Diagnostics port DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 357 of 2627

DIAGNOSIS AND TESTINGÐTHERMOSTAT

ON-BOARD DIAGNOSTICS

Allgasoline powered modelsare equipped with

On-Board Diagnostics for certain cooling system com-

ponents. Refer to On-Board Diagnostics (OBD) in the

Diagnosis section of this group for additional infor-

mation. If the powertrain control module (PCM)

detects low engine coolant temperature, it will record

a Diagnostic Trouble Code (DTC) in the PCM mem-

ory. Do not change a thermostat for lack of heat as

indicated by the instrument panel gauge or by poor

heater performance unless a DTC is present. Refer to

the Diagnosis section of this group for other probable

causes.

The DTC can also be accessed through the

DRBIIItscan tool. Refer to the appropriate Power-

train Diagnostic Procedures information for diagnos-

tic information and operation of the DRBIIItscan

tool.

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE COOLING SYSTEM HOT

AND PRESSURIZED. SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for

reuse.

If the thermostat is being replaced, be sure that

the replacement is the specified thermostat for the

vehicle model and engine type.

Factory installed thermostat housings on 5.9L

engine is installed on a gasket with an anti-stick

coating. This will aid in gasket removal and clean-up.

(1) Disconnect the negative battery cable.

(2) Drain the cooling system until the coolant level

is below the thermostat (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Air Conditioned vehicles: Remove the support

bracket (generator mounting bracket-to-intake mani-

fold) located near the rear of the generator (Fig. 17).

NOTE: On air conditioning equipped vehicles, the

generator must be partially removed.

(4) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL) (Fig. 18).

(5) Remove the generator mounting bolts. Do not

remove any of the wiring at the generator. If

equipped with 4WD, unplug the 4WD indicator lamp

wiring harness (located near rear of generator).

(6) Remove the generator. Position the generator

to gain access for the thermostat gasket removal.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

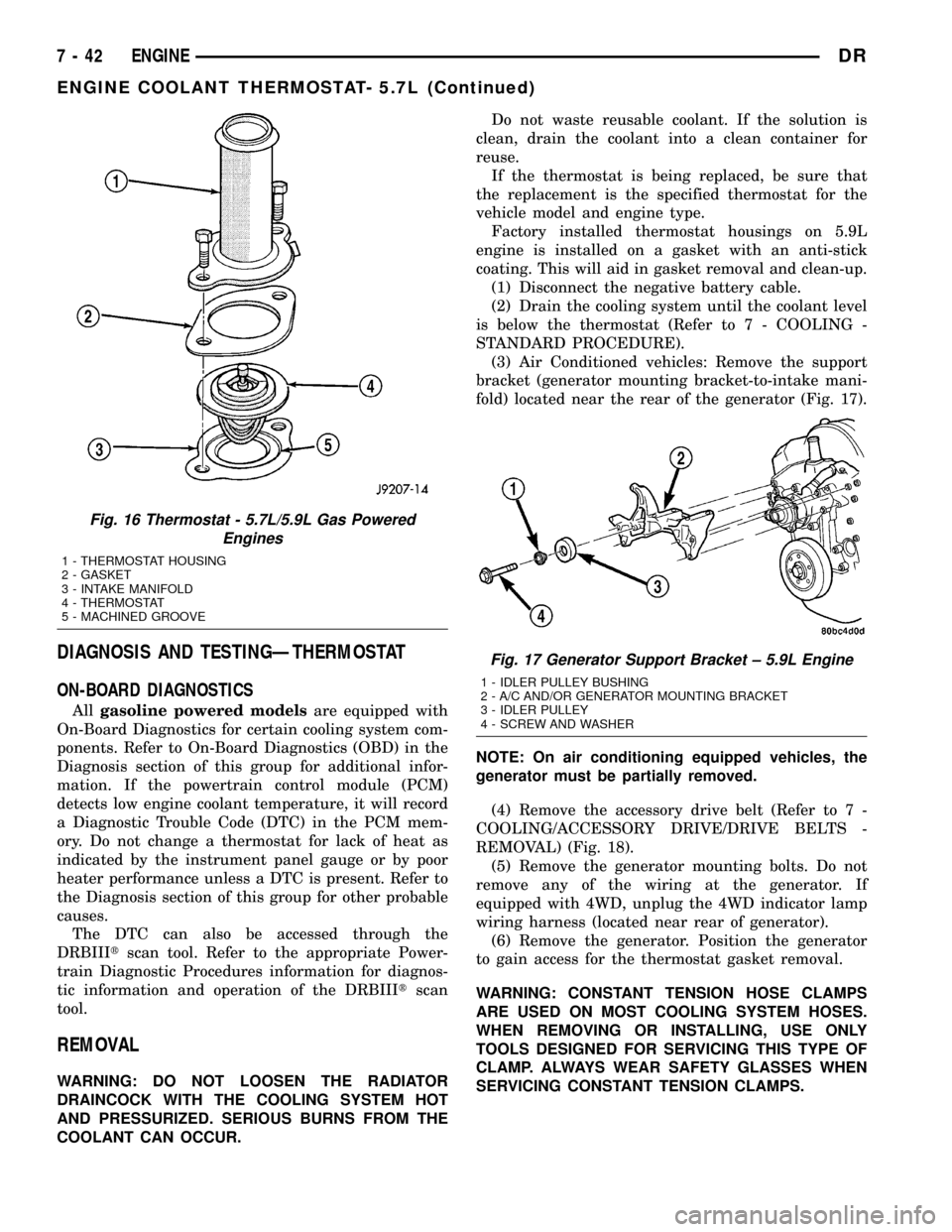

Fig. 16 Thermostat - 5.7L/5.9L Gas Powered

Engines

1 - THERMOSTAT HOUSING

2 - GASKET

3 - INTAKE MANIFOLD

4 - THERMOSTAT

5 - MACHINED GROOVE

Fig. 17 Generator Support Bracket ± 5.9L Engine

1 - IDLER PULLEY BUSHING

2 - A/C AND/OR GENERATOR MOUNTING BRACKET

3 - IDLER PULLEY

4 - SCREW AND WASHER

7 - 42 ENGINEDR

ENGINE COOLANT THERMOSTAT- 5.7L (Continued)

Page 359 of 2627

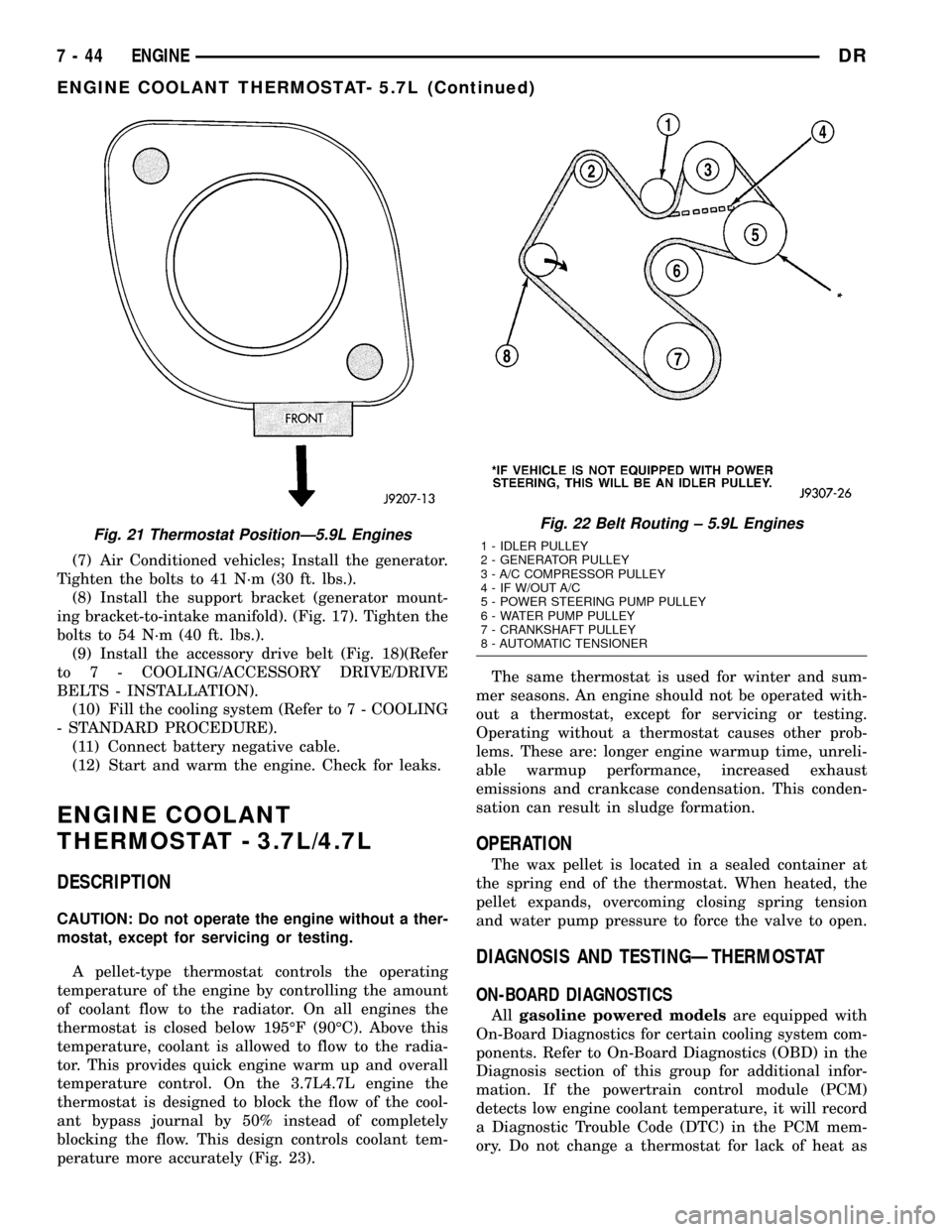

(7) Air Conditioned vehicles; Install the generator.

Tighten the bolts to 41 N´m (30 ft. lbs.).

(8) Install the support bracket (generator mount-

ing bracket-to-intake manifold). (Fig. 17). Tighten the

bolts to 54 N´m (40 ft. lbs.).

(9) Install the accessory drive belt (Fig. 18)(Refer

to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - INSTALLATION).

(10) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(11) Connect battery negative cable.

(12) Start and warm the engine. Check for leaks.

ENGINE COOLANT

THERMOSTAT - 3.7L/4.7L

DESCRIPTION

CAUTION: Do not operate the engine without a ther-

mostat, except for servicing or testing.

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator. On all engines the

thermostat is closed below 195ÉF (90ÉC). Above this

temperature, coolant is allowed to flow to the radia-

tor. This provides quick engine warm up and overall

temperature control. On the 3.7L4.7L engine the

thermostat is designed to block the flow of the cool-

ant bypass journal by 50% instead of completely

blocking the flow. This design controls coolant tem-

perature more accurately (Fig. 23).The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes other prob-

lems. These are: longer engine warmup time, unreli-

able warmup performance, increased exhaust

emissions and crankcase condensation. This conden-

sation can result in sludge formation.

OPERATION

The wax pellet is located in a sealed container at

the spring end of the thermostat. When heated, the

pellet expands, overcoming closing spring tension

and water pump pressure to force the valve to open.

DIAGNOSIS AND TESTINGÐTHERMOSTAT

ON-BOARD DIAGNOSTICS

Allgasoline powered modelsare equipped with

On-Board Diagnostics for certain cooling system com-

ponents. Refer to On-Board Diagnostics (OBD) in the

Diagnosis section of this group for additional infor-

mation. If the powertrain control module (PCM)

detects low engine coolant temperature, it will record

a Diagnostic Trouble Code (DTC) in the PCM mem-

ory. Do not change a thermostat for lack of heat as

Fig. 21 Thermostat PositionÐ5.9L EnginesFig. 22 Belt Routing ± 5.9L Engines

1 - IDLER PULLEY

2 - GENERATOR PULLEY

3 - A/C COMPRESSOR PULLEY

4 - IF W/OUT A/C

5 - POWER STEERING PUMP PULLEY

6 - WATER PUMP PULLEY

7 - CRANKSHAFT PULLEY

8 - AUTOMATIC TENSIONER

7 - 44 ENGINEDR

ENGINE COOLANT THERMOSTAT- 5.7L (Continued)

Page 427 of 2627

TRANSMISSION CONTROL

MODULE

DESCRIPTION

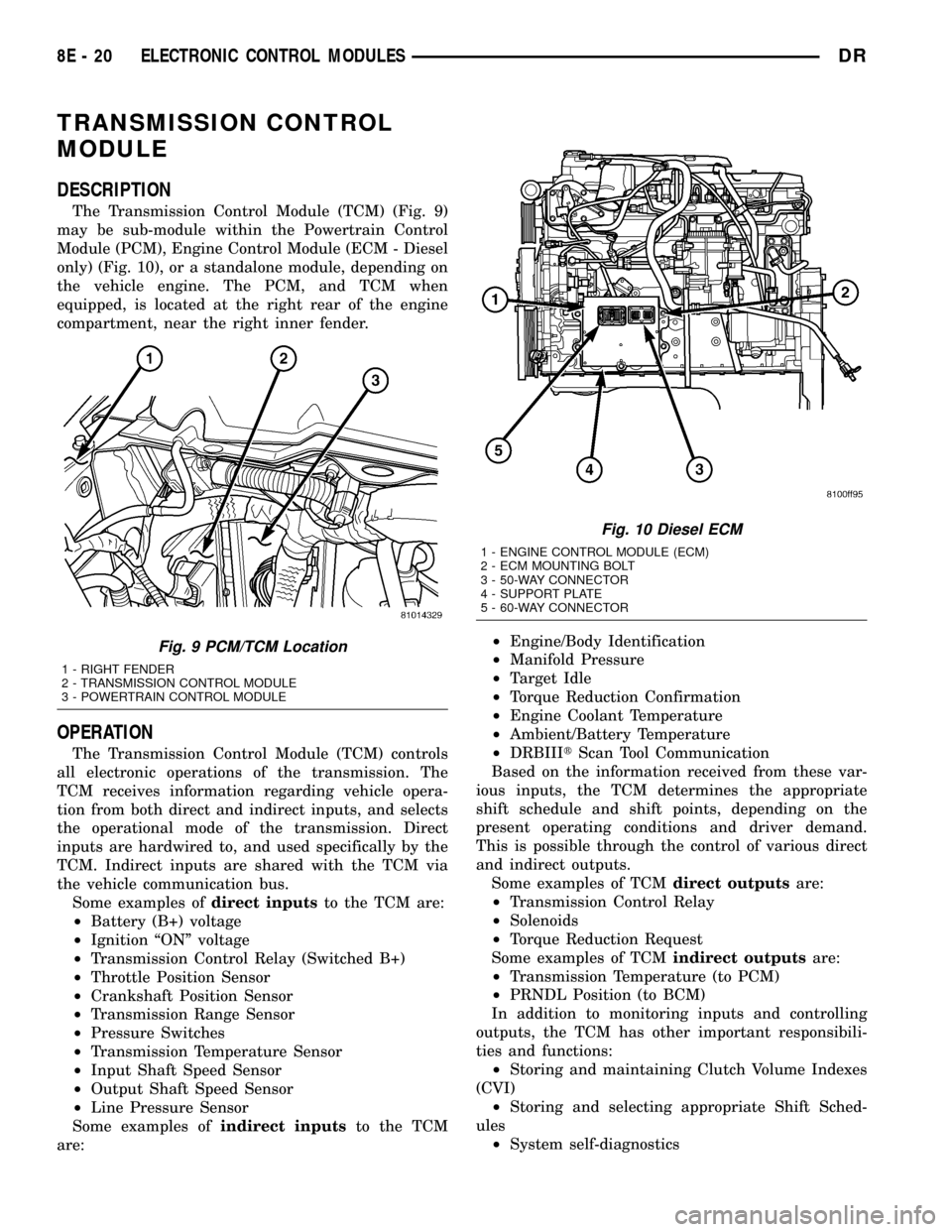

The Transmission Control Module (TCM) (Fig. 9)

may be sub-module within the Powertrain Control

Module (PCM), Engine Control Module (ECM - Diesel

only) (Fig. 10), or a standalone module, depending on

the vehicle engine. The PCM, and TCM when

equipped, is located at the right rear of the engine

compartment, near the right inner fender.

OPERATION

The Transmission Control Module (TCM) controls

all electronic operations of the transmission. The

TCM receives information regarding vehicle opera-

tion from both direct and indirect inputs, and selects

the operational mode of the transmission. Direct

inputs are hardwired to, and used specifically by the

TCM. Indirect inputs are shared with the TCM via

the vehicle communication bus.

Some examples ofdirect inputsto the TCM are:

²Battery (B+) voltage

²Ignition ªONº voltage

²Transmission Control Relay (Switched B+)

²Throttle Position Sensor

²Crankshaft Position Sensor

²Transmission Range Sensor

²Pressure Switches

²Transmission Temperature Sensor

²Input Shaft Speed Sensor

²Output Shaft Speed Sensor

²Line Pressure Sensor

Some examples ofindirect inputsto the TCM

are:²Engine/Body Identification

²Manifold Pressure

²Target Idle

²Torque Reduction Confirmation

²Engine Coolant Temperature

²Ambient/Battery Temperature

²DRBIIItScan Tool Communication

Based on the information received from these var-

ious inputs, the TCM determines the appropriate

shift schedule and shift points, depending on the

present operating conditions and driver demand.

This is possible through the control of various direct

and indirect outputs.

Some examples of TCMdirect outputsare:

²Transmission Control Relay

²Solenoids

²Torque Reduction Request

Some examples of TCMindirect outputsare:

²Transmission Temperature (to PCM)

²PRNDL Position (to BCM)

In addition to monitoring inputs and controlling

outputs, the TCM has other important responsibili-

ties and functions:

²Storing and maintaining Clutch Volume Indexes

(CVI)

²Storing and selecting appropriate Shift Sched-

ules

²System self-diagnostics

Fig. 9 PCM/TCM Location

1 - RIGHT FENDER

2 - TRANSMISSION CONTROL MODULE

3 - POWERTRAIN CONTROL MODULE

Fig. 10 Diesel ECM

1 - ENGINE CONTROL MODULE (ECM)

2 - ECM MOUNTING BOLT

3 - 50-WAY CONNECTOR

4 - SUPPORT PLATE

5 - 60-WAY CONNECTOR

8E - 20 ELECTRONIC CONTROL MODULESDR

Page 433 of 2627

For battery system maintenance schedules and

jump starting procedures, see the owner's manual in

the vehicle glove box. Optionally, refer to the Lubri-

cation and Maintenance section of this manual for

the proper battery jump starting procedure. While

battery charging can be considered a maintenance

procedure, the battery charging procedure and

related information are located later in this section of

the service manual. This was done because the bat-

tery must be fully-charged before any battery system

diagnosis or testing procedures can be performed.

OPERATION

The battery system is designed to provide a safe,

efficient, reliable and mobile means of delivering and

storing electrical energy. This electrical energy is

required to operate the engine starting system, as

well as to operate many of the other vehicle acces-

sory systems for limited durations while the engine

and/or the charging system are not operating. The

battery system is also designed to provide a reserve

of electrical energy to supplement the charging sys-

tem for short durations while the engine is running

and the electrical current demands of the vehicle

exceed the output of the charging system. In addition

to delivering, and storing electrical energy for the

vehicle, the battery system serves as a capacitor and

voltage stabilizer for the vehicle electrical system. It

absorbs most abnormal or transient voltages caused

by the switching of any of the electrical components

or circuits in the vehicle.

DIAGNOSIS AND TESTING - BATTERY SYSTEM

The battery, starting, and charging systems in the

vehicle operate with one another and must be tested

as a complete system. In order for the engine to start

and the battery to maintain its charge properly, all of

the components that are used in these systems must

perform within specifications. It is important thatthe battery, starting, and charging systems be thor-

oughly tested and inspected any time a battery needs

to be charged or replaced. The cause of abnormal bat-

tery discharge, overcharging or early battery failure

must be diagnosed and corrected before a battery is

replaced and before a vehicle is returned to service.

The service information for these systems has been

separated within this service manual to make it eas-

ier to locate the specific information you are seeking.

However, when attempting to diagnose any of these

systems, it is important that you keep their interde-

pendency in mind.

The diagnostic procedures used for the battery,

starting, and charging systems include the most

basic conventional diagnostic methods, to the more

sophisticated On-Board Diagnostics (OBD) built into

the Powertrain Control Module (PCM). Use of an

induction-type milliampere ammeter, a volt/ohmme-

ter, a battery charger, a carbon pile rheostat (load

tester), a 12-volt test lamp and/or special service

tools may be required. All OBD-sensed systems are

monitored by the PCM. Each monitored circuit is

assigned a Diagnostic Trouble Code (DTC). The PCM

will store a DTC in electronic memory for any failure

it detects. Always check the PCM for stored trouble

codes before returning the vehicle to service. Refer to

Charging System for the proper charging system test

procedures. Refer to Starting System for the proper

starting system test procedures.

MICRO 420 BATTERY TESTER

The Micro 420 automotive battery tester is

designed to help the dealership technician diagnose a

defective battery. Follow the instruction manual sup-

plied with the tester to properly diagnose a battery.

If the instruction manual is not available, refer to

the standard procedure in this section, which

includes the directions for using the Micro 420 bat-

tery tester.

8F - 2 BATTERY SYSTEMDR

BATTERY SYSTEM (Continued)

Page 477 of 2627

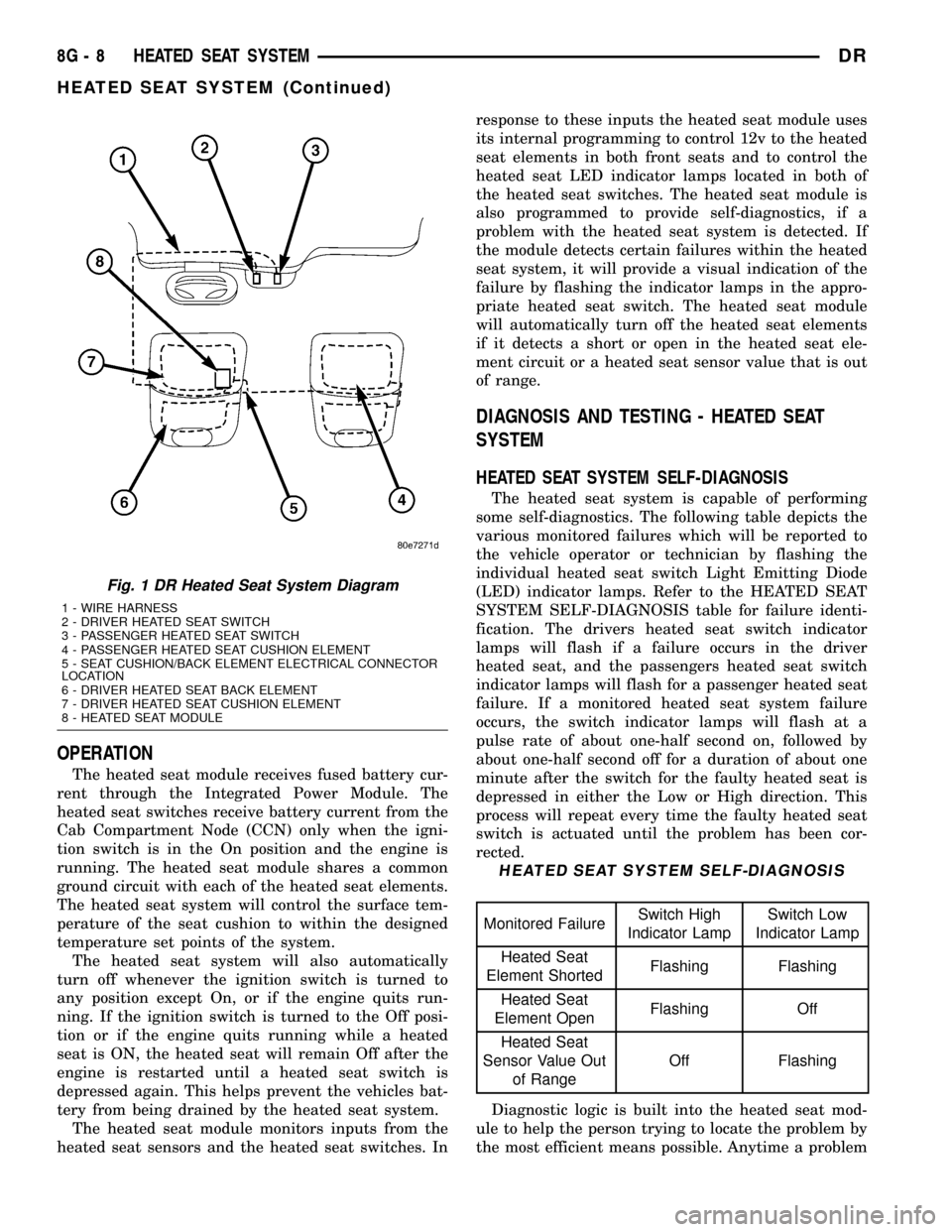

OPERATION

The heated seat module receives fused battery cur-

rent through the Integrated Power Module. The

heated seat switches receive battery current from the

Cab Compartment Node (CCN) only when the igni-

tion switch is in the On position and the engine is

running. The heated seat module shares a common

ground circuit with each of the heated seat elements.

The heated seat system will control the surface tem-

perature of the seat cushion to within the designed

temperature set points of the system.

The heated seat system will also automatically

turn off whenever the ignition switch is turned to

any position except On, or if the engine quits run-

ning. If the ignition switch is turned to the Off posi-

tion or if the engine quits running while a heated

seat is ON, the heated seat will remain Off after the

engine is restarted until a heated seat switch is

depressed again. This helps prevent the vehicles bat-

tery from being drained by the heated seat system.

The heated seat module monitors inputs from the

heated seat sensors and the heated seat switches. Inresponse to these inputs the heated seat module uses

its internal programming to control 12v to the heated

seat elements in both front seats and to control the

heated seat LED indicator lamps located in both of

the heated seat switches. The heated seat module is

also programmed to provide self-diagnostics, if a

problem with the heated seat system is detected. If

the module detects certain failures within the heated

seat system, it will provide a visual indication of the

failure by flashing the indicator lamps in the appro-

priate heated seat switch. The heated seat module

will automatically turn off the heated seat elements

if it detects a short or open in the heated seat ele-

ment circuit or a heated seat sensor value that is out

of range.

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM

HEATED SEAT SYSTEM SELF-DIAGNOSIS

The heated seat system is capable of performing

some self-diagnostics. The following table depicts the

various monitored failures which will be reported to

the vehicle operator or technician by flashing the

individual heated seat switch Light Emitting Diode

(LED) indicator lamps. Refer to the HEATED SEAT

SYSTEM SELF-DIAGNOSIS table for failure identi-

fication. The drivers heated seat switch indicator

lamps will flash if a failure occurs in the driver

heated seat, and the passengers heated seat switch

indicator lamps will flash for a passenger heated seat

failure. If a monitored heated seat system failure

occurs, the switch indicator lamps will flash at a

pulse rate of about one-half second on, followed by

about one-half second off for a duration of about one

minute after the switch for the faulty heated seat is

depressed in either the Low or High direction. This

process will repeat every time the faulty heated seat

switch is actuated until the problem has been cor-

rected.

HEATED SEAT SYSTEM SELF-DIAGNOSIS

Monitored FailureSwitch High

Indicator LampSwitch Low

Indicator Lamp

Heated Seat

Element ShortedFlashing Flashing

Heated Seat

Element OpenFlashing Off

Heated Seat

Sensor Value Out

of RangeOff Flashing

Diagnostic logic is built into the heated seat mod-

ule to help the person trying to locate the problem by

the most efficient means possible. Anytime a problem

Fig. 1 DR Heated Seat System Diagram

1 - WIRE HARNESS

2 - DRIVER HEATED SEAT SWITCH

3 - PASSENGER HEATED SEAT SWITCH

4 - PASSENGER HEATED SEAT CUSHION ELEMENT

5 - SEAT CUSHION/BACK ELEMENT ELECTRICAL CONNECTOR

LOCATION

6 - DRIVER HEATED SEAT BACK ELEMENT

7 - DRIVER HEATED SEAT CUSHION ELEMENT

8 - HEATED SEAT MODULE

8G - 8 HEATED SEAT SYSTEMDR

HEATED SEAT SYSTEM (Continued)

Page 540 of 2627

MALFUNCTION INDICATOR

LAMP (MIL)

DESCRIPTION

A Malfunction Indicator Lamp (MIL) is standard

equipment on all instrument clusters (Fig. 22). The

MIL is located on the left side of the instrument clus-

ter, to the left of the voltage gauge. The MIL consists

of a stencil-like cutout of the International Control

and Display Symbol icon for ªEngineº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. An

amber Light Emitting Diode (LED) behind the cutout

in the opaque layer of the overlay causes the icon to

appear in amber through the translucent outer layer

of the overlay when the indicator is illuminated from

behind by the LED, which is soldered onto the

instrument cluster electronic circuit board. The MIL

is serviced as a unit with the instrument cluster.

OPERATION

The Malfunction Indicator Lamp (MIL) gives an

indication to the vehicle operator when the Power-

train Control Module (PCM) on vehicles with a gaso-

line engine, or the Engine Control Module (ECM) on

vehicles with a diesel engine has recorded a Diagnos-

tic Trouble Code (DTC) for an On-Board Diagnostics

II (OBDII) emissions-related circuit or component

malfunction. The MIL is controlled by a transistor on

the instrument cluster circuit board based upon clus-

ter programming and electronic messages received by

the cluster from the PCM or ECM over the Program-

mable Communications Interface (PCI) data bus. The

MIL Light Emitting Diode (LED) is completely con-

trolled by the instrument cluster logic circuit, and

that logic will only allow this indicator to operate

when the instrument cluster receives a battery cur-

rent input on the fused ignition switch output (run-

start) circuit. Therefore, the LED will always be off

when the ignition switch is in any position except On

or Start. The LED only illuminates when it is pro-

vided a path to ground by the instrument cluster

transistor. The instrument cluster will turn on the

MIL for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the indicator is illuminated

for about two seconds as a bulb test. The entire two

second bulb test is a function of the PCM or ECM.²MIL Lamp-On Message- Each time the clus-

ter receives a MIL lamp-on message from the PCM

or ECM, the indicator will be illuminated. The indi-

cator can be flashed on and off, or illuminated solid,

as dictated by the PCM or ECM message. For some

DTC's, if a problem does not recur, the PCM or ECM

will send a lamp-off message automatically. Other

DTC's may require that a fault be repaired and the

PCM or ECM be reset before a lamp-off message will

be sent. For more information on the PCM, the ECM,

and the DTC set and reset parameters, (Refer to 25 -

EMISSIONS CONTROL - OPERATION).

²Communication Error- If the cluster receives

no lamp-on message from the PCM or ECM for ten

seconds, the MIL is illuminated by the instrument

cluster to indicate a loss of bus communication. The

indicator remains controlled and illuminated by the

cluster until a valid lamp-on message is received

from the PCM or ECM.

²Actuator Test- Each time the cluster is put

through the actuator test, the MIL indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the LED and the cluster

control circuitry.

On vehicles with a gasoline engine, the PCM con-

tinually monitors the fuel and emissions system cir-

cuits and sensors to decide whether the system is in

good operating condition. On vehicles with a diesel

engine, the ECM continually monitors the fuel and

emissions system circuits and sensors to decide

whether the system is in good operating condition.

The PCM or ECM then sends the proper lamp-on or

lamp-off messages to the instrument cluster. For fur-

ther diagnosis of the MIL or the instrument cluster

circuitry that controls the LED, (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). If the instrument cluster turns on

the MIL after the bulb test, it may indicate that a

malfunction has occurred and that the fuel and emis-

sions systems may require service. For proper diag-

nosis of the fuel and emissions systems, the PCM,

the ECM, the PCI data bus, or the electronic mes-

sage inputs to the instrument cluster that control the

MIL, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

Fig. 22 Malfunction Indicator Lamp (MIL)

DRINSTRUMENT CLUSTER 8J - 31

Page 630 of 2627

AIRBAG CONTROL MODULE

DESCRIPTION

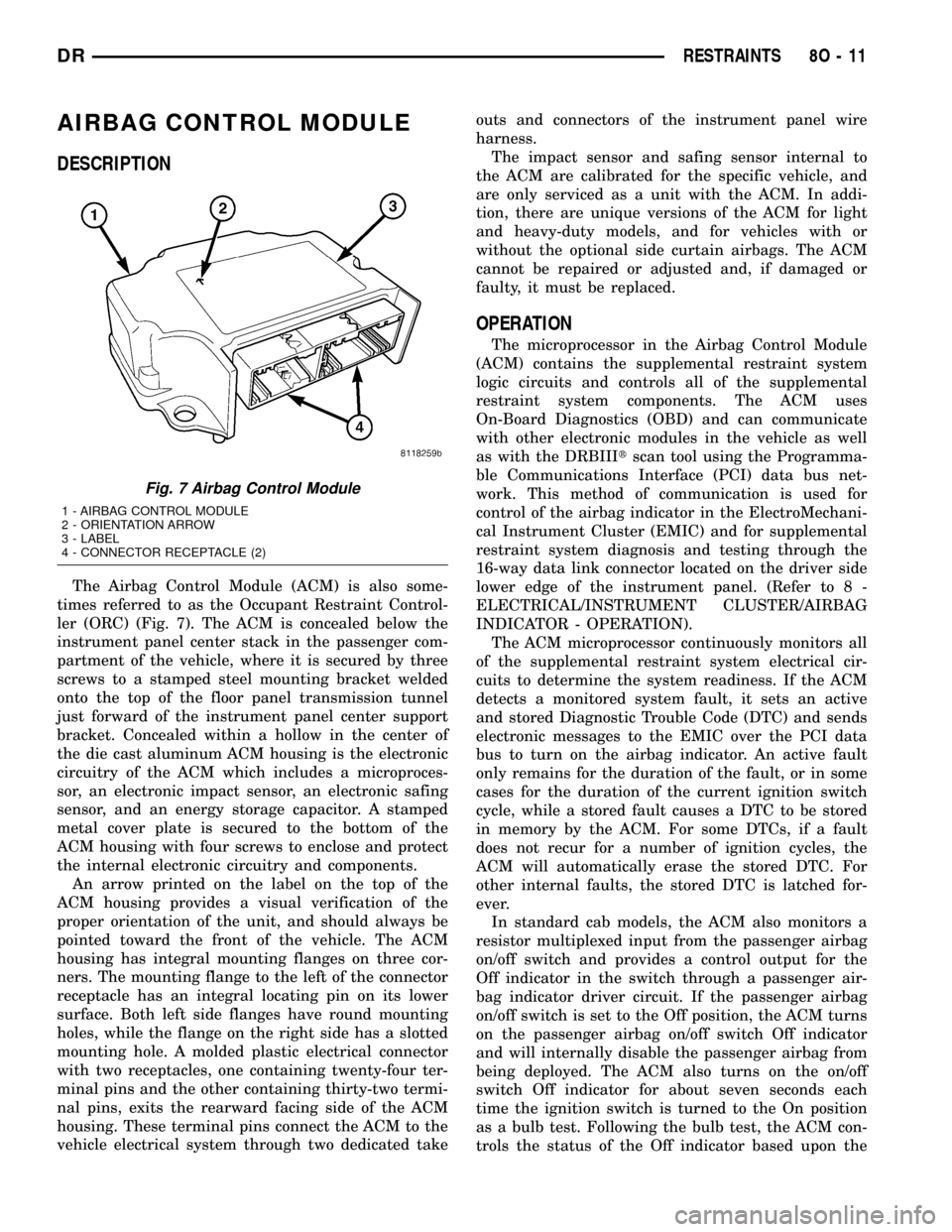

The Airbag Control Module (ACM) is also some-

times referred to as the Occupant Restraint Control-

ler (ORC) (Fig. 7). The ACM is concealed below the

instrument panel center stack in the passenger com-

partment of the vehicle, where it is secured by three

screws to a stamped steel mounting bracket welded

onto the top of the floor panel transmission tunnel

just forward of the instrument panel center support

bracket. Concealed within a hollow in the center of

the die cast aluminum ACM housing is the electronic

circuitry of the ACM which includes a microproces-

sor, an electronic impact sensor, an electronic safing

sensor, and an energy storage capacitor. A stamped

metal cover plate is secured to the bottom of the

ACM housing with four screws to enclose and protect

the internal electronic circuitry and components.

An arrow printed on the label on the top of the

ACM housing provides a visual verification of the

proper orientation of the unit, and should always be

pointed toward the front of the vehicle. The ACM

housing has integral mounting flanges on three cor-

ners. The mounting flange to the left of the connector

receptacle has an integral locating pin on its lower

surface. Both left side flanges have round mounting

holes, while the flange on the right side has a slotted

mounting hole. A molded plastic electrical connector

with two receptacles, one containing twenty-four ter-

minal pins and the other containing thirty-two termi-

nal pins, exits the rearward facing side of the ACM

housing. These terminal pins connect the ACM to the

vehicle electrical system through two dedicated takeouts and connectors of the instrument panel wire

harness.

The impact sensor and safing sensor internal to

the ACM are calibrated for the specific vehicle, and

are only serviced as a unit with the ACM. In addi-

tion, there are unique versions of the ACM for light

and heavy-duty models, and for vehicles with or

without the optional side curtain airbags. The ACM

cannot be repaired or adjusted and, if damaged or

faulty, it must be replaced.

OPERATION

The microprocessor in the Airbag Control Module

(ACM) contains the supplemental restraint system

logic circuits and controls all of the supplemental

restraint system components. The ACM uses

On-Board Diagnostics (OBD) and can communicate

with other electronic modules in the vehicle as well

as with the DRBIIItscan tool using the Programma-

ble Communications Interface (PCI) data bus net-

work. This method of communication is used for

control of the airbag indicator in the ElectroMechani-

cal Instrument Cluster (EMIC) and for supplemental

restraint system diagnosis and testing through the

16-way data link connector located on the driver side

lower edge of the instrument panel. (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER/AIRBAG

INDICATOR - OPERATION).

The ACM microprocessor continuously monitors all

of the supplemental restraint system electrical cir-

cuits to determine the system readiness. If the ACM

detects a monitored system fault, it sets an active

and stored Diagnostic Trouble Code (DTC) and sends

electronic messages to the EMIC over the PCI data

bus to turn on the airbag indicator. An active fault

only remains for the duration of the fault, or in some

cases for the duration of the current ignition switch

cycle, while a stored fault causes a DTC to be stored

in memory by the ACM. For some DTCs, if a fault

does not recur for a number of ignition cycles, the

ACM will automatically erase the stored DTC. For

other internal faults, the stored DTC is latched for-

ever.

In standard cab models, the ACM also monitors a

resistor multiplexed input from the passenger airbag

on/off switch and provides a control output for the

Off indicator in the switch through a passenger air-

bag indicator driver circuit. If the passenger airbag

on/off switch is set to the Off position, the ACM turns

on the passenger airbag on/off switch Off indicator

and will internally disable the passenger airbag from

being deployed. The ACM also turns on the on/off

switch Off indicator for about seven seconds each

time the ignition switch is turned to the On position

as a bulb test. Following the bulb test, the ACM con-

trols the status of the Off indicator based upon the

Fig. 7 Airbag Control Module

1 - AIRBAG CONTROL MODULE

2 - ORIENTATION ARROW

3 - LABEL

4 - CONNECTOR RECEPTACLE (2)

DRRESTRAINTS 8O - 11

Page 2574 of 2627

FUEL FILLER CAP

DESCRIPTION

The plastic fuel tank filler tube cap is threaded

onto the end of the fuel fill tube. Certain models are

equipped with a 1/4 turn cap.

OPERATION

The loss of any fuel or vapor out of fuel filler tube

is prevented by the use of a pressure-vacuum fuel fill

cap. Relief valves inside the cap will release fuel tank

pressure at predetermined pressures. Fuel tank vac-

uum will also be released at predetermined values.

This cap must be replaced by a similar unit if

replacement is necessary. This is in order for the sys-

tem to remain effective.

CAUTION: Remove fill cap before servicing any fuel

system component to relieve tank pressure. If

equipped with a Leak Detection Pump (LDP), or

NVLD system, the cap must be tightened securely.

If cap is left loose, a Diagnostic Trouble Code (DTC)

may be set.

REMOVAL

REMOVAL/INSTALLATION

If replacement of the 1/4 turn fuel tank filler tube

cap is necessary, it must be replaced with an identi-

cal cap to be sure of correct system operation.

CAUTION: Remove the fuel tank filler tube cap to

relieve fuel tank pressure. The cap must be

removed prior to disconnecting any fuel system

component or before draining the fuel tank.

LEAK DETECTION PUMP

DESCRIPTION

Vehicles equipped with JTEC engine control mod-

ules use a leak detection pump. Vehicles equipped

with NGC engine control modules use an NVLD

pump. Refer to Natural Vacuum - Leak Detection

(NVLD) for additional information.

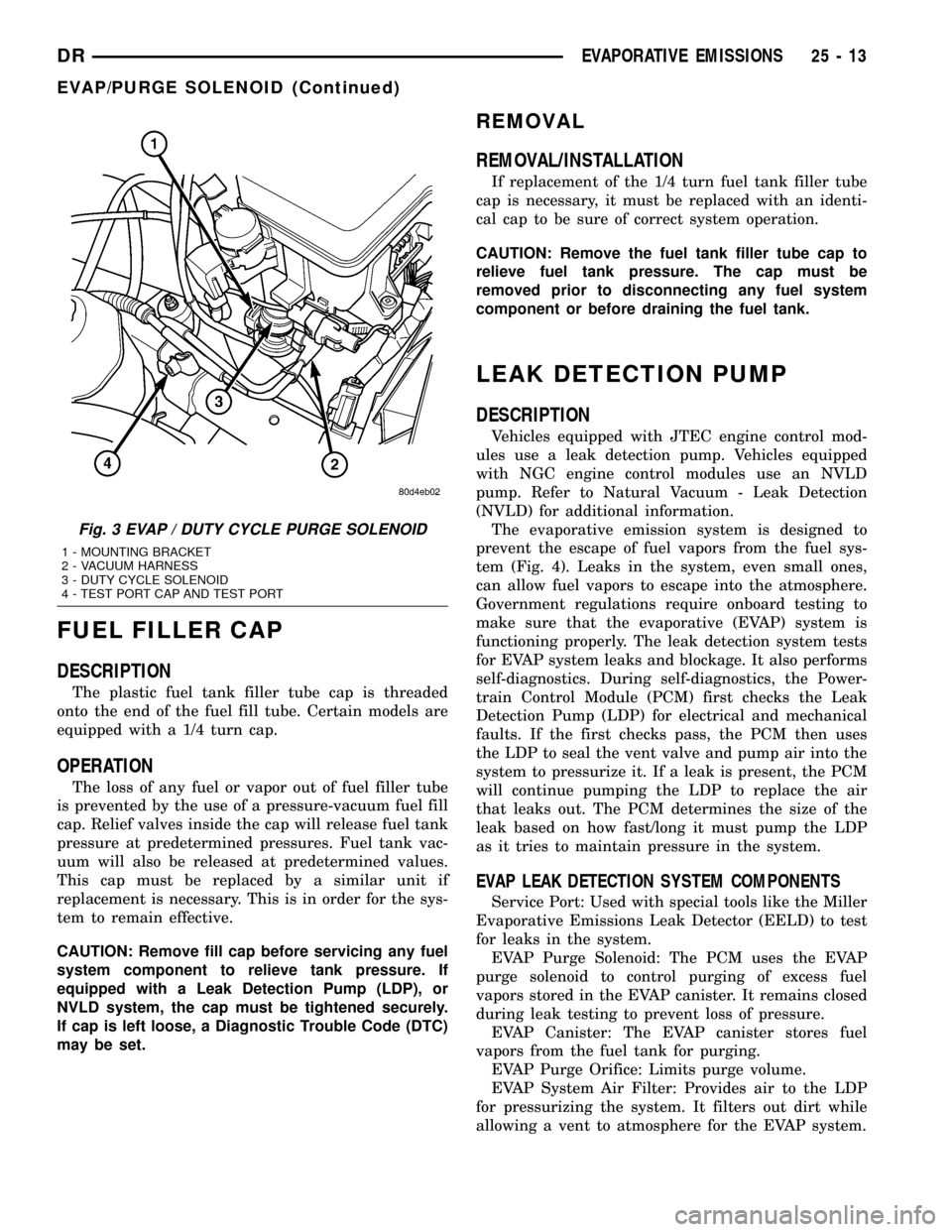

The evaporative emission system is designed to

prevent the escape of fuel vapors from the fuel sys-

tem (Fig. 4). Leaks in the system, even small ones,

can allow fuel vapors to escape into the atmosphere.

Government regulations require onboard testing to

make sure that the evaporative (EVAP) system is

functioning properly. The leak detection system tests

for EVAP system leaks and blockage. It also performs

self-diagnostics. During self-diagnostics, the Power-

train Control Module (PCM) first checks the Leak

Detection Pump (LDP) for electrical and mechanical

faults. If the first checks pass, the PCM then uses

the LDP to seal the vent valve and pump air into the

system to pressurize it. If a leak is present, the PCM

will continue pumping the LDP to replace the air

that leaks out. The PCM determines the size of the

leak based on how fast/long it must pump the LDP

as it tries to maintain pressure in the system.

EVAP LEAK DETECTION SYSTEM COMPONENTS

Service Port: Used with special tools like the Miller

Evaporative Emissions Leak Detector (EELD) to test

for leaks in the system.

EVAP Purge Solenoid: The PCM uses the EVAP

purge solenoid to control purging of excess fuel

vapors stored in the EVAP canister. It remains closed

during leak testing to prevent loss of pressure.

EVAP Canister: The EVAP canister stores fuel

vapors from the fuel tank for purging.

EVAP Purge Orifice: Limits purge volume.

EVAP System Air Filter: Provides air to the LDP

for pressurizing the system. It filters out dirt while

allowing a vent to atmosphere for the EVAP system.

Fig. 3 EVAP / DUTY CYCLE PURGE SOLENOID

1 - MOUNTING BRACKET

2 - VACUUM HARNESS

3 - DUTY CYCLE SOLENOID

4 - TEST PORT CAP AND TEST PORT

DREVAPORATIVE EMISSIONS 25 - 13

EVAP/PURGE SOLENOID (Continued)

Page 2609 of 2627

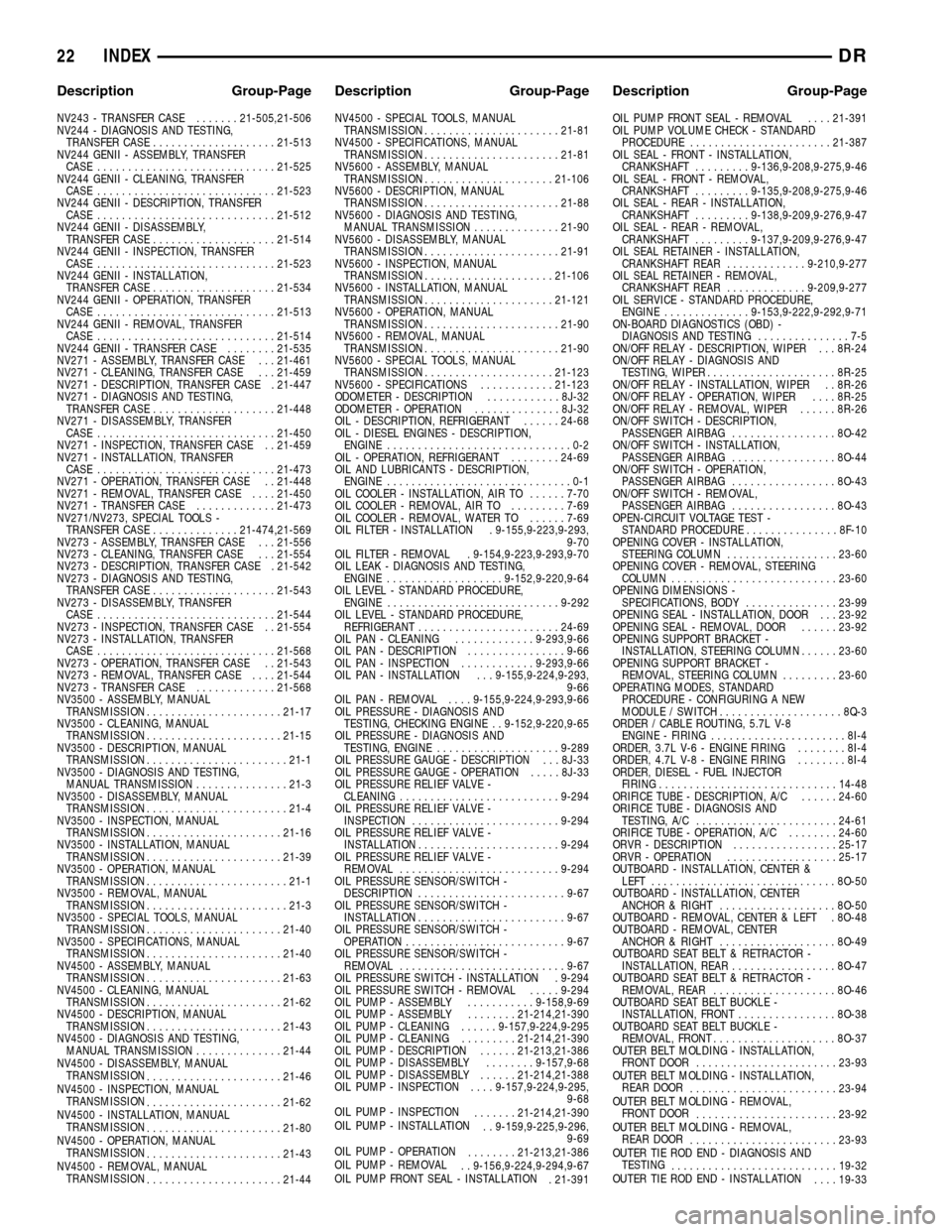

NV243 - TRANSFER CASE.......21-505,21-506

NV244 - DIAGNOSIS AND TESTING,

TRANSFER CASE....................21-513

NV244 GENII - ASSEMBLY, TRANSFER

CASE.............................21-525

NV244 GENII - CLEANING, TRANSFER

CASE.............................21-523

NV244 GENII - DESCRIPTION, TRANSFER

CASE.............................21-512

NV244 GENII - DISASSEMBLY,

TRANSFER CASE....................21-514

NV244 GENII - INSPECTION, TRANSFER

CASE.............................21-523

NV244 GENII - INSTALLATION,

TRANSFER CASE....................21-534

NV244 GENII - OPERATION, TRANSFER

CASE.............................21-513

NV244 GENII - REMOVAL, TRANSFER

CASE.............................21-514

NV244 GENII - TRANSFER CASE........21-535

NV271 - ASSEMBLY, TRANSFER CASE . . . 21-461

NV271 - CLEANING, TRANSFER CASE . . . 21-459

NV271 - DESCRIPTION, TRANSFER CASE . 21-447

NV271 - DIAGNOSIS AND TESTING,

TRANSFER CASE....................21-448

NV271 - DISASSEMBLY, TRANSFER

CASE.............................21-450

NV271 - INSPECTION, TRANSFER CASE . . 21-459

NV271 - INSTALLATION, TRANSFER

CASE.............................21-473

NV271 - OPERATION, TRANSFER CASE . . 21-448

NV271 - REMOVAL, TRANSFER CASE....21-450

NV271 - TRANSFER CASE.............21-473

NV271/NV273, SPECIAL TOOLS -

TRANSFER CASE..............21-474,21-569

NV273 - ASSEMBLY, TRANSFER CASE . . . 21-556

NV273 - CLEANING, TRANSFER CASE . . . 21-554

NV273 - DESCRIPTION, TRANSFER CASE . 21-542

NV273 - DIAGNOSIS AND TESTING,

TRANSFER CASE....................21-543

NV273 - DISASSEMBLY, TRANSFER

CASE.............................21-544

NV273 - INSPECTION, TRANSFER CASE . . 21-554

NV273 - INSTALLATION, TRANSFER

CASE.............................21-568

NV273 - OPERATION, TRANSFER CASE . . 21-543

NV273 - REMOVAL, TRANSFER CASE....21-544

NV273 - TRANSFER CASE.............21-568

NV3500 - ASSEMBLY, MANUAL

TRANSMISSION......................21-17

NV3500 - CLEANING, MANUAL

TRANSMISSION......................21-15

NV3500 - DESCRIPTION, MANUAL

TRANSMISSION.......................21-1

NV3500 - DIAGNOSIS AND TESTING,

MANUAL TRANSMISSION...............21-3

NV3500 - DISASSEMBLY, MANUAL

TRANSMISSION.......................21-4

NV3500 - INSPECTION, MANUAL

TRANSMISSION......................21-16

NV3500 - INSTALLATION, MANUAL

TRANSMISSION......................21-39

NV3500 - OPERATION, MANUAL

TRANSMISSION.......................21-1

NV3500 - REMOVAL, MANUAL

TRANSMISSION.......................21-3

NV3500 - SPECIAL TOOLS, MANUAL

TRANSMISSION......................21-40

NV3500 - SPECIFICATIONS, MANUAL

TRANSMISSION......................21-40

NV4500 - ASSEMBLY, MANUAL

TRANSMISSION......................21-63

NV4500 - CLEANING, MANUAL

TRANSMISSION......................21-62

NV4500 - DESCRIPTION, MANUAL

TRANSMISSION......................21-43

NV4500 - DIAGNOSIS AND TESTING,

MANUAL TRANSMISSION..............21-44

NV4500 - DISASSEMBLY, MANUAL

TRANSMISSION

......................21-46

NV4500 - INSPECTION, MANUAL

TRANSMISSION

......................21-62

NV4500 - INSTALLATION, MANUAL

TRANSMISSION

......................21-80

NV4500 - OPERATION, MANUAL

TRANSMISSION

......................21-43

NV4500 - REMOVAL, MANUAL

TRANSMISSION

......................21-44NV4500 - SPECIAL TOOLS, MANUAL

TRANSMISSION......................21-81

NV4500 - SPECIFICATIONS, MANUAL

TRANSMISSION......................21-81

NV5600 - ASSEMBLY, MANUAL

TRANSMISSION.....................21-106

NV5600 - DESCRIPTION, MANUAL

TRANSMISSION......................21-88

NV5600 - DIAGNOSIS AND TESTING,

MANUAL TRANSMISSION..............21-90

NV5600 - DISASSEMBLY, MANUAL

TRANSMISSION......................21-91

NV5600 - INSPECTION, MANUAL

TRANSMISSION.....................21-106

NV5600 - INSTALLATION, MANUAL

TRANSMISSION.....................21-121

NV5600 - OPERATION, MANUAL

TRANSMISSION......................21-90

NV5600 - REMOVAL, MANUAL

TRANSMISSION......................21-90

NV5600 - SPECIAL TOOLS, MANUAL

TRANSMISSION.....................21-123

NV5600 - SPECIFICATIONS............21-123

ODOMETER - DESCRIPTION............8J-32

ODOMETER - OPERATION..............8J-32

OIL - DESCRIPTION, REFRIGERANT......24-68

OIL - DIESEL ENGINES - DESCRIPTION,

ENGINE..............................0-2

OIL - OPERATION, REFRIGERANT........24-69

OIL AND LUBRICANTS - DESCRIPTION,

ENGINE..............................0-1

OIL COOLER - INSTALLATION, AIR TO......7-70

OIL COOLER - REMOVAL, AIR TO.........7-69

OIL COOLER - REMOVAL, WATER TO......7-69

OIL FILTER - INSTALLATION . 9-155,9-223,9-293,

9-70

OIL FILTER - REMOVAL . 9-154,9-223,9-293,9-70

OIL LEAK - DIAGNOSIS AND TESTING,

ENGINE...................9-152,9-220,9-64

OIL LEVEL - STANDARD PROCEDURE,

ENGINE............................9-292

OIL LEVEL - STANDARD PROCEDURE,

REFRIGERANT.......................24-69

OIL PAN - CLEANING.............9-293,9-66

OIL PAN - DESCRIPTION................9-66

OIL PAN - INSPECTION............9-293,9-66

OIL PAN - INSTALLATION . . . 9-155,9-224,9-293,

9-66

OIL PAN - REMOVAL....9-155,9-224,9-293,9-66

OIL PRESSURE - DIAGNOSIS AND

TESTING, CHECKING ENGINE . . 9-152,9-220,9-65

OIL PRESSURE - DIAGNOSIS AND

TESTING, ENGINE....................9-289

OIL PRESSURE GAUGE - DESCRIPTION . . . 8J-33

OIL PRESSURE GAUGE - OPERATION.....8J-33

OIL PRESSURE RELIEF VALVE -

CLEANING..........................9-294

OIL PRESSURE RELIEF VALVE -

INSPECTION........................9-294

OIL PRESSURE RELIEF VALVE -

INSTALLATION.......................9-294

OIL PRESSURE RELIEF VALVE -

REMOVAL..........................9-294

OIL PRESSURE SENSOR/SWITCH -

DESCRIPTION........................9-67

OIL PRESSURE SENSOR/SWITCH -

INSTALLATION........................9-67

OIL PRESSURE SENSOR/SWITCH -

OPERATION..........................9-67

OIL PRESSURE SENSOR/SWITCH -

REMOVAL...........................9-67

OIL PRESSURE SWITCH - INSTALLATION . 9-294

OIL PRESSURE SWITCH - REMOVAL.....9-294

OIL PUMP - ASSEMBLY...........9-158,9-69

OIL PUMP - ASSEMBLY........21-214,21-390

OIL PUMP - CLEANING......9-157,9-224,9-295

OIL PUMP - CLEANING.........21-214,21-390

OIL PUMP - DESCRIPTION......21-213,21-386

OIL PUMP - DISASSEMBLY........9-157,9-68

OIL PUMP - DISASSEMBLY......21-214,21-388

OIL PUMP - INSPECTION....9-157,9-224,9-295,

9-68

OIL PUMP - INSPECTION

.......21-214,21-390

OIL PUMP - INSTALLATION

. . 9-159,9-225,9-296,

9-69

OIL PUMP - OPERATION

........21-213,21-386

OIL PUMP - REMOVAL

. . 9-156,9-224,9-294,9-67

OIL PUMP FRONT SEAL - INSTALLATION

. 21-391OIL PUMP FRONT SEAL - REMOVAL....21-391

OIL PUMP VOLUME CHECK - STANDARD

PROCEDURE.......................21-387

OIL SEAL - FRONT - INSTALLATION,

CRANKSHAFT.........9-136,9-208,9-275,9-46

OIL SEAL - FRONT - REMOVAL,

CRANKSHAFT.........9-135,9-208,9-275,9-46

OIL SEAL - REAR - INSTALLATION,

CRANKSHAFT.........9-138,9-209,9-276,9-47

OIL SEAL - REAR - REMOVAL,

CRANKSHAFT.........9-137,9-209,9-276,9-47

OIL SEAL RETAINER - INSTALLATION,

CRANKSHAFT REAR.............9-210,9-277

OIL SEAL RETAINER - REMOVAL,

CRANKSHAFT REAR.............9-209,9-277

OIL SERVICE - STANDARD PROCEDURE,

ENGINE..............9-153,9-222,9-292,9-71

ON-BOARD DIAGNOSTICS (OBD) -

DIAGNOSIS AND TESTING...............7-5

ON/OFF RELAY - DESCRIPTION, WIPER . . . 8R-24

ON/OFF RELAY - DIAGNOSIS AND

TESTING, WIPER.....................8R-25

ON/OFF RELAY - INSTALLATION, WIPER . . 8R-26

ON/OFF RELAY - OPERATION, WIPER....8R-25

ON/OFF RELAY - REMOVAL, WIPER......8R-26

ON/OFF SWITCH - DESCRIPTION,

PASSENGER AIRBAG.................8O-42

ON/OFF SWITCH - INSTALLATION,

PASSENGER AIRBAG.................8O-44

ON/OFF SWITCH - OPERATION,

PASSENGER AIRBAG.................8O-43

ON/OFF SWITCH - REMOVAL,

PASSENGER AIRBAG.................8O-43

OPEN-CIRCUIT VOLTAGE TEST -

STANDARD PROCEDURE...............8F-10

OPENING COVER - INSTALLATION,

STEERING COLUMN..................23-60

OPENING COVER - REMOVAL, STEERING

COLUMN...........................23-60

OPENING DIMENSIONS -

SPECIFICATIONS, BODY...............23-99

OPENING SEAL - INSTALLATION, DOOR . . . 23-92

OPENING SEAL - REMOVAL, DOOR......23-92

OPENING SUPPORT BRACKET -

INSTALLATION, STEERING COLUMN......23-60

OPENING SUPPORT BRACKET -

REMOVAL, STEERING COLUMN.........23-60

OPERATING MODES, STANDARD

PROCEDURE - CONFIGURING A NEW

MODULE / SWITCH....................8Q-3

ORDER / CABLE ROUTING, 5.7L V-8

ENGINE - FIRING......................8I-4

ORDER, 3.7L V-6 - ENGINE FIRING........8I-4

ORDER, 4.7L V-8 - ENGINE FIRING........8I-4

ORDER, DIESEL - FUEL INJECTOR

FIRING.............................14-48

ORIFICE TUBE - DESCRIPTION, A/C......24-60

ORIFICE TUBE - DIAGNOSIS AND

TESTING, A/C.......................24-61

ORIFICE TUBE - OPERATION, A/C........24-60

ORVR - DESCRIPTION.................25-17

ORVR - OPERATION..................25-17

OUTBOARD - INSTALLATION, CENTER &

LEFT..............................8O-50

OUTBOARD - INSTALLATION, CENTER

ANCHOR & RIGHT...................8O-50

OUTBOARD - REMOVAL, CENTER & LEFT . 8O-48

OUTBOARD - REMOVAL, CENTER

ANCHOR & RIGHT...................8O-49

OUTBOARD SEAT BELT & RETRACTOR -

INSTALLATION, REAR.................8O-47

OUTBOARD SEAT BELT & RETRACTOR -

REMOVAL, REAR....................8O-46

OUTBOARD SEAT BELT BUCKLE -

INSTALLATION, FRONT................8O-38

OUTBOARD SEAT BELT BUCKLE -

REMOVAL, FRONT....................8O-37

OUTER BELT MOLDING - INSTALLATION,

FRONT DOOR.......................23-93

OUTER BELT MOLDING - INSTALLATION,

REAR DOOR

........................23-94

OUTER BELT MOLDING - REMOVAL,

FRONT DOOR

.......................23-92

OUTER BELT MOLDING - REMOVAL,

REAR DOOR

........................23-93

OUTER TIE ROD END - DIAGNOSIS AND

TESTING

...........................19-32

OUTER TIE ROD END - INSTALLATION

....19-33

22 INDEXDR

Description Group-Page Description Group-Page Description Group-Page