One DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2101 of 2627

SHIFT MECHANISM

DESCRIPTION

The gear shift mechanism provides six shift posi-

tions which are:

²Park (P)

²Reverse (R)

²Neutral (N)

²Drive (D)

²Manual second (2)

²Manual low (1)

OPERATION

MANUAL LOW (1) range provides first gear only.

Overrun braking is also provided in this range.

MANUAL SECOND (2) range provides first and sec-

ond gear only.

DRIVE range provides FIRST, SECOND, THIRD,

OVERDRIVE FOURTH, and OVERDRIVE FIFTH (if

applicable) gear ranges. The shift into OVERDRIVE

FOURTH and FIFTH (if applicable) gear ranges

occurs only after the transmission has completed the

shift into D THIRD gear range. No further movement

of the shift mechanism is required to complete the

3-4 or 4-5 (if applicable) shifts.

The FOURTH and FIFTH (if applicable) gear

upshifts occur automatically when the overdrive

selector switch is in the ON position. No upshift to

FOURTH or FIFTH (if applicable) gears will occur if

any of the following are true:

²The transmission fluid temperature is below 10É

C (50É F) or above 121É C (250É F).

²The shift to THIRD is not yet complete.

²Vehicle speed is too low for the 3-4 or 4-5 (if

applicable) shifts to occur.

Upshifts into FOURTH or FIFTH (if applicable)

will be delayed when the transmission fluid temper-

ature is below 4.5É C (40É F) or above 115.5É C (240É

F).

SOLENOID SWITCH VALVE

DESCRIPTION

The Solenoid Switch Valve (SSV) is located in the

valve body and controls the direction of the transmis-

sion fluid when the L/R-TCC solenoid is energized.

OPERATION

The Solenoid Switch Valve controls line pressure

from the LR-TCC solenoid. In 1st gear, the SSV will

be in the downshifted position, thus directing fluid to

the L/R clutch circuit. In 2nd, 3rd, 4th, and 5th (if

applicable) gears, the solenoid switch valve will be in

the upshifted position and directs the fluid into the

torque converter clutch (TCC) circuit.When shifting into 1st gear, a special hydraulic

sequence is performed to ensure SSV movement into

the downshifted position. The L/R pressure switch is

monitored to confirm SSV movement. If the move-

ment is not confirmed (the L/R pressure switch does

not close), 2nd gear is substituted for 1st. A DTC will

be set after three unsuccessful attempts are made to

get into 1st gear in one given key start.

SOLENOIDS

DESCRIPTION

The typical electrical solenoid used in automotive

applications is a linear actuator. It is a device that

produces motion in a straight line. This straight line

motion can be either forward or backward in direc-

tion, and short or long distance.

A solenoid is an electromechanical device that uses

a magnetic force to perform work. It consists of a coil

of wire, wrapped around a magnetic core made from

steel or iron, and a spring loaded, movable plunger,

which performs the work, or straight line motion.

The solenoids used in transmission applications

are attached to valves which can be classified asnor-

mally openornormally closed. Thenormally

opensolenoid valve is defined as a valve which

allows hydraulic flow when no current or voltage is

applied to the solenoid. Thenormally closedsole-

noid valve is defined as a valve which does not allow

hydraulic flow when no current or voltage is applied

to the solenoid. These valves perform hydraulic con-

trol functions for the transmission and must there-

fore be durable and tolerant of dirt particles. For

these reasons, the valves have hardened steel pop-

pets and ball valves. The solenoids operate the valves

directly, which means that the solenoids must have

very high outputs to close the valves against the siz-

able flow areas and line pressures found in current

transmissions. Fast response time is also necessary

to ensure accurate control of the transmission.

The strength of the magnetic field is the primary

force that determines the speed of operation in a par-

ticular solenoid design. A stronger magnetic field will

cause the plunger to move at a greater speed than a

weaker one. There are basically two ways to increase

the force of the magnetic field:

1. Increase the amount of current applied to the

coil or

2. Increase the number of turns of wire in the coil.

The most common practice is to increase the num-

ber of turns by using thin wire that can completely

fill the available space within the solenoid housing.

The strength of the spring and the length of the

plunger also contribute to the response speed possi-

ble by a particular solenoid design.

21 - 398 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2103 of 2627

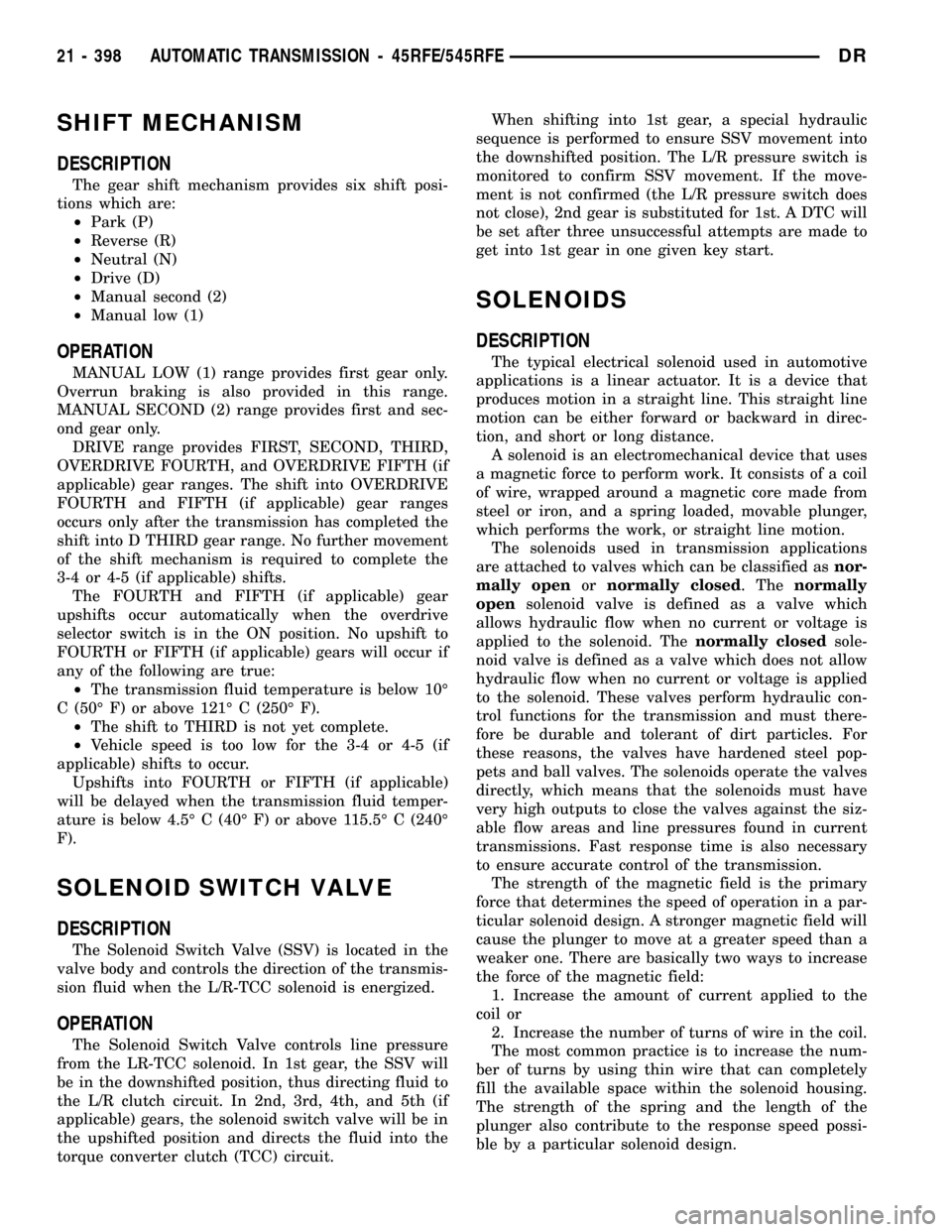

IMPELLER

The impeller (Fig. 118) is an integral part of the

converter housing. The impeller consists of curved

blades placed radially along the inside of the housing

on the transmission side of the converter. As the con-

verter housing is rotated by the engine, so is the

impeller, because they are one and the same and are

the driving members of the system.

Fig. 118 Impeller

1 - ENGINE FLEXPLATE 4 - ENGINE ROTATION

2 - OIL FLOW FROM IMPELLER SECTION INTO TURBINE

SECTION5 - ENGINE ROTATION

3 - IMPELLER VANES AND COVER ARE INTEGRAL

21 - 400 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

TORQUE CONVERTER (Continued)

Page 2105 of 2627

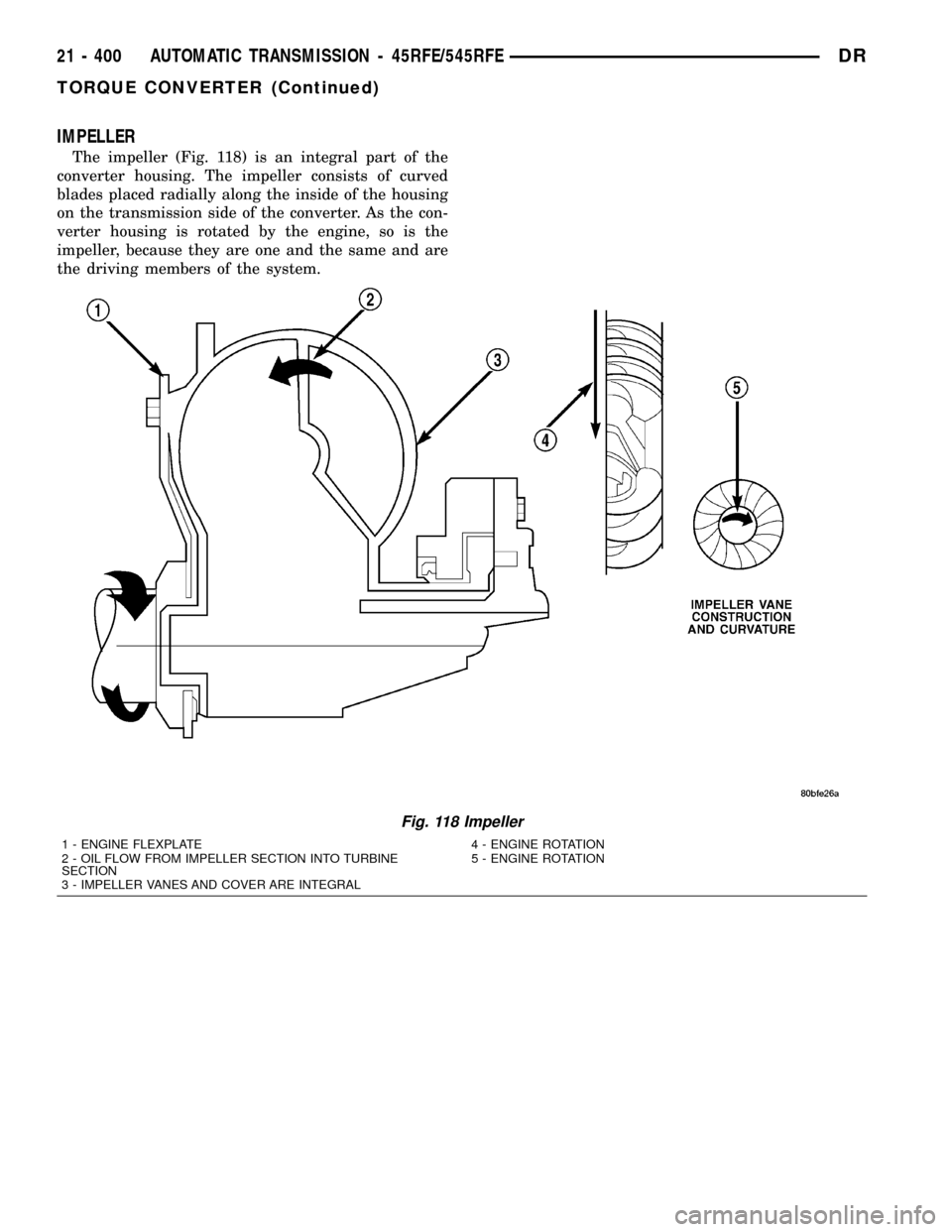

STATOR

The stator assembly (Fig. 120) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 121).

The stator contains an over-running clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the over-run-

ning clutch, the torque multiplication feature of the

torque converter is operational.

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 122) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock-free power transfer, it is

natural for all fluid couplings to slip. If the impeller

and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston with friction material was added to the tur-

bine assembly to provide this mechanical lock-up.

In order to reduce heat build-up in the transmis-

sion and buffer the powertrain against torsional

vibrations, the TCM can duty cycle the L/R-CC Sole-

noid to achieve a smooth application of the torque

converter clutch. This function, referred to as Elec-

tronically Modulated Converter Clutch (EMCC) can

occur at various times depending on the following

variables:

²Shift lever position

²Current gear range

²Transmission fluid temperature

²Engine coolant temperature

²Input speed

²Throttle angle²Engine speed

Fig. 120 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 121 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 122 Torque Converter Clutch (TCC)

1 - IMPELLER FRONT COVER

2 - THRUST WASHER ASSEMBLY

3 - IMPELLER

4-STATOR

5 - TURBINE

6 - PISTON

7 - FRICTION DISC

21 - 402 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

TORQUE CONVERTER (Continued)

Page 2107 of 2627

control switch is in the OFF position, the clutch will

engage after the shift to third gear.

The TCM controls the torque converter by way of

internal logic software. The programming of the soft-

ware provides the TCM with control over the L/R-CC

Solenoid. There are four output logic states that can

be applied as follows:

²No EMCC

²Partial EMCC

²Full EMCC

²Gradual-to-no EMCC

NO EMCC

Under No EMCC conditions, the L/R Solenoid is

OFF. There are several conditions that can result in

NO EMCC operations. No EMCC can be initiated

due to a fault in the transmission or because the

TCM does not see the need for EMCC under current

driving conditions.

PARTIAL EMCC

Partial EMCC operation modulates the L/R Sole-

noid (duty cycle) to obtain partial torque converter

clutch application. Partial EMCC operation is main-

tained until Full EMCC is called for and actuated.

During Partial EMCC some slip does occur. Partial

EMCC will usually occur at low speeds, low load and

light throttle situations.

FULL EMCC

During Full EMCC operation, the TCM increases

the L/R Solenoid duty cycle to full ON after Partial

EMCC control brings the engine speed within thedesired slip range of transmission input speed rela-

tive to engine rpm.

GRADUAL-TO-NO EMCC

This operation is to soften the change from Full or

Partial EMCC to No EMCC. This is done at mid-

throttle by decreasing the L/R Solenoid duty cycle.

REMOVAL

(1) Remove transmission and torque converter

from vehicle.

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive flats for sharp

edges, burrs, scratches, or nicks. Polish the hub and

flats with 320/400 grit paper or crocus cloth if neces-

sary. Verify that the converter hub o-ring is properly

installed and is free from debris. The hub must be

smooth to avoid damaging the pump seal at installa-

tion.

(1) Lubricate oil pump seal lip with transmission

fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or con-

verter hub o-ring while inserting torque converter

into the front of the transmission.

(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 125). Surface of converter lugs

should be at least 13 mm (1/2 in.) to rear of straight-

edge when converter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle.

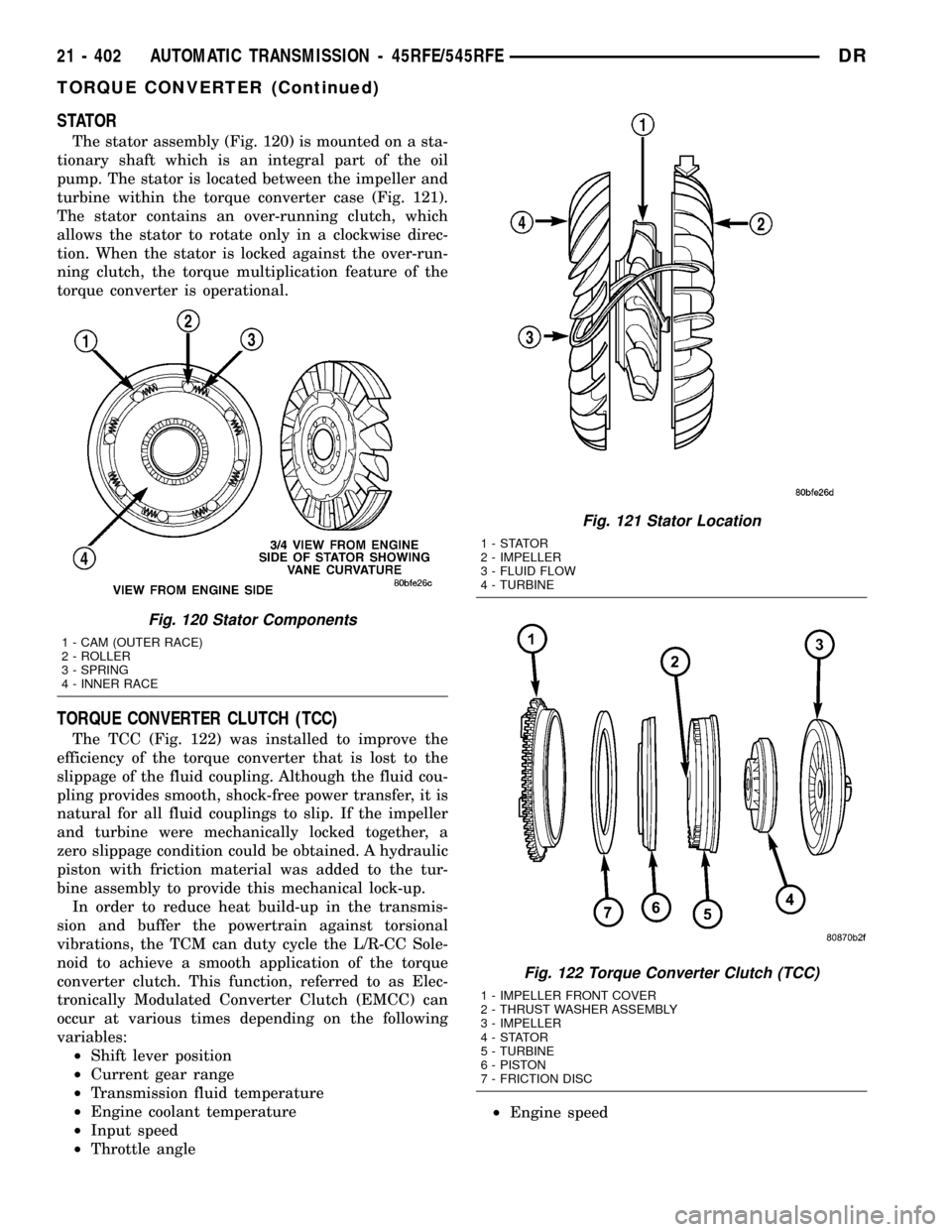

Fig. 124 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

21 - 404 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

TORQUE CONVERTER (Continued)

Page 2109 of 2627

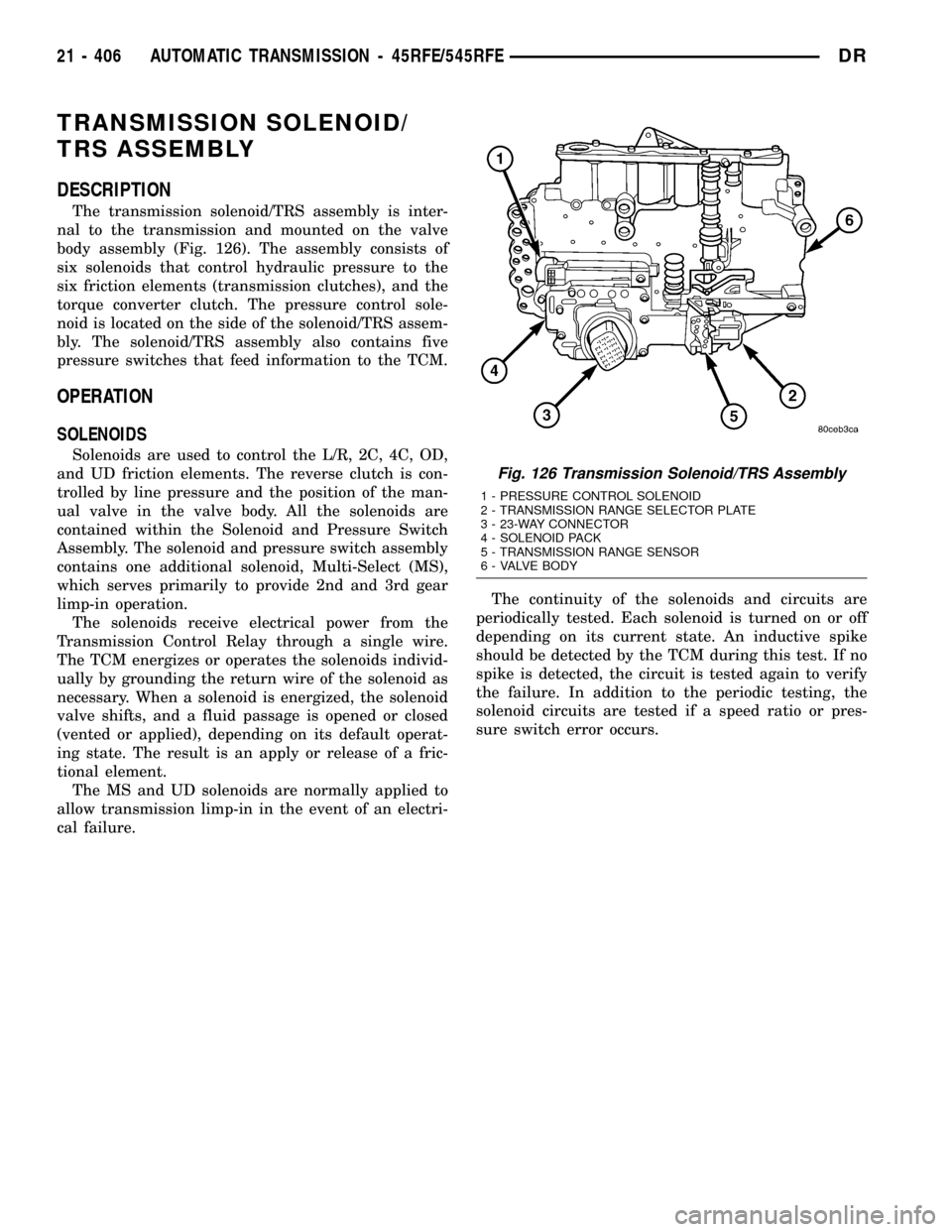

TRANSMISSION SOLENOID/

TRS ASSEMBLY

DESCRIPTION

The transmission solenoid/TRS assembly is inter-

nal to the transmission and mounted on the valve

body assembly (Fig. 126). The assembly consists of

six solenoids that control hydraulic pressure to the

six friction elements (transmission clutches), and the

torque converter clutch. The pressure control sole-

noid is located on the side of the solenoid/TRS assem-

bly. The solenoid/TRS assembly also contains five

pressure switches that feed information to the TCM.

OPERATION

SOLENOIDS

Solenoids are used to control the L/R, 2C, 4C, OD,

and UD friction elements. The reverse clutch is con-

trolled by line pressure and the position of the man-

ual valve in the valve body. All the solenoids are

contained within the Solenoid and Pressure Switch

Assembly. The solenoid and pressure switch assembly

contains one additional solenoid, Multi-Select (MS),

which serves primarily to provide 2nd and 3rd gear

limp-in operation.

The solenoids receive electrical power from the

Transmission Control Relay through a single wire.

The TCM energizes or operates the solenoids individ-

ually by grounding the return wire of the solenoid as

necessary. When a solenoid is energized, the solenoid

valve shifts, and a fluid passage is opened or closed

(vented or applied), depending on its default operat-

ing state. The result is an apply or release of a fric-

tional element.

The MS and UD solenoids are normally applied to

allow transmission limp-in in the event of an electri-

cal failure.The continuity of the solenoids and circuits are

periodically tested. Each solenoid is turned on or off

depending on its current state. An inductive spike

should be detected by the TCM during this test. If no

spike is detected, the circuit is tested again to verify

the failure. In addition to the periodic testing, the

solenoid circuits are tested if a speed ratio or pres-

sure switch error occurs.

Fig. 126 Transmission Solenoid/TRS Assembly

1 - PRESSURE CONTROL SOLENOID

2 - TRANSMISSION RANGE SELECTOR PLATE

3 - 23-WAY CONNECTOR

4 - SOLENOID PACK

5 - TRANSMISSION RANGE SENSOR

6 - VALVE BODY

21 - 406 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2111 of 2627

INSTALLATION

(1) Place TRS selector plate in the PARK position.

(2) Position the transmission solenoid/TRS assem-

bly onto the valve body. Be sure that both alignment

dowels are fully seated in the valve body and that

the TRS switch contacts are properly positioned in

the selector plate

(3) Install the screws to hold the transmission

solenoid/TRS assembly onto the valve body.

(4) Tighten the solenoid assembly screws adjacent

to the arrows cast into the bottom of the valve body

first. Tighten the screws to 5.7 N´m (50 in.lbs.).

(5) Tighten the remainder of the solenoid assembly

screws to 5.7 N´m (50 in.lbs.).

(6) Install the valve body into the transmission.

TRANSMISSION

TEMPERATURE SENSOR

DESCRIPTION

The transmission temperature sensor is a ther-

mistor that is integral to the Transmission Range

Sensor (TRS).

OPERATION

The transmission temperature sensor is used by

the TCM to sense the temperature of the fluid in the

sump. Since fluid temperature can affect transmis-

sion shift quality and convertor lock up, the TCM

requires this information to determine which shift

schedule to operate in.

Calculated Temperature

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-

dicted fluid temperature which is calculated from a

combination of inputs:

²Battery (ambient) temperature

²Engine coolant temperature

²In-gear run time since start-up

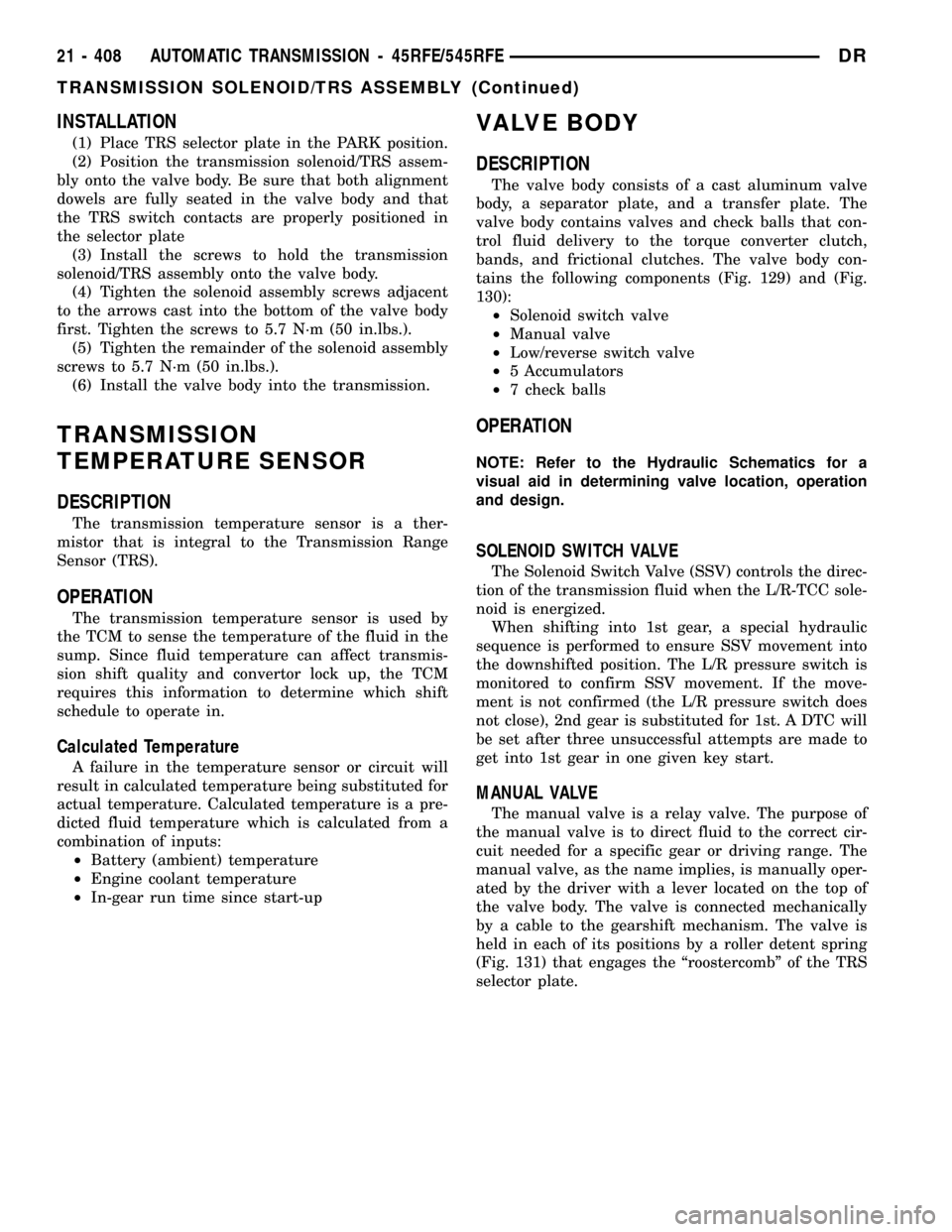

VALVE BODY

DESCRIPTION

The valve body consists of a cast aluminum valve

body, a separator plate, and a transfer plate. The

valve body contains valves and check balls that con-

trol fluid delivery to the torque converter clutch,

bands, and frictional clutches. The valve body con-

tains the following components (Fig. 129) and (Fig.

130):

²Solenoid switch valve

²Manual valve

²Low/reverse switch valve

²5 Accumulators

²7 check balls

OPERATION

NOTE: Refer to the Hydraulic Schematics for a

visual aid in determining valve location, operation

and design.

SOLENOID SWITCH VALVE

The Solenoid Switch Valve (SSV) controls the direc-

tion of the transmission fluid when the L/R-TCC sole-

noid is energized.

When shifting into 1st gear, a special hydraulic

sequence is performed to ensure SSV movement into

the downshifted position. The L/R pressure switch is

monitored to confirm SSV movement. If the move-

ment is not confirmed (the L/R pressure switch does

not close), 2nd gear is substituted for 1st. A DTC will

be set after three unsuccessful attempts are made to

get into 1st gear in one given key start.

MANUAL VALVE

The manual valve is a relay valve. The purpose of

the manual valve is to direct fluid to the correct cir-

cuit needed for a specific gear or driving range. The

manual valve, as the name implies, is manually oper-

ated by the driver with a lever located on the top of

the valve body. The valve is connected mechanically

by a cable to the gearshift mechanism. The valve is

held in each of its positions by a roller detent spring

(Fig. 131) that engages the ªroostercombº of the TRS

selector plate.

21 - 408 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

TRANSMISSION SOLENOID/TRS ASSEMBLY (Continued)

Page 2112 of 2627

Fig. 129 Valve Body Components

1 - LOW/REVERSE ACCUMULATOR 6 - OVERDRIVE ACCUMULATOR

2 - LOW/REVERSE SWITCH VALVE 7 - UNDERDRIVE ACCUMULATOR

3 - UPPER VALVE BODY 8 - 4C ACCUMULATOR

4 - MANUAL VALVE 9 - 2C ACCUMULATOR

5 - SOLENOID SWITCH VALVE

Fig. 130 Check Ball Locations

Fig. 131 TRS Selector Plate and Detent Spring

1 - TRS SELECTOR PLATE

2 - DETENT SPRING

3 - CLUTCH PASSAGE SEALS

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 409

VALVE BODY (Continued)

Page 2113 of 2627

LOW/REVERSE SWITCH VALVE

The low/reverse switch valve allows the low/reverse

clutch to be operated by either the LR/CC solenoid or

the MS solenoid.

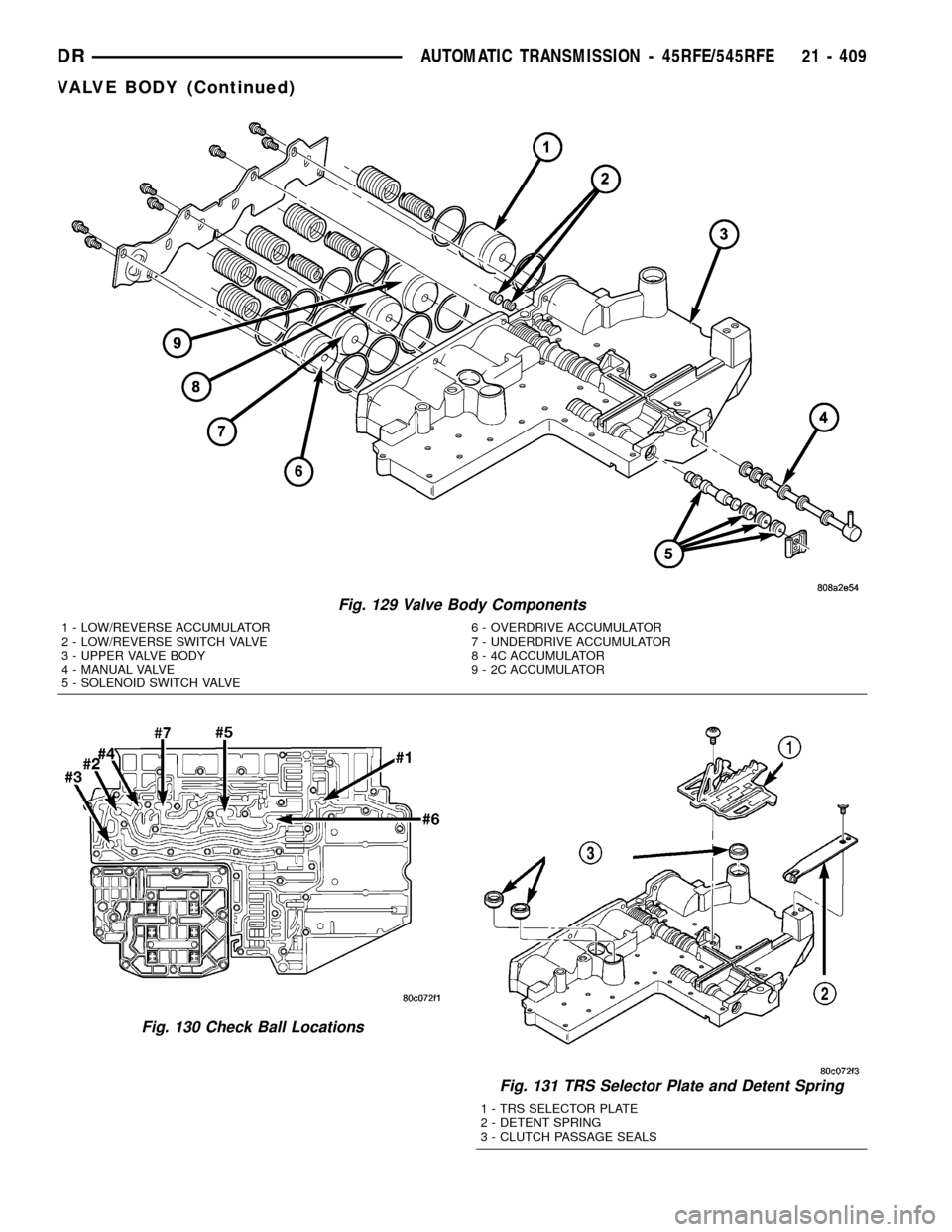

REMOVAL

The valve body can be removed for service without

having to remove the transmission assembly.

The valve body can be disassembled for cleaning

and inspection of the individual components. (Refer

to 21 - TRANSMISSION/AUTOMATIC - 45RFE/

VALVE BODY - DISASSEMBLY)

(1) Shift transmission into PARK.

(2) Raise vehicle.

(3) Disconnect wires at the solenoid and pressure

switch assembly connector.

(4) Position drain pan under transmission oil pan.

(5) Remove transmission oil pan.

(6) Remove the primary oil filter from valve body.

(Fig. 132)

(7) Remove bolts attaching valve body to transmis-

sion case (Fig. 133).

(8) Lower the valve body and work the electrical

connector out of transmission case.

(9) Separate the valve body from the transmission.

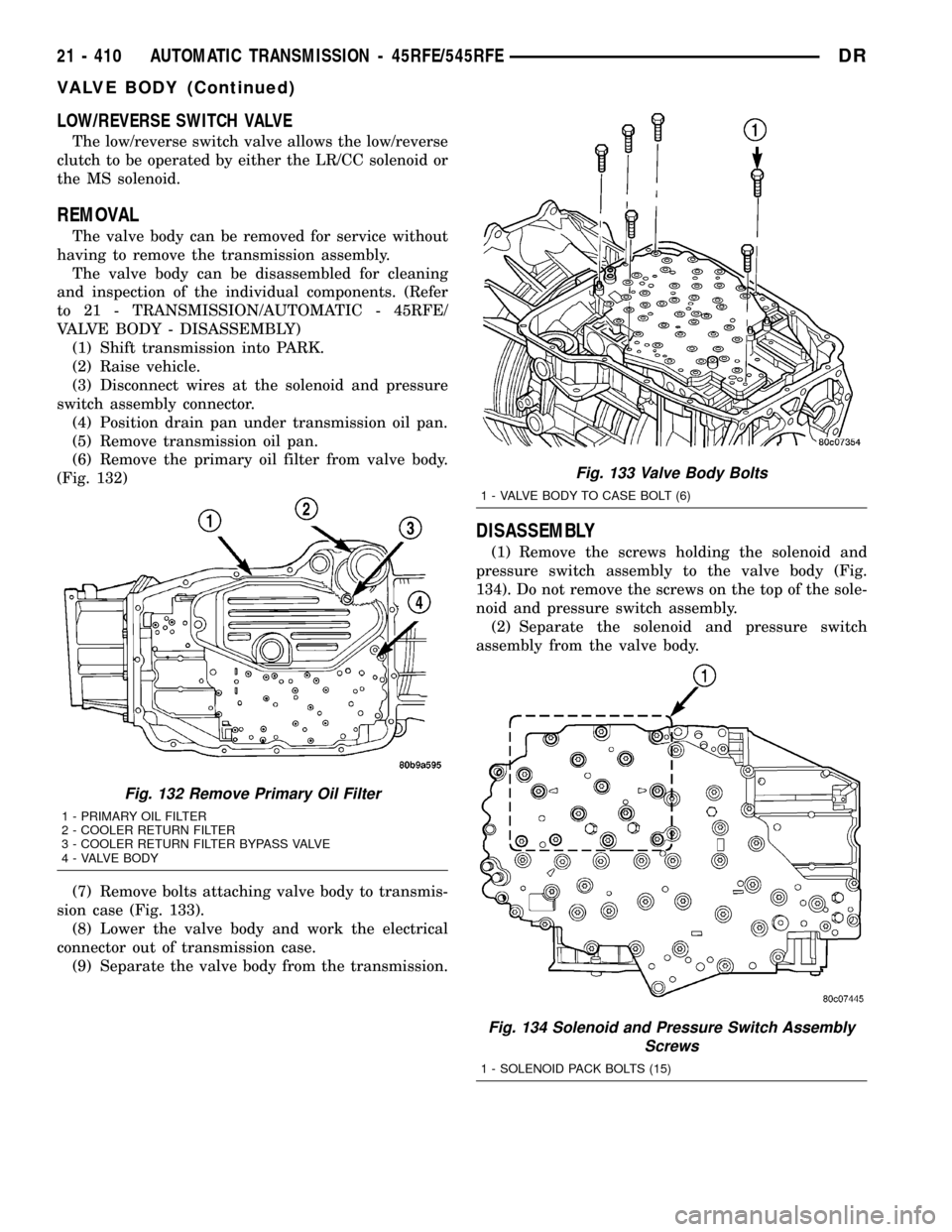

DISASSEMBLY

(1) Remove the screws holding the solenoid and

pressure switch assembly to the valve body (Fig.

134). Do not remove the screws on the top of the sole-

noid and pressure switch assembly.

(2) Separate the solenoid and pressure switch

assembly from the valve body.

Fig. 132 Remove Primary Oil Filter

1 - PRIMARY OIL FILTER

2 - COOLER RETURN FILTER

3 - COOLER RETURN FILTER BYPASS VALVE

4 - VALVE BODY

Fig. 133 Valve Body Bolts

1 - VALVE BODY TO CASE BOLT (6)

Fig. 134 Solenoid and Pressure Switch Assembly

Screws

1 - SOLENOID PACK BOLTS (15)

21 - 410 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

VALVE BODY (Continued)

Page 2114 of 2627

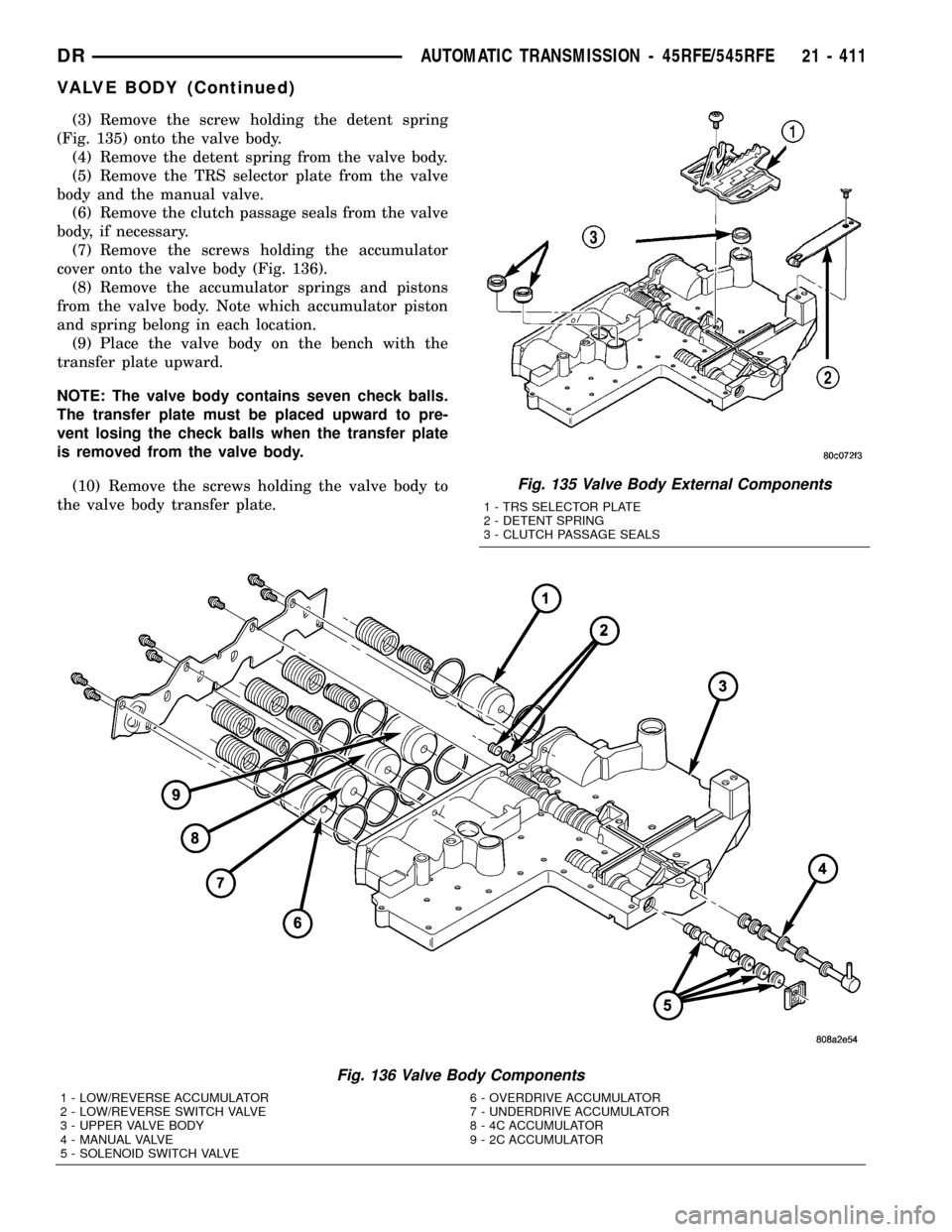

(3) Remove the screw holding the detent spring

(Fig. 135) onto the valve body.

(4) Remove the detent spring from the valve body.

(5) Remove the TRS selector plate from the valve

body and the manual valve.

(6) Remove the clutch passage seals from the valve

body, if necessary.

(7) Remove the screws holding the accumulator

cover onto the valve body (Fig. 136).

(8) Remove the accumulator springs and pistons

from the valve body. Note which accumulator piston

and spring belong in each location.

(9) Place the valve body on the bench with the

transfer plate upward.

NOTE: The valve body contains seven check balls.

The transfer plate must be placed upward to pre-

vent losing the check balls when the transfer plate

is removed from the valve body.

(10) Remove the screws holding the valve body to

the valve body transfer plate.

Fig. 135 Valve Body External Components

1 - TRS SELECTOR PLATE

2 - DETENT SPRING

3 - CLUTCH PASSAGE SEALS

Fig. 136 Valve Body Components

1 - LOW/REVERSE ACCUMULATOR 6 - OVERDRIVE ACCUMULATOR

2 - LOW/REVERSE SWITCH VALVE 7 - UNDERDRIVE ACCUMULATOR

3 - UPPER VALVE BODY 8 - 4C ACCUMULATOR

4 - MANUAL VALVE 9 - 2C ACCUMULATOR

5 - SOLENOID SWITCH VALVE

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 411

VALVE BODY (Continued)

Page 2115 of 2627

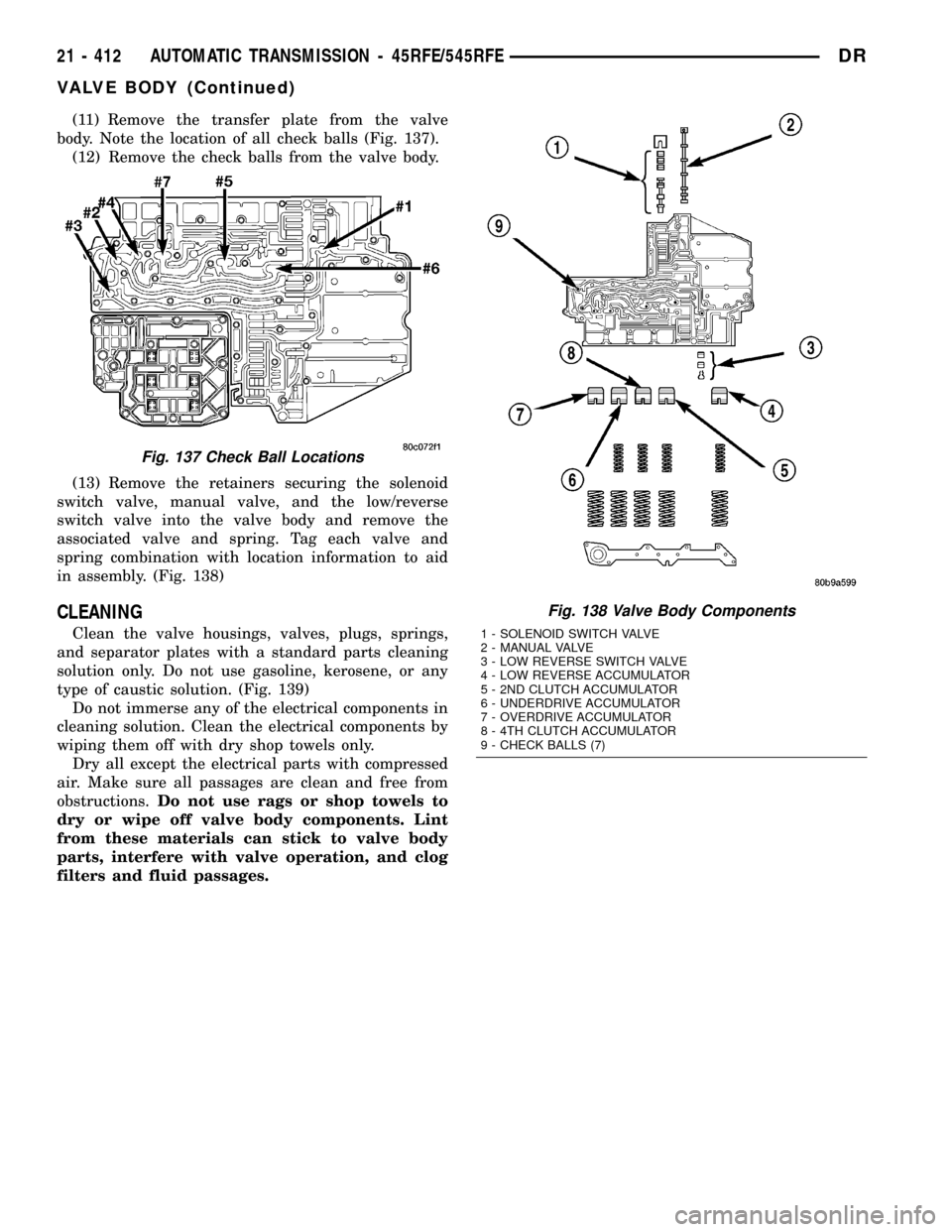

(11) Remove the transfer plate from the valve

body. Note the location of all check balls (Fig. 137).

(12) Remove the check balls from the valve body.

(13) Remove the retainers securing the solenoid

switch valve, manual valve, and the low/reverse

switch valve into the valve body and remove the

associated valve and spring. Tag each valve and

spring combination with location information to aid

in assembly. (Fig. 138)

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaning

solution only. Do not use gasoline, kerosene, or any

type of caustic solution. (Fig. 139)

Do not immerse any of the electrical components in

cleaning solution. Clean the electrical components by

wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

Fig. 137 Check Ball Locations

Fig. 138 Valve Body Components

1 - SOLENOID SWITCH VALVE

2 - MANUAL VALVE

3 - LOW REVERSE SWITCH VALVE

4 - LOW REVERSE ACCUMULATOR

5 - 2ND CLUTCH ACCUMULATOR

6 - UNDERDRIVE ACCUMULATOR

7 - OVERDRIVE ACCUMULATOR

8 - 4TH CLUTCH ACCUMULATOR

9 - CHECK BALLS (7)

21 - 412 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

VALVE BODY (Continued)