central timer module DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 424 of 2889

AUDIO

TABLE OF CONTENTS

page page

AUDIO

DESCRIPTION............................1

OPERATION.............................2

DIAGNOSIS AND TESTING..................2

AUDIO................................2

SPECIAL TOOLS..........................4

ANTENNA BODY & CABLE

DESCRIPTION............................4

OPERATION.............................4

DIAGNOSIS AND TESTING..................5

ANTENNA.............................5

REMOVAL...............................6

INSTALLATION............................7

RADIO CHOKE RELAY

DESCRIPTION............................8

OPERATION.............................8

DIAGNOSIS AND TESTING..................8

RADIO CHOKE RELAY....................8

REMOVAL...............................9

INSTALLATION............................9

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL...............................9

INSTALLATION...........................10

RADIO

DESCRIPTION...........................10

OPERATION.............................10

DIAGNOSIS AND TESTING.................10

RADIO...............................10

REMOVAL..............................11

INSTALLATION...........................12

RADIO NOISE SUPPRESSION COMPONENTS

DESCRIPTION...........................12

DIAGNOSIS AND TESTING.................12

RADIO NOISE SUPPRESSION

COMPONENTS.........................12ENGINE-TO-BODY GROUND STRAP

REMOVAL..............................13

INSTALLATION...........................13

CAB-TO- BED GROUND STRAP

REMOVAL..............................14

INSTALLATION...........................14

HEATER CORE GROUND STRAP

REMOVAL..............................14

INSTALLATION...........................15

REMOTE SWITCHES

DESCRIPTION...........................15

OPERATION.............................15

DIAGNOSIS AND TESTING.................16

REMOTE SWITCHES....................16

REMOVAL..............................16

INSTALLATION...........................17

SPEAKER

DESCRIPTION...........................17

OPERATION.............................17

DIAGNOSIS AND TESTING.................18

SPEAKER............................18

A-PILLAR TWEETER SPEAKER

REMOVAL..............................19

INSTALLATION...........................19

FRONT DOOR SPEAKER

REMOVAL..............................20

INSTALLATION...........................20

REAR CAB SIDE PANEL SPEAKER

REMOVAL..............................20

INSTALLATION...........................21

REAR DOOR SPEAKER

REMOVAL..............................21

INSTALLATION...........................21

AUDIO

DESCRIPTION

An audio system is standard factory-installed equip-

ment on this model, unless the vehicle is ordered with

an available radio delete option. The standard equip-

ment audio system includes an AM/FM/cassette (RAS

sales code) receiver, and speakers in four locations. Sev-

eral combinations of radio receivers and speaker systems

are offered as optional equipment on this model. The

audio system uses an ignition switched source of battery

current so that the system will only operate when theignition switch is in the On or Accessory positions. The

audio system includes the following components:

²Antenna

²Clockspring (with remote radio switches only)

²Filter, choke and speaker relay (with premium

speaker system only)

²High-line or premium Central Timer Module

(CTM) (with remote radio switches)

²Radio noise suppression components

²Radio receiver

²Remote radio switches (optional with RAZ radio

receiver only)

²Speakers

BR/BEAUDIO 8A - 1

Page 425 of 2889

Refer to Electrical, Restraints for more information

on the clockspring. Refer to Electrical, Body Control/

Central Control Module for more information on the

Central Timer Module. Refer to the appropriate wir-

ing information. The wiring information includes wir-

ing diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds. Following are general descriptions of

the remaining major components in the standard and

optional factory-installed audio systems.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of each of the available audio systems.

CENTRAL TIMER MODULE

The high-line or premium Central Timer Module

(CTM) can also control some features of the audio

system when the vehicle is equipped with the

optional RAZ radio receiver and remote radio

switches. A high-line CTM is used on high-line ver-

sions of this vehicle. A premium CTM is used on

vehicles equipped with the optional heated seats. The

CTM combines the functions of a chime/buzzer mod-

ule, an intermittent wipe module, an illuminated

entry module, a remote keyless entry module, and a

vehicle theft security system module in a single unit.

The high-line or premium CTM also controls and

integrates many of the additional electronic functions

and features included on models with this option.The RAZ radio receiver with a remote radio switch

option is one of the features that the CTM controls.

The CTM is programmed to send switch status mes-

sages over the Chrysler Collision Detection (CCD)

data bus to control the volume, seek, and pre-set sta-

tion advance functions of the RAZ radio receiver. The

CTM monitors the status of the remote radio

switches located on the steering wheel through a

hard wired circuit. The CTM then sends the proper

switch status messages to the radio receiver. The

electronic circuitry within the radio receiver responds

to the switch status messages it receives by adjusting

the radio settings as requested.

Refer to Electrical, Body Control/Central Timer

Module for more information on the high-line CTM.

Refer to Remote Radio Switch in Description and

Operation for more information on this component.

In addition, radio receivers connected to the CCD

data bus have several audio system functions that

can be diagnosed using a DRBIIItscan tool. Refer to

the proper Diagnostic Procedures manual for more

information on DRBIIIttesting of the audio systems.

DIAGNOSIS AND TESTING - AUDIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

8A - 2 AUDIOBR/BE

AUDIO (Continued)

Page 431 of 2889

securely to the connector on the end of the antenna

cable being installed into the instrument panel. This

cord will be used to pull or ªfishº the cable back into

position.

(2) Using the cord or twine, pull the antenna cable

through the radio receiver opening from under the

instrument panel.

(3) Install the radio receiver onto the instrument

panel.

(4) Reach through the glove box opening to engage

the antenna cable with the retainer clips on the back

of the instrument panel.

(5) Install the glove box onto the instrument panel.

(6) Untie the cord or twine from the instrument

panel antenna cable connector.

(7) Reach under the passenger side of the instru-

ment panel near the right cowl side inner panel to

reconnect the two halves of the radio antenna coaxial

cable connector. Wrap the connection with a piece of

foam tape.

(8) Engage the coaxial cable connector with the

retainer clip located on the bottom of the heater-A/C

housing.

(9) Reconnect the battery negative cable.

RADIO CHOKE RELAY

DESCRIPTION

Models equipped with the Infinity premium

speaker package have a filter, choke, and speaker

relay unit. The filter, choke, and speaker relay unit is

mounted to the lower instrument panel center brace,

inboard of the Central Timer Module (CTM) and

directly above the 16-way data link connector. The

filter, choke, and speaker relay unit can be accessed

for service without instrument panel disassembly or

removal.

The filter, choke, and speaker relay unit should be

checked if there is no sound output noted from the

speakers. The filter, choke, and speaker relay unit

cannot be repaired or adjusted and, if faulty or dam-

aged, the unit must be replaced.

OPERATION

The filter, choke, and speaker relay unit is used to

control the supply of fused battery current to the

front door speaker-mounted dual amplifiers. The

speaker relay is energized by a fused 12 volt output

from the radio receiver whenever the radio is turned

on. For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information andlocation views for the various wire harness connec-

tors, splices and grounds.

DIAGNOSIS AND TESTING - RADIO CHOKE

RELAY

The filter, choke and speaker relay is used to

switch power to the individual speaker amplifiers

used with the Infinity premium speaker package.

The choke and relay are serviced only as a unit. If all

of the speakers are inoperative the filter, choke and

speaker relay unit should be considered suspect.

However, before replacement make the following

checks of the filter, choke and speaker relay circuits.

For complete circuit diagrams, refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

(1)

Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the battery as

required.

(3) Disconnect the instrument panel wire harness

connector from the filter, choke and speaker relay

unit. Check for battery voltage at the fused B(+) cir-

cuit cavity of the instrument panel wire harness con-

nector for the filter, choke and speaker relay unit. If

OK, go to Step 4. If not OK, repair the open fused

B(+) circuit to the junction block fuse as required.

(4) Probe the ground circuit cavity of the instru-

ment panel wire harness connector for the filter,

choke and speaker relay unit. Check for continuity to

a good ground. There should be continuity. If OK, go

to Step 5. If not OK, repair the open ground circuit to

ground as required.

(5) Turn the ignition switch to the On position and

turn the radio on. Check for battery voltage at the

radio 12-volt output circuit cavity of the instrument

panel wire harness connector for the filter, choke and

speaker relay unit. If OK, go to Step 6. If not OK,

repair the open radio 12-volt output circuit to the

radio as required.

(6) Turn the radio and ignition switches to the Off

position. Reconnect the instrument panel wire har-

ness connector to the filter, choke and speaker relay

unit. Check for battery voltage at the amplified

speaker (+) circuit cavity of the instrument panel

wire harness connector for the filter, choke and

speaker relay unit. There should be zero volts. Turn

the ignition and radio switches to the On position.

8A - 8 AUDIOBR/BE

ANTENNA BODY & CABLE (Continued)

Page 438 of 2889

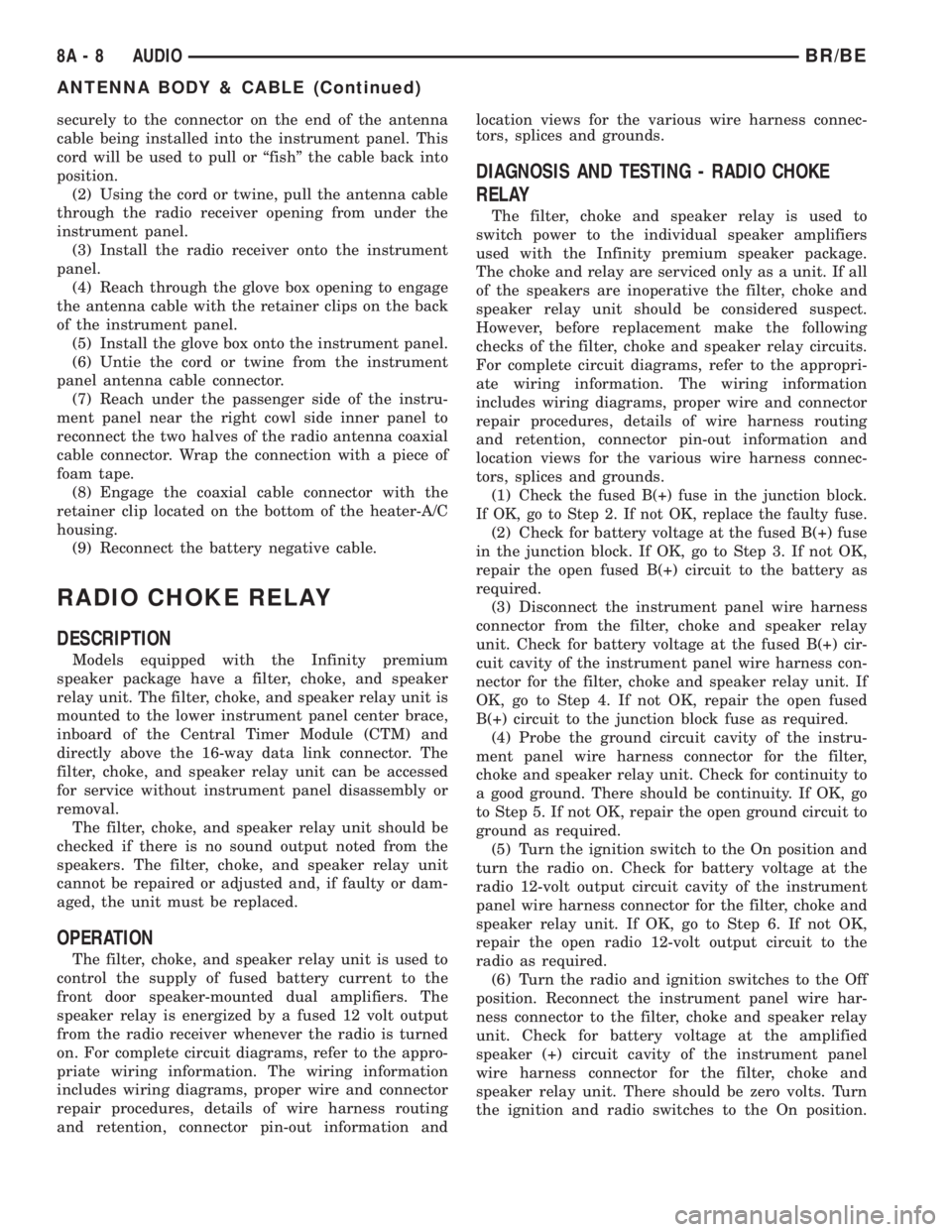

(6) Remove the heater core ground strap from the

top of the heater-A/C housing.

INSTALLATION

(1) Position the heater core ground strap and the

heater core tube retaining strap to the top of the

heater-A/C housing.

(2) Install and tighten the screw that secures the

heater core ground strap eyelet and the heater core

tube retaining strap to the top of the heater-A/C

housing. Tighten the screw to 2.2 N´m (20 in. lbs.).

(3) Position the heater core ground strap eyelet

over the stud on the dash panel.

(4) Install and tighten the nut that secures the

heater core ground strap eyelet to the stud on the

dash panel. Tighten the nut to 3.9 N´m (35 in. lbs.).

(5) Install the glove box onto the instrument panel.

Refer to Body, Instrument Panel for the procedures.

(6) Reconnect the battery negative cable.

REMOTE SWITCHES

DESCRIPTION

A remote radio switch option is available on models

equipped with the AM/FM/CD/cassette/3-band

graphic equalizer (RAZ sales code) radio receiver and

the high-line Central Timer Module (CTM). Refer to

Electrical, Body Control/Central Timer Module for

more information on this component.

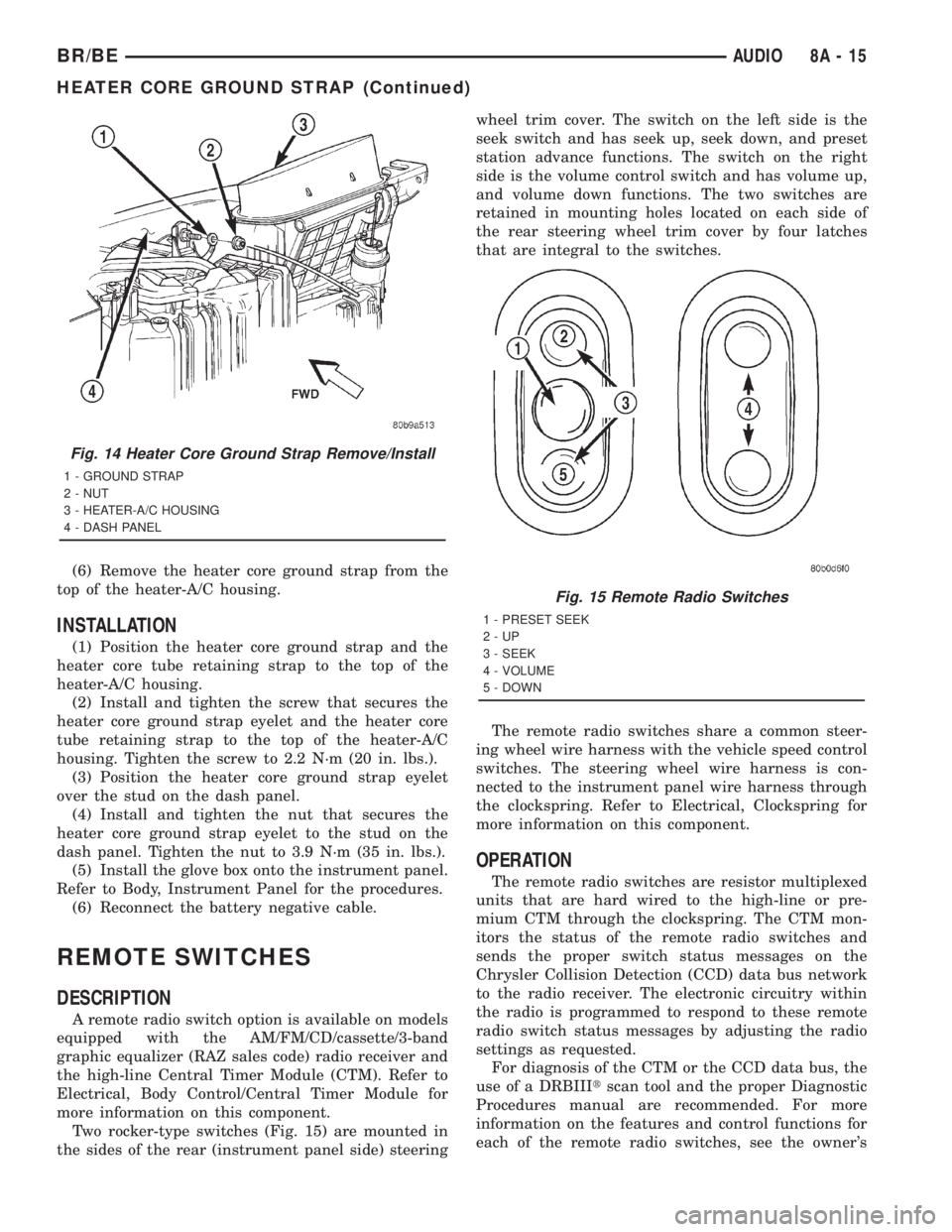

Two rocker-type switches (Fig. 15) are mounted in

the sides of the rear (instrument panel side) steeringwheel trim cover. The switch on the left side is the

seek switch and has seek up, seek down, and preset

station advance functions. The switch on the right

side is the volume control switch and has volume up,

and volume down functions. The two switches are

retained in mounting holes located on each side of

the rear steering wheel trim cover by four latches

that are integral to the switches.

The remote radio switches share a common steer-

ing wheel wire harness with the vehicle speed control

switches. The steering wheel wire harness is con-

nected to the instrument panel wire harness through

the clockspring. Refer to Electrical, Clockspring for

more information on this component.

OPERATION

The remote radio switches are resistor multiplexed

units that are hard wired to the high-line or pre-

mium CTM through the clockspring. The CTM mon-

itors the status of the remote radio switches and

sends the proper switch status messages on the

Chrysler Collision Detection (CCD) data bus network

to the radio receiver. The electronic circuitry within

the radio is programmed to respond to these remote

radio switch status messages by adjusting the radio

settings as requested.

For diagnosis of the CTM or the CCD data bus, the

use of a DRBIIItscan tool and the proper Diagnostic

Procedures manual are recommended. For more

information on the features and control functions for

each of the remote radio switches, see the owner's

Fig. 14 Heater Core Ground Strap Remove/Install

1 - GROUND STRAP

2 - NUT

3 - HEATER-A/C HOUSING

4 - DASH PANEL

Fig. 15 Remote Radio Switches

1 - PRESET SEEK

2-UP

3 - SEEK

4 - VOLUME

5 - DOWN

BR/BEAUDIO 8A - 15

HEATER CORE GROUND STRAP (Continued)

Page 439 of 2889

manual in the vehicle glove box. For complete circuit

diagrams, refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

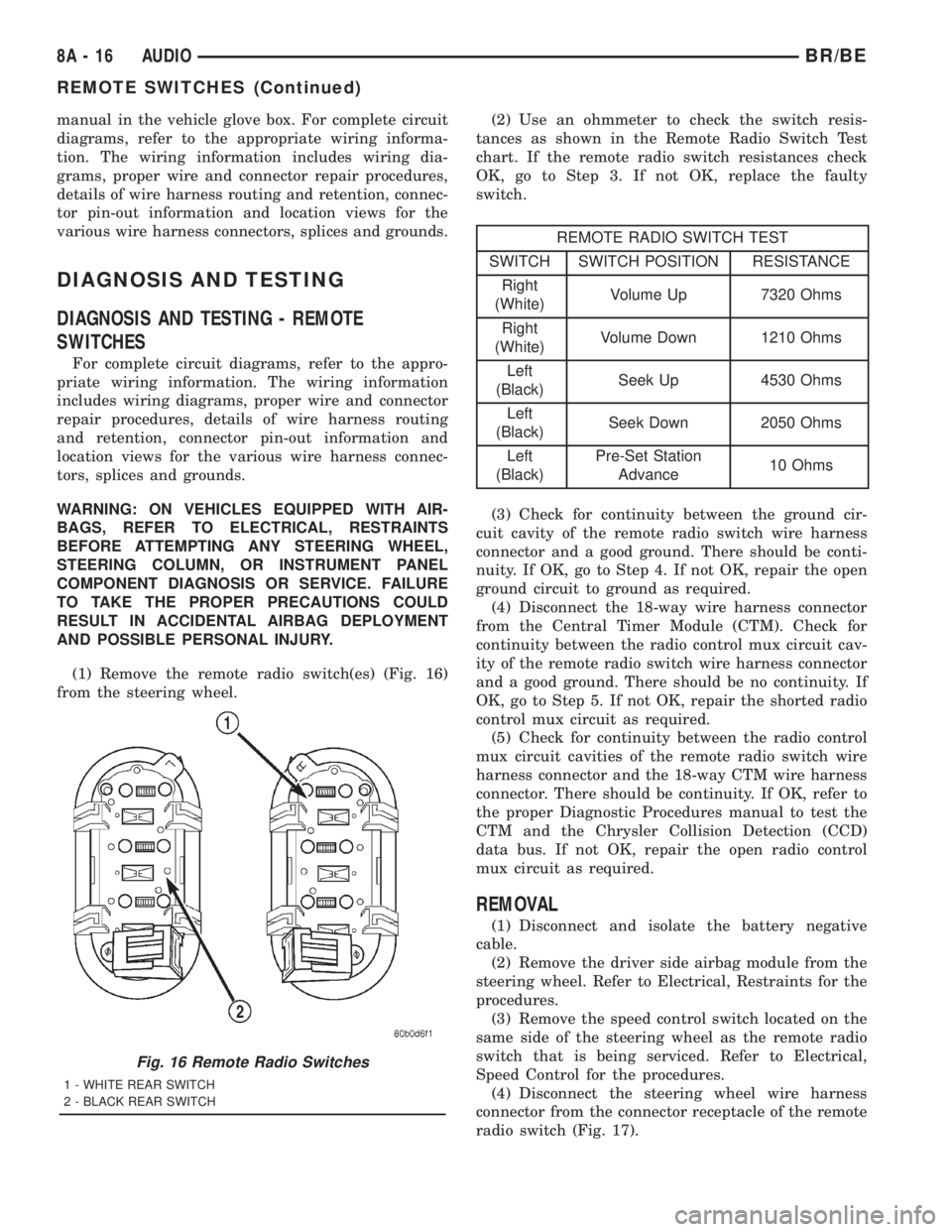

(1) Remove the remote radio switch(es) (Fig. 16)

from the steering wheel.(2) Use an ohmmeter to check the switch resis-

tances as shown in the Remote Radio Switch Test

chart. If the remote radio switch resistances check

OK, go to Step 3. If not OK, replace the faulty

switch.

REMOTE RADIO SWITCH TEST

SWITCH SWITCH POSITION RESISTANCE

Right

(White)Volume Up 7320 Ohms

Right

(White)Volume Down 1210 Ohms

Left

(Black)Seek Up 4530 Ohms

Left

(Black)Seek Down 2050 Ohms

Left

(Black)Pre-Set Station

Advance10 Ohms

(3) Check for continuity between the ground cir-

cuit cavity of the remote radio switch wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Disconnect the 18-way wire harness connector

from the Central Timer Module (CTM). Check for

continuity between the radio control mux circuit cav-

ity of the remote radio switch wire harness connector

and a good ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted radio

control mux circuit as required.

(5) Check for continuity between the radio control

mux circuit cavities of the remote radio switch wire

harness connector and the 18-way CTM wire harness

connector. There should be continuity. If OK, refer to

the proper Diagnostic Procedures manual to test the

CTM and the Chrysler Collision Detection (CCD)

data bus. If not OK, repair the open radio control

mux circuit as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side airbag module from the

steering wheel. Refer to Electrical, Restraints for the

procedures.

(3) Remove the speed control switch located on the

same side of the steering wheel as the remote radio

switch that is being serviced. Refer to Electrical,

Speed Control for the procedures.

(4) Disconnect the steering wheel wire harness

connector from the connector receptacle of the remote

radio switch (Fig. 17).

Fig. 16 Remote Radio Switches

1 - WHITE REAR SWITCH

2 - BLACK REAR SWITCH

8A - 16 AUDIOBR/BE

REMOTE SWITCHES (Continued)

Page 446 of 2889

CHIME/BUZZER

TABLE OF CONTENTS

page page

CHIME WARNING SYSTEM

DESCRIPTION............................1

OPERATION.............................1DIAGNOSIS AND TESTING..................2

CHIME WARNING SYSTEM................2

CHIME WARNING SYSTEM

DESCRIPTION

A chime warning system is standard factory-in-

stalled equipment on this model. The chime warning

system uses a single chime tone generator that is

integral to the Central Timer Module (CTM) to pro-

vide an audible indication of various vehicle condi-

tions that may require the attention of the vehicle

operator. The chime warning system includes the fol-

lowing major components, which are described in fur-

ther detail elsewhere in this service manual:

²Central Timer Module- The Central Timer

Module (CTM) is located under the driver side end of

the instrument panel, inboard of the instrument

panel steering column opening. The CTM contains an

integral chime tone generator to provide all of the

proper chime warning system features based upon

the monitored inputs.

²Door Ajar Switch- A door ajar switch is inte-

gral to the driver side front door latch. This switch

provides an input to the chime warning system indi-

cating whether the driver side front door is open or

closed.

²Headlamp Switch- The headlamp switch is

located on the instrument panel outboard of the

steering column. The headlamp switch provides an

input to the chime warning system indicating when

the exterior lamps are turned On or Off.

²Ignition Switch- A key-in ignition switch is

integral to the ignition switch. The key-in ignition

switch provides an input to the chime warning sys-

tem indicating whether a key is present in the igni-

tion lock cylinder.

²Seat Belt Switch- A seat belt switch is inte-

gral to the driver side front seat belt retractor unit.

The seat belt switch provides an input to the chime

warning system indicating whether the driver side

front seat belt is fastened.

Hard wired circuitry connects many of the chime

warning system components to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained bymany different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the chime warning system components

through the use of a combination of soldered splices,

splice block connectors, and many different types of

wire harness terminal connectors and insulators.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

The CTM chime warning system circuitry and the

integral chime tone generator cannot be adjusted or

repaired. If the CTM or the chime tone generator are

damaged or faulty, the CTM unit must be replaced.

OPERATION

The chime warning system is designed to provide an

audible output as an indication of various conditions

that may require the attention or awareness of the

vehicle operator. The chime warning system compo-

nents operate on battery current received through a

fused B(+) fuse in the Junction Block (JB) on a non-

switched fused B(+) circuit so that the system may

operate regardless of the ignition switch position.

The chime warning system provides an audible

indication to the vehicle operator under the following

conditions:

²Fasten Seat Belt Warning- The Central

Timer Module (CTM) chime tone generator will gen-

erate repetitive chime tones at a slow rate to

announce that a hard wired input from the seat belt

switch to the Electro-Mechanical Instrument Cluster

(EMIC) indicates that the driver side front seat belt

is not fastened with the ignition switch in the On

position. Unless the driver side front seat belt is fas-

tened, the chimes will continue to sound for a dura-

tion of about seven seconds each time the ignition

switch is turned to the On position or until the driver

side front seat belt is fastened, whichever occurs

first. This chime tone is based upon a hard wired

chime request input to the CTM from the EMIC, but

is not related to the operation of the EMIC ªSeatbeltº

indicator.

BR/BECHIME/BUZZER 8B - 1

Page 447 of 2889

²Head/Park Lights-On Warning- The CTM

chime tone generator will generate repetitive chime

tones at a fast rate to announce that hard wired

inputs from the driver door ajar switch, headlamp

switch, and ignition switch indicate that the exterior

lamps are turned On with the driver side front door

opened and the ignition switch in the Off position.

The chimes will continue to sound until the exterior

lamps are turned Off, the driver side front door is

closed, or the ignition switch is turned to the On

position, whichever occurs first.

²Key-In-Ignition Warning- The BCM chime

tone generator will generate repetitive chime tones at

a fast rate to announce that hard wired inputs from

the driver door ajar switch, headlamp switch, and

ignition switch indicate that the key is in the ignition

lock cylinder with the driver side front door opened

and the ignition switch in the Off position. The

chimes will continue to sound until the key is

removed from the ignition lock cylinder, the driver

side front door is closed, or the ignition switch is

turned to the On position, whichever occurs first.

²Warning Chime Support- The CTM chime

tone generator will generate repetitive chime tones at

a slow rate to announce that a hard wired chime

request input has been received from the EMIC.

These chime tones provide an audible alert to the

vehicle operator that supplements certain visual indi-

cations displayed by the EMIC. Supplemented indica-

tions include the following:

²The ªAirbagº indicator is illuminated. The

chimes will continue to sound for a duration of about

four seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªCheck Gagesº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªLow Fuelº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªLow Washº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªTrans Tempº indicator is illuminated (auto-

matic transmission only). The chimes will continue to

sound for a duration of about two seconds each time

the indicator is illuminated or until the ignition

switch is turned to the Off position, whichever occurs

first.²The vehicle is over a programmed speed value

(Middle East Gulf Coast Country (GCC) only). The

CTM chime tone generator will generate repetitive

chime tones at a slow rate to announce that the vehi-

cle speed exceeds a programmed value. The chimes

will continue to sound until the vehicle speed is

below the programmed value.

²The ªWater-In-Fuelº indicator is illuminated

(diesel engine only). The chimes will continue to

sound for a duration of about two seconds each time

the indicator is illuminated or until the ignition

switch is turned to the Off position, whichever occurs

first.

The CTM provides chime service for all available

features in the chime warning system. The CTM

relies upon hard wired inputs from the driver door

ajar switch, the EMIC, the headlamp switch, and the

key-in ignition switch (ignition switch) to provide

chime service for all of the chime warning system

features. Upon receiving the proper inputs, the CTM

activates the integral chime tone generator to pro-

vide the audible chime tone to the vehicle operator.

The chime tone generator in the CTM is capable of

producing repeated chime tones at two different

rates, slow or fast. The slow chime rate is about fifty

chime tones per minute, while the fast chime rate is

about 180 chime tones per minute. The internal pro-

gramming of the CTM and the EMIC determines the

priority of each chime tone request input that is

received, as well as the rate and duration of each

chime tone that is to be generated.

The hard wired chime warning system inputs to

the CTM and the EMIC, as well as other hard wired

circuits for this system may be diagnosed and tested

using conventional diagnostic tools and procedures.

See the owner's manual in the vehicle glove box for

more information on the features provided by the

chime warning system.

DIAGNOSIS AND TESTING - CHIME WARNING

SYSTEM

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. The hard wired

chime warning system inputs to the Central Timer

Module (CTM) and the Electro-Mechanical Instru-

ment Cluster (EMIC), as well as other hard wired

circuits for this system may be diagnosed and tested

using conventional diagnostic tools and procedures.

8B - 2 CHIME/BUZZERBR/BE

CHIME WARNING SYSTEM (Continued)

Page 452 of 2889

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

BODY CONTROL/CENTRAL TIMER MODULE

DESCRIPTION............................1

OPERATION.............................3

DIAGNOSIS AND TESTING..................4

CENTRAL TIMER MODULE................4

REMOVAL...............................5

INSTALLATION............................6

COMMUNICATION

DESCRIPTION............................6

OPERATION.............................7

DIAGNOSIS AND TESTING.................11

CCDDATABUS ........................11

CONTROLLER ANTILOCK BRAKE

DESCRIPTION...........................11

OPERATION.............................11REMOVAL..............................12

INSTALLATION...........................12

DATA LINK CONNECTOR

DESCRIPTION...........................12

OPERATION.............................12

ENGINE CONTROL MODULE

DESCRIPTION...........................13

OPERATION.............................13

REMOVAL..............................14

INSTALLATION...........................14

POWERTRAIN CONTROL MODULE

DESCRIPTION...........................14

OPERATION.............................17

REMOVAL..............................19

INSTALLATION...........................20

BODY CONTROL/CENTRAL

TIMER MODULE

DESCRIPTION

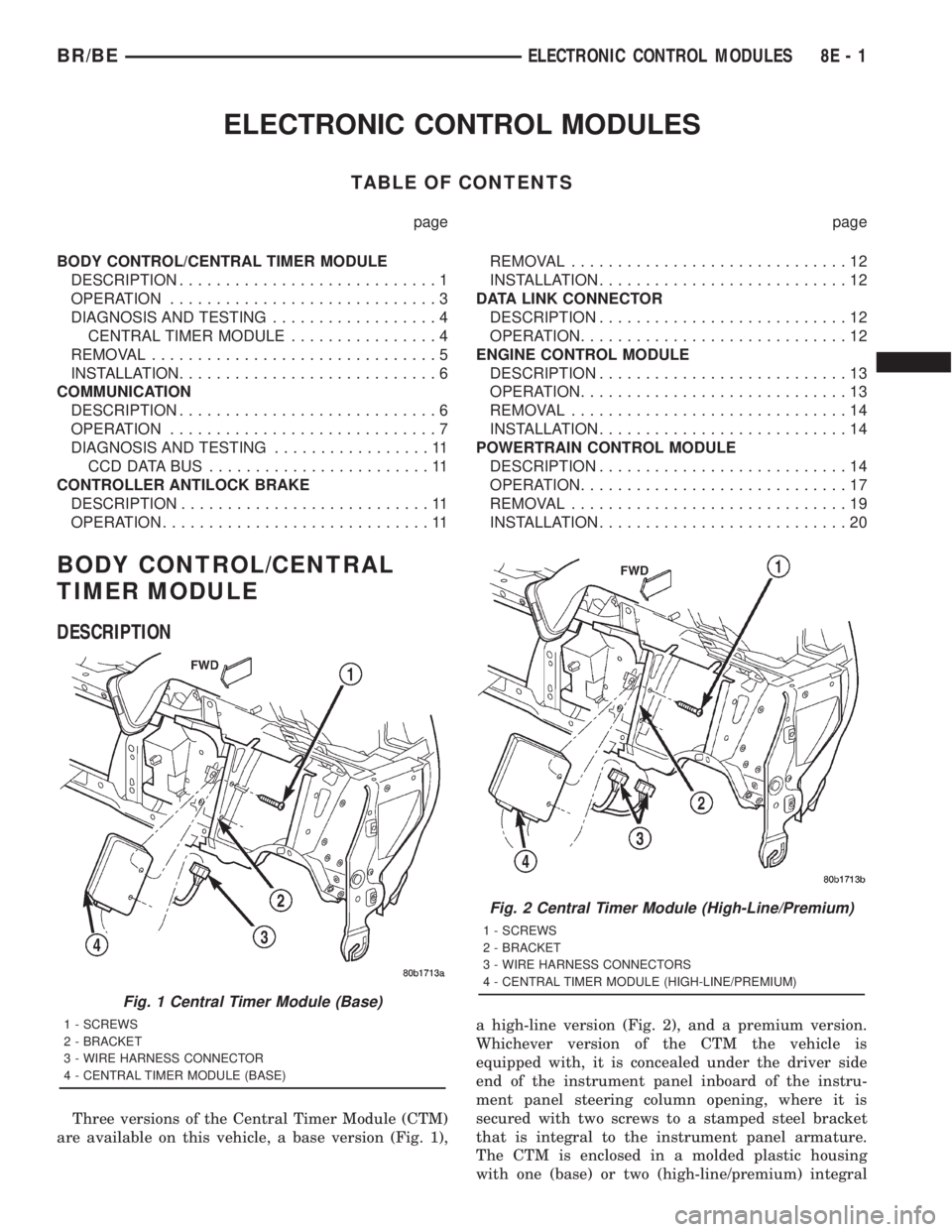

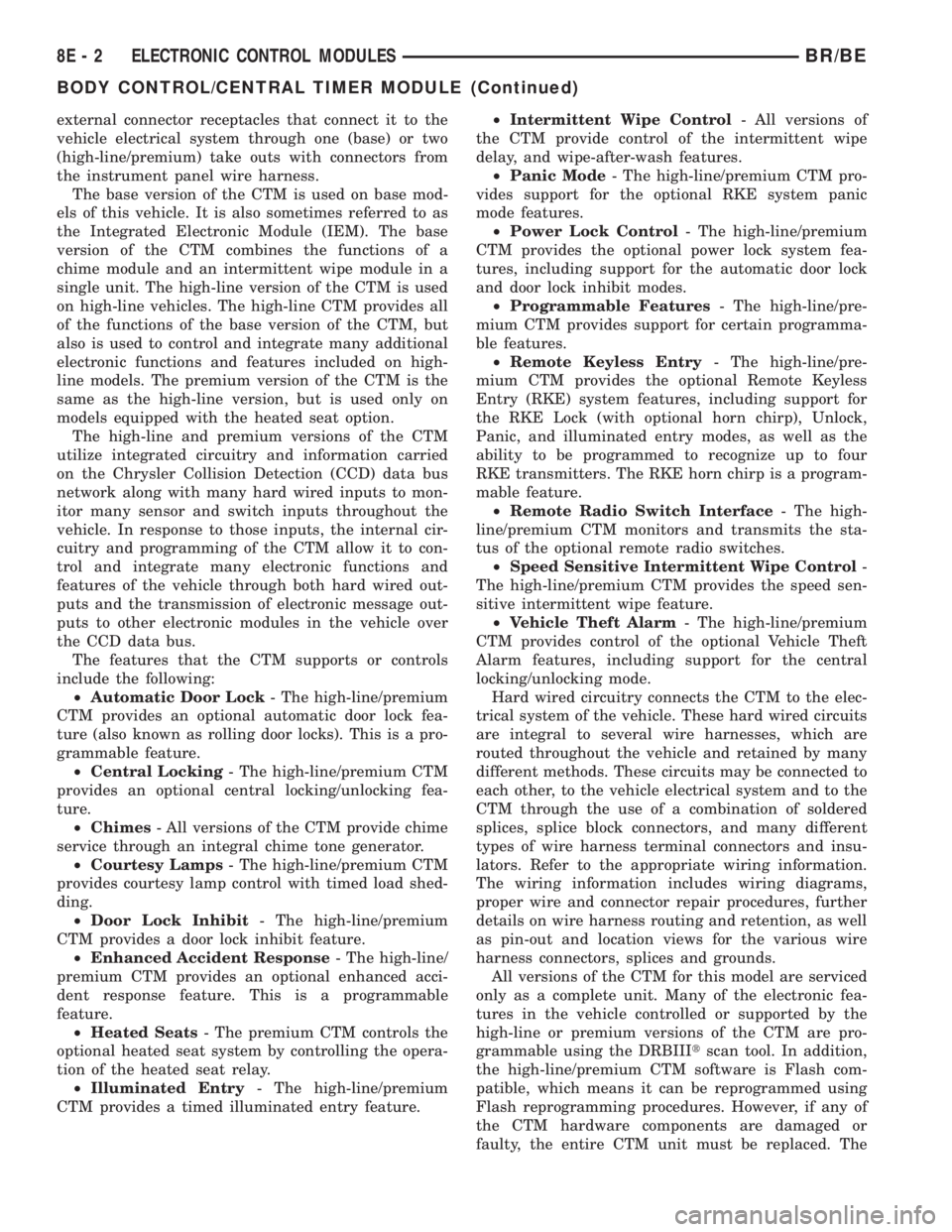

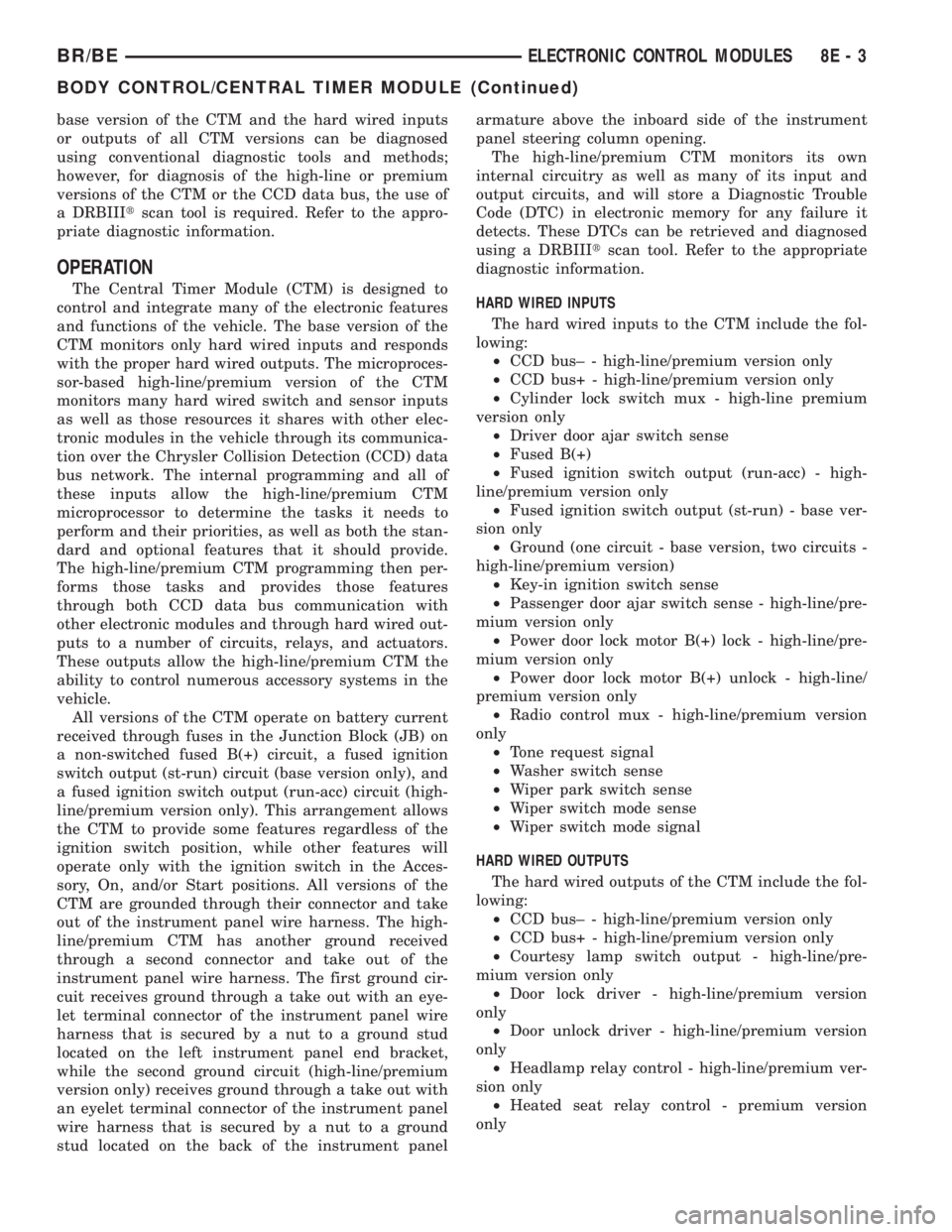

Three versions of the Central Timer Module (CTM)

are available on this vehicle, a base version (Fig. 1),a high-line version (Fig. 2), and a premium version.

Whichever version of the CTM the vehicle is

equipped with, it is concealed under the driver side

end of the instrument panel inboard of the instru-

ment panel steering column opening, where it is

secured with two screws to a stamped steel bracket

that is integral to the instrument panel armature.

The CTM is enclosed in a molded plastic housing

with one (base) or two (high-line/premium) integral

Fig. 1 Central Timer Module (Base)

1 - SCREWS

2 - BRACKET

3 - WIRE HARNESS CONNECTOR

4 - CENTRAL TIMER MODULE (BASE)

Fig. 2 Central Timer Module (High-Line/Premium)

1 - SCREWS

2 - BRACKET

3 - WIRE HARNESS CONNECTORS

4 - CENTRAL TIMER MODULE (HIGH-LINE/PREMIUM)

BR/BEELECTRONIC CONTROL MODULES 8E - 1

Page 453 of 2889

external connector receptacles that connect it to the

vehicle electrical system through one (base) or two

(high-line/premium) take outs with connectors from

the instrument panel wire harness.

The base version of the CTM is used on base mod-

els of this vehicle. It is also sometimes referred to as

the Integrated Electronic Module (IEM). The base

version of the CTM combines the functions of a

chime module and an intermittent wipe module in a

single unit. The high-line version of the CTM is used

on high-line vehicles. The high-line CTM provides all

of the functions of the base version of the CTM, but

also is used to control and integrate many additional

electronic functions and features included on high-

line models. The premium version of the CTM is the

same as the high-line version, but is used only on

models equipped with the heated seat option.

The high-line and premium versions of the CTM

utilize integrated circuitry and information carried

on the Chrysler Collision Detection (CCD) data bus

network along with many hard wired inputs to mon-

itor many sensor and switch inputs throughout the

vehicle. In response to those inputs, the internal cir-

cuitry and programming of the CTM allow it to con-

trol and integrate many electronic functions and

features of the vehicle through both hard wired out-

puts and the transmission of electronic message out-

puts to other electronic modules in the vehicle over

the CCD data bus.

The features that the CTM supports or controls

include the following:

²Automatic Door Lock- The high-line/premium

CTM provides an optional automatic door lock fea-

ture (also known as rolling door locks). This is a pro-

grammable feature.

²Central Locking- The high-line/premium CTM

provides an optional central locking/unlocking fea-

ture.

²Chimes- All versions of the CTM provide chime

service through an integral chime tone generator.

²Courtesy Lamps- The high-line/premium CTM

provides courtesy lamp control with timed load shed-

ding.

²Door Lock Inhibit- The high-line/premium

CTM provides a door lock inhibit feature.

²Enhanced Accident Response- The high-line/

premium CTM provides an optional enhanced acci-

dent response feature. This is a programmable

feature.

²Heated Seats- The premium CTM controls the

optional heated seat system by controlling the opera-

tion of the heated seat relay.

²Illuminated Entry- The high-line/premium

CTM provides a timed illuminated entry feature.²Intermittent Wipe Control- All versions of

the CTM provide control of the intermittent wipe

delay, and wipe-after-wash features.

²Panic Mode- The high-line/premium CTM pro-

vides support for the optional RKE system panic

mode features.

²Power Lock Control- The high-line/premium

CTM provides the optional power lock system fea-

tures, including support for the automatic door lock

and door lock inhibit modes.

²Programmable Features- The high-line/pre-

mium CTM provides support for certain programma-

ble features.

²Remote Keyless Entry- The high-line/pre-

mium CTM provides the optional Remote Keyless

Entry (RKE) system features, including support for

the RKE Lock (with optional horn chirp), Unlock,

Panic, and illuminated entry modes, as well as the

ability to be programmed to recognize up to four

RKE transmitters. The RKE horn chirp is a program-

mable feature.

²Remote Radio Switch Interface- The high-

line/premium CTM monitors and transmits the sta-

tus of the optional remote radio switches.

²Speed Sensitive Intermittent Wipe Control-

The high-line/premium CTM provides the speed sen-

sitive intermittent wipe feature.

²Vehicle Theft Alarm- The high-line/premium

CTM provides control of the optional Vehicle Theft

Alarm features, including support for the central

locking/unlocking mode.

Hard wired circuitry connects the CTM to the elec-

trical system of the vehicle. These hard wired circuits

are integral to several wire harnesses, which are

routed throughout the vehicle and retained by many

different methods. These circuits may be connected to

each other, to the vehicle electrical system and to the

CTM through the use of a combination of soldered

splices, splice block connectors, and many different

types of wire harness terminal connectors and insu-

lators. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

All versions of the CTM for this model are serviced

only as a complete unit. Many of the electronic fea-

tures in the vehicle controlled or supported by the

high-line or premium versions of the CTM are pro-

grammable using the DRBIIItscan tool. In addition,

the high-line/premium CTM software is Flash com-

patible, which means it can be reprogrammed using

Flash reprogramming procedures. However, if any of

the CTM hardware components are damaged or

faulty, the entire CTM unit must be replaced. The

8E - 2 ELECTRONIC CONTROL MODULESBR/BE

BODY CONTROL/CENTRAL TIMER MODULE (Continued)

Page 454 of 2889

base version of the CTM and the hard wired inputs

or outputs of all CTM versions can be diagnosed

using conventional diagnostic tools and methods;

however, for diagnosis of the high-line or premium

versions of the CTM or the CCD data bus, the use of

a DRBIIItscan tool is required. Refer to the appro-

priate diagnostic information.

OPERATION

The Central Timer Module (CTM) is designed to

control and integrate many of the electronic features

and functions of the vehicle. The base version of the

CTM monitors only hard wired inputs and responds

with the proper hard wired outputs. The microproces-

sor-based high-line/premium version of the CTM

monitors many hard wired switch and sensor inputs

as well as those resources it shares with other elec-

tronic modules in the vehicle through its communica-

tion over the Chrysler Collision Detection (CCD) data

bus network. The internal programming and all of

these inputs allow the high-line/premium CTM

microprocessor to determine the tasks it needs to

perform and their priorities, as well as both the stan-

dard and optional features that it should provide.

The high-line/premium CTM programming then per-

forms those tasks and provides those features

through both CCD data bus communication with

other electronic modules and through hard wired out-

puts to a number of circuits, relays, and actuators.

These outputs allow the high-line/premium CTM the

ability to control numerous accessory systems in the

vehicle.

All versions of the CTM operate on battery current

received through fuses in the Junction Block (JB) on

a non-switched fused B(+) circuit, a fused ignition

switch output (st-run) circuit (base version only), and

a fused ignition switch output (run-acc) circuit (high-

line/premium version only). This arrangement allows

the CTM to provide some features regardless of the

ignition switch position, while other features will

operate only with the ignition switch in the Acces-

sory, On, and/or Start positions. All versions of the

CTM are grounded through their connector and take

out of the instrument panel wire harness. The high-

line/premium CTM has another ground received

through a second connector and take out of the

instrument panel wire harness. The first ground cir-

cuit receives ground through a take out with an eye-

let terminal connector of the instrument panel wire

harness that is secured by a nut to a ground stud

located on the left instrument panel end bracket,

while the second ground circuit (high-line/premium

version only) receives ground through a take out with

an eyelet terminal connector of the instrument panel

wire harness that is secured by a nut to a ground

stud located on the back of the instrument panelarmature above the inboard side of the instrument

panel steering column opening.

The high-line/premium CTM monitors its own

internal circuitry as well as many of its input and

output circuits, and will store a Diagnostic Trouble

Code (DTC) in electronic memory for any failure it

detects. These DTCs can be retrieved and diagnosed

using a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

HARD WIRED INPUTS

The hard wired inputs to the CTM include the fol-

lowing:

²CCD bus± - high-line/premium version only

²CCD bus+ - high-line/premium version only

²Cylinder lock switch mux - high-line premium

version only

²Driver door ajar switch sense

²Fused B(+)

²Fused ignition switch output (run-acc) - high-

line/premium version only

²Fused ignition switch output (st-run) - base ver-

sion only

²Ground (one circuit - base version, two circuits -

high-line/premium version)

²Key-in ignition switch sense

²Passenger door ajar switch sense - high-line/pre-

mium version only

²Power door lock motor B(+) lock - high-line/pre-

mium version only

²Power door lock motor B(+) unlock - high-line/

premium version only

²Radio control mux - high-line/premium version

only

²Tone request signal

²Washer switch sense

²Wiper park switch sense

²Wiper switch mode sense

²Wiper switch mode signal

HARD WIRED OUTPUTS

The hard wired outputs of the CTM include the fol-

lowing:

²CCD bus± - high-line/premium version only

²CCD bus+ - high-line/premium version only

²Courtesy lamp switch output - high-line/pre-

mium version only

²Door lock driver - high-line/premium version

only

²Door unlock driver - high-line/premium version

only

²Headlamp relay control - high-line/premium ver-

sion only

²Heated seat relay control - premium version

only

BR/BEELECTRONIC CONTROL MODULES 8E - 3

BODY CONTROL/CENTRAL TIMER MODULE (Continued)