Removal DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2200 of 2627

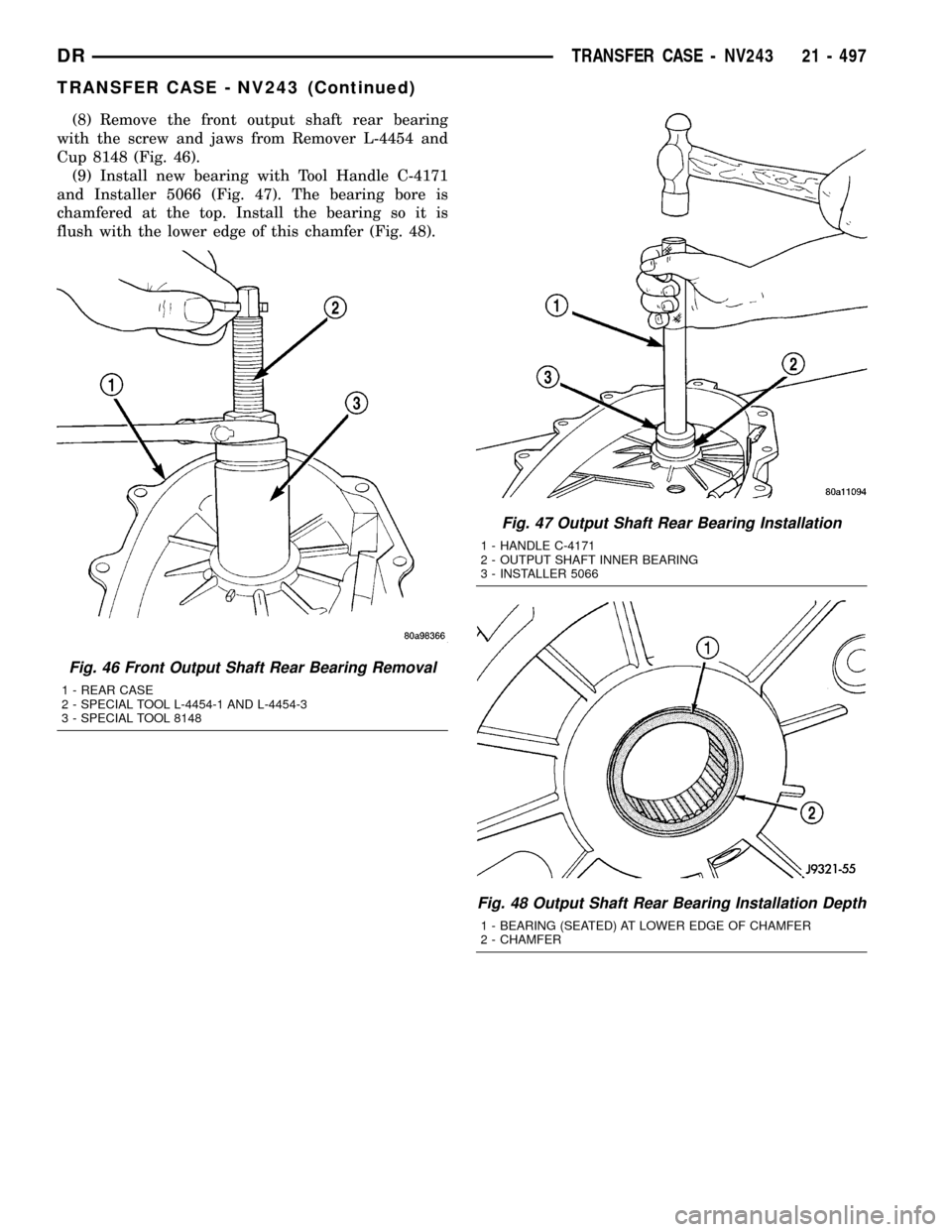

(8) Remove the front output shaft rear bearing

with the screw and jaws from Remover L-4454 and

Cup 8148 (Fig. 46).

(9) Install new bearing with Tool Handle C-4171

and Installer 5066 (Fig. 47). The bearing bore is

chamfered at the top. Install the bearing so it is

flush with the lower edge of this chamfer (Fig. 48).

Fig. 46 Front Output Shaft Rear Bearing Removal

1 - REAR CASE

2 - SPECIAL TOOL L-4454-1 AND L-4454-3

3 - SPECIAL TOOL 8148

Fig. 47 Output Shaft Rear Bearing Installation

1 - HANDLE C-4171

2 - OUTPUT SHAFT INNER BEARING

3 - INSTALLER 5066

Fig. 48 Output Shaft Rear Bearing Installation Depth

1 - BEARING (SEATED) AT LOWER EDGE OF CHAMFER

2 - CHAMFER

DRTRANSFER CASE - NV243 21 - 497

TRANSFER CASE - NV243 (Continued)

Page 2210 of 2627

EXTENSION HOUSING SEAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Using a suitable pry tool or slide-hammer

mounted screw, remove the extension housing seal.

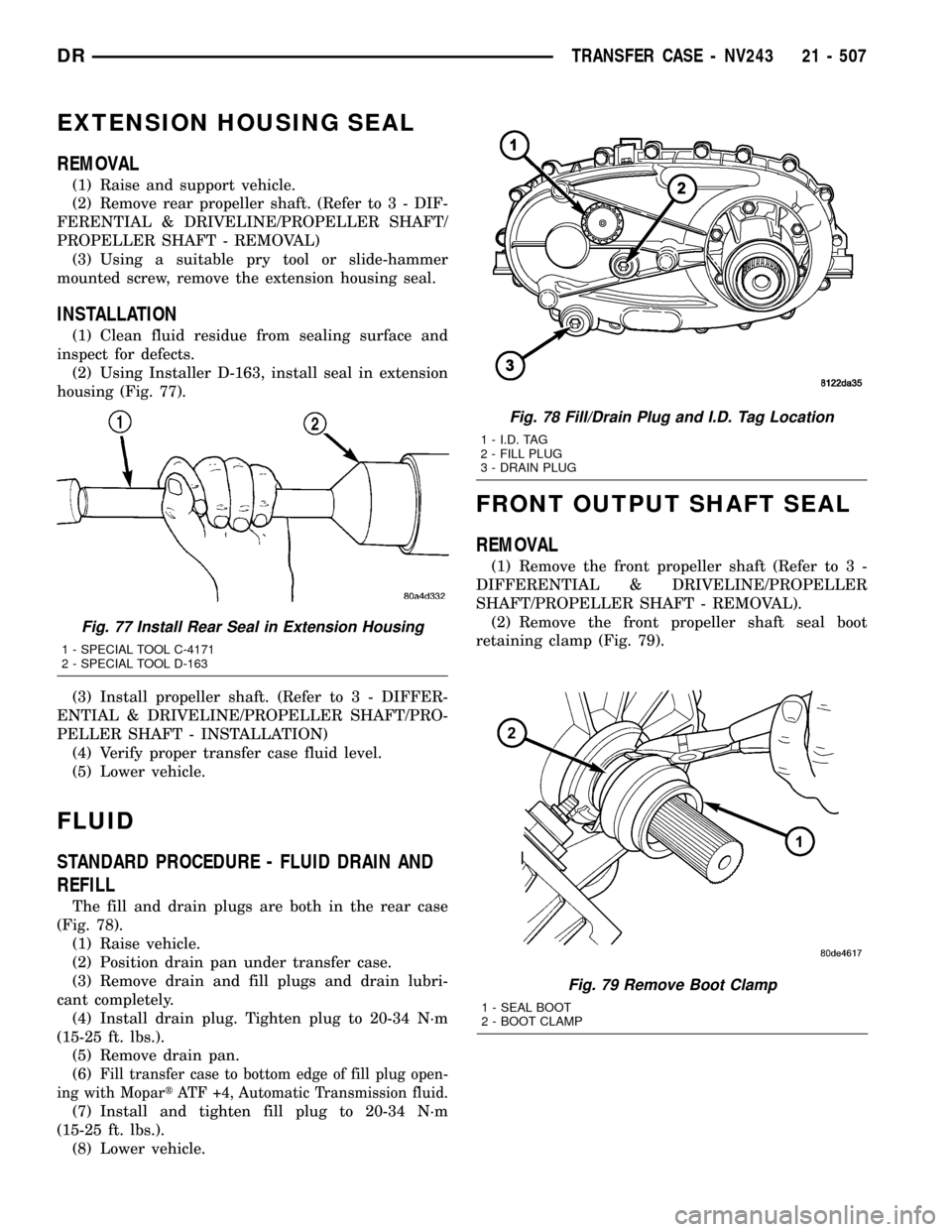

INSTALLATION

(1) Clean fluid residue from sealing surface and

inspect for defects.

(2) Using Installer D-163, install seal in extension

housing (Fig. 77).

(3) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)

(4) Verify proper transfer case fluid level.

(5) Lower vehicle.

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL

The fill and drain plugs are both in the rear case

(Fig. 78).

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 20-34 N´m

(15-25 ft. lbs.).

(5) Remove drain pan.

(6)

Fill transfer case to bottom edge of fill plug open-

ing with MopartATF +4, Automatic Transmission fluid.

(7) Install and tighten fill plug to 20-34 N´m

(15-25 ft. lbs.).

(8) Lower vehicle.

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Remove the front propeller shaft (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL).

(2) Remove the front propeller shaft seal boot

retaining clamp (Fig. 79).

Fig. 79 Remove Boot Clamp

1 - SEAL BOOT

2 - BOOT CLAMP

Fig. 77 Install Rear Seal in Extension Housing

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL D-163

Fig. 78 Fill/Drain Plug and I.D. Tag Location

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

DRTRANSFER CASE - NV243 21 - 507

Page 2214 of 2627

²A flashing operating mode LED for the desired

gear indicates that a shift to that position has been

requested, but all of the driver controllable conditions

have not been met. This is in an attempt to notify the

driver that the transmission needs to be put into NEU-

TRAL, the vehicle speed is too great, or some other con-

dition outlined (other than a diagnostic failure that

would prevent this shift) elsewhere (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/TRANS-

FER CASE CONTROL MODULE - OPERATION) is not

met. Note that this flashing will continue indefinitely

until the conditions are eventually met, or the selector

switch position is changed, or if diagnostic routines no

longer allow the requested shift.

²If the driver attempts to make a shift into transfer

case NEUTRAL, and any of the driver controllable con-

ditions are not met, the request will be ignored until all

of the conditions are met or until the NEUTRAL select

button is released. Additionally the neutral lamp will

flash, or begin to flash while the button is depressed

and operator controllable conditions are not being met.

All of the LED's except the Neutral will flash if any of

the operator controllable conditions for shifting are not

met while the Neutral button is depressed. This9toggle9

type of feature is necessary because the TCCM would

interpret another request immediately after the shift

into transfer case NEUTRAL has completed.

²No LED's illuminated indicate a fault in the

transfer case control system.

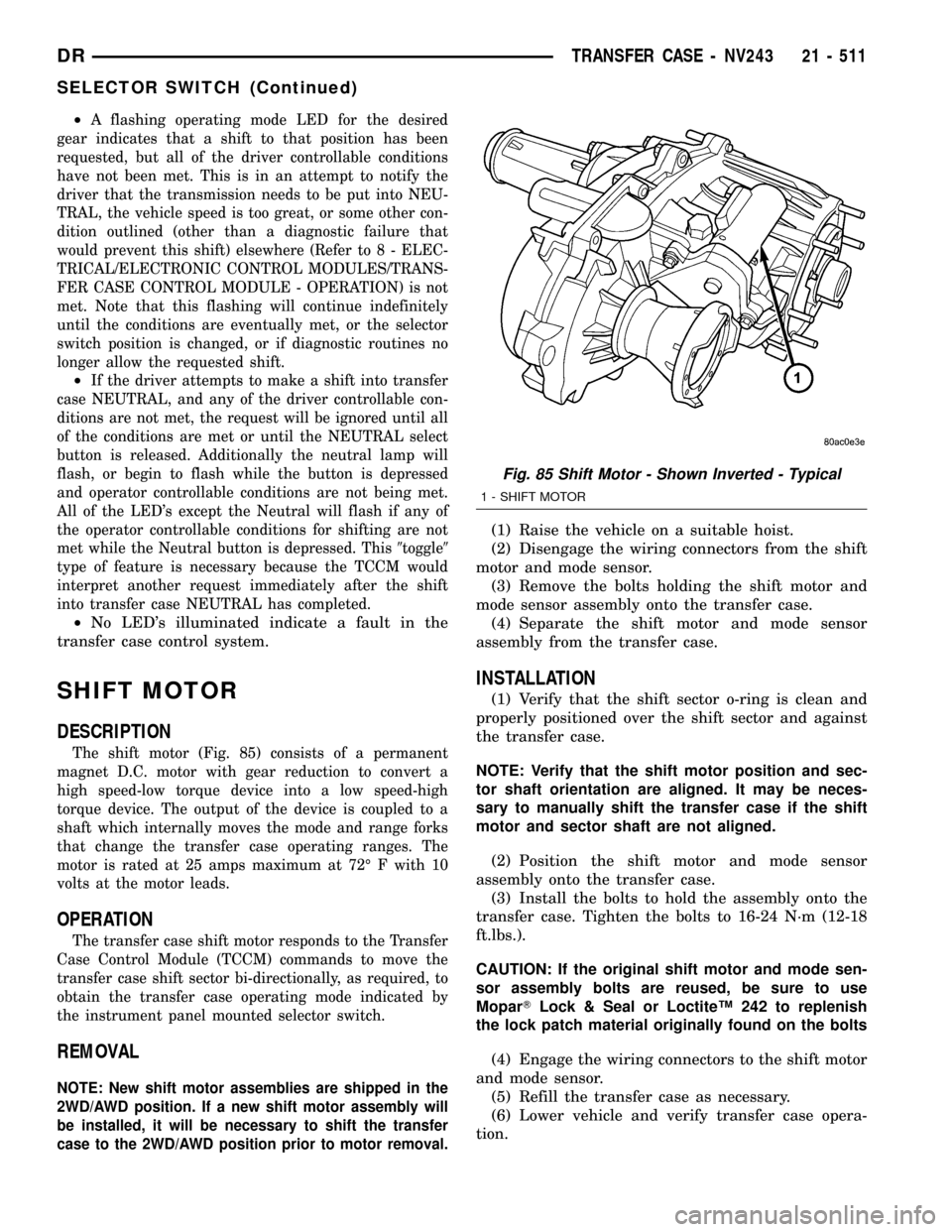

SHIFT MOTOR

DESCRIPTION

The shift motor (Fig. 85) consists of a permanent

magnet D.C. motor with gear reduction to convert a

high speed-low torque device into a low speed-high

torque device. The output of the device is coupled to a

shaft which internally moves the mode and range forks

that change the transfer case operating ranges. The

motor is rated at 25 amps maximum at 72É F with 10

volts at the motor leads.

OPERATION

The transfer case shift motor responds to the Transfer

Case Control Module (TCCM) commands to move the

transfer case shift sector bi-directionally, as required, to

obtain the transfer case operating mode indicated by

the instrument panel mounted selector switch.

REMOVAL

NOTE: New shift motor assemblies are shipped in the

2WD/AWD position. If a new shift motor assembly will

be installed, it will be necessary to shift the transfer

case to the 2WD/AWD position prior to motor removal.

(1) Raise the vehicle on a suitable hoist.

(2) Disengage the wiring connectors from the shift

motor and mode sensor.

(3) Remove the bolts holding the shift motor and

mode sensor assembly onto the transfer case.

(4) Separate the shift motor and mode sensor

assembly from the transfer case.

INSTALLATION

(1) Verify that the shift sector o-ring is clean and

properly positioned over the shift sector and against

the transfer case.

NOTE: Verify that the shift motor position and sec-

tor shaft orientation are aligned. It may be neces-

sary to manually shift the transfer case if the shift

motor and sector shaft are not aligned.

(2) Position the shift motor and mode sensor

assembly onto the transfer case.

(3) Install the bolts to hold the assembly onto the

transfer case. Tighten the bolts to 16-24 N´m (12-18

ft.lbs.).

CAUTION: If the original shift motor and mode sen-

sor assembly bolts are reused, be sure to use

MoparTLock & Seal or LoctiteŸ 242 to replenish

the lock patch material originally found on the bolts

(4) Engage the wiring connectors to the shift motor

and mode sensor.

(5) Refill the transfer case as necessary.

(6) Lower vehicle and verify transfer case opera-

tion.

Fig. 85 Shift Motor - Shown Inverted - Typical

1 - SHIFT MOTOR

DRTRANSFER CASE - NV243 21 - 511

SELECTOR SWITCH (Continued)

Page 2215 of 2627

TRANSFER CASE - NV244 GENII

TABLE OF CONTENTS

page page

TRANSFER CASE - NV244 GENII

DESCRIPTION........................512

OPERATION..........................513

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV244.......................513

REMOVAL............................514

DISASSEMBLY........................514

CLEANING...........................523

INSPECTION.........................523

ASSEMBLY...........................525

INSTALLATION........................534

SPECIFICATIONS

TRANSFER CASE - NV244 GENII........535

SPECIAL TOOLS

TRANSFER CASE - NV244 GENII........535

EXTENSION HOUSING SEAL

REMOVAL............................536

INSTALLATION........................536FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL............................537

FRONT OUTPUT SHAFT SEAL

REMOVAL............................537

INSTALLATION........................538

MODE SENSOR

DESCRIPTION........................538

OPERATION..........................539

SELECTOR SWITCH

DESCRIPTION........................539

OPERATION..........................540

SHIFT MOTOR

DESCRIPTION........................541

OPERATION..........................541

REMOVAL............................541

INSTALLATION........................541

TRANSFER CASE - NV244

GENII

DESCRIPTION

The NV244 GENII is an electronically controlled

full and part-time transfer case with no two wheel

drive operation.

A differential in the transfer case is used to control

torque transfer to the front and rear axles. A low

range gear reduction system provides increased low

speed torque capability for off road operation. The

low range provides a 2.72:1 reduction ratio.

The geartrain is mounted in two aluminum case

halves attached with bolts. The mainshaft front and

rear bearings are mounted in aluminum retainer

housings bolted to the case halves.

OPERATING RANGES

NV244 GENII operating ranges are:

²AWD(All-Wheel Drive)

²4HI (Part-time)

²4LO

²NEUTRAL

The AWD mode can be used at any time and on

any road surface.The 4HI (Part-time) and 4LO ranges are for off

road use only. The only time these ranges can be

used is when the road surface is covered with snow,

ice, or other loose slippery material.

SHIFT MECHANISM

Operating ranges are selected with a dash

mounted shift selector switch. The shift selector

switch provides a input to the Transfer Case Control

Module (TCCM) to indicate the driver's desire to

change operating ranges. The TCCM uses this input,

along with the input from the transfer case mounted

mode sensor and information from the vehicle's bus,

to determine if a shift is permitted. If the TCCM

decides the shift is permitted, the TCCM controls the

shift motor, mounted to the exterior of the transfer

case, to perform the shift.

21 - 512 TRANSFER CASE - NV244 GENIIDR

Page 2217 of 2627

CONDITION POSSIBLE CAUSE CORRECTION

Lubricant leaking from transfer case

seals or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Transfer case vent closed or

restricted.2) Clean or replace vent as

necessary.

3) Transfer case seals damaged or

installed incorrectly.3) Replace suspect seal.

Transfer case will not shift through

4HI (Part-time) range.1) Incomplete shift due to drivetrain

torque load.1) Drive in a straight line and

momentarily release the accelerator

pedal to complete the shift.

2) Incorrect tire pressure. 2) Correct tire pressure as

necessary.

3) Excessive tire wear. 3) Correct tire condition as

necessary.

4) Excessive vehicle loading. 4) Correct as necessary.

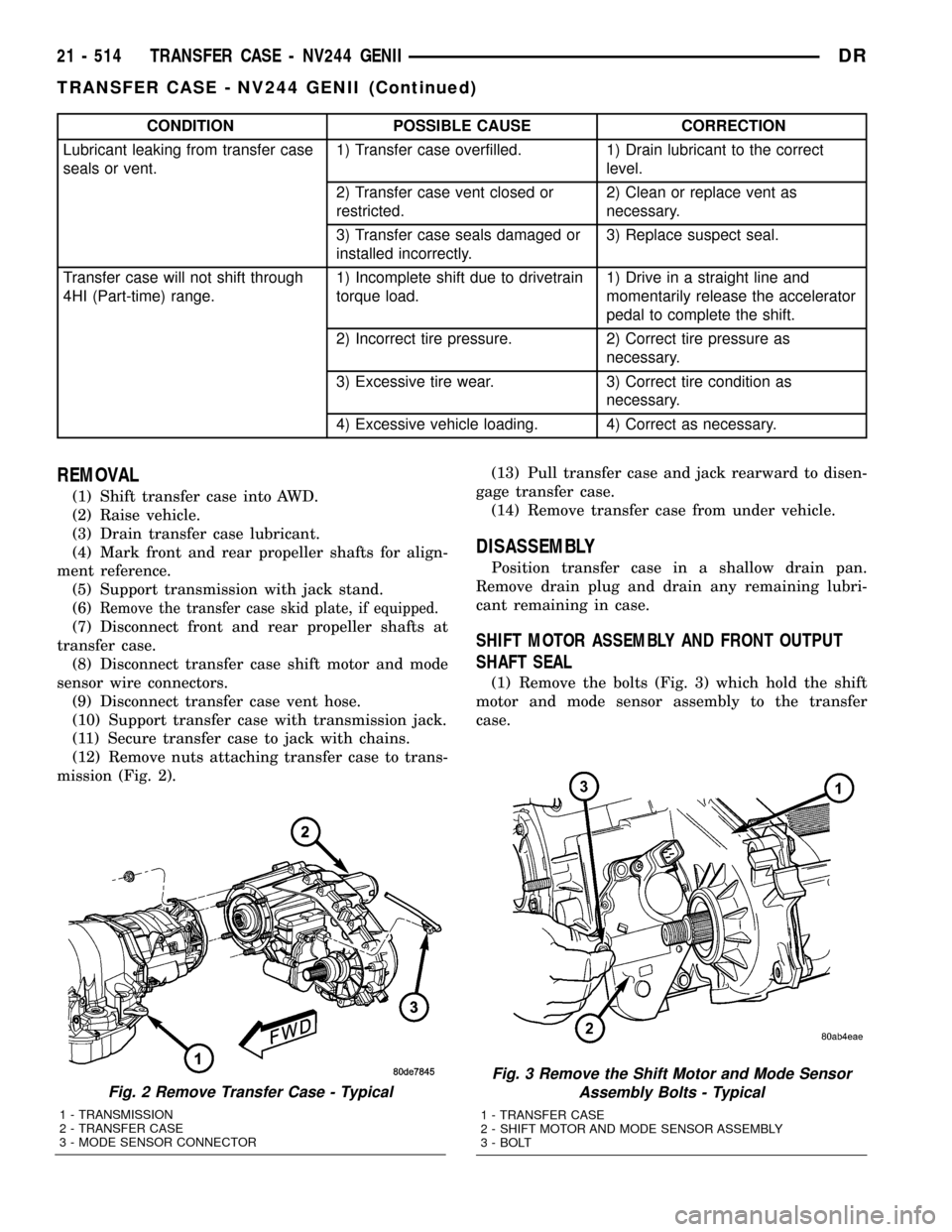

REMOVAL

(1) Shift transfer case into AWD.

(2) Raise vehicle.

(3) Drain transfer case lubricant.

(4) Mark front and rear propeller shafts for align-

ment reference.

(5) Support transmission with jack stand.

(6)

Remove the transfer case skid plate, if equipped.

(7) Disconnect front and rear propeller shafts at

transfer case.

(8) Disconnect transfer case shift motor and mode

sensor wire connectors.

(9) Disconnect transfer case vent hose.

(10) Support transfer case with transmission jack.

(11) Secure transfer case to jack with chains.

(12) Remove nuts attaching transfer case to trans-

mission (Fig. 2).(13) Pull transfer case and jack rearward to disen-

gage transfer case.

(14) Remove transfer case from under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan.

Remove drain plug and drain any remaining lubri-

cant remaining in case.

SHIFT MOTOR ASSEMBLY AND FRONT OUTPUT

SHAFT SEAL

(1) Remove the bolts (Fig. 3) which hold the shift

motor and mode sensor assembly to the transfer

case.

Fig. 2 Remove Transfer Case - Typical

1 - TRANSMISSION

2 - TRANSFER CASE

3 - MODE SENSOR CONNECTOR

Fig. 3 Remove the Shift Motor and Mode Sensor

Assembly Bolts - Typical

1 - TRANSFER CASE

2 - SHIFT MOTOR AND MODE SENSOR ASSEMBLY

3 - BOLT

21 - 514 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2222 of 2627

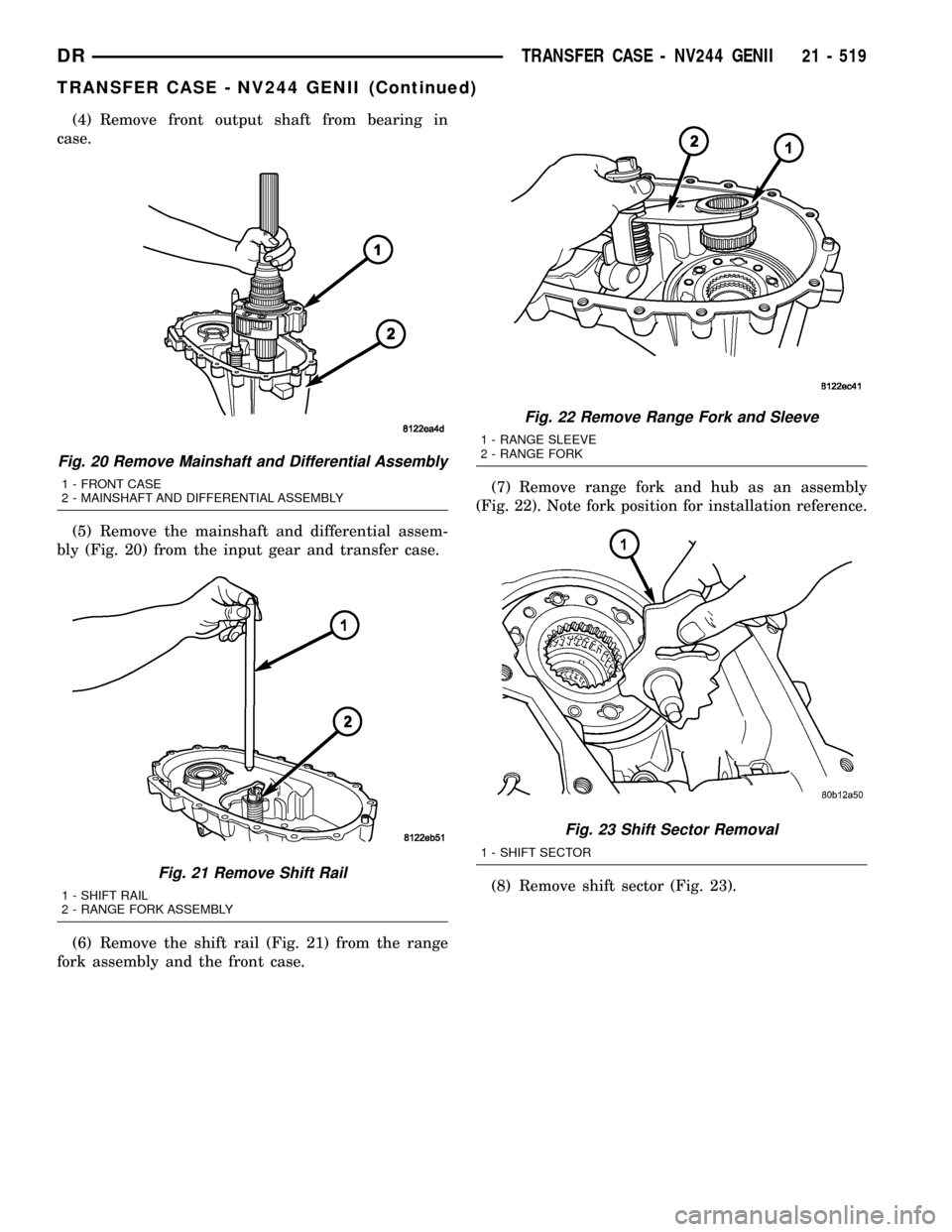

(4) Remove front output shaft from bearing in

case.

(5) Remove the mainshaft and differential assem-

bly (Fig. 20) from the input gear and transfer case.

(6) Remove the shift rail (Fig. 21) from the range

fork assembly and the front case.(7) Remove range fork and hub as an assembly

(Fig. 22). Note fork position for installation reference.

(8) Remove shift sector (Fig. 23).

Fig. 20 Remove Mainshaft and Differential Assembly

1 - FRONT CASE

2 - MAINSHAFT AND DIFFERENTIAL ASSEMBLY

Fig. 21 Remove Shift Rail

1 - SHIFT RAIL

2 - RANGE FORK ASSEMBLY

Fig. 22 Remove Range Fork and Sleeve

1 - RANGE SLEEVE

2 - RANGE FORK

Fig. 23 Shift Sector Removal

1 - SHIFT SECTOR

DRTRANSFER CASE - NV244 GENII 21 - 519

TRANSFER CASE - NV244 GENII (Continued)

Page 2225 of 2627

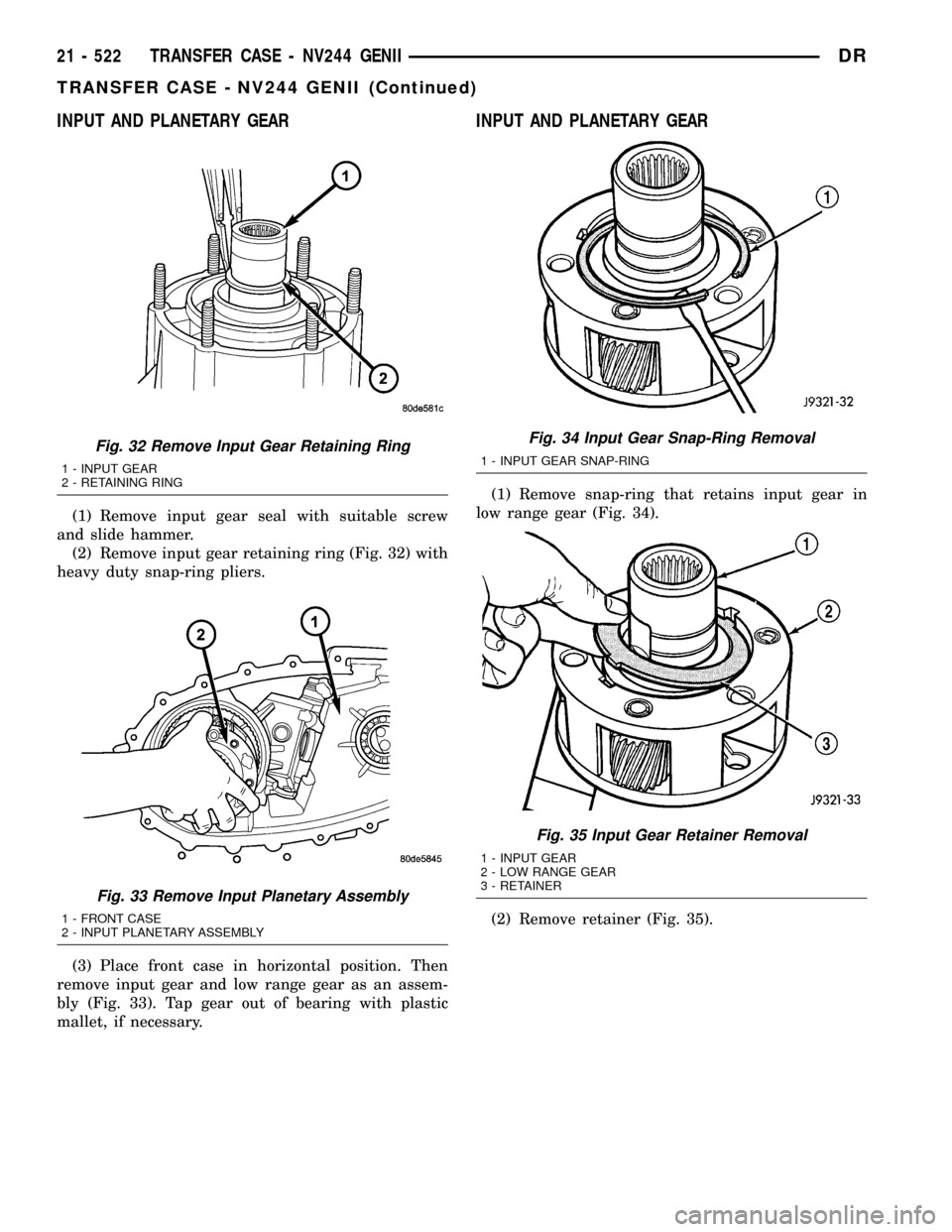

INPUT AND PLANETARY GEAR

(1) Remove input gear seal with suitable screw

and slide hammer.

(2) Remove input gear retaining ring (Fig. 32) with

heavy duty snap-ring pliers.

(3) Place front case in horizontal position. Then

remove input gear and low range gear as an assem-

bly (Fig. 33). Tap gear out of bearing with plastic

mallet, if necessary.

INPUT AND PLANETARY GEAR

(1) Remove snap-ring that retains input gear in

low range gear (Fig. 34).

(2) Remove retainer (Fig. 35).

Fig. 32 Remove Input Gear Retaining Ring

1 - INPUT GEAR

2 - RETAINING RING

Fig. 33 Remove Input Planetary Assembly

1 - FRONT CASE

2 - INPUT PLANETARY ASSEMBLY

Fig. 34 Input Gear Snap-Ring Removal

1 - INPUT GEAR SNAP-RING

Fig. 35 Input Gear Retainer Removal

1 - INPUT GEAR

2 - LOW RANGE GEAR

3 - RETAINER

21 - 522 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2226 of 2627

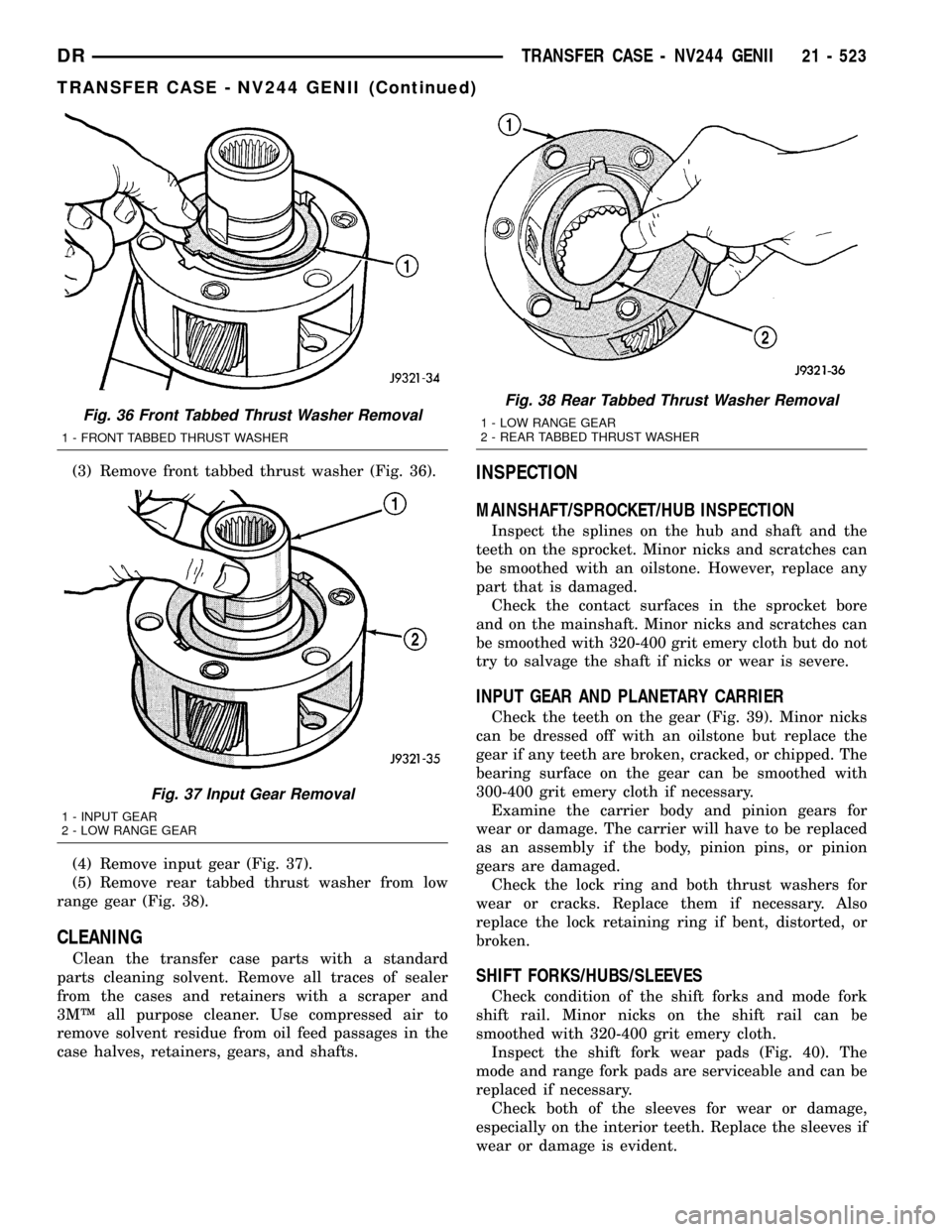

(3) Remove front tabbed thrust washer (Fig. 36).

(4) Remove input gear (Fig. 37).

(5) Remove rear tabbed thrust washer from low

range gear (Fig. 38).

CLEANING

Clean the transfer case parts with a standard

parts cleaning solvent. Remove all traces of sealer

from the cases and retainers with a scraper and

3MŸ all purpose cleaner. Use compressed air to

remove solvent residue from oil feed passages in the

case halves, retainers, gears, and shafts.

INSPECTION

MAINSHAFT/SPROCKET/HUB INSPECTION

Inspect the splines on the hub and shaft and the

teeth on the sprocket. Minor nicks and scratches can

be smoothed with an oilstone. However, replace any

part that is damaged.

Check the contact surfaces in the sprocket bore

and on the mainshaft. Minor nicks and scratches can

be smoothed with 320-400 grit emery cloth but do not

try to salvage the shaft if nicks or wear is severe.

INPUT GEAR AND PLANETARY CARRIER

Check the teeth on the gear (Fig. 39). Minor nicks

can be dressed off with an oilstone but replace the

gear if any teeth are broken, cracked, or chipped. The

bearing surface on the gear can be smoothed with

300-400 grit emery cloth if necessary.

Examine the carrier body and pinion gears for

wear or damage. The carrier will have to be replaced

as an assembly if the body, pinion pins, or pinion

gears are damaged.

Check the lock ring and both thrust washers for

wear or cracks. Replace them if necessary. Also

replace the lock retaining ring if bent, distorted, or

broken.

SHIFT FORKS/HUBS/SLEEVES

Check condition of the shift forks and mode fork

shift rail. Minor nicks on the shift rail can be

smoothed with 320-400 grit emery cloth.

Inspect the shift fork wear pads (Fig. 40). The

mode and range fork pads are serviceable and can be

replaced if necessary.

Check both of the sleeves for wear or damage,

especially on the interior teeth. Replace the sleeves if

wear or damage is evident.

Fig. 36 Front Tabbed Thrust Washer Removal

1 - FRONT TABBED THRUST WASHER

Fig. 37 Input Gear Removal

1 - INPUT GEAR

2 - LOW RANGE GEAR

Fig. 38 Rear Tabbed Thrust Washer Removal

1 - LOW RANGE GEAR

2 - REAR TABBED THRUST WASHER

DRTRANSFER CASE - NV244 GENII 21 - 523

TRANSFER CASE - NV244 GENII (Continued)

Page 2228 of 2627

FRONT AND REAR CASES

Inspect the cases for wear and damage.

Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with Helicoiltstain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

ASSEMBLY

BEARINGS AND SEALS

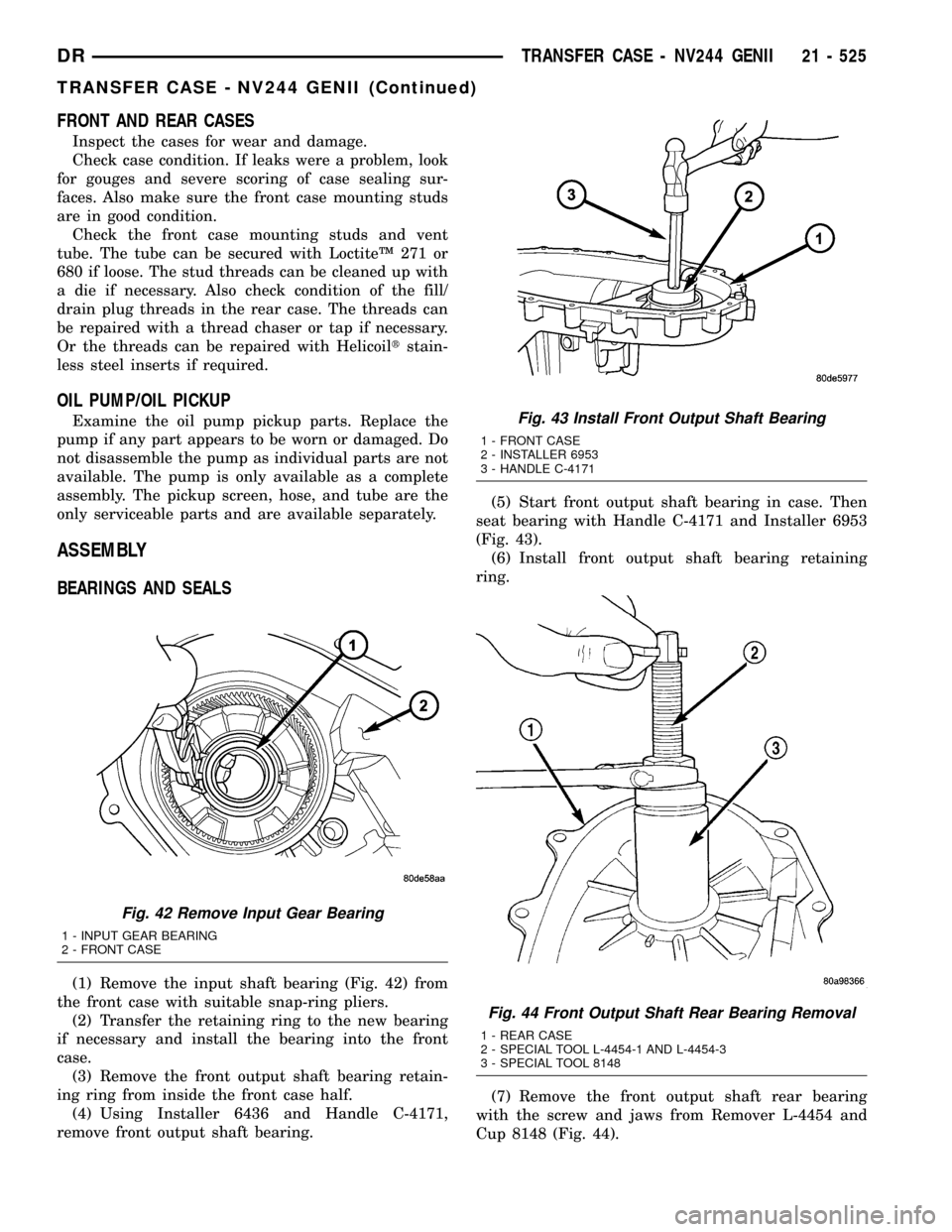

(1) Remove the input shaft bearing (Fig. 42) from

the front case with suitable snap-ring pliers.

(2) Transfer the retaining ring to the new bearing

if necessary and install the bearing into the front

case.

(3) Remove the front output shaft bearing retain-

ing ring from inside the front case half.

(4) Using Installer 6436 and Handle C-4171,

remove front output shaft bearing.(5) Start front output shaft bearing in case. Then

seat bearing with Handle C-4171 and Installer 6953

(Fig. 43).

(6) Install front output shaft bearing retaining

ring.

(7) Remove the front output shaft rear bearing

with the screw and jaws from Remover L-4454 and

Cup 8148 (Fig. 44).

Fig. 42 Remove Input Gear Bearing

1 - INPUT GEAR BEARING

2 - FRONT CASE

Fig. 43 Install Front Output Shaft Bearing

1 - FRONT CASE

2 - INSTALLER 6953

3 - HANDLE C-4171

Fig. 44 Front Output Shaft Rear Bearing Removal

1 - REAR CASE

2 - SPECIAL TOOL L-4454-1 AND L-4454-3

3 - SPECIAL TOOL 8148

DRTRANSFER CASE - NV244 GENII 21 - 525

TRANSFER CASE - NV244 GENII (Continued)

Page 2230 of 2627

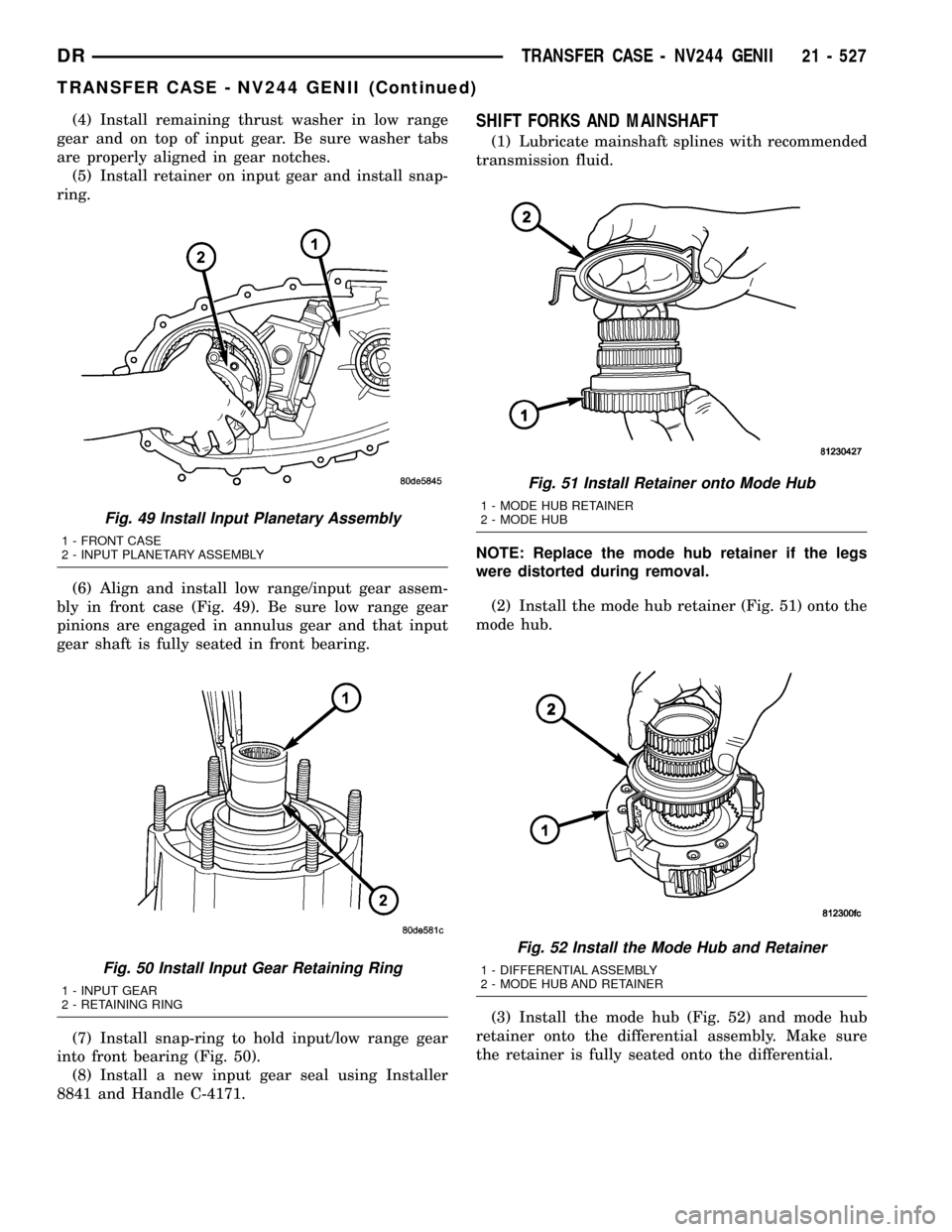

(4) Install remaining thrust washer in low range

gear and on top of input gear. Be sure washer tabs

are properly aligned in gear notches.

(5) Install retainer on input gear and install snap-

ring.

(6) Align and install low range/input gear assem-

bly in front case (Fig. 49). Be sure low range gear

pinions are engaged in annulus gear and that input

gear shaft is fully seated in front bearing.

(7) Install snap-ring to hold input/low range gear

into front bearing (Fig. 50).

(8) Install a new input gear seal using Installer

8841 and Handle C-4171.SHIFT FORKS AND MAINSHAFT

(1) Lubricate mainshaft splines with recommended

transmission fluid.

NOTE: Replace the mode hub retainer if the legs

were distorted during removal.

(2) Install the mode hub retainer (Fig. 51) onto the

mode hub.

(3) Install the mode hub (Fig. 52) and mode hub

retainer onto the differential assembly. Make sure

the retainer is fully seated onto the differential.

Fig. 49 Install Input Planetary Assembly

1 - FRONT CASE

2 - INPUT PLANETARY ASSEMBLY

Fig. 50 Install Input Gear Retaining Ring

1 - INPUT GEAR

2 - RETAINING RING

Fig. 51 Install Retainer onto Mode Hub

1 - MODE HUB RETAINER

2 - MODE HUB

Fig. 52 Install the Mode Hub and Retainer

1 - DIFFERENTIAL ASSEMBLY

2 - MODE HUB AND RETAINER

DRTRANSFER CASE - NV244 GENII 21 - 527

TRANSFER CASE - NV244 GENII (Continued)