Flywheel bolts DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 302 of 2627

CLUTCH

TABLE OF CONTENTS

page page

CLUTCH

WARNING.............................1

DIAGNOSIS AND TESTING................1

SPECIFICATIONS........................5

CLUTCH DISC

REMOVAL.............................5

INSTALLATION..........................5

CLUTCH HOUSING

DIAGNOSIS AND TESTING................7

REMOVAL.............................9

INSTALLATION..........................9

CLUTCH RELEASE BEARING

REMOVAL.............................9

INSTALLATION.........................10

FLYWHEEL

DIAGNOSIS AND TESTING................10REMOVAL.............................11

DISASSEMBLY.........................11

ASSEMBLY............................11

INSTALLATION.........................11

PILOT BEARING

REMOVAL.............................11

INSTALLATION.........................12

LINKAGE

REMOVAL.............................12

INSTALLATION.........................12

CLUTCH PEDAL POSITION SWITCH

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING................13

CLUTCH

WARNING

WARNING: Exercise care when servicing clutch

components. Factory installed clutch discs do not

contain asbestos fibers. Dust and dirt on clutch

parts may contain asbestos fibers from aftermarket

components. Breathing excessive concentrations of

these fibers can cause serious bodily harm. Wear a

respirator during service and never clean clutch

components with compressed air or with a dry

brush. Either clean the components with water

dampened rags or use a vacuum cleaner specifi-

cally designed to remove asbestos fibers and dust.

Do not create dust by sanding a clutch discs.

Replace the disc if the friction material is damaged.

Dispose of all dust and dirt containing asbestos

fibers in sealed bags or containers. This will mini-

mize exposure to yourself and to others. Follow all

recommended safety practices prescribed by the

occupational safety and health administration

(OSHA) and the environmental safety agency (EPA),

for the handling and disposal of products contain-

ing asbestos. Failure to follow these instructions

may result in personal injury or death

DIAGNOSIS AND TESTING

Road test and inspect components to determine a

clutch problem. Road test the vehicle at normalspeeds. Shift the transmission through all gear

ranges and observe clutch action. If clutch chatters,

grabs, slips or does not release properly, remove and

inspect clutch components. If problem is noise or

hard shifting, further diagnosis may be needed to the

transmission and driveline component.

CLUTCH CONTAMINATION

Contamination is a frequent cause of clutch mal-

functions. Oil, water or clutch fluid on the clutch disc

and pressure plate surfaces will cause chatter, slip

and grab. Oil contamination indicates a leak at

either the rear main seal or transmission input shaft.

Clutch fluid leaks are usually from damaged slave

cylinder push rod seals. Heat buildup caused by slip-

page between the pressure plate, disc and flywheel

can bake the oil residue onto the components. The

glaze-like residue ranges in color from amber to

black.

Road splash contamination is dirt/water entering

the clutch housing due to loose bolts, housing cracks.

Driving through deep water puddles can force water/

road splash into the housing through such openings.

IMPROPER RELEASE OR CLUTCH ENGAGEMENT

Clutch release or engagement problems can be

caused by worn or damage clutch components.

Release problems can cause hard shifting and

noise. Look for leaks at clutch cylinders, connecting

line and loose slave cylinder bolts. Also worn/loose

release fork, pivot stud, clutch disc, pressure plate or

release bearing.

DRCLUTCH 6 - 1

Page 303 of 2627

Engagement problems can cause slip, chatter/shud-

der and noisy operation. The causes may be clutch

disc contamination, wear, distortion or flywheel dam-

age.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment

with the crankshaft and transmission input shaft.

Misalignment caused by excessive runout or warpage

of any clutch component will cause grab, chatter and

improper clutch release.

CLUTCH COVER AND DISC RUNOUT

Check the clutch disc before installation. Axial

(face) runout of anewdisc should not exceed 0.50

mm (0.020 in.). Measure runout about 6 mm (1/4 in.)

from the outer edge of the disc facing. Obtain

another disc if runout is excessive.

Check condition of the clutch before installation. A

warped cover or diaphragm spring will cause grab

and incomplete release or engagement. Be careful

when handling the cover and disc. Impact can distort

the cover, diaphragm spring, release fingers and the

hub of the clutch disc.

Use an alignment tool when positioning the disc on

the flywheel. The tool prevents accidental misalign-

ment which could result in cover distortion and disc

damage.

A frequent cause of clutch cover distortion (and

consequent misalignment) is improper bolt tighten-

ing.

FLYWHEEL RUNOUT

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator.

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. Minor fly-

wheel scoring can be cleaned up by hand with 180

grit emery or with turning equipment. Remove only

enough material to reduce scoring (approximately

0.001 - 0.003 in.). Heavy stock removal isnot rec-

ommended.Replace the flywheel if scoring is severe

and deeper than 0.076 mm (0.003 in.). Excessive

stock removal can result in flywheel cracking or

warpage after installation; it can also weaken the fly-

wheel and interfere with proper clutch release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with Mopar Lock And Seal or equivalent.

Tighten flywheel bolts to specified torque only. Over-

tightening can distort the flywheel hub causing

runout.

DIAGNOSIS CHART

The diagnosis charts Diagnosis Chart describe

common clutch problems, causes and correction.

DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Disc facing worn out 1. Normal wear. 1. Replace cover and disc.

2. Driver frequently rides (slips) the

clutch. Results in rapid overheating

and wear.2. Replace cover and disc.

3. Insufficient clutch cover

diaphragm spring tension.3. Replace cover and disc.

6 - 2 CLUTCHDR

CLUTCH (Continued)

Page 306 of 2627

CONDITION POSSIBLE CAUSES CORRECTION

Partial engagement of clutch disc.

One side of disc is worn and the

other side is glazed and lightly

worn.1. Clutch pressure plate position

incorrect.1. Replace clutch disc and cover.

2. Clutch cover, spring, or release

fingers bent or distorted.2. Replace clutch disc and cover.

3. Clutch disc damaged or

distorted.2. Replace clutch disc.

4. Clutch misalignment. 4. Check alignment and runout of

flywheel, disc, pressure plate, andùr

clutch housing. Correct as

necessary.

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Slave Cylinder Nuts 23 17 -

Clutch Master Cylinder

Nuts28 21 -

Pressure Plate Bolts - V6

&V850 37 -

Pressure Plate Bolts - V10 30 22.5 -

Pressure Plate Bolts -

Diesel30 22.5 -

Release Bearing Pivot 23 17 -

Flywheel Bolts 95 70 -

CLUTCH DISC

REMOVAL

(1) Support engine with wood block and adjustable

jack stand, to prevent strain on engine mounts.

(2) Remove transmission and transfer case, if

equipped.

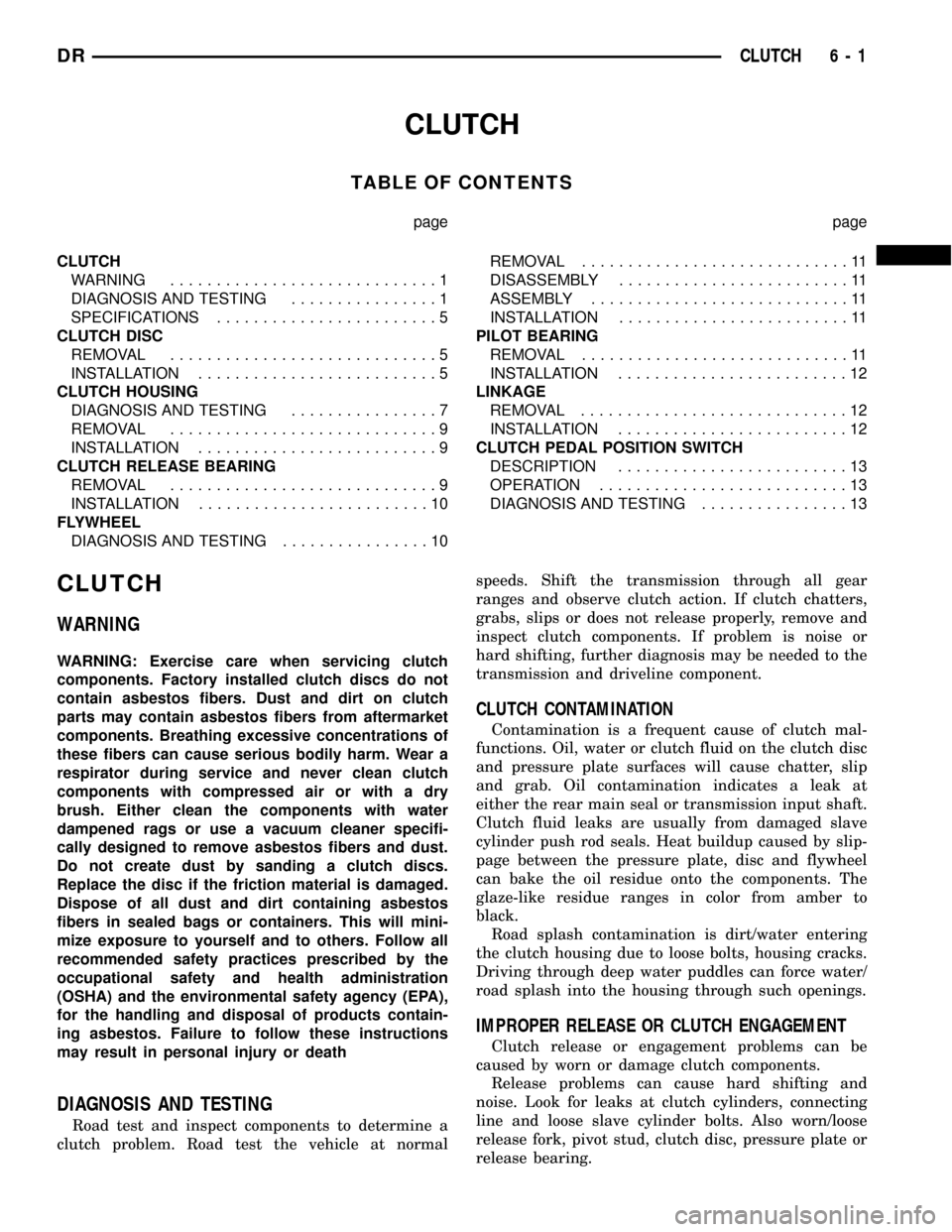

(3) If pressure plate will be reused, mark the posi-

tion on flywheel with paint or scriber (Fig. 1). Also

note location marks on the pressure next to the bolt

holes. The mark will be a L or a circle with an X in

it.

(4) Insert clutch alignment tool through clutch disc

and into pilot bushing, to hold disc in place while

removing bolts.

(5) Loosen pressure plate bolts evenly, a few

threads at a time and in a diagonal pattern to pre-

vent warping the plate.

(6) Remove bolts completely and remove pressure

plate, disc and alignment tool.

INSTALLATION

(1) Check runout and free operation of new clutch

disc.

(2) Lubricate crankshaft pilot bearing with a NLGI

- 2 rated grease.

(3) Install clutch alignment tool in clutch disc hub

with the raised side of hub is facing away from the

flywheel.

NOTE: Flywheel side is imprinted on the disc face.

(4) Install alignment tool in pilot bearing and posi-

tion disc on the flywheel.

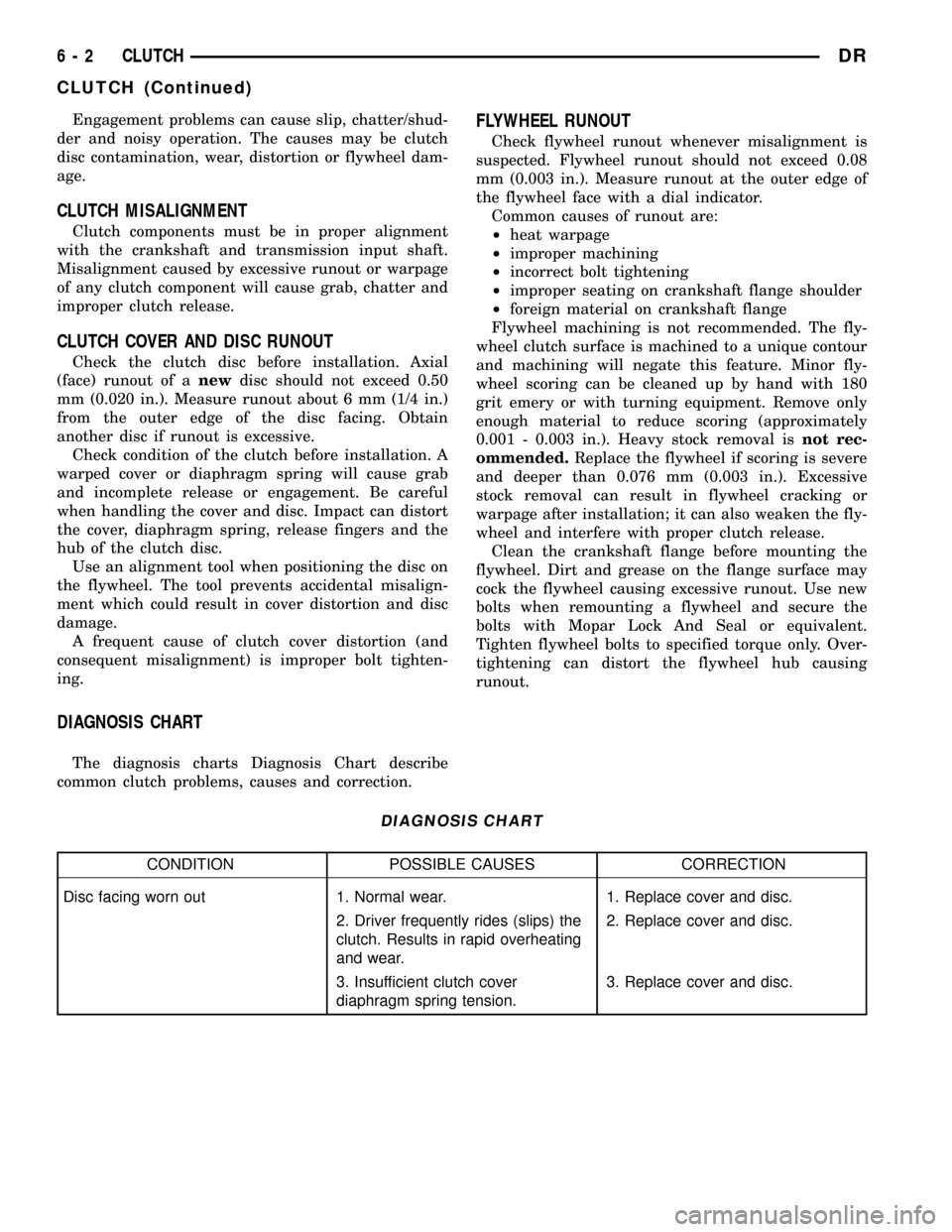

(5) Position pressure plate over disc and onto the

flywheel (Fig. 2).

(6) Align and hold pressure plate in position and

install bolts finger tight.

(7) Tighten bolts evenly and a few threads at a

time in a diagonal pattern.

CAUTION: Bolts must be tightened evenly and to

specified torque to avoid warping pressure plate

cover.

DRCLUTCH 6 - 5

CLUTCH (Continued)

Page 307 of 2627

(8) Tighten pressure plate bolts to:

²V6 & V8 Engines - 50 N´m (37 ft. lbs.)

²V10 & Diesel Engines - 30 N´m (22.5 ft. lbs.)

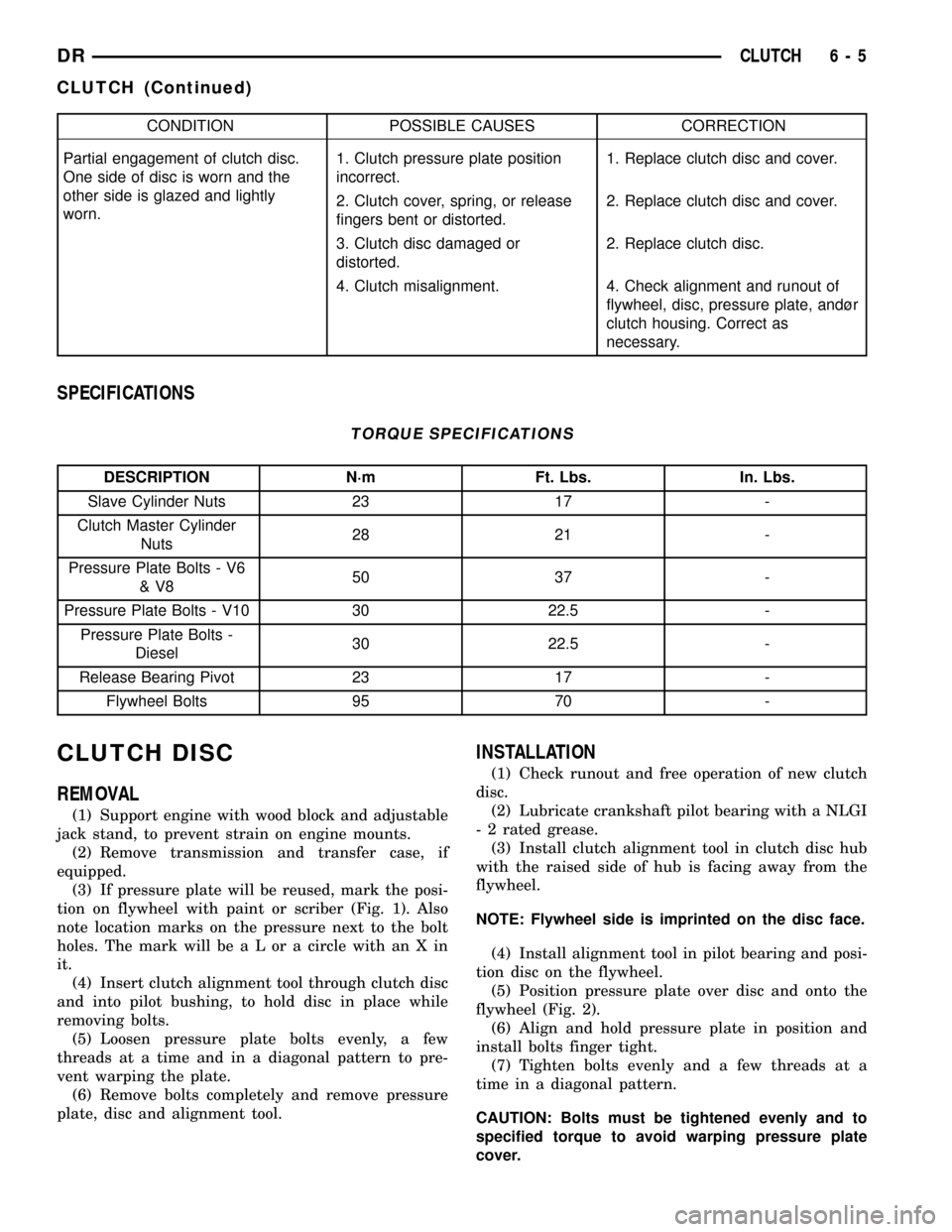

(9) Remove release lever and release bearing from

clutch housing. Apply Mopar high temperature bear-

ing grease to bore of release bearing, release lever

contact surfaces and release lever pivot stud (Fig. 3).

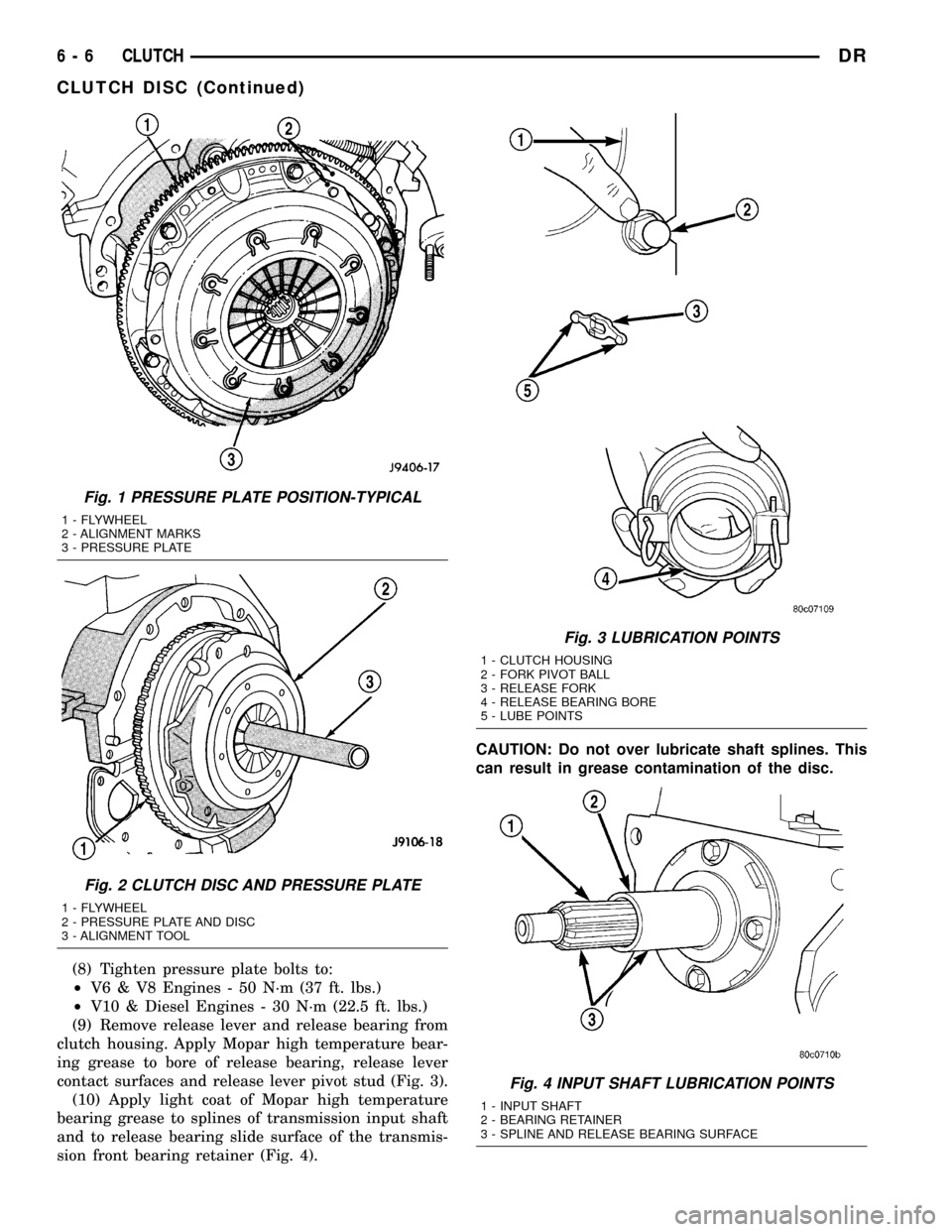

(10) Apply light coat of Mopar high temperature

bearing grease to splines of transmission input shaft

and to release bearing slide surface of the transmis-

sion front bearing retainer (Fig. 4).CAUTION: Do not over lubricate shaft splines. This

can result in grease contamination of the disc.

Fig. 1 PRESSURE PLATE POSITION-TYPICAL

1 - FLYWHEEL

2 - ALIGNMENT MARKS

3 - PRESSURE PLATE

Fig. 2 CLUTCH DISC AND PRESSURE PLATE

1 - FLYWHEEL

2 - PRESSURE PLATE AND DISC

3 - ALIGNMENT TOOL

Fig. 3 LUBRICATION POINTS

1 - CLUTCH HOUSING

2 - FORK PIVOT BALL

3 - RELEASE FORK

4 - RELEASE BEARING BORE

5 - LUBE POINTS

Fig. 4 INPUT SHAFT LUBRICATION POINTS

1 - INPUT SHAFT

2 - BEARING RETAINER

3 - SPLINE AND RELEASE BEARING SURFACE

6 - 6 CLUTCHDR

CLUTCH DISC (Continued)

Page 308 of 2627

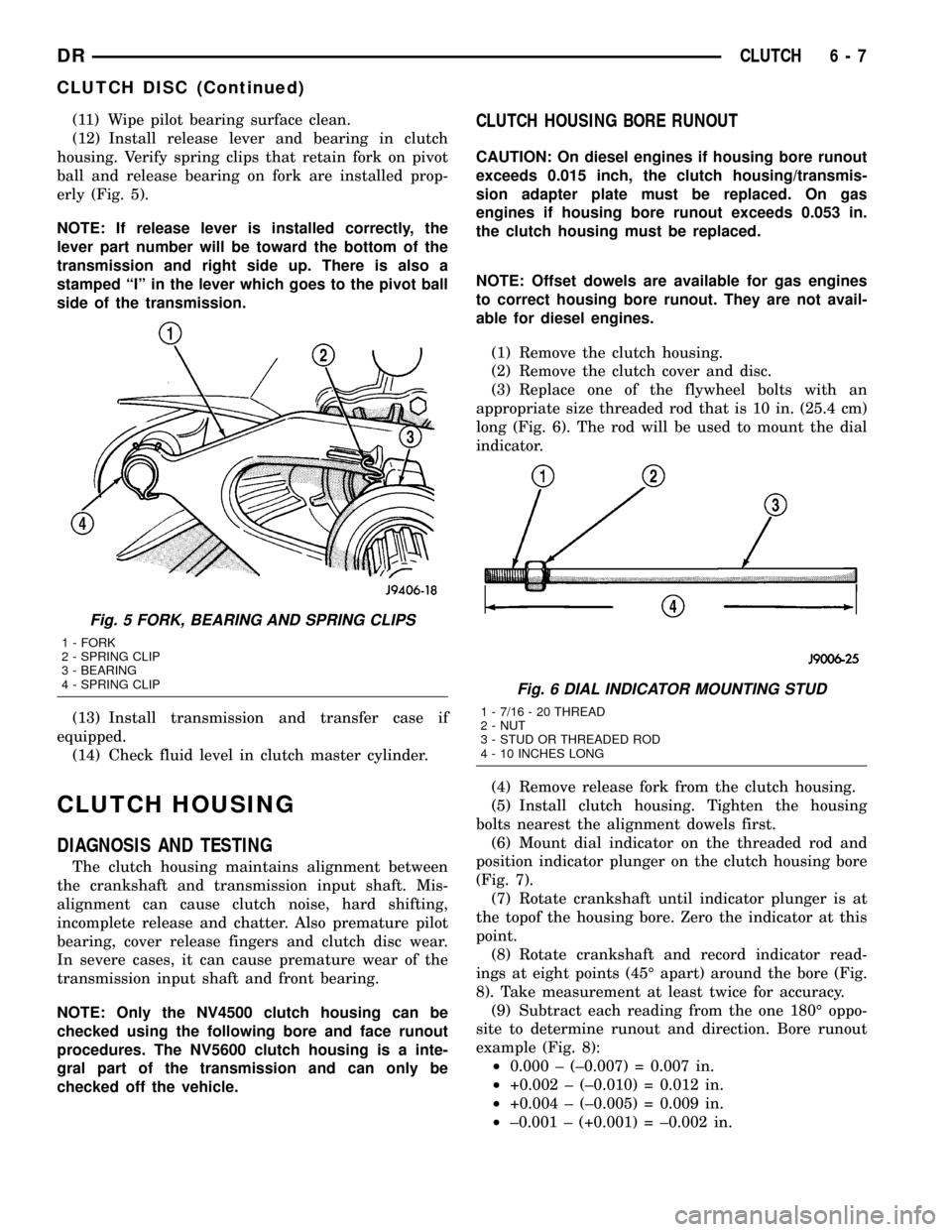

(11) Wipe pilot bearing surface clean.

(12) Install release lever and bearing in clutch

housing. Verify spring clips that retain fork on pivot

ball and release bearing on fork are installed prop-

erly (Fig. 5).

NOTE: If release lever is installed correctly, the

lever part number will be toward the bottom of the

transmission and right side up. There is also a

stamped ªIº in the lever which goes to the pivot ball

side of the transmission.

(13) Install transmission and transfer case if

equipped.

(14) Check fluid level in clutch master cylinder.

CLUTCH HOUSING

DIAGNOSIS AND TESTING

The clutch housing maintains alignment between

the crankshaft and transmission input shaft. Mis-

alignment can cause clutch noise, hard shifting,

incomplete release and chatter. Also premature pilot

bearing, cover release fingers and clutch disc wear.

In severe cases, it can cause premature wear of the

transmission input shaft and front bearing.

NOTE: Only the NV4500 clutch housing can be

checked using the following bore and face runout

procedures. The NV5600 clutch housing is a inte-

gral part of the transmission and can only be

checked off the vehicle.

CLUTCH HOUSING BORE RUNOUT

CAUTION: On diesel engines if housing bore runout

exceeds 0.015 inch, the clutch housing/transmis-

sion adapter plate must be replaced. On gas

engines if housing bore runout exceeds 0.053 in.

the clutch housing must be replaced.

NOTE: Offset dowels are available for gas engines

to correct housing bore runout. They are not avail-

able for diesel engines.

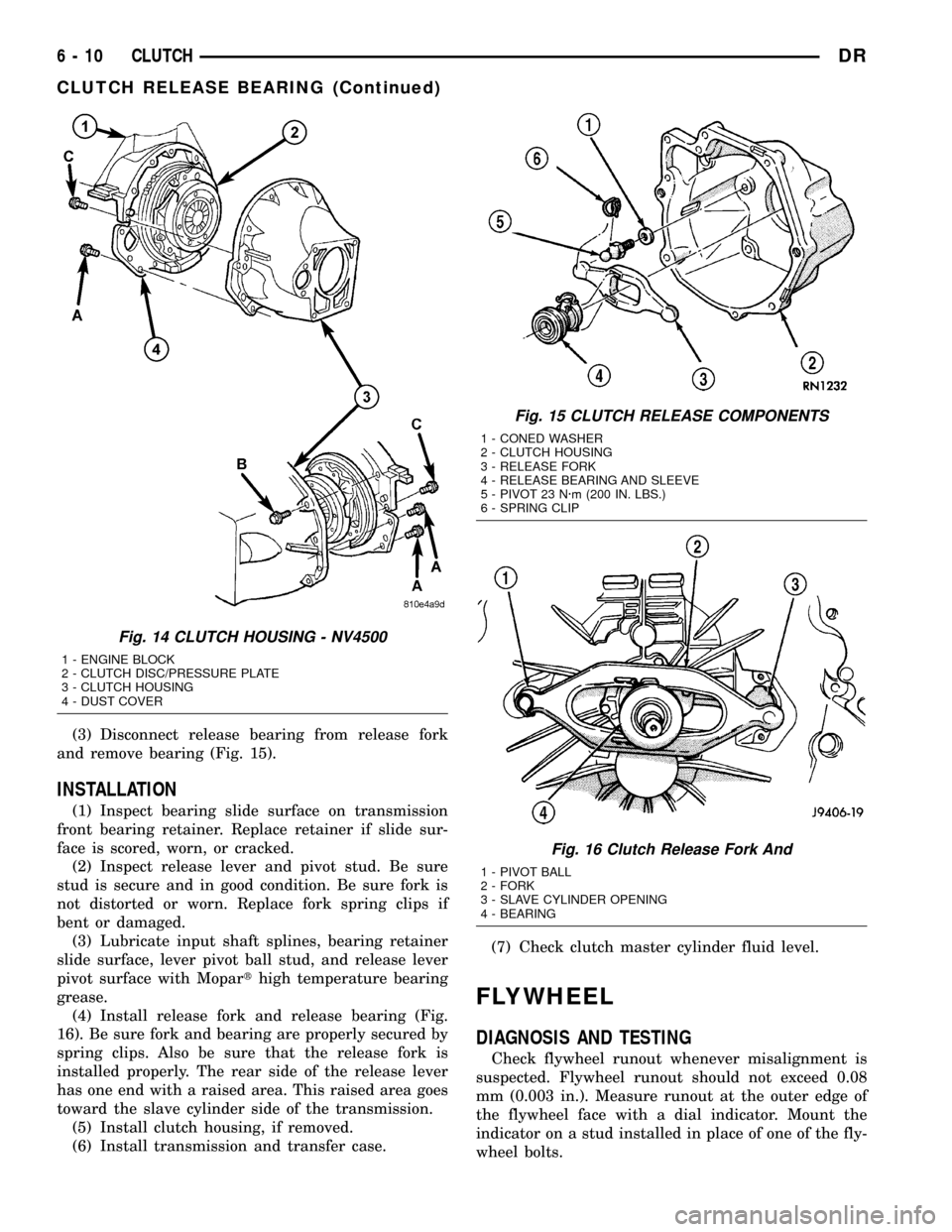

(1) Remove the clutch housing.

(2) Remove the clutch cover and disc.

(3) Replace one of the flywheel bolts with an

appropriate size threaded rod that is 10 in. (25.4 cm)

long (Fig. 6). The rod will be used to mount the dial

indicator.

(4) Remove release fork from the clutch housing.

(5) Install clutch housing. Tighten the housing

bolts nearest the alignment dowels first.

(6) Mount dial indicator on the threaded rod and

position indicator plunger on the clutch housing bore

(Fig. 7).

(7) Rotate crankshaft until indicator plunger is at

the topof the housing bore. Zero the indicator at this

point.

(8) Rotate crankshaft and record indicator read-

ings at eight points (45É apart) around the bore (Fig.

8). Take measurement at least twice for accuracy.

(9) Subtract each reading from the one 180É oppo-

site to determine runout and direction. Bore runout

example (Fig. 8):

²0.000 ± (±0.007) = 0.007 in.

²+0.002 ± (±0.010) = 0.012 in.

²+0.004 ± (±0.005) = 0.009 in.

²±0.001 ± (+0.001) = ±0.002 in.

Fig. 5 FORK, BEARING AND SPRING CLIPS

1 - FORK

2 - SPRING CLIP

3 - BEARING

4 - SPRING CLIP

Fig. 6 DIAL INDICATOR MOUNTING STUD

1 - 7/16 - 20 THREAD

2 - NUT

3 - STUD OR THREADED ROD

4 - 10 INCHES LONG

DRCLUTCH 6 - 7

CLUTCH DISC (Continued)

Page 311 of 2627

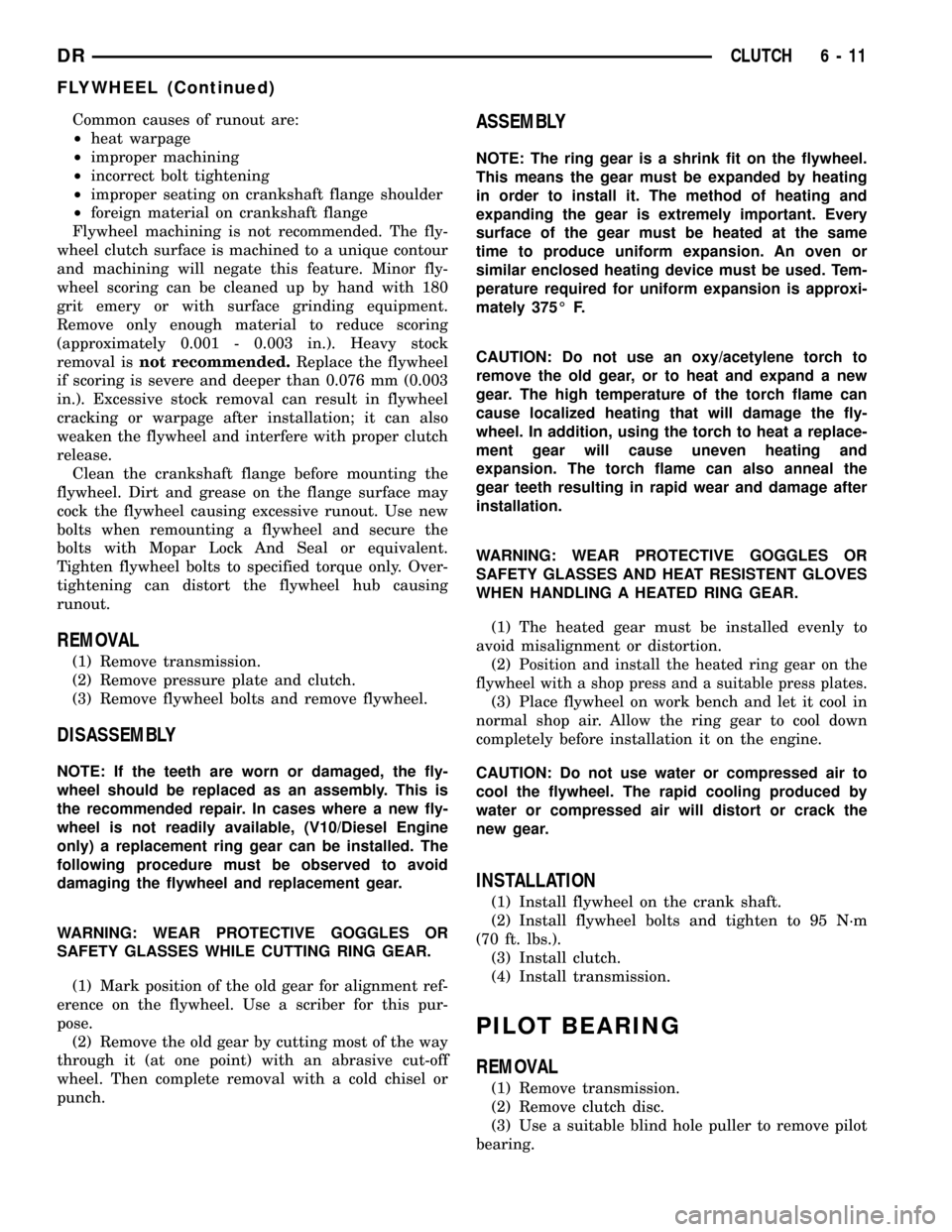

(3) Disconnect release bearing from release fork

and remove bearing (Fig. 15).

INSTALLATION

(1) Inspect bearing slide surface on transmission

front bearing retainer. Replace retainer if slide sur-

face is scored, worn, or cracked.

(2) Inspect release lever and pivot stud. Be sure

stud is secure and in good condition. Be sure fork is

not distorted or worn. Replace fork spring clips if

bent or damaged.

(3) Lubricate input shaft splines, bearing retainer

slide surface, lever pivot ball stud, and release lever

pivot surface with Moparthigh temperature bearing

grease.

(4) Install release fork and release bearing (Fig.

16). Be sure fork and bearing are properly secured by

spring clips. Also be sure that the release fork is

installed properly. The rear side of the release lever

has one end with a raised area. This raised area goes

toward the slave cylinder side of the transmission.

(5) Install clutch housing, if removed.

(6) Install transmission and transfer case.(7) Check clutch master cylinder fluid level.

FLYWHEEL

DIAGNOSIS AND TESTING

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator. Mount the

indicator on a stud installed in place of one of the fly-

wheel bolts.

Fig. 14 CLUTCH HOUSING - NV4500

1 - ENGINE BLOCK

2 - CLUTCH DISC/PRESSURE PLATE

3 - CLUTCH HOUSING

4 - DUST COVER

Fig. 15 CLUTCH RELEASE COMPONENTS

1 - CONED WASHER

2 - CLUTCH HOUSING

3 - RELEASE FORK

4 - RELEASE BEARING AND SLEEVE

5 - PIVOT 23 N´m (200 IN. LBS.)

6 - SPRING CLIP

Fig. 16 Clutch Release Fork And

1 - PIVOT BALL

2 - FORK

3 - SLAVE CYLINDER OPENING

4 - BEARING

6 - 10 CLUTCHDR

CLUTCH RELEASE BEARING (Continued)

Page 312 of 2627

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. Minor fly-

wheel scoring can be cleaned up by hand with 180

grit emery or with surface grinding equipment.

Remove only enough material to reduce scoring

(approximately 0.001 - 0.003 in.). Heavy stock

removal isnot recommended.Replace the flywheel

if scoring is severe and deeper than 0.076 mm (0.003

in.). Excessive stock removal can result in flywheel

cracking or warpage after installation; it can also

weaken the flywheel and interfere with proper clutch

release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with Mopar Lock And Seal or equivalent.

Tighten flywheel bolts to specified torque only. Over-

tightening can distort the flywheel hub causing

runout.

REMOVAL

(1) Remove transmission.

(2) Remove pressure plate and clutch.

(3) Remove flywheel bolts and remove flywheel.

DISASSEMBLY

NOTE: If the teeth are worn or damaged, the fly-

wheel should be replaced as an assembly. This is

the recommended repair. In cases where a new fly-

wheel is not readily available, (V10/Diesel Engine

only) a replacement ring gear can be installed. The

following procedure must be observed to avoid

damaging the flywheel and replacement gear.

WARNING: WEAR PROTECTIVE GOGGLES OR

SAFETY GLASSES WHILE CUTTING RING GEAR.

(1) Mark position of the old gear for alignment ref-

erence on the flywheel. Use a scriber for this pur-

pose.

(2) Remove the old gear by cutting most of the way

through it (at one point) with an abrasive cut-off

wheel. Then complete removal with a cold chisel or

punch.

ASSEMBLY

NOTE: The ring gear is a shrink fit on the flywheel.

This means the gear must be expanded by heating

in order to install it. The method of heating and

expanding the gear is extremely important. Every

surface of the gear must be heated at the same

time to produce uniform expansion. An oven or

similar enclosed heating device must be used. Tem-

perature required for uniform expansion is approxi-

mately 375É F.

CAUTION: Do not use an oxy/acetylene torch to

remove the old gear, or to heat and expand a new

gear. The high temperature of the torch flame can

cause localized heating that will damage the fly-

wheel. In addition, using the torch to heat a replace-

ment gear will cause uneven heating and

expansion. The torch flame can also anneal the

gear teeth resulting in rapid wear and damage after

installation.

WARNING: WEAR PROTECTIVE GOGGLES OR

SAFETY GLASSES AND HEAT RESISTENT GLOVES

WHEN HANDLING A HEATED RING GEAR.

(1) The heated gear must be installed evenly to

avoid misalignment or distortion.

(2)

Position and install the heated ring gear on the

flywheel with a shop press and a suitable press plates.

(3) Place flywheel on work bench and let it cool in

normal shop air. Allow the ring gear to cool down

completely before installation it on the engine.

CAUTION: Do not use water or compressed air to

cool the flywheel. The rapid cooling produced by

water or compressed air will distort or crack the

new gear.

INSTALLATION

(1) Install flywheel on the crank shaft.

(2) Install flywheel bolts and tighten to 95 N´m

(70 ft. lbs.).

(3) Install clutch.

(4) Install transmission.

PILOT BEARING

REMOVAL

(1) Remove transmission.

(2) Remove clutch disc.

(3) Use a suitable blind hole puller to remove pilot

bearing.

DRCLUTCH 6 - 11

FLYWHEEL (Continued)

Page 1412 of 2627

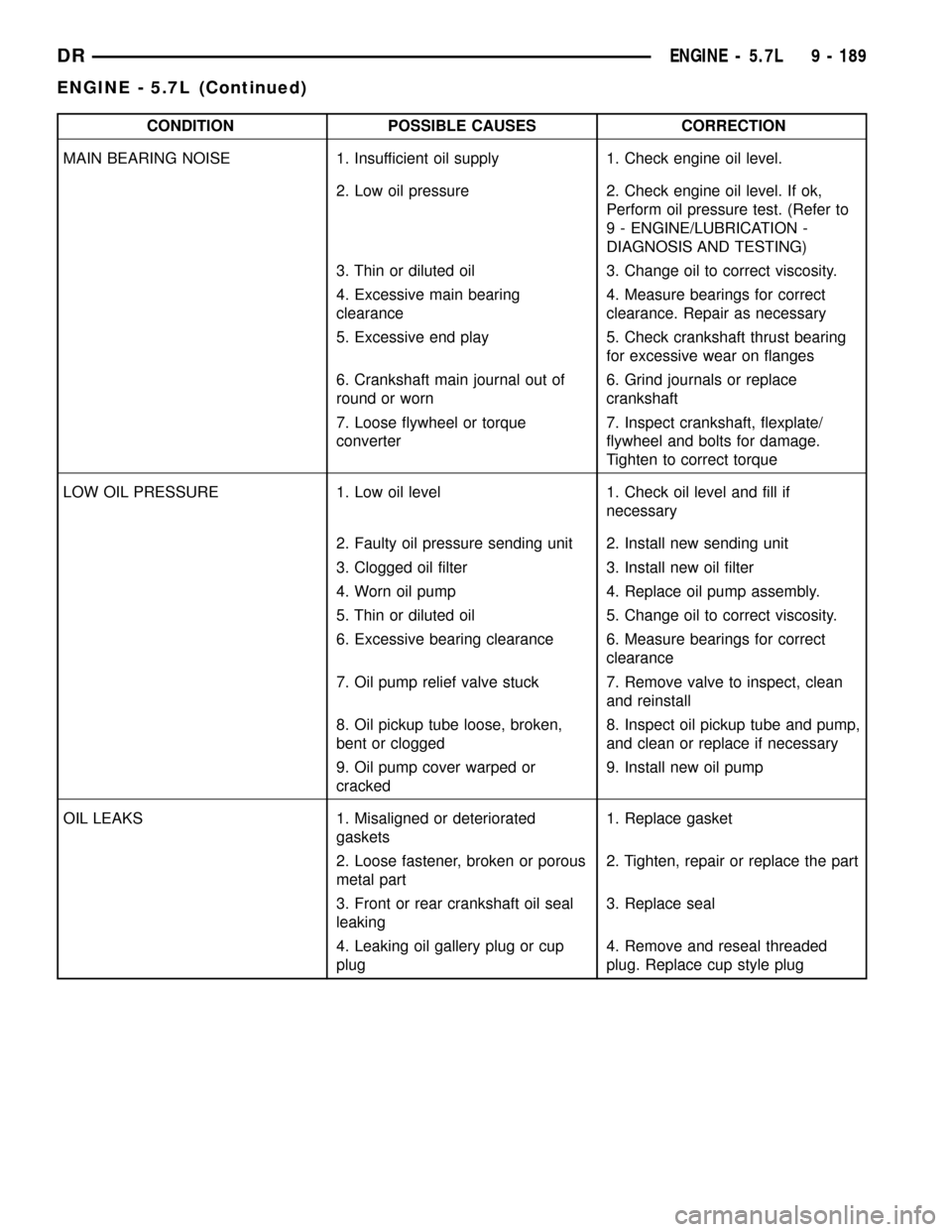

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply 1. Check engine oil level.

2. Low oil pressure 2. Check engine oil level. If ok,

Perform oil pressure test. (Refer to

9 - ENGINE/LUBRICATION -

DIAGNOSIS AND TESTING)

3. Thin or diluted oil 3. Change oil to correct viscosity.

4. Excessive main bearing

clearance4. Measure bearings for correct

clearance. Repair as necessary

5. Excessive end play 5. Check crankshaft thrust bearing

for excessive wear on flanges

6. Crankshaft main journal out of

round or worn6. Grind journals or replace

crankshaft

7. Loose flywheel or torque

converter7. Inspect crankshaft, flexplate/

flywheel and bolts for damage.

Tighten to correct torque

LOW OIL PRESSURE 1. Low oil level 1. Check oil level and fill if

necessary

2. Faulty oil pressure sending unit 2. Install new sending unit

3. Clogged oil filter 3. Install new oil filter

4. Worn oil pump 4. Replace oil pump assembly.

5. Thin or diluted oil 5. Change oil to correct viscosity.

6. Excessive bearing clearance 6. Measure bearings for correct

clearance

7. Oil pump relief valve stuck 7. Remove valve to inspect, clean

and reinstall

8. Oil pickup tube loose, broken,

bent or clogged8. Inspect oil pickup tube and pump,

and clean or replace if necessary

9. Oil pump cover warped or

cracked9. Install new oil pump

OIL LEAKS 1. Misaligned or deteriorated

gaskets1. Replace gasket

2. Loose fastener, broken or porous

metal part2. Tighten, repair or replace the part

3. Front or rear crankshaft oil seal

leaking3. Replace seal

4. Leaking oil gallery plug or cup

plug4. Remove and reseal threaded

plug. Replace cup style plug

DRENGINE - 5.7L 9 - 189

ENGINE - 5.7L (Continued)

Page 1418 of 2627

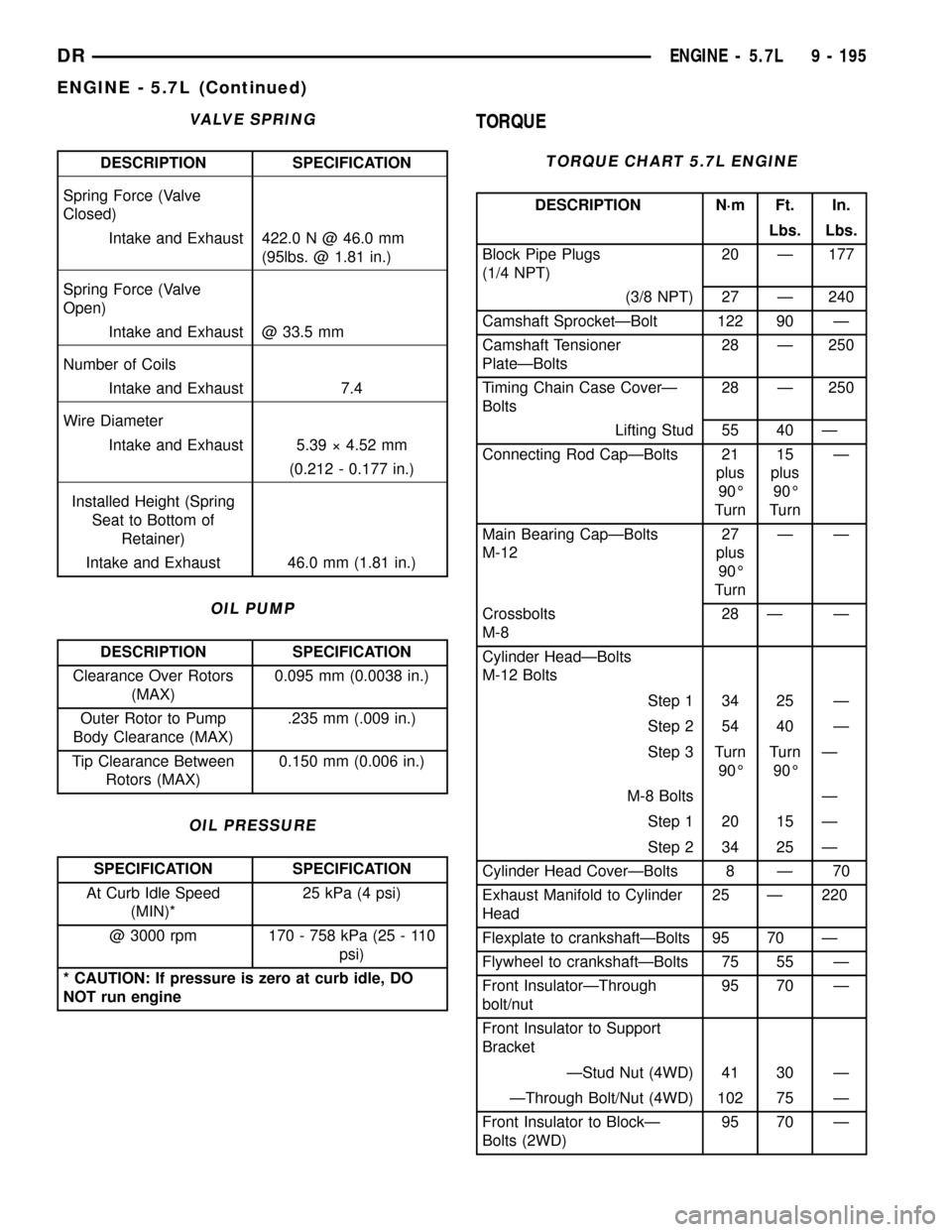

VALVE SPRING

DESCRIPTION SPECIFICATION

Spring Force (Valve

Closed)

Intake and Exhaust 422.0 N @ 46.0 mm

(95lbs. @ 1.81 in.)

Spring Force (Valve

Open)

Intake and Exhaust @ 33.5 mm

Number of Coils

Intake and Exhaust 7.4

Wire Diameter

Intake and Exhaust 5.39 ý 4.52 mm

(0.212 - 0.177 in.)

Installed Height (Spring

Seat to Bottom of

Retainer)

Intake and Exhaust 46.0 mm (1.81 in.)

OIL PUMP

DESCRIPTION SPECIFICATION

Clearance Over Rotors

(MAX)0.095 mm (0.0038 in.)

Outer Rotor to Pump

Body Clearance (MAX).235 mm (.009 in.)

Tip Clearance Between

Rotors (MAX)0.150 mm (0.006 in.)

OIL PRESSURE

SPECIFICATION SPECIFICATION

At Curb Idle Speed

(MIN)*25 kPa (4 psi)

@ 3000 rpm 170 - 758 kPa (25 - 110

psi)

* CAUTION: If pressure is zero at curb idle, DO

NOT run engine

TORQUE

TORQUE CHART 5.7L ENGINE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Block Pipe Plugs

(1/4 NPT)20 Ð 177

(3/8 NPT) 27 Ð 240

Camshaft SprocketÐBolt 122 90 Ð

Camshaft Tensioner

PlateÐBolts28 Ð 250

Timing Chain Case CoverÐ

Bolts28 Ð 250

Lifting Stud 55 40 Ð

Connecting Rod CapÐBolts 21

plus

90É

Turn15

plus

90É

TurnÐ

Main Bearing CapÐBolts

M-1227

plus

90É

TurnÐÐ

Crossbolts

M-828 Ð Ð

Cylinder HeadÐBolts

M-12 Bolts

Step 1 34 25 Ð

Step 2 54 40 Ð

Step 3 Turn

90ÉTurn

90ÉÐ

M-8 Bolts Ð

Step 1 20 15 Ð

Step 2 34 25 Ð

Cylinder Head CoverÐBolts 8 Ð 70

Exhaust Manifold to Cylinder

Head25 Ð 220

Flexplate to crankshaftÐBolts 95 70 Ð

Flywheel to crankshaftÐBolts 75 55 Ð

Front InsulatorÐThrough

bolt/nut95 70 Ð

Front Insulator to Support

Bracket

ÐStud Nut (4WD) 41 30 Ð

ÐThrough Bolt/Nut (4WD) 102 75 Ð

Front Insulator to BlockÐ

Bolts (2WD)95 70 Ð

DRENGINE - 5.7L 9 - 195

ENGINE - 5.7L (Continued)

Page 1432 of 2627

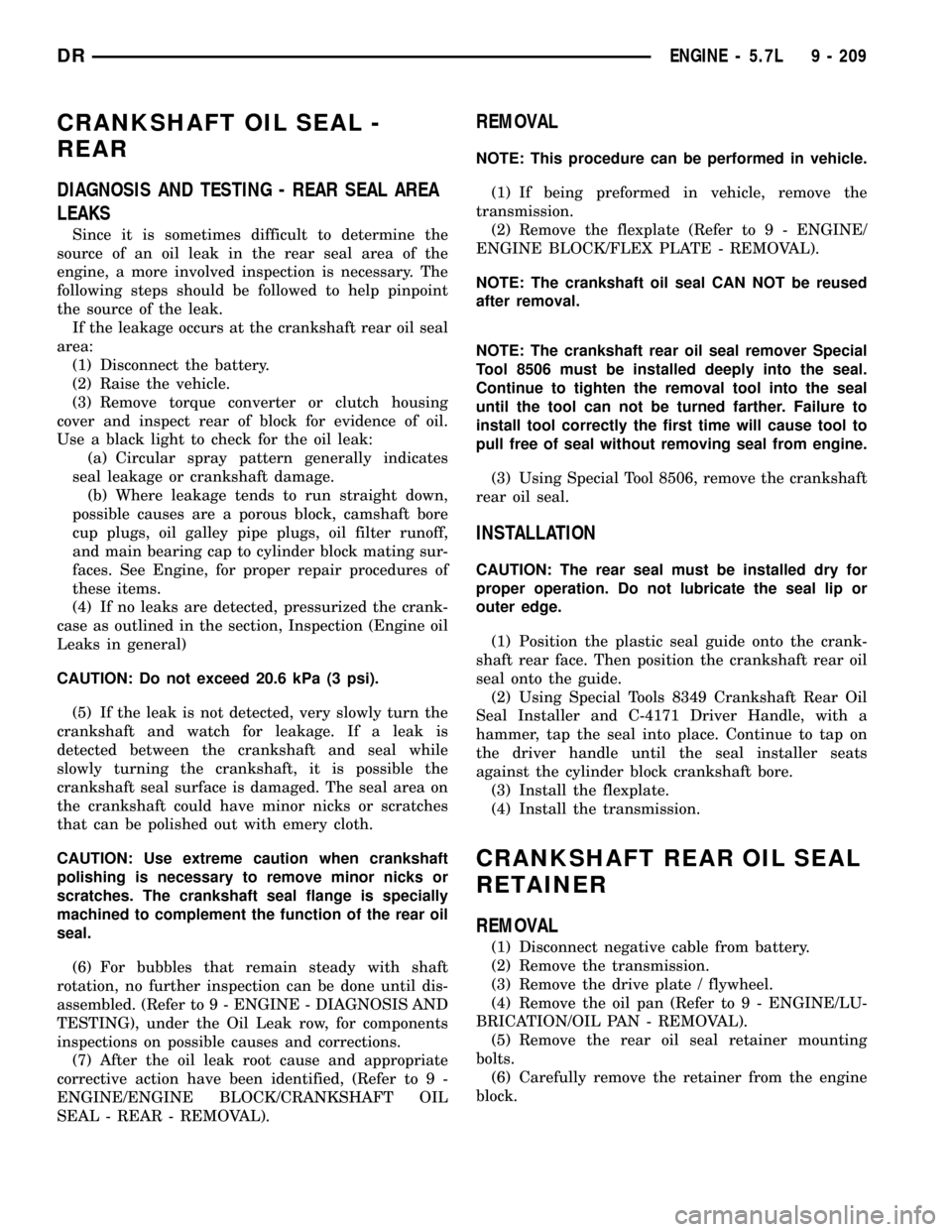

CRANKSHAFT OIL SEAL -

REAR

DIAGNOSIS AND TESTING - REAR SEAL AREA

LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, camshaft bore

cup plugs, oil galley pipe plugs, oil filter runoff,

and main bearing cap to cylinder block mating sur-

faces. See Engine, for proper repair procedures of

these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the section, Inspection (Engine oil

Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. (Refer to 9 - ENGINE - DIAGNOSIS AND

TESTING), under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

REMOVAL

NOTE: This procedure can be performed in vehicle.

(1) If being preformed in vehicle, remove the

transmission.

(2) Remove the flexplate (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - REMOVAL).

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Special

Tool 8506 must be installed deeply into the seal.

Continue to tighten the removal tool into the seal

until the tool can not be turned farther. Failure to

install tool correctly the first time will cause tool to

pull free of seal without removing seal from engine.

(3) Using Special Tool 8506, remove the crankshaft

rear oil seal.

INSTALLATION

CAUTION: The rear seal must be installed dry for

proper operation. Do not lubricate the seal lip or

outer edge.

(1) Position the plastic seal guide onto the crank-

shaft rear face. Then position the crankshaft rear oil

seal onto the guide.

(2) Using Special Tools 8349 Crankshaft Rear Oil

Seal Installer and C-4171 Driver Handle, with a

hammer, tap the seal into place. Continue to tap on

the driver handle until the seal installer seats

against the cylinder block crankshaft bore.

(3) Install the flexplate.

(4) Install the transmission.

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the transmission.

(3) Remove the drive plate / flywheel.

(4) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(5) Remove the rear oil seal retainer mounting

bolts.

(6) Carefully remove the retainer from the engine

block.

DRENGINE - 5.7L 9 - 209