Headlight DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 4 of 2627

BODY CODE PLATE

DESCRIPTION

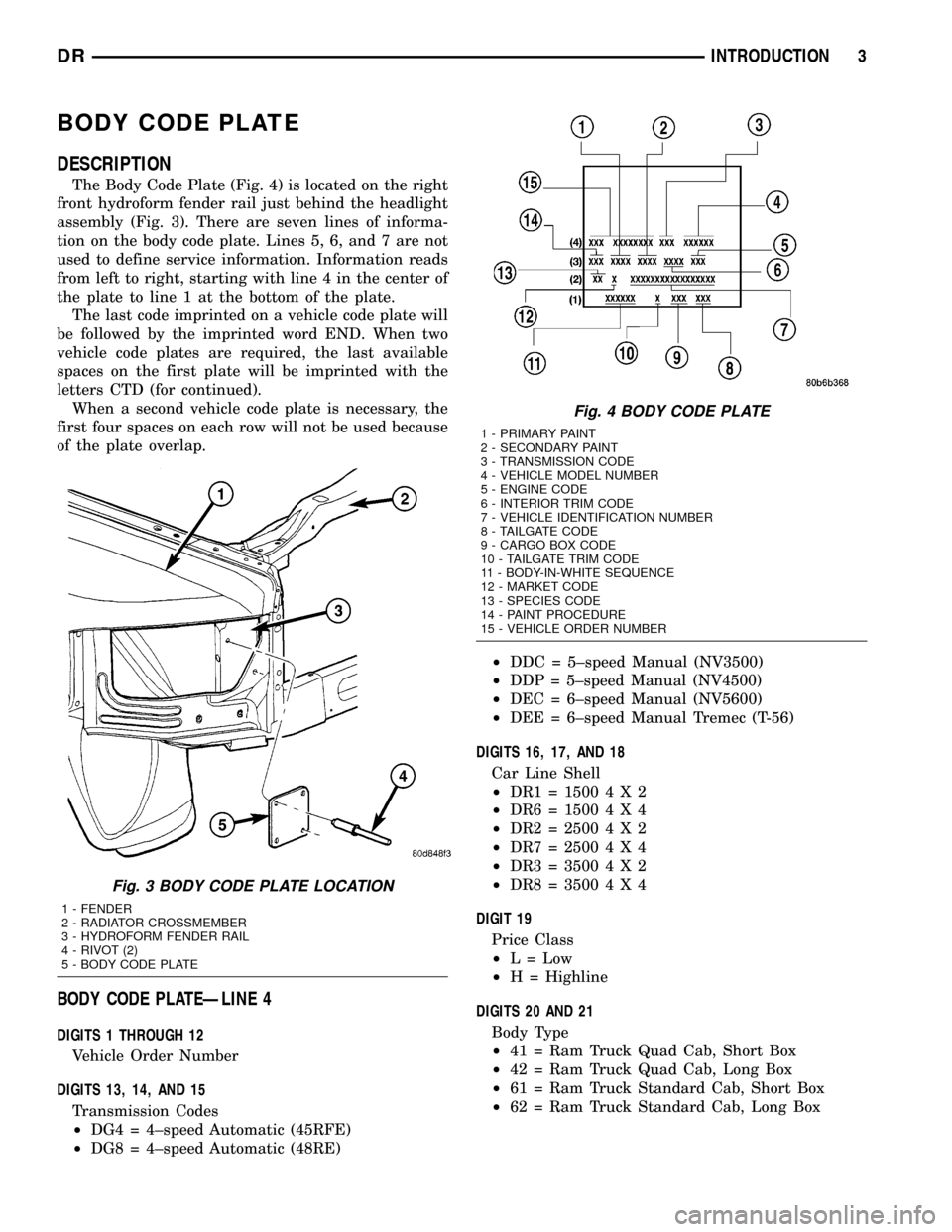

The Body Code Plate (Fig. 4) is located on the right

front hydroform fender rail just behind the headlight

assembly (Fig. 3). There are seven lines of informa-

tion on the body code plate. Lines 5, 6, and 7 are not

used to define service information. Information reads

from left to right, starting with line 4 in the center of

the plate to line 1 at the bottom of the plate.

The last code imprinted on a vehicle code plate will

be followed by the imprinted word END. When two

vehicle code plates are required, the last available

spaces on the first plate will be imprinted with the

letters CTD (for continued).

When a second vehicle code plate is necessary, the

first four spaces on each row will not be used because

of the plate overlap.

BODY CODE PLATEÐLINE 4

DIGITS 1 THROUGH 12

Vehicle Order Number

DIGITS 13, 14, AND 15

Transmission Codes

²DG4 = 4±speed Automatic (45RFE)

²DG8 = 4±speed Automatic (48RE)²DDC = 5±speed Manual (NV3500)

²DDP = 5±speed Manual (NV4500)

²DEC = 6±speed Manual (NV5600)

²DEE = 6±speed Manual Tremec (T-56)

DIGITS 16, 17, AND 18

Car Line Shell

²DR1=15004X2

²DR6=15004X4

²DR2=25004X2

²DR7=25004X4

²DR3=35004X2

²DR8=35004X4

DIGIT 19

Price Class

²L = Low

²H = Highline

DIGITS 20 AND 21

Body Type

²41 = Ram Truck Quad Cab, Short Box

²42 = Ram Truck Quad Cab, Long Box

²61 = Ram Truck Standard Cab, Short Box

²62 = Ram Truck Standard Cab, Long Box

Fig. 3 BODY CODE PLATE LOCATION

1 - FENDER

2 - RADIATOR CROSSMEMBER

3 - HYDROFORM FENDER RAIL

4 - RIVOT (2)

5 - BODY CODE PLATE

Fig. 4 BODY CODE PLATE

1 - PRIMARY PAINT

2 - SECONDARY PAINT

3 - TRANSMISSION CODE

4 - VEHICLE MODEL NUMBER

5 - ENGINE CODE

6 - INTERIOR TRIM CODE

7 - VEHICLE IDENTIFICATION NUMBER

8 - TAILGATE CODE

9 - CARGO BOX CODE

10 - TAILGATE TRIM CODE

11 - BODY-IN-WHITE SEQUENCE

12 - MARKET CODE

13 - SPECIES CODE

14 - PAINT PROCEDURE

15 - VEHICLE ORDER NUMBER

DRINTRODUCTION 3

Page 604 of 2627

DRIVER DOOR MODULE SWITCH TESTS

LEFT FRONT DOWN PINS9&12

RIGHT FRONT UP PINS3&9

RIGHT FRONT DOWN PINS6&9

LEFT REAR UP PINS4&9

LEFT REAR DOWN PINS9&10

RIGHT REAR UP PINS2&9

RIGHT REAR DOWN PINS1&9

POWER WINDOW LOCKOUT SWITCH

SWITCH POSITION CONTINUITY BETWEEN

OFF (SWITCH BUTTON

RAISED - NOT

DEPRESSED)PIN 9 OF CONNECTOR

C-1&PIN8OF

CONNECTOR C-2

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Remove the driver door module from the trim

panel bezel.

INSTALLATION

(1) Install driver door module to trim panel bezel.

(2) Install door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION).

(3) Connect battery negative cable.

REMOTE KEYLESS ENTRY

MODULE

DESCRIPTION

When an RKE lock message is sent to the instru-

ment cluster, the instrument cluster actuates the

door locks, the interior lighting is turned off, the

horn chirps (if this feature is enabled), the park

lamps flash (if this feature is enabled) and, if the

vehicle is so equipped, the Vehicle Theft Security

System (VTSS) is armed. When an RKE unlock mes-

sage is sent to the instrument cluster, the instrument

cluster actuates the driver side front door (or all

doors if this feature is enabled) unlock, the interior

lighting is turned on and, if the vehicle is so

equipped, the VTSS is disarmed.

When an RKE panic message is sent to the instru-

ment cluster, the instrument cluster actuates the

driver side front door (or all doors if this feature is

enabled) unlock, the interior lighting is turned on

and, if the vehicle is so equipped, the VTSS is dis-

armed. The panic message will also cause the exte-

rior lamps (including the headlights) to flash, andthe horn to sound for about three minutes, or until a

second panic message is sent to the instrument clus-

ter. A vehicle speed of about 25.7 kilometers-per-hour

(15 miles-per-hour) will also cancel the panic event.

Refer to the owner's manual for more information

on the features, use and operation of the RKE sys-

tem.

OPERATION

Whenever the vehicle battery power is interrupted,

the Remote Keyless Module (RKE) Module will retain

all vehicle access codes in its memory. When replac-

ing or adding a key fob transmitter (maximum of 4) a

DRB IIItscan tool is required to program the RKE

Module to accept the new Vehicle Access Code if a

customer owned transmitter is not available.

If a functioning transmitter is available, (Refer to 8

- ELECTRICAL/POWER LOCKS/KEYLESS ENTRY

TRANSMITTER - STANDARD PROCEDURE)

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY MODULE

The most reliable, efficient, and accurate means to

diagnose the power lock system requires the use of a

DRBIIItscan tool and the proper Diagnostic Proce-

dures manual.

Refer to the appropriate wiring information.

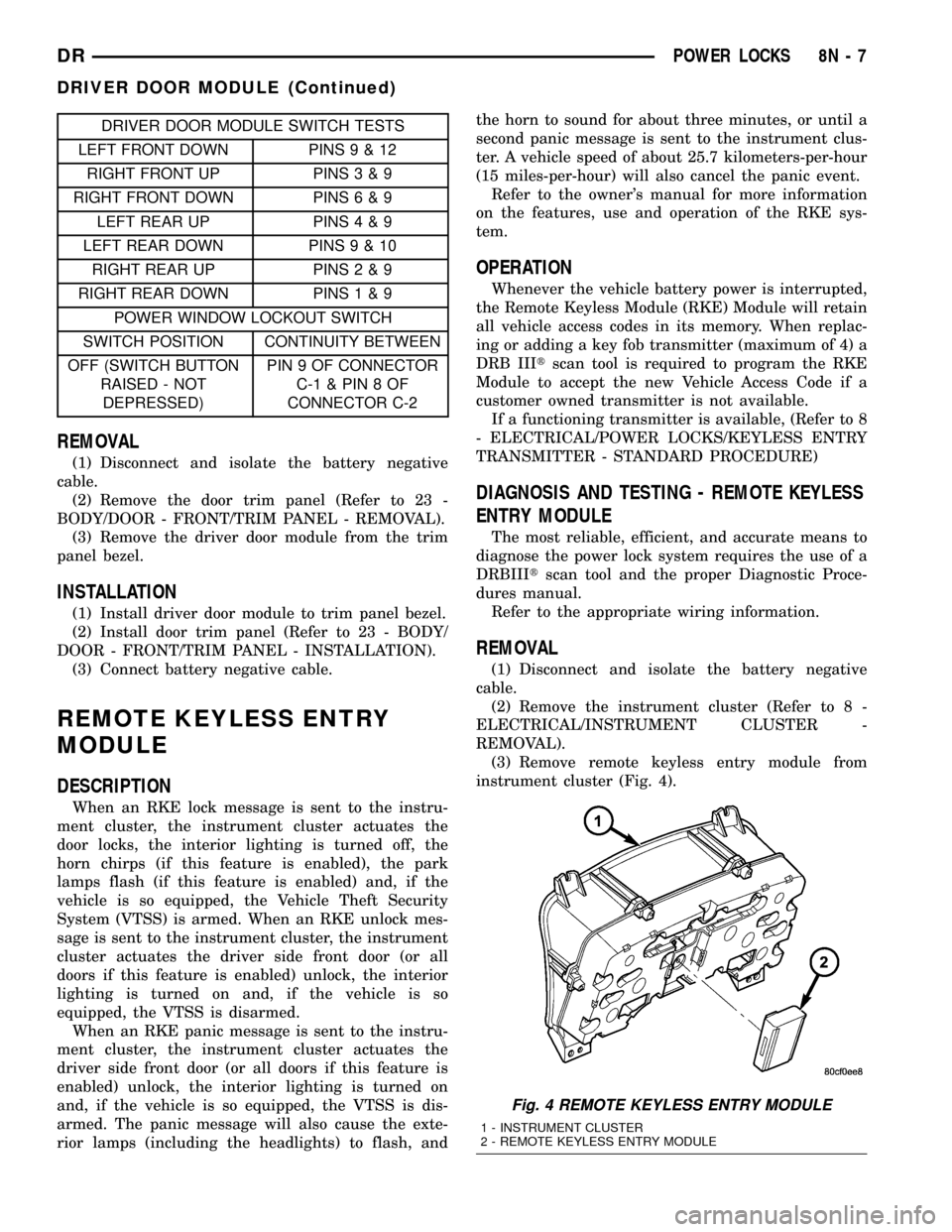

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER -

REMOVAL).

(3) Remove remote keyless entry module from

instrument cluster (Fig. 4).

Fig. 4 REMOTE KEYLESS ENTRY MODULE

1 - INSTRUMENT CLUSTER

2 - REMOTE KEYLESS ENTRY MODULE

DRPOWER LOCKS 8N - 7

DRIVER DOOR MODULE (Continued)

Page 2351 of 2627

(8) Install the left a-pillar trim. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM - INSTALLA-

TION)

(9) Position the left end cap and seat the attach-

ment clips fully.

(10) Install the right side mounting bolts on the

a-pillar and one right mounting bolt on the cowl side

panel and tighten to 12 N´m (9 ft. lbs.).

(11) Install the right a-pillar trim panel. (Refer to

23 - BODY/INTERIOR/A-PILLAR TRIM - INSTAL-

LATION)

(12) Position the right end cap and seat the

attachment clips fully.

(13) Install the one HVAC mounting screw.

(14) Connect the radio antenna.

(15) Connect the two electrical connectors at the

right cowl panel.

(16) Install the right cowl trim cover. (Refer to 23 -

BODY/INTERIOR/COWL TRIM - INSTALLATION)

(17) Connect the air bag control module electrical

connector.

(18) Install the center bracket bolts and tighten to

12 N´m (9 ft. lbs.).

(19) Install the floor console, if equipped. (Refer to

23 - BODY/INTERIOR/FLOOR CONSOLE - INSTAL-

LATION)

(20) Install the air bag control module cover, if

equipped.

(21) Connect the park brake release handle actua-

tor rod.

(22) Install the hood release handle and tighten

the screws.

(23) Install the two bolts at the column support

bracket and tighten to 14 N´m (10 ft. lbs.).

(24) Install the steering column. (Refer to 19 -

STEERING/COLUMN - INSTALLATION)

(25) Connect the wire harness electrical connectors

above the brake pedal.

(26) Install the two top instrument panel bolts and

tighten to 12 N´m (9 ft. lbs.).

(27) Install the four top instrument panel screws.

(28) Install the instrument panel top cover. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - INSTALLATION)

INSTRUMENT PANEL

HEADLAMP SWITCH BEZEL

REMOVAL

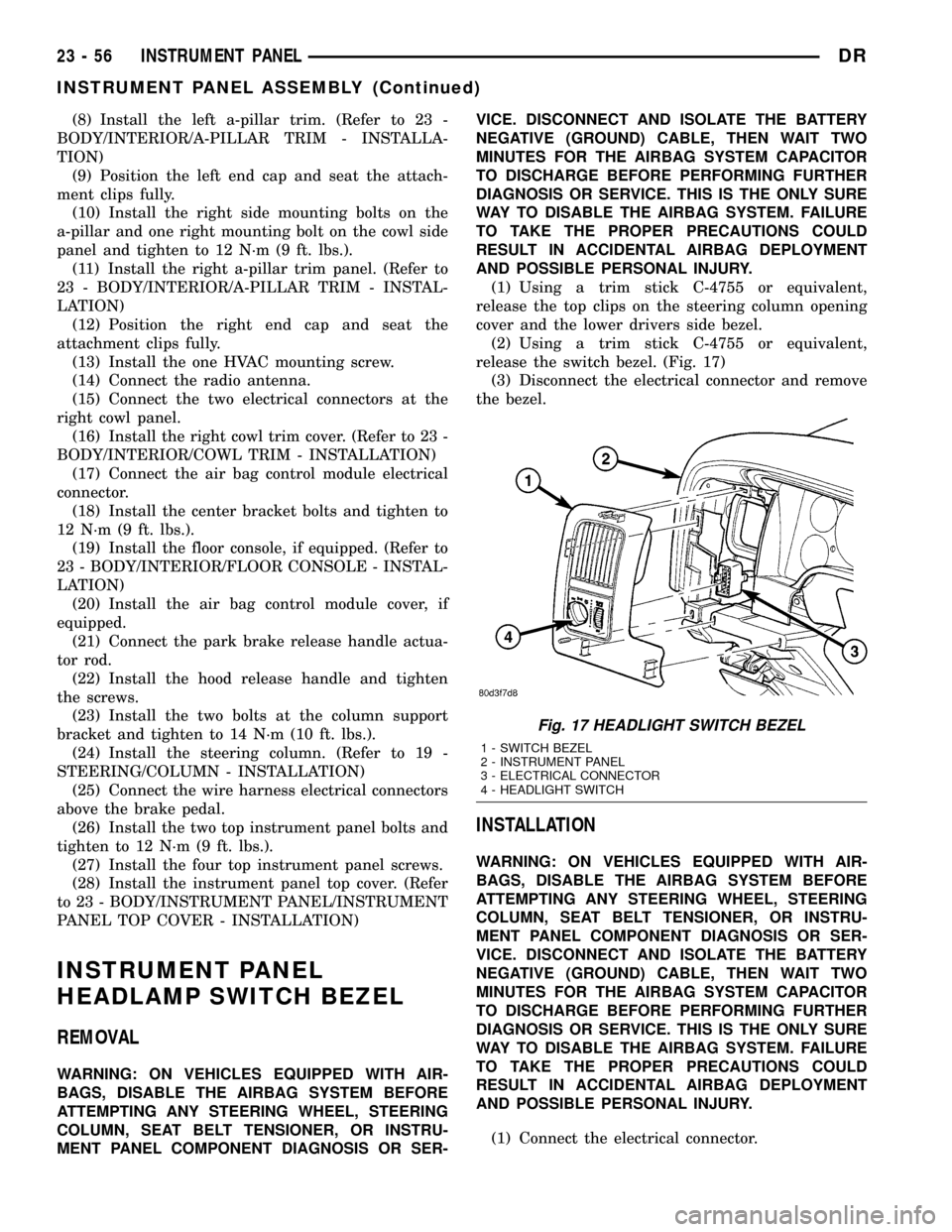

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Using a trim stick C-4755 or equivalent,

release the top clips on the steering column opening

cover and the lower drivers side bezel.

(2) Using a trim stick C-4755 or equivalent,

release the switch bezel. (Fig. 17)

(3) Disconnect the electrical connector and remove

the bezel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Connect the electrical connector.

Fig. 17 HEADLIGHT SWITCH BEZEL

1 - SWITCH BEZEL

2 - INSTRUMENT PANEL

3 - ELECTRICAL CONNECTOR

4 - HEADLIGHT SWITCH

23 - 56 INSTRUMENT PANELDR

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 2514 of 2627

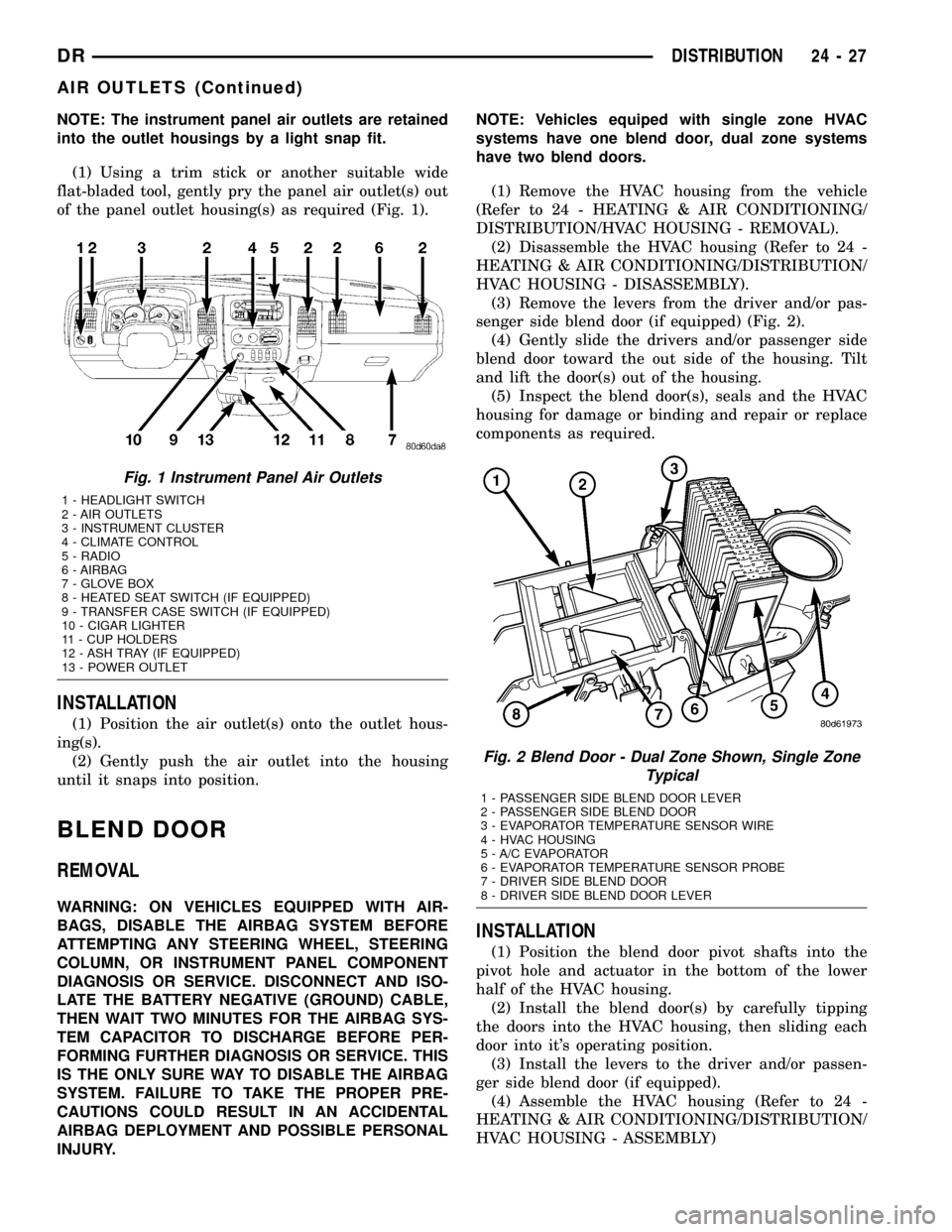

NOTE: The instrument panel air outlets are retained

into the outlet housings by a light snap fit.

(1) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the panel air outlet(s) out

of the panel outlet housing(s) as required (Fig. 1).

INSTALLATION

(1) Position the air outlet(s) onto the outlet hous-

ing(s).

(2) Gently push the air outlet into the housing

until it snaps into position.

BLEND DOOR

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.NOTE: Vehicles equiped with single zone HVAC

systems have one blend door, dual zone systems

have two blend doors.

(1) Remove the HVAC housing from the vehicle

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL).

(2) Disassemble the HVAC housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - DISASSEMBLY).

(3) Remove the levers from the driver and/or pas-

senger side blend door (if equipped) (Fig. 2).

(4) Gently slide the drivers and/or passenger side

blend door toward the out side of the housing. Tilt

and lift the door(s) out of the housing.

(5) Inspect the blend door(s), seals and the HVAC

housing for damage or binding and repair or replace

components as required.

INSTALLATION

(1) Position the blend door pivot shafts into the

pivot hole and actuator in the bottom of the lower

half of the HVAC housing.

(2) Install the blend door(s) by carefully tipping

the doors into the HVAC housing, then sliding each

door into it's operating position.

(3) Install the levers to the driver and/or passen-

ger side blend door (if equipped).

(4) Assemble the HVAC housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - ASSEMBLY)

Fig. 1 Instrument Panel Air Outlets

1 - HEADLIGHT SWITCH

2 - AIR OUTLETS

3 - INSTRUMENT CLUSTER

4 - CLIMATE CONTROL

5 - RADIO

6 - AIRBAG

7 - GLOVE BOX

8 - HEATED SEAT SWITCH (IF EQUIPPED)

9 - TRANSFER CASE SWITCH (IF EQUIPPED)

10 - CIGAR LIGHTER

11 - CUP HOLDERS

12 - ASH TRAY (IF EQUIPPED)

13 - POWER OUTLET

Fig. 2 Blend Door - Dual Zone Shown, Single Zone

Typical

1 - PASSENGER SIDE BLEND DOOR LEVER

2 - PASSENGER SIDE BLEND DOOR

3 - EVAPORATOR TEMPERATURE SENSOR WIRE

4 - HVAC HOUSING

5 - A/C EVAPORATOR

6 - EVAPORATOR TEMPERATURE SENSOR PROBE

7 - DRIVER SIDE BLEND DOOR

8 - DRIVER SIDE BLEND DOOR LEVER

DRDISTRIBUTION 24 - 27

AIR OUTLETS (Continued)