Removal DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2180 of 2627

(6) Fill transfer case to bottom edge of fill plug

opening with MopartATF +4, Automatic Transmis-

sion fluid.

(7) Install and tighten fill plug to 41-54 N´m

(30-40 ft. lbs.).

(8) Lower vehicle.

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Remove the front propeller shaft (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL).

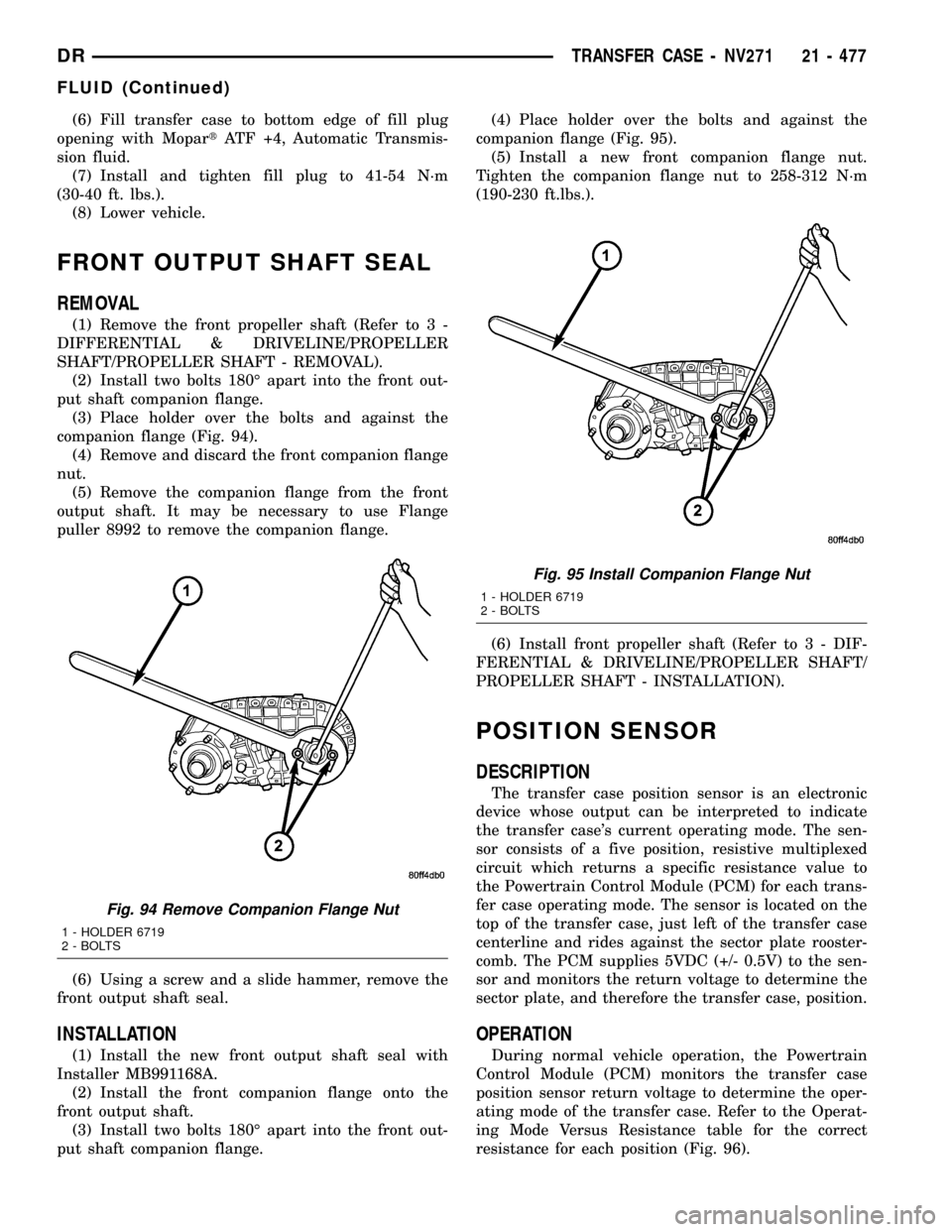

(2) Install two bolts 180É apart into the front out-

put shaft companion flange.

(3) Place holder over the bolts and against the

companion flange (Fig. 94).

(4) Remove and discard the front companion flange

nut.

(5) Remove the companion flange from the front

output shaft. It may be necessary to use Flange

puller 8992 to remove the companion flange.

(6) Using a screw and a slide hammer, remove the

front output shaft seal.

INSTALLATION

(1) Install the new front output shaft seal with

Installer MB991168A.

(2) Install the front companion flange onto the

front output shaft.

(3) Install two bolts 180É apart into the front out-

put shaft companion flange.(4) Place holder over the bolts and against the

companion flange (Fig. 95).

(5) Install a new front companion flange nut.

Tighten the companion flange nut to 258-312 N´m

(190-230 ft.lbs.).

(6) Install front propeller shaft (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION).

POSITION SENSOR

DESCRIPTION

The transfer case position sensor is an electronic

device whose output can be interpreted to indicate

the transfer case's current operating mode. The sen-

sor consists of a five position, resistive multiplexed

circuit which returns a specific resistance value to

the Powertrain Control Module (PCM) for each trans-

fer case operating mode. The sensor is located on the

top of the transfer case, just left of the transfer case

centerline and rides against the sector plate rooster-

comb. The PCM supplies 5VDC (+/- 0.5V) to the sen-

sor and monitors the return voltage to determine the

sector plate, and therefore the transfer case, position.

OPERATION

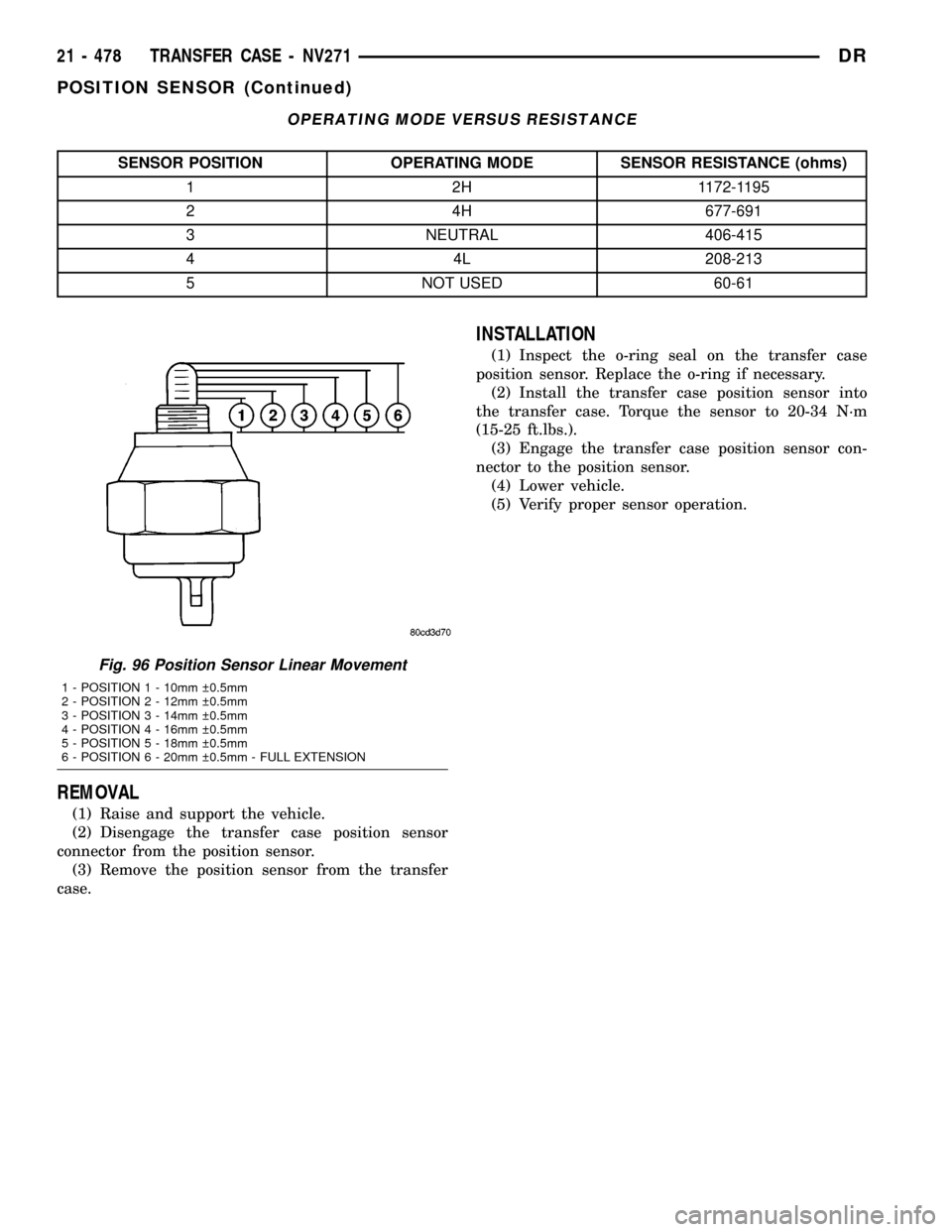

During normal vehicle operation, the Powertrain

Control Module (PCM) monitors the transfer case

position sensor return voltage to determine the oper-

ating mode of the transfer case. Refer to the Operat-

ing Mode Versus Resistance table for the correct

resistance for each position (Fig. 96).

Fig. 94 Remove Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

Fig. 95 Install Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

DRTRANSFER CASE - NV271 21 - 477

FLUID (Continued)

Page 2181 of 2627

OPERATING MODE VERSUS RESISTANCE

SENSOR POSITION OPERATING MODE SENSOR RESISTANCE (ohms)

1 2H 1172-1195

2 4H 677-691

3 NEUTRAL 406-415

4 4L 208-213

5 NOT USED 60-61

REMOVAL

(1) Raise and support the vehicle.

(2) Disengage the transfer case position sensor

connector from the position sensor.

(3) Remove the position sensor from the transfer

case.

INSTALLATION

(1) Inspect the o-ring seal on the transfer case

position sensor. Replace the o-ring if necessary.

(2) Install the transfer case position sensor into

the transfer case. Torque the sensor to 20-34 N´m

(15-25 ft.lbs.).

(3) Engage the transfer case position sensor con-

nector to the position sensor.

(4) Lower vehicle.

(5) Verify proper sensor operation.

Fig. 96 Position Sensor Linear Movement

1 - POSITION 1 - 10mm 0.5mm

2 - POSITION 2 - 12mm 0.5mm

3 - POSITION 3 - 14mm 0.5mm

4 - POSITION 4 - 16mm 0.5mm

5 - POSITION 5 - 18mm 0.5mm

6 - POSITION 6 - 20mm 0.5mm - FULL EXTENSION

21 - 478 TRANSFER CASE - NV271DR

POSITION SENSOR (Continued)

Page 2182 of 2627

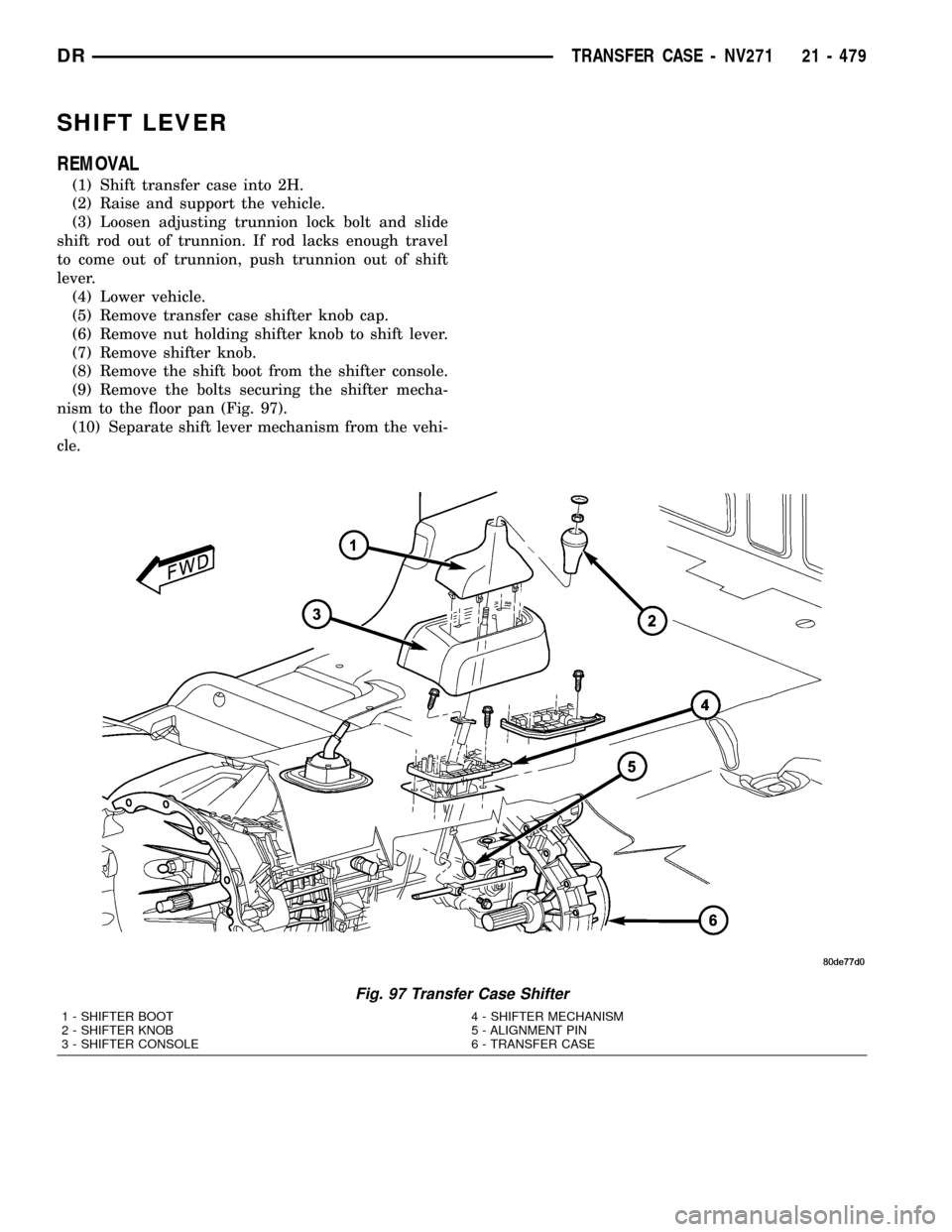

SHIFT LEVER

REMOVAL

(1) Shift transfer case into 2H.

(2) Raise and support the vehicle.

(3) Loosen adjusting trunnion lock bolt and slide

shift rod out of trunnion. If rod lacks enough travel

to come out of trunnion, push trunnion out of shift

lever.

(4) Lower vehicle.

(5) Remove transfer case shifter knob cap.

(6) Remove nut holding shifter knob to shift lever.

(7) Remove shifter knob.

(8) Remove the shift boot from the shifter console.

(9) Remove the bolts securing the shifter mecha-

nism to the floor pan (Fig. 97).

(10) Separate shift lever mechanism from the vehi-

cle.

Fig. 97 Transfer Case Shifter

1 - SHIFTER BOOT 4 - SHIFTER MECHANISM

2 - SHIFTER KNOB 5 - ALIGNMENT PIN

3 - SHIFTER CONSOLE 6 - TRANSFER CASE

DRTRANSFER CASE - NV271 21 - 479

Page 2185 of 2627

TRANSFER CASE - NV243

TABLE OF CONTENTS

page page

TRANSFER CASE - NV243

DESCRIPTION........................482

OPERATION..........................483

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV243.......................483

REMOVAL............................484

DISASSEMBLY........................484

CLEANING...........................493

INSPECTION.........................493

ASSEMBLY...........................496

INSTALLATION........................505

SPECIFICATIONS

TRANSFER CASE - NV243.............505

SPECIAL TOOLS

TRANSFER CASE - NV243.............506

EXTENSION HOUSING SEAL

REMOVAL............................507

INSTALLATION........................507FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL............................507

FRONT OUTPUT SHAFT SEAL

REMOVAL............................507

INSTALLATION........................508

MODE SENSOR

DESCRIPTION........................509

OPERATION..........................509

SELECTOR SWITCH

DESCRIPTION........................510

OPERATION..........................510

SHIFT MOTOR

DESCRIPTION........................511

OPERATION..........................511

REMOVAL............................511

INSTALLATION........................511

TRANSFER CASE - NV243

DESCRIPTION

The NV243 is an electronically controlled part-time

transfer case with a low range gear reduction system.

The NV243 has three operating ranges plus a NEU-

TRAL position. The low range system provides a gear

reduction ratio for increased low speed torque capa-

bility.

The geartrain is mounted in two aluminum case

halves attached with bolts. The mainshaft front and

rear bearings are mounted in aluminum retainer

housings bolted to the case halves.

OPERATING RANGES

Transfer case operating ranges are:

²2WD (2-wheel drive)

²4HI (4-wheel drive)

²4LO (4-wheel drive low range)

²NEUTRAL

The 2WD range is for use on any road surface at

any time.The 4HI and 4LO ranges are for off road use only.

They are not for use on hard surface roads. The only

exception being when the road surface is wet or slip-

pery or covered by ice and snow.

The low range reduction gear system is operative

in 4LO range only. This range is for extra pulling

power in off road situations. Low range reduction

ratio is 2.72:1.

SHIFT MECHANISM

Operating ranges are selected with a dash

mounted shift selector switch. The shift selector

switch provides a input to the Transfer Case Control

Module (TCCM) to indicate the driver's desire to

change operating ranges. The TCCM uses this input,

along with input from the transfer case mounted

mode sensor and information from the vehicle's bus,

to determine if a shift is permitted. If the TCCM

decides the shift is permitted, the TCCM controls the

shift motor, mounted to the exterior of the transfer

case, to perform the shift.

21 - 482 TRANSFER CASE - NV243DR

Page 2187 of 2627

Condition Possible Cause Correction

Transfer case noisy while in, or

jumps out of, 4LO mode.1) Transfer case not completely

engaged in 4LO position.1) While rolling 2-3 MPH and the

transmission in NEUTRAL, or clutch

depressed on vehicles equipped

with a manual transmission, shift

transfer case to the 2WD or 4HI

position, and then back into the 4LO

position.

2) Range fork damaged, inserts

worn, or fork is binding on the shift

rail.2) Repair or replace components as

necessary.

3) Low range gear worn or

damaged.3) Repair or replace components as

necessary.

Lubricant leaking from transfer case

seals or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Transfer case vent closed or

restricted.2) Clean or replace vent as

necessary.

3) Transfer case seals damaged or

installed incorrectly.3) Replace suspect seal.

Abnormal tire wear. 1) Extended operation in 4HI mode

on dry surfaces,1) Operate vehicle in 2WD mode on

dry surfaces.

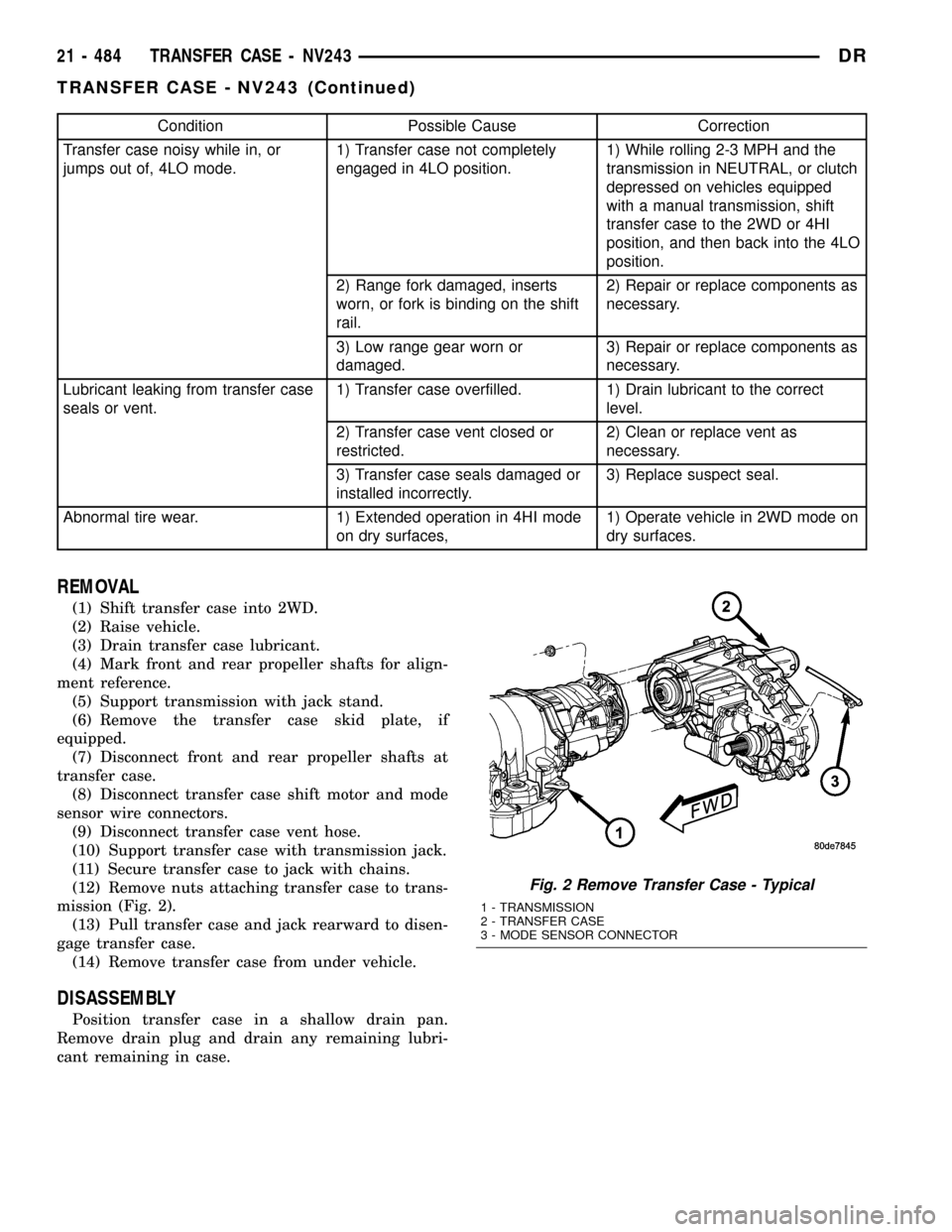

REMOVAL

(1) Shift transfer case into 2WD.

(2) Raise vehicle.

(3) Drain transfer case lubricant.

(4) Mark front and rear propeller shafts for align-

ment reference.

(5) Support transmission with jack stand.

(6) Remove the transfer case skid plate, if

equipped.

(7) Disconnect front and rear propeller shafts at

transfer case.

(8) Disconnect transfer case shift motor and mode

sensor wire connectors.

(9) Disconnect transfer case vent hose.

(10) Support transfer case with transmission jack.

(11) Secure transfer case to jack with chains.

(12) Remove nuts attaching transfer case to trans-

mission (Fig. 2).

(13) Pull transfer case and jack rearward to disen-

gage transfer case.

(14) Remove transfer case from under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan.

Remove drain plug and drain any remaining lubri-

cant remaining in case.

Fig. 2 Remove Transfer Case - Typical

1 - TRANSMISSION

2 - TRANSFER CASE

3 - MODE SENSOR CONNECTOR

21 - 484 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2190 of 2627

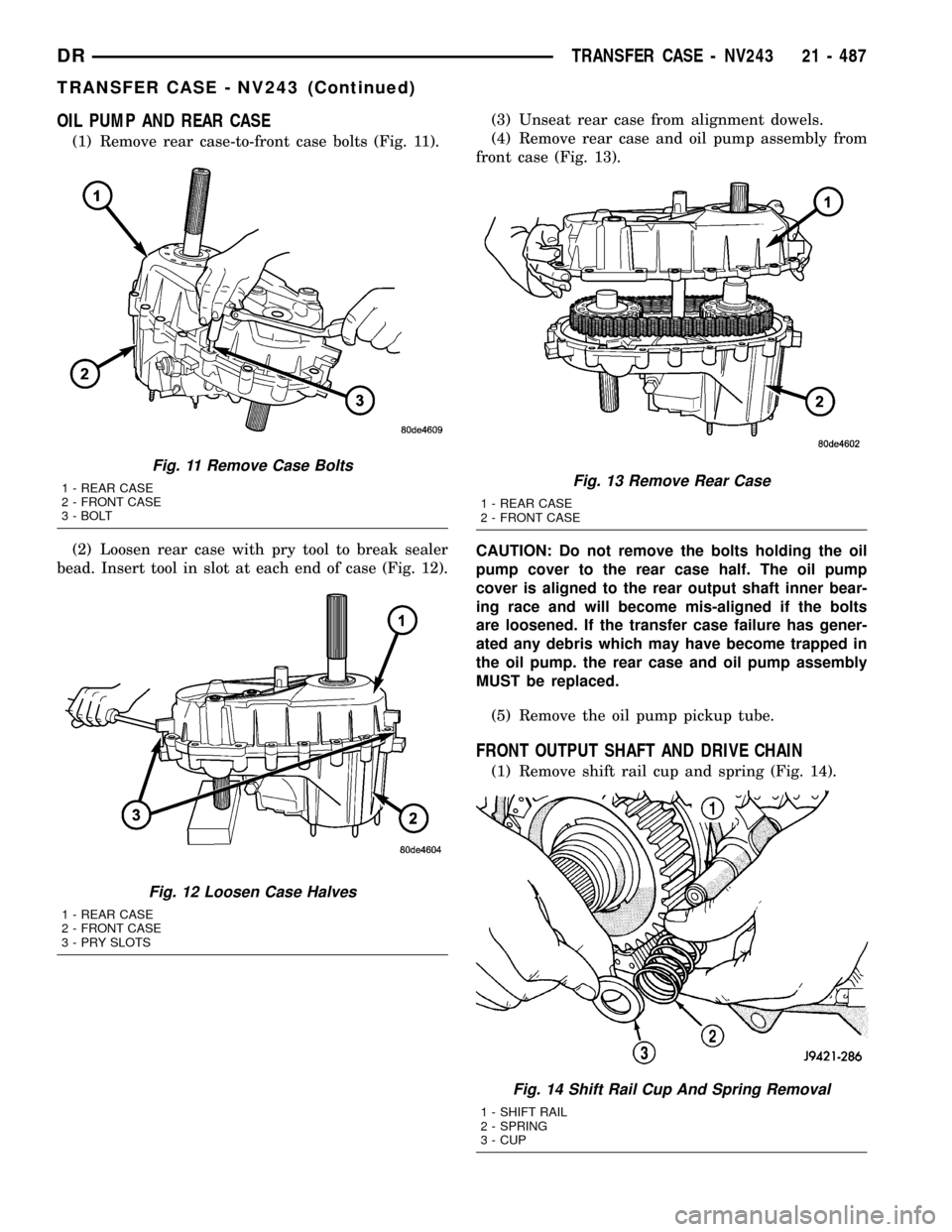

OIL PUMP AND REAR CASE

(1) Remove rear case-to-front case bolts (Fig. 11).

(2) Loosen rear case with pry tool to break sealer

bead. Insert tool in slot at each end of case (Fig. 12).(3) Unseat rear case from alignment dowels.

(4) Remove rear case and oil pump assembly from

front case (Fig. 13).

CAUTION: Do not remove the bolts holding the oil

pump cover to the rear case half. The oil pump

cover is aligned to the rear output shaft inner bear-

ing race and will become mis-aligned if the bolts

are loosened. If the transfer case failure has gener-

ated any debris which may have become trapped in

the oil pump. the rear case and oil pump assembly

MUST be replaced.

(5) Remove the oil pump pickup tube.

FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Remove shift rail cup and spring (Fig. 14).

Fig. 11 Remove Case Bolts

1 - REAR CASE

2 - FRONT CASE

3 - BOLT

Fig. 12 Loosen Case Halves

1 - REAR CASE

2 - FRONT CASE

3 - PRY SLOTS

Fig. 13 Remove Rear Case

1 - REAR CASE

2 - FRONT CASE

Fig. 14 Shift Rail Cup And Spring Removal

1 - SHIFT RAIL

2 - SPRING

3 - CUP

DRTRANSFER CASE - NV243 21 - 487

TRANSFER CASE - NV243 (Continued)

Page 2192 of 2627

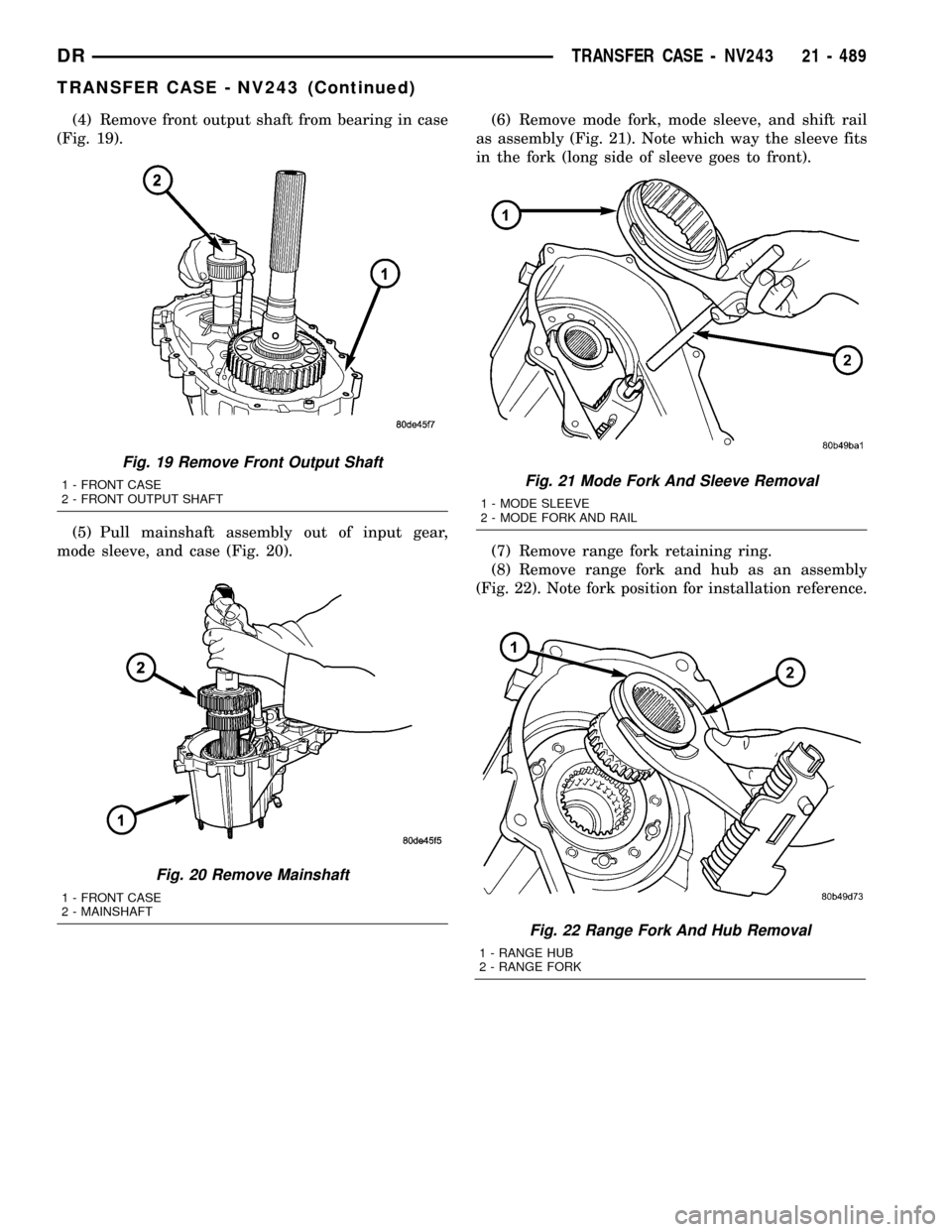

(4) Remove front output shaft from bearing in case

(Fig. 19).

(5) Pull mainshaft assembly out of input gear,

mode sleeve, and case (Fig. 20).(6) Remove mode fork, mode sleeve, and shift rail

as assembly (Fig. 21). Note which way the sleeve fits

in the fork (long side of sleeve goes to front).

(7) Remove range fork retaining ring.

(8) Remove range fork and hub as an assembly

(Fig. 22). Note fork position for installation reference.

Fig. 22 Range Fork And Hub Removal

1 - RANGE HUB

2 - RANGE FORK

Fig. 19 Remove Front Output Shaft

1 - FRONT CASE

2 - FRONT OUTPUT SHAFT

Fig. 20 Remove Mainshaft

1 - FRONT CASE

2 - MAINSHAFT

Fig. 21 Mode Fork And Sleeve Removal

1 - MODE SLEEVE

2 - MODE FORK AND RAIL

DRTRANSFER CASE - NV243 21 - 489

TRANSFER CASE - NV243 (Continued)

Page 2193 of 2627

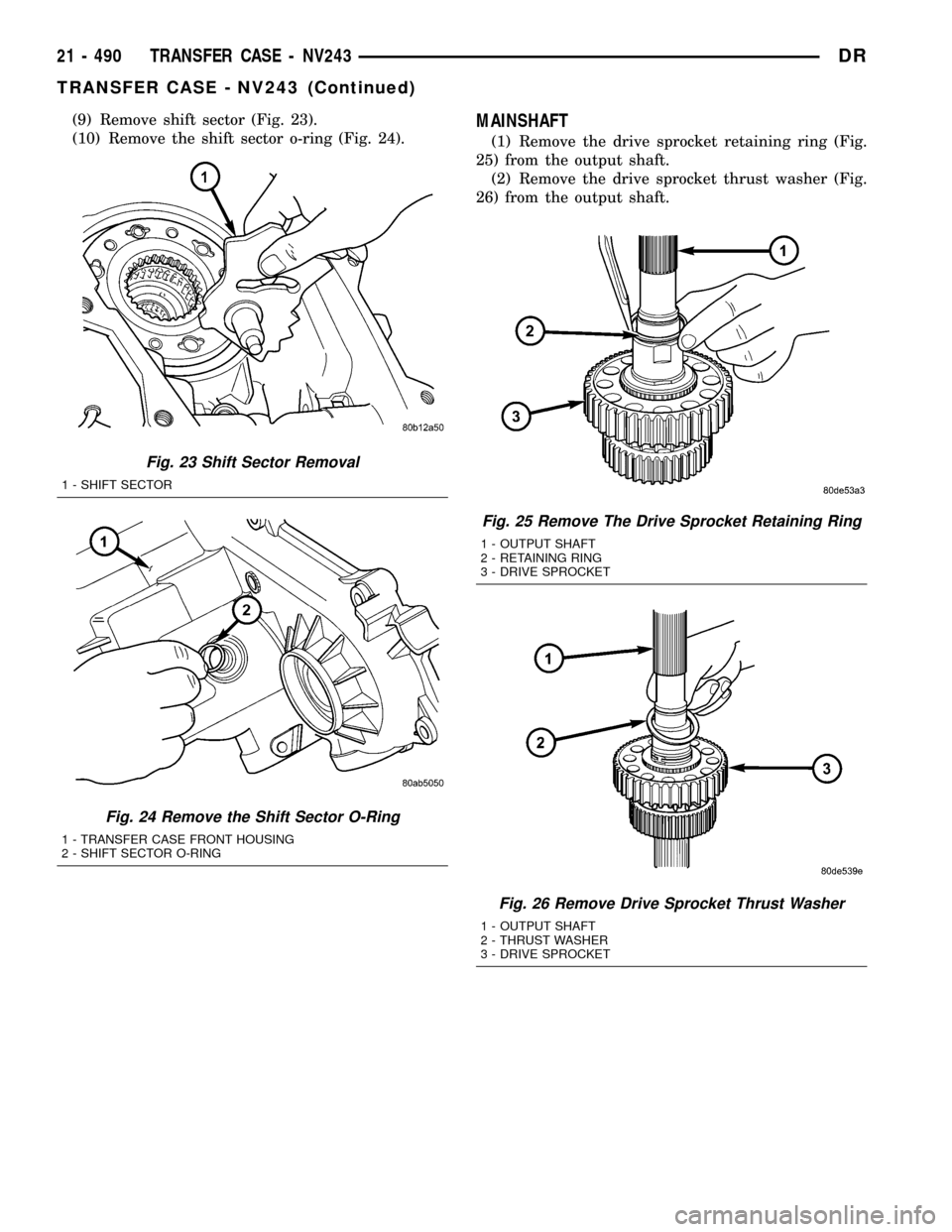

(9) Remove shift sector (Fig. 23).

(10) Remove the shift sector o-ring (Fig. 24).MAINSHAFT

(1) Remove the drive sprocket retaining ring (Fig.

25) from the output shaft.

(2) Remove the drive sprocket thrust washer (Fig.

26) from the output shaft.

Fig. 23 Shift Sector Removal

1 - SHIFT SECTOR

Fig. 24 Remove the Shift Sector O-Ring

1 - TRANSFER CASE FRONT HOUSING

2 - SHIFT SECTOR O-RING

Fig. 25 Remove The Drive Sprocket Retaining Ring

1 - OUTPUT SHAFT

2 - RETAINING RING

3 - DRIVE SPROCKET

Fig. 26 Remove Drive Sprocket Thrust Washer

1 - OUTPUT SHAFT

2 - THRUST WASHER

3 - DRIVE SPROCKET

21 - 490 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2195 of 2627

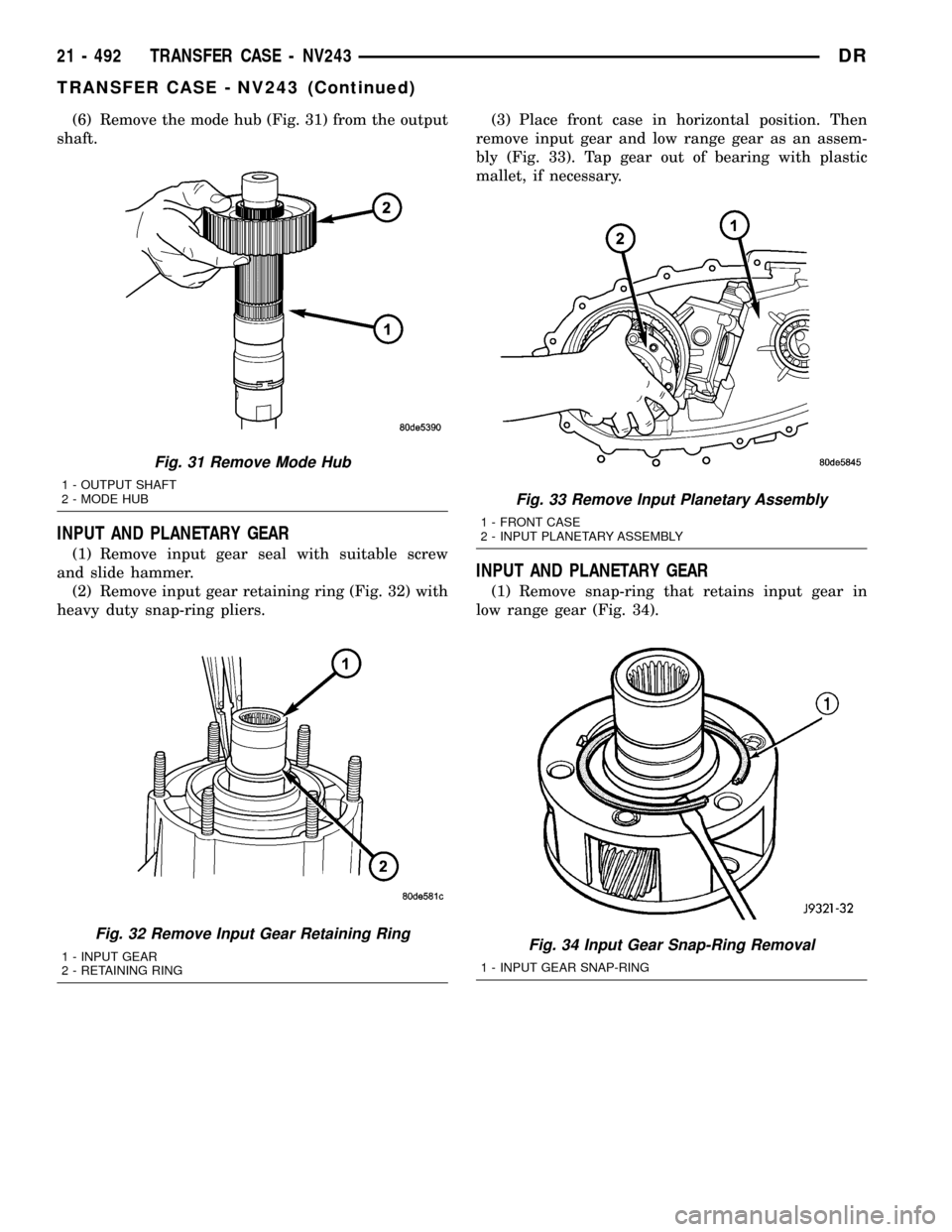

(6) Remove the mode hub (Fig. 31) from the output

shaft.

INPUT AND PLANETARY GEAR

(1) Remove input gear seal with suitable screw

and slide hammer.

(2) Remove input gear retaining ring (Fig. 32) with

heavy duty snap-ring pliers.(3) Place front case in horizontal position. Then

remove input gear and low range gear as an assem-

bly (Fig. 33). Tap gear out of bearing with plastic

mallet, if necessary.

INPUT AND PLANETARY GEAR

(1) Remove snap-ring that retains input gear in

low range gear (Fig. 34).

Fig. 34 Input Gear Snap-Ring Removal

1 - INPUT GEAR SNAP-RING

Fig. 31 Remove Mode Hub

1 - OUTPUT SHAFT

2 - MODE HUB

Fig. 32 Remove Input Gear Retaining Ring

1 - INPUT GEAR

2 - RETAINING RING

Fig. 33 Remove Input Planetary Assembly

1 - FRONT CASE

2 - INPUT PLANETARY ASSEMBLY

21 - 492 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2196 of 2627

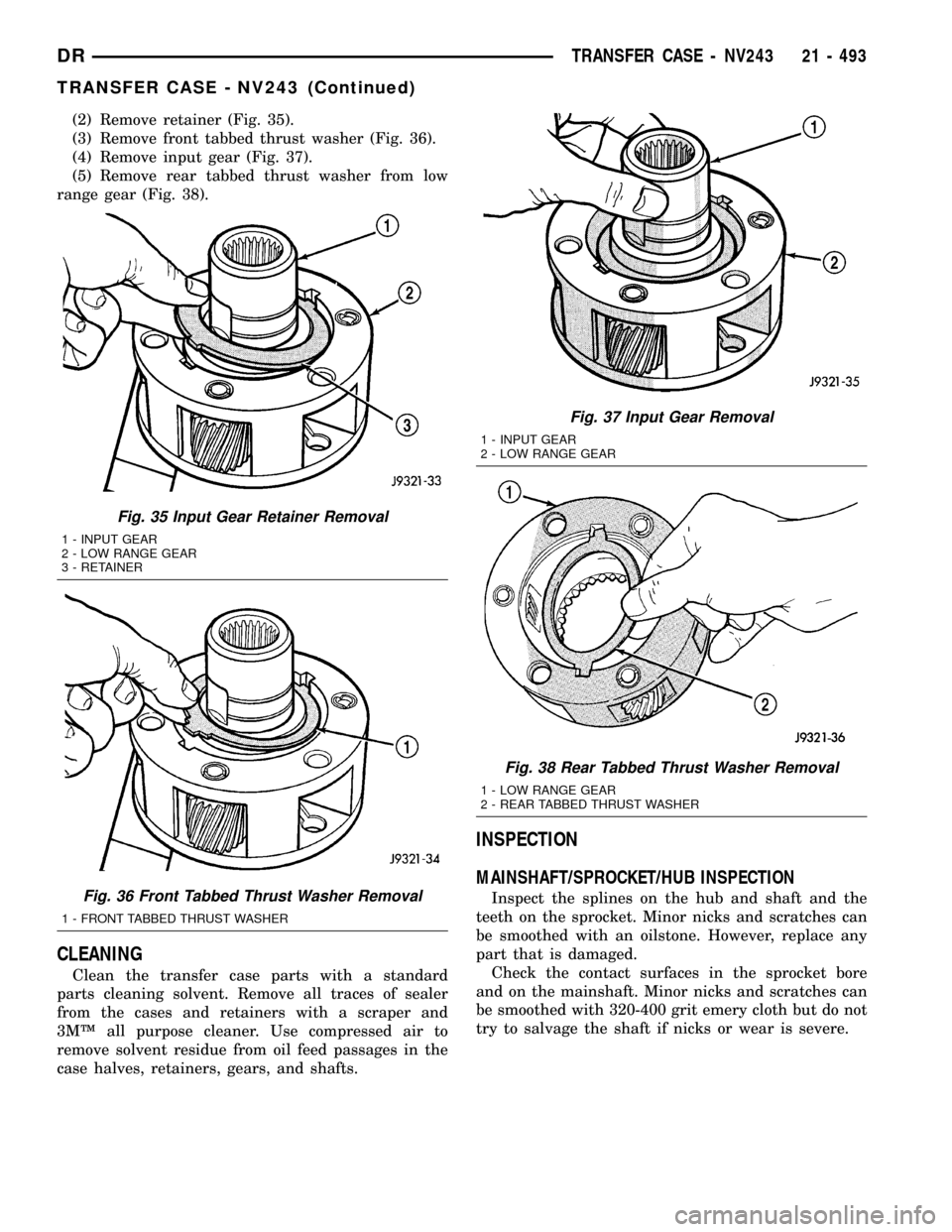

(2) Remove retainer (Fig. 35).

(3) Remove front tabbed thrust washer (Fig. 36).

(4) Remove input gear (Fig. 37).

(5) Remove rear tabbed thrust washer from low

range gear (Fig. 38).

CLEANING

Clean the transfer case parts with a standard

parts cleaning solvent. Remove all traces of sealer

from the cases and retainers with a scraper and

3MŸ all purpose cleaner. Use compressed air to

remove solvent residue from oil feed passages in the

case halves, retainers, gears, and shafts.

INSPECTION

MAINSHAFT/SPROCKET/HUB INSPECTION

Inspect the splines on the hub and shaft and the

teeth on the sprocket. Minor nicks and scratches can

be smoothed with an oilstone. However, replace any

part that is damaged.

Check the contact surfaces in the sprocket bore

and on the mainshaft. Minor nicks and scratches can

be smoothed with 320-400 grit emery cloth but do not

try to salvage the shaft if nicks or wear is severe.

Fig. 35 Input Gear Retainer Removal

1 - INPUT GEAR

2 - LOW RANGE GEAR

3 - RETAINER

Fig. 36 Front Tabbed Thrust Washer Removal

1 - FRONT TABBED THRUST WASHER

Fig. 37 Input Gear Removal

1 - INPUT GEAR

2 - LOW RANGE GEAR

Fig. 38 Rear Tabbed Thrust Washer Removal

1 - LOW RANGE GEAR

2 - REAR TABBED THRUST WASHER

DRTRANSFER CASE - NV243 21 - 493

TRANSFER CASE - NV243 (Continued)