clock DODGE RAM 1999 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: RAM, Model: DODGE RAM 1999Pages: 1691, PDF Size: 40.34 MB

Page 174 of 1691

protective cover is fitted to front of air bag module bearing the SRS

air bag logo. Air bag module contains air bag cushion, inflator and

supporting components. Air bag module is a sealed unit and is not

serviceable. The module inflator assembly produces nitrogen gas to

fill air bag cushion when a small amount of current from ACM is

applied to the ignitor assembly. Gas pressure builds and discharges

from inflator through a diffuser and screen assembly, forcing steering

wheel cover to burst along its seams until air bag is fully inflated.

Once air bag cushion is fully inflated, gas escapes from bag through

vents, away from driver.

Passenger-Side

Air bag module is mounted to instrument panel mounting

bracket. Module is covered by a protective door bearing the SRS air

bag logo. When supplied an electrical signal, inflator will discharge

argon gas directly into air bag. When air bag inflates, protective

door will pivot aside allowing air bag to deploy.

AIR BAG CONTROL MODULE (ACM)

ACM is located under instrument panel, on transmission

tunnel. Impact sensor, energy reserve capacitor and On-Board

Diagnostics (OBD) are an integral part of ACM. ACM monitors critical

input and output circuits within air bag system, ensuring they are

operating correctly. Some circuits are tested continuously; others are

checked only under certain conditions. ACM provides information about

air bag system through AIR BAG warning light and Data Link Connector

(DLC). When diagnostic trouble code (fault message) is stored, AIR B\

AG

warning light will be activated for 12 seconds or more.

DATA LINK CONNECTOR (DLC)

DLC is located under left side of instrument panel, left of

steering column. DLC is used to access SRS on-board diagnostics.

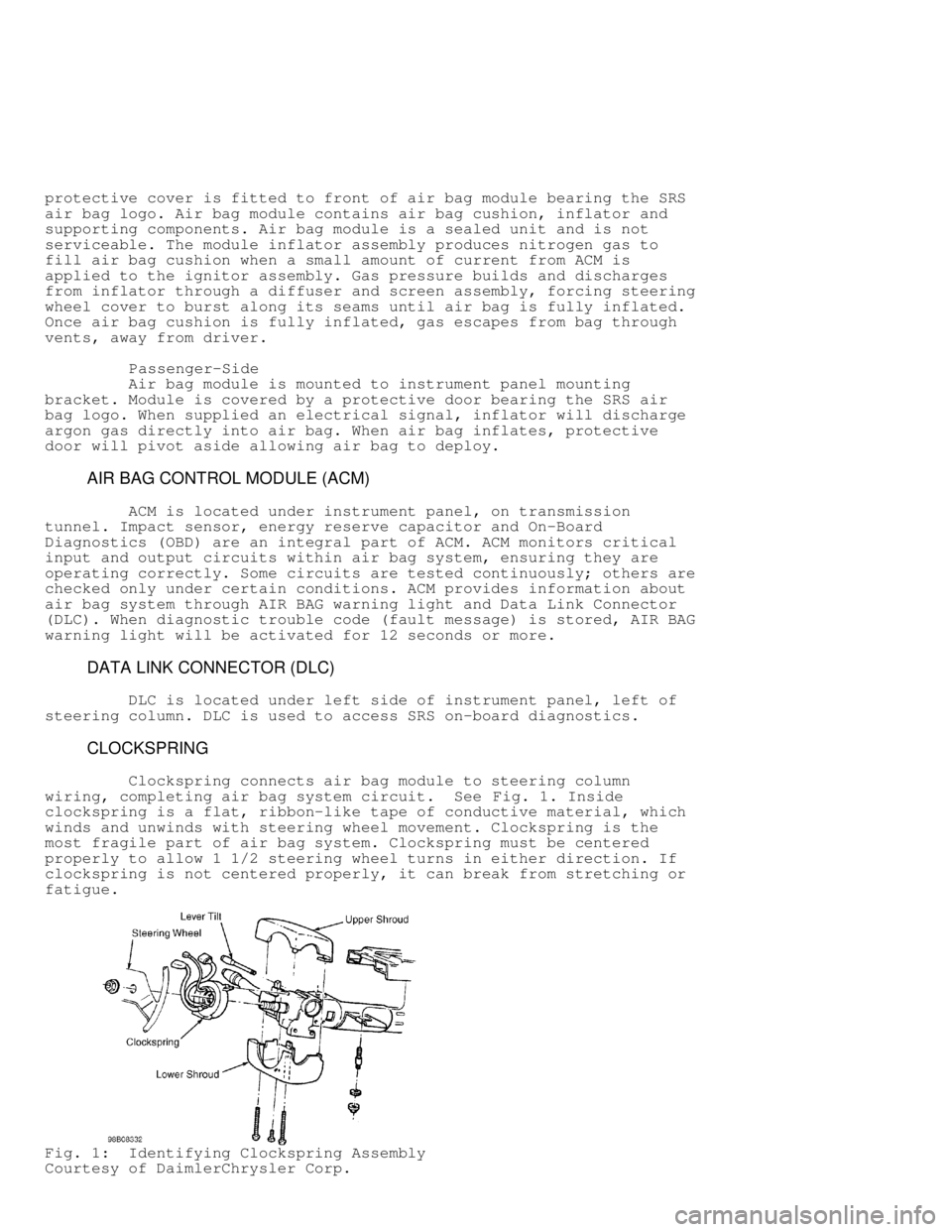

CLOCKSPRING

Clockspring connects air bag module to steering column

wiring, completing air bag system circuit. See Fig. 1. Inside

clockspring is a flat, ribbon-like tape of conductive material, which

winds and unwinds with steering wheel movement. Clockspring is the

most fragile part of air bag system. Clockspring must be centered

properly to allow 1 1/2 steering wheel turns in either direction. If

clockspring is not centered properly, it can break from stretching or

fatigue.

Fig. 1: Identifying Clockspring Assembly

Courtesy of DaimlerChrysler Corp.

Page 177 of 1691

WARNING: Vehicle interior will contain sodium hydroxide powder, a

by-product of air bag deployment. Since this powder can

irritate skin, eyes, nose, or throat, be sure to wear

safety glasses, rubber gloves and long-sleeved shirt

during clean-up.

1) Begin clean-up by putting tape over air bag exhaust vent,

so no additional powder will escape into vehicle interior. Remove air

bag modules. Use a vacuum cleaner to remove any residual powder from

vehicle interior. To avoid kneeling or sitting on a non-cleaned area,

clean from outside vehicle and work your way inside.

2) Remove any residual powder from A/C-heater outlets. Turn

blower motor to low for a few minutes and exit vehicle. Turn blower

off. Vacuum any additional powder expelled from plenum. Vacuum

interior a second time to recover all powder.

DEPLOYED AIR BAG

Dispose of deployed air bag module as any other part. No

special disposal procedure is required.

UNDEPLOYED AIR BAG

NOTE: Information on passenger-side air bag deployment is not

available from manufacturer.

Procedure 1: In-Vehicle Deployment (Driver-Side Air Bag)

1) Use this procedure if scrapping a vehicle with an

undeployed air bag. This procedure assumes that air bag wiring is

intact.

2) Disconnect and shield negative battery cable. Disconnect

2-pin clockspring at base of steering column. Cut 2-pin clockspring

connector of at clockspring side of harness.

3) Strip 1" (25 mm) of insulation from wire ends. Make a

harness consisting of 2 wires 20 feet or longer. Connect 20-foot wires

to clockspring harness. Ensure there are no loose parts in passenger

compartment and no one is within 20 feet of vehicle.

4) Staying at least 20 feet away from vehicle, connect other

2 ends of 20 foot wires to terminals of a 12-volt battery. When

deployment is achieved, loud bang will be heard and air bag will

inflate. After air bag module deploys, let module cool and dust settle

before approaching. If air bag fails to deploy, go to PROCEDURE 2.

Procedure 2: Remote Deployment (Driver-Side Air Bag)

1) Use this procedure if scrapping a vehicle with a live air

bag, but a problem in electrical system prevent deployment with air

bag still installed in vehicle. Also use this procedure if PROCEDURE 1

was unsuccessful.

WARNING: Perform remote deployment outdoors. Never attempt to deploy

air bag module inside a building, within 20 feet of

personnel, or with air bag trim cover face down.

2) Before proceeding, see SERVICE PRECAUTIONS. Disable air

bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM . Remove air bag

module. See DRIVER-SIDE AIR BAG MODULE under REMOVAL & INSTALLATION.

3) cut pigtail wiring harness between clockspring and air bag

as close to clockspring housing as possible. Reconnect other end of

pigtail harness back into air bag module.

4) Strip 1" (25 mm) of insulation from cut ends of harness.

Place air bag module face (trim cover) up. Connect two 20-foot wires

to end of harness wires. Move 20 feet away. Connect other end of 200-

Page 180 of 1691

CAUTION: When removing a deployed air bag, wear eye protection, rubber

gloves and a long-sleeve shirt. Powder residue from air bag

deployment may irritate skin and eyes.

CAUTION: Before removing steering wheel, position front wheels in

straight-ahead position and lock steering column by removing

ignition key. Failure to do so could damage clockspring or

cause clockspring to be off-centered. DO NOT hammer on

steering wheel during removal, or collapsible column could be

damaged.

Removal

1) Before proceeding, see SERVICE PRECAUTIONS. Disable air

bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM . Air bag module

is mounted on face of steering wheel. Ensure wheels are pointed

straight-ahead and steering wheel is locked.

2) Remove air bag module-to-steering wheel screws from back

side of steering wheel. Lift air bag module and disconnect electrical

connectors from rear of module.

Installation

Connect air bag, cruise control and horn harness connectors

to rear of air bag module. Secure module to steering wheel. Tighten

air bag module-to-steering wheel screws to specification. See

TORQUE SPECIFICATIONS . DO NOT connect negative battery cable at this

time. Go to SYSTEM OPERATION CHECK .

PASSENGER-SIDE AIR BAG MODULE

Removal

1) Before proceeding, see SERVICE PRECAUTIONS. Disable air

bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM .

2) Open glove box. Holding glove box door, push center of

glove box bin towards front of vehicle. Flex glove box bin far enough

so glove box stops will clear sides of instrument panel opening. Roll

glove box down until stop bumpers are beyond sides of instrument panel

opening. Release bin. Lift bottom of glove box upward to disengage

hinge hooks form hinge pins.

3) Remove 3 screws securing instrument panel glove box

opening upper trim strip to instrument panel glove box opening upper

reinforcement, then remove trim strip. Remove 4 screws that secure 2

plastic support brackets of passenger-side air bag door panel outlet

housing to glove box opening upper reinforcement.

4) Reach through and above glove box opening to access and

disconnect air bag module harness connector. Remove 2 screws securing

passenger-side air bag module front bracket to instrument panel

structural support. Remove 3 screws securing passenger-side air bag

module rear bracket to glove box opening upper reinforcement.

5) Using trim stick, gently pry passenger-side air bag door

(starting at lower left edge) away from instrument panel top cover.

Remove air bag module, air bag door and panel outlet housing and

barrel assembly from instrument panel as a unit.

Installation

To install, reverse removal procedure. Ensure air bag door is

securely attached to instrument panel. Ensure air bag harness

connector latches fully engaged. DO NOT connect negative battery cable

at this time. Go to SYSTEM OPERATION CHECK .

CLOCKSPRING

CAUTION: Failure to position wheels in the straight-ahead position

with steering wheel locked when removing steering wheel could

Page 181 of 1691

damage clockspring and/or require clockspring to be

readjusted.

NOTE: Clockspring is self-centering and will automatically lock in

the centered position when steering wheel is removed.

Adjustment is only required if centering position is

disturbed.

Removal

1) Before proceeding, see SERVICE PRECAUTIONS. Disable air

bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM .

2) Clockspring is located behind steering wheel. See Fig. 1.

Ensure front wheels are in straight-ahead position. Lock steering

wheel. Remove air bag module. See AIR BAG MODULE.

3) Remove steering wheel nut. Using appropriate steering

wheel puller, remove steering wheel. When steering wheel is removed,

self-centering clockspring will automatically lock in place. Remove

upper and lower steering column shrouds to gain access to clockspring

wiring.

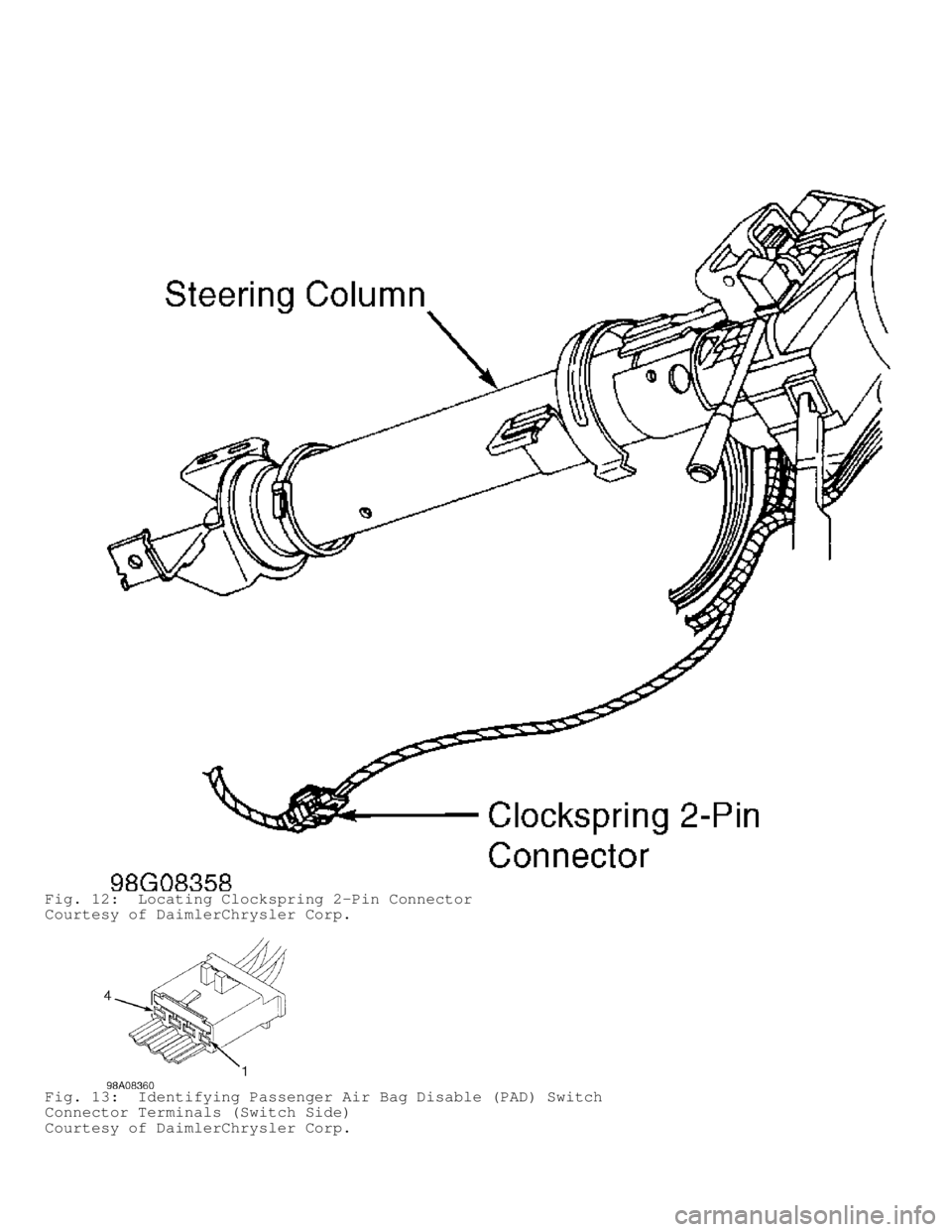

4) Remove knee bolster (if equipped). Disconnect Yellow 2-wa\

y

clockspring harness connector between clockspring and instrument panel

wiring harness, at base of steering column. See Fig. 13. Remove

clockspring by releasing 2 tabs on side of clockspring. Clockspring

cannot be repaired and must be replaced if faulty.

Installation

1) Snap clockspring onto steering column. If clockspring

centering adjustment is disturbed, adjust clockspring before

installing steering wheel. See CLOCKSPRING CENTERING under

ADJUSTMENTS. Connect clockspring wiring connectors. Install steering

column covers. Install knee bolster (if removed).

2) Position steering wheel on steering column. Ensure flats

on steering wheel hub fit formations on inside of clockspring. Pull

clockspring, cruise control switch (if equipped) and horn wires

through lower large holes and upper small holes in steering wheel.

3) Install steering wheel retaining nut and tighten to 45 ft.

lbs. (61 N.m). Connect horn and cruise control wires (if equipped).

Connect clockspring wire to air bag module. To ensure complete

connector connection, latching arms must be visible on top of

connector housing. DO NOT connect negative battery cable at this time.

Go to SYSTEM OPERATION CHECK .

PASSENGER AIR BAG DISARM (PAD) SWITCH

Removal & Installation

1) Before proceeding, see SERVICE PRECAUTIONS. Disable air

bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM .

2) If vehicle is equipped with automatic transmission, turn

ignition switch to UNLOCK position, set parking brake and place

transmission selector lever in LOW position. Tilt steering column to

lowest position (if equipped). Using trim stick, gently pry around

perimeter of cluster bezel and remove bezel.

3) Open glove box. Holding glove box door, push center of

glove box bin towards front of vehicle. Flex glove box bin far enough

so glove box stops will clear sides of instrument panel opening. Roll

glove box down until stop bumpers are beyond sides of instrument panel

opening. Release bin. Lift bottom of glove box upward to disengage

hinge hooks form hinge pins.

4) Reach through glove box opening to access and disconnect 2

passenger-side air bag disarm switch harness connectors. Connectors

are attached to bracket located on inboard glove box opening

reinforcement. See Fig. 4. Remove 3 screws retaining passenger-side

air bag disarm switch bezel to instrument panel.

Page 183 of 1691

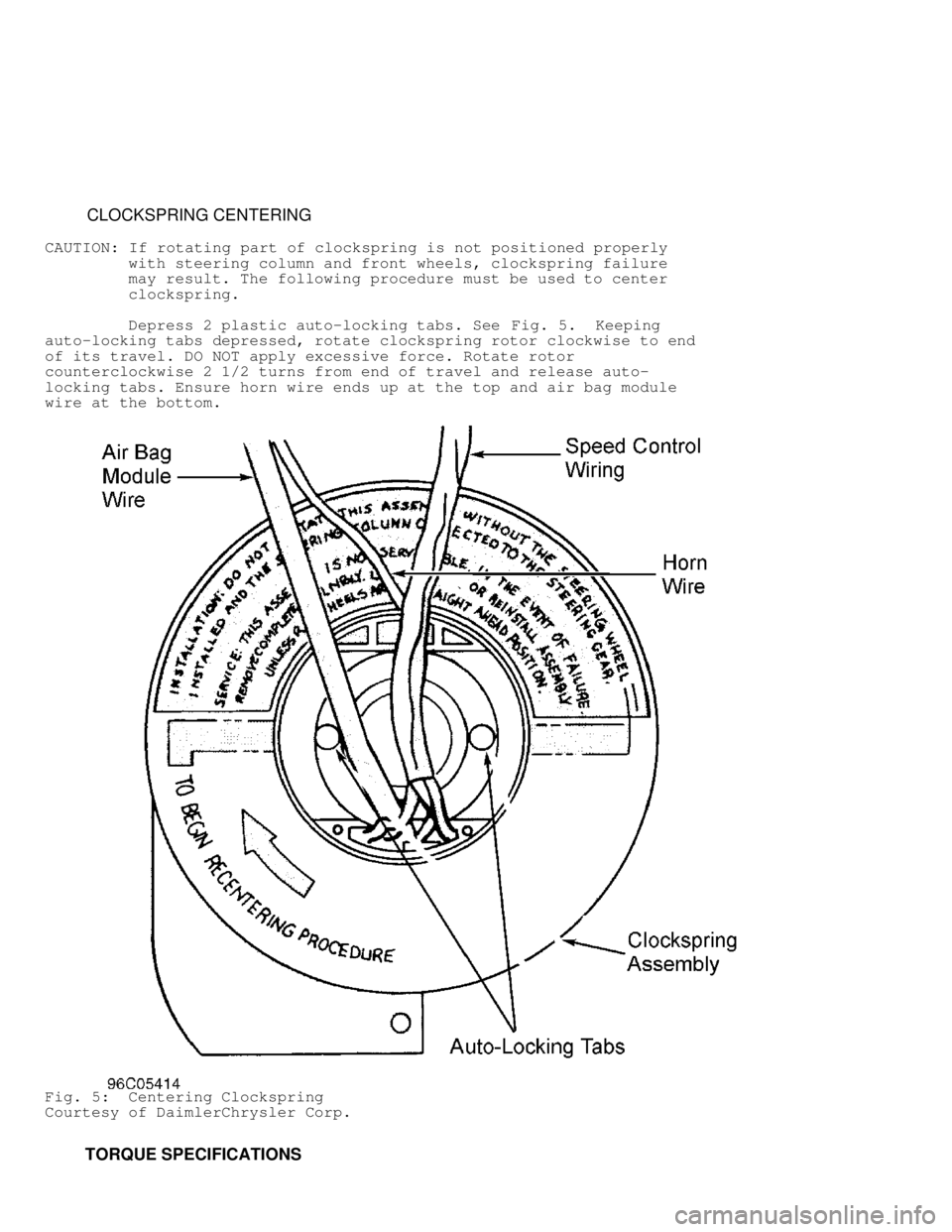

CLOCKSPRING CENTERING

CAUTION: If rotating part of clockspring is not positioned properly

with steering column and front wheels, clockspring failure

may result. The following procedure must be used to center

clockspring.

Depress 2 plastic auto-locking tabs. See Fig. 5. Keeping

auto-locking tabs depressed, rotate clockspring rotor clockwise to end

of its travel. DO NOT apply excessive force. Rotate rotor

counterclockwise 2 1/2 turns from end of travel and release auto-

locking tabs. Ensure horn wire ends up at the top and air bag module

wire at the bottom.

Fig. 5: Centering Clockspring

Courtesy of DaimlerChrysler Corp.

TORQUE SPECIFICATIONS

Page 190 of 1691

Fig. 12: Locating Clockspring 2-Pin Connector

Courtesy of DaimlerChrysler Corp.

Fig. 13: Identifying Passenger Air Bag Disable (PAD) Switch

Connector Terminals (Switch Side)

Courtesy of DaimlerChrysler Corp.

Page 194 of 1691

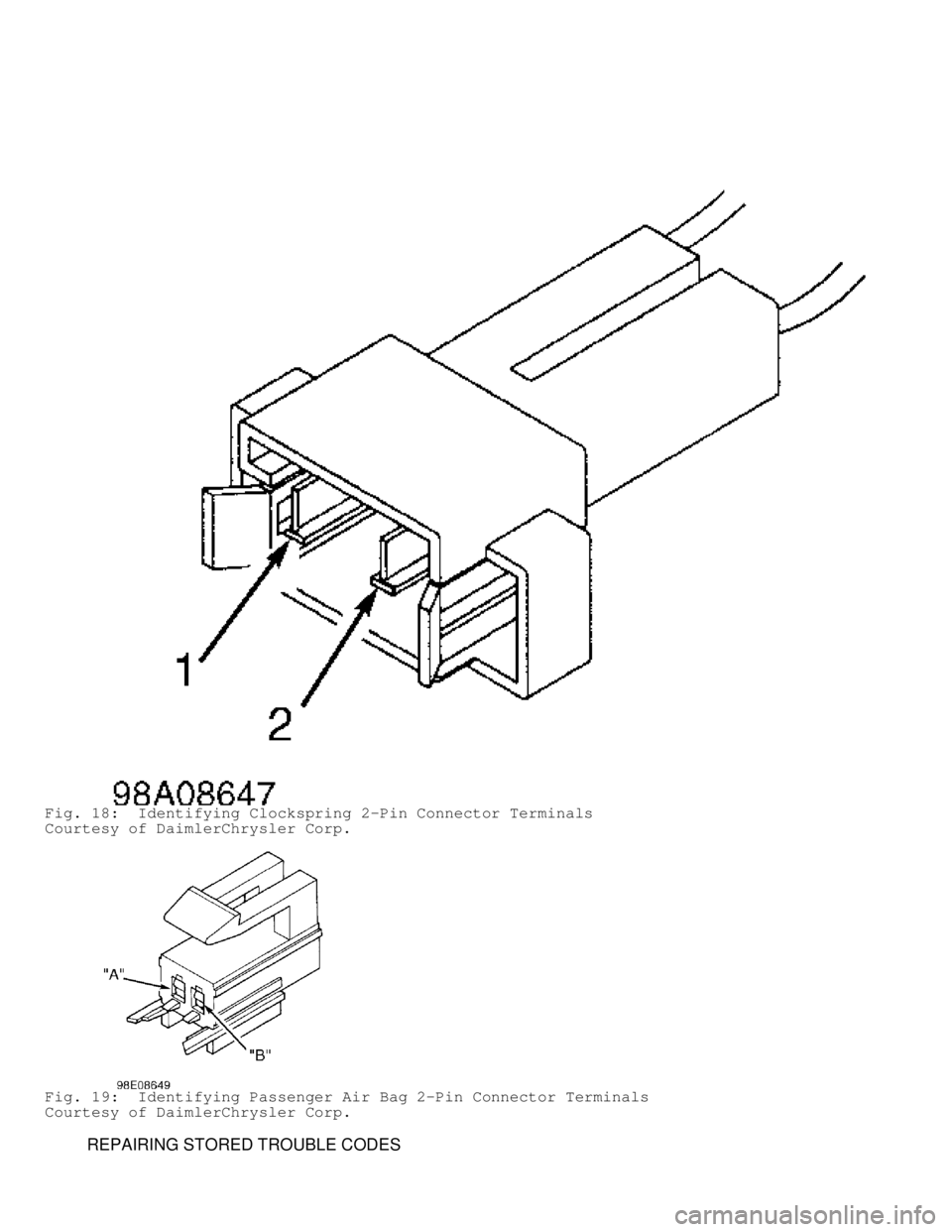

Fig. 18: Identifying Clockspring 2-Pin Connector Terminals

Courtesy of DaimlerChrysler Corp.

Fig. 19: Identifying Passenger Air Bag 2-Pin Connector Terminals

Courtesy of DaimlerChrysler Corp.

REPAIRING STORED TROUBLE CODES

Page 196 of 1691

it to ensure it is in good condition. Always focus on circuit

being tested. Dirt, water and corrosion, are most common

problems in connectors. Due to manufacturer changes in wire

colors, use terminal identification whenever possible.

1) Disconnect battery and wait 2 minutes before proceeding.

Disconnect driver-side air bag module squib connector. Connect a

jumper wire between driver-side air bag (squib) 2-pin connector

terminal No. 1 (Black/Light Blue wire) and terminal No. 2 (Dark

Green/Light Blue wire). Turn ignition on (engine off). Reconnect

battery. Using DRB, read active codes. If DRB displays DRIVER SQUIB

CIRCUIT SHORTED, replace driver-side air bag module. If not, go to

next step.

2) Disconnect clockspring 2-pin connector. Connect a jumper

wire between clockspring 2-pin connector terminals No. 1 (Black/Light

Blue wire) and No. 2 (Dark Green/Light Blue wire). Using DRB, read

active codes. If DRB displays DRIVER SQUIB CIRCUIT SHORTED, replace

clockspring. If not, go to next step.

3) Disconnect battery and wait 2 minutes before proceeding.

Remove jumper wires. Disconnect ACM connector. ACM is located under

instrument panel, on transmission tunnel. Using an ohmmeter, check

resistance between ACM connector terminal No. 6 (Dark Green/Light Blue

wire) and clockspring 2-pin connector terminal No. 2 (Dark Green/Light\

Blue wire). If resistance is less than 5 ohms, go to next step. If

resistance is more than 5 ohms, repair open or high resistance in Dark

Green/Light Blue wire.

4) Check resistance between ACM connector terminal No. 5

(Black/Light Blue wire) and clockspring 2-pin connector terminal No. 1\

(Black/Light Blue wire). If resistance is less than 5 ohms, go to next\

step. If resistance is more than 5 ohms, repair open or high

resistance in Black/Light Blue wire.

5) If there are no potential causes for this DTC remaining,

ACM is assumed to be defective. Replace ACM. See

AIR BAG CONTROL MODULE (ACM) under REMOVAL & INSTALLATION.

DRIVER SQUIB CIRCUIT SHORTED

NOTE: Perform AIR BAG VERIFICATION TEST after

all repairs. Each time a connector is disconnected, inspect

it to ensure it is in good condition. Always focus on circuit

being tested. Dirt, water and corrosion, are most common

problems in connectors. Due to manufacturer changes in wire

colors, use terminal identification whenever possible.

1) Disconnect battery and wait 2 minutes before proceeding.

Ensure driver-side air bag module connector is completely connected

before disconnecting it. If driver-side air bag module connector is

not completely connected, reconnect it. If driver-side air bag

connector is completely connected, go to next step.

2) Disconnect driver-side air bag module. Turn ignition on

(engine off). Reconnect battery. Using DRB, read active codes. If DRB

displays DRIVER SQUIB CIRCUIT OPEN, replace driver-side air bag

module. If not, go to next step.

3) Disconnect clockspring 2-pin connector. Using DRB, read

active codes. If DRB displays DRIVER SQUIB CIRCUIT OPEN, replace

clockspring. If not, go to next step.

4) Turn ignition off, disconnect battery and wait 2 minutes

before proceeding. Disconnect passenger-side air bag module connector.

Using an ohmmeter, check resistance between clockspring 2-pin

connector terminal No. 1 (Black/Light Blue wire) and passenger-side

air bag 2-pin connector terminal "A" (Black/Yellow wire). If

resistance is less than 5 ohms, repair short between Black/Light Blue

wire and Black/Yellow wire. If resistance is more than 5 ohms, go to

Page 197 of 1691

next step.

5) Using an ohmmeter, check resistance between clockspring 2-

pin connector terminals No. 1 (Black/Light Blue wire) and No. 2 (Dark\

Green/Light Blue wire). If resistance is less than 5 ohms, repair

short between Dark Green/Light Blue wire and Black/Light Blue wire. If

resistance is more than 5 ohms, go to next step.

6) If there are no potential causes for this DTC remaining,

ACM is assumed to be defective. Replace ACM. See

AIR BAG CONTROL MODULE (ACM) under REMOVAL & INSTALLATION.

DRIVER SQUIB CIRCUIT SHORTED TO BATTERY

NOTE: Perform AIR BAG VERIFICATION TEST after

all repairs. Each time a connector is disconnected, inspect

it to ensure it is in good condition. Always focus on circuit

being tested. Dirt, water and corrosion, are most common

problems in connectors. Due to manufacturer changes in wire

colors, use terminal identification whenever possible.

1) Disconnect battery and wait 2 minutes before proceeding.

Disconnect driver-side air bag module. Turn ignition on and reconnect

battery. Using DRB, read active codes. If DRB does not display DRIVER

SQUIB CIRCUIT SHORTED TO VOLTAGE, replace driver-side air bag module.

If DRB displays DRIVER SQUIB CIRCUIT SHORTED TO VOLTAGE, go to next

step.

2) Disconnect clockspring 2-pin connector. Using DRB, read

active codes. If DRB does not display DRIVER SQUIB CIRCUIT SHORTED TO

VOLTAGE, replace clockspring. If DRB displays DRIVER SQUIB CIRCUIT

SHORTED TO VOLTAGE, go to next step.

3) Disconnect battery and wait 2 minutes before proceeding.

Disconnect ACM 23-pin connector. Using a voltmeter, check voltage

between ground and clockspring connector terminals No. 1 (Black/Light

Blue wire) and No. 2 (Dark Green/Light Blue wire). If voltage is more\

than 5 volts on either circuit, repair short to voltage in Dark

Green/Light Blue wire or Black/Light Blue wire. If voltage is less

than 5 volts on either circuit, go to next step.

4) If there are no potential causes for this DTC remaining,

ACM is assumed to be defective. Replace ACM. See

AIR BAG CONTROL MODULE (ACM) under REMOVAL & INSTALLATION.

DRIVER SQUIB CIRCUIT SHORTED TO GROUND

NOTE: Perform AIR BAG VERIFICATION TEST after

all repairs. Each time a connector is disconnected, inspect

it to ensure it is in good condition. Always focus on circuit

being tested. Dirt, water and corrosion, are most common

problems in connectors. Due to manufacturer changes in wire

colors, use terminal identification whenever possible.

1) Disconnect battery and wait 2 minutes before proceeding.

Disconnect driver-side air bag module. Turn ignition on (engine off)

and reconnect battery. Using DRB, read active codes. If DRB does not

display DRIVER SQUIB CIRCUIT SHORTED TO GROUND, replace driver-side

air bag module. If DRB displays DRIVER SQUIB CIRCUIT SHORTED TO

GROUND, go to next step.

2) Disconnect clockspring 2-pin connector. Using DRB, read

active codes. If DRB does not display DRIVER SQUIB CIRCUIT SHORTED TO

GROUND, replace clockspring. If DRB displays DRIVER SQUIB CIRCUIT

SHORTED TO GROUND, go to next step.

3) Disconnect battery and wait 2 minutes before proceeding.

Disconnect ACM 23-pin connector. Using an ohmmeter, check resistance

between ground and clockspring connector terminals No. 1 (Black/Light

Blue wire) and No. 2 (Dark Green/Light Blue wire). If resistance is

Page 201 of 1691

wire) and No. 3 (Black/Yellow wire). If resistance is more than 5 ohm\

s

on either circuit, replace PAD switch. If resistance is less than 5

ohms on either circuit, go to next step.

5) Using an ohmmeter, check resistance between ACM connector

terminal No. 7 (Brown/Yellow wire) and PAD switch 4-pin connector

(harness side) terminal No. 4 (Dark Green/Yellow wire). If resistanc\

e

is more than 5 ohms, repair open or high resistance in Brown/Yellow

wire. If resistance is less than 5 ohms, go to next step.

6) Using an ohmmeter, check resistance between ACM connector

terminal No. 8 (Violet/Yellow wire) and PAD switch 4-pin connector

(harness side) terminal No. 3 (Black/Yellow wire). If resistance is

more than 5 ohms, repair open or high resistance in Violet/Yellow

wire. If resistance is less than 5 ohms, go to next step.

7) If there are no potential causes for this DTC remaining,

ACM is assumed to be defective. Replace ACM. See

AIR BAG CONTROL MODULE (ACM) under REMOVAL & INSTALLATION.

PASSENGER SQUIB CIRCUIT SHORTED

NOTE: Perform AIR BAG VERIFICATION TEST after

all repairs. Each time a connector is disconnected, inspect

it to ensure it is in good condition. Always focus on circuit

being tested. Dirt, water and corrosion, are most common

problems in connectors. Due to manufacturer changes in wire

colors, use terminal identification whenever possible.

1) Turn ignition off. Turn PAD switch to the ON position.

Turn ignition on (engine off). Using DRB, read active codes. If DRB

displays PASSENGER SIDE SQUIB SHORTED DTC, go to next step. If DRB

does not display PASSENGER SIDE SQUIB SHORTED DTC, go to appropriate

diagnostic test.

2) Turn ignition off. Disconnect battery and wait 2 minutes

before proceeding. Disconnect passenger-side air bag module connector.

Disconnect clockspring connector. Go to next step.

3) Using an ohmmeter, check resistance between Passenger-side

air bag 2-pin connector terminal "B" (Dark Green/Yellow wire) and

clockspring 2-pin connector terminal No. 1 (Black/Light Blue wire). If\

resistance is less than 5 ohms, repair short between Dark Green/Yellow

wire and Black/Light Blue wire. If resistance is more than 5 ohms, go

to next step.

4) Using an ohmmeter, check resistance between passenger-side

air bag module 2-pin connector terminal "A" (Black/Yellow wire) and

clockspring 2-pin connector terminal No. 2 (Dark Green/Light Blue

wire). If resistance is less than 5 ohms, repair short between

Black/Yellow wire and Dark Green/Light Blue wire. If resistance is

more than 5 ohms, go to next step.

5) Using an ohmmeter, check resistance between passenger-side

air bag clockspring 2-pin connector terminals. If resistance is less

than 5 ohms, go to next step. If resistance is more than 5 ohms,

replace passenger-side air bag module.

6) Disconnect PAD switch 4-pin connector. Using an ohmmeter,

check resistance between passenger-side air bag module 4-pin connector

(harness side) terminals "A" (Black/Yellow wire) and "B" (Dark

Green/Yellow wire). If resistance is less than 5 ohms, repair short

between Dark Green/Yellow wire Black/Yellow wire. If resistance is

more than 5 ohms, go to next step.

7) Using an ohmmeter, check resistance between PAD switch 4-

pin connector (harness side) terminals No. 1 (Brown/Yellow wire) and\

No. 2 (Violet/Yellow wire). If resistance is less than 5 ohms in

either circuit, repair short between Brown/Yellow wire and

Violet/Yellow wire. If resistance is more than 5 ohms, go to next

step.

8) If there are no potential causes for this DTC remaining,