39

DOOR ACTUATOR - DESCRIPTION,

BLEND.............................24-17

DOOR ACTUATOR - DESCRIPTION,

DEFROST...........................24-20

DOOR ACTUATOR - DESCRIPTION,

MODE.............................24-23

DOOR ACTUATOR - DESCRIPTION,

RECIRCULATION.....................24-24

DOOR ACTUATOR - INSTALLATION,

BLEND.............................24-18

DOOR ACTUATOR - INSTALLATION,

DEFROST...........................24-21

DOOR ACTUATOR - INSTALLATION,

MODE.............................24-23

DOOR ACTUATOR - INSTALLATION,

RECIRCULATION.....................24-25

DOOR ACTUATOR - OPERATION, BLEND . . 24-17

DOOR ACTUATOR - OPERATION,

DEFROST...........................24-21

DOOR ACTUATOR - OPERATION, MODE . . . 24-23

DOOR ACTUATOR - OPERATION,

RECIRCULATION

.....................24-24

DOOR ACTUATOR - REMOVAL, BLEND

....24-17

DOOR ACTUATOR - REMOVAL, DEFROST

. . 24-21

DOOR ACTUATOR - REMOVAL, MODE

....24-23

DOOR ACTUATOR - REMOVAL,

RECIRCULATION

.....................24-24

DOOR AJAR INDICATOR - DESCRIPTION

. . 8J-23

DOOR AJAR INDICATOR - OPERATION

....8J-23

DOOR AJAR SWITCH - DESCRIPTION

....8L-27

DOOR AJAR SWITCH - OPERATION

......8L-27

DOOR GLASS - INSTALLATION

.....23-20,23-30

DOOR GLASS - REMOVAL

........23-20,23-30

DOOR GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT

................23-92

DOOR GLASS RUN WEATHERSTRIP -

INSTALLATION, REAR

.................23-93

10 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2615 of 2627

RKE TRANSMITTER CUSTOMER

PREFERENCES - STANDARD

PROCEDURE.........................8N-8

RKE TRANSMITTER PROGRAMING -

STANDARD PROCEDURE...............8N-9

ROCKER ARM / ADJUSTER ASSEMBLY -

DESCRIPTION.......................9-125

ROCKER ARM / ADJUSTER ASSEMBLY -

INSTALLATION.......................9-126

ROCKER ARM / ADJUSTER ASSEMBLY -

REMOVAL..........................9-126

ROCKER ARM / ADJUSTER ASSY -

CLEANING..........................9-262

ROCKER ARM / ADJUSTER ASSY -

DESCRIPTION.......................9-261

ROCKER ARM / ADJUSTER ASSY -

INSPECTION........................9-262

ROCKER ARM / ADJUSTER ASSY -

INSTALLATION..................9-203,9-263

ROCKER ARM / ADJUSTER ASSY -

REMOVAL.....................9-203,9-261

ROCKER ARM - DESCRIPTION.......9-31,9-37

ROCKER ARM - INSTALLATION..........9-31

ROCKER ARM - REMOVAL..........9-31,9-37

ROCKER HOUSING - INSTALLATION......9-255

ROCKER HOUSING - REMOVAL.........9-255

ROD - INSPECTION, CONNECTING.......9-283

ROD - INSPECTION, PISTON &

CONNECTING...................9-140,9-213

ROD - INSTALLATION, PISTON &

CONNECTING...................9-140,9-213

ROD - REMOVAL, PISTON &

CONNECTING..............9-139,9-212,9-281

ROD BEARING AND CRANKSHAFT

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING............9-272

ROD BEARING FITTING - STANDARD

PROCEDURE, CONNECTING............9-129

ROD BEARING FITTING, STANDARD

PROCEDURE - CONNECTING.............9-49

ROD END - DIAGNOSIS AND TESTING,

OUTER TIE..........................19-32

ROD END - INSTALLATION, OUTER TIE . . . 19-33

ROD END - INSTALLATION, TIE.........19-37

ROD END - REMOVAL, OUTER TIE.......19-32

ROD END - REMOVAL, TIE.............19-37

ROTATION - STANDARD PROCEDURE,

TIRE................................22-3

ROTOR, DIAGNOSIS AND TESTING -

DISC BRAKE.........................5-32

ROUTING, 5.7L V-8 ENGINE - FIRING

ORDER / CABLE.......................8I-4

RUN CHANNEL - INSTALLATION, GLASS . . 23-22,

23-31

RUN CHANNEL - REMOVAL, GLASS . 23-21,23-30

RUN WEATHERSTRIP - INSTALLATION,

FRONT DOOR GLASS.................23-92

RUN WEATHERSTRIP - INSTALLATION,

REAR DOOR GLASS..................23-93

RUN WEATHERSTRIP - REMOVAL,

FRONT DOOR GLASS.................23-92

RUN WEATHERSTRIP - REMOVAL, REAR

DOOR GLASS.......................23-93

RUNOUT - DIAGNOSIS AND TESTING,

TIRE AND WHEEL.....................22-1

RWAL VALVE - DESCRIPTION

............5-50

RWAL VALVE - INSTALLATION

...........5-51

RWAL VALVE - OPERATION

.............5-50

RWAL VALVE - REMOVAL

...............5-51

SAFETY PRECAUTIONS AND WARNINGS,

WARNING

...........................23-1

SAFETY PRECAUTIONS AND WARNINGS,

WARNING

...........................13-4

SAFETY PRECAUTIONS, STANDARD

PROCEDURE

.........................8L-7

SAFETY PRECAUTIONS, WARNING -

WINDSHIELD

........................23-88

SANDING/BUFFING & POLISHING -

DESCRIPTION, FINESSE

...............23-74

SCHEDULES, 24-VALVE CUMMINS

TURBO DIESEL - MAINTENANCE

.........0-12

SCHEMATICS AND DIAGRAMS -

HYDRAULIC SCHEMATICS

.......21-176,21-337

SCHEMATICS, SCHEMATICS AND

DIAGRAMS - HYDRAULIC

.......21-176,21-337

SEAL - DIAGNOSIS AND TESTING,

RADIATOR CAP-TO-FILLER NECK

.........7-58SEAL - FRONT - INSTALLATION,

CRANKSHAFT OIL......9-136,9-208,9-275,9-46

SEAL - FRONT - REMOVAL,

CRANKSHAFT OIL......9-135,9-208,9-275,9-46

SEAL - INSTALLATION, ADAPTER

HOUSING...............21-128,21-364,21-85

SEAL - INSTALLATION, DOOR OPENING . . . 23-92

SEAL - INSTALLATION, EXTENSION

HOUSING . . . 21-128,21-201,21-507,21-536,21-85

SEAL - INSTALLATION, EXTENSION

HOUSING BUSHING..................21-440

SEAL - INSTALLATION, FRONT OUTPUT

SHAFT....21-442,21-477,21-508,21-538,21-572

SEAL - INSTALLATION, OIL PUMP

FRONT............................21-391

SEAL - INSTALLATION, PINION....3-126,3-154,

3-45,3-71,3-96

SEAL - INSTALLATION, STEERING GEAR

INPUT SHAFT.......................19-29

SEAL - REAR - INSTALLATION,

CRANKSHAFT OIL......9-138,9-209,9-276,9-47

SEAL - REAR - REMOVAL, CRANKSHAFT

OIL .................9-137,9-209,9-276,9-47

SEAL - REMOVAL, ADAPTER HOUSING . . 21-128,

21-364,21-85

SEAL - REMOVAL, DOOR OPENING......23-92

SEAL - REMOVAL, EXTENSION

HOUSING . . . 21-128,21-201,21-507,21-536,21-85

SEAL - REMOVAL, EXTENSION HOUSING

BUSHING..........................21-440

SEAL - REMOVAL, FRONT OUTPUT

SHAFT....21-441,21-477,21-507,21-537,21-572

SEAL - REMOVAL, OIL PUMP FRONT.....21-391

SEAL - REMOVAL, PINION....3-126,3-153,3-44,

3-70,3-95

SEAL - REMOVAL, STEERING GEAR

INPUT SHAFT.......................19-27

SEAL AND DUST BOOT - INSTALLATION,

EXTENSION HOUSING..........21-476,21-571

SEAL AND DUST BOOT - REMOVAL,

EXTENSION HOUSING..........21-476,21-571

SEAL AREA LEAKS - DIAGNOSIS AND

TESTING, REAR.............9-137,9-209,9-65

SEAL RETAINER - INSTALLATION,

CRANKSHAFT REAR OIL..........9-210,9-277

SEAL RETAINER - REMOVAL,

CRANKSHAFT REAR OIL..........9-209,9-277

SEALER LOCATIONS - SPECIFICATIONS . . 23-102

SEALERS - STANDARD PROCEDURE,

FORM-IN-PLACE GASKETS......9-239,9-9,9-94

SEALS - DESCRIPTION, VALVE GUIDE . 9-32,9-38

SEALS - DESCRIPTION, VALVE STEM....9-127,

9-203

SEALS - INSTALLATION, AXLE SHAFT . 3-43,3-70,

3-94

SEALS - REMOVAL, AXLE SHAFT . 3-43,3-69,3-94

SEALS - REMOVAL, VALVE SPRINGS.....9-260

SEAT - FRONT - INSTALLATION.........23-81

SEAT - FRONT - REMOVAL.............23-81

SEAT - INSTALLATION, CENTER.........23-76

SEAT - REAR - INSTALLATION..........23-83

SEAT - REAR - REMOVAL..............23-83

SEAT - REMOVAL, CENTER.............23-75

SEAT BACK - INSTALLATION, CENTER

ARMREST..........................23-77

SEAT BACK - REAR - INSTALLATION

.....23-83

SEAT BACK - REAR - REMOVAL

.........23-83

SEAT BACK - REMOVAL, CENTER

ARMREST

..........................23-76

SEAT BACK CUSHION / COVER - FRONT

- INSTALLATION

.....................23-82

SEAT BACK CUSHION / COVER - FRONT

- REMOVAL

.........................23-82

SEAT BACK CUSHION / COVER - REAR -

INSTALLATION

.......................23-84

SEAT BACK CUSHION / COVER - REAR -

REMOVAL

..........................23-84

SEAT BACK HINGE - INSTALLATION,

CENTER

............................23-79

SEAT BACK HINGE - REMOVAL, CENTER

. . 23-78

SEAT BACK INERTIA HINGE COVER -

INSTALLATION, CENTER

...............23-77

SEAT BACK INERTIA HINGE COVER -

REMOVAL, CENTER

...................23-77

SEAT BACK LID - INSTALLATION,

CENTER

............................23-79

SEAT BACK LID - REMOVAL, CENTER

....23-79SEAT BACK REAR - FOOTMANS LOOP

BRACKETS - INSTALLATION............23-85

SEAT BACK REAR - FOOTMANS LOOP

BRACKETS - REMOVAL................23-85

SEAT BELT - INSTALLATION, FRONT

CENTER............................8O-31

SEAT BELT - REMOVAL, FRONT CENTER . . 8O-30

SEAT BELT & RETRACTOR -

INSTALLATION, FRONT CENTER.........8O-29

SEAT BELT & RETRACTOR -

INSTALLATION, REAR CENTER..........8O-45

SEAT BELT & RETRACTOR -

INSTALLATION, REAR OUTBOARD.......8O-47

SEAT BELT & RETRACTOR - REMOVAL,

FRONT CENTER......................8O-29

SEAT BELT & RETRACTOR - REMOVAL,

REAR CENTER.......................8O-44

SEAT BELT & RETRACTOR - REMOVAL,

REAR OUTBOARD....................8O-46

SEAT BELT BUCKLE - INSTALLATION,

FRONT OUTBOARD...................8O-38

SEAT BELT BUCKLE - REMOVAL, FRONT

OUTBOARD.........................8O-37

SEAT BELT SWITCH - DESCRIPTION.....8O-51

SEAT BELT SWITCH - DIAGNOSIS AND

TESTING...........................8O-51

SEAT BELT SWITCH - OPERATION.......8O-51

SEAT BELT TENSION REDUCER -

DESCRIPTION.......................8O-53

SEAT BELT TENSION REDUCER -

DIAGNOSIS AND TESTING.............8O-54

SEAT BELT TENSION REDUCER -

OPERATION..........................8O-54

SEAT BELT TENSIONER - DESCRIPTION . . . 8O-52

SEAT BELT TENSIONER - OPERATION....8O-53

SEAT BELT TURNING LOOP ADJUSTER -

INSTALLATION......................8O-55

SEAT BELT TURNING LOOP ADJUSTER -

REMOVAL..........................8O-55

SEAT CUSHION / COVER - FRONT -

INSTALLATION.......................23-83

SEAT CUSHION / COVER - FRONT -

REMOVAL..........................23-83

SEAT CUSHION / COVER - REAR -

INSTALLATION.......................23-84

SEAT CUSHION / COVER - REAR -

REMOVAL..........................23-84

SEAT CUSHION - INSTALLATION,

CENTER............................23-79

SEAT CUSHION - REMOVAL, CENTER.....23-79

SEAT CUSHION COVER - INSTALLATION,

CENTER............................23-79

SEAT CUSHION COVER - REMOVAL,

CENTER............................23-79

SEAT CUSHION FRAME - REAR -

INSTALLATION.......................23-85

SEAT CUSHION FRAME - REAR -

REMOVAL..........................23-85

SEAT ELEMENT - DESCRIPTION, HEATED . . 8G-9

SEAT ELEMENT - DIAGNOSIS AND

TESTING, HEATED....................8G-10

SEAT ELEMENT - INSTALLATION,

HEATED............................8G-10

SEAT ELEMENT - OPERATION, HEATED . . . 8G-10

SEAT ELEMENT - REMOVAL, HEATED....8G-10

SEAT MODULE - DESCRIPTION, HEATED . . . 8E-6

SEAT MODULE - DESCRIPTION, HEATED . . 8G-13

SEAT MODULE - DIAGNOSIS AND

TESTING, HEATED.....................8E-6

SEAT MODULE - DIAGNOSIS AND

TESTING, HEATED....................8G-14

SEAT MODULE - INSTALLATION, HEATED

. . . 8E-7

SEAT MODULE - INSTALLATION, HEATED

. 8G-15

SEAT MODULE - OPERATION, HEATED

.....8E-6

SEAT MODULE - OPERATION, HEATED

....8G-14

SEAT MODULE - REMOVAL, HEATED

......8E-7

SEAT MODULE - REMOVAL, HEATED

.....8G-15

SEAT SENSOR - DESCRIPTION, HEATED

. . 8G-11

SEAT SENSOR - DIAGNOSIS AND

TESTING, HEATED

....................8G-11

SEAT SENSOR - OPERATION, HEATED

....8G-11

SEAT SENSOR - REMOVAL, HEATED

.....8G-11

SEAT STORAGE BIN - INSTALLATION,

UNDER

............................23-80

SEAT STORAGE BIN - REMOVAL, UNDER

. . 23-80

SEAT STORAGE BIN COVERING -

INSTALLATION, UNDER

................23-80

28 INDEXDR

Description Group-Page Description Group-Page Description Group-Page