Fuel injector DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1610 of 2627

(11) Install air resonator tube to throttle body.

(12) Before starting engine, operate accelerator

pedal to check for any binding.

5.7L V-8

(1) Attach cable to Accelerator Pedal Position Sen-

sor (APPS). Refer to APPS Removal / Installation.

(2) Push cable housing into rubber grommet and

through opening in dash panel.

(3) From inside vehicle, install clip holding cable

to dashpanel (Fig. 1).

(4) From inside vehicle, slide throttle cable core

wire into opening in top of pedal arm.

(5) Push cable retainer (clip) into pedal arm open-

ing until it snaps in place.

(6) Before starting engine, operate accelerator

pedal to check for any binding.

(7) If necessary, use DRB IIItScan Tool to erase

any APPS Diagnostic Trouble Codes (DTC's) from

PCM.

THROTTLE POSITION SENSOR

DESCRIPTION

The 3-wire Throttle Position Sensor (TPS) is

mounted on the throttle body and is connected to the

throttle blade shaft.

The 5.7L V-8 engine does not use a separate TPS

on the throttle body.

OPERATION

The 5.7L V-8 engine does not use a separate Throt-

tle Position Sensor (TPS) on the throttle body.

The 3±wire TPS provides the Powertrain Control

Module (PCM) with an input signal (voltage) that

represents the throttle blade position of the throttle

body. The sensor is connected to the throttle blade

shaft. As the position of the throttle blade changes,

the output voltage of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the TPS.

This will vary in an approximate range of from .26

volts at minimum throttle opening (idle), to 4.49 volts

at wide open throttle. Along with inputs from other

sensors, the PCM uses the TPS input to determine

current engine operating conditions. In response to

engine operating conditions, the PCM will adjust fuel

injector pulse width and ignition timing.The PCM needs to identify the actions and position

of the throttle blade at all times. This information is

needed to assist in performing the following calcula-

tions:

²Ignition timing advance

²Fuel injection pulse-width

²Idle (learned value or minimum TPS)

²Off-idle (0.06 volt)

²Wide Open Throttle (WOT) open loop (2.608

volts above learned idle voltage)

²Deceleration fuel lean out

²Fuel cutoff during cranking at WOT (2.608 volts

above learned idle voltage)

²A/C WOT cutoff (certain automatic transmis-

sions only)

REMOVAL

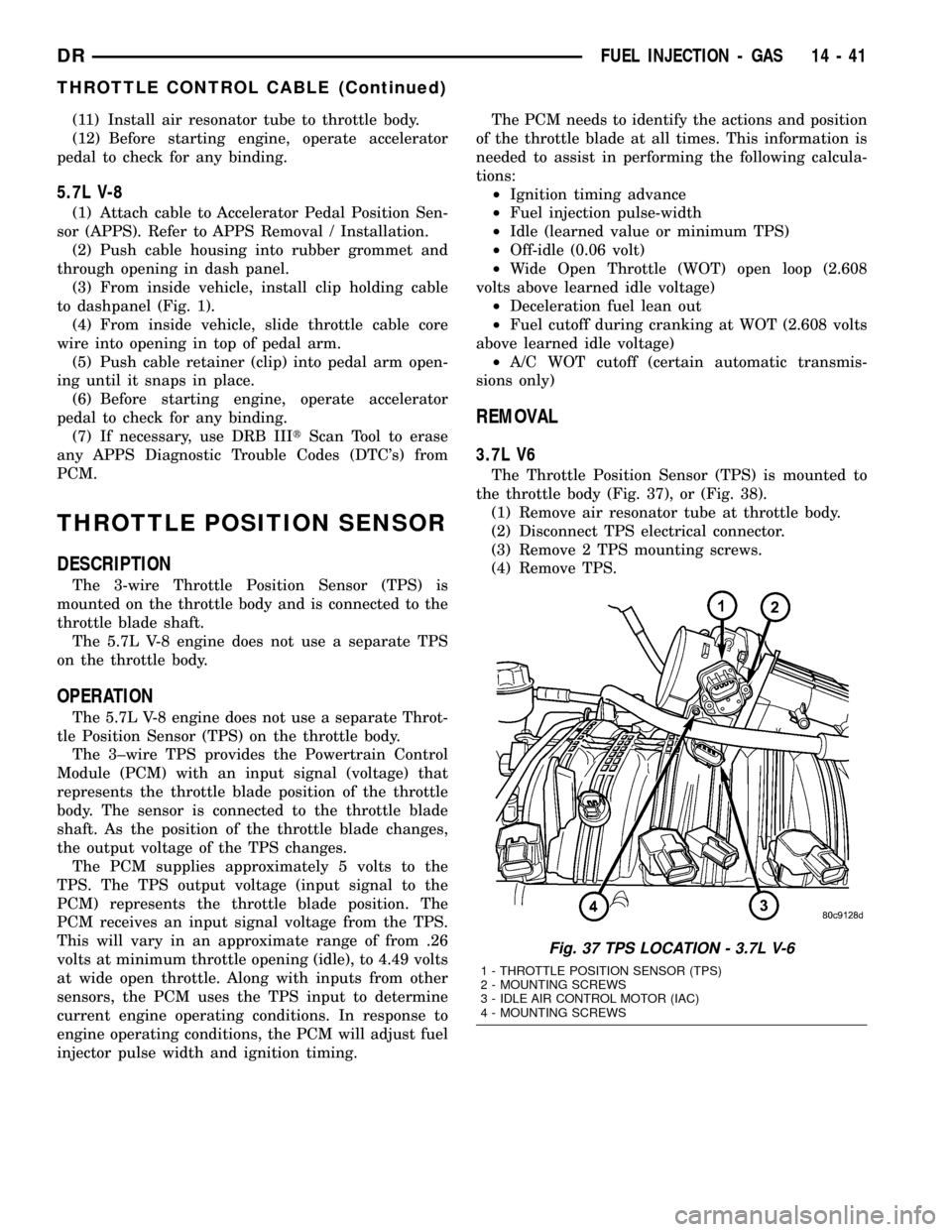

3.7L V6

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 37), or (Fig. 38).

(1) Remove air resonator tube at throttle body.

(2) Disconnect TPS electrical connector.

(3) Remove 2 TPS mounting screws.

(4) Remove TPS.

Fig. 37 TPS LOCATION - 3.7L V-6

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

DRFUEL INJECTION - GAS 14 - 41

THROTTLE CONTROL CABLE (Continued)

Page 1613 of 2627

FUEL DELIVERY - DIESEL

TABLE OF CONTENTS

page page

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM.....45

STANDARD PROCEDURE

STANDARD PROCEDURES - WATER

DRAINING AT FUEL FILTER..............47

STANDARD PROCEDURES - CLEANING

FUEL SYSTEM PARTS.................47

STANDARD PROCEDURE - FUEL SYSTEM

PRIMING............................47

SPECIFICATIONS

FUEL INJECTOR FIRING ORDER - DIESEL . 48

TORQUE - FUEL SYSTEM - DIESEL

ENGINE.............................48

SPECIAL TOOLS

DIESEL FUEL SYSTEM.................49

FUEL FILTER / WATER SEPARATOR

DESCRIPTION.........................50

OPERATION...........................50

REMOVAL.............................50

INSTALLATION.........................50

FUEL HEATER

DESCRIPTION.........................51

OPERATION...........................51

DIAGNOSIS AND TESTING - FUEL HEATER . . . 52

REMOVAL

REMOVAL/INSTALLATION...............52

FUEL HEATER RELAY

DESCRIPTION.........................52

OPERATION...........................52

REMOVAL.............................52

INSTALLATION.........................53

FUEL INJECTION PUMP

DESCRIPTION.........................53

OPERATION...........................53

DIAGNOSIS AND TESTING - FUEL INJECTION

PUMP TIMING........................53

REMOVAL.............................54

INSTALLATION.........................55

FUEL LEVEL SENDING UNIT / SENSOR

DESCRIPTION.........................57

OPERATION...........................57

REMOVAL

REMOVAL/INSTALLATION...............57FUEL LINES

DESCRIPTION.........................57

OPERATION...........................57

DIAGNOSIS AND TESTING - HIGH-

PRESSURE FUEL LINE LEAKS...........58

REMOVAL.............................58

INSTALLATION.........................60

FUEL PRESSURE SENSOR

DESCRIPTION.........................60

OPERATION...........................60

REMOVAL.............................60

INSTALLATION.........................61

FUEL PRESSURE LIMITING VALVE

DESCRIPTION.........................61

OPERATION...........................61

REMOVAL.............................61

INSTALLATION.........................61

FUEL TANK

DESCRIPTION - DIESEL..................62

REMOVAL - DIESEL.....................62

INSTALLATION - DIESEL.................62

FUEL TANK MODULE

DESCRIPTION.........................63

OPERATION...........................63

REMOVAL.............................63

INSTALLATION.........................64

FUEL TRANSFER PUMP

DESCRIPTION.........................64

OPERATION...........................64

REMOVAL.............................64

INSTALLATION.........................65

CASCADE OVERFLOW VALVE

DESCRIPTION.........................66

OPERATION...........................66

REMOVAL

REMOVAL/INSTALLATION...............66

WATER IN FUEL SENSOR

DESCRIPTION.........................66

OPERATION...........................66

REMOVAL.............................66

FUEL DRAIN CIRCUIT

OPERATION...........................67

14 - 44 FUEL DELIVERY - DIESELDR

Page 1614 of 2627

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM

The fuel system used on the Cummins engine is an

electronically controlled, Bosch HPCR (High-Pressure

Common Rail) system. The HPCR system consists of

five main components:

²Electric Fuel Transfer (lift) Pump

²Fuel Pump/Gear Pump (attached to fuel injec-

tion pump)

²High-Pressure Fuel Injection Pump

²Fuel Injection Rail

²Fuel Injectors

Also to be considered as part of the overall fuel

system are:

²Accelerator Pedal

²Air Cleaner Housing/Element

²Fuel Drain Manifold (passage)

²Fuel Drain Valve (at filter)

²Fuel Filter/Water Separator

²Fuel Heater

²Fuel Heater Relay

²Fuel Level (gauge) Sending Unit

²Fuel Pressure Limiting Valve

²Fuel Tank

²Fuel Tank Module (containing fuel gauge send-

ing unit and separate fuel filter located at bottom of

tank module)

²Fuel Tank Filler/Vent Tube Assembly

²Fuel Tank Filler Tube Cap

²Fuel Tubes/Lines/Hoses

²High-Pressure Fuel Injector Lines

²In-Tank Fuel Filter (at bottom of fuel tank mod-

ule)

²Low-Pressure Fuel Supply Lines

²Low-Pressure Fuel Return Line

²Overflow Valve

²Quick-Connect Fuel Line Fittings

²Throttle Cable

²Water Draining (maintenance)

²Water-In-Fuel (WIF) Sensor

The fuel injection pump supplies high pressure to

the fuel rail independent of engine speed. This high

pressure fuel is then accumulated in the fuel rail.

High pressure fuel is constantly supplied to the injec-

tors by the fuel rail. The Engine Control Module

(ECM) controls the fueling and timing of the engine

by actuating the injectors.Fuel enters the system from the electric fuel trans-

fer (lift) pump, which is attached to the fuel filter

assembly. Fuel is forced through the fuel filter ele-

ment and then enters the Fuel Pump/Gear Pump,

which is attached to the rear of the fuel injection

pump. The Fuel Pump/Gear Pump is a low-pressure

pump and produce pressures ranging from 551.5 kpa

(80 psi) to 1241 kpa (180) psi. Fuel then enters the

fuel injection pump. Low pressure fuel is then sup-

plied to the FCA (Fuel Control Actuator).

The FCA is an electronically controlled solenoid

valve. The ECM controls the amount of fuel that

enters the high-pressure pumping chambers by open-

ing and closing the FCA based on a demanded fuel

pressure. The FPS (Fuel Pressure Sensor) on the fuel

rail monitors the actual fuel pressure and provides it

as an input to the ECM. When the actuator is

opened, the maximum amount of fuel is being sup-

plied to the fuel injection pump. Any fuel that does

not enter the injection pump is directed to the over-

flow valve. The overflow valve regulates how much

excess fuel is used for lubrication of the pump and

how much is returned to the tank through the drain

manifold.

Fuel entering the injection pump is pressurized to

between 300-1600 bar (4351-23,206 psi) by three

radial pumping chambers. The pressurized fuel is

then supplied to the fuel rail.

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 160,000 KPA (23,206

PSI). USE EXTREME CAUTION WHEN INSPECTING

FOR HIGH-PRESSURE FUEL LEAKS. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD. HIGH FUEL INJECTION PRESSURE

CAN CAUSE PERSONAL INJURY IF CONTACT IS

MADE WITH THE SKIN.

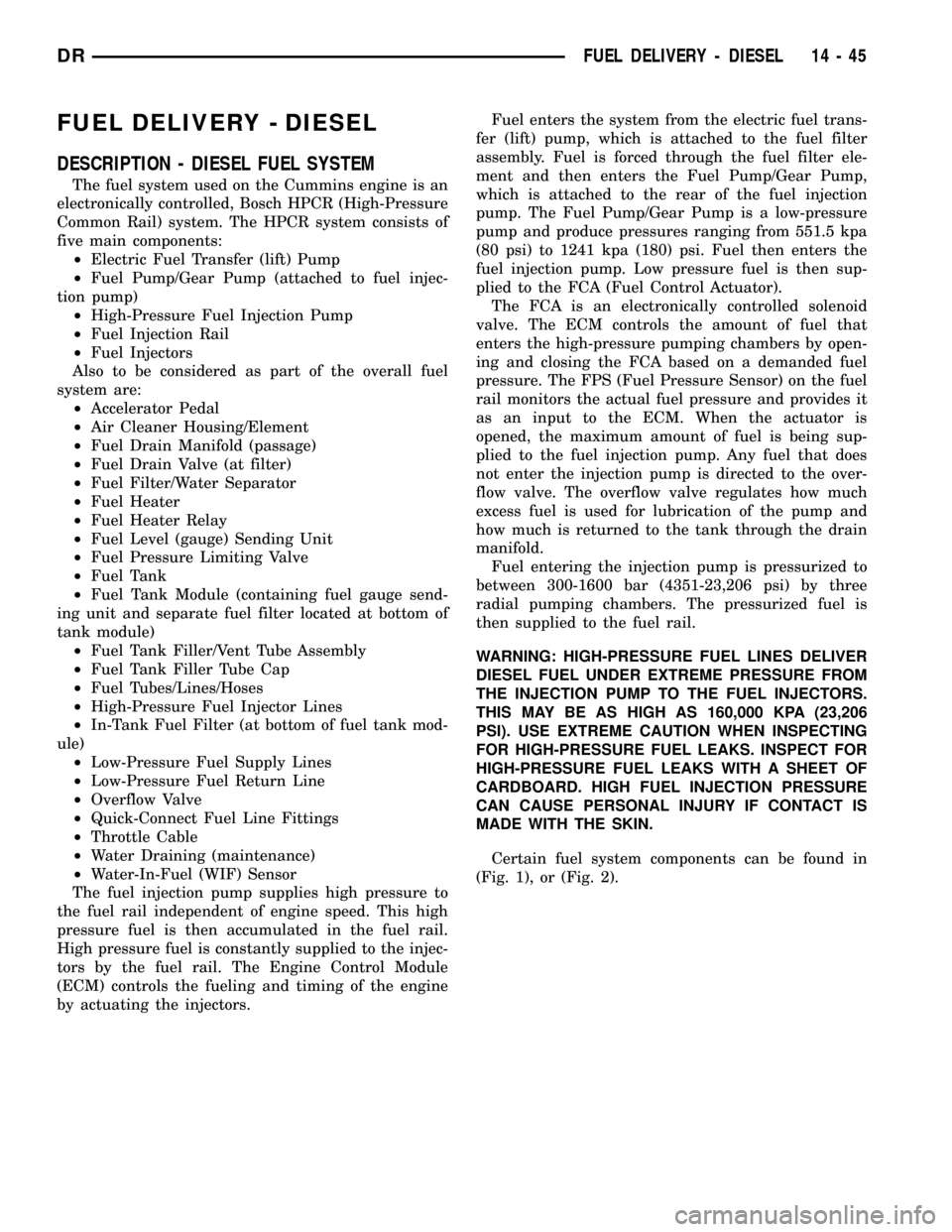

Certain fuel system components can be found in

(Fig. 1), or (Fig. 2).

DRFUEL DELIVERY - DIESEL 14 - 45

Page 1616 of 2627

STANDARD PROCEDURE

STANDARD PROCEDURES - WATER DRAINING

AT FUEL FILTER

Refer to Fuel Filter/Water Separator removal/in-

stallation for procedures.

STANDARD PROCEDURES - CLEANING FUEL

SYSTEM PARTS

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

STANDARD PROCEDURE - FUEL SYSTEM

PRIMING

A certain amount of air becomes trapped in the

fuel system when fuel system components on the

supply and/or high-pressure side are serviced or

replaced. Fuel system priming is accomplished using

the electric fuel transfer (lift) pump.

Servicing or replacing fuel system components will

not require fuel system priming.

The fuel transfer (lift) pump is self-priming: When

the key is first turned on (without cranking engine),

the pump operates for approximately 1 to 2 second

and then shuts off. The pump will also operate for up

to 25 seconds after the starter is quickly engaged,

and then disengaged without allowing the engine to

start. The pump shuts off immediately if the key is

on and the engine stops running.

(1) Turn key to CRANK position and quickly

release key to ON position before engine starts. This

will operate fuel transfer pump for approximately 25

seconds.

(2) Crank engine. If the engine does not start after

25 seconds, turn key OFF. Repeat previous step until

engine starts.

(3) Fuel system priming is now completed.

(4) Attempt to start engine. If engine will not

start, proceed to following steps.When engine does

start, it may run erratically and be noisy for a

few minutes. This is a normal condition.

CAUTION: Do not engage the starter motor for more

than 30 seconds at a time. Allow two minutes

between cranking intervals.

(5) Perform previous fuel priming procedure steps

using fuel transfer pump. Be sure fuel is present at

fuel tank.

(6) Crank the engine for 30 seconds at a time to

allow fuel system to prime.

WARNING: THE FUEL INJECTION PUMP SUPPLIES

EXTREMELY HIGH FUEL PRESSURE TO EACH INDI-

VIDUAL INJECTOR THROUGH THE HIGH-PRES-

SURE LINES. FUEL UNDER THIS AMOUNT OF

PRESSURE CAN PENETRATE THE SKIN AND

CAUSE PERSONAL INJURY. WEAR SAFETY GOG-

GLES AND ADEQUATE PROTECTIVE CLOTHING.

DO NOT LOOSEN FUEL FITTINGS WHILE ENGINE

IS RUNNING.

WARNING: ENGINE MAY START WHILE CRANKING

STARTER MOTOR.

Fig. 2 FUEL INJECTORS

1 - SOLENOID CONNECTIONS

2 - ROCKER HOUSING

3 - FUEL INJECTOR

4 - PASSTHROUGH CONNECTOR

DRFUEL DELIVERY - DIESEL 14 - 47

FUEL DELIVERY - DIESEL (Continued)

Page 1617 of 2627

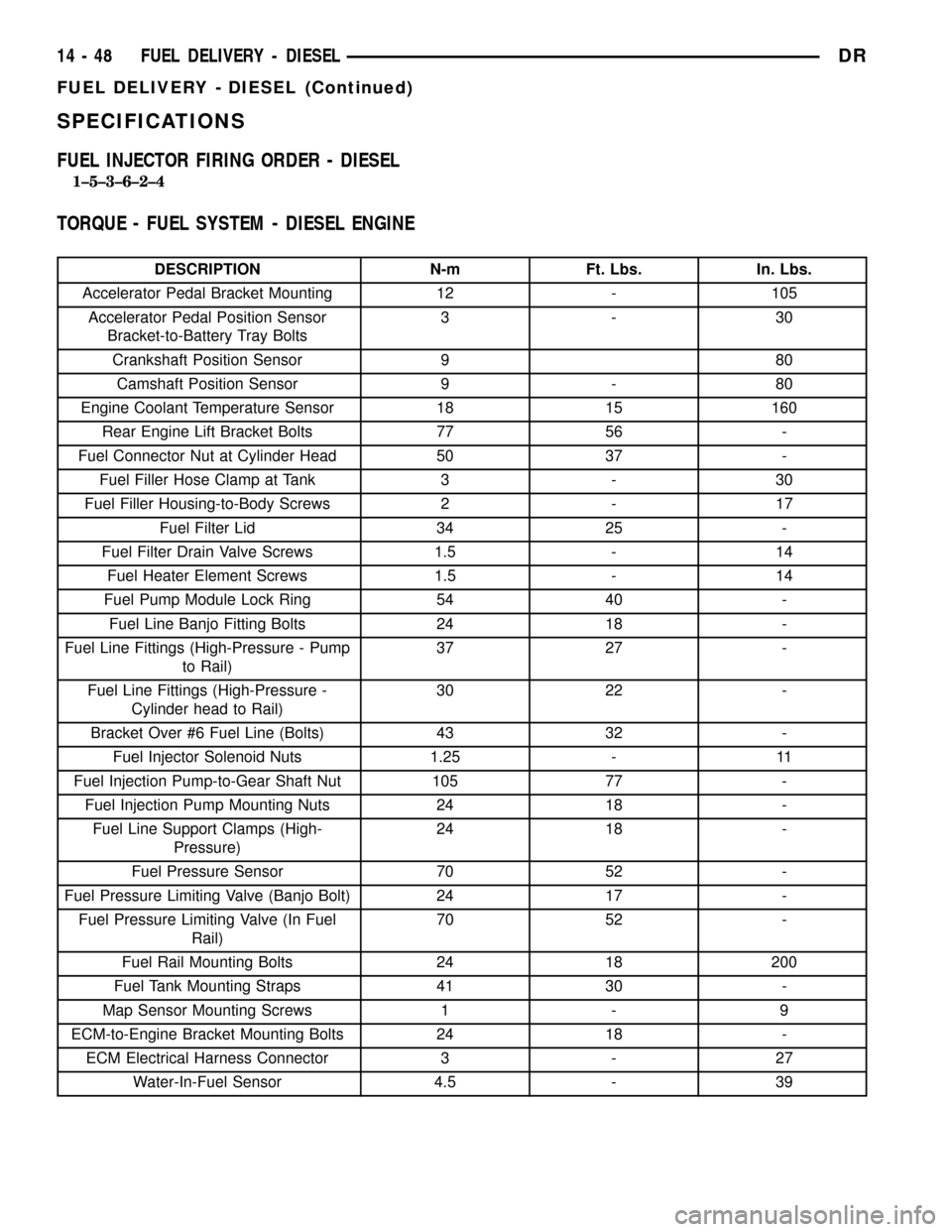

SPECIFICATIONS

FUEL INJECTOR FIRING ORDER - DIESEL

1±5±3±6±2±4

TORQUE - FUEL SYSTEM - DIESEL ENGINE

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket Mounting 12 - 105

Accelerator Pedal Position Sensor

Bracket-to-Battery Tray Bolts3-30

Crankshaft Position Sensor 9 80

Camshaft Position Sensor 9 - 80

Engine Coolant Temperature Sensor 18 15 160

Rear Engine Lift Bracket Bolts 77 56 -

Fuel Connector Nut at Cylinder Head 50 37 -

Fuel Filler Hose Clamp at Tank 3 - 30

Fuel Filler Housing-to-Body Screws 2 - 17

Fuel Filter Lid 34 25 -

Fuel Filter Drain Valve Screws 1.5 - 14

Fuel Heater Element Screws 1.5 - 14

Fuel Pump Module Lock Ring 54 40 -

Fuel Line Banjo Fitting Bolts 24 18 -

Fuel Line Fittings (High-Pressure - Pump

to Rail)37 27 -

Fuel Line Fittings (High-Pressure -

Cylinder head to Rail)30 22 -

Bracket Over #6 Fuel Line (Bolts) 43 32 -

Fuel Injector Solenoid Nuts 1.25 - 11

Fuel Injection Pump-to-Gear Shaft Nut 105 77 -

Fuel Injection Pump Mounting Nuts 24 18 -

Fuel Line Support Clamps (High-

Pressure)24 18 -

Fuel Pressure Sensor 70 52 -

Fuel Pressure Limiting Valve (Banjo Bolt) 24 17 -

Fuel Pressure Limiting Valve (In Fuel

Rail)70 52 -

Fuel Rail Mounting Bolts 24 18 200

Fuel Tank Mounting Straps 41 30 -

Map Sensor Mounting Screws 1 - 9

ECM-to-Engine Bracket Mounting Bolts 24 18 -

ECM Electrical Harness Connector 3 - 27

Water-In-Fuel Sensor 4.5 - 39

14 - 48 FUEL DELIVERY - DIESELDR

FUEL DELIVERY - DIESEL (Continued)

Page 1618 of 2627

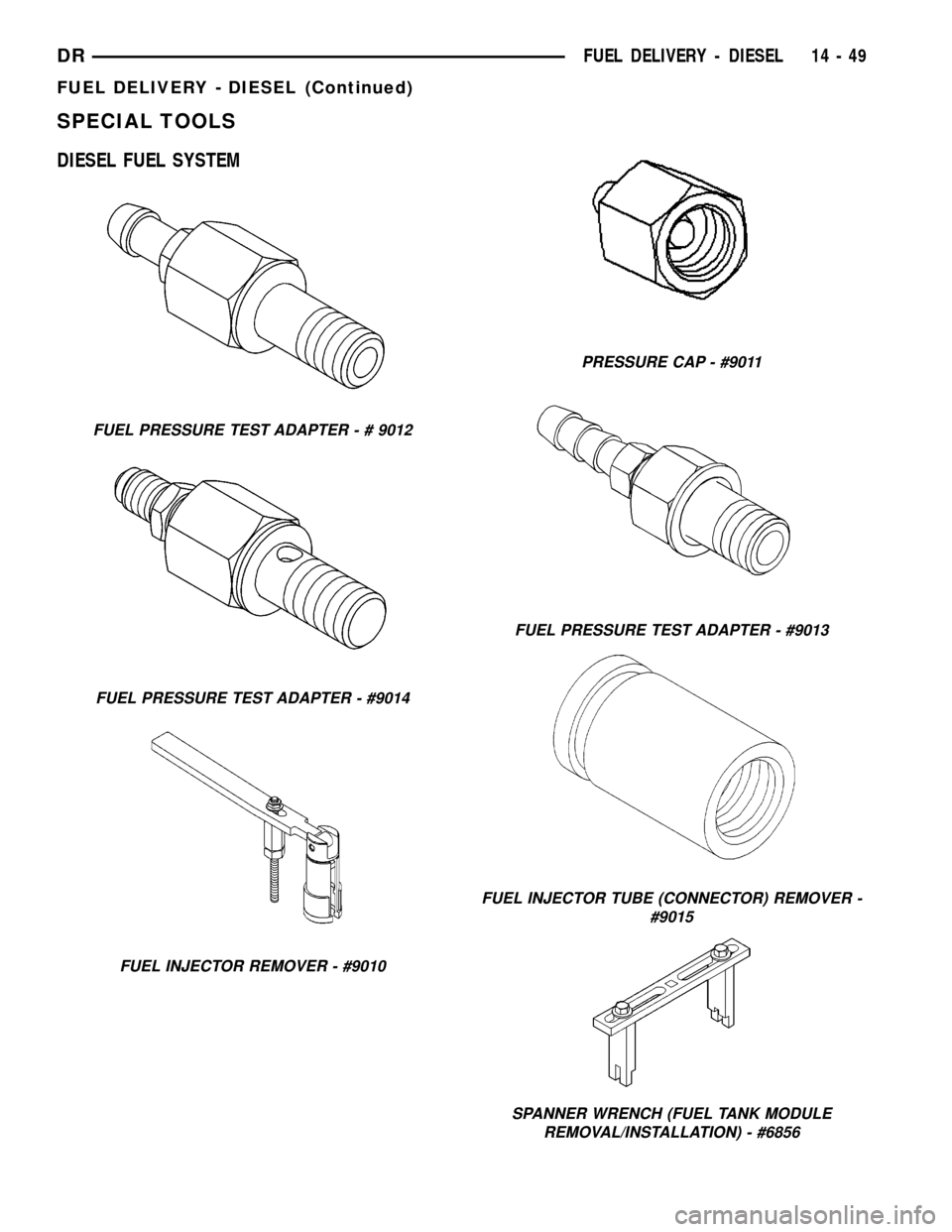

SPECIAL TOOLS

DIESEL FUEL SYSTEM

FUEL PRESSURE TEST ADAPTER - # 9012

FUEL PRESSURE TEST ADAPTER - #9014

FUEL INJECTOR REMOVER - #9010

PRESSURE CAP - #9011

FUEL PRESSURE TEST ADAPTER - #9013

FUEL INJECTOR TUBE (CONNECTOR) REMOVER -

#9015

SPANNER WRENCH (FUEL TANK MODULE

REMOVAL/INSTALLATION) - #6856

DRFUEL DELIVERY - DIESEL 14 - 49

FUEL DELIVERY - DIESEL (Continued)

Page 1622 of 2627

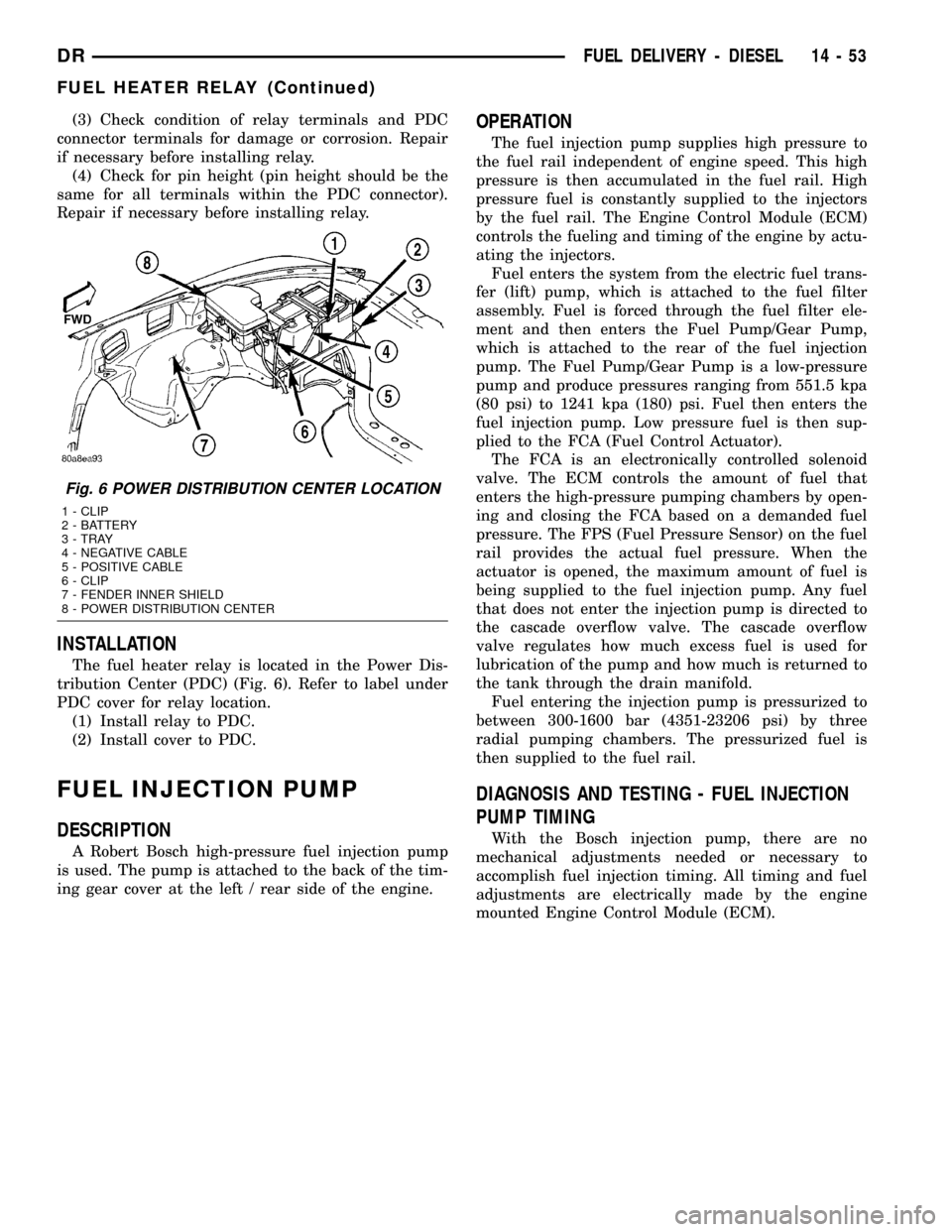

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel heater relay is located in the Power Dis-

tribution Center (PDC) (Fig. 6). Refer to label under

PDC cover for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

FUEL INJECTION PUMP

DESCRIPTION

A Robert Bosch high-pressure fuel injection pump

is used. The pump is attached to the back of the tim-

ing gear cover at the left / rear side of the engine.

OPERATION

The fuel injection pump supplies high pressure to

the fuel rail independent of engine speed. This high

pressure is then accumulated in the fuel rail. High

pressure fuel is constantly supplied to the injectors

by the fuel rail. The Engine Control Module (ECM)

controls the fueling and timing of the engine by actu-

ating the injectors.

Fuel enters the system from the electric fuel trans-

fer (lift) pump, which is attached to the fuel filter

assembly. Fuel is forced through the fuel filter ele-

ment and then enters the Fuel Pump/Gear Pump,

which is attached to the rear of the fuel injection

pump. The Fuel Pump/Gear Pump is a low-pressure

pump and produce pressures ranging from 551.5 kpa

(80 psi) to 1241 kpa (180) psi. Fuel then enters the

fuel injection pump. Low pressure fuel is then sup-

plied to the FCA (Fuel Control Actuator).

The FCA is an electronically controlled solenoid

valve. The ECM controls the amount of fuel that

enters the high-pressure pumping chambers by open-

ing and closing the FCA based on a demanded fuel

pressure. The FPS (Fuel Pressure Sensor) on the fuel

rail provides the actual fuel pressure. When the

actuator is opened, the maximum amount of fuel is

being supplied to the fuel injection pump. Any fuel

that does not enter the injection pump is directed to

the cascade overflow valve. The cascade overflow

valve regulates how much excess fuel is used for

lubrication of the pump and how much is returned to

the tank through the drain manifold.

Fuel entering the injection pump is pressurized to

between 300-1600 bar (4351-23206 psi) by three

radial pumping chambers. The pressurized fuel is

then supplied to the fuel rail.

DIAGNOSIS AND TESTING - FUEL INJECTION

PUMP TIMING

With the Bosch injection pump, there are no

mechanical adjustments needed or necessary to

accomplish fuel injection timing. All timing and fuel

adjustments are electrically made by the engine

mounted Engine Control Module (ECM).

Fig. 6 POWER DISTRIBUTION CENTER LOCATION

1 - CLIP

2 - BATTERY

3 - TRAY

4 - NEGATIVE CABLE

5 - POSITIVE CABLE

6 - CLIP

7 - FENDER INNER SHIELD

8 - POWER DISTRIBUTION CENTER

DRFUEL DELIVERY - DIESEL 14 - 53

FUEL HEATER RELAY (Continued)

Page 1623 of 2627

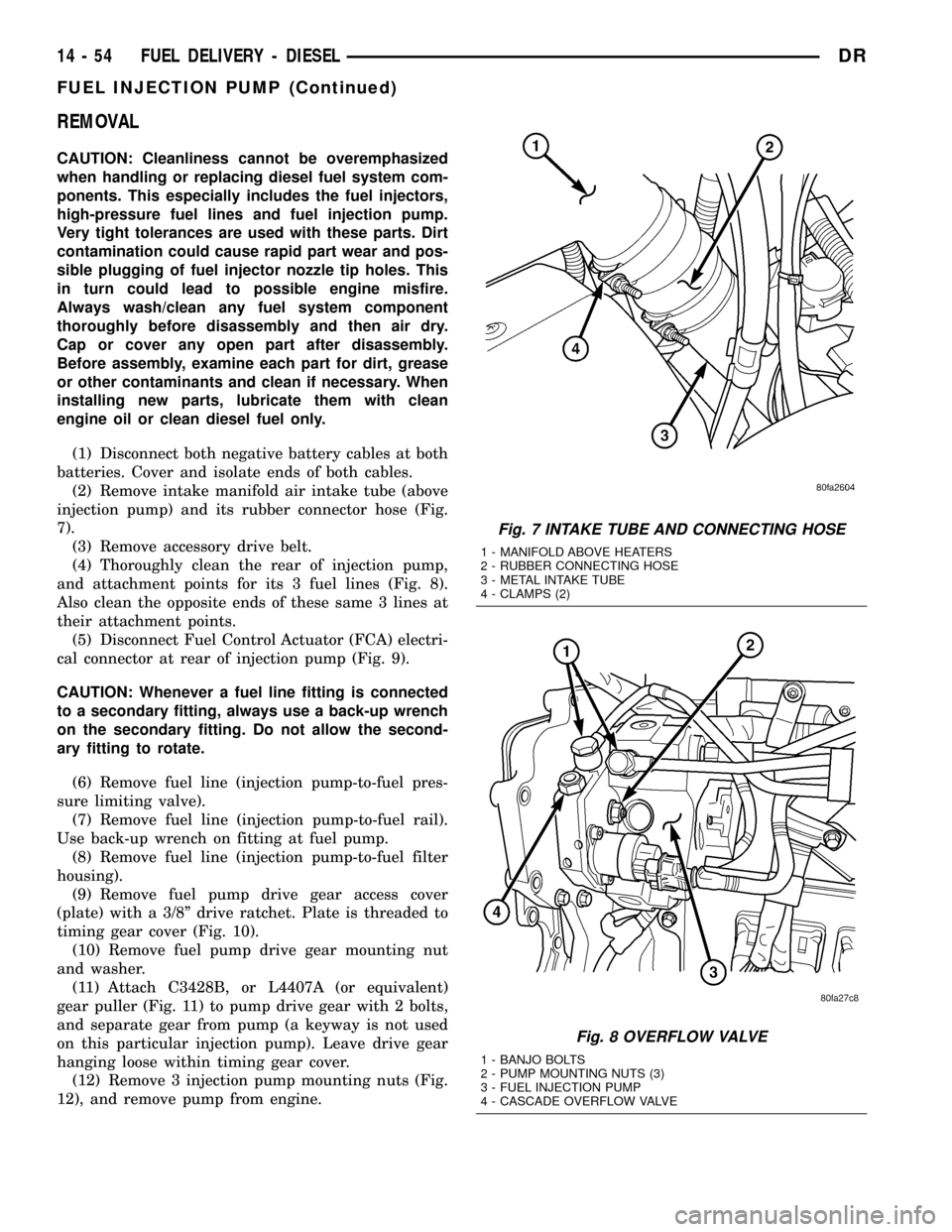

REMOVAL

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

(1) Disconnect both negative battery cables at both

batteries. Cover and isolate ends of both cables.

(2) Remove intake manifold air intake tube (above

injection pump) and its rubber connector hose (Fig.

7).

(3) Remove accessory drive belt.

(4) Thoroughly clean the rear of injection pump,

and attachment points for its 3 fuel lines (Fig. 8).

Also clean the opposite ends of these same 3 lines at

their attachment points.

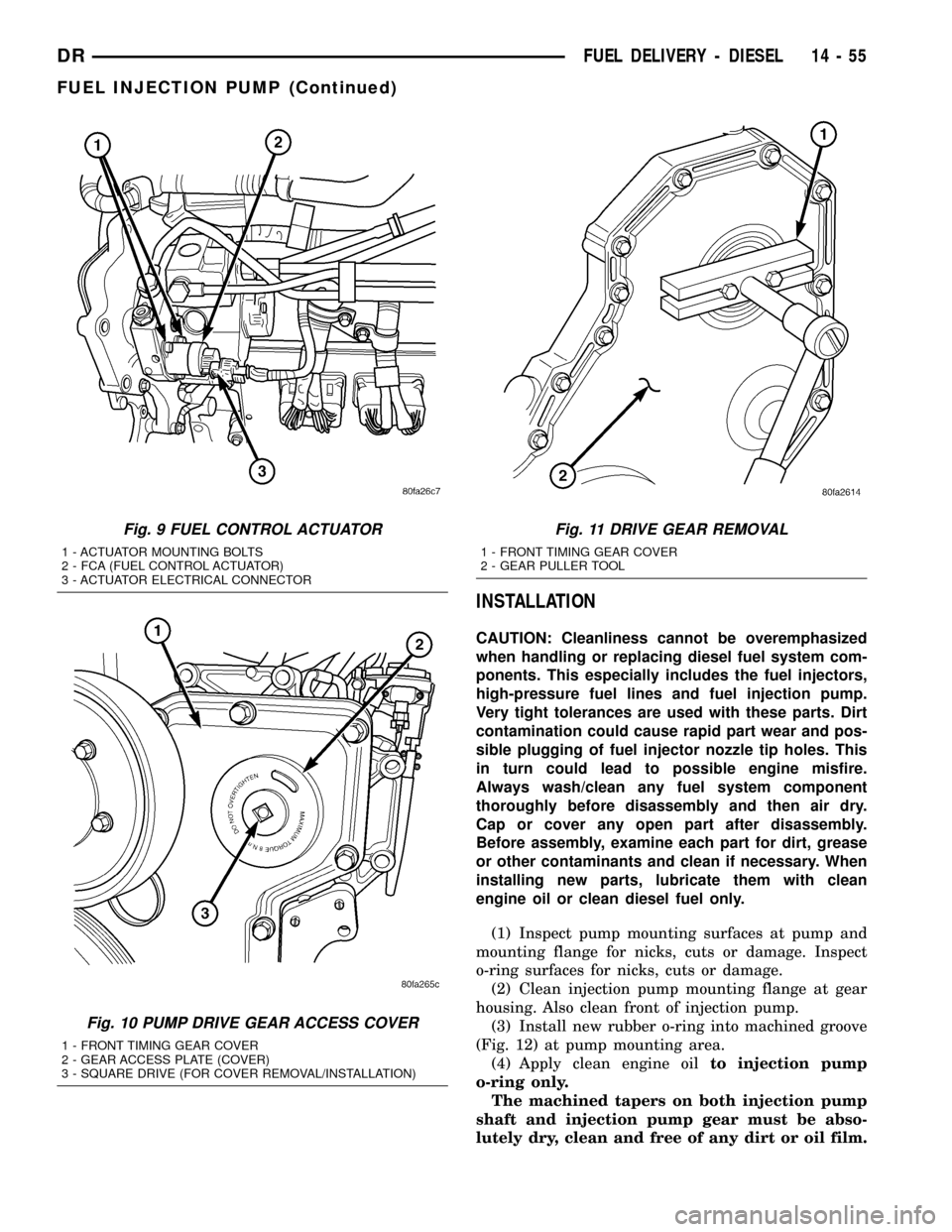

(5) Disconnect Fuel Control Actuator (FCA) electri-

cal connector at rear of injection pump (Fig. 9).

CAUTION: Whenever a fuel line fitting is connected

to a secondary fitting, always use a back-up wrench

on the secondary fitting. Do not allow the second-

ary fitting to rotate.

(6) Remove fuel line (injection pump-to-fuel pres-

sure limiting valve).

(7) Remove fuel line (injection pump-to-fuel rail).

Use back-up wrench on fitting at fuel pump.

(8) Remove fuel line (injection pump-to-fuel filter

housing).

(9) Remove fuel pump drive gear access cover

(plate) with a 3/8º drive ratchet. Plate is threaded to

timing gear cover (Fig. 10).

(10) Remove fuel pump drive gear mounting nut

and washer.

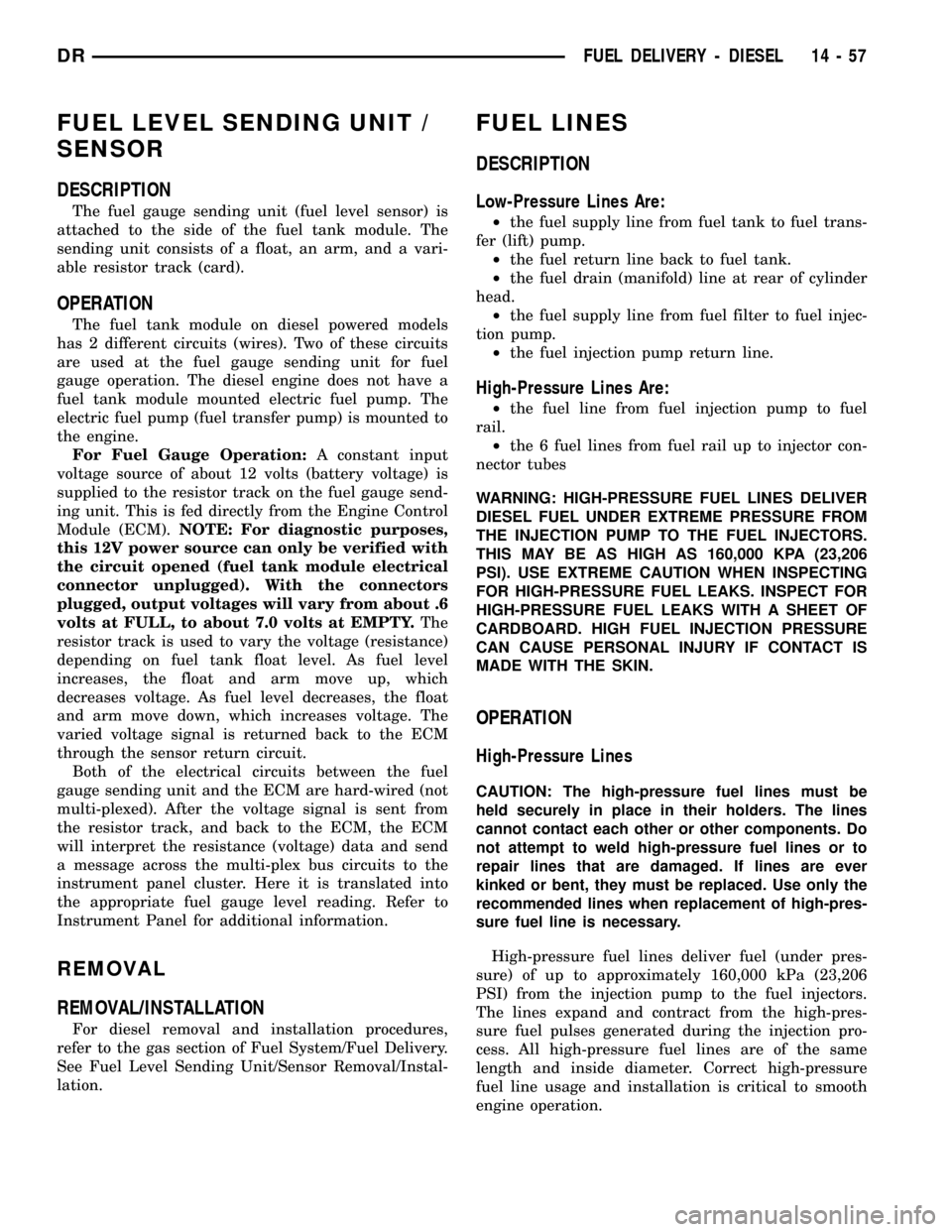

(11) Attach C3428B, or L4407A (or equivalent)

gear puller (Fig. 11) to pump drive gear with 2 bolts,

and separate gear from pump (a keyway is not used

on this particular injection pump). Leave drive gear

hanging loose within timing gear cover.

(12) Remove 3 injection pump mounting nuts (Fig.

12), and remove pump from engine.

Fig. 7 INTAKE TUBE AND CONNECTING HOSE

1 - MANIFOLD ABOVE HEATERS

2 - RUBBER CONNECTING HOSE

3 - METAL INTAKE TUBE

4 - CLAMPS (2)

Fig. 8 OVERFLOW VALVE

1 - BANJO BOLTS

2 - PUMP MOUNTING NUTS (3)

3 - FUEL INJECTION PUMP

4 - CASCADE OVERFLOW VALVE

14 - 54 FUEL DELIVERY - DIESELDR

FUEL INJECTION PUMP (Continued)

Page 1624 of 2627

INSTALLATION

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

(1) Inspect pump mounting surfaces at pump and

mounting flange for nicks, cuts or damage. Inspect

o-ring surfaces for nicks, cuts or damage.

(2) Clean injection pump mounting flange at gear

housing. Also clean front of injection pump.

(3) Install new rubber o-ring into machined groove

(Fig. 12) at pump mounting area.

(4) Apply clean engine oilto injection pump

o-ring only.

The machined tapers on both injection pump

shaft and injection pump gear must be abso-

lutely dry, clean and free of any dirt or oil film.

Fig. 9 FUEL CONTROL ACTUATOR

1 - ACTUATOR MOUNTING BOLTS

2 - FCA (FUEL CONTROL ACTUATOR)

3 - ACTUATOR ELECTRICAL CONNECTOR

Fig. 10 PUMP DRIVE GEAR ACCESS COVER

1 - FRONT TIMING GEAR COVER

2 - GEAR ACCESS PLATE (COVER)

3 - SQUARE DRIVE (FOR COVER REMOVAL/INSTALLATION)

Fig. 11 DRIVE GEAR REMOVAL

1 - FRONT TIMING GEAR COVER

2 - GEAR PULLER TOOL

DRFUEL DELIVERY - DIESEL 14 - 55

FUEL INJECTION PUMP (Continued)

Page 1626 of 2627

FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel tank module. The

sending unit consists of a float, an arm, and a vari-

able resistor track (card).

OPERATION

The fuel tank module on diesel powered models

has 2 different circuits (wires). Two of these circuits

are used at the fuel gauge sending unit for fuel

gauge operation. The diesel engine does not have a

fuel tank module mounted electric fuel pump. The

electric fuel pump (fuel transfer pump) is mounted to

the engine.

For Fuel Gauge Operation:A constant input

voltage source of about 12 volts (battery voltage) is

supplied to the resistor track on the fuel gauge send-

ing unit. This is fed directly from the Engine Control

Module (ECM).NOTE: For diagnostic purposes,

this 12V power source can only be verified with

the circuit opened (fuel tank module electrical

connector unplugged). With the connectors

plugged, output voltages will vary from about .6

volts at FULL, to about 7.0 volts at EMPTY.The

resistor track is used to vary the voltage (resistance)

depending on fuel tank float level. As fuel level

increases, the float and arm move up, which

decreases voltage. As fuel level decreases, the float

and arm move down, which increases voltage. The

varied voltage signal is returned back to the ECM

through the sensor return circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the ECM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the ECM, the ECM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

REMOVAL

REMOVAL/INSTALLATION

For diesel removal and installation procedures,

refer to the gas section of Fuel System/Fuel Delivery.

See Fuel Level Sending Unit/Sensor Removal/Instal-

lation.

FUEL LINES

DESCRIPTION

Low-Pressure Lines Are:

²the fuel supply line from fuel tank to fuel trans-

fer (lift) pump.

²the fuel return line back to fuel tank.

²the fuel drain (manifold) line at rear of cylinder

head.

²the fuel supply line from fuel filter to fuel injec-

tion pump.

²the fuel injection pump return line.

High-Pressure Lines Are:

²the fuel line from fuel injection pump to fuel

rail.

²the 6 fuel lines from fuel rail up to injector con-

nector tubes

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 160,000 KPA (23,206

PSI). USE EXTREME CAUTION WHEN INSPECTING

FOR HIGH-PRESSURE FUEL LEAKS. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD. HIGH FUEL INJECTION PRESSURE

CAN CAUSE PERSONAL INJURY IF CONTACT IS

MADE WITH THE SKIN.

OPERATION

High-Pressure Lines

CAUTION: The high-pressure fuel lines must be

held securely in place in their holders. The lines

cannot contact each other or other components. Do

not attempt to weld high-pressure fuel lines or to

repair lines that are damaged. If lines are ever

kinked or bent, they must be replaced. Use only the

recommended lines when replacement of high-pres-

sure fuel line is necessary.

High-pressure fuel lines deliver fuel (under pres-

sure) of up to approximately 160,000 kPa (23,206

PSI) from the injection pump to the fuel injectors.

The lines expand and contract from the high-pres-

sure fuel pulses generated during the injection pro-

cess. All high-pressure fuel lines are of the same

length and inside diameter. Correct high-pressure

fuel line usage and installation is critical to smooth

engine operation.

DRFUEL DELIVERY - DIESEL 14 - 57