DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1931 of 2889

(3) Install the ECE check ball into the transfer

plate (Fig. 290). The ECE check ball is approximately

4.8 mm (3/16 in.) in diameter.

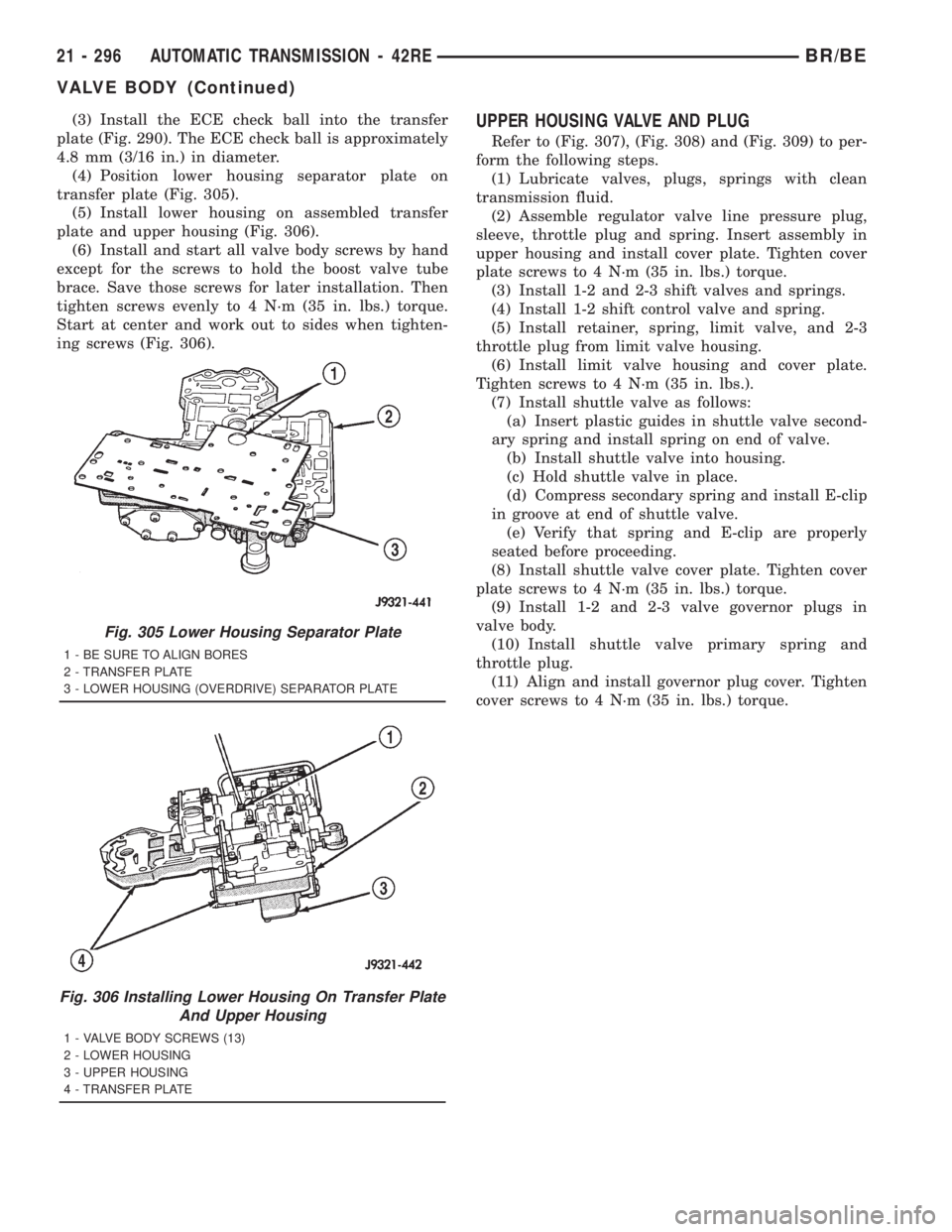

(4) Position lower housing separator plate on

transfer plate (Fig. 305).

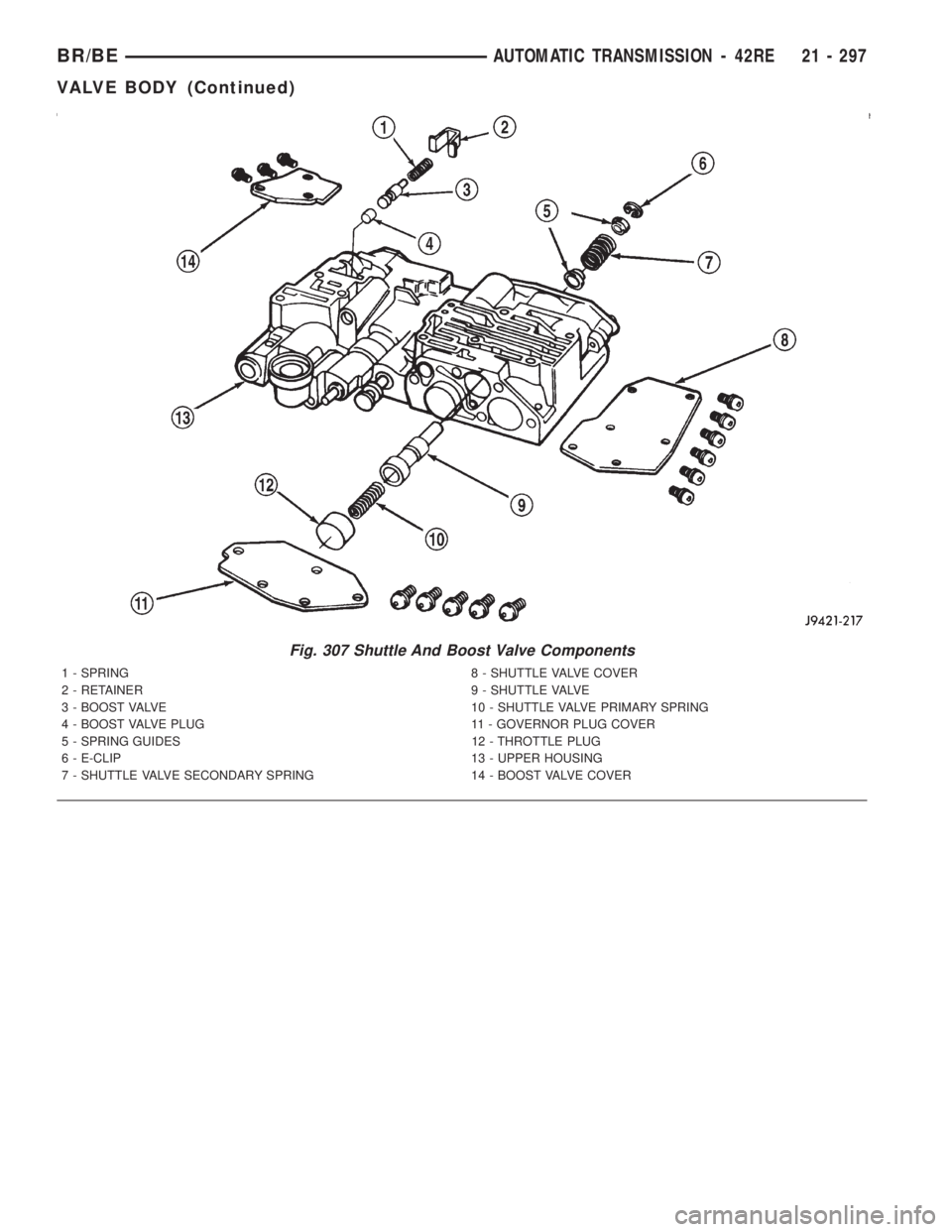

(5) Install lower housing on assembled transfer

plate and upper housing (Fig. 306).

(6) Install and start all valve body screws by hand

except for the screws to hold the boost valve tube

brace. Save those screws for later installation. Then

tighten screws evenly to 4 N´m (35 in. lbs.) torque.

Start at center and work out to sides when tighten-

ing screws (Fig. 306).UPPER HOUSING VALVE AND PLUG

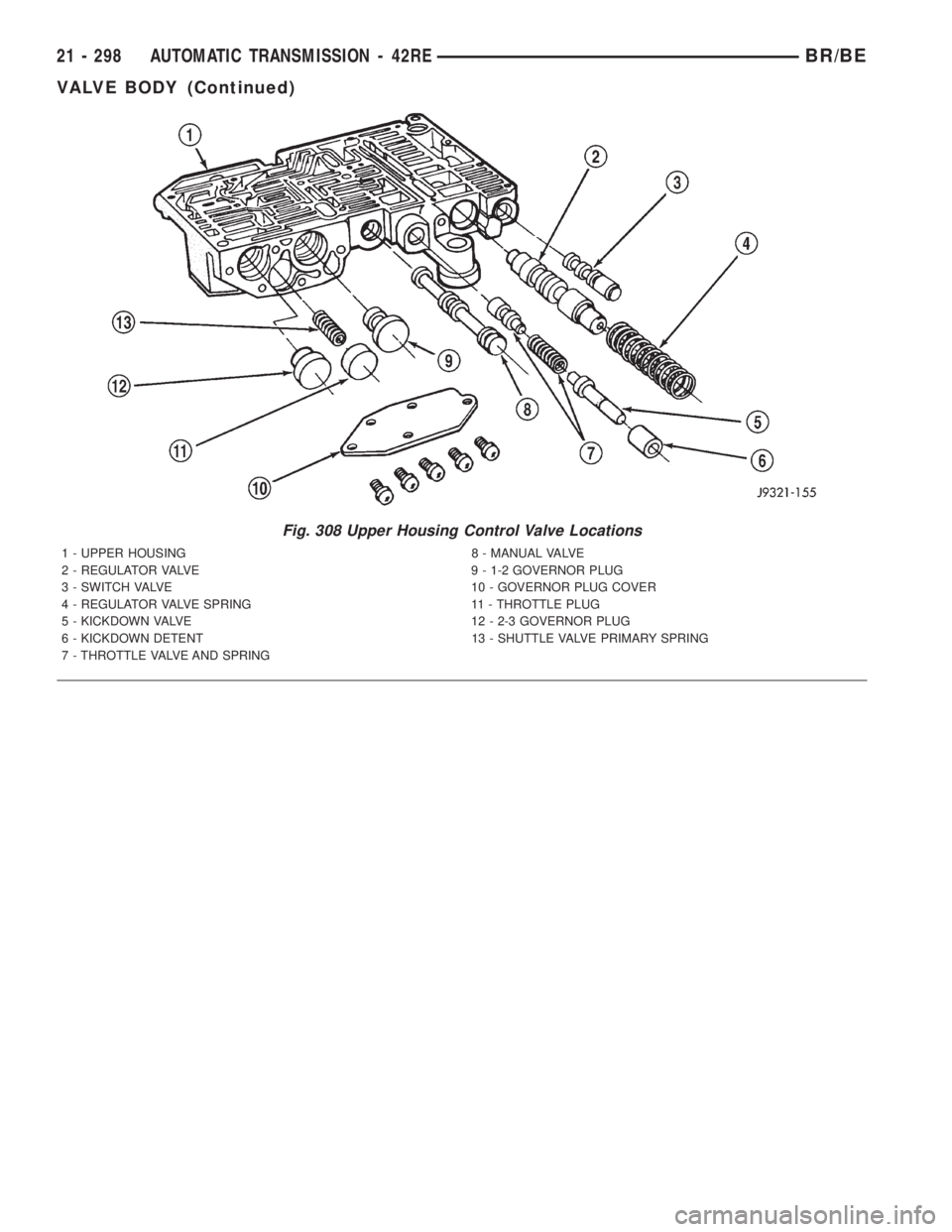

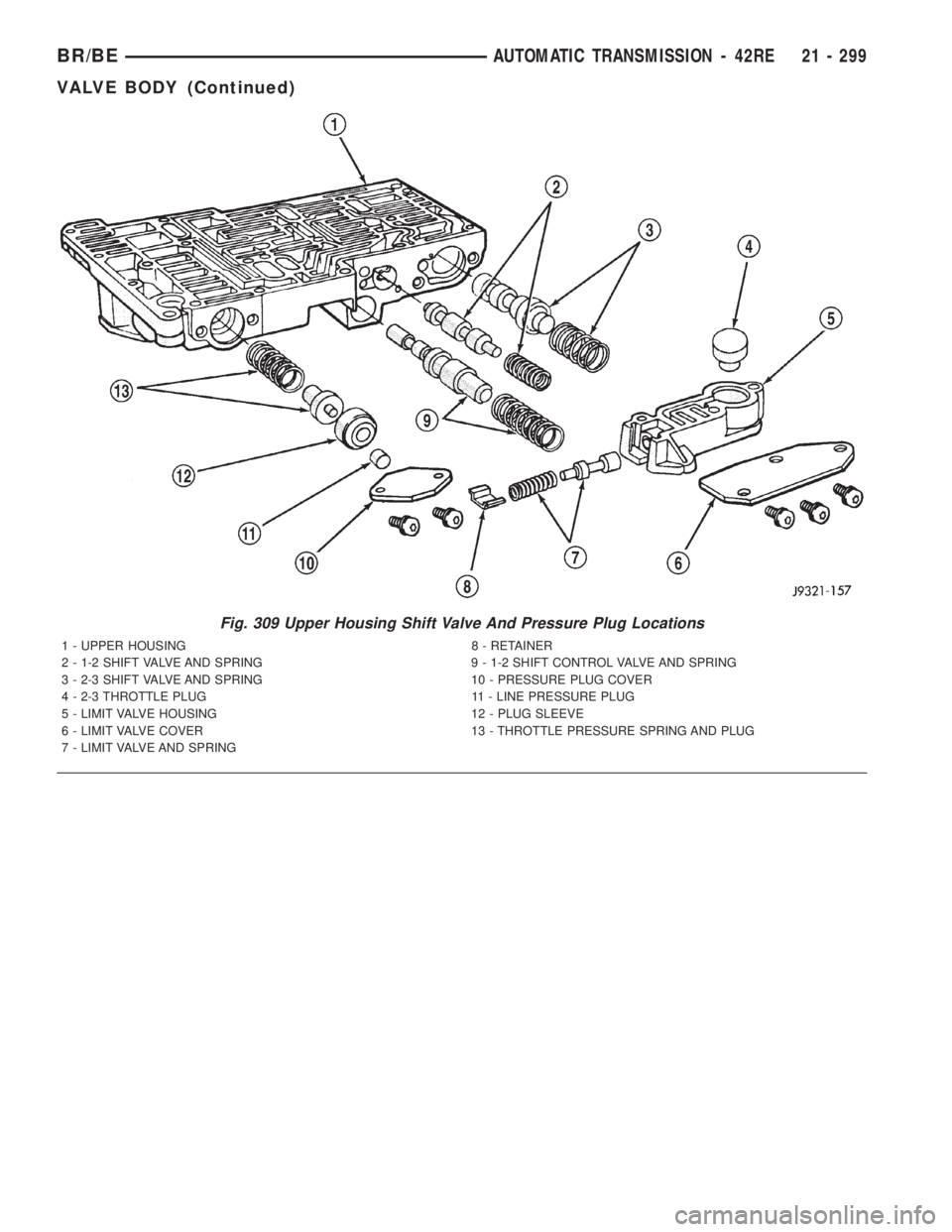

Refer to (Fig. 307), (Fig. 308) and (Fig. 309) to per-

form the following steps.

(1) Lubricate valves, plugs, springs with clean

transmission fluid.

(2) Assemble regulator valve line pressure plug,

sleeve, throttle plug and spring. Insert assembly in

upper housing and install cover plate. Tighten cover

plate screws to 4 N´m (35 in. lbs.) torque.

(3) Install 1-2 and 2-3 shift valves and springs.

(4) Install 1-2 shift control valve and spring.

(5) Install retainer, spring, limit valve, and 2-3

throttle plug from limit valve housing.

(6) Install limit valve housing and cover plate.

Tighten screws to 4 N´m (35 in. lbs.).

(7) Install shuttle valve as follows:

(a) Insert plastic guides in shuttle valve second-

ary spring and install spring on end of valve.

(b) Install shuttle valve into housing.

(c) Hold shuttle valve in place.

(d) Compress secondary spring and install E-clip

in groove at end of shuttle valve.

(e) Verify that spring and E-clip are properly

seated before proceeding.

(8) Install shuttle valve cover plate. Tighten cover

plate screws to 4 N´m (35 in. lbs.) torque.

(9) Install 1-2 and 2-3 valve governor plugs in

valve body.

(10) Install shuttle valve primary spring and

throttle plug.

(11) Align and install governor plug cover. Tighten

cover screws to 4 N´m (35 in. lbs.) torque.

Fig. 305 Lower Housing Separator Plate

1 - BE SURE TO ALIGN BORES

2 - TRANSFER PLATE

3 - LOWER HOUSING (OVERDRIVE) SEPARATOR PLATE

Fig. 306 Installing Lower Housing On Transfer Plate

And Upper Housing

1 - VALVE BODY SCREWS (13)

2 - LOWER HOUSING

3 - UPPER HOUSING

4 - TRANSFER PLATE

21 - 296 AUTOMATIC TRANSMISSION - 42REBR/BE

VALVE BODY (Continued)

Page 1932 of 2889

Fig. 307 Shuttle And Boost Valve Components

1 - SPRING 8 - SHUTTLE VALVE COVER

2 - RETAINER 9 - SHUTTLE VALVE

3 - BOOST VALVE 10 - SHUTTLE VALVE PRIMARY SPRING

4 - BOOST VALVE PLUG 11 - GOVERNOR PLUG COVER

5 - SPRING GUIDES 12 - THROTTLE PLUG

6 - E-CLIP 13 - UPPER HOUSING

7 - SHUTTLE VALVE SECONDARY SPRING 14 - BOOST VALVE COVER

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 297

VALVE BODY (Continued)

Page 1933 of 2889

Fig. 308 Upper Housing Control Valve Locations

1 - UPPER HOUSING 8 - MANUAL VALVE

2 - REGULATOR VALVE 9 - 1-2 GOVERNOR PLUG

3 - SWITCH VALVE 10 - GOVERNOR PLUG COVER

4 - REGULATOR VALVE SPRING 11 - THROTTLE PLUG

5 - KICKDOWN VALVE 12 - 2-3 GOVERNOR PLUG

6 - KICKDOWN DETENT 13 - SHUTTLE VALVE PRIMARY SPRING

7 - THROTTLE VALVE AND SPRING

21 - 298 AUTOMATIC TRANSMISSION - 42REBR/BE

VALVE BODY (Continued)

Page 1934 of 2889

Fig. 309 Upper Housing Shift Valve And Pressure Plug Locations

1 - UPPER HOUSING 8 - RETAINER

2 - 1-2 SHIFT VALVE AND SPRING 9 - 1-2 SHIFT CONTROL VALVE AND SPRING

3 - 2-3 SHIFT VALVE AND SPRING 10 - PRESSURE PLUG COVER

4 - 2-3 THROTTLE PLUG 11 - LINE PRESSURE PLUG

5 - LIMIT VALVE HOUSING 12 - PLUG SLEEVE

6 - LIMIT VALVE COVER 13 - THROTTLE PRESSURE SPRING AND PLUG

7 - LIMIT VALVE AND SPRING

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 299

VALVE BODY (Continued)

Page 1935 of 2889

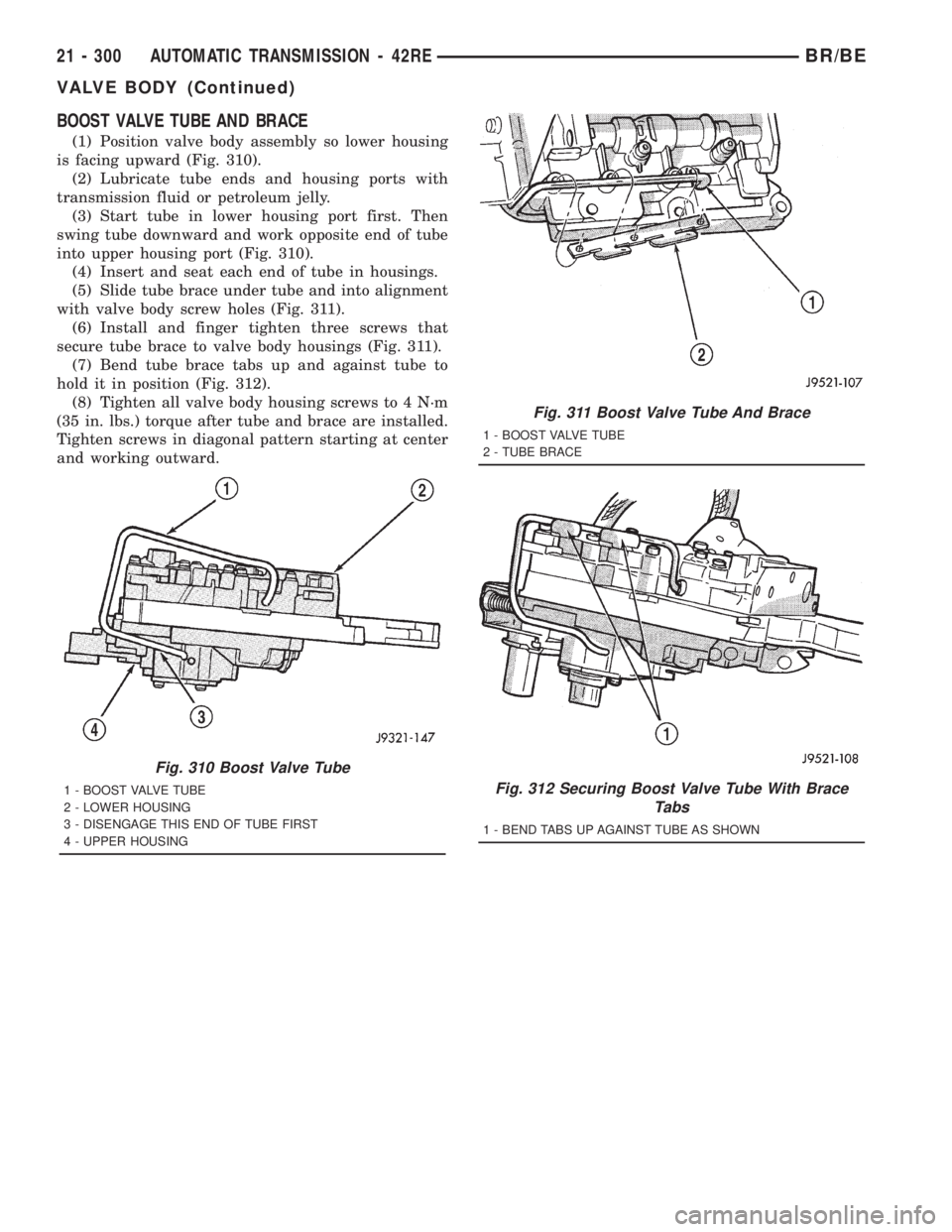

BOOST VALVE TUBE AND BRACE

(1) Position valve body assembly so lower housing

is facing upward (Fig. 310).

(2) Lubricate tube ends and housing ports with

transmission fluid or petroleum jelly.

(3) Start tube in lower housing port first. Then

swing tube downward and work opposite end of tube

into upper housing port (Fig. 310).

(4) Insert and seat each end of tube in housings.

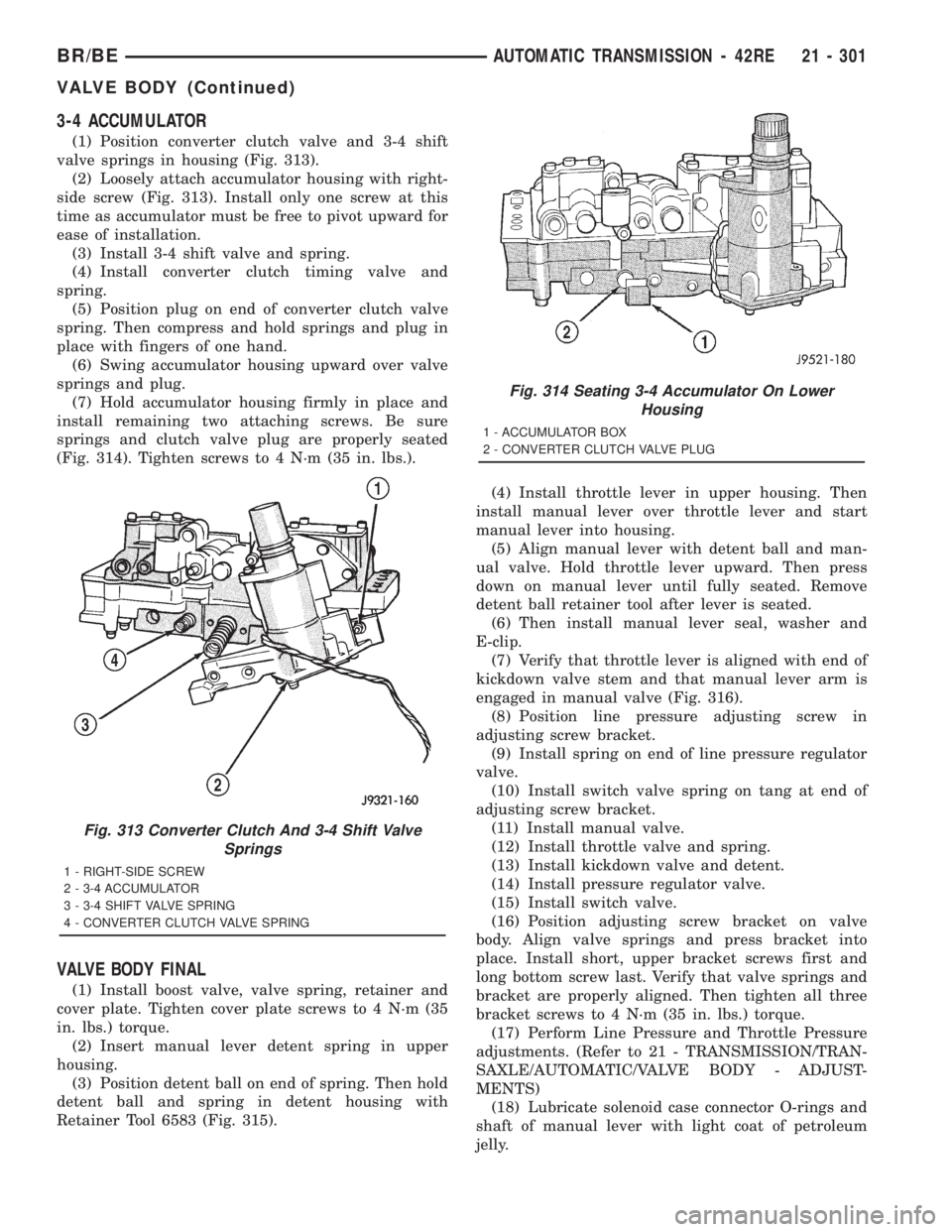

(5) Slide tube brace under tube and into alignment

with valve body screw holes (Fig. 311).

(6) Install and finger tighten three screws that

secure tube brace to valve body housings (Fig. 311).

(7) Bend tube brace tabs up and against tube to

hold it in position (Fig. 312).

(8) Tighten all valve body housing screws to 4 N´m

(35 in. lbs.) torque after tube and brace are installed.

Tighten screws in diagonal pattern starting at center

and working outward.

Fig. 310 Boost Valve Tube

1 - BOOST VALVE TUBE

2 - LOWER HOUSING

3 - DISENGAGE THIS END OF TUBE FIRST

4 - UPPER HOUSING

Fig. 311 Boost Valve Tube And Brace

1 - BOOST VALVE TUBE

2 - TUBE BRACE

Fig. 312 Securing Boost Valve Tube With Brace

Tabs

1 - BEND TABS UP AGAINST TUBE AS SHOWN

21 - 300 AUTOMATIC TRANSMISSION - 42REBR/BE

VALVE BODY (Continued)

Page 1936 of 2889

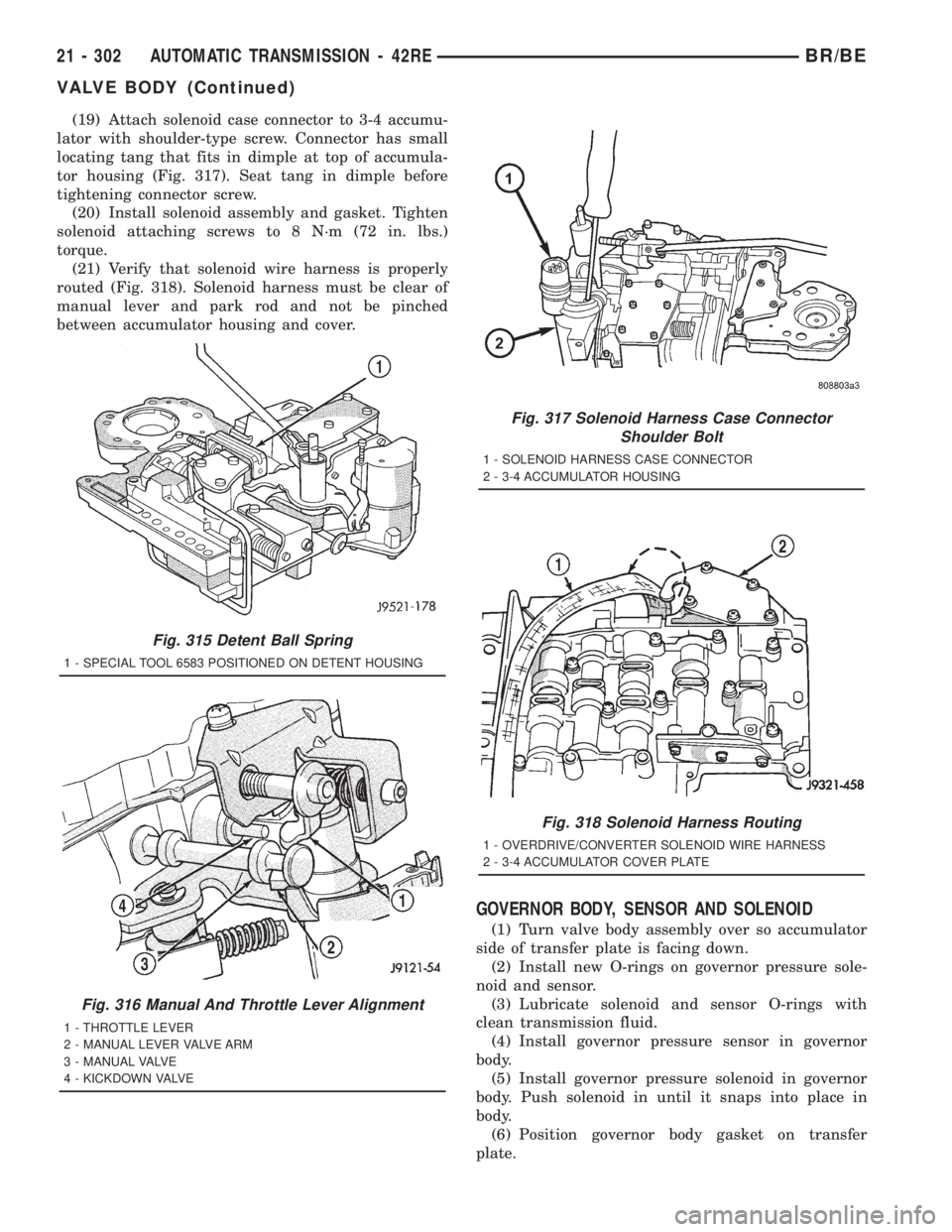

3-4 ACCUMULATOR

(1) Position converter clutch valve and 3-4 shift

valve springs in housing (Fig. 313).

(2) Loosely attach accumulator housing with right-

side screw (Fig. 313). Install only one screw at this

time as accumulator must be free to pivot upward for

ease of installation.

(3) Install 3-4 shift valve and spring.

(4) Install converter clutch timing valve and

spring.

(5) Position plug on end of converter clutch valve

spring. Then compress and hold springs and plug in

place with fingers of one hand.

(6) Swing accumulator housing upward over valve

springs and plug.

(7) Hold accumulator housing firmly in place and

install remaining two attaching screws. Be sure

springs and clutch valve plug are properly seated

(Fig. 314). Tighten screws to 4 N´m (35 in. lbs.).

VALVE BODY FINAL

(1) Install boost valve, valve spring, retainer and

cover plate. Tighten cover plate screws to 4 N´m (35

in. lbs.) torque.

(2) Insert manual lever detent spring in upper

housing.

(3) Position detent ball on end of spring. Then hold

detent ball and spring in detent housing with

Retainer Tool 6583 (Fig. 315).(4) Install throttle lever in upper housing. Then

install manual lever over throttle lever and start

manual lever into housing.

(5) Align manual lever with detent ball and man-

ual valve. Hold throttle lever upward. Then press

down on manual lever until fully seated. Remove

detent ball retainer tool after lever is seated.

(6) Then install manual lever seal, washer and

E-clip.

(7) Verify that throttle lever is aligned with end of

kickdown valve stem and that manual lever arm is

engaged in manual valve (Fig. 316).

(8) Position line pressure adjusting screw in

adjusting screw bracket.

(9) Install spring on end of line pressure regulator

valve.

(10) Install switch valve spring on tang at end of

adjusting screw bracket.

(11) Install manual valve.

(12) Install throttle valve and spring.

(13) Install kickdown valve and detent.

(14) Install pressure regulator valve.

(15) Install switch valve.

(16) Position adjusting screw bracket on valve

body. Align valve springs and press bracket into

place. Install short, upper bracket screws first and

long bottom screw last. Verify that valve springs and

bracket are properly aligned. Then tighten all three

bracket screws to 4 N´m (35 in. lbs.) torque.

(17) Perform Line Pressure and Throttle Pressure

adjustments. (Refer to 21 - TRANSMISSION/TRAN-

SAXLE/AUTOMATIC/VALVE BODY - ADJUST-

MENTS)

(18) Lubricate solenoid case connector O-rings and

shaft of manual lever with light coat of petroleum

jelly.

Fig. 313 Converter Clutch And 3-4 Shift Valve

Springs

1 - RIGHT-SIDE SCREW

2 - 3-4 ACCUMULATOR

3 - 3-4 SHIFT VALVE SPRING

4 - CONVERTER CLUTCH VALVE SPRING

Fig. 314 Seating 3-4 Accumulator On Lower

Housing

1 - ACCUMULATOR BOX

2 - CONVERTER CLUTCH VALVE PLUG

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 301

VALVE BODY (Continued)

Page 1937 of 2889

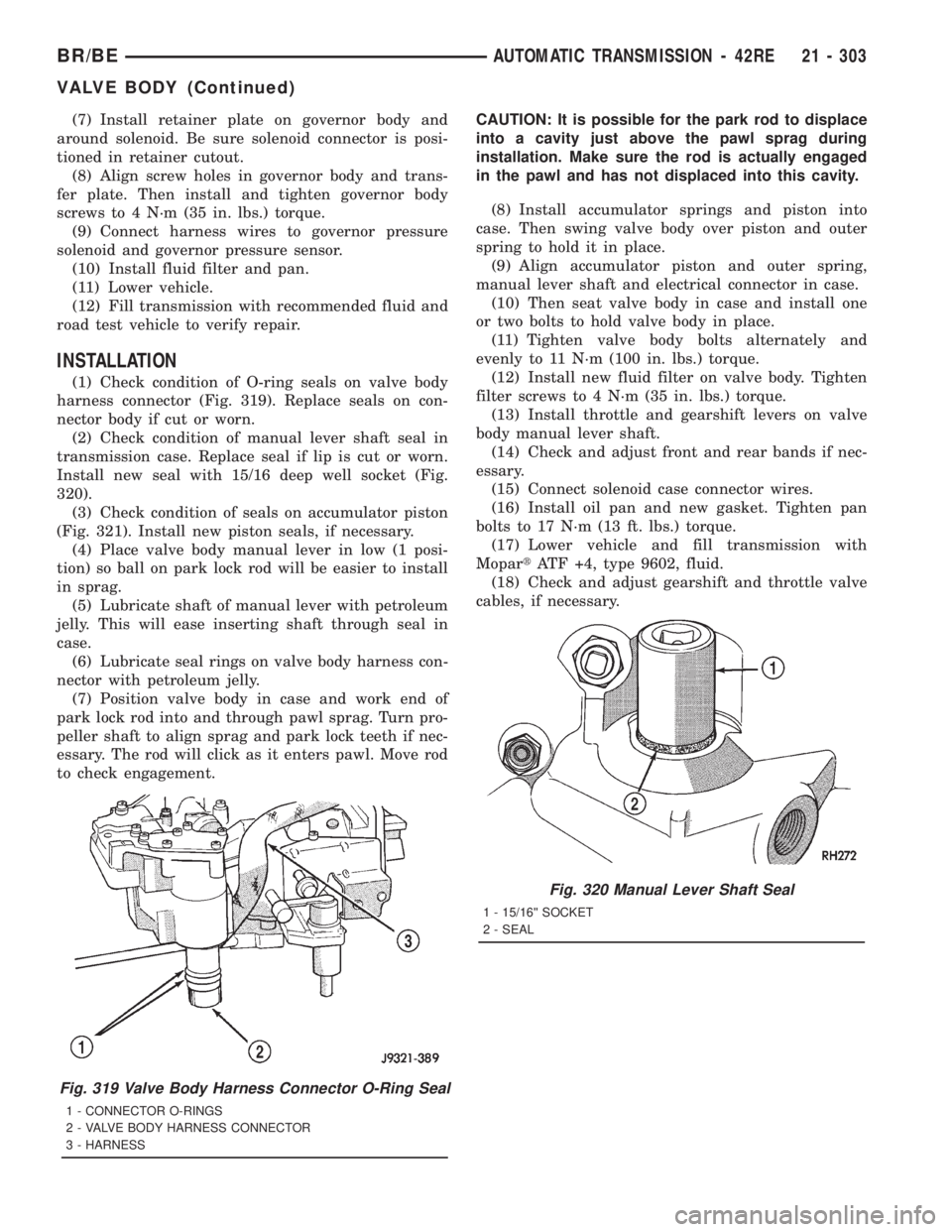

(19) Attach solenoid case connector to 3-4 accumu-

lator with shoulder-type screw. Connector has small

locating tang that fits in dimple at top of accumula-

tor housing (Fig. 317). Seat tang in dimple before

tightening connector screw.

(20) Install solenoid assembly and gasket. Tighten

solenoid attaching screws to 8 N´m (72 in. lbs.)

torque.

(21) Verify that solenoid wire harness is properly

routed (Fig. 318). Solenoid harness must be clear of

manual lever and park rod and not be pinched

between accumulator housing and cover.

GOVERNOR BODY, SENSOR AND SOLENOID

(1) Turn valve body assembly over so accumulator

side of transfer plate is facing down.

(2) Install new O-rings on governor pressure sole-

noid and sensor.

(3) Lubricate solenoid and sensor O-rings with

clean transmission fluid.

(4) Install governor pressure sensor in governor

body.

(5) Install governor pressure solenoid in governor

body. Push solenoid in until it snaps into place in

body.

(6) Position governor body gasket on transfer

plate.

Fig. 315 Detent Ball Spring

1 - SPECIAL TOOL 6583 POSITIONED ON DETENT HOUSING

Fig. 316 Manual And Throttle Lever Alignment

1 - THROTTLE LEVER

2 - MANUAL LEVER VALVE ARM

3 - MANUAL VALVE

4 - KICKDOWN VALVE

Fig. 317 Solenoid Harness Case Connector

Shoulder Bolt

1 - SOLENOID HARNESS CASE CONNECTOR

2 - 3-4 ACCUMULATOR HOUSING

Fig. 318 Solenoid Harness Routing

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

21 - 302 AUTOMATIC TRANSMISSION - 42REBR/BE

VALVE BODY (Continued)

Page 1938 of 2889

(7) Install retainer plate on governor body and

around solenoid. Be sure solenoid connector is posi-

tioned in retainer cutout.

(8) Align screw holes in governor body and trans-

fer plate. Then install and tighten governor body

screws to 4 N´m (35 in. lbs.) torque.

(9) Connect harness wires to governor pressure

solenoid and governor pressure sensor.

(10) Install fluid filter and pan.

(11) Lower vehicle.

(12) Fill transmission with recommended fluid and

road test vehicle to verify repair.

INSTALLATION

(1) Check condition of O-ring seals on valve body

harness connector (Fig. 319). Replace seals on con-

nector body if cut or worn.

(2) Check condition of manual lever shaft seal in

transmission case. Replace seal if lip is cut or worn.

Install new seal with 15/16 deep well socket (Fig.

320).

(3) Check condition of seals on accumulator piston

(Fig. 321). Install new piston seals, if necessary.

(4) Place valve body manual lever in low (1 posi-

tion) so ball on park lock rod will be easier to install

in sprag.

(5) Lubricate shaft of manual lever with petroleum

jelly. This will ease inserting shaft through seal in

case.

(6) Lubricate seal rings on valve body harness con-

nector with petroleum jelly.

(7) Position valve body in case and work end of

park lock rod into and through pawl sprag. Turn pro-

peller shaft to align sprag and park lock teeth if nec-

essary. The rod will click as it enters pawl. Move rod

to check engagement.CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into this cavity.

(8) Install accumulator springs and piston into

case. Then swing valve body over piston and outer

spring to hold it in place.

(9) Align accumulator piston and outer spring,

manual lever shaft and electrical connector in case.

(10) Then seat valve body in case and install one

or two bolts to hold valve body in place.

(11) Tighten valve body bolts alternately and

evenly to 11 N´m (100 in. lbs.) torque.

(12) Install new fluid filter on valve body. Tighten

filter screws to 4 N´m (35 in. lbs.) torque.

(13) Install throttle and gearshift levers on valve

body manual lever shaft.

(14) Check and adjust front and rear bands if nec-

essary.

(15) Connect solenoid case connector wires.

(16) Install oil pan and new gasket. Tighten pan

bolts to 17 N´m (13 ft. lbs.) torque.

(17) Lower vehicle and fill transmission with

MopartATF +4, type 9602, fluid.

(18) Check and adjust gearshift and throttle valve

cables, if necessary.

Fig. 319 Valve Body Harness Connector O-Ring Seal

1 - CONNECTOR O-RINGS

2 - VALVE BODY HARNESS CONNECTOR

3 - HARNESS

Fig. 320 Manual Lever Shaft Seal

1 - 15/16©© SOCKET

2 - SEAL

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 303

VALVE BODY (Continued)

Page 1939 of 2889

ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

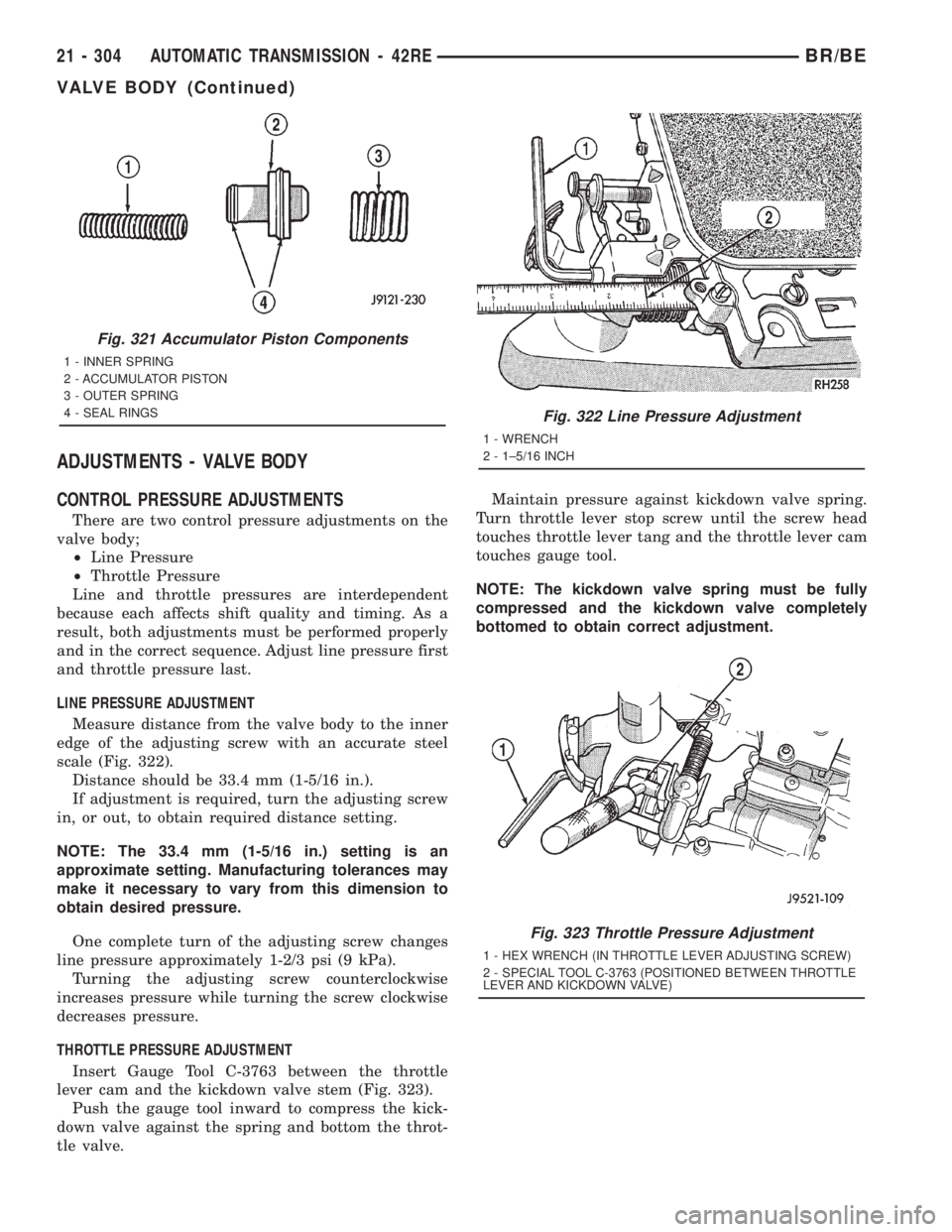

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 322).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).

Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.

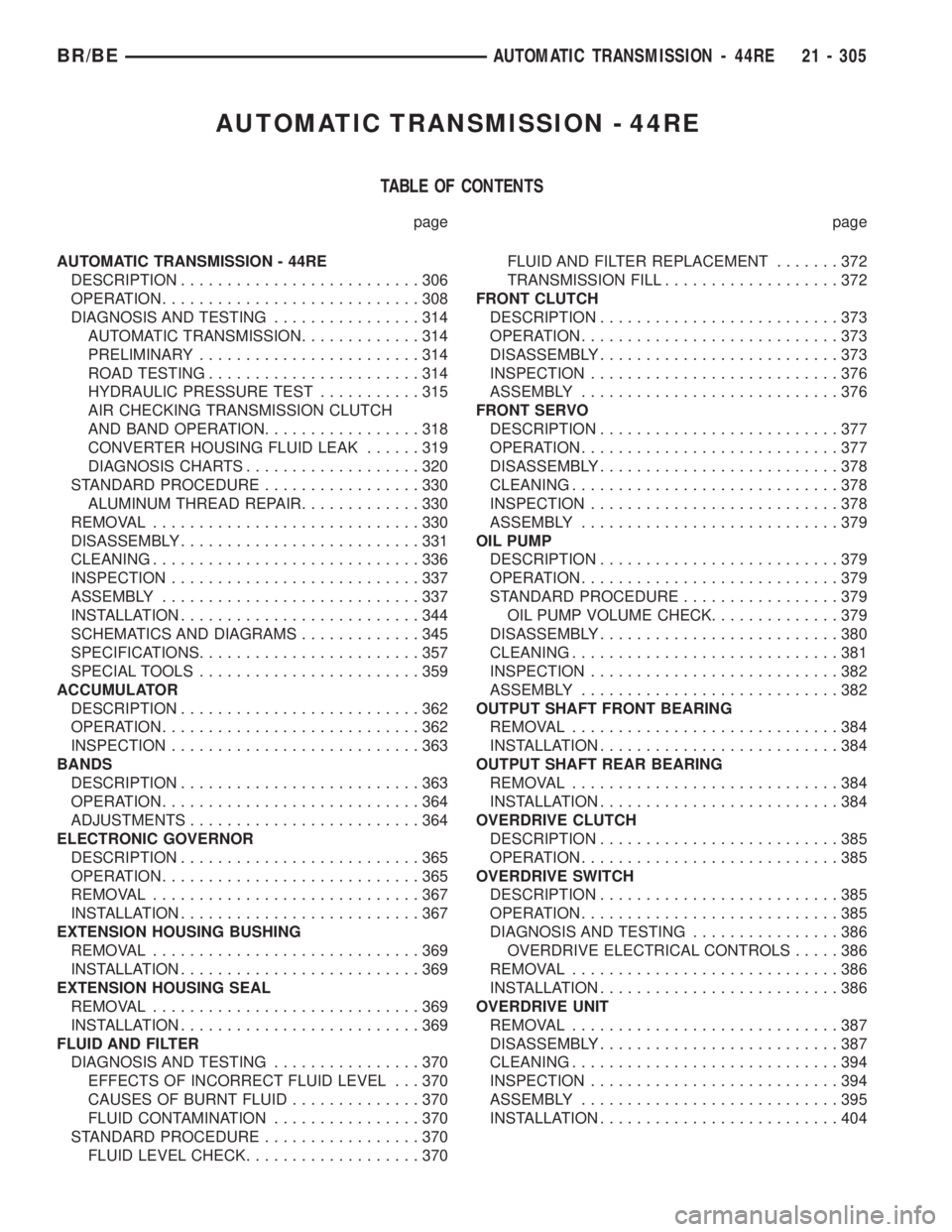

THROTTLE PRESSURE ADJUSTMENT

Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (Fig. 323).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

Fig. 321 Accumulator Piston Components

1 - INNER SPRING

2 - ACCUMULATOR PISTON

3 - OUTER SPRING

4 - SEAL RINGS

Fig. 322 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

Fig. 323 Throttle Pressure Adjustment

1 - HEX WRENCH (IN THROTTLE LEVER ADJUSTING SCREW)

2 - SPECIAL TOOL C-3763 (POSITIONED BETWEEN THROTTLE

LEVER AND KICKDOWN VALVE)

21 - 304 AUTOMATIC TRANSMISSION - 42REBR/BE

VALVE BODY (Continued)

Page 1940 of 2889

AUTOMATIC TRANSMISSION - 44RE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 44RE

DESCRIPTION..........................306

OPERATION............................308

DIAGNOSIS AND TESTING................314

AUTOMATIC TRANSMISSION.............314

PRELIMINARY........................314

ROAD TESTING.......................314

HYDRAULIC PRESSURE TEST...........315

AIR CHECKING TRANSMISSION CLUTCH

AND BAND OPERATION.................318

CONVERTER HOUSING FLUID LEAK......319

DIAGNOSIS CHARTS...................320

STANDARD PROCEDURE.................330

ALUMINUM THREAD REPAIR.............330

REMOVAL.............................330

DISASSEMBLY..........................331

CLEANING.............................336

INSPECTION...........................337

ASSEMBLY............................337

INSTALLATION..........................344

SCHEMATICS AND DIAGRAMS.............345

SPECIFICATIONS........................357

SPECIAL TOOLS........................359

ACCUMULATOR

DESCRIPTION..........................362

OPERATION............................362

INSPECTION...........................363

BANDS

DESCRIPTION..........................363

OPERATION............................364

ADJUSTMENTS.........................364

ELECTRONIC GOVERNOR

DESCRIPTION..........................365

OPERATION............................365

REMOVAL.............................367

INSTALLATION..........................367

EXTENSION HOUSING BUSHING

REMOVAL.............................369

INSTALLATION..........................369

EXTENSION HOUSING SEAL

REMOVAL.............................369

INSTALLATION..........................369

FLUID AND FILTER

DIAGNOSIS AND TESTING................370

EFFECTS OF INCORRECT FLUID LEVEL . . . 370

CAUSES OF BURNT FLUID..............370

FLUID CONTAMINATION................370

STANDARD PROCEDURE.................370

FLUID LEVEL CHECK...................370FLUID AND FILTER REPLACEMENT.......372

TRANSMISSION FILL...................372

FRONT CLUTCH

DESCRIPTION..........................373

OPERATION............................373

DISASSEMBLY..........................373

INSPECTION...........................376

ASSEMBLY............................376

FRONT SERVO

DESCRIPTION..........................377

OPERATION............................377

DISASSEMBLY..........................378

CLEANING.............................378

INSPECTION...........................378

ASSEMBLY............................379

OIL PUMP

DESCRIPTION..........................379

OPERATION............................379

STANDARD PROCEDURE.................379

OIL PUMP VOLUME CHECK..............379

DISASSEMBLY..........................380

CLEANING.............................381

INSPECTION...........................382

ASSEMBLY............................382

OUTPUT SHAFT FRONT BEARING

REMOVAL.............................384

INSTALLATION..........................384

OUTPUT SHAFT REAR BEARING

REMOVAL.............................384

INSTALLATION..........................384

OVERDRIVE CLUTCH

DESCRIPTION..........................385

OPERATION............................385

OVERDRIVE SWITCH

DESCRIPTION..........................385

OPERATION............................385

DIAGNOSIS AND TESTING................386

OVERDRIVE ELECTRICAL CONTROLS.....386

REMOVAL.............................386

INSTALLATION..........................386

OVERDRIVE UNIT

REMOVAL.............................387

DISASSEMBLY..........................387

CLEANING.............................394

INSPECTION...........................394

ASSEMBLY............................395

INSTALLATION..........................404

BR/BEAUTOMATIC TRANSMISSION - 44RE 21 - 305