mirror DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 489 of 2889

(4) Clean the battery cable terminal clamps and

the battery terminal posts. Refer toBattery System

in this group for the location of the proper battery

system cleaning and inspection procedures.

(5) Reconnect the battery positive cable terminal

clamp to the battery positive terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 4 N´m (35

in. lbs.).

(6) Reconnect the battery negative cable terminal

clamp to the battery negative terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 4 N´m (35

in. lbs.).

(7) Apply a thin coating of petroleum jelly or chas-

sis grease to the exposed surfaces of the battery cable

terminal clamps and the battery terminal posts.

BATTERY HOLDDOWN

DESCRIPTION

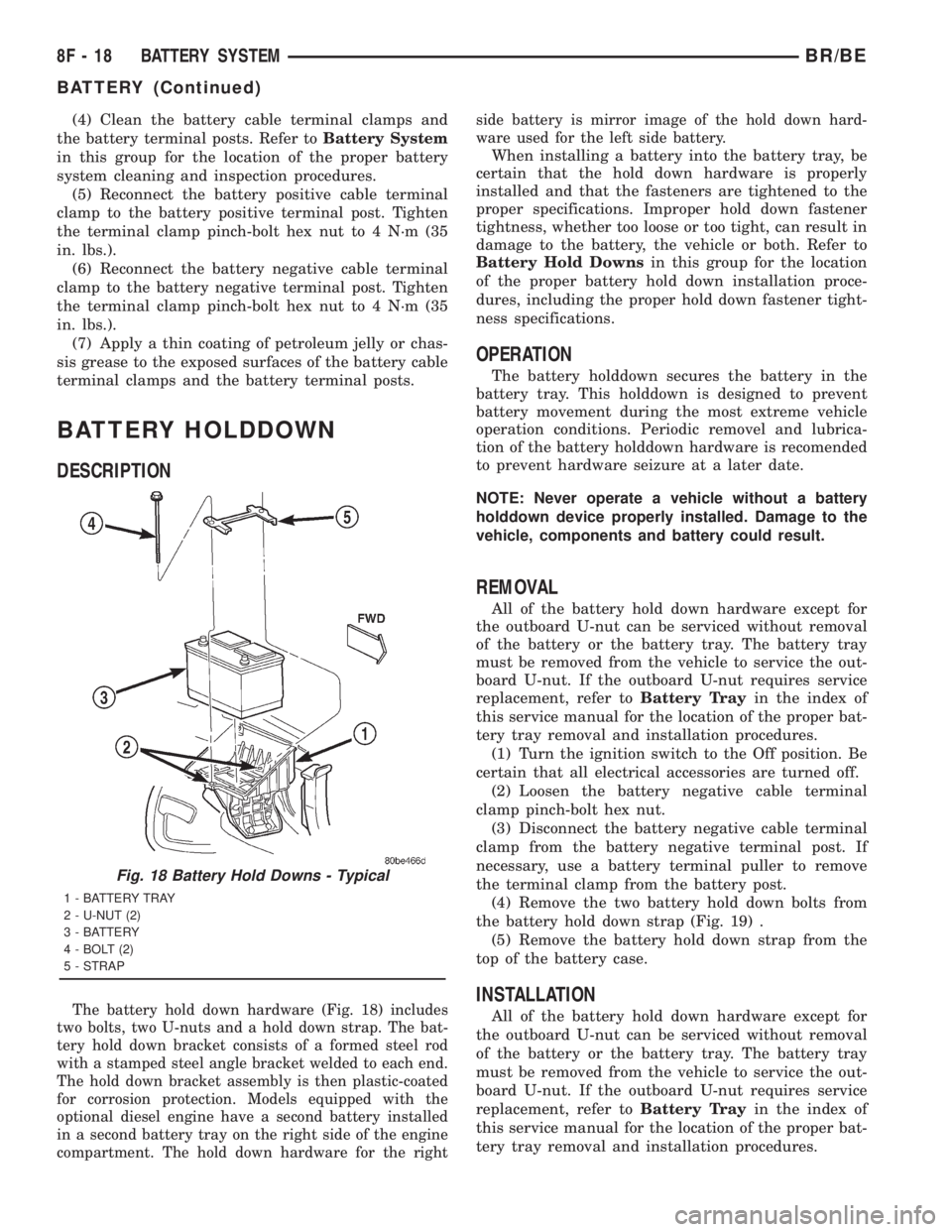

The battery hold down hardware (Fig. 18) includes

two bolts, two U-nuts and a hold down strap. The bat-

tery hold down bracket consists of a formed steel rod

with a stamped steel angle bracket welded to each end.

The hold down bracket assembly is then plastic-coated

for corrosion protection. Models equipped with the

optional diesel engine have a second battery installed

in a second battery tray on the right side of the engine

compartment. The hold down hardware for the rightside battery is mirror image of the hold down hard-

ware used for the left side battery.

When installing a battery into the battery tray, be

certain that the hold down hardware is properly

installed and that the fasteners are tightened to the

proper specifications. Improper hold down fastener

tightness, whether too loose or too tight, can result in

damage to the battery, the vehicle or both. Refer to

Battery Hold Downsin this group for the location

of the proper battery hold down installation proce-

dures, including the proper hold down fastener tight-

ness specifications.

OPERATION

The battery holddown secures the battery in the

battery tray. This holddown is designed to prevent

battery movement during the most extreme vehicle

operation conditions. Periodic removel and lubrica-

tion of the battery holddown hardware is recomended

to prevent hardware seizure at a later date.

NOTE: Never operate a vehicle without a battery

holddown device properly installed. Damage to the

vehicle, components and battery could result.

REMOVAL

All of the battery hold down hardware except for

the outboard U-nut can be serviced without removal

of the battery or the battery tray. The battery tray

must be removed from the vehicle to service the out-

board U-nut. If the outboard U-nut requires service

replacement, refer toBattery Trayin the index of

this service manual for the location of the proper bat-

tery tray removal and installation procedures.

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

(3) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post.

(4) Remove the two battery hold down bolts from

the battery hold down strap (Fig. 19) .

(5) Remove the battery hold down strap from the

top of the battery case.

INSTALLATION

All of the battery hold down hardware except for

the outboard U-nut can be serviced without removal

of the battery or the battery tray. The battery tray

must be removed from the vehicle to service the out-

board U-nut. If the outboard U-nut requires service

replacement, refer toBattery Trayin the index of

this service manual for the location of the proper bat-

tery tray removal and installation procedures.

Fig. 18 Battery Hold Downs - Typical

1 - BATTERY TRAY

2 - U-NUT (2)

3 - BATTERY

4 - BOLT (2)

5 - STRAP

8F - 18 BATTERY SYSTEMBR/BE

BATTERY (Continued)

Page 495 of 2889

NEGATIVE CABLE INSTALLATION - GASOLINE

(1) Position the battery wire harness into the

engine compartment and under the compressor

mounting bracket, if equipped.

(2) Install and tighten the nut that secures the

battery negative cable ground eyelet terminal to the

stud on the power steering pump pivot bolt.

(3) Install the generator output cable eyelet termi-

nal onto the generator output terminal stud.

(4) Install and tighten the nut that secures the

generator output cable eyelet terminal to the genera-

tor output terminal stud. Tighten the nut to 8.4 N´m

(75 in. lbs.).

(5) Position the cover for the generator output ter-

minal stud housing onto the back of the generator

and snap it into place.

(6) Secure wire assembly in place with pushpin

retainers in there original positions.

(7) Install and tighten the screw that secures the

battery negative cable eyelet terminal to the radiator

closure panel, near the battery. Tighten the screw to

40 in. lbs.

(8) Install and tighten the screw that secures the

battery negative cable eyelet terminal to the left

front side of the frame assembly. Tighten the screw

to 80 in. lbs.

(9) Install and tighten the nut that secures the

battery positive cable eyelet terminal and the gener-

ator output cable eyelet terminal to the PDC B(+)

terminal stud. Tighten the nut to 80 in. lbs.

(10) Reconnect the battery negative cable terminal

clamp to the battery negative terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 35 in. lbs.

(11)

Apply a thin coating of petroleum jelly or chassis

grease to the exposed surfaces of the battery cable ter-

minal clamps and the battery terminal posts.

BATTERY TRAY

DESCRIPTION

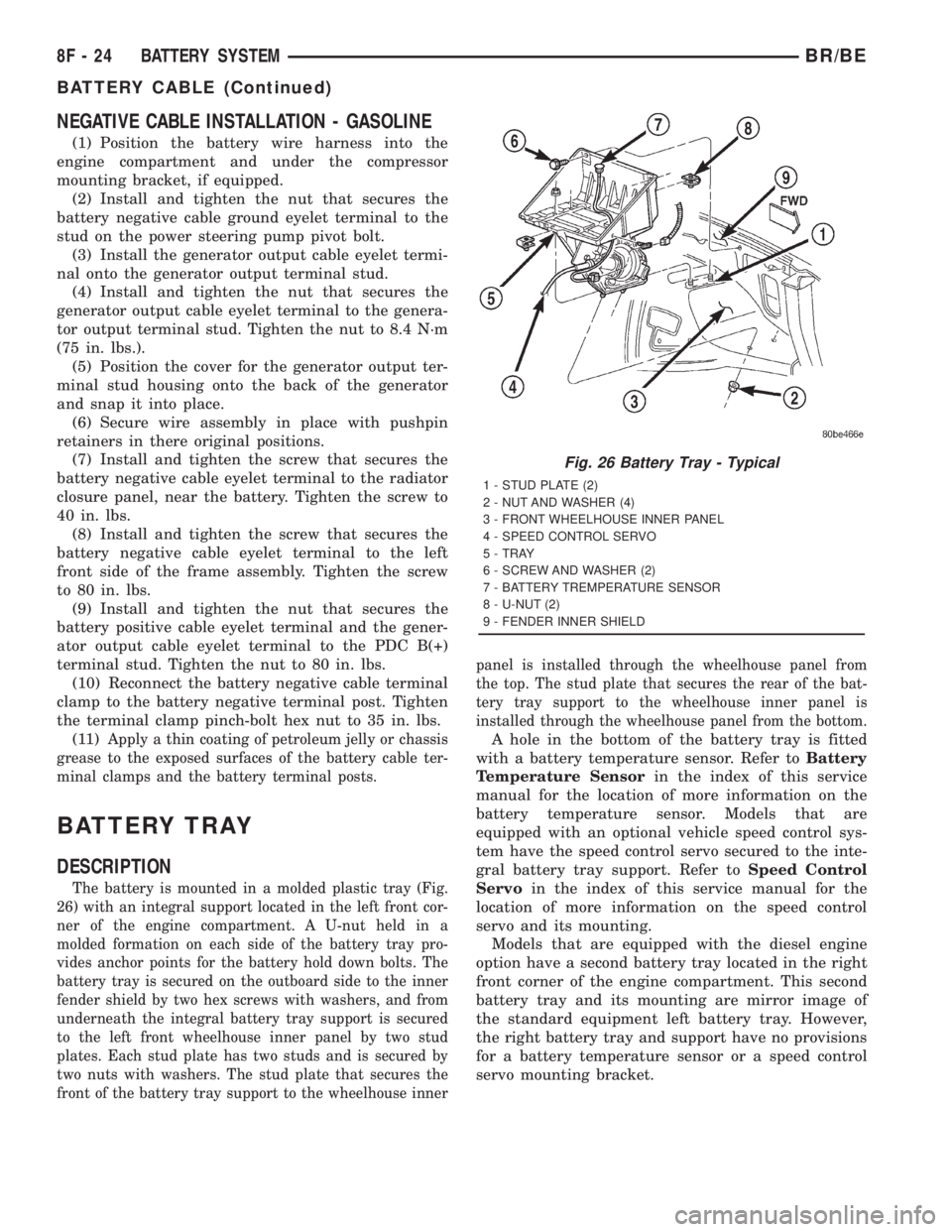

The battery is mounted in a molded plastic tray (Fig.

26) with an integral support located in the left front cor-

ner of the engine compartment. A U-nut held in a

molded formation on each side of the battery tray pro-

vides anchor points for the battery hold down bolts. The

battery tray is secured on the outboard side to the inner

fender shield by two hex screws with washers, and from

underneath the integral battery tray support is secured

to the left front wheelhouse inner panel by two stud

plates. Each stud plate has two studs and is secured by

two nuts with washers. The stud plate that secures the

front of the battery tray support to the wheelhouse innerpanel is installed through the wheelhouse panel from

the top. The stud plate that secures the rear of the bat-

tery tray support to the wheelhouse inner panel is

installed through the wheelhouse panel from the bottom.

A hole in the bottom of the battery tray is fitted

with a battery temperature sensor. Refer toBattery

Temperature Sensorin the index of this service

manual for the location of more information on the

battery temperature sensor. Models that are

equipped with an optional vehicle speed control sys-

tem have the speed control servo secured to the inte-

gral battery tray support. Refer toSpeed Control

Servoin the index of this service manual for the

location of more information on the speed control

servo and its mounting.

Models that are equipped with the diesel engine

option have a second battery tray located in the right

front corner of the engine compartment. This second

battery tray and its mounting are mirror image of

the standard equipment left battery tray. However,

the right battery tray and support have no provisions

for a battery temperature sensor or a speed control

servo mounting bracket.

Fig. 26 Battery Tray - Typical

1 - STUD PLATE (2)

2 - NUT AND WASHER (4)

3 - FRONT WHEELHOUSE INNER PANEL

4 - SPEED CONTROL SERVO

5 - TRAY

6 - SCREW AND WASHER (2)

7 - BATTERY TREMPERATURE SENSOR

8 - U-NUT (2)

9 - FENDER INNER SHIELD

8F - 24 BATTERY SYSTEMBR/BE

BATTERY CABLE (Continued)

Page 516 of 2889

HEATED SYSTEMS

TABLE OF CONTENTS

page page

HEATED MIRRORS......................... 1 HEATED SEATSYSTEM..................... 5

HEATED MIRRORS

TABLE OF CONTENTS

page page

HEATED MIRRORS

DESCRIPTION............................1

OPERATION.............................2

DIAGNOSIS AND TESTING..................2

HEATED MIRROR SYSTEM................2

MIRROR SWITCH

DESCRIPTION............................3

OPERATION.............................3DIAGNOSIS AND TESTING..................3

HEATED MIRROR SWITCH................3

HEATED MIRROR GRID

DESCRIPTION............................4

OPERATION.............................4

DIAGNOSIS AND TESTING..................0

HEATED MIRROR GRID...................4

HEATED MIRRORS

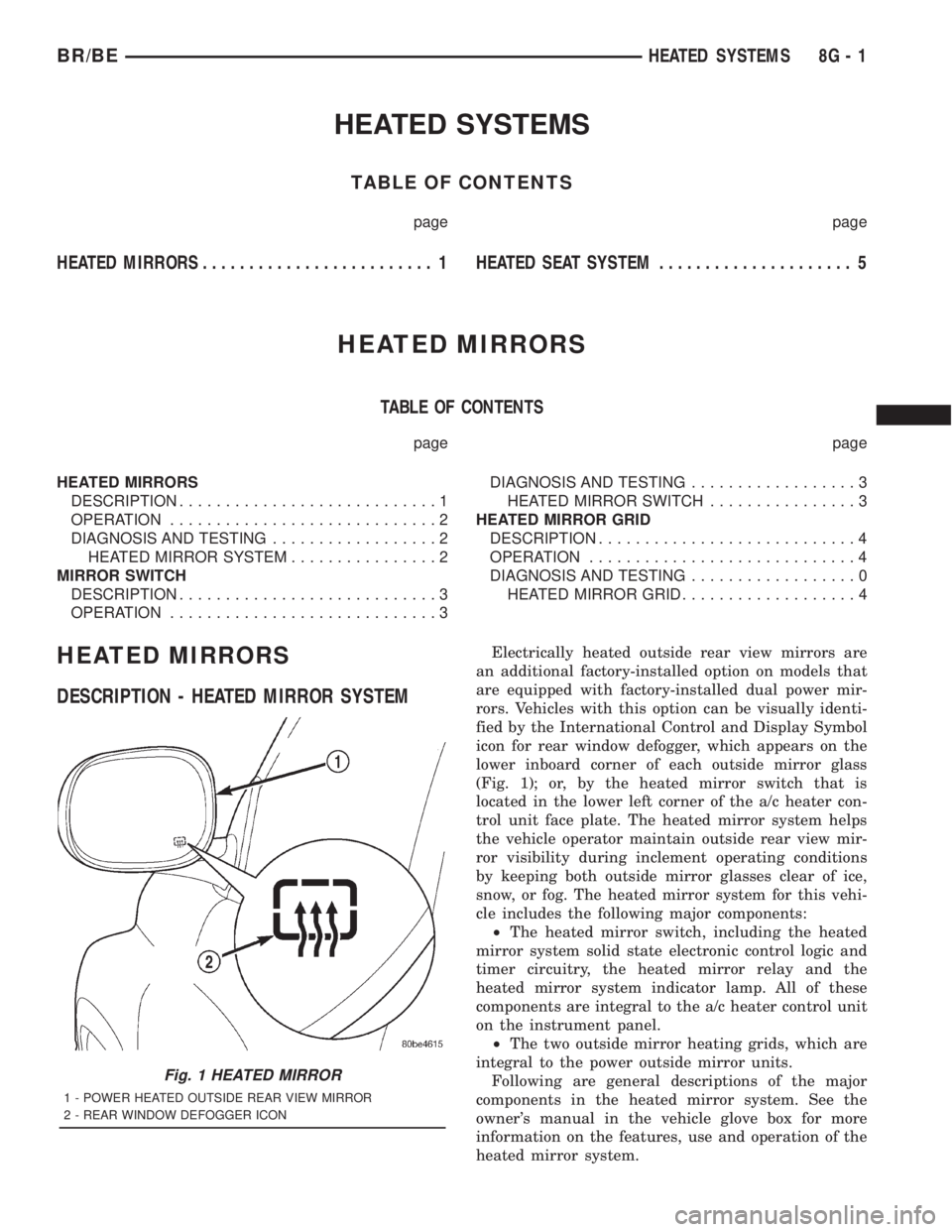

DESCRIPTION - HEATED MIRROR SYSTEM

Electrically heated outside rear view mirrors are

an additional factory-installed option on models that

are equipped with factory-installed dual power mir-

rors. Vehicles with this option can be visually identi-

fied by the International Control and Display Symbol

icon for rear window defogger, which appears on the

lower inboard corner of each outside mirror glass

(Fig. 1); or, by the heated mirror switch that is

located in the lower left corner of the a/c heater con-

trol unit face plate. The heated mirror system helps

the vehicle operator maintain outside rear view mir-

ror visibility during inclement operating conditions

by keeping both outside mirror glasses clear of ice,

snow, or fog. The heated mirror system for this vehi-

cle includes the following major components:

²The heated mirror switch, including the heated

mirror system solid state electronic control logic and

timer circuitry, the heated mirror relay and the

heated mirror system indicator lamp. All of these

components are integral to the a/c heater control unit

on the instrument panel.

²The two outside mirror heating grids, which are

integral to the power outside mirror units.

Following are general descriptions of the major

components in the heated mirror system. See the

owner's manual in the vehicle glove box for more

information on the features, use and operation of the

heated mirror system.

Fig. 1 HEATED MIRROR

1 - POWER HEATED OUTSIDE REAR VIEW MIRROR

2 - REAR WINDOW DEFOGGER ICON

BR/BEHEATED SYSTEMS 8G - 1

Page 517 of 2889

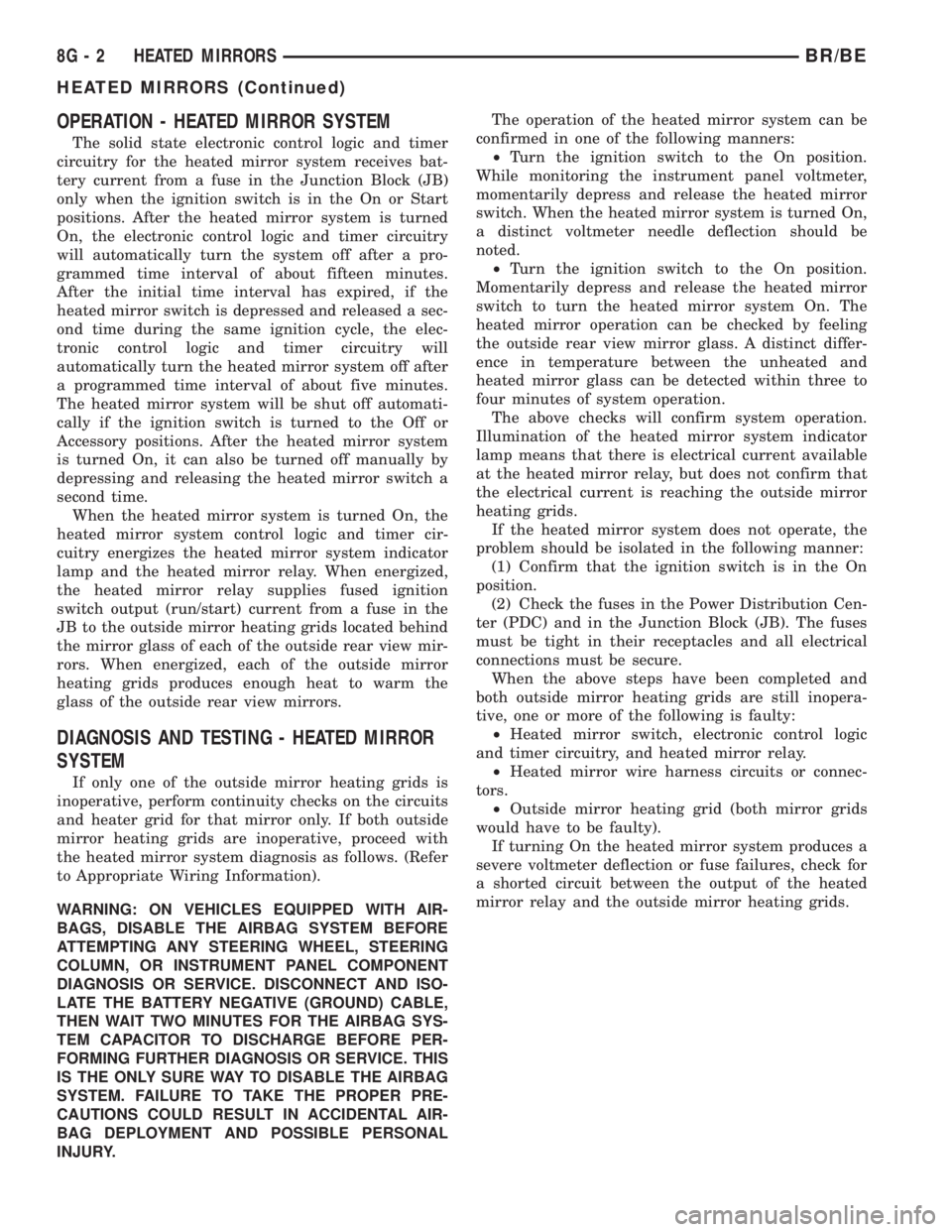

OPERATION - HEATED MIRROR SYSTEM

The solid state electronic control logic and timer

circuitry for the heated mirror system receives bat-

tery current from a fuse in the Junction Block (JB)

only when the ignition switch is in the On or Start

positions. After the heated mirror system is turned

On, the electronic control logic and timer circuitry

will automatically turn the system off after a pro-

grammed time interval of about fifteen minutes.

After the initial time interval has expired, if the

heated mirror switch is depressed and released a sec-

ond time during the same ignition cycle, the elec-

tronic control logic and timer circuitry will

automatically turn the heated mirror system off after

a programmed time interval of about five minutes.

The heated mirror system will be shut off automati-

cally if the ignition switch is turned to the Off or

Accessory positions. After the heated mirror system

is turned On, it can also be turned off manually by

depressing and releasing the heated mirror switch a

second time.

When the heated mirror system is turned On, the

heated mirror system control logic and timer cir-

cuitry energizes the heated mirror system indicator

lamp and the heated mirror relay. When energized,

the heated mirror relay supplies fused ignition

switch output (run/start) current from a fuse in the

JB to the outside mirror heating grids located behind

the mirror glass of each of the outside rear view mir-

rors. When energized, each of the outside mirror

heating grids produces enough heat to warm the

glass of the outside rear view mirrors.

DIAGNOSIS AND TESTING - HEATED MIRROR

SYSTEM

If only one of the outside mirror heating grids is

inoperative, perform continuity checks on the circuits

and heater grid for that mirror only. If both outside

mirror heating grids are inoperative, proceed with

the heated mirror system diagnosis as follows. (Refer

to Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.The operation of the heated mirror system can be

confirmed in one of the following manners:

²Turn the ignition switch to the On position.

While monitoring the instrument panel voltmeter,

momentarily depress and release the heated mirror

switch. When the heated mirror system is turned On,

a distinct voltmeter needle deflection should be

noted.

²Turn the ignition switch to the On position.

Momentarily depress and release the heated mirror

switch to turn the heated mirror system On. The

heated mirror operation can be checked by feeling

the outside rear view mirror glass. A distinct differ-

ence in temperature between the unheated and

heated mirror glass can be detected within three to

four minutes of system operation.

The above checks will confirm system operation.

Illumination of the heated mirror system indicator

lamp means that there is electrical current available

at the heated mirror relay, but does not confirm that

the electrical current is reaching the outside mirror

heating grids.

If the heated mirror system does not operate, the

problem should be isolated in the following manner:

(1) Confirm that the ignition switch is in the On

position.

(2) Check the fuses in the Power Distribution Cen-

ter (PDC) and in the Junction Block (JB). The fuses

must be tight in their receptacles and all electrical

connections must be secure.

When the above steps have been completed and

both outside mirror heating grids are still inopera-

tive, one or more of the following is faulty:

²Heated mirror switch, electronic control logic

and timer circuitry, and heated mirror relay.

²Heated mirror wire harness circuits or connec-

tors.

²Outside mirror heating grid (both mirror grids

would have to be faulty).

If turning On the heated mirror system produces a

severe voltmeter deflection or fuse failures, check for

a shorted circuit between the output of the heated

mirror relay and the outside mirror heating grids.

8G - 2 HEATED MIRRORSBR/BE

HEATED MIRRORS (Continued)

Page 518 of 2889

MIRROR SWITCH

DESCRIPTION

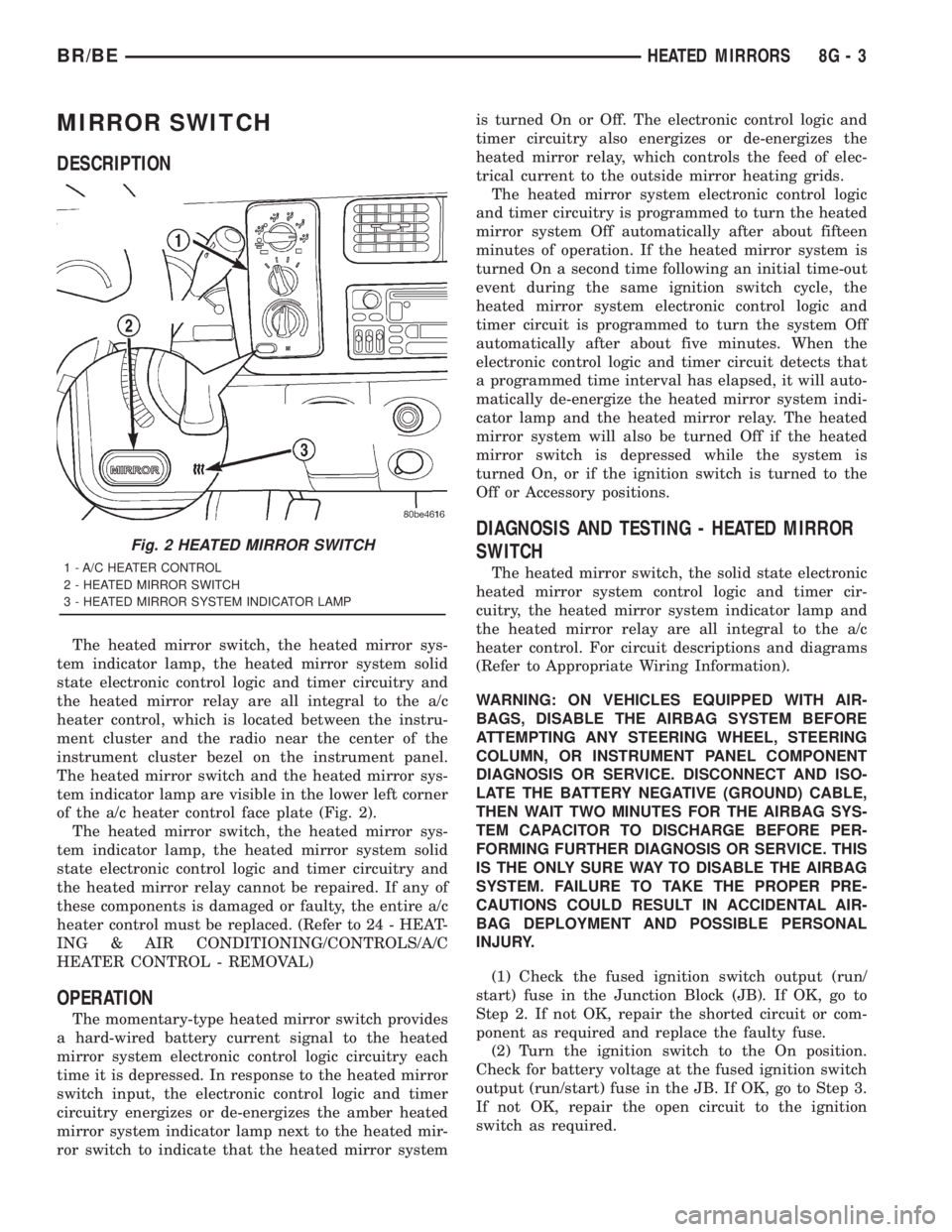

The heated mirror switch, the heated mirror sys-

tem indicator lamp, the heated mirror system solid

state electronic control logic and timer circuitry and

the heated mirror relay are all integral to the a/c

heater control, which is located between the instru-

ment cluster and the radio near the center of the

instrument cluster bezel on the instrument panel.

The heated mirror switch and the heated mirror sys-

tem indicator lamp are visible in the lower left corner

of the a/c heater control face plate (Fig. 2).

The heated mirror switch, the heated mirror sys-

tem indicator lamp, the heated mirror system solid

state electronic control logic and timer circuitry and

the heated mirror relay cannot be repaired. If any of

these components is damaged or faulty, the entire a/c

heater control must be replaced. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/CONTROLS/A/C

HEATER CONTROL - REMOVAL)

OPERATION

The momentary-type heated mirror switch provides

a hard-wired battery current signal to the heated

mirror system electronic control logic circuitry each

time it is depressed. In response to the heated mirror

switch input, the electronic control logic and timer

circuitry energizes or de-energizes the amber heated

mirror system indicator lamp next to the heated mir-

ror switch to indicate that the heated mirror systemis turned On or Off. The electronic control logic and

timer circuitry also energizes or de-energizes the

heated mirror relay, which controls the feed of elec-

trical current to the outside mirror heating grids.

The heated mirror system electronic control logic

and timer circuitry is programmed to turn the heated

mirror system Off automatically after about fifteen

minutes of operation. If the heated mirror system is

turned On a second time following an initial time-out

event during the same ignition switch cycle, the

heated mirror system electronic control logic and

timer circuit is programmed to turn the system Off

automatically after about five minutes. When the

electronic control logic and timer circuit detects that

a programmed time interval has elapsed, it will auto-

matically de-energize the heated mirror system indi-

cator lamp and the heated mirror relay. The heated

mirror system will also be turned Off if the heated

mirror switch is depressed while the system is

turned On, or if the ignition switch is turned to the

Off or Accessory positions.

DIAGNOSIS AND TESTING - HEATED MIRROR

SWITCH

The heated mirror switch, the solid state electronic

heated mirror system control logic and timer cir-

cuitry, the heated mirror system indicator lamp and

the heated mirror relay are all integral to the a/c

heater control. For circuit descriptions and diagrams

(Refer to Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check the fused ignition switch output (run/

start) fuse in the Junction Block (JB). If OK, go to

Step 2. If not OK, repair the shorted circuit or com-

ponent as required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the JB. If OK, go to Step 3.

If not OK, repair the open circuit to the ignition

switch as required.

Fig. 2 HEATED MIRROR SWITCH

1 - A/C HEATER CONTROL

2 - HEATED MIRROR SWITCH

3 - HEATED MIRROR SYSTEM INDICATOR LAMP

BR/BEHEATED MIRRORS 8G - 3

Page 519 of 2889

(3) Disconnect and isolate the battery negative

cable. Disconnect the 3-way instrument panel wire

harness connector for the heated mirror switch from

the heated mirror switch connector receptacle on the

back of the a/c heater control. Check for continuity

between the ground circuit cavity of the wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run/start)

circuit cavity of the 3-way instrument panel wire

harness connector for the heated mirror switch. If

OK, go to Step 5. If not OK, repair the open fused

ignition switch output (run/start) circuit to the fuse

in the JB as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Reconnect the 3-way instrument panel wire harness

connector for the heated mirror switch to the heated

mirror switch connector receptacle on the back of the

a/c heater control. Reconnect the battery negative

cable. Turn the ignition switch to the On position.

Depress and release the heated mirror switch. The

amber heated mirror system indicator lamp next to

the heated mirror switch button should light. If OK,

go to Step 6. If not OK, replace the faulty a/c heater

control.

(6) Back probe the fused heated mirror relay out-

put circuit cavity of the 3-way instrument panel wire

harness connector for the heated mirror switch on

the back of the a/c heater control and check for volt-

age (battery voltage less the resistance in both out-

side mirror heating grids). If OK, (Refer to 8 -

ELECTRICAL/HEATED MIRRORS/HEATED MIR-

ROR GRID - DIAGNOSIS AND TESTING).

HEATED MIRROR GRID

DESCRIPTION

Vehicles equipped with the optional heated mirror

system have an electrically operated heating grid

located behind the mirror glass of each power oper-

ated outside rear view mirror. The outside mirror

heating grid consists of two thin laminations of plas-

tic that approximate the outer dimensions and shape

of the mirror glass. A single length of resistor wire

weaves in a back and forth pattern between, and is

held in place by the two thin laminations of plastic.

The two ends of the resistor wire terminate near the

inboard edge of the grid, where they are soldered to

the ground feed and battery current feed wires con-

tained in the power mirror wire harness. The heating

grid is then sandwiched between the back of themolded plastic mirror glass case and the mirror

glass, where it remains in direct contact with the

back of the mirror glass at all times.

The outside mirror heating grids cannot be

repaired and, if faulty or damaged, the entire outside

power mirror unit must be replaced. Refer to Power

Mirrors for the service procedures.

OPERATION

One end of the outside mirror heating grid resistor

wire is connected to a ground feed at all times

through a body ground screw located inside the left

rear corner of the truck cab. Battery current is

directed to the other end of the outside mirror heat-

ing grid resistor wire by the energized heated mirror

relay when the heated mirror switch is in the On

position. As electrical current passes through the

heating grid, the resistance of the wire in the heating

grid converts some of that electrical current into

heat. The heat produced by the heating grid is then

conducted through the back of the mirror glass to

help keep the glass clear of ice, snow or fog.

DIAGNOSIS AND TESTING - HEATED MIRROR

GRID

For circuit descriptions and diagrams (Refer to

Appropriate Wiring Information).

(1) Disconnect and isolate the battery negative

cable. Disconnect the door wire harness connector

from the power mirror wire harness connector at the

power mirror with the inoperative heating grid.

Check for continuity between the ground circuit cav-

ity in the door wire harness connector for the power

mirror and a good ground. If OK, go to Step 2. If not

OK, repair the open ground circuit to ground as

required.

(2) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Turn on the

heated mirror system. Check for voltage (battery

voltage less the resistance in the outside mirror heat-

ing grid that is still connected) at the fused heated

mirror relay output circuit cavity in the door wire

harness connector for the power mirror. If OK, go to

Step 3. If not OK, repair the open fused heated mir-

ror relay output circuit to the heater and air condi-

tioner control unit as required.

(3) Check the outside mirror heating grid by test-

ing for continuity between the ground circuit and the

fused heated mirror relay output circuit cavities in

the power mirror wire harness connector. There

should be continuity. If not OK, replace the faulty

power mirror. If OK, check the resistance through

the outside mirror heating grid. The correct resis-

tance should be from 10 to 16 ohms when measured

at an ambient temperature of 21É C (70É F). If not

OK, replace the faulty power mirror.

8G - 4 HEATED MIRRORSBR/BE

MIRROR SWITCH (Continued)

Page 630 of 2889

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS........................33

DOME LAMP

REMOVAL..............................33

INSTALLATION...........................33

DOOR AJAR SWITCH

DESCRIPTION...........................34

DIAGNOSIS AND TESTING.................34

DOOR AJAR SWITCH....................34

REMOVAL..............................35

INSTALLATION...........................35GLOVE BOX LAMP AND SWITCH

REMOVAL..............................35

INSTALLATION...........................35

READING LAMP

DESCRIPTION...........................36

OPERATION.............................36

REMOVAL..............................36

INSTALLATION...........................36

VANITY LAMP

REMOVAL..............................37

INSTALLATION...........................37

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS

LAMP BULB

A/C HEATER CONTROL 158

ASH RECEIVER 161

CIGAR LIGHTER 161

HEADLAMP SWITCH 158

HEATER CONTROL 158

INSTRUMENT CLUSTER PC194

RADIO ASC

AIRBAG HIGH LINE PC194

AIRBAG LOW LINE PC74

ANTI-LOCK BRAKE PC74

BATTERY VOLTAGE PC194

BRAKE WARNING PC194

CHECK ENGINE PC74

ENGINE OIL PRESSURE PC74

FOUR WHEEL DRIVE PC194

HIGH BEAM PC194

LOW FUEL PC194

LOW WASHER FLUID PC74

MAINTENANCE

REQUIREDPC74

MESSAGE CENTER PC194

SEAT BELT PC74

LAMP BULB

TURN SIGNAL PC194

UPSHIFT PC74

DOME 1004

GLOVE COMPARTMENT 1891

VANITY MIRROR LAMP P/N 6501966

DOME LAMP

REMOVAL

(1) Using a small flat blade, pry the left side (driv-

er's side) of the dome lamp lens downward from

dome lamp.

(2) Allow the lens to hang down (Fig. 1) , this will

disengage the right side of the lamp (passenger's

side) from the headliner.

(3) Pull the right side of the lamp down and slide

the lamp to the right (Fig. 2) .

(4) Separate the lamp from the headliner.

(5) Disengage dome lamp wire connector from body

wire harness.

(6) Separate dome lamp from vehicle.

INSTALLATION

(1) Position dome lamp at headliner.

(2) Connect dome lamp wire connector to body

wire harness.

(3) Position the left side of the lamp in the head-

liner opening and slide lamp to the left.

(4) Push the right side of the lamp in the head-

liner opening and push the lamp lens up into the

lamp to secure.

BR/BELAMPS/LIGHTING - INTERIOR 8L - 33

Page 650 of 2889

POWER SYSTEMS

TABLE OF CONTENTS

page page

POWER LOCKS............................ 1

POWER MIRRORS........................ 10POWER SEAT SYSTEM..................... 15

POWER WINDOWS........................ 23

POWER LOCKS

TABLE OF CONTENTS

page page

POWER LOCKS

DESCRIPTION............................1

OPERATION.............................3

DIAGNOSIS AND TESTING..................4

POWER LOCK SYSTEM...................4

POWER LOCK & REMOTE KEYLESS

ENTRY SYSTEM.........................4

DOOR CYLINDER LOCK SWITCH

DESCRIPTION............................5

OPERATION.............................5

DIAGNOSIS AND TESTING..................5

DOOR CYLINDER LOCK SWITCH...........5

REMOVAL...............................6

INSTALLATION............................6

POWER LOCK MOTOR

DESCRIPTION............................6OPERATION.............................6

DIAGNOSIS AND TESTING..................7

POWER LOCK MOTOR...................7

REMOTE KEYLESS ENTRY TRANSMITTER

DESCRIPTION............................7

OPERATION.............................7

DIAGNOSIS AND TESTING..................7

REMOTE KEYLESS ENTRY TRANSMITTER....7

STANDARD PROCEDURE...................8

RKE TRANSMITTER PROGRAMMING........8

RKE TRANSMITTER BATTERIES............8

POWER LOCK SWITCH

DESCRIPTION............................8

OPERATION.............................8

DIAGNOSIS AND TESTING..................8

POWER LOCK SWITCH...................8

POWER LOCKS

DESCRIPTION - POWER LOCK SYSTEM

Two different power lock systems are offered as

optional factory-installed equipment on this model.

Both power lock systems are offered only on models

that are also equipped with power windows. On mod-

els without the optional Remote Keyless Entry (RKE)

system, a base version of the Central Timer Module

(CTM) is used. In this version of the power lock sys-

tem, the power lock switches provide the only control

over the operation of the power lock motors. On mod-

els with the optional RKE system, a high-line or pre-

mium version of the CTM is used to provide many

electronic features and conveniences that are not pos-

sible with the base version CTM. In this power lock

system, the power lock motors are controlled by the

microprocessor-based high-line or premium version ofthe CTM based upon the CTM programming and

electronic message inputs received from other elec-

tronic modules in the vehicle over the Chrysler Col-

lision Detection (CCD) data bus network, Radio

Frequency (RF) inputs received from the RKE trans-

mitters, as well as many hard wired inputs.

Both versions of the power lock system include the

following major components, which are described in

further detail elsewhere in this service manual:

²Power Lock Motors- A reversible electric

motor integral to the door latch of each front door

locks or unlocks the front door latch when provided

with the appropriate electrical inputs.

²Power Lock Switches- A power lock switch

integral to the power window/lock switch unit located

near the forward end of the arm rest on each front

door trim panel allows the power door lock system to

be operated by either the driver or the front seat pas-

senger.

BR/BEPOWER SYSTEMS 8N - 1

Page 659 of 2889

POWER MIRRORS

TABLE OF CONTENTS

page page

POWER MIRRORS

DESCRIPTION...........................10

OPERATION.............................10

AUTOMATIC DAY / NIGHT MIRROR

DESCRIPTION...........................10

OPERATION.............................11

DIAGNOSIS AND TESTING.................11

AUTOMATIC DAY/NIGHT MIRROR..........11

REMOVAL..............................12

INSTALLATION...........................12

POWER MIRROR SWITCH

DESCRIPTION...........................12OPERATION.............................12

REMOVAL..............................12

INSTALLATION...........................13

SIDEVIEW MIRROR

DESCRIPTION...........................13

OPERATION.............................13

DIAGNOSIS AND TESTING.................13

SIDEVIEW MIRROR.....................13

REMOVAL..............................14

POWER MIRRORS

DESCRIPTION

AUTOMATIC DAY / NIGHT MIRROR

The automatic day/night mirror system is able to

automatically change the reflectance of the inside

rear view mirror in order to reduce the glare of head-

lamps approaching the vehicle from the rear. The

automatic day/night rear view mirror receives bat-

tery current through a fuse in the junction block only

when the ignition switch is in the On position.

OUTSIDE REAR VIEW MIRROR

The heated mirror option includes an electric heat-

ing grid behind the mirror glass in each outside mir-

ror, which can clear the mirror glass of ice, snow, or

fog. The heating grid receives fused battery current

through the heated mirror relay in the heater and air

conditioner control only when the ignition switch is

in the On position, and the heated mirror system is

turned on. (Refer to 8 - ELECTRICAL/HEATED

MIRRORS - DESCRIPTION) for more information.

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the power mirror system.

OPERATION

AUTOMATIC DAY / NIGHT MIRROR

A switch located on the bottom of the automatic

day/night mirror housing allows the vehicle operator

to select whether the automatic dimming feature is

operational. When the automatic day/night mirror isturned on, the mirror switch is lighted by an integral

Light-Emitting Diode (LED). The mirror will auto-

matically disable its self-dimming feature whenever

the vehicle is being driven in reverse.

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the automatic day/night mirror system.

OUTSIDE REAR VIEW MIRROR

The heated mirror option includes an electric heat-

ing grid behind the mirror glass in each outside mir-

ror, which can clear the mirror glass of ice, snow, or

fog. The heating grid receives fused battery current

through the heated mirror relay in the heater and air

conditioner control only when the ignition switch is

in the On position, and the heated mirror system is

turned on. (Refer to 8 - ELECTRICAL/HEATED

MIRRORS - OPERATION) for more information.

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the power mirror system.

AUTOMATIC DAY / NIGHT

MIRROR

DESCRIPTION

The automatic day/night mirror uses a thin layer

of electrochromic material between two pieces of con-

ductive glass to make up the face of the mirror.

When the mirror switch is in the On position, two

photocell sensors are used by the mirror circuitry to

monitor external light levels and adjust the reflec-

tance of the mirror.

8N - 10 POWER MIRRORSBR/BE

Page 660 of 2889

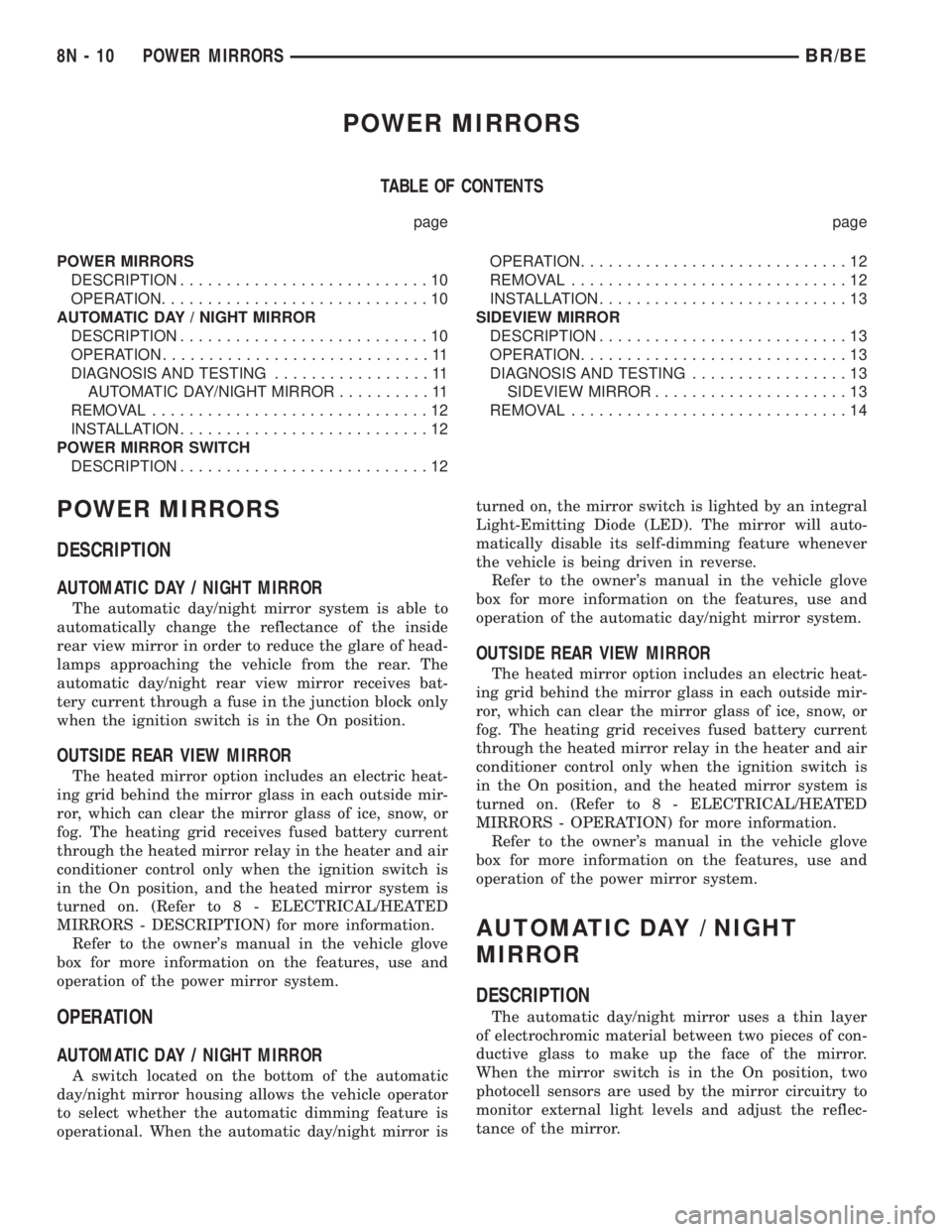

OPERATION

The ambient photocell sensor is located on the for-

ward-facing (windshield side) of the rear view mirror

housing, and detects the ambient light levels outside

of the vehicle. The headlamp photocell sensor is

located inside the rear view mirror housing behind

the mirror glass and faces rearward, to detect the

level of the light being received at the rear window

side of the mirror. When the circuitry of the auto-

matic day/night mirror detects that the difference

between the two light levels is too great (the light

level received at the rear of the mirror is much

higher than that at the front of the mirror), it begins

to darken the mirror.

The automatic day/night mirror circuitry also mon-

itors the transmission using an input from the

backup lamp circuit. The mirror circuitry is pro-

grammed to automatically disable its self-dimming

feature whenever it senses that the transmission

backup lamp circuit is energized.

The automatic day/night mirror is a completely

self-contained unit and cannot be repaired. If faulty

or damaged, the entire mirror assembly must be

replaced.

DIAGNOSIS AND TESTING - AUTOMATIC

DAY/NIGHT MIRROR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check the fuse in the junction block. If OK, go

to Step 2. If not OK, repair the shorted circuit or

component as required replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 3. If not OK, repair the open

circuit to the ignition switch as required.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Unplug the wire harness connector from the auto-

matic day/night mirror (Fig. 1). Connect the battery

negative cable. Turn the ignition switch to the On

position. Check for battery voltage at the fused igni-

tion switch output (run/start) circuit cavity of the

automatic day/night mirror wire harness connector. If

OK, go to Step 4. If not OK, repair the open circuit to

the junction block as required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Check for continuity between the ground circuit cav-

ity of the automatic day/night mirror wire harness

connector and a good ground. There should be conti-nuity. If OK, go to Step 5. If not OK, repair the cir-

cuit to ground as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the On position. Set the parking

brake. Place the transmission gear selector lever in

the Reverse position. Check for battery voltage at the

backup lamp switch output circuit cavity of the auto-

matic day/night mirror wire harness connector. If

OK, go to Step 6. If not OK, repair the open circuit

as required.

(6) Turn the ignition switch to the Off position.

Disconnect the battery negative cable. Plug in the

automatic day/night mirror wire harness connector.

Connect the battery negative cable. Turn the ignition

switch to the On position. Place the transmission

gear selector lever in the Neutral position. Place the

mirror switch in the On (LED in the mirror switch is

lighted) position. Cover the forward facing ambient

photocell sensor to keep out any ambient light.

NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The mirror glass should

darken. If OK, go to Step 8. If not OK, replace the

faulty automatic day/night mirror unit.

(8) With the mirror glass darkened, place the

transmission gear selector lever in the Reverse posi-

tion. The mirror should return to its normal reflec-

tance. If not OK, replace the faulty automatic day/

night mirror unit.

Fig. 1 Automatic Day/Night Mirror

BR/BEPOWER MIRRORS 8N - 11

AUTOMATIC DAY / NIGHT MIRROR (Continued)