table of contents DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1403 of 2627

ENGINE - 5.7L

TABLE OF CONTENTS

page page

ENGINE - 5.7L

DESCRIPTION........................182

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION..........183

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE..........183

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL............185

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE............186

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE.....186

DIAGNOSIS AND TESTINGÐENGINE

DIAGNOSIS - LUBRICATION............187

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL............188

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR

DAMAGED OR WORN THREADS........190

STANDARD PROCEDUREÐHYDROSTATIC

LOCK..............................190

REMOVAL............................190

INSTALLATION........................191

SPECIFICATIONS

5.7L ENGINE........................192

TORQUE...........................195

SPECIAL TOOLS

5.7L ENGINE........................196

AIR INTAKE SYSTEM

REMOVAL............................199

INSTALLATION........................199

CYLINDER HEAD

OPERATIONÐCYLINDER HEAD...........199

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE....................199

REMOVAL............................200

CLEANING...........................200

INSPECTION.........................200

INSTALLATION........................200

CYLINDER HEAD COVER(S)

REMOVAL............................201

INSTALLATION........................201

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION

DESCRIPTION - VALVE GUIDES.........202

DESCRIPTION.......................202

STANDARD PROCEDURE - REFACING.....202

REMOVAL............................203INSTALLATION........................203

ROCKER ARM / ADJUSTER ASSY

REMOVAL............................203

INSTALLATION........................203

VALVE STEM SEALS

DESCRIPTION........................203

VALVE SPRINGS

REMOVAL............................204

INSTALLATION........................204

ENGINE BLOCK

CLEANING...........................205

INSPECTION.........................205

CAMSHAFT & BEARINGS (IN BLOCK)

REMOVAL

REMOVAL - CAMSHAFT CORE HOLE PLUG. 205

REMOVAL - CAMSHAFT...............205

INSPECTION.........................206

INSTALLATION

INSTALLATION - CAMSHAFT CORE HOLE

PLUG..............................206

INSTALLATION - CAMSHAFT............206

CRANKSHAFT

REMOVAL............................206

INSTALLATION........................207

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE - CRANKSHAFT

MAIN BEARING - FITTING..............207

INSPECTION.........................208

CRANKSHAFT OIL SEAL - FRONT

REMOVAL............................208

INSTALLATION........................208

CRANKSHAFT OIL SEAL - REAR

DIAGNOSIS AND TESTING - REAR SEAL

AREA LEAKS........................209

REMOVAL............................209

INSTALLATION........................209

CRANKSHAFT REAR OIL SEAL RETAINER

REMOVAL............................209

INSTALLATION........................210

FLEX PLATE

REMOVAL............................210

INSTALLATION........................210

HYDRAULIC TAPPETS

DIAGNOSIS AND TESTING - HYDRAULIC

TAPPETS...........................210

REMOVAL............................211

INSTALLATION........................211

PISTON & CONNECTING ROD

DESCRIPTION........................211

9 - 180 ENGINE - 5.7LDR

Page 1453 of 2627

ENGINE 5.9L DIESEL

TABLE OF CONTENTS

page page

ENGINE 5.9L DIESEL

DESCRIPTION........................232

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE

DIAGNOSIS - MECHANICAL............233

DIAGNOSIS AND TESTINGÐSMOKE

DIAGNOSIS CHARTS.................236

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION/LEAKAGE TESTS.......239

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS........239

STANDARD PROCEDURE - REPAIR

DAMAGED OR WORN THREADS........240

STANDARD PROCEDUREÐHYDROSTATIC

LOCK..............................240

REMOVAL

REMOVAL - ENGINE..................241

REMOVALÐCRANKCASE BREATHER....242

INSTALLATION

INSTALLATION - ENGINE..............242

INSTALLATIONÐCRANKCASE BREATHER . 243

SPECIFICATIONS

SPECIFICATIONS - 5.9L DIESEL.........244

TORQUE...........................245

SPECIAL TOOLS

5.9L DIESEL ENGINE.................246

ENGINE DATA PLATE

DESCRIPTION........................248

AIR CLEANER ELEMENT

REMOVAL............................248

INSTALLATION........................249

CYLINDER HEAD

DESCRIPTION........................249

REMOVAL............................249

CLEANING

CLEANINGÐCYLINDER HEAD..........251

CLEANINGÐCROSSHEADS............251

CLEANINGÐPUSHRODS..............252

INSPECTION

INSPECTION - CYLINDER HEAD.........252

INSPECTIONÐCROSSHEADS..........252

INSPECTIONÐPUSHRODS.............253

INSTALLATION........................253

CYLINDER HEAD COVER(S)

REMOVAL

REMOVALÐCYLINDER HEAD COVER....255

REMOVALÐROCKER HOUSING.........255

CLEANING...........................255INSPECTION.........................255

INSTALLATION

INSTALLATIONÐCYLINDER HEAD COVER . 255

INSTALLATION - ROCKER HOUSING.....255

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION........................256

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVES,

GUIDES AND SPRINGS................256

STANDARD PROCEDURE - VALVE LASH

ADJUSTMENT AND VERIFICATION.......259

REMOVAL - VALVE SPRINGS AND SEALS . . . 260

INSTALLATION........................261

ROCKER ARM / ADJUSTER ASSY

DESCRIPTION........................261

REMOVAL............................261

CLEANING...........................262

INSPECTION.........................262

INSTALLATION........................263

ENGINE BLOCK

STANDARD PROCEDURE

STANDARD PROCEDURE - CYLINDER

BLOCK REFACING...................264

STANDARD PROCEDURE - CYLINDER

BORE - DE-GLAZE...................264

STANDARD PROCEDUREÐCYLINDER

BORE REPAIR.......................265

STANDARD PROCEDUREÐCAM BORE

REPAIR ............................267

INSPECTION.........................267

CAMSHAFT & BEARINGS (IN BLOCK)

REMOVAL

REMOVALÐCAMSHAFT BEARINGS......268

REMOVAL - CAMSHAFT...............268

INSPECTION.........................270

INSTALLATION

INSTALLATION - CAMSHAFT BEARINGS . . 271

INSTALLATION - CAMSHAFT............271

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING

ROD BEARING AND CRANKSHAFT

JOURNAL CLEARANCE................272

CRANKSHAFT AND GEAR

DESCRIPTION........................273

REMOVAL - GEAR.....................273

INSTALLATION - GEAR..................273

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE - MAIN BEARING

CLEARANCE........................274

9 - 230 ENGINE 5.9L DIESELDR

Page 1526 of 2627

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

EXHAUST SYSTEM

DESCRIPTION

DESCRIPTION........................1

DESCRIPTION - 5.9L DIESEL.............3

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - GAS ENGINE . . . 4

DIAGNOSIS AND TESTING - DIESEL

ENGINE..............................5

SPECIFICATIONS - TORQUE...............5

SPECIAL TOOLS........................6

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER.....6

OPERATION............................6

REMOVAL

REMOVAL............................6

REMOVAL............................6

INSPECTION...........................6

INSTALLATION

INSTALLATION........................6

INSTALLATION........................7

EXHAUST PIPE

REMOVAL - 3.7L/4.7L/5.7L.................7

INSPECTION...........................7

INSTALLATION - 3.7L/4.7L/5.7L..............7

EXHAUST PIPE

REMOVAL - DIESEL......................7

INSPECTION...........................8

INSTALLATION - DIESEL..................8

HEAT SHIELDS

DESCRIPTION..........................8

REMOVAL.............................8

INSTALLATION..........................8

MUFFLER

REMOVAL.............................9INSTALLATION..........................9

MUFFLER - 5.9L DIESEL

REMOVAL.............................10

INSTALLATION.........................10

TAILPIPE - 5.9L DIESEL

REMOVAL.............................10

INSPECTION..........................10

INSTALLATION.........................11

TAILPIPE

REMOVAL.............................11

INSPECTION..........................11

INSTALLATION.........................11

TURBOCHARGER SYSTEM

DIAGNOSIS AND TESTING -

TURBOCHARGER BOOST PRESSURE.....11

TURBOCHARGER

DESCRIPTION.........................12

OPERATION...........................13

REMOVAL.............................14

CLEANING............................15

INSPECTION..........................15

INSTALLATION.........................15

CHARGE AIR COOLER AND PLUMBING

DESCRIPTION.........................16

OPERATION...........................16

DIAGNOSIS AND TESTING - CHARGE AIR

COOLER SYSTEM - LEAKS..............16

REMOVAL.............................17

CLEANING............................17

INSPECTION..........................17

INSTALLATION.........................17

EXHAUST SYSTEM

DESCRIPTION

DESCRIPTION

CAUTION: Avoid application of rust prevention com-

pounds or undercoating materials to exhaust sys-

tem floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.The federal gasoline engine exhaust system con-

sists of engine exhaust manifolds, exhaust pipes, cat-

alytic converter(s), extension pipe (if needed),

exhaust heat shields, muffler and exhaust tailpipe

(Fig. 1), (Fig. 2), (Fig. 3)

The California emission vehicles exhaust system

also contains the above components as well as mini

catalytic converters added to the exhaust pipe.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. Minimum

clearance between any exhaust component and the

body or frame is 25.4 mm (1.0 in.). If the system con-

tacts any body panel, it may amplify objectionable

noises from the engine or body.

DREXHAUST SYSTEM 11 - 1

Page 1544 of 2627

FRAMES & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

SPECIFICATIONS - TORQUE...............1

FRONT AIR DAM

REMOVAL.............................2

INSTALLATION..........................2

FRONT BUMPER

REMOVAL.............................2

INSTALLATION..........................2

FRONT FASCIA

REMOVAL.............................2

INSTALLATION..........................3

REAR BUMPER

REMOVAL.............................3

INSTALLATION..........................4

FRAME

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 4

STANDARD PROCEDURE

STANDARD PROCEDURE - LIGHT DUTY

FRONT FRAME RAIL TIP REPLACEMENT....4

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR.................11

STANDARD PROCEDURE - REAR FRAME

H-SECTION REPLACEMENT.............13SPECIFICATIONS

SPECIFICATIONS - WELD PROCESS......15

SPECIFICATIONS - FRAME DIMENSIONS . . . 16

SPECIFICATIONS - TORQUE............22

FRONT CROSSMEMBER

REMOVAL.............................22

INSTALLATION.........................22

FRONT SKID PLATE

REMOVAL.............................23

INSTALLATION.........................23

FRONT TOW HOOK ASSEMBLY

REMOVAL.............................23

INSTALLATION.........................23

TRANSMISSION CROSSMEMBER

REMOVAL.............................24

INSTALLATION.........................24

TRAILER HITCH

REMOVAL.............................25

INSTALLATION.........................25

TRANSFER CASE SKID PLATE

REMOVAL.............................26

INSTALLATION.........................26

BUMPERS

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front bumper center bracket nuts 95 70 Ð

Front bumper stud plate nuts 95 70 Ð

License plate hitch reinforcement bolts 54 40 Ð

Rear bumper support bracket stud plate nuts 54 40 Ð

Rear bumper support bracket to hitch bolts 54 40 Ð

Rear bumper to hitch bolts 54 40 Ð

DRFRAMES & BUMPERS 13 - 1

Page 1570 of 2627

FUEL SYSTEM

TABLE OF CONTENTS

page page

FUEL DELIVERY - GAS....................1

FUEL INJECTION - GAS...................21FUEL DELIVERY - DIESEL.................44

FUEL INJECTION - DIESEL................68

FUEL DELIVERY - GAS

TABLE OF CONTENTS

page page

FUEL DELIVERY - GAS

DESCRIPTION..........................1

OPERATION............................2

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE...................2

SPECIFICATIONS

FUEL SYSTEM PRESSURE..............3

TORQUE - FUEL SYSTEM - EXCEPT

DIESEL..............................3

SPECIAL TOOLS

FUEL SYSTEM........................5

FUEL FILTER/PRESSURE REGULATOR

DESCRIPTION..........................5

OPERATION............................6

FUEL LEVEL SENDING UNIT / SENSOR

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................7

INSTALLATION..........................7

FUEL LINES

DESCRIPTION..........................7

QUICK CONNECT FITTING

DESCRIPTION..........................8STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS............................8

FUEL PUMP

DESCRIPTION.........................11

OPERATION...........................11

FUEL PUMP MODULE

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................12

INSTALLATION.........................12

FUEL RAIL

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................13

INSTALLATION.........................15

FUEL TANK

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL- EXCEPT DIESEL..............17

INSTALLATION - EXCEPT DIESEL..........19

INLET FILTER

REMOVAL.............................20

INSTALLATION.........................20

FUEL DELIVERY - GAS

DESCRIPTION

The fuel delivery system consists of:

²a fuel pump module containing the electric fuel

pump, fuel filter/fuel pressure regulator, fuel gauge

sending unit (fuel level sensor) and a secondary fuel

filter located at the bottom of the pump module

²fuel tubes/lines/hoses

²a combination fuel filter/fuel pressure regulator

²quick-connect fittings²fuel injector rail

²fuel tank

²fuel tank filler/vent tube assembly

²fuel tank filler tube cap

²accelerator pedal

²throttle cable

Certain fuel delivery components can be found in

(Fig. 1).

DRFUEL SYSTEM 14 - 1

Page 1590 of 2627

FUEL INJECTION - GAS

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL

REMOVAL.............................21

INSTALLATION.........................21

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................22

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................24

INSTALLATION.........................25

FUEL INJECTOR

DESCRIPTION.........................26

OPERATION

OPERATION - FUEL INJECTOR..........26

OPERATION - PCM OUTPUT............27

REMOVAL.............................27

INSTALLATION.........................27

FUEL PUMP RELAY

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................28

INSTALLATION.........................28

IDLE AIR CONTROL MOTOR

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................29

INSTALLATION.........................29INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION.........................30

OPERATION...........................30

REMOVAL.............................30

INSTALLATION.........................31

MAP SENSOR

DESCRIPTION.........................32

OPERATION...........................32

REMOVAL.............................33

INSTALLATION.........................34

OXYGEN SENSOR

DESCRIPTION.........................35

REMOVAL.............................35

INSTALLATION.........................36

PTO SWITCH

DESCRIPTION.........................36

OPERATION...........................36

THROTTLE BODY

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................37

THROTTLE CONTROL CABLE

REMOVAL.............................38

INSTALLATION.........................40

THROTTLE POSITION SENSOR

DESCRIPTION.........................41

OPERATION...........................41

REMOVAL.............................41

INSTALLATION.........................43

ACCELERATOR PEDAL

REMOVAL

The following procedure applies only to vehicles

without the Adjustable Pedal Package (code XAP).

The accelerator pedal is serviced as a complete

assembly including the bracket.

The accelerator cable is connected to the upper

part of the accelerator pedal arm by a plastic

retainer (clip) (Fig. 1). This plastic retainer snaps

into the top of the accelerator pedal arm.

(1) From inside the vehicle, hold up accelerator

pedal. Remove plastic cable retainer (clip) and throt-

tle cable core wire from upper end of accelerator

pedal arm (Fig. 1). Plastic cable retainer (clip) snaps

into pedal arm.(2) Remove 2 accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.INSTALLATION

(1) Place accelerator pedal assembly over 2 studs.

(2) Install and tighten 2 mounting nuts. Refer to

Torque Specifications.

(3) Slide throttle cable into opening slot in top of

pedal arm.

(4) Push plastic cable retainer (clip) into accelera-

tor pedal arm opening until it snaps into place.

(5) Before starting engine, operate accelerator

pedal to check for any binding.

DRFUEL INJECTION - GAS 14 - 21

Page 1613 of 2627

FUEL DELIVERY - DIESEL

TABLE OF CONTENTS

page page

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM.....45

STANDARD PROCEDURE

STANDARD PROCEDURES - WATER

DRAINING AT FUEL FILTER..............47

STANDARD PROCEDURES - CLEANING

FUEL SYSTEM PARTS.................47

STANDARD PROCEDURE - FUEL SYSTEM

PRIMING............................47

SPECIFICATIONS

FUEL INJECTOR FIRING ORDER - DIESEL . 48

TORQUE - FUEL SYSTEM - DIESEL

ENGINE.............................48

SPECIAL TOOLS

DIESEL FUEL SYSTEM.................49

FUEL FILTER / WATER SEPARATOR

DESCRIPTION.........................50

OPERATION...........................50

REMOVAL.............................50

INSTALLATION.........................50

FUEL HEATER

DESCRIPTION.........................51

OPERATION...........................51

DIAGNOSIS AND TESTING - FUEL HEATER . . . 52

REMOVAL

REMOVAL/INSTALLATION...............52

FUEL HEATER RELAY

DESCRIPTION.........................52

OPERATION...........................52

REMOVAL.............................52

INSTALLATION.........................53

FUEL INJECTION PUMP

DESCRIPTION.........................53

OPERATION...........................53

DIAGNOSIS AND TESTING - FUEL INJECTION

PUMP TIMING........................53

REMOVAL.............................54

INSTALLATION.........................55

FUEL LEVEL SENDING UNIT / SENSOR

DESCRIPTION.........................57

OPERATION...........................57

REMOVAL

REMOVAL/INSTALLATION...............57FUEL LINES

DESCRIPTION.........................57

OPERATION...........................57

DIAGNOSIS AND TESTING - HIGH-

PRESSURE FUEL LINE LEAKS...........58

REMOVAL.............................58

INSTALLATION.........................60

FUEL PRESSURE SENSOR

DESCRIPTION.........................60

OPERATION...........................60

REMOVAL.............................60

INSTALLATION.........................61

FUEL PRESSURE LIMITING VALVE

DESCRIPTION.........................61

OPERATION...........................61

REMOVAL.............................61

INSTALLATION.........................61

FUEL TANK

DESCRIPTION - DIESEL..................62

REMOVAL - DIESEL.....................62

INSTALLATION - DIESEL.................62

FUEL TANK MODULE

DESCRIPTION.........................63

OPERATION...........................63

REMOVAL.............................63

INSTALLATION.........................64

FUEL TRANSFER PUMP

DESCRIPTION.........................64

OPERATION...........................64

REMOVAL.............................64

INSTALLATION.........................65

CASCADE OVERFLOW VALVE

DESCRIPTION.........................66

OPERATION...........................66

REMOVAL

REMOVAL/INSTALLATION...............66

WATER IN FUEL SENSOR

DESCRIPTION.........................66

OPERATION...........................66

REMOVAL.............................66

FUEL DRAIN CIRCUIT

OPERATION...........................67

14 - 44 FUEL DELIVERY - DIESELDR

Page 1637 of 2627

FUEL INJECTION - DIESEL

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................68

OPERATION...........................68

REMOVAL.............................68

INSTALLATION.........................71

CAMSHAFT POSITION SENSOR

DESCRIPTION.........................71

OPERATION...........................71

REMOVAL.............................72

INSTALLATION.........................72

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................72

OPERATION...........................72

REMOVAL.............................73

INSTALLATION.........................73

FUEL CONTROL ACTUATOR

DESCRIPTION.........................74

OPERATION...........................74

REMOVAL.............................74

FUEL INJECTOR

DESCRIPTION.........................74

OPERATION...........................74

REMOVAL.............................75

INSTALLATION.........................77

FUEL INJECTOR RAIL

DESCRIPTION.........................78

OPERATION...........................78

REMOVAL.............................78

INSTALLATION.........................78INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR

DESCRIPTION.........................79

OPERATION...........................79

REMOVAL.............................79

INSTALLATION.........................79

INTAKE AIR HEATER

DESCRIPTION.........................80

OPERATION...........................80

REMOVAL.............................80

INSTALLATION.........................80

INTAKE AIR HEATER RELAY

DESCRIPTION.........................82

OPERATION...........................82

REMOVAL.............................82

INSTALLATION.........................82

INTAKE AIR TEMPERATURE SENSOR/MAP

SENSOR

DESCRIPTION.........................82

OPERATION...........................82

REMOVAL.............................82

INSTALLATION.........................82

MAP SENSOR

DESCRIPTION.........................83

THROTTLE CONTROL CABLE

REMOVAL.............................83

INSTALLATION.........................84

PTO SWITCH

DESCRIPTION.........................85

OPERATION...........................85

ACCELERATOR PEDAL

POSITION SENSOR

DESCRIPTION

Engine Mounted Sensor:The APPS assembly is

located at the top-left-front of the engine. A plastic

cover is used to cover the assembly. The actual sen-

sor is located behind its mounting bracket.

Battery Tray Mounted Sensor:The Accelerator

Pedal Position Sensor (APPS) assembly is located

under the vehicle battery tray. A cable connects the

assembly to the accelerator pedal. A plastic cover

with a movable door is used to cover the assembly.

OPERATION

Engine Mounted Sensor:The Accelerator Pedal

Position Sensor (APPS) is a linear potentiometer. Itprovides the Engine Control Module (ECM) with a

DC voltage signal proportional to the angle, or posi-

tion of the accelerator pedal.

Battery Tray Mounted Sensor:The APPS pro-

vides the ECM with two DC voltage signals which

change as the position of the accelerator changes.

One of the DC voltage signals will be half the voltage

of the other signal.

REMOVAL

Engine Mounted Sensor :

The APPS is serviced (replaced) as one assembly

including the lever, brackets and sensor. The APPS is

calibrated to its mounting bracket. The APPS assem-

bly is located at left-front of engine below plastic

cable/lever/linkage cover (Fig. 1).

14 - 68 FUEL INJECTION - DIESELDR

Page 1656 of 2627

STEERING

TABLE OF CONTENTS

page page

STEERING

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER

STEERING SYSTEM....................2

DIAGNOSIS AND TESTING - POWER

STEERING FLOW AND PRESSURE........4

SPECIAL TOOLS

STEERING...........................5COLUMN...............................6

GEAR - INDEPENDENT FRONT SUSPENSION..17

GEAR - LINK/COIL.......................20

LINKAGE - INDEPENDENT FRONT

SUSPENSION...........................32

LINKAGE - LINK/COIL....................34

PUMP.................................39

STEERING

DESCRIPTION

CAUTION: MOPARTATF+4 is to be used in the

power steering system. No other power steering or

automatic transmission fluid is to be used in the

system. Damage may result to the power steering

pump and system if any other fluid is used, and do

not overfill.

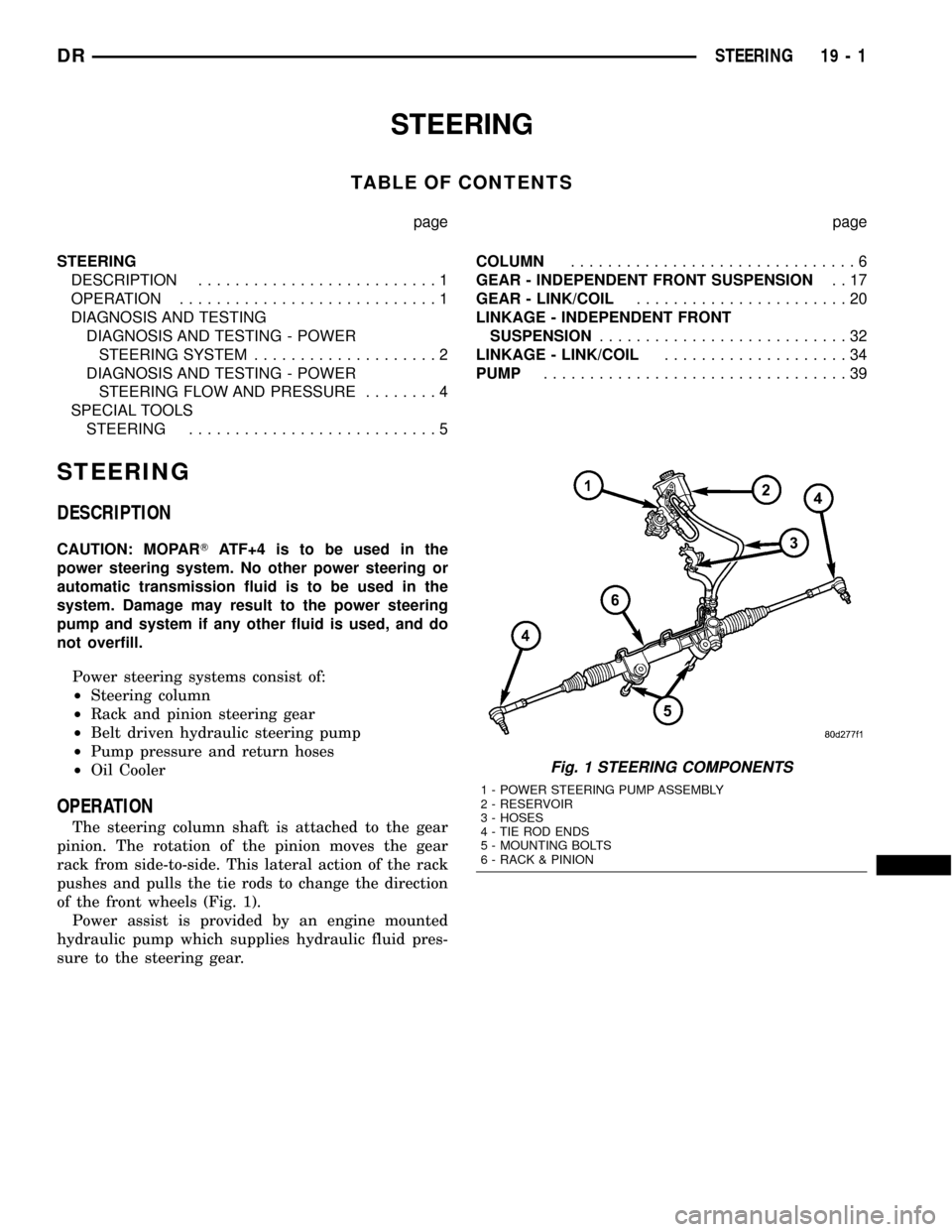

Power steering systems consist of:

²Steering column

²Rack and pinion steering gear

²Belt driven hydraulic steering pump

²Pump pressure and return hoses

²Oil Cooler

OPERATION

The steering column shaft is attached to the gear

pinion. The rotation of the pinion moves the gear

rack from side-to-side. This lateral action of the rack

pushes and pulls the tie rods to change the direction

of the front wheels (Fig. 1).

Power assist is provided by an engine mounted

hydraulic pump which supplies hydraulic fluid pres-

sure to the steering gear.

Fig. 1 STEERING COMPONENTS

1 - POWER STEERING PUMP ASSEMBLY

2 - RESERVOIR

3 - HOSES

4 - TIE ROD ENDS

5 - MOUNTING BOLTS

6 - RACK & PINION

DRSTEERING 19 - 1

Page 1661 of 2627

COLUMN

TABLE OF CONTENTS

page page

COLUMN

DESCRIPTION..........................6

DIAGNOSIS AND TESTING - STEERING

COLUMN.............................7

REMOVAL.............................7

INSTALLATION..........................9

IGNITION SWITCH

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - IGNITION

SWITCH.............................9

REMOVAL.............................10

INSTALLATION.........................11

KEY-IN IGNITION SWITCH

DESCRIPTION.........................11

DIAGNOSIS AND TESTING - IGNITION

SWITCH AND KEY LOCK CYLINDER.......11

KEY CYLINDER

REMOVAL.............................12

INSTALLATION.........................12GEAR SHIFT LEVER

REMOVAL.............................12

INSTALLATION.........................12

UPPER STEERING COUPLING

REMOVAL.............................13

INSTALLATION.........................13

LOWER STEERING COUPLING

REMOVAL

REMOVAL - ALL LD & HD EXCEPT 4X4 HD . 14

REMOVAL - 4X4 HD...................14

INSTALLATION

INSTALLATION - ALL LD & HD EXCEPT 4X4

HD.................................14

INSTALLATION - 4X4 HD................15

STEERING WHEEL

REMOVAL.............................15

INSTALLATION.........................15

TILT LEVER KNOB RELEASE

REMOVAL.............................16

INSTALLATION.........................16

COLUMN

DESCRIPTION

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative meth-

ods of locking the steering wheel for service will

have to be used.

The tilt and standard column (Fig. 1) has been

designed to be serviced as an assembly; less wiring,

switches, shrouds, steering wheel, etc. Most steering

column components can be serviced without remov-

ing the steering column from the vehicle.

To service the steering wheel, switches or airbag,

refer to Restraints and follow all WARNINGS and

CAUTIONS.

WARNING: THE AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIRBAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT INACCIDENTAL DEPLOYMENT OF THE AIRBAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIRBAG COMPONENTS, HAVE SPECIAL COAT-

INGS AND ARE SPECIFICALLY DESIGNED FOR THE

AIRBAG SYSTEM. THEY MUST NEVER BE

REPLACED WITH ANY SUBSTITUTES. ANYTIME A

NEW FASTENER IS NEEDED, REPLACE WITH THE

CORRECT FASTENERS PROVIDED IN THE SERVICE

PACKAGE OR FASTENERS LISTED IN THE PARTS

BOOKS.

CAUTION: Do not hammer on steering column

shaft. This may cause damage to the shaft or bear-

ing.

CAUTION: Do not attempt to remove the pivot bolts

to disassemble the tilting mechanism. Do not

remove shaft lock plate or plate retainer. This will

damage the column.

CAUTION: Do not attempt to remove or modify the

park lock slider or link.

19 - 6 COLUMNDR