cruise control DODGE RAM 2001 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1517 of 2889

(11) Inspect accelerator cable, transmission throt-

tle cable (if equipped) and cruise control cable con-

nections (if equipped). Check their connections to the

throttle arm of throttle body for any binding or

restrictions.

(12) If equipped with vacuum brake booster, verify

that vacuum booster hose is firmly connected to fit-

ting on intake manifold. Also check connection to

brake vacuum booster.

(13) Inspect the air cleaner inlet and air cleaner

element for dirt or restrictions.

(14) Inspect radiator grille area, radiator fins and

air conditioning condenser for restrictions.

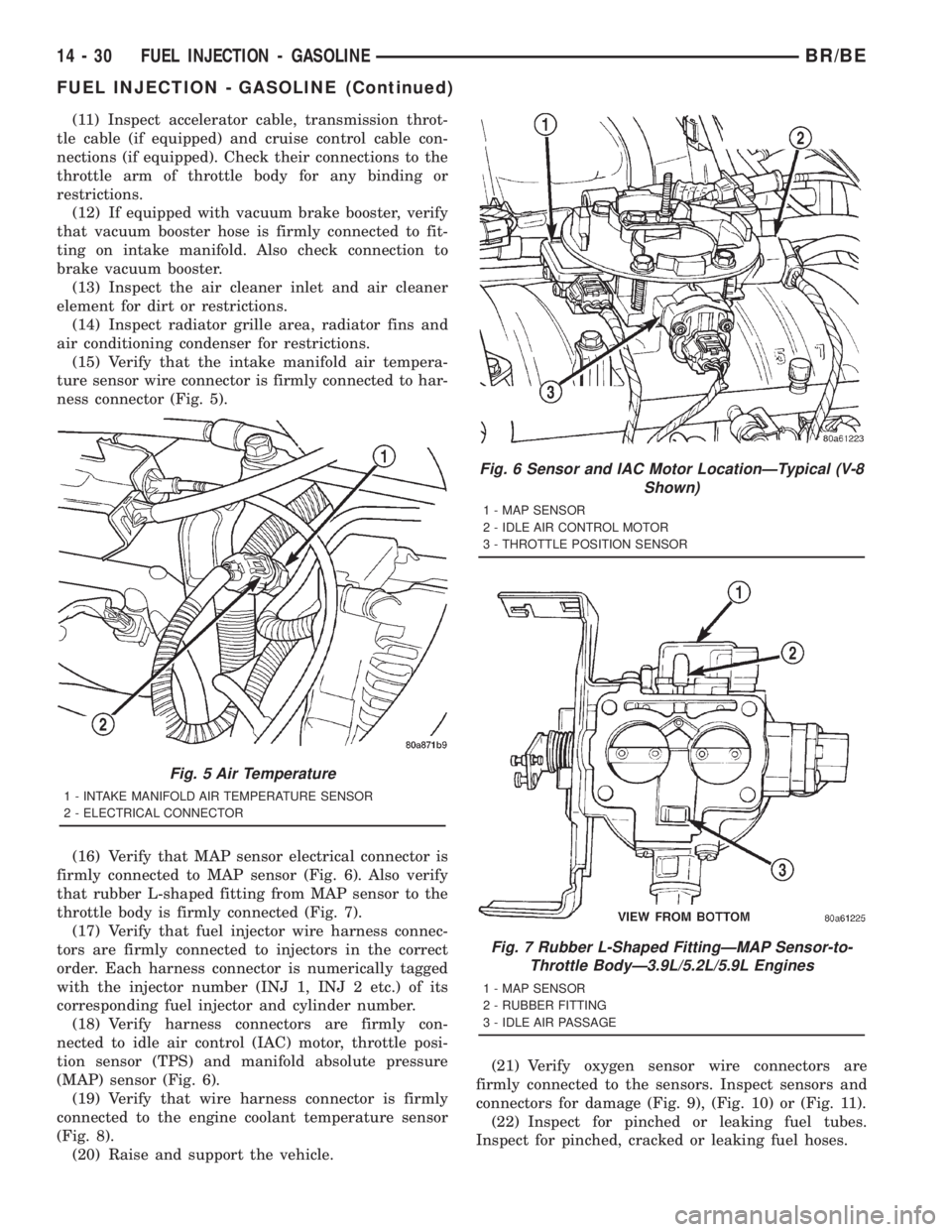

(15) Verify that the intake manifold air tempera-

ture sensor wire connector is firmly connected to har-

ness connector (Fig. 5).

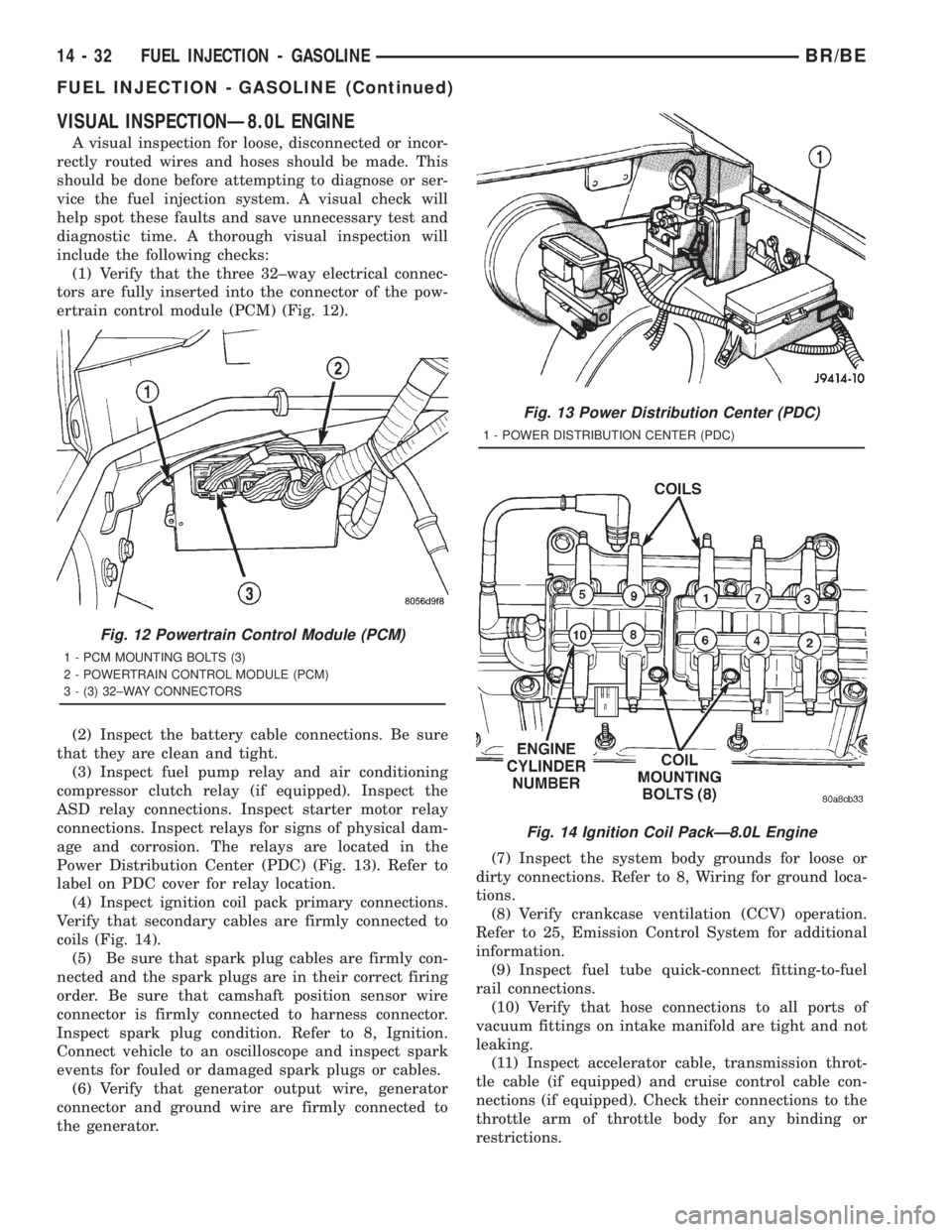

(16) Verify that MAP sensor electrical connector is

firmly connected to MAP sensor (Fig. 6). Also verify

that rubber L-shaped fitting from MAP sensor to the

throttle body is firmly connected (Fig. 7).

(17) Verify that fuel injector wire harness connec-

tors are firmly connected to injectors in the correct

order. Each harness connector is numerically tagged

with the injector number (INJ 1, INJ 2 etc.) of its

corresponding fuel injector and cylinder number.

(18) Verify harness connectors are firmly con-

nected to idle air control (IAC) motor, throttle posi-

tion sensor (TPS) and manifold absolute pressure

(MAP) sensor (Fig. 6).

(19) Verify that wire harness connector is firmly

connected to the engine coolant temperature sensor

(Fig. 8).

(20) Raise and support the vehicle.(21) Verify oxygen sensor wire connectors are

firmly connected to the sensors. Inspect sensors and

connectors for damage (Fig. 9), (Fig. 10) or (Fig. 11).

(22) Inspect for pinched or leaking fuel tubes.

Inspect for pinched, cracked or leaking fuel hoses.

Fig. 5 Air Temperature

1 - INTAKE MANIFOLD AIR TEMPERATURE SENSOR

2 - ELECTRICAL CONNECTOR

Fig. 6 Sensor and IAC Motor LocationÐTypical (V-8

Shown)

1 - MAP SENSOR

2 - IDLE AIR CONTROL MOTOR

3 - THROTTLE POSITION SENSOR

Fig. 7 Rubber L-Shaped FittingÐMAP Sensor-to-

Throttle BodyÐ3.9L/5.2L/5.9L Engines

1 - MAP SENSOR

2 - RUBBER FITTING

3 - IDLE AIR PASSAGE

14 - 30 FUEL INJECTION - GASOLINEBR/BE

FUEL INJECTION - GASOLINE (Continued)

Page 1519 of 2889

VISUAL INSPECTIONÐ8.0L ENGINE

A visual inspection for loose, disconnected or incor-

rectly routed wires and hoses should be made. This

should be done before attempting to diagnose or ser-

vice the fuel injection system. A visual check will

help spot these faults and save unnecessary test and

diagnostic time. A thorough visual inspection will

include the following checks:

(1) Verify that the three 32±way electrical connec-

tors are fully inserted into the connector of the pow-

ertrain control module (PCM) (Fig. 12).

(2) Inspect the battery cable connections. Be sure

that they are clean and tight.

(3) Inspect fuel pump relay and air conditioning

compressor clutch relay (if equipped). Inspect the

ASD relay connections. Inspect starter motor relay

connections. Inspect relays for signs of physical dam-

age and corrosion. The relays are located in the

Power Distribution Center (PDC) (Fig. 13). Refer to

label on PDC cover for relay location.

(4) Inspect ignition coil pack primary connections.

Verify that secondary cables are firmly connected to

coils (Fig. 14).

(5) Be sure that spark plug cables are firmly con-

nected and the spark plugs are in their correct firing

order. Be sure that camshaft position sensor wire

connector is firmly connected to harness connector.

Inspect spark plug condition. Refer to 8, Ignition.

Connect vehicle to an oscilloscope and inspect spark

events for fouled or damaged spark plugs or cables.

(6) Verify that generator output wire, generator

connector and ground wire are firmly connected to

the generator.(7) Inspect the system body grounds for loose or

dirty connections. Refer to 8, Wiring for ground loca-

tions.

(8) Verify crankcase ventilation (CCV) operation.

Refer to 25, Emission Control System for additional

information.

(9) Inspect fuel tube quick-connect fitting-to-fuel

rail connections.

(10) Verify that hose connections to all ports of

vacuum fittings on intake manifold are tight and not

leaking.

(11) Inspect accelerator cable, transmission throt-

tle cable (if equipped) and cruise control cable con-

nections (if equipped). Check their connections to the

throttle arm of throttle body for any binding or

restrictions.

Fig. 12 Powertrain Control Module (PCM)

1 - PCM MOUNTING BOLTS (3)

2 - POWERTRAIN CONTROL MODULE (PCM)

3 - (3) 32±WAY CONNECTORS

Fig. 13 Power Distribution Center (PDC)

1 - POWER DISTRIBUTION CENTER (PDC)

Fig. 14 Ignition Coil PackÐ8.0L Engine

14 - 32 FUEL INJECTION - GASOLINEBR/BE

FUEL INJECTION - GASOLINE (Continued)

Page 2865 of 2889

HORN RELAY - DIAGNOSIS AND

TESTING............................8H-3

HORN RELAY - OPERATION.............8H-3

HORN SWITCH - DESCRIPTION..........8H-4

HORN SWITCH - DIAGNOSIS AND

TESTING............................8H-5

HORN SWITCH - OPERATION............8H-5

HOSE - OPERATION, CRANKCASE VENT . . . 25-32

HOSE CLAMPS - DESCRIPTION...........7-2

HOSE CLAMPS - OPERATION.............7-2

HOSE WITH AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-77

HOSE WITH AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-74

HOSE WITHOUT AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-78

HOSE WITHOUT AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-77

HOSES - PRESSURE - DESCRIPTION.....19-37

HOSES - PRESSURE - OPERATION.......19-37

HOSES - RETURN - DESCRIPTION.......19-37

HOSES - RETURN - OPERATION.........19-37

HOSES/LINES/TUBES PRECAUTIONS -

CAUTION, REFRIGERANT..............24-42

HOSES/TUBES - DESCRIPTION, WASHER . . 8R-8

HOSES/TUBES - OPERATION, WASHER....8R-8

HOUSING - ASSEMBLY, HVAC...........24-36

HOUSING - DIAGNOSIS AND TESTING,

CLUTCH.............................6-11

HOUSING - DISASSEMBLY, HVAC........24-36

HOUSING - INSTALLATION, CLUTCH......6-13

HOUSING - INSTALLATION, GEAR........9-305

HOUSING - INSTALLATION, HVAC........24-37

HOUSING - INSTALLATION, LOCK

CYLINDER..........................19-11

HOUSING - REMOVAL, CLUTCH..........6-13

HOUSING - REMOVAL, GEAR...........9-304

HOUSING - REMOVAL, HVAC...........24-35

HOUSING - REMOVAL, LOCK CYLINDER . . 19-10

HOUSING BUSHING - INSTALLATION,

EXTENSION......21-198,21-369,21-544,21-714

HOUSING BUSHING - REMOVAL,

EXTENSION......21-198,21-369,21-544,21-714

HOUSING BUSHING AND SEAL -

INSTALLATION, EXTENSION.....21-850,21-885,

21-921

HOUSING BUSHING AND SEAL -

REMOVAL, EXTENSION . . . 21-850,21-885,21-921

HOUSING COVER - INSTALLATION, GEAR . 9-307

HOUSING COVER - REMOVAL, GEAR.....9-306

HOUSING FLUID LEAK - DIAGNOSIS AND

TESTING, CONVERTER . . . 21-148,21-319,21-491,

21-662

HOUSING INLET BAFFLE -

INSTALLATION, HVAC.................24-37

HOUSING INLET BAFFLE - REMOVAL,

HVAC..............................24-36

HOUSING PLUG - INSTALLATION,

STEERING GEAR.....................19-27

HOUSING PLUG - REMOVAL, STEERING

GEAR..............................19-27

HOUSING SEAL - INSTALLATION,

ADAPTER.....................21-132,21-87

HOUSING SEAL - INSTALLATION,

EXTENSION......21-132,21-198,21-369,21-544,

21-715,21-87

HOUSING SEAL - REMOVAL, ADAPTER . . 21-132,

21-87

HOUSING SEAL - REMOVAL,

EXTENSION......21-132,21-198,21-369,21-544,

21-714,21-87

HOW TO USE WIRING DIAGRAMS -

DESCRIPTION.....................8W-01-1

H.P. - DESCRIPTION, FUEL PUMP 235....14-66

H.P. - DESCRIPTION, FUEL PUMP 245....14-65

HUB / BEARING - INSTALLATION..........2-9

HUB / BEARING - REMOVAL..............2-9

HVAC HOUSING - ASSEMBLY...........24-36

HVAC HOUSING - DISASSEMBLY........24-36

HVAC HOUSING - INSTALLATION........24-37

HVAC HOUSING - REMOVAL

............24-35

HVAC HOUSING INLET BAFFLE -

INSTALLATION

.......................24-37

HVAC HOUSING INLET BAFFLE -

REMOVAL

..........................24-36

HVAC SYSTEM AIRFLOW - DESCRIPTION

. 24-31

HYDRAULIC BOOSTER - DIAGNOSIS

AND TESTING

........................5-17HYDRAULIC LIFTERS - CLEANING . . 9-152,9-208

HYDRAULIC LIFTERS - INSTALLATION . . . 9-152,

9-208

HYDRAULIC LIFTERS - REMOVAL . . . 9-152,9-207

HYDRAULIC LIFTERS (CAM IN BLOCK) -

CLEANING.......................9-39,9-96

HYDRAULIC LIFTERS (CAM IN BLOCK) -

INSTALLATION....................9-39,9-96

HYDRAULIC LIFTERS (CAM IN BLOCK) -

REMOVAL.......................9-39,9-96

HYDRAULIC PRESSURE TEST -

DIAGNOSIS AND TESTING......21-144,21-315,

21-487,21-658

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS . . 21-174,21-345,21-520,21-690

HYDRAULIC TAPPETS - DIAGNOSIS AND

TESTING..............9-151,9-206,9-38,9-95

HYDRAULIC/MECHANICAL -

DESCRIPTION.........................5-4

HYDRAULIC/MECHANICAL - WARNING.....5-5

HYDROMETER TEST - STANDARD

PROCEDURE........................8F-12

HYDROSTATIC LOCK - STANDARD

PROCEDURE......9-11,9-125,9-181,9-238,9-68

IDENTIFICATION - DESCRIPTION,

FASTENER.........................Intro.-3

IDENTIFICATION LAMP - INSTALLATION,

OUTBOARD.........................8L-29

IDENTIFICATION LAMP - REMOVAL,

OUTBOARD.........................8L-28

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE.............Intro.-10

IDENTIFICATION PLATE - DESCRIPTION,

EQUIPMENT......................Intro.-12

IDLE AIR CONTROL MOTOR -

DESCRIPTION.......................14-41

IDLE AIR CONTROL MOTOR -

OPERATION.........................14-41

I.F.S. - STANDARD PROCEDURES,

ALIGNMENT...........................2-2

IGNITION - SPECIFICATIONS, TORQUE.....8I-2

IGNITION CIRCUIT SENSE -

DESCRIPTION.......................8E-17

IGNITION CIRCUIT SENSE - OPERATION . . 8E-19

IGNITION COIL RESISTANCE, 3.9L/5.2L/

5.9L ENGINES........................8I-3

IGNITION COIL RESISTANCE, 8.0L V-10

ENGINE..............................8I-3

IGNITION SWITCH - DESCRIPTION.......19-11

IGNITION SWITCH - DESCRIPTION,

KEY-IN..............................19-9

IGNITION SWITCH - DIAGNOSIS AND

TESTING...........................19-11

IGNITION SWITCH - INSTALLATION......19-12

IGNITION SWITCH - OPERATION........19-11

IGNITION SWITCH - REMOVAL..........19-12

IGNITION SWITCH AND KEY LOCK

CYLINDER - DIAGNOSIS AND TESTING . . . 19-10

IGNITION TIMING, SPECIFICATIONS.......8I-3

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE........................8F-15

IMPORTANCE OF CAREFUL NEW

VEHICLE PREPARATION -

DESCRIPTION, THE....................30-1

INCH - INSTALLATION, 12 1/8...........5-28

INCH - INSTALLATION, REAR BRAKE

SHOES-11...........................5-27

INCH - REMOVAL, 12 1/8...............5-26

INCH - REMOVAL, REAR BRAKE

SHOES-11...........................5-25

INCORRECT FLUID LEVEL - DIAGNOSIS

AND TESTING, EFFECTS OF.....21-199,21-370,

21-545,21-715

INDEPENDENT FRONT SUSPENSION,

SPECIAL TOOLS.......................2-9

INDICATOR - DESCRIPTION, ABS........8J-14

INDICATOR - DESCRIPTION, AIRBAG.....8J-15

INDICATOR - DESCRIPTION, BRAKE/

PARK BRAKE........................8J-16

INDICATOR - DESCRIPTION, CHECK

GAUGES............................8J-17

INDICATOR - DESCRIPTION, CRUISE

.....8J-18

INDICATOR - DESCRIPTION, GEAR

SELECTOR

..........................8J-21

INDICATOR - DESCRIPTION, HIGH BEAM

. . 8J-21

INDICATOR - DESCRIPTION, LOW FUEL

. . . 8J-23

INDICATOR - DESCRIPTION, OVERDRIVE

OFF

...............................8J-27INDICATOR - DESCRIPTION, SEATBELT . . . 8J-27

INDICATOR - DESCRIPTION, SERVICE

REMINDER..........................8J-28

INDICATOR - DESCRIPTION,

TRANSMISSION OVERTEMP............8J-31

INDICATOR - DESCRIPTION, UPSHIFT....8J-33

INDICATOR - DESCRIPTION, VTSS........8Q-3

INDICATOR - DESCRIPTION, WAIT-TO-

START .............................8J-34

INDICATOR - DESCRIPTION, WASHER

FLUID..............................8J-35

INDICATOR - DESCRIPTION, WATER-IN-

FUEL..............................8J-36

INDICATOR - DIAGNOSIS AND TESTING,

BRAKE.............................8J-16

INDICATOR - DIAGNOSIS AND TESTING,

FOUR-WHEEL DRIVE..................8J-29

INDICATOR - DIAGNOSIS AND TESTING,

HIGH BEAM.........................8J-22

INDICATOR - DIAGNOSIS AND TESTING,

VTSS...............................8Q-3

INDICATOR - DIAGNOSIS AND TESTING,

WASHER FLUID......................8J-36

INDICATOR - OPERATION, ABS..........8J-14

INDICATOR - OPERATION, AIRBAG.......8J-15

INDICATOR - OPERATION, BRAKE/PARK

BRAKE.............................8J-16

INDICATOR - OPERATION, CHECK

GAUGES............................8J-17

INDICATOR - OPERATION, CRUISE.......8J-18

INDICATOR - OPERATION, GEAR

SELECTOR...........................8J-21

INDICATOR - OPERATION, HIGH BEAM....8J-22

INDICATOR - OPERATION, LOW FUEL.....8J-23

INDICATOR - OPERATION, OVERDRIVE

OFF ...............................8J-27

INDICATOR - OPERATION, SEATBELT.....8J-27

INDICATOR - OPERATION, SERVICE

REMINDER..........................8J-28

INDICATOR - OPERATION,

TRANSMISSION OVERTEMP............8J-31

INDICATOR - OPERATION, UPSHIFT......8J-33

INDICATOR - OPERATION, VTSS.........8Q-3

INDICATOR - OPERATION, WAIT-TO-

START .............................8J-35

INDICATOR - OPERATION, WASHER

FLUID..............................8J-35

INDICATOR - OPERATION, WATER-IN-

FUEL..............................8J-37

INDICATOR LAMP (MIL) - DESCRIPTION,

MALFUNCTION.......................8J-24

INDICATOR LAMP (MIL) - OPERATION,

MALFUNCTION.......................8J-24

INDICATOR TEST - STANDARD

PROCEDURE, BUILT-IN................8F-11

INDICATOR (TRANSFER CASE) -

DESCRIPTION, SHIFT.................8J-29

INDICATOR (TRANSFER CASE) -

OPERATION, SHIFT...................8J-29

INDICATORS - DESCRIPTION, TURN

SIGNAL............................8J-32

INDICATORS - DIAGNOSIS AND

TESTING, TREAD WEAR................22-7

INDICATORS - DIAGNOSIS AND

TESTING, TURN SIGNAL...............8J-32

INDICATORS - OPERATION, TURN

SIGNAL............................8J-32

INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING

PUMP

.............................19-31

INJECTION - SPECIFICATIONS, TORQUE -

GAS FUEL

..........................14-35

INJECTION PUMP - DESCRIPTION, AIR

. . . 25-28

INJECTION PUMP - DIAGNOSIS AND

TESTING, AIR

.......................25-28

INJECTION PUMP - INSTALLATION, AIR

. . . 25-29

INJECTION PUMP - INSTALLATION, FUEL

. 14-71

INJECTION PUMP - OPERATION, AIR

.....25-28

INJECTION PUMP - OPERATION, FUEL

....14-66

INJECTION PUMP - REMOVAL, AIR

......25-29

INJECTION PUMP - REMOVAL, FUEL

.....14-68

INJECTION PUMP DATA PLATE,

SPECIFICATIONS - FUEL

...............14-73

INJECTION PUMP RELAY -

DESCRIPTION, FUEL

..................14-99

INJECTION PUMP RELAY - OPERATION,

FUEL

..............................14-99

18 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page