Transmission fill DODGE RAM 1500 1998 2.G Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2014 of 2627

AUTOMATIC TRANSMISSION - 45RFE/545RFE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 45RFE/545RFE

DESCRIPTION........................312

OPERATION..........................313

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION.....................314

DIAGNOSIS AND TESTING -

PRELIMINARY.......................314

DIAGNOSIS AND TESTING - ROAD

TESTING...........................314

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST....................316

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH OPERATION....317

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK................318

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR.....................318

REMOVAL............................318

DISASSEMBLY........................320

CLEANING...........................326

INSPECTION.........................326

ASSEMBLY...........................326

INSTALLATION........................333

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS.............337

SPECIFICATIONS

TRANSMISSION.....................358

SPECIAL TOOLS

RFE TRANSMISSION.................359

4C RETAINER/BULKHEAD

DISASSEMBLY........................362

ASSEMBLY...........................363

ADAPTER HOUSING SEAL

REMOVAL............................364

INSTALLATION........................364

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM

DESCRIPTION........................364

OPERATION..........................364

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK......364

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK...................365

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL.............366

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID.......................366DIAGNOSIS AND TESTING - FLUID

CONTAMINATION....................366

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK............................366

STANDARD PROCEDURE - FLUID AND

FILTER REPLACEMENT...............367

STANDARD PROCEDURE - TRANSMISSION

FILL...............................368

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE.............................368

REMOVAL............................369

INSTALLATION........................370

ADJUSTMENTS

GEARSHIFT CABLE..................370

HOLDING CLUTCHES

DESCRIPTION........................371

OPERATION..........................372

INPUT CLUTCH ASSEMBLY

DESCRIPTION........................373

OPERATION..........................373

DISASSEMBLY........................374

ASSEMBLY...........................378

INPUT SPEED SENSOR

DESCRIPTION........................382

OPERATION..........................382

REMOVAL............................382

INSTALLATION........................382

LINE PRESSURE (LP) SENSOR

DESCRIPTION........................382

OPERATION..........................383

REMOVAL............................383

INSTALLATION........................383

LOW/REVERSE CLUTCH

DISASSEMBLY........................384

CLEANING...........................385

INSPECTION.........................385

ASSEMBLY...........................385

OIL PUMP

DESCRIPTION........................386

OPERATION..........................386

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................387

DISASSEMBLY........................388

CLEANING...........................390

INSPECTION.........................390

ASSEMBLY...........................390

OIL PUMP FRONT SEAL

REMOVAL............................391

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 311

Page 2021 of 2627

is applied. The clutch application can also be felt by

touching the appropriate element while applying air

pressure. As the air pressure is released, the clutch

should also release.

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK

When diagnosing converter housing fluid leaks,

two items must be established before repair.

(1) Verify that a leak condition actually exists.

(2) Determined the true source of the leak.

Some suspected converter housing fluid leaks may

not be leaks at all. They may only be the result of

residual fluid in the converter housing, or excess

fluid spilled during factory fill or fill after repair.

Converter housing leaks have several potential

sources. Through careful observation, a leak source

can be identified before removing the transmission

for repair. Torque converter seal leaks tend to move

along the drive hub and onto the rear of the con-

verter. Pump cover seal tend to run down the cover

and the inside surface of the bellhousing.

Some leaks, or suspected leaks, may be particu-

larly difficult to locate. If necessary, a Mopart

approved dye may be used to locate a leak.

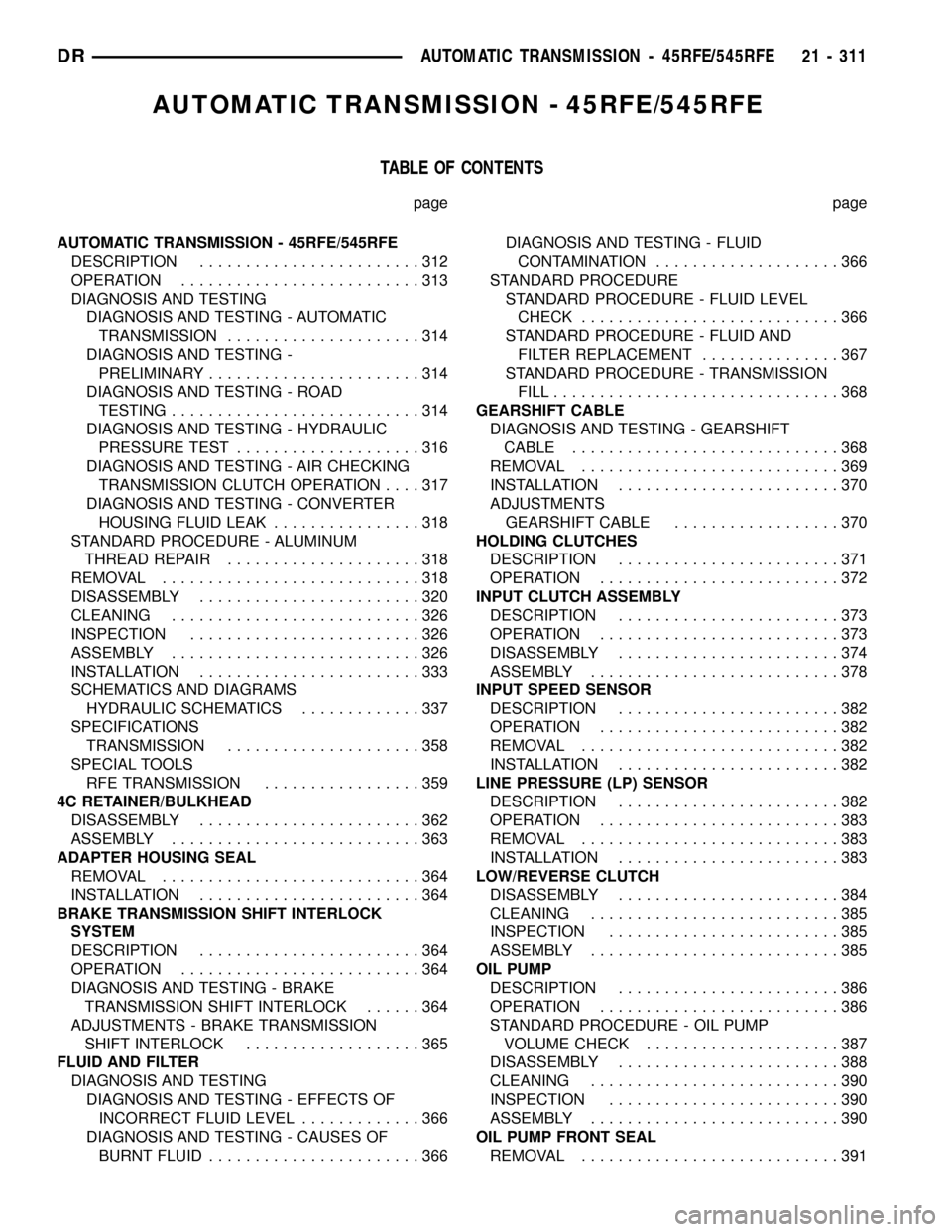

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

(1) Leaks at the weld joint around the outside

diameter weld (Fig. 7).

(2) Leaks at the converter hub weld (Fig. 7).

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle

(3) Remove any necessary skid plates. (Refer to 13

- FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - REMOVAL)

(4) Mark propeller shaft and axle companion

flanges for assembly alignment.

(5) Remove the rear propeller shaft

(6) Remove the front propeller shaft, if necessary.

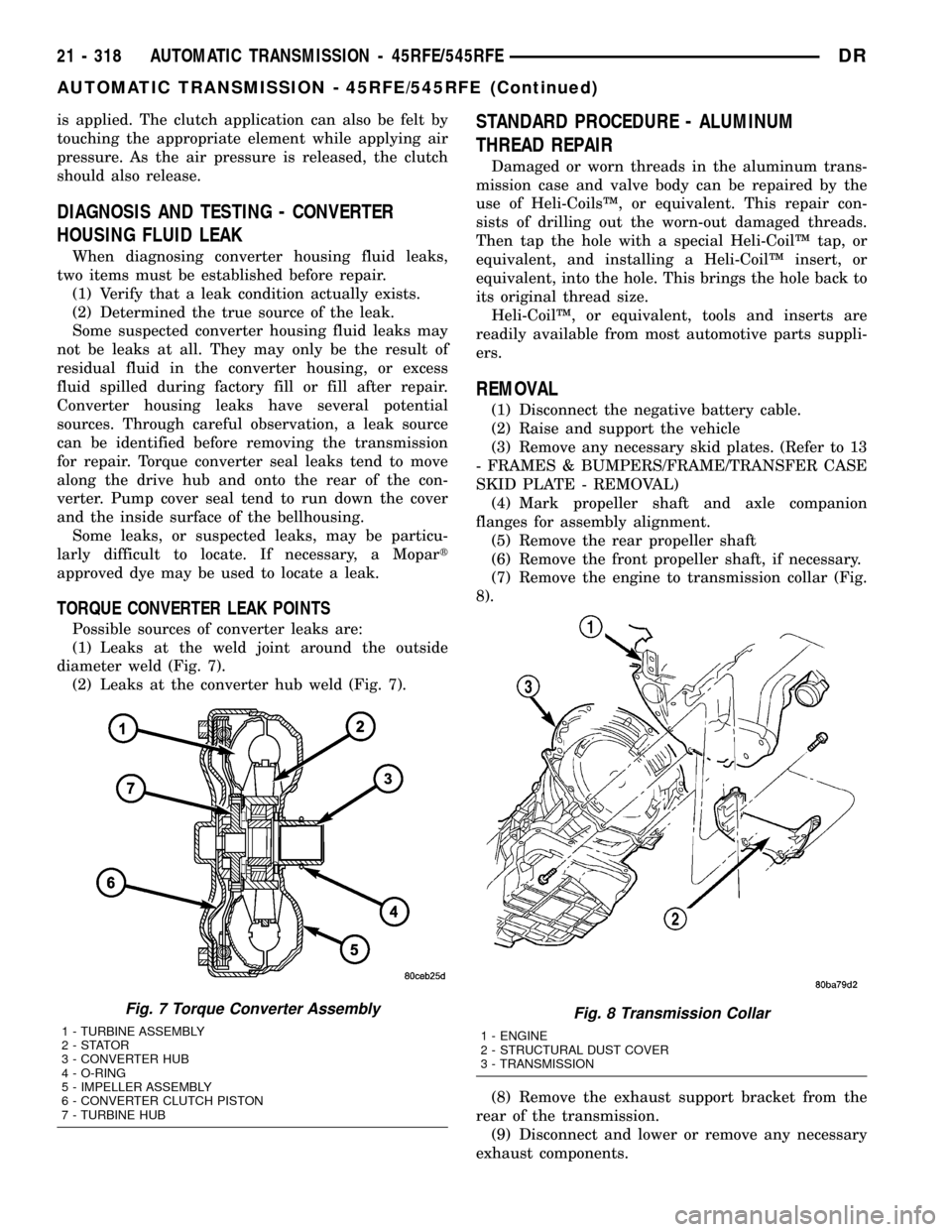

(7) Remove the engine to transmission collar (Fig.

8).

(8) Remove the exhaust support bracket from the

rear of the transmission.

(9) Disconnect and lower or remove any necessary

exhaust components.

Fig. 7 Torque Converter Assembly

1 - TURBINE ASSEMBLY

2-STATOR

3 - CONVERTER HUB

4 - O-RING

5 - IMPELLER ASSEMBLY

6 - CONVERTER CLUTCH PISTON

7 - TURBINE HUB

Fig. 8 Transmission Collar

1 - ENGINE

2 - STRUCTURAL DUST COVER

3 - TRANSMISSION

21 - 318 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2039 of 2627

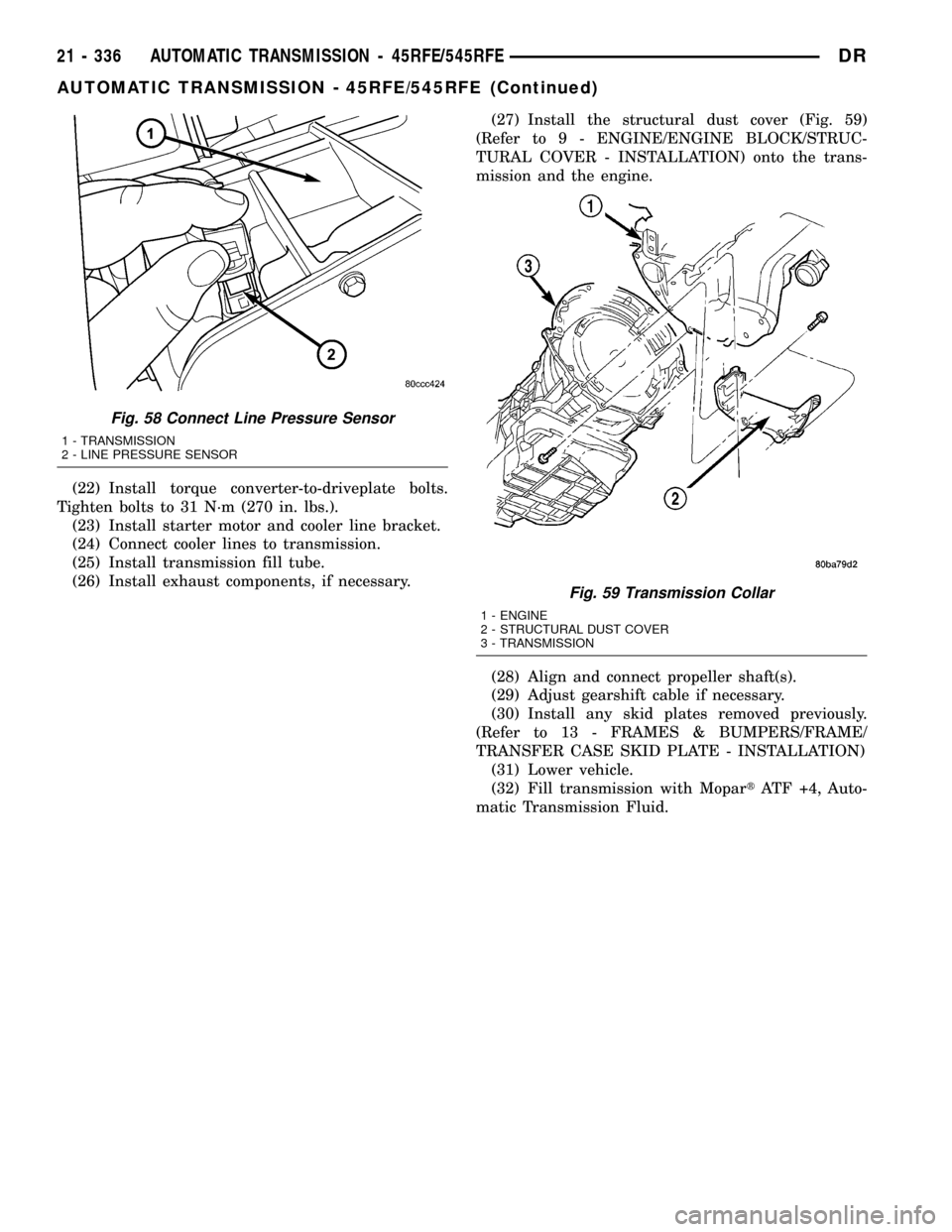

(22) Install torque converter-to-driveplate bolts.

Tighten bolts to 31 N´m (270 in. lbs.).

(23) Install starter motor and cooler line bracket.

(24) Connect cooler lines to transmission.

(25) Install transmission fill tube.

(26) Install exhaust components, if necessary.(27) Install the structural dust cover (Fig. 59)

(Refer to 9 - ENGINE/ENGINE BLOCK/STRUC-

TURAL COVER - INSTALLATION) onto the trans-

mission and the engine.

(28) Align and connect propeller shaft(s).

(29) Adjust gearshift cable if necessary.

(30) Install any skid plates removed previously.

(Refer to 13 - FRAMES & BUMPERS/FRAME/

TRANSFER CASE SKID PLATE - INSTALLATION)

(31) Lower vehicle.

(32) Fill transmission with MopartATF +4, Auto-

matic Transmission Fluid.

Fig. 58 Connect Line Pressure Sensor

1 - TRANSMISSION

2 - LINE PRESSURE SENSOR

Fig. 59 Transmission Collar

1 - ENGINE

2 - STRUCTURAL DUST COVER

3 - TRANSMISSION

21 - 336 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2069 of 2627

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn the

fluid into foam. This aerates the fluid and causing

the same conditions occurring with a low level. In

either case, air bubbles cause fluid overheating, oxi-

dation and varnish buildup which interferes with

valve and clutch operation. Foaming also causes fluid

expansion which can result in fluid overflow from the

transmission vent or fill tube. Fluid overflow can eas-

ily be mistaken for a leak if inspection is not careful.

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID

Burnt, discolored fluid is a result of overheating

which has three primary causes.

(1) Internal clutch slippage, usually caused by low

line pressure, inadequate clutch apply pressure, or

clutch seal failure.

(2) A result of restricted fluid flow through the

main and/or auxiliary cooler. This condition is usu-

ally the result of a faulty or improperly installed

drainback valve, a damaged main cooler, or severe

restrictions in the coolers and lines caused by debris

or kinked lines.

(3) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to replace contaminated converter after

repairThe use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The torque converter should also be replaced when-

ever a failure generates sludge and debris. This is

necessary because normal converter flushing proce-

dures will not remove all contaminants.

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transmission vent where it may be mis-

taken for a leak.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

The torque converter fills in both the P (PARK)

and N (NEUTRAL) positions. Place the selector lever

in P (PARK) to be sure that the fluid level check is

accurate.The engine should be running at idle

speed for at least one minute, with the vehicle

on level ground.At normal operating temperature

(approximately 82 C. or 180 F.), the fluid level is cor-

rect if it is in the HOT region (cross-hatched area) on

the oil level indicator. The fluid level will be approx-

21 - 366 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2070 of 2627

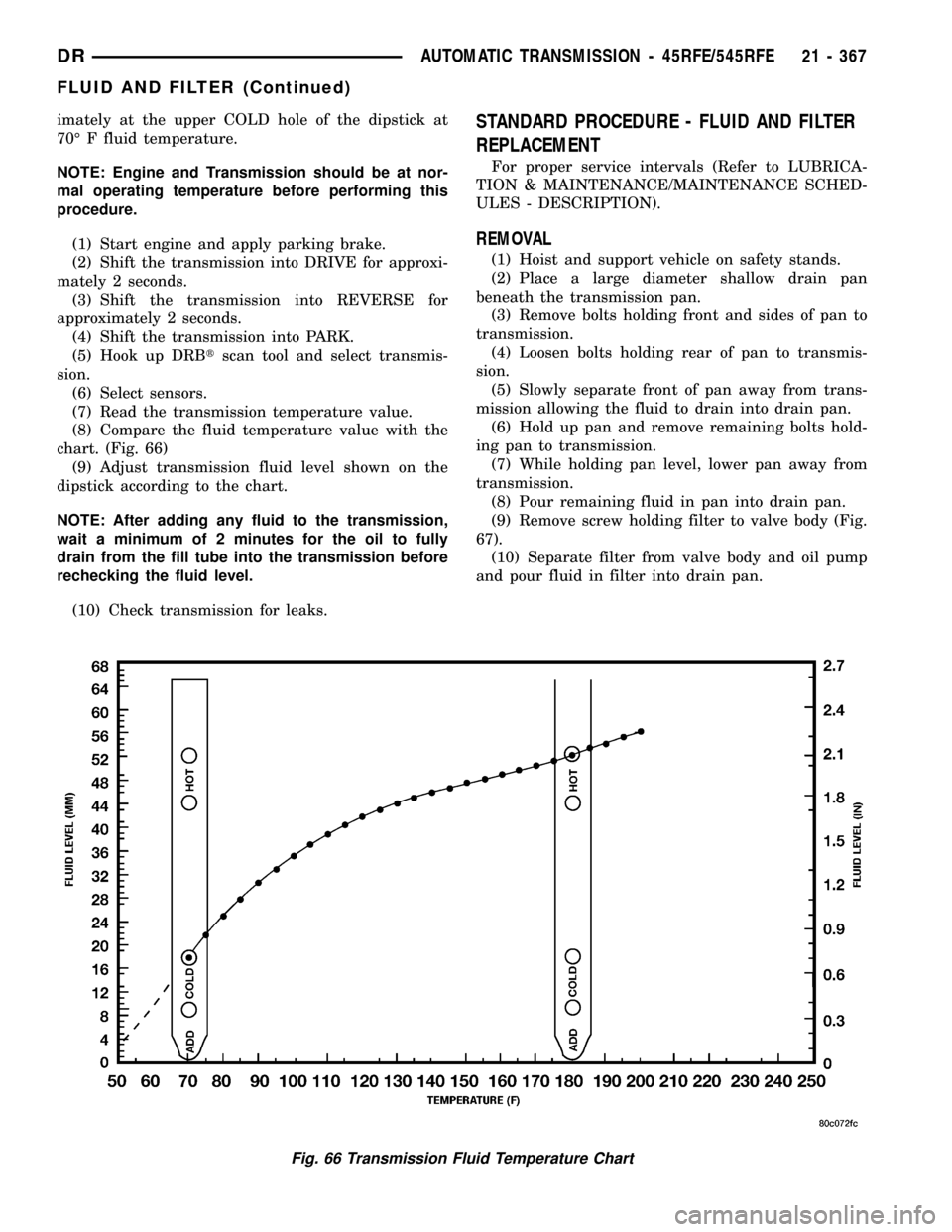

imately at the upper COLD hole of the dipstick at

70É F fluid temperature.

NOTE: Engine and Transmission should be at nor-

mal operating temperature before performing this

procedure.

(1) Start engine and apply parking brake.

(2) Shift the transmission into DRIVE for approxi-

mately 2 seconds.

(3) Shift the transmission into REVERSE for

approximately 2 seconds.

(4) Shift the transmission into PARK.

(5) Hook up DRBtscan tool and select transmis-

sion.

(6) Select sensors.

(7) Read the transmission temperature value.

(8) Compare the fluid temperature value with the

chart. (Fig. 66)

(9) Adjust transmission fluid level shown on the

dipstick according to the chart.

NOTE: After adding any fluid to the transmission,

wait a minimum of 2 minutes for the oil to fully

drain from the fill tube into the transmission before

rechecking the fluid level.

(10) Check transmission for leaks.STANDARD PROCEDURE - FLUID AND FILTER

REPLACEMENT

For proper service intervals (Refer to LUBRICA-

TION & MAINTENANCE/MAINTENANCE SCHED-

ULES - DESCRIPTION).

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Place a large diameter shallow drain pan

beneath the transmission pan.

(3) Remove bolts holding front and sides of pan to

transmission.

(4) Loosen bolts holding rear of pan to transmis-

sion.

(5) Slowly separate front of pan away from trans-

mission allowing the fluid to drain into drain pan.

(6) Hold up pan and remove remaining bolts hold-

ing pan to transmission.

(7) While holding pan level, lower pan away from

transmission.

(8) Pour remaining fluid in pan into drain pan.

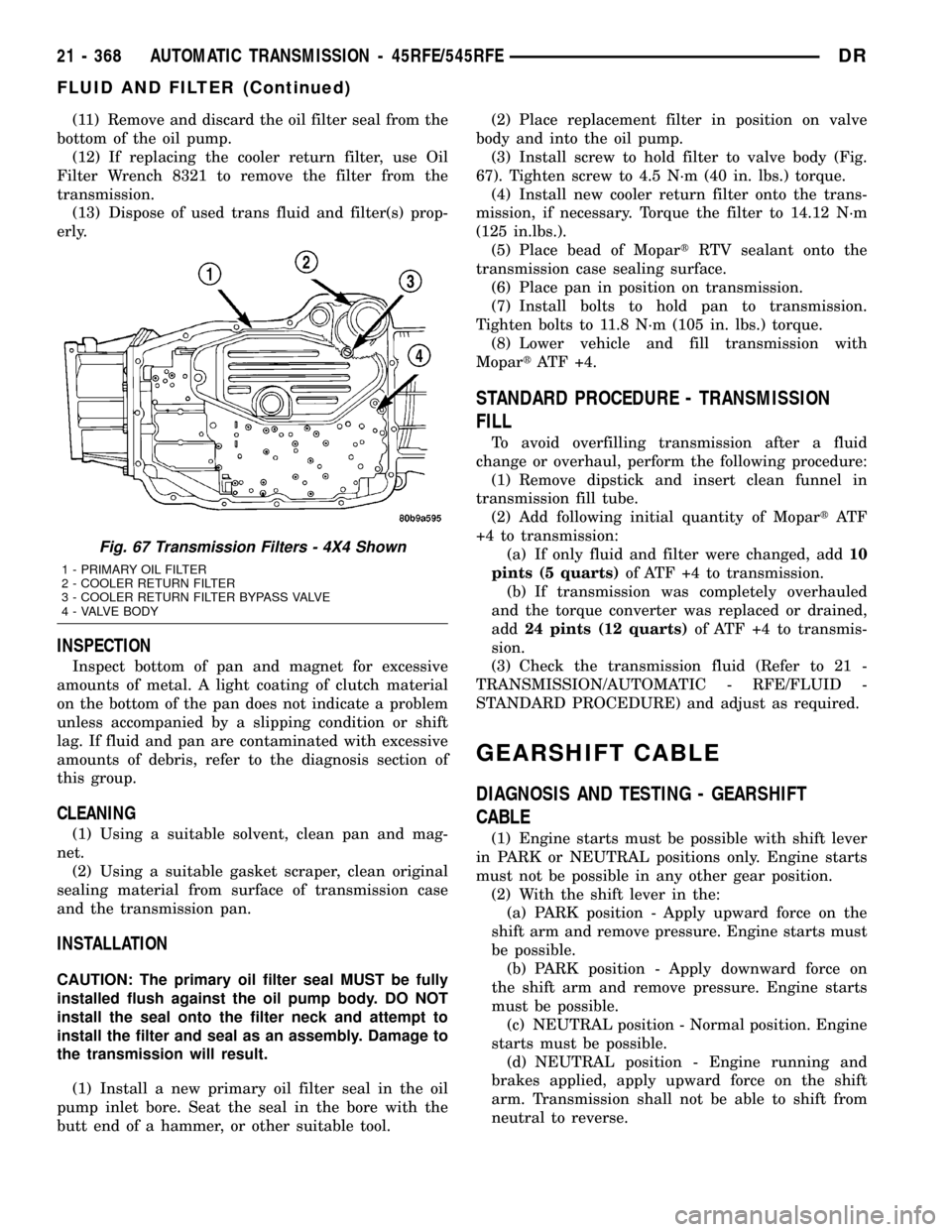

(9) Remove screw holding filter to valve body (Fig.

67).

(10) Separate filter from valve body and oil pump

and pour fluid in filter into drain pan.

Fig. 66 Transmission Fluid Temperature Chart

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 367

FLUID AND FILTER (Continued)

Page 2071 of 2627

(11) Remove and discard the oil filter seal from the

bottom of the oil pump.

(12) If replacing the cooler return filter, use Oil

Filter Wrench 8321 to remove the filter from the

transmission.

(13) Dispose of used trans fluid and filter(s) prop-

erly.

INSPECTION

Inspect bottom of pan and magnet for excessive

amounts of metal. A light coating of clutch material

on the bottom of the pan does not indicate a problem

unless accompanied by a slipping condition or shift

lag. If fluid and pan are contaminated with excessive

amounts of debris, refer to the diagnosis section of

this group.

CLEANING

(1) Using a suitable solvent, clean pan and mag-

net.

(2) Using a suitable gasket scraper, clean original

sealing material from surface of transmission case

and the transmission pan.

INSTALLATION

CAUTION: The primary oil filter seal MUST be fully

installed flush against the oil pump body. DO NOT

install the seal onto the filter neck and attempt to

install the filter and seal as an assembly. Damage to

the transmission will result.

(1) Install a new primary oil filter seal in the oil

pump inlet bore. Seat the seal in the bore with the

butt end of a hammer, or other suitable tool.(2) Place replacement filter in position on valve

body and into the oil pump.

(3) Install screw to hold filter to valve body (Fig.

67). Tighten screw to 4.5 N´m (40 in. lbs.) torque.

(4) Install new cooler return filter onto the trans-

mission, if necessary. Torque the filter to 14.12 N´m

(125 in.lbs.).

(5) Place bead of MopartRTV sealant onto the

transmission case sealing surface.

(6) Place pan in position on transmission.

(7) Install bolts to hold pan to transmission.

Tighten bolts to 11.8 N´m (105 in. lbs.) torque.

(8) Lower vehicle and fill transmission with

MopartATF +4.

STANDARD PROCEDURE - TRANSMISSION

FILL

To avoid overfilling transmission after a fluid

change or overhaul, perform the following procedure:

(1) Remove dipstick and insert clean funnel in

transmission fill tube.

(2) Add following initial quantity of MopartAT F

+4 to transmission:

(a) If only fluid and filter were changed, add10

pints (5 quarts)of ATF +4 to transmission.

(b) If transmission was completely overhauled

and the torque converter was replaced or drained,

add24 pints (12 quarts)of ATF +4 to transmis-

sion.

(3) Check the transmission fluid (Refer to 21 -

TRANSMISSION/AUTOMATIC - RFE/FLUID -

STANDARD PROCEDURE) and adjust as required.

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE

(1) Engine starts must be possible with shift lever

in PARK or NEUTRAL positions only. Engine starts

must not be possible in any other gear position.

(2) With the shift lever in the:

(a) PARK position - Apply upward force on the

shift arm and remove pressure. Engine starts must

be possible.

(b) PARK position - Apply downward force on

the shift arm and remove pressure. Engine starts

must be possible.

(c) NEUTRAL position - Normal position. Engine

starts must be possible.

(d) NEUTRAL position - Engine running and

brakes applied, apply upward force on the shift

arm. Transmission shall not be able to shift from

neutral to reverse.

Fig. 67 Transmission Filters - 4X4 Shown

1 - PRIMARY OIL FILTER

2 - COOLER RETURN FILTER

3 - COOLER RETURN FILTER BYPASS VALVE

4 - VALVE BODY

21 - 368 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

FLUID AND FILTER (Continued)

Page 2090 of 2627

CONVERTER CLUTCH REGULATOR VALVE

The converter clutch regulator valve is used to con-

trol the hydraulic pressure supplied to the back (ON)

side of the torque converter clutch.

TORQUE CONVERTER LIMIT VALVE

The torque converter limit valve serves to limit the

available line pressure to the torque converter clutch.

STANDARD PROCEDURE - OIL PUMP VOLUME

CHECK

Measuring the oil pump output volume will deter-

mine if sufficient oil flow to the transmission oil

cooler exists, and whether or not an internal trans-

mission failure is present.Verify that the transmission fluid is at the proper

level. Refer to the Fluid Level Check procedure in

this section. If necessary, fill the transmission to the

proper level with MopartATF +4, Automatic Trans-

mission Fluid.

(1) Disconnect theTo coolerline at the cooler

inlet and place a collecting container under the dis-

connected line.

CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(2) Run the engineat 1800 rpm, with the shift

selector in neutral. Verify that the transmission fluid

temperature is below 104.5É C (220É F) for this test.

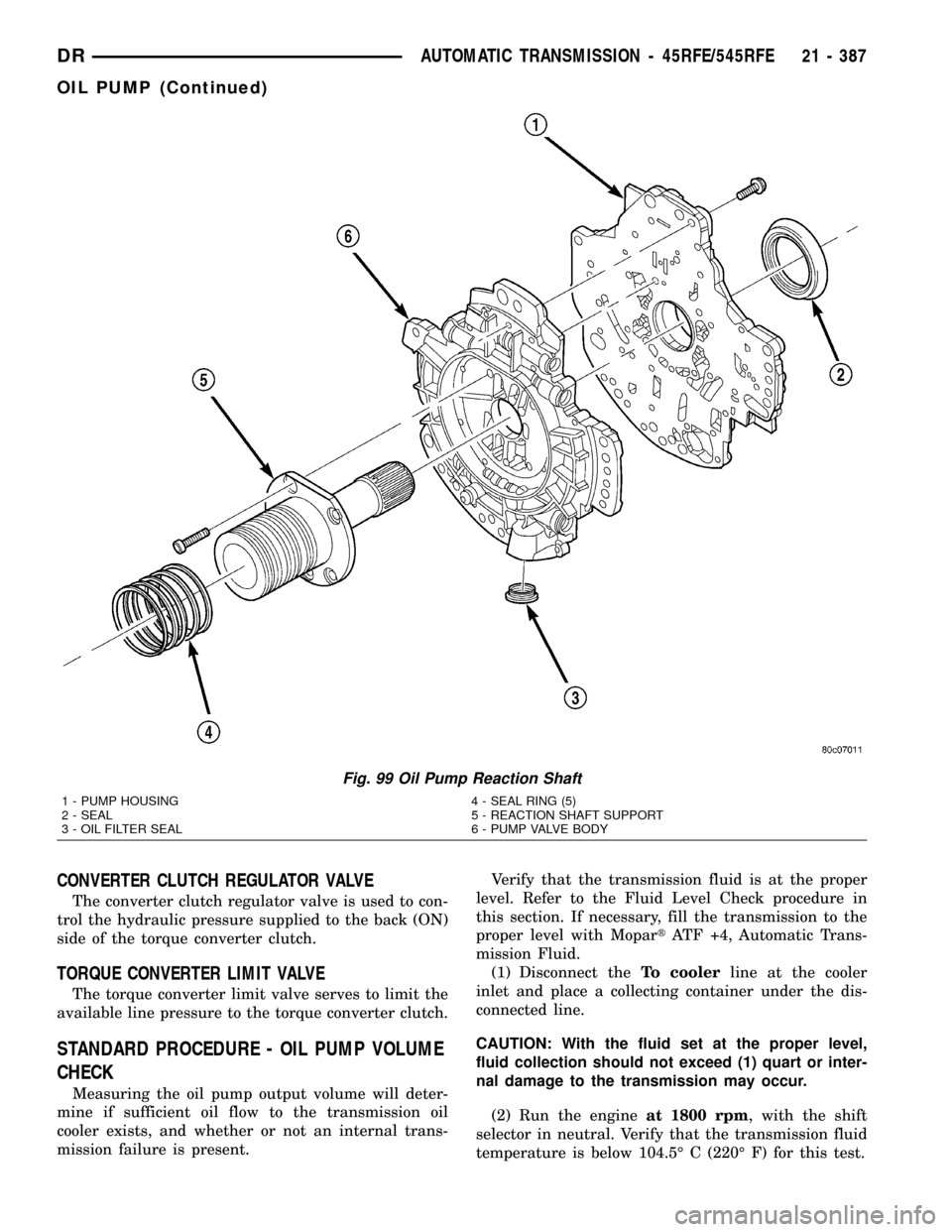

Fig. 99 Oil Pump Reaction Shaft

1 - PUMP HOUSING 4 - SEAL RING (5)

2 - SEAL 5 - REACTION SHAFT SUPPORT

3 - OIL FILTER SEAL 6 - PUMP VALVE BODY

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 387

OIL PUMP (Continued)

Page 2091 of 2627

(3) If one quart of transmission fluid is collected in

the container in 30 seconds or less, oil pump flow vol-

ume is within acceptable limits. If fluid flow is inter-

mittent, or it takes more than 30 seconds to collect

one quart of fluid, refer to the Hydraulic Pressure

tests in this section for further diagnosis.

(4) Re-connect theTo coolerline to the transmis-

sion cooler inlet.

(5) Refill the transmission to proper level.

DISASSEMBLY

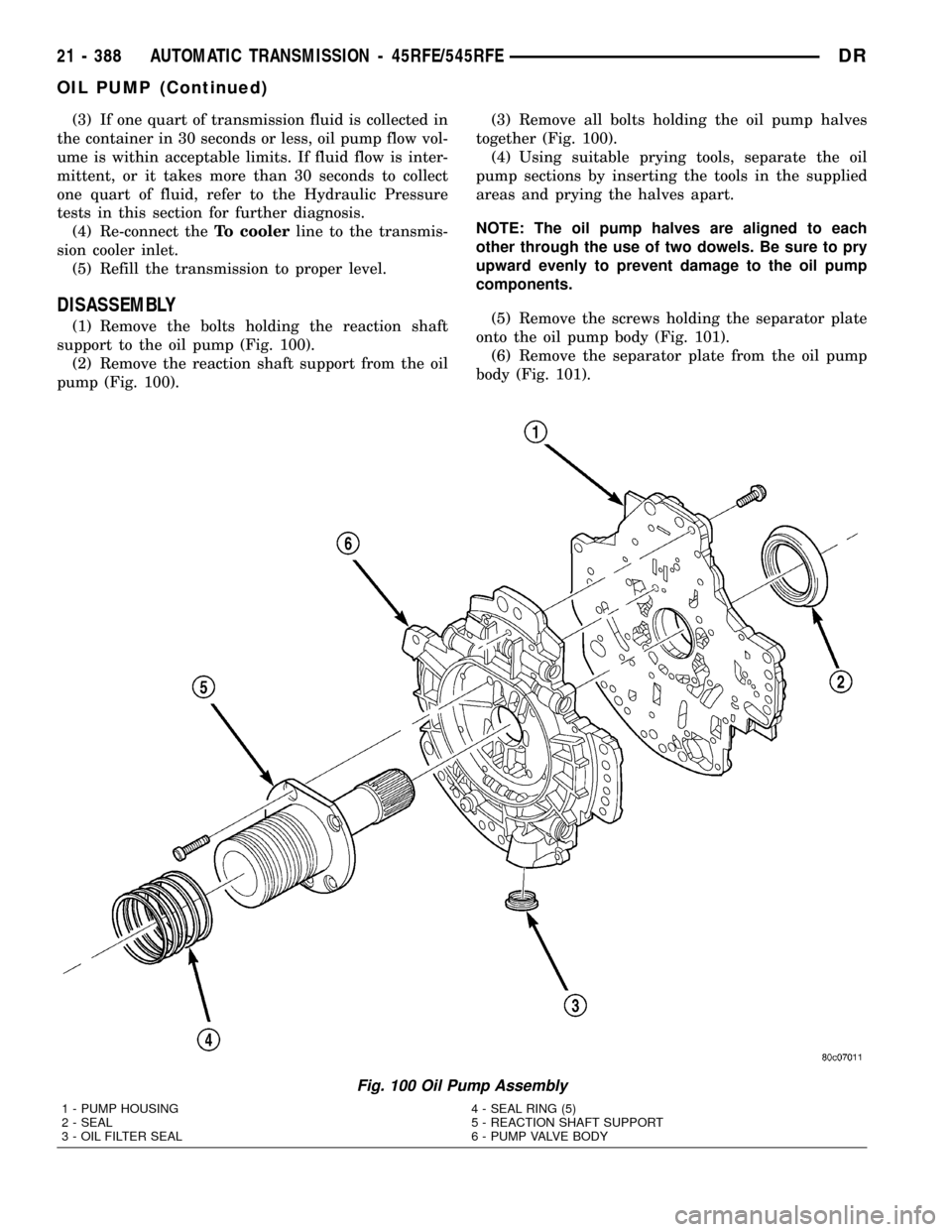

(1) Remove the bolts holding the reaction shaft

support to the oil pump (Fig. 100).

(2) Remove the reaction shaft support from the oil

pump (Fig. 100).(3) Remove all bolts holding the oil pump halves

together (Fig. 100).

(4) Using suitable prying tools, separate the oil

pump sections by inserting the tools in the supplied

areas and prying the halves apart.

NOTE: The oil pump halves are aligned to each

other through the use of two dowels. Be sure to pry

upward evenly to prevent damage to the oil pump

components.

(5) Remove the screws holding the separator plate

onto the oil pump body (Fig. 101).

(6) Remove the separator plate from the oil pump

body (Fig. 101).

Fig. 100 Oil Pump Assembly

1 - PUMP HOUSING 4 - SEAL RING (5)

2 - SEAL 5 - REACTION SHAFT SUPPORT

3 - OIL FILTER SEAL 6 - PUMP VALVE BODY

21 - 388 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

OIL PUMP (Continued)

Page 2097 of 2627

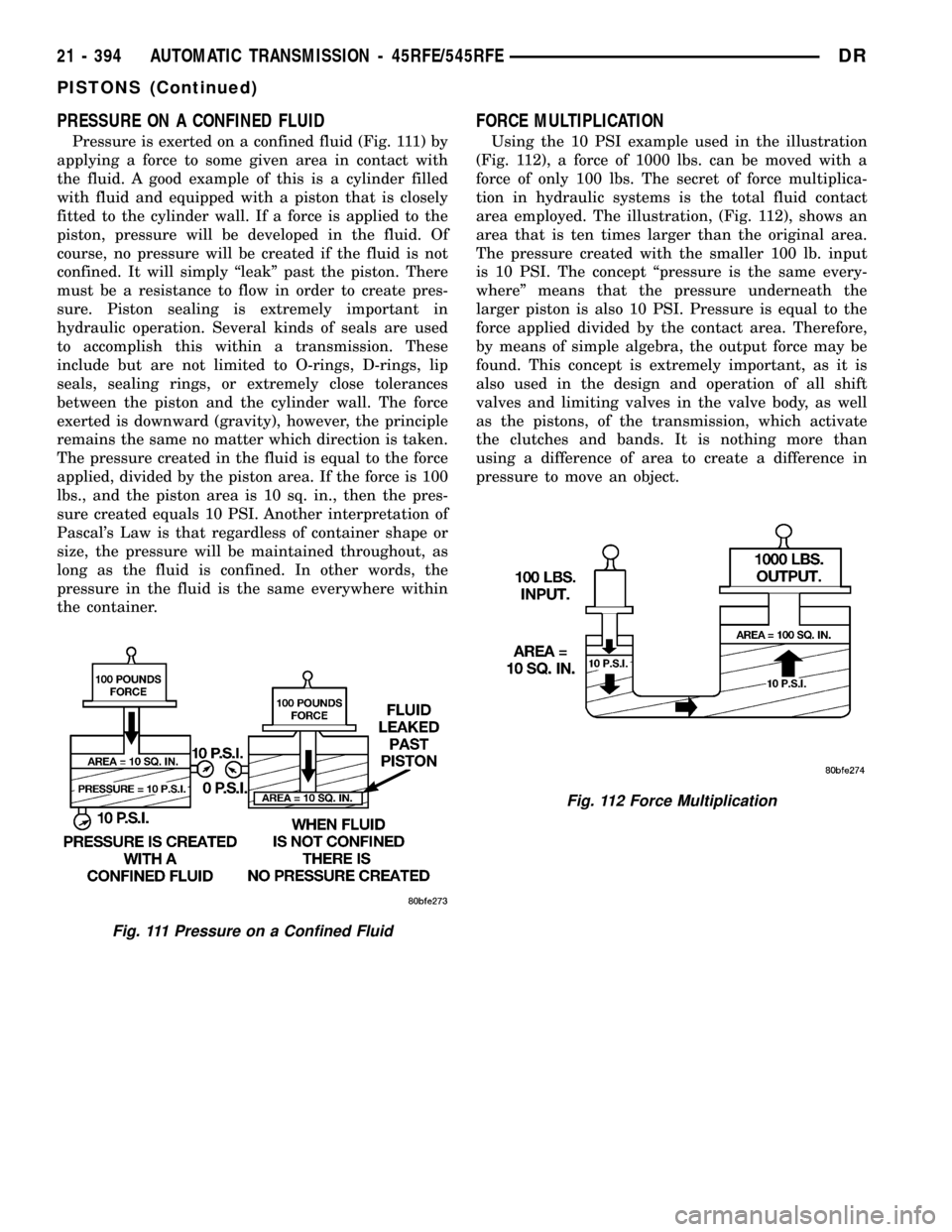

PRESSURE ON A CONFINED FLUID

Pressure is exerted on a confined fluid (Fig. 111) by

applying a force to some given area in contact with

the fluid. A good example of this is a cylinder filled

with fluid and equipped with a piston that is closely

fitted to the cylinder wall. If a force is applied to the

piston, pressure will be developed in the fluid. Of

course, no pressure will be created if the fluid is not

confined. It will simply ªleakº past the piston. There

must be a resistance to flow in order to create pres-

sure. Piston sealing is extremely important in

hydraulic operation. Several kinds of seals are used

to accomplish this within a transmission. These

include but are not limited to O-rings, D-rings, lip

seals, sealing rings, or extremely close tolerances

between the piston and the cylinder wall. The force

exerted is downward (gravity), however, the principle

remains the same no matter which direction is taken.

The pressure created in the fluid is equal to the force

applied, divided by the piston area. If the force is 100

lbs., and the piston area is 10 sq. in., then the pres-

sure created equals 10 PSI. Another interpretation of

Pascal's Law is that regardless of container shape or

size, the pressure will be maintained throughout, as

long as the fluid is confined. In other words, the

pressure in the fluid is the same everywhere within

the container.

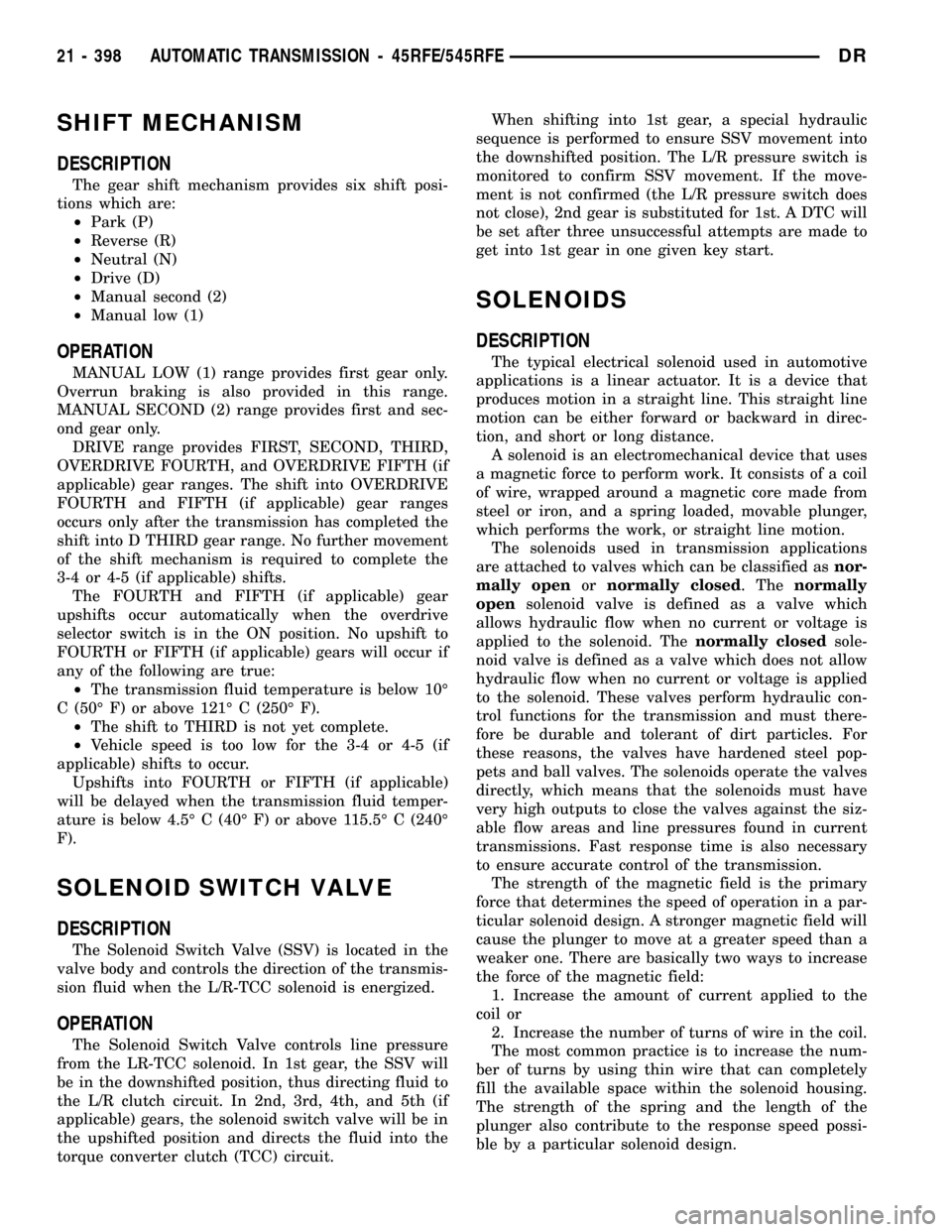

FORCE MULTIPLICATION

Using the 10 PSI example used in the illustration

(Fig. 112), a force of 1000 lbs. can be moved with a

force of only 100 lbs. The secret of force multiplica-

tion in hydraulic systems is the total fluid contact

area employed. The illustration, (Fig. 112), shows an

area that is ten times larger than the original area.

The pressure created with the smaller 100 lb. input

is 10 PSI. The concept ªpressure is the same every-

whereº means that the pressure underneath the

larger piston is also 10 PSI. Pressure is equal to the

force applied divided by the contact area. Therefore,

by means of simple algebra, the output force may be

found. This concept is extremely important, as it is

also used in the design and operation of all shift

valves and limiting valves in the valve body, as well

as the pistons, of the transmission, which activate

the clutches and bands. It is nothing more than

using a difference of area to create a difference in

pressure to move an object.

Fig. 111 Pressure on a Confined Fluid

Fig. 112 Force Multiplication

21 - 394 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

PISTONS (Continued)

Page 2101 of 2627

SHIFT MECHANISM

DESCRIPTION

The gear shift mechanism provides six shift posi-

tions which are:

²Park (P)

²Reverse (R)

²Neutral (N)

²Drive (D)

²Manual second (2)

²Manual low (1)

OPERATION

MANUAL LOW (1) range provides first gear only.

Overrun braking is also provided in this range.

MANUAL SECOND (2) range provides first and sec-

ond gear only.

DRIVE range provides FIRST, SECOND, THIRD,

OVERDRIVE FOURTH, and OVERDRIVE FIFTH (if

applicable) gear ranges. The shift into OVERDRIVE

FOURTH and FIFTH (if applicable) gear ranges

occurs only after the transmission has completed the

shift into D THIRD gear range. No further movement

of the shift mechanism is required to complete the

3-4 or 4-5 (if applicable) shifts.

The FOURTH and FIFTH (if applicable) gear

upshifts occur automatically when the overdrive

selector switch is in the ON position. No upshift to

FOURTH or FIFTH (if applicable) gears will occur if

any of the following are true:

²The transmission fluid temperature is below 10É

C (50É F) or above 121É C (250É F).

²The shift to THIRD is not yet complete.

²Vehicle speed is too low for the 3-4 or 4-5 (if

applicable) shifts to occur.

Upshifts into FOURTH or FIFTH (if applicable)

will be delayed when the transmission fluid temper-

ature is below 4.5É C (40É F) or above 115.5É C (240É

F).

SOLENOID SWITCH VALVE

DESCRIPTION

The Solenoid Switch Valve (SSV) is located in the

valve body and controls the direction of the transmis-

sion fluid when the L/R-TCC solenoid is energized.

OPERATION

The Solenoid Switch Valve controls line pressure

from the LR-TCC solenoid. In 1st gear, the SSV will

be in the downshifted position, thus directing fluid to

the L/R clutch circuit. In 2nd, 3rd, 4th, and 5th (if

applicable) gears, the solenoid switch valve will be in

the upshifted position and directs the fluid into the

torque converter clutch (TCC) circuit.When shifting into 1st gear, a special hydraulic

sequence is performed to ensure SSV movement into

the downshifted position. The L/R pressure switch is

monitored to confirm SSV movement. If the move-

ment is not confirmed (the L/R pressure switch does

not close), 2nd gear is substituted for 1st. A DTC will

be set after three unsuccessful attempts are made to

get into 1st gear in one given key start.

SOLENOIDS

DESCRIPTION

The typical electrical solenoid used in automotive

applications is a linear actuator. It is a device that

produces motion in a straight line. This straight line

motion can be either forward or backward in direc-

tion, and short or long distance.

A solenoid is an electromechanical device that uses

a magnetic force to perform work. It consists of a coil

of wire, wrapped around a magnetic core made from

steel or iron, and a spring loaded, movable plunger,

which performs the work, or straight line motion.

The solenoids used in transmission applications

are attached to valves which can be classified asnor-

mally openornormally closed. Thenormally

opensolenoid valve is defined as a valve which

allows hydraulic flow when no current or voltage is

applied to the solenoid. Thenormally closedsole-

noid valve is defined as a valve which does not allow

hydraulic flow when no current or voltage is applied

to the solenoid. These valves perform hydraulic con-

trol functions for the transmission and must there-

fore be durable and tolerant of dirt particles. For

these reasons, the valves have hardened steel pop-

pets and ball valves. The solenoids operate the valves

directly, which means that the solenoids must have

very high outputs to close the valves against the siz-

able flow areas and line pressures found in current

transmissions. Fast response time is also necessary

to ensure accurate control of the transmission.

The strength of the magnetic field is the primary

force that determines the speed of operation in a par-

ticular solenoid design. A stronger magnetic field will

cause the plunger to move at a greater speed than a

weaker one. There are basically two ways to increase

the force of the magnetic field:

1. Increase the amount of current applied to the

coil or

2. Increase the number of turns of wire in the coil.

The most common practice is to increase the num-

ber of turns by using thin wire that can completely

fill the available space within the solenoid housing.

The strength of the spring and the length of the

plunger also contribute to the response speed possi-

ble by a particular solenoid design.

21 - 398 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR