Engine control 2 DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 448 of 2627

(2) Disconnect and isolate the remote battery neg-

ative cable terminal.

(3) Remove the battery from the vehicle. Refer to

the procedure in this group.

(4) One at a time, trace the battery cable retaining

pushpins, fasteners and routing clips until the cable

is free from the vehicle.

(5) Remove the battery cable from the engine com-

partment.

INSTALLATION

(1) Position the battery cable in the engine com-

partment.

(2) One at a time, install the battery cable retain-

ing pushpins, fasteners and routing clips until the

cable is installed exactly where it was in the vehicle.

Refer to Wiring for illustrations.

(3) Install the battery in the vehicle. Refer to the

procedure in this group.

(4) Connect the battery negative cable terminal.

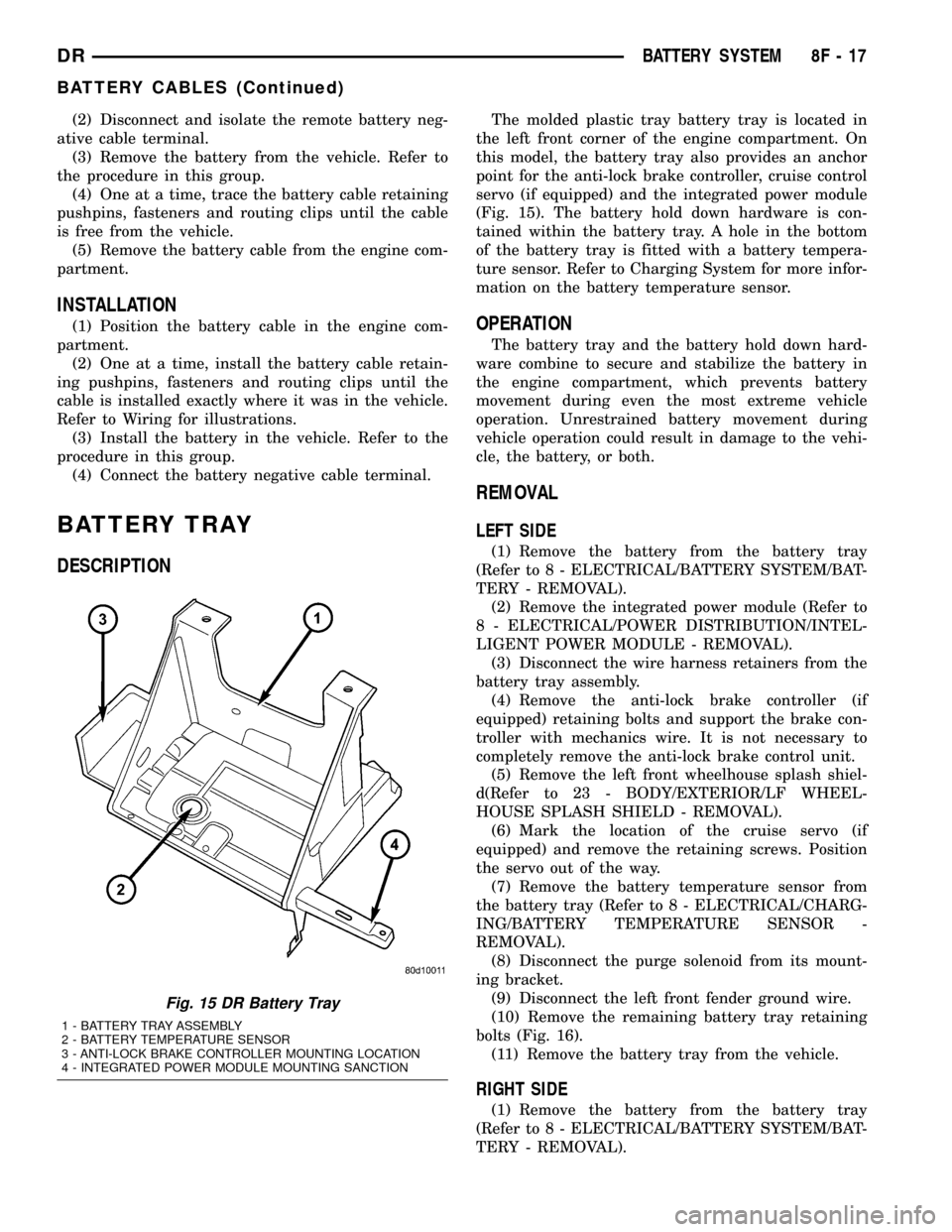

BATTERY TRAY

DESCRIPTION

The molded plastic tray battery tray is located in

the left front corner of the engine compartment. On

this model, the battery tray also provides an anchor

point for the anti-lock brake controller, cruise control

servo (if equipped) and the integrated power module

(Fig. 15). The battery hold down hardware is con-

tained within the battery tray. A hole in the bottom

of the battery tray is fitted with a battery tempera-

ture sensor. Refer to Charging System for more infor-

mation on the battery temperature sensor.

OPERATION

The battery tray and the battery hold down hard-

ware combine to secure and stabilize the battery in

the engine compartment, which prevents battery

movement during even the most extreme vehicle

operation. Unrestrained battery movement during

vehicle operation could result in damage to the vehi-

cle, the battery, or both.

REMOVAL

LEFT SIDE

(1) Remove the battery from the battery tray

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - REMOVAL).

(2) Remove the integrated power module (Refer to

8 - ELECTRICAL/POWER DISTRIBUTION/INTEL-

LIGENT POWER MODULE - REMOVAL).

(3) Disconnect the wire harness retainers from the

battery tray assembly.

(4) Remove the anti-lock brake controller (if

equipped) retaining bolts and support the brake con-

troller with mechanics wire. It is not necessary to

completely remove the anti-lock brake control unit.

(5) Remove the left front wheelhouse splash shiel-

d(Refer to 23 - BODY/EXTERIOR/LF WHEEL-

HOUSE SPLASH SHIELD - REMOVAL).

(6) Mark the location of the cruise servo (if

equipped) and remove the retaining screws. Position

the servo out of the way.

(7) Remove the battery temperature sensor from

the battery tray (Refer to 8 - ELECTRICAL/CHARG-

ING/BATTERY TEMPERATURE SENSOR -

REMOVAL).

(8) Disconnect the purge solenoid from its mount-

ing bracket.

(9) Disconnect the left front fender ground wire.

(10) Remove the remaining battery tray retaining

bolts (Fig. 16).

(11) Remove the battery tray from the vehicle.

RIGHT SIDE

(1) Remove the battery from the battery tray

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - REMOVAL).

Fig. 15 DR Battery Tray

1 - BATTERY TRAY ASSEMBLY

2 - BATTERY TEMPERATURE SENSOR

3 - ANTI-LOCK BRAKE CONTROLLER MOUNTING LOCATION

4 - INTEGRATED POWER MODULE MOUNTING SANCTION

DRBATTERY SYSTEM 8F - 17

BATTERY CABLES (Continued)

Page 450 of 2627

CHARGING

TABLE OF CONTENTS

page page

CHARGING

DESCRIPTION.........................19

OPERATION...........................19

DIAGNOSIS AND TESTING - CHARGING

SYSTEM............................19

SPECIFICATIONS

GENERATOR RATINGS.................20

SPECIFICATIONS - TORQUE - GENERATOR

/ CHARGING SYSTEM..................20

BATTERY TEMPERATURE SENSOR

DESCRIPTION.........................21OPERATION...........................21

REMOVAL.............................21

INSTALLATION.........................21

GENERATOR

DESCRIPTION.........................21

OPERATION...........................21

REMOVAL.............................22

INSTALLATION.........................24

VOLTAGE REGULATOR

DESCRIPTION.........................25

OPERATION...........................25

CHARGING

DESCRIPTION

The charging system consists of:

²Generator

²Electronic Voltage Regulator (EVR) circuitry

within the Powertrain Control Module (PCM). Elec-

tronic Control Module (ECM) for diesel engines.

²Ignition switch

²Battery (refer to 8, Battery for information)

²Battery temperature sensor

²Check Gauges Lamp (if equipped)

²Voltmeter (refer to 8, Instrument Panel and

Gauges for information)

²Wiring harness and connections (refer to 8, Wir-

ing Diagrams for information)

OPERATION

The charging system is turned on and off with the

ignition switch. The system is on when the engine is

running and the ASD relay is energized. When the

ASD relay is on, voltage is supplied to the ASD relay

sense circuit at the PCM (ECM Diesel). This voltage

is connected through the PCM (ECM Diesel) and sup-

plied to one of the generator field terminals (Gen.

Source +) at the back of the generator.

The amount of direct current produced by the gen-

erator is controlled by the EVR (field control) cir-

cuitry contained within the PCM (ECM Diesel). This

circuitry is connected in series with the second rotor

field terminal and ground.

A battery temperature sensor, located in the bat-

tery tray housing, is used to sense battery tempera-

ture. This temperature data, along with data from

monitored line voltage, is used by the PCM (ECM

Diesel) to vary the battery charging rate. This isdone by cycling the ground path to control the

strength of the rotor magnetic field. The PCM then

compensates and regulates generator current output

accordingly.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including EVR

(field control) circuitry, are monitored by the PCM

(ECM Diesel). Each monitored circuit is assigned a

Diagnostic Trouble Code (DTC). The PCM will store a

DTC in electronic memory for certain failures it

detects.

The Check Gauges Lamp (if equipped) monitors:

charging system voltage,engine coolant tempera-

ture and engine oil pressure. If an extreme condition

is indicated, the lamp will be illuminated. This is

done as reminder to check the three gauges. The sig-

nal to activate the lamp is sent via the CCD bus cir-

cuits. The lamp is located on the instrument panel.

Refer to 8, Instrument Panel and Gauges for addi-

tional information.

DIAGNOSIS AND TESTING - CHARGING

SYSTEM

The following procedures may be used to diagnose

the charging system if:

²the check gauges lamp (if equipped) is illumi-

nated with the engine running

²the voltmeter (if equipped) does not register

properly

²an undercharged or overcharged battery condi-

tion occurs.

Remember that an undercharged battery is often

caused by:

²accessories being left on with the engine not

running

DRCHARGING 8F - 19

Page 451 of 2627

²a faulty or improperly adjusted switch that

allows a lamp to stay on. Refer to Ignition-Off Draw

Test in 8, Battery for more information.

INSPECTION

The PCM (Powertrain Control Module), or ECM

(Diesel) monitors critical input and output circuits of

the charging system, making sure they are opera-

tional. A Diagnostic Trouble Code (DTC) is assigned

to each input and output circuit monitored by the

On-Board Diagnostic (OBD) system. Some charging

system circuits are checked continuously, and some

are checked only under certain conditions.

Refer to Diagnostic Trouble Codes in; Powertrain

Control Module; Electronic Control Modules for more

DTC information. This will include a complete list of

DTC's including DTC's for the charging system.

To perform a complete test of the charging system,

refer to the appropriate Powertrain Diagnostic Proce-

dures service manual and the DRBtscan tool. Per-

form the following inspections before attaching the

scan tool.

(1) Inspect the battery condition. Refer to 8, Bat-

tery for procedures.(2) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(3) Inspect all fuses in both the fuseblock and

Power Distribution Center (PDC) for tightness in

receptacles. They should be properly installed and

tight. Repair or replace as required.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts if required. Refer to the Gen-

erator Removal/Installation section of this group for

torque specifications.

(5) Inspect generator drive belt condition and ten-

sion. Tighten or replace belt as required. Refer to

Belt Tension Specifications in 7, Cooling System.

(6) Inspect automatic belt tensioner (if equipped).

Refer to 7, Cooling System for information.

(7) Inspect generator electrical connections at gen-

erator field, battery output, and ground terminal (if

equipped). Also check generator ground wire connec-

tion at engine (if equipped). They should all be clean

and tight. Repair as required.

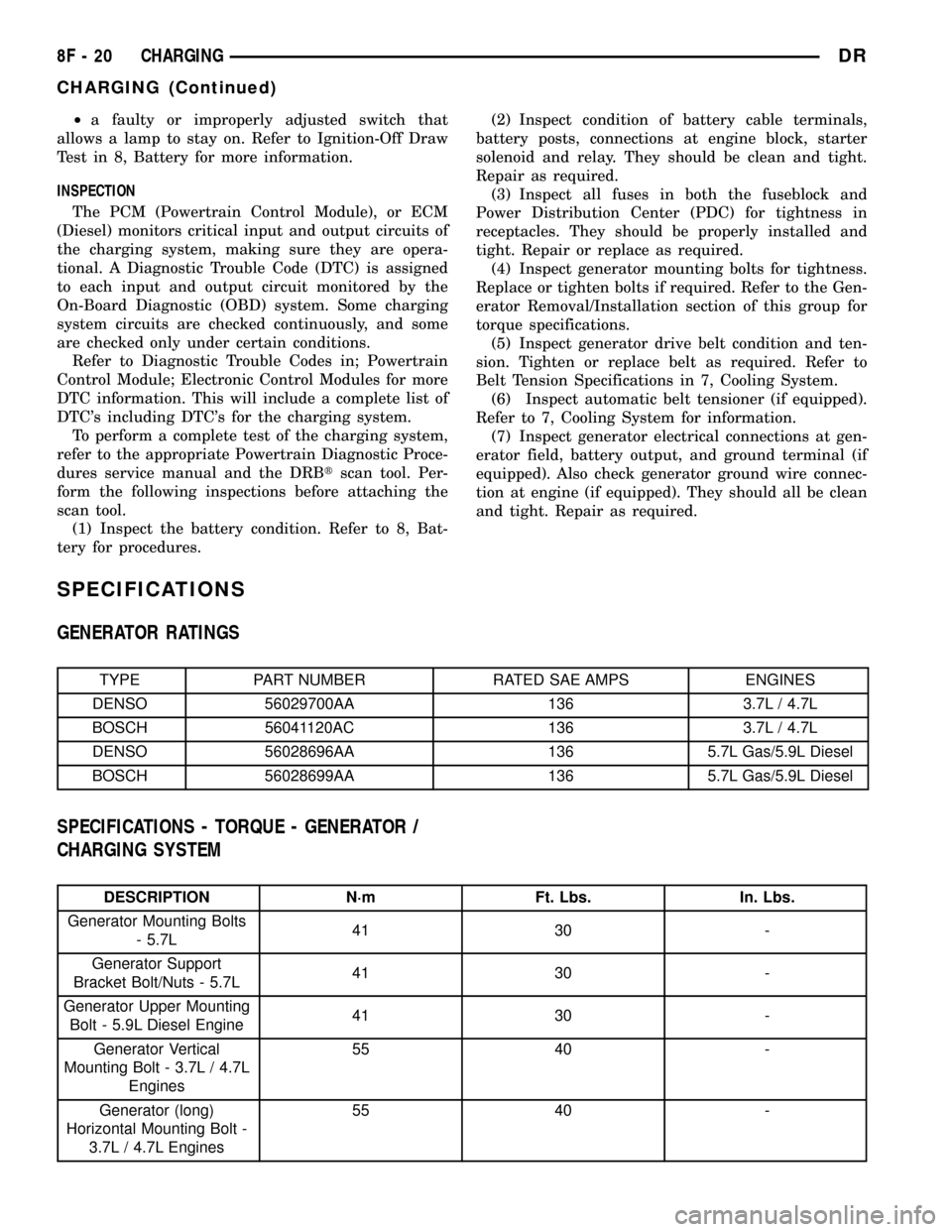

SPECIFICATIONS

GENERATOR RATINGS

TYPE PART NUMBER RATED SAE AMPS ENGINES

DENSO 56029700AA 136 3.7L / 4.7L

BOSCH 56041120AC 136 3.7L / 4.7L

DENSO 56028696AA 136 5.7L Gas/5.9L Diesel

BOSCH 56028699AA 136 5.7L Gas/5.9L Diesel

SPECIFICATIONS - TORQUE - GENERATOR /

CHARGING SYSTEM

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Generator Mounting Bolts

- 5.7L41 30 -

Generator Support

Bracket Bolt/Nuts - 5.7L41 30 -

Generator Upper Mounting

Bolt - 5.9L Diesel Engine41 30 -

Generator Vertical

Mounting Bolt - 3.7L / 4.7L

Engines55 40 -

Generator (long)

Horizontal Mounting Bolt -

3.7L / 4.7L Engines55 40 -

8F - 20 CHARGINGDR

CHARGING (Continued)

Page 452 of 2627

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Generator (short)

Horizontal Mounting Bolt -

3.7L / 4.7L Engines74 55 -

Generator B+ Output

Cable Terminal Nut12 - 108

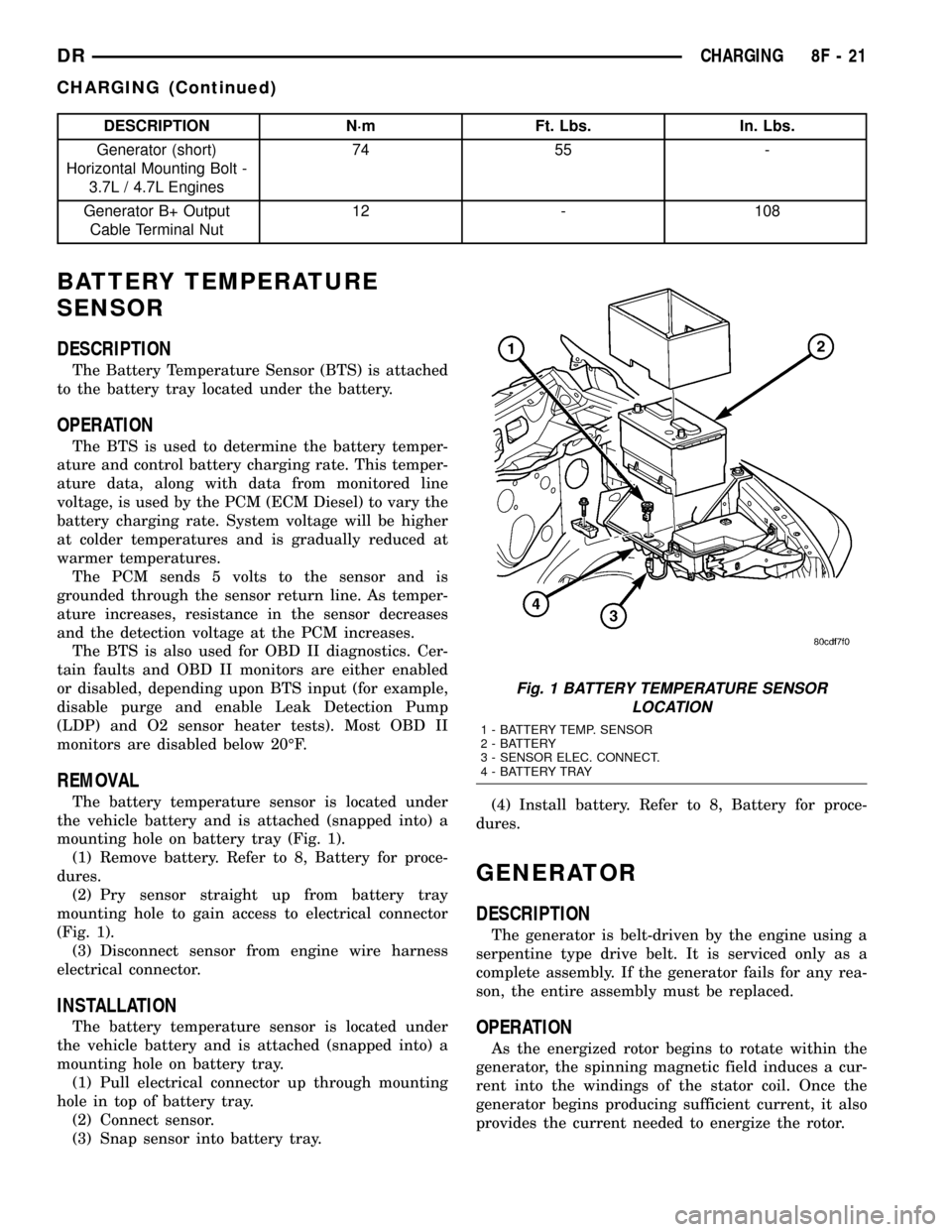

BATTERY TEMPERATURE

SENSOR

DESCRIPTION

The Battery Temperature Sensor (BTS) is attached

to the battery tray located under the battery.

OPERATION

The BTS is used to determine the battery temper-

ature and control battery charging rate. This temper-

ature data, along with data from monitored line

voltage, is used by the PCM (ECM Diesel) to vary the

battery charging rate. System voltage will be higher

at colder temperatures and is gradually reduced at

warmer temperatures.

The PCM sends 5 volts to the sensor and is

grounded through the sensor return line. As temper-

ature increases, resistance in the sensor decreases

and the detection voltage at the PCM increases.

The BTS is also used for OBD II diagnostics. Cer-

tain faults and OBD II monitors are either enabled

or disabled, depending upon BTS input (for example,

disable purge and enable Leak Detection Pump

(LDP) and O2 sensor heater tests). Most OBD II

monitors are disabled below 20ÉF.

REMOVAL

The battery temperature sensor is located under

the vehicle battery and is attached (snapped into) a

mounting hole on battery tray (Fig. 1).

(1) Remove battery. Refer to 8, Battery for proce-

dures.

(2) Pry sensor straight up from battery tray

mounting hole to gain access to electrical connector

(Fig. 1).

(3) Disconnect sensor from engine wire harness

electrical connector.

INSTALLATION

The battery temperature sensor is located under

the vehicle battery and is attached (snapped into) a

mounting hole on battery tray.

(1) Pull electrical connector up through mounting

hole in top of battery tray.

(2) Connect sensor.

(3) Snap sensor into battery tray.(4) Install battery. Refer to 8, Battery for proce-

dures.

GENERATOR

DESCRIPTION

The generator is belt-driven by the engine using a

serpentine type drive belt. It is serviced only as a

complete assembly. If the generator fails for any rea-

son, the entire assembly must be replaced.

OPERATION

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

Fig. 1 BATTERY TEMPERATURE SENSOR

LOCATION

1 - BATTERY TEMP. SENSOR

2 - BATTERY

3 - SENSOR ELEC. CONNECT.

4 - BATTERY TRAY

DRCHARGING 8F - 21

CHARGING (Continued)

Page 456 of 2627

(6) Install both negative battery cables to both bat-

teries.

VOLTAGE REGULATOR

DESCRIPTION

The Electronic Voltage Regulator (EVR) is not a

separate component. It is actually a voltage regulat-

ing circuit located within the PCM (Powertrain Con-

trol Module) (within the ECM for diesel engines). The

EVR is not serviced separately. If replacement is nec-

essary, the PCM must be replaced.

OPERATION

The amount of direct current produced by the gen-

erator is controlled by EVR circuitry contained

within the PCM. This circuitry is connected in series

with the generators second rotor field terminal and

its ground.Voltage is regulated by cycling the ground path to

control the strength of the rotor magnetic field. The

EVR circuitry monitors system line voltage (B+) and

battery temperature (refer to Battery Temperature

Sensor for more information). It then determines a

target charging voltage. If sensed battery voltage is

0.5 volts or lower than the target voltage, the PCM

grounds the field winding until sensed battery volt-

age is 0.5 volts above target voltage. A circuit in the

PCM cycles the ground side of the generator field up

to 100 times per second (100Hz), but has the capabil-

ity to ground the field control wire 100% of the time

(full field) to achieve the target voltage. If the charg-

ing rate cannot be monitored (limp-in), a duty cycle

of 25% is used by the PCM in order to have some

generator output. Also refer to Charging System

Operation for additional information.

DRCHARGING 8F - 25

GENERATOR (Continued)

Page 457 of 2627

STARTING

TABLE OF CONTENTS

page page

STARTING

DESCRIPTION.........................26

OPERATION...........................26

DIAGNOSIS AND TESTING - STARTING

SYSTEM............................27

SPECIFICATIONS

STARTING SYSTEM...................31

SPECIFICATIONS - TORQUE - STARTING

SYSTEM............................32

STARTER MOTOR

DIAGNOSIS AND TESTING - STARTER

MOTOR .............................32REMOVAL.............................33

INSTALLATION.........................34

STARTER MOTOR RELAY

DESCRIPTION.........................35

OPERATION...........................36

DIAGNOSIS AND TESTING - STARTER RELAY . 36

REMOVAL.............................37

INSTALLATION.........................37

STARTING

DESCRIPTION

The starting system consists of:

²Starter relay

²Starter motor (including an integral starter sole-

noid)

Other components to be considered as part of start-

ing system are:

²Battery

²Battery cables

²Ignition switch and key lock cylinder

²Clutch pedal position switch (manual transmis-

sion)

²Park/neutral position switch (automatic trans-

mission)

²Wire harnesses and connections.

The Battery, Starting, and Charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct operation of

starting/charging systems, all components used in

these 3 systems must perform within specifications.

When attempting to diagnose any of these systems, it

is important that you keep their interdependency in

mind.

The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Powertrain Control Mod-

ule (PCM). Use of an induction-type milliampere

ammeter, volt/ohmmeter, battery charger, carbon pile

rheostat (load tester), and 12-volt test lamp may be

required.Certain starting system components are monitored

by the PCM and may produce a Diagnostic Trouble

Code (DTC). Refer to Diagnostic Trouble Codes in

Emission Control for a list of codes.

OPERATION

The starting system components form two separate

circuits. A high-amperage feed circuit that feeds the

starter motor between 150 and 350 amperes (700

amperes - diesel engine), and a low-amperage control

circuit that operates on less than 20 amperes. The

high-amperage feed circuit components include the

battery, the battery cables, the contact disc portion of

the starter solenoid, and the starter motor. The low-

amperage control circuit components include the igni-

tion switch, the clutch pedal position switch (manual

transmission), the park/neutral position switch (auto-

matic transmission), the starter relay, the electro-

magnetic windings of the starter solenoid, and the

connecting wire harness components.

If the vehicle is equipped with a manual transmis-

sion, it has a clutch pedal position switch installed in

series between the ignition switch and the coil bat-

tery terminal of the starter relay. This normally open

switch prevents the starter relay from being ener-

gized when the ignition switch is turned to the Start

position, unless the clutch pedal is depressed. This

feature prevents starter motor operation while the

clutch disc and the flywheel are engaged. The starter

relay coil ground terminal is always grounded on

vehicles with a manual transmission.

8F - 26 STARTINGDR

Page 458 of 2627

If the vehicle is equipped with an automatic trans-

mission, battery voltage is supplied through the low-

amperage control circuit to the coil battery terminal

of the starter relay when the ignition switch is

turned to the Start position. The park/neutral posi-

tion switch is installed in series between the starter

relay coil ground terminal and ground. This normally

open switch prevents the starter relay from being

energized and the starter motor from operating

unless the automatic transmission gear selector is in

the Neutral or Park positions.

When the starter relay coil is energized, the nor-

mally open relay contacts close. The relay contacts

connect the relay common feed terminal to the relay

normally open terminal. The closed relay contacts

energize the starter solenoid coil windings.

The energized solenoid pull-in coil pulls in the sole-

noid plunger. The solenoid plunger pulls the shift

lever in the starter motor. This engages the starter

overrunning clutch and pinion gear with the starter

ring gear.

As the solenoid plunger reaches the end of its

travel, the solenoid contact disc completes the high-

amperage starter feed circuit and energizes the sole-

noid plunger hold-in coil. Current now flows between

the solenoid battery terminal and the starter motor,

energizing the starter.Once the engine starts, the overrunning clutch pro-

tects the starter motor from damage by allowing the

starter pinion gear to spin faster than the pinion

shaft. When the ignition switch is released to the On

position, the starter relay coil is de-energized. This

causes the relay contacts to open. When the relay

contacts open, the starter solenoid plunger hold-in

coil is de-energized.

When the solenoid plunger hold-in coil is de-ener-

gized, the solenoid plunger return spring returns the

plunger to its relaxed position. This causes the con-

tact disc to open the starter feed circuit, and the shift

lever to disengage the overrunning clutch and pinion

gear from the starter ring gear.

DIAGNOSIS AND TESTING - STARTING

SYSTEM

The battery, starting, and charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct starting/

charging system operation, all of the components

involved in these 3 systems must perform within

specifications.

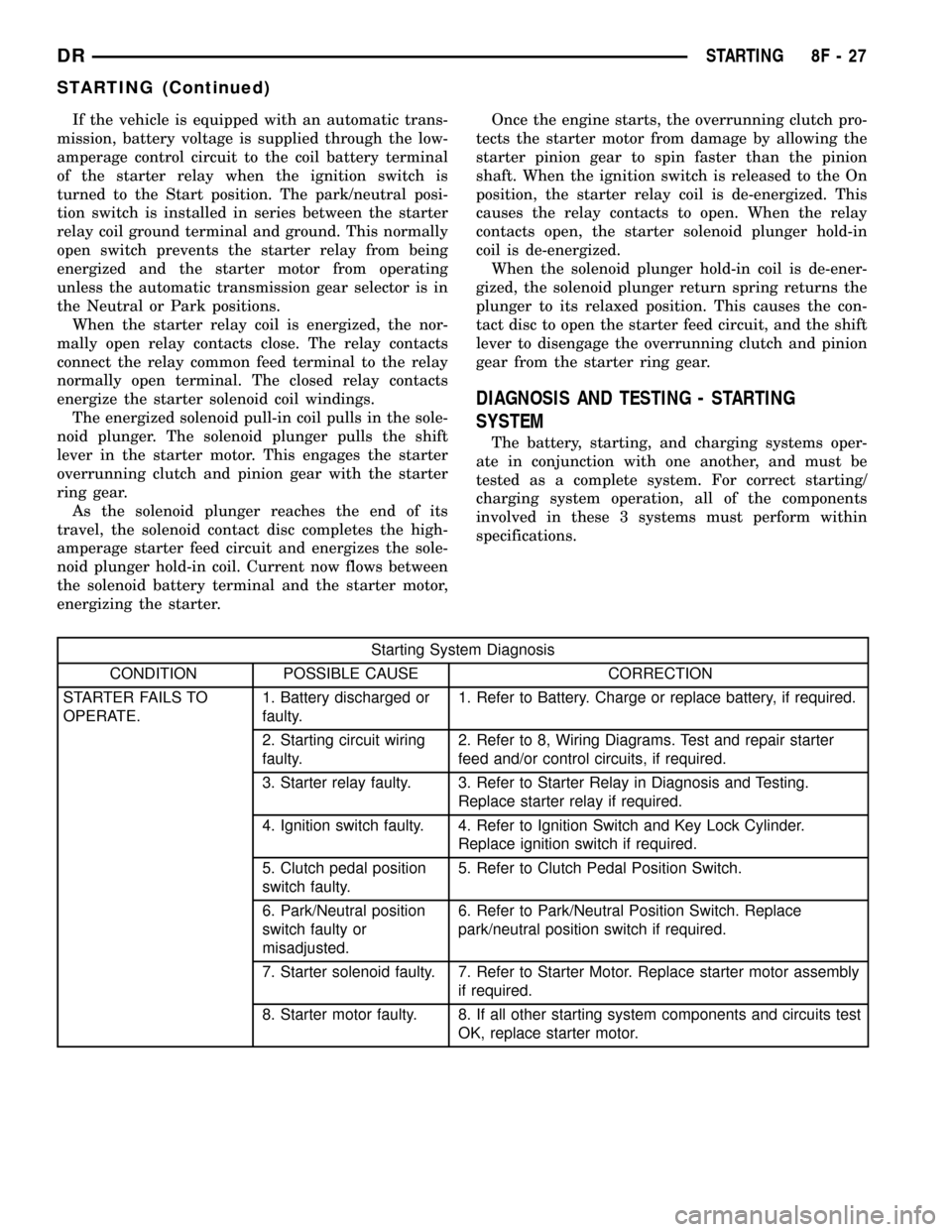

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS TO

OPERATE.1. Battery discharged or

faulty.1. Refer to Battery. Charge or replace battery, if required.

2. Starting circuit wiring

faulty.2. Refer to 8, Wiring Diagrams. Test and repair starter

feed and/or control circuits, if required.

3. Starter relay faulty. 3. Refer to Starter Relay in Diagnosis and Testing.

Replace starter relay if required.

4. Ignition switch faulty. 4. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch if required.

5. Clutch pedal position

switch faulty.5. Refer to Clutch Pedal Position Switch.

6. Park/Neutral position

switch faulty or

misadjusted.6. Refer to Park/Neutral Position Switch. Replace

park/neutral position switch if required.

7. Starter solenoid faulty. 7. Refer to Starter Motor. Replace starter motor assembly

if required.

8. Starter motor faulty. 8. If all other starting system components and circuits test

OK, replace starter motor.

DRSTARTING 8F - 27

STARTING (Continued)

Page 459 of 2627

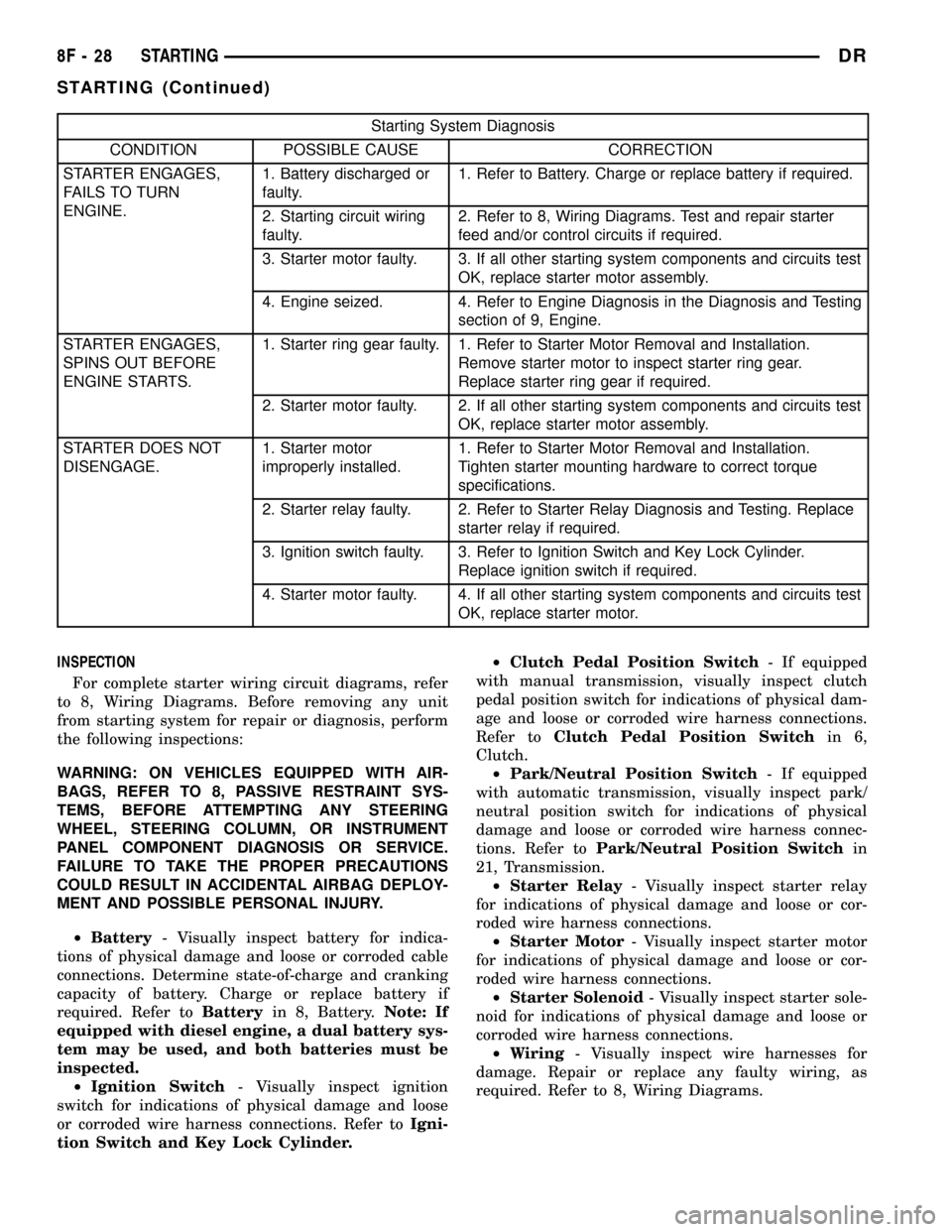

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER ENGAGES,

FAILS TO TURN

ENGINE.1. Battery discharged or

faulty.1. Refer to Battery. Charge or replace battery if required.

2. Starting circuit wiring

faulty.2. Refer to 8, Wiring Diagrams. Test and repair starter

feed and/or control circuits if required.

3. Starter motor faulty. 3. If all other starting system components and circuits test

OK, replace starter motor assembly.

4. Engine seized. 4. Refer to Engine Diagnosis in the Diagnosis and Testing

section of 9, Engine.

STARTER ENGAGES,

SPINS OUT BEFORE

ENGINE STARTS.1. Starter ring gear faulty. 1. Refer to Starter Motor Removal and Installation.

Remove starter motor to inspect starter ring gear.

Replace starter ring gear if required.

2. Starter motor faulty. 2. If all other starting system components and circuits test

OK, replace starter motor assembly.

STARTER DOES NOT

DISENGAGE.1. Starter motor

improperly installed.1. Refer to Starter Motor Removal and Installation.

Tighten starter mounting hardware to correct torque

specifications.

2. Starter relay faulty. 2. Refer to Starter Relay Diagnosis and Testing. Replace

starter relay if required.

3. Ignition switch faulty. 3. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch if required.

4. Starter motor faulty. 4. If all other starting system components and circuits test

OK, replace starter motor.

INSPECTION

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. Before removing any unit

from starting system for repair or diagnosis, perform

the following inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO 8, PASSIVE RESTRAINT SYS-

TEMS, BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY.

²Battery- Visually inspect battery for indica-

tions of physical damage and loose or corroded cable

connections. Determine state-of-charge and cranking

capacity of battery. Charge or replace battery if

required. Refer toBatteryin 8, Battery.Note: If

equipped with diesel engine, a dual battery sys-

tem may be used, and both batteries must be

inspected.

²Ignition Switch- Visually inspect ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer toIgni-

tion Switch and Key Lock Cylinder.²Clutch Pedal Position Switch- If equipped

with manual transmission, visually inspect clutch

pedal position switch for indications of physical dam-

age and loose or corroded wire harness connections.

Refer toClutch Pedal Position Switchin 6,

Clutch.

²Park/Neutral Position Switch- If equipped

with automatic transmission, visually inspect park/

neutral position switch for indications of physical

damage and loose or corroded wire harness connec-

tions. Refer toPark/Neutral Position Switchin

21, Transmission.

²Starter Relay- Visually inspect starter relay

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Motor- Visually inspect starter motor

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Solenoid- Visually inspect starter sole-

noid for indications of physical damage and loose or

corroded wire harness connections.

²Wiring- Visually inspect wire harnesses for

damage. Repair or replace any faulty wiring, as

required. Refer to 8, Wiring Diagrams.

8F - 28 STARTINGDR

STARTING (Continued)

Page 460 of 2627

TESTING

COLD CRANKING TEST

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. The battery must be fully-

charged and load-tested before proceeding. Refer to

Batteryin 8, Battery.

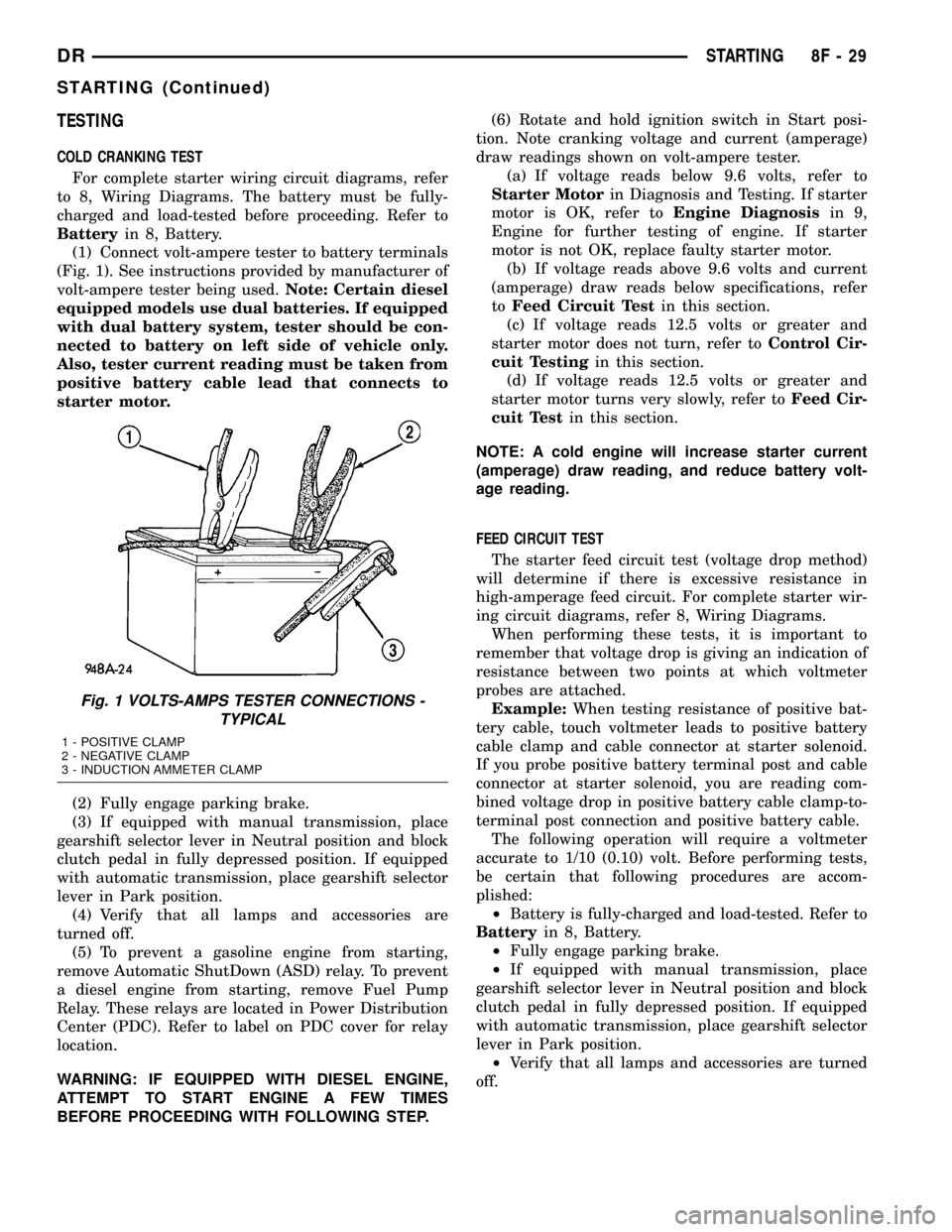

(1) Connect volt-ampere tester to battery terminals

(Fig. 1). See instructions provided by manufacturer of

volt-ampere tester being used.Note: Certain diesel

equipped models use dual batteries. If equipped

with dual battery system, tester should be con-

nected to battery on left side of vehicle only.

Also, tester current reading must be taken from

positive battery cable lead that connects to

starter motor.

(2) Fully engage parking brake.

(3) If equipped with manual transmission, place

gearshift selector lever in Neutral position and block

clutch pedal in fully depressed position. If equipped

with automatic transmission, place gearshift selector

lever in Park position.

(4) Verify that all lamps and accessories are

turned off.

(5) To prevent a gasoline engine from starting,

remove Automatic ShutDown (ASD) relay. To prevent

a diesel engine from starting, remove Fuel Pump

Relay. These relays are located in Power Distribution

Center (PDC). Refer to label on PDC cover for relay

location.

WARNING: IF EQUIPPED WITH DIESEL ENGINE,

ATTEMPT TO START ENGINE A FEW TIMES

BEFORE PROCEEDING WITH FOLLOWING STEP.(6) Rotate and hold ignition switch in Start posi-

tion. Note cranking voltage and current (amperage)

draw readings shown on volt-ampere tester.

(a) If voltage reads below 9.6 volts, refer to

Starter Motorin Diagnosis and Testing. If starter

motor is OK, refer toEngine Diagnosisin 9,

Engine for further testing of engine. If starter

motor is not OK, replace faulty starter motor.

(b) If voltage reads above 9.6 volts and current

(amperage) draw reads below specifications, refer

toFeed Circuit Testin this section.

(c) If voltage reads 12.5 volts or greater and

starter motor does not turn, refer toControl Cir-

cuit Testingin this section.

(d) If voltage reads 12.5 volts or greater and

starter motor turns very slowly, refer toFeed Cir-

cuit Testin this section.

NOTE: A cold engine will increase starter current

(amperage) draw reading, and reduce battery volt-

age reading.

FEED CIRCUIT TEST

The starter feed circuit test (voltage drop method)

will determine if there is excessive resistance in

high-amperage feed circuit. For complete starter wir-

ing circuit diagrams, refer 8, Wiring Diagrams.

When performing these tests, it is important to

remember that voltage drop is giving an indication of

resistance between two points at which voltmeter

probes are attached.

Example:When testing resistance of positive bat-

tery cable, touch voltmeter leads to positive battery

cable clamp and cable connector at starter solenoid.

If you probe positive battery terminal post and cable

connector at starter solenoid, you are reading com-

bined voltage drop in positive battery cable clamp-to-

terminal post connection and positive battery cable.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing tests,

be certain that following procedures are accom-

plished:

²Battery is fully-charged and load-tested. Refer to

Batteryin 8, Battery.

²Fully engage parking brake.

²If equipped with manual transmission, place

gearshift selector lever in Neutral position and block

clutch pedal in fully depressed position. If equipped

with automatic transmission, place gearshift selector

lever in Park position.

²Verify that all lamps and accessories are turned

off.

Fig. 1 VOLTS-AMPS TESTER CONNECTIONS -

TYPICAL

1 - POSITIVE CLAMP

2 - NEGATIVE CLAMP

3 - INDUCTION AMMETER CLAMP

DRSTARTING 8F - 29

STARTING (Continued)

Page 462 of 2627

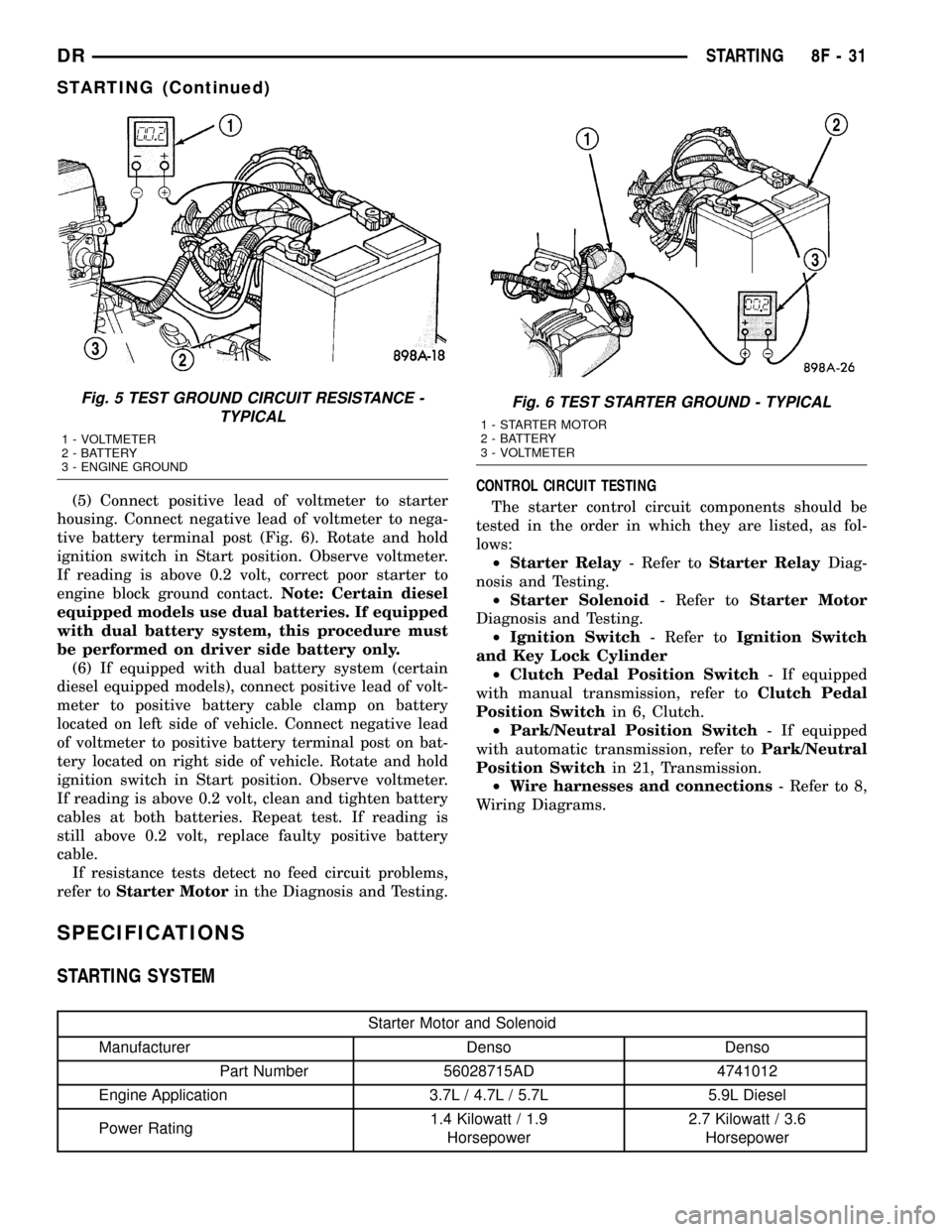

(5) Connect positive lead of voltmeter to starter

housing. Connect negative lead of voltmeter to nega-

tive battery terminal post (Fig. 6). Rotate and hold

ignition switch in Start position. Observe voltmeter.

If reading is above 0.2 volt, correct poor starter to

engine block ground contact.Note: Certain diesel

equipped models use dual batteries. If equipped

with dual battery system, this procedure must

be performed on driver side battery only.

(6) If equipped with dual battery system (certain

diesel equipped models), connect positive lead of volt-

meter to positive battery cable clamp on battery

located on left side of vehicle. Connect negative lead

of voltmeter to positive battery terminal post on bat-

tery located on right side of vehicle. Rotate and hold

ignition switch in Start position. Observe voltmeter.

If reading is above 0.2 volt, clean and tighten battery

cables at both batteries. Repeat test. If reading is

still above 0.2 volt, replace faulty positive battery

cable.

If resistance tests detect no feed circuit problems,

refer toStarter Motorin the Diagnosis and Testing.CONTROL CIRCUIT TESTING

The starter control circuit components should be

tested in the order in which they are listed, as fol-

lows:

²Starter Relay- Refer toStarter RelayDiag-

nosis and Testing.

²Starter Solenoid- Refer toStarter Motor

Diagnosis and Testing.

²Ignition Switch- Refer toIgnition Switch

and Key Lock Cylinder

²Clutch Pedal Position Switch- If equipped

with manual transmission, refer toClutch Pedal

Position Switchin 6, Clutch.

²Park/Neutral Position Switch- If equipped

with automatic transmission, refer toPark/Neutral

Position Switchin 21, Transmission.

²Wire harnesses and connections- Refer to 8,

Wiring Diagrams.

SPECIFICATIONS

STARTING SYSTEM

Starter Motor and Solenoid

Manufacturer Denso Denso

Part Number 56028715AD 4741012

Engine Application 3.7L / 4.7L / 5.7L 5.9L Diesel

Power Rating1.4 Kilowatt / 1.9

Horsepower2.7 Kilowatt / 3.6

Horsepower

Fig. 5 TEST GROUND CIRCUIT RESISTANCE -

TYPICAL

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

Fig. 6 TEST STARTER GROUND - TYPICAL

1 - STARTER MOTOR

2 - BATTERY

3 - VOLTMETER

DRSTARTING 8F - 31

STARTING (Continued)