fuel cap DODGE RAM 2001 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 644 of 2889

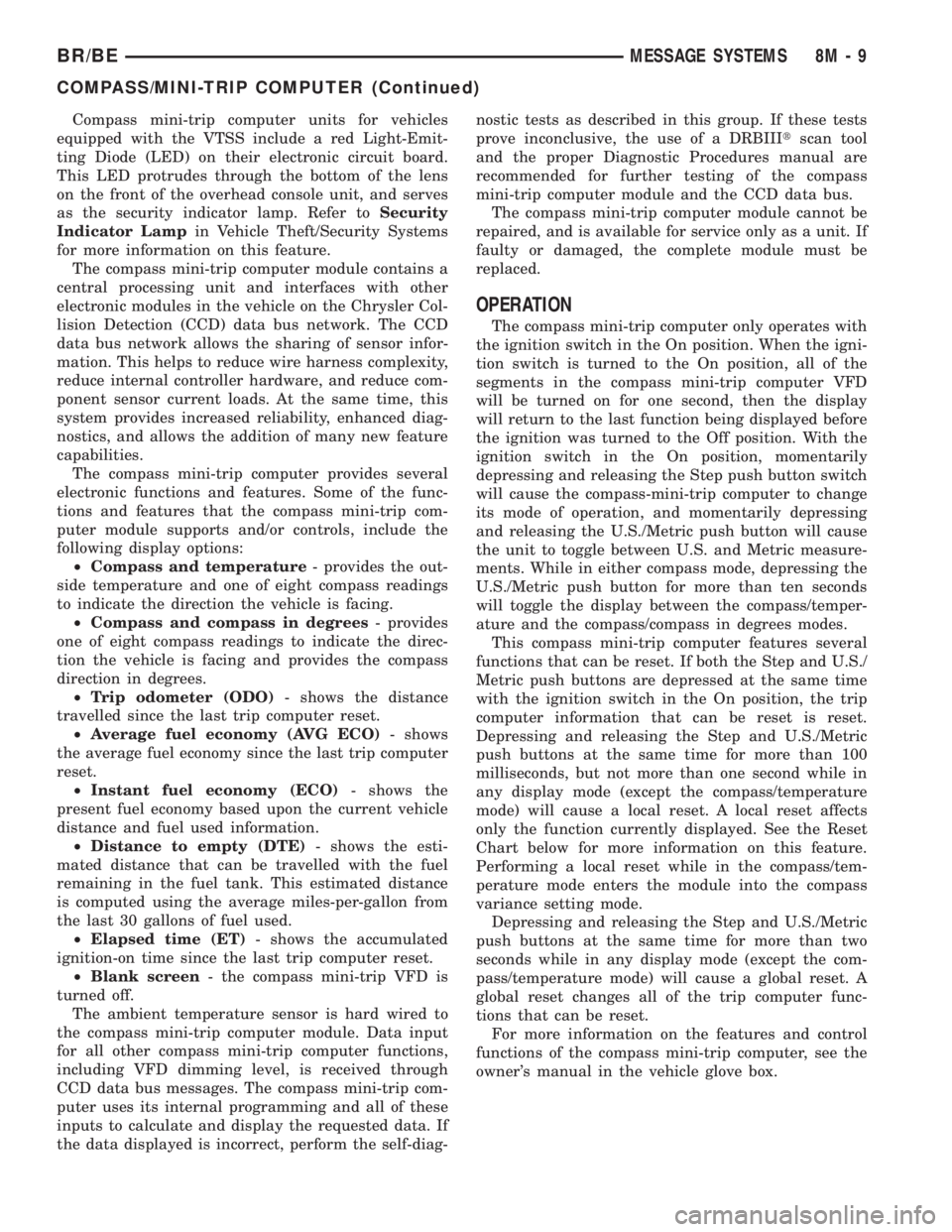

Compass mini-trip computer units for vehicles

equipped with the VTSS include a red Light-Emit-

ting Diode (LED) on their electronic circuit board.

This LED protrudes through the bottom of the lens

on the front of the overhead console unit, and serves

as the security indicator lamp. Refer toSecurity

Indicator Lampin Vehicle Theft/Security Systems

for more information on this feature.

The compass mini-trip computer module contains a

central processing unit and interfaces with other

electronic modules in the vehicle on the Chrysler Col-

lision Detection (CCD) data bus network. The CCD

data bus network allows the sharing of sensor infor-

mation. This helps to reduce wire harness complexity,

reduce internal controller hardware, and reduce com-

ponent sensor current loads. At the same time, this

system provides increased reliability, enhanced diag-

nostics, and allows the addition of many new feature

capabilities.

The compass mini-trip computer provides several

electronic functions and features. Some of the func-

tions and features that the compass mini-trip com-

puter module supports and/or controls, include the

following display options:

²Compass and temperature- provides the out-

side temperature and one of eight compass readings

to indicate the direction the vehicle is facing.

²Compass and compass in degrees- provides

one of eight compass readings to indicate the direc-

tion the vehicle is facing and provides the compass

direction in degrees.

²Trip odometer (ODO)- shows the distance

travelled since the last trip computer reset.

²Average fuel economy (AVG ECO)- shows

the average fuel economy since the last trip computer

reset.

²Instant fuel economy (ECO)- shows the

present fuel economy based upon the current vehicle

distance and fuel used information.

²Distance to empty (DTE)- shows the esti-

mated distance that can be travelled with the fuel

remaining in the fuel tank. This estimated distance

is computed using the average miles-per-gallon from

the last 30 gallons of fuel used.

²Elapsed time (ET)- shows the accumulated

ignition-on time since the last trip computer reset.

²Blank screen- the compass mini-trip VFD is

turned off.

The ambient temperature sensor is hard wired to

the compass mini-trip computer module. Data input

for all other compass mini-trip computer functions,

including VFD dimming level, is received through

CCD data bus messages. The compass mini-trip com-

puter uses its internal programming and all of these

inputs to calculate and display the requested data. If

the data displayed is incorrect, perform the self-diag-nostic tests as described in this group. If these tests

prove inconclusive, the use of a DRBIIItscan tool

and the proper Diagnostic Procedures manual are

recommended for further testing of the compass

mini-trip computer module and the CCD data bus.

The compass mini-trip computer module cannot be

repaired, and is available for service only as a unit. If

faulty or damaged, the complete module must be

replaced.

OPERATION

The compass mini-trip computer only operates with

the ignition switch in the On position. When the igni-

tion switch is turned to the On position, all of the

segments in the compass mini-trip computer VFD

will be turned on for one second, then the display

will return to the last function being displayed before

the ignition was turned to the Off position. With the

ignition switch in the On position, momentarily

depressing and releasing the Step push button switch

will cause the compass-mini-trip computer to change

its mode of operation, and momentarily depressing

and releasing the U.S./Metric push button will cause

the unit to toggle between U.S. and Metric measure-

ments. While in either compass mode, depressing the

U.S./Metric push button for more than ten seconds

will toggle the display between the compass/temper-

ature and the compass/compass in degrees modes.

This compass mini-trip computer features several

functions that can be reset. If both the Step and U.S./

Metric push buttons are depressed at the same time

with the ignition switch in the On position, the trip

computer information that can be reset is reset.

Depressing and releasing the Step and U.S./Metric

push buttons at the same time for more than 100

milliseconds, but not more than one second while in

any display mode (except the compass/temperature

mode) will cause a local reset. A local reset affects

only the function currently displayed. See the Reset

Chart below for more information on this feature.

Performing a local reset while in the compass/tem-

perature mode enters the module into the compass

variance setting mode.

Depressing and releasing the Step and U.S./Metric

push buttons at the same time for more than two

seconds while in any display mode (except the com-

pass/temperature mode) will cause a global reset. A

global reset changes all of the trip computer func-

tions that can be reset.

For more information on the features and control

functions of the compass mini-trip computer, see the

owner's manual in the vehicle glove box.

BR/BEMESSAGE SYSTEMS 8M - 9

COMPASS/MINI-TRIP COMPUTER (Continued)

Page 756 of 2889

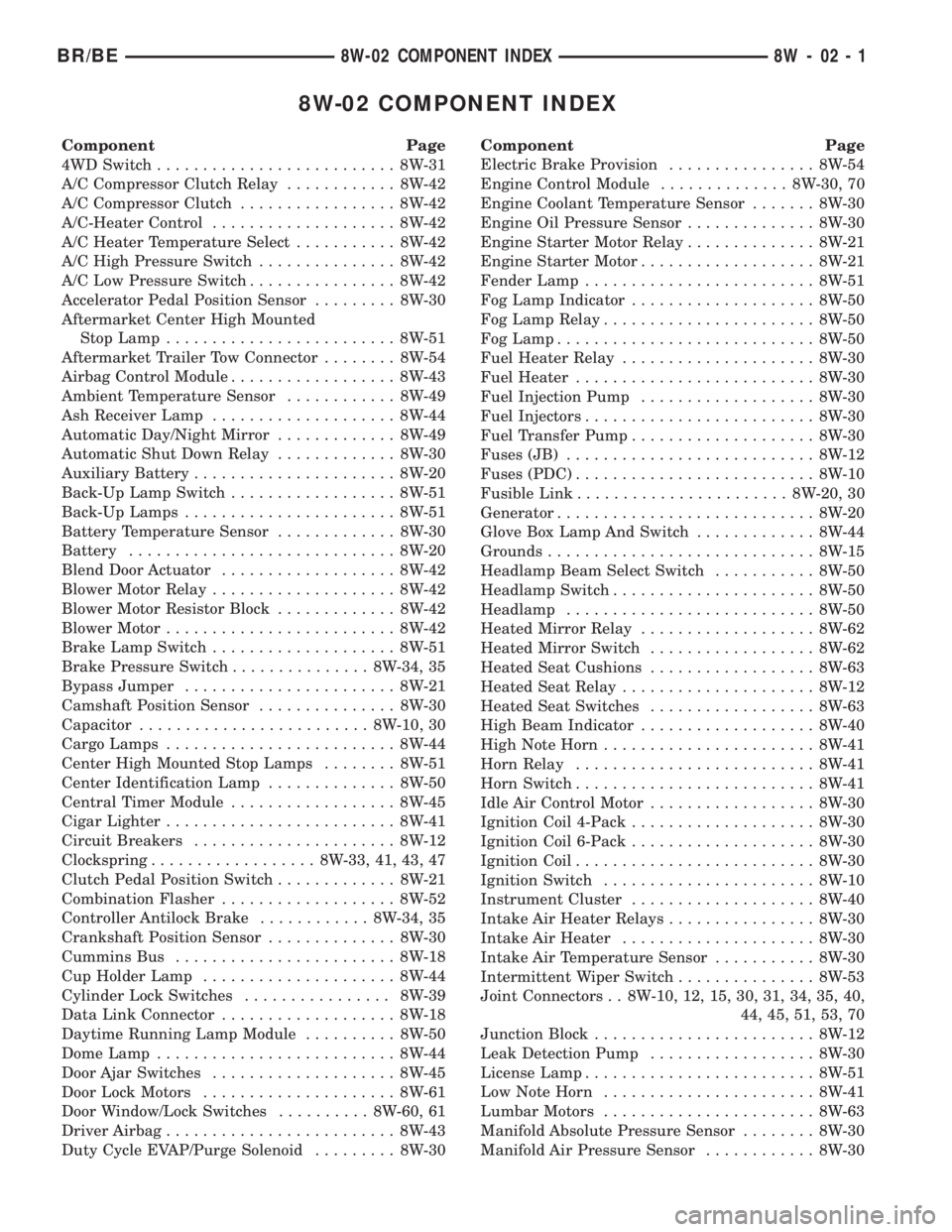

8W-02 COMPONENT INDEX

Component Page

4WD Switch.......................... 8W-31

A/C Compressor Clutch Relay............ 8W-42

A/C Compressor Clutch................. 8W-42

A/C-Heater Control.................... 8W-42

A/C Heater Temperature Select........... 8W-42

A/C High Pressure Switch............... 8W-42

A/C Low Pressure Switch................ 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Aftermarket Center High Mounted

Stop Lamp......................... 8W-51

Aftermarket Trailer Tow Connector........ 8W-54

Airbag Control Module.................. 8W-43

Ambient Temperature Sensor............ 8W-49

Ash Receiver Lamp.................... 8W-44

Automatic Day/Night Mirror............. 8W-49

Automatic Shut Down Relay............. 8W-30

Auxiliary Battery...................... 8W-20

Back-Up Lamp Switch.................. 8W-51

Back-Up Lamps....................... 8W-51

Battery Temperature Sensor............. 8W-30

Battery............................. 8W-20

Blend Door Actuator................... 8W-42

Blower Motor Relay.................... 8W-42

Blower Motor Resistor Block............. 8W-42

Blower Motor......................... 8W-42

Brake Lamp Switch.................... 8W-51

Brake Pressure Switch............... 8W-34, 35

Bypass Jumper....................... 8W-21

Camshaft Position Sensor............... 8W-30

Capacitor......................... 8W-10, 30

Cargo Lamps......................... 8W-44

Center High Mounted Stop Lamps........ 8W-51

Center Identification Lamp.............. 8W-50

Central Timer Module.................. 8W-45

Cigar Lighter......................... 8W-41

Circuit Breakers...................... 8W-12

Clockspring.................. 8W-33, 41, 43, 47

Clutch Pedal Position Switch............. 8W-21

Combination Flasher................... 8W-52

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cummins Bus........................ 8W-18

Cup Holder Lamp..................... 8W-44

Cylinder Lock Switches................ 8W-39

Data Link Connector................... 8W-18

Daytime Running Lamp Module.......... 8W-50

Dome Lamp.......................... 8W-44

Door Ajar Switches.................... 8W-45

Door Lock Motors..................... 8W-61

Door Window/Lock Switches.......... 8W-60, 61

Driver Airbag......................... 8W-43

Duty Cycle EVAP/Purge Solenoid......... 8W-30Component Page

Electric Brake Provision................ 8W-54

Engine Control Module.............. 8W-30, 70

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Sensor.............. 8W-30

Engine Starter Motor Relay.............. 8W-21

Engine Starter Motor................... 8W-21

Fender Lamp......................... 8W-51

Fog Lamp Indicator.................... 8W-50

Fog Lamp Relay....................... 8W-50

Fog Lamp............................ 8W-50

Fuel Heater Relay..................... 8W-30

Fuel Heater.......................... 8W-30

Fuel Injection Pump................... 8W-30

Fuel Injectors......................... 8W-30

Fuel Transfer Pump.................... 8W-30

Fuses (JB)........................... 8W-12

Fuses (PDC).......................... 8W-10

Fusible Link....................... 8W-20, 30

Generator............................ 8W-20

Glove Box Lamp And Switch............. 8W-44

Grounds............................. 8W-15

Headlamp Beam Select Switch........... 8W-50

Headlamp Switch...................... 8W-50

Headlamp........................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Mirror Switch.................. 8W-62

Heated Seat Cushions.................. 8W-63

Heated Seat Relay..................... 8W-12

Heated Seat Switches.................. 8W-63

High Beam Indicator................... 8W-40

High Note Horn....................... 8W-41

Horn Relay.......................... 8W-41

Horn Switch.......................... 8W-41

Idle Air Control Motor.................. 8W-30

Ignition Coil 4-Pack.................... 8W-30

Ignition Coil 6-Pack.................... 8W-30

Ignition Coil.......................... 8W-30

Ignition Switch....................... 8W-10

Instrument Cluster.................... 8W-40

Intake Air Heater Relays................ 8W-30

Intake Air Heater..................... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intermittent Wiper Switch............... 8W-53

Joint Connectors . . 8W-10, 12, 15, 30, 31, 34, 35, 40,

44, 45, 51, 53, 70

Junction Block........................ 8W-12

Leak Detection Pump.................. 8W-30

License Lamp......................... 8W-51

Low Note Horn....................... 8W-41

Lumbar Motors....................... 8W-63

Manifold Absolute Pressure Sensor........ 8W-30

Manifold Air Pressure Sensor............ 8W-30

BR/BE8W-02 COMPONENT INDEX 8W - 02 - 1

Page 758 of 2889

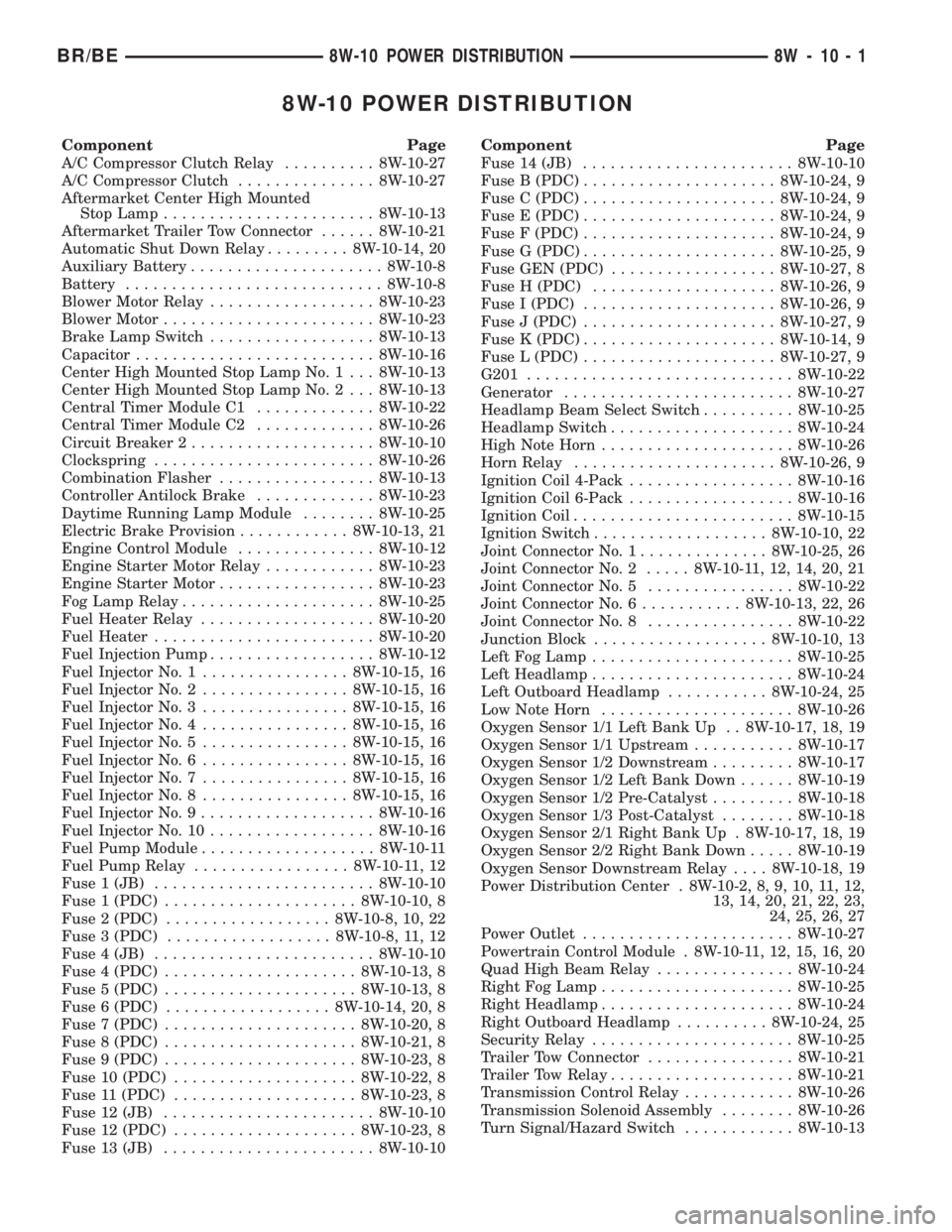

8W-10 POWER DISTRIBUTION

Component Page

A/C Compressor Clutch Relay.......... 8W-10-27

A/C Compressor Clutch............... 8W-10-27

Aftermarket Center High Mounted

Stop Lamp....................... 8W-10-13

Aftermarket Trailer Tow Connector...... 8W-10-21

Automatic Shut Down Relay......... 8W-10-14, 20

Auxiliary Battery..................... 8W-10-8

Battery............................ 8W-10-8

Blower Motor Relay.................. 8W-10-23

Blower Motor....................... 8W-10-23

Brake Lamp Switch.................. 8W-10-13

Capacitor.......................... 8W-10-16

Center High Mounted Stop Lamp No. 1 . . . 8W-10-13

Center High Mounted Stop Lamp No. 2 . . . 8W-10-13

Central Timer Module C1............. 8W-10-22

Central Timer Module C2............. 8W-10-26

Circuit Breaker 2.................... 8W-10-10

Clockspring........................ 8W-10-26

Combination Flasher................. 8W-10-13

Controller Antilock Brake............. 8W-10-23

Daytime Running Lamp Module........ 8W-10-25

Electric Brake Provision............ 8W-10-13, 21

Engine Control Module............... 8W-10-12

Engine Starter Motor Relay............ 8W-10-23

Engine Starter Motor................. 8W-10-23

Fog Lamp Relay..................... 8W-10-25

Fuel Heater Relay................... 8W-10-20

Fuel Heater........................ 8W-10-20

Fuel Injection Pump.................. 8W-10-12

Fuel Injector No. 1................ 8W-10-15, 16

Fuel Injector No. 2................ 8W-10-15, 16

Fuel Injector No. 3................ 8W-10-15, 16

Fuel Injector No. 4................ 8W-10-15, 16

Fuel Injector No. 5................ 8W-10-15, 16

Fuel Injector No. 6................ 8W-10-15, 16

Fuel Injector No. 7................ 8W-10-15, 16

Fuel Injector No. 8................ 8W-10-15, 16

Fuel Injector No. 9................... 8W-10-16

Fuel Injector No. 10.................. 8W-10-16

Fuel Pump Module................... 8W-10-11

Fuel Pump Relay................. 8W-10-11, 12

Fuse 1 (JB)........................ 8W-10-10

Fuse 1 (PDC)..................... 8W-10-10, 8

Fuse 2 (PDC).................. 8W-10-8, 10, 22

Fuse 3 (PDC).................. 8W-10-8, 11, 12

Fuse 4 (JB)........................ 8W-10-10

Fuse 4 (PDC)..................... 8W-10-13, 8

Fuse 5 (PDC)..................... 8W-10-13, 8

Fuse 6 (PDC).................. 8W-10-14, 20, 8

Fuse 7 (PDC)..................... 8W-10-20, 8

Fuse 8 (PDC)..................... 8W-10-21, 8

Fuse 9 (PDC)..................... 8W-10-23, 8

Fuse 10 (PDC).................... 8W-10-22, 8

Fuse 11 (PDC).................... 8W-10-23, 8

Fuse 12 (JB)....................... 8W-10-10

Fuse 12 (PDC).................... 8W-10-23, 8

Fuse 13 (JB)....................... 8W-10-10Component Page

Fuse 14 (JB)....................... 8W-10-10

Fuse B (PDC)..................... 8W-10-24, 9

Fuse C (PDC)..................... 8W-10-24, 9

Fuse E (PDC)..................... 8W-10-24, 9

Fuse F (PDC)..................... 8W-10-24, 9

Fuse G (PDC)..................... 8W-10-25, 9

Fuse GEN (PDC).................. 8W-10-27, 8

Fuse H (PDC).................... 8W-10-26, 9

Fuse I (PDC)..................... 8W-10-26, 9

Fuse J (PDC)..................... 8W-10-27, 9

Fuse K (PDC)..................... 8W-10-14, 9

Fuse L (PDC)..................... 8W-10-27, 9

G201............................. 8W-10-22

Generator......................... 8W-10-27

Headlamp Beam Select Switch.......... 8W-10-25

Headlamp Switch.................... 8W-10-24

High Note Horn..................... 8W-10-26

Horn Relay...................... 8W-10-26, 9

Ignition Coil 4-Pack.................. 8W-10-16

Ignition Coil 6-Pack.................. 8W-10-16

Ignition Coil........................ 8W-10-15

Ignition Switch................... 8W-10-10, 22

Joint Connector No. 1.............. 8W-10-25, 26

Joint Connector No. 2..... 8W-10-11, 12, 14, 20, 21

Joint Connector No. 5................ 8W-10-22

Joint Connector No. 6........... 8W-10-13, 22, 26

Joint Connector No. 8................ 8W-10-22

Junction Block................... 8W-10-10, 13

Left Fog Lamp...................... 8W-10-25

Left Headlamp...................... 8W-10-24

Left Outboard Headlamp........... 8W-10-24, 25

Low Note Horn..................... 8W-10-26

Oxygen Sensor 1/1 Left Bank Up . . 8W-10-17, 18, 19

Oxygen Sensor 1/1 Upstream........... 8W-10-17

Oxygen Sensor 1/2 Downstream......... 8W-10-17

Oxygen Sensor 1/2 Left Bank Down...... 8W-10-19

Oxygen Sensor 1/2 Pre-Catalyst......... 8W-10-18

Oxygen Sensor 1/3 Post-Catalyst........ 8W-10-18

Oxygen Sensor 2/1 Right Bank Up . 8W-10-17, 18, 19

Oxygen Sensor 2/2 Right Bank Down..... 8W-10-19

Oxygen Sensor Downstream Relay.... 8W-10-18, 19

Power Distribution Center . 8W-10-2, 8, 9, 10, 11, 12,

13, 14, 20, 21, 22, 23,

24, 25, 26, 27

Power Outlet....................... 8W-10-27

Powertrain Control Module . 8W-10-11, 12, 15, 16, 20

Quad High Beam Relay............... 8W-10-24

Right Fog Lamp..................... 8W-10-25

Right Headlamp..................... 8W-10-24

Right Outboard Headlamp.......... 8W-10-24, 25

Security Relay...................... 8W-10-25

Trailer Tow Connector................ 8W-10-21

Trailer Tow Relay.................... 8W-10-21

Transmission Control Relay............ 8W-10-26

Transmission Solenoid Assembly........ 8W-10-26

Turn Signal/Hazard Switch............ 8W-10-13

BR/BE8W-10 POWER DISTRIBUTION 8W - 10 - 1

Page 838 of 2889

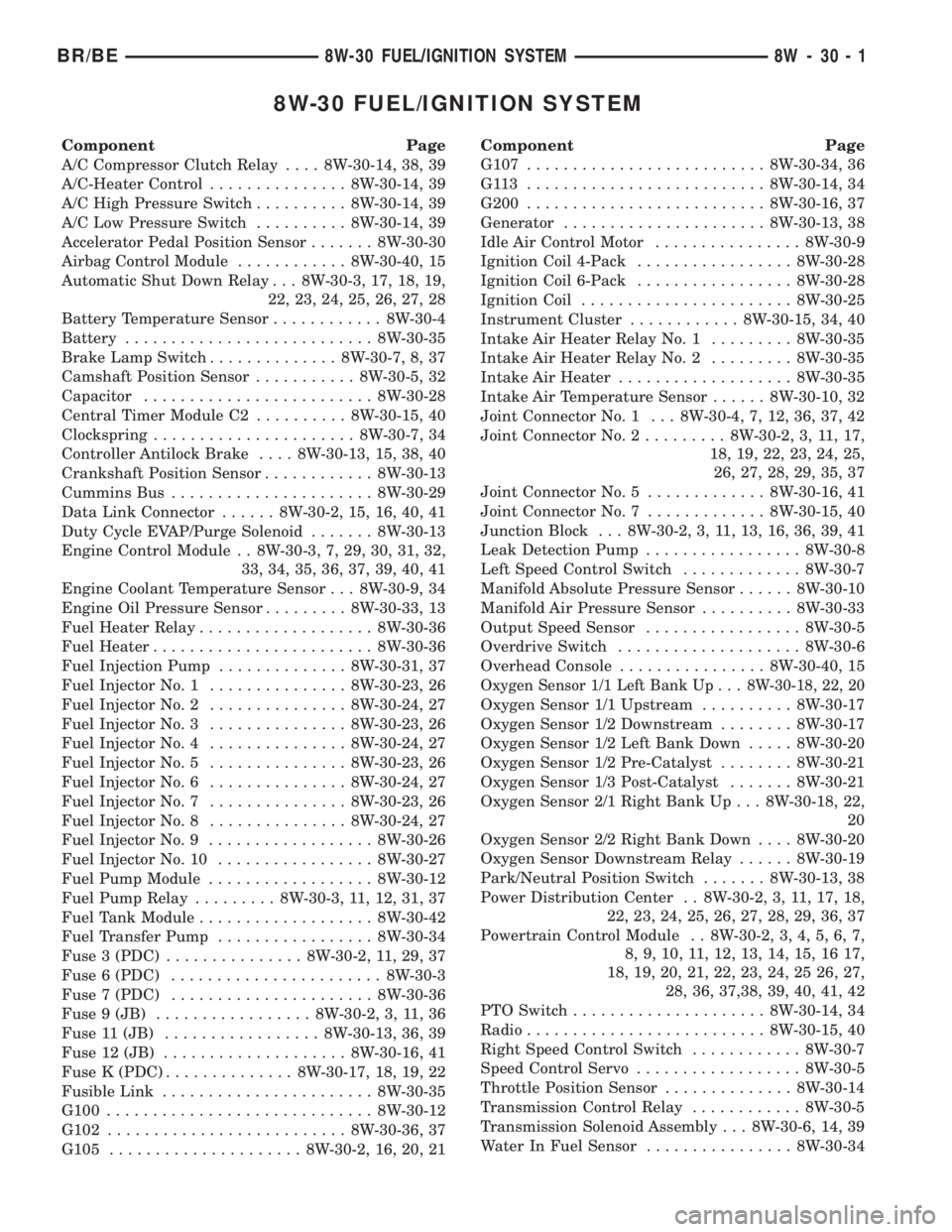

8W-30 FUEL/IGNITION SYSTEM

Component Page

A/C Compressor Clutch Relay.... 8W-30-14, 38, 39

A/C-Heater Control............... 8W-30-14, 39

A/C High Pressure Switch.......... 8W-30-14, 39

A/C Low Pressure Switch.......... 8W-30-14, 39

Accelerator Pedal Position Sensor....... 8W-30-30

Airbag Control Module............ 8W-30-40, 15

Automatic Shut Down Relay . . . 8W-30-3, 17, 18, 19,

22, 23, 24, 25, 26, 27, 28

Battery Temperature Sensor............ 8W-30-4

Battery........................... 8W-30-35

Brake Lamp Switch.............. 8W-30-7, 8, 37

Camshaft Position Sensor........... 8W-30-5, 32

Capacitor......................... 8W-30-28

Central Timer Module C2.......... 8W-30-15, 40

Clockspring...................... 8W-30-7, 34

Controller Antilock Brake.... 8W-30-13, 15, 38, 40

Crankshaft Position Sensor............ 8W-30-13

Cummins Bus...................... 8W-30-29

Data Link Connector...... 8W-30-2, 15, 16, 40, 41

Duty Cycle EVAP/Purge Solenoid....... 8W-30-13

Engine Control Module . . 8W-30-3, 7, 29, 30, 31, 32,

33, 34, 35, 36, 37, 39, 40, 41

Engine Coolant Temperature Sensor . . . 8W-30-9, 34

Engine Oil Pressure Sensor......... 8W-30-33, 13

Fuel Heater Relay................... 8W-30-36

Fuel Heater........................ 8W-30-36

Fuel Injection Pump.............. 8W-30-31, 37

Fuel Injector No. 1............... 8W-30-23, 26

Fuel Injector No. 2............... 8W-30-24, 27

Fuel Injector No. 3............... 8W-30-23, 26

Fuel Injector No. 4............... 8W-30-24, 27

Fuel Injector No. 5............... 8W-30-23, 26

Fuel Injector No. 6............... 8W-30-24, 27

Fuel Injector No. 7............... 8W-30-23, 26

Fuel Injector No. 8............... 8W-30-24, 27

Fuel Injector No. 9.................. 8W-30-26

Fuel Injector No. 10................. 8W-30-27

Fuel Pump Module.................. 8W-30-12

Fuel Pump Relay......... 8W-30-3, 11, 12, 31, 37

Fuel Tank Module................... 8W-30-42

Fuel Transfer Pump................. 8W-30-34

Fuse 3 (PDC)............... 8W-30-2, 11, 29, 37

Fuse 6 (PDC)....................... 8W-30-3

Fuse 7 (PDC)...................... 8W-30-36

Fuse 9 (JB)................. 8W-30-2, 3, 11, 36

Fuse 11 (JB)................. 8W-30-13, 36, 39

Fuse 12 (JB).................... 8W-30-16, 41

Fuse K (PDC).............. 8W-30-17, 18, 19, 22

Fusible Link....................... 8W-30-35

G100............................. 8W-30-12

G102.......................... 8W-30-36, 37

G105..................... 8W-30-2, 16, 20, 21Component Page

G107.......................... 8W-30-34, 36

G113 .......................... 8W-30-14, 34

G200.......................... 8W-30-16, 37

Generator...................... 8W-30-13, 38

Idle Air Control Motor................ 8W-30-9

Ignition Coil 4-Pack................. 8W-30-28

Ignition Coil 6-Pack................. 8W-30-28

Ignition Coil....................... 8W-30-25

Instrument Cluster............ 8W-30-15, 34, 40

Intake Air Heater Relay No. 1......... 8W-30-35

Intake Air Heater Relay No. 2......... 8W-30-35

Intake Air Heater................... 8W-30-35

Intake Air Temperature Sensor...... 8W-30-10, 32

Joint Connector No. 1 . . . 8W-30-4, 7, 12, 36, 37, 42

Joint Connector No. 2......... 8W-30-2, 3, 11, 17,

18, 19, 22, 23, 24, 25,

26, 27, 28, 29, 35, 37

Joint Connector No. 5............. 8W-30-16, 41

Joint Connector No. 7............. 8W-30-15, 40

Junction Block . . . 8W-30-2, 3, 11, 13, 16, 36, 39, 41

Leak Detection Pump................. 8W-30-8

Left Speed Control Switch............. 8W-30-7

Manifold Absolute Pressure Sensor...... 8W-30-10

Manifold Air Pressure Sensor.......... 8W-30-33

Output Speed Sensor................. 8W-30-5

Overdrive Switch.................... 8W-30-6

Overhead Console................ 8W-30-40, 15

Oxygen Sensor 1/1 Left Bank Up . . . 8W-30-18, 22, 20

Oxygen Sensor 1/1 Upstream.......... 8W-30-17

Oxygen Sensor 1/2 Downstream........ 8W-30-17

Oxygen Sensor 1/2 Left Bank Down..... 8W-30-20

Oxygen Sensor 1/2 Pre-Catalyst........ 8W-30-21

Oxygen Sensor 1/3 Post-Catalyst....... 8W-30-21

Oxygen Sensor 2/1 Right Bank Up . . . 8W-30-18, 22,

20

Oxygen Sensor 2/2 Right Bank Down.... 8W-30-20

Oxygen Sensor Downstream Relay...... 8W-30-19

Park/Neutral Position Switch....... 8W-30-13, 38

Power Distribution Center . . 8W-30-2, 3, 11, 17, 18,

22, 23, 24, 25, 26, 27, 28, 29, 36, 37

Powertrain Control Module . . 8W-30-2, 3, 4, 5, 6, 7,

8, 9, 10, 11, 12, 13, 14, 15, 16 17,

18, 19, 20, 21, 22, 23, 24, 25 26, 27,

28, 36, 37,38, 39, 40, 41, 42

PTO Switch..................... 8W-30-14, 34

Radio.......................... 8W-30-15, 40

Right Speed Control Switch............ 8W-30-7

Speed Control Servo.................. 8W-30-5

Throttle Position Sensor.............. 8W-30-14

Transmission Control Relay............ 8W-30-5

Transmission Solenoid Assembly . . . 8W-30-6, 14, 39

Water In Fuel Sensor................ 8W-30-34

BR/BE8W-30 FUEL/IGNITION SYSTEM 8W - 30 - 1

Page 1159 of 2889

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the upper crossmember and top core

support.

(4) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).(5) Discharge the air conditioning system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove the A/C compressor with the lines

attached. Set aside.

(8) If equipped, remove the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - REMOVAL).

(9) Remove the washer bottle.

(10) Remove the fan and fan shroud (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(11) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(12) Remove the generator with the wire connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - REMOVAL).

(13) Remove the air cleaner box.

(14) Disconnect the throttle linkage.

(15) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(16) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(17) Remove the distributor cap and wiring.

(18) Disconnect the heater hoses.

(19) Disconnect the power steering hoses, if

equipped.

(20) Perform the Fuel System Pressure release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE).Disconnect

the fuel supply line (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/QUICK CONNECT FITTING -

STANDARD PROCEDURE).

(21) On Manual Transmission vehicles, remove the

shift lever.

(22) Raise and support the vehicle on a hoist.

(23) Remove the drain plug and drain the engine

oil.

(24) Remove engine front mount through-bolt nuts.

(25)Automatic TransmissionRemove the trans-

mission cooler line brackets from oil pan.

(26) Disconnect exhaust pipe at manifold.

(27) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL).

(28)Manual TransmissionRemove the transmis-

sion.(Refer to 21 - TRANSMISSION/TRANSAXLE/

MANUAL - REMOVAL).

(29) Lower the vehicle.

CAUTION: DO NOT lift the engine by the intake

manifold.

(30) Install an engine lifting fixture.

9 - 12 ENGINE 3.9LBR/BE

ENGINE 3.9L (Continued)

Page 1160 of 2889

(31) Remove engine from vehicle and install

engine assembly on a repair stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the

through-bolt into the support cushion brackets.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4)Manual TransmissionInstall the transmis-

sion (Refer to 21 - TRANSMISSION/TRANSAXLE/

MANUAL - INSTALLATION).

(5) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(6) Install exhaust pipe to manifold.

(7)Automatic TransmissionInstall the trans-

mission cooler line brackets on oil pan.

(8) Install engine front mount through-bolt nuts.

Tighten the nuts.

(9) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(10) Lower the vehicle.

(11) Remove engine-lifting fixture.

(12) On Manual Transmission vehicles, install the

shift lever.

(13) Connect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(14) Connect the power steering hoses, if equipped.

(15) Connect the heater hoses.

(16) Install the distributor cap and wiring.

(17) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).(18) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(19) Connect the throttle linkage.

(20) Install the air cleaner box.

(21) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/STARTING/STARTER

MOTOR - INSTALLATION).

(22) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(23) Install the fan and fan shroud (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(24) Install the washer bottle.

(25) If equipped, install the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - INSTALLATION).

(26) Install the A/C compressor with the lines

attached.

(27) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(28) Evacuate and charge the air conditioning sys-

tem, if equipped (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE).

(29) Install the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

(30) Install the upper crossmember and top core

support.

(31) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(32) Connect the negative cable to the battery.

(33) Start engine and check for leaks.

BR/BEENGINE 3.9L 9 - 13

ENGINE 3.9L (Continued)

Page 1169 of 2889

CYLINDER HEAD

DESCRIPTIONÐCYLINDER HEAD

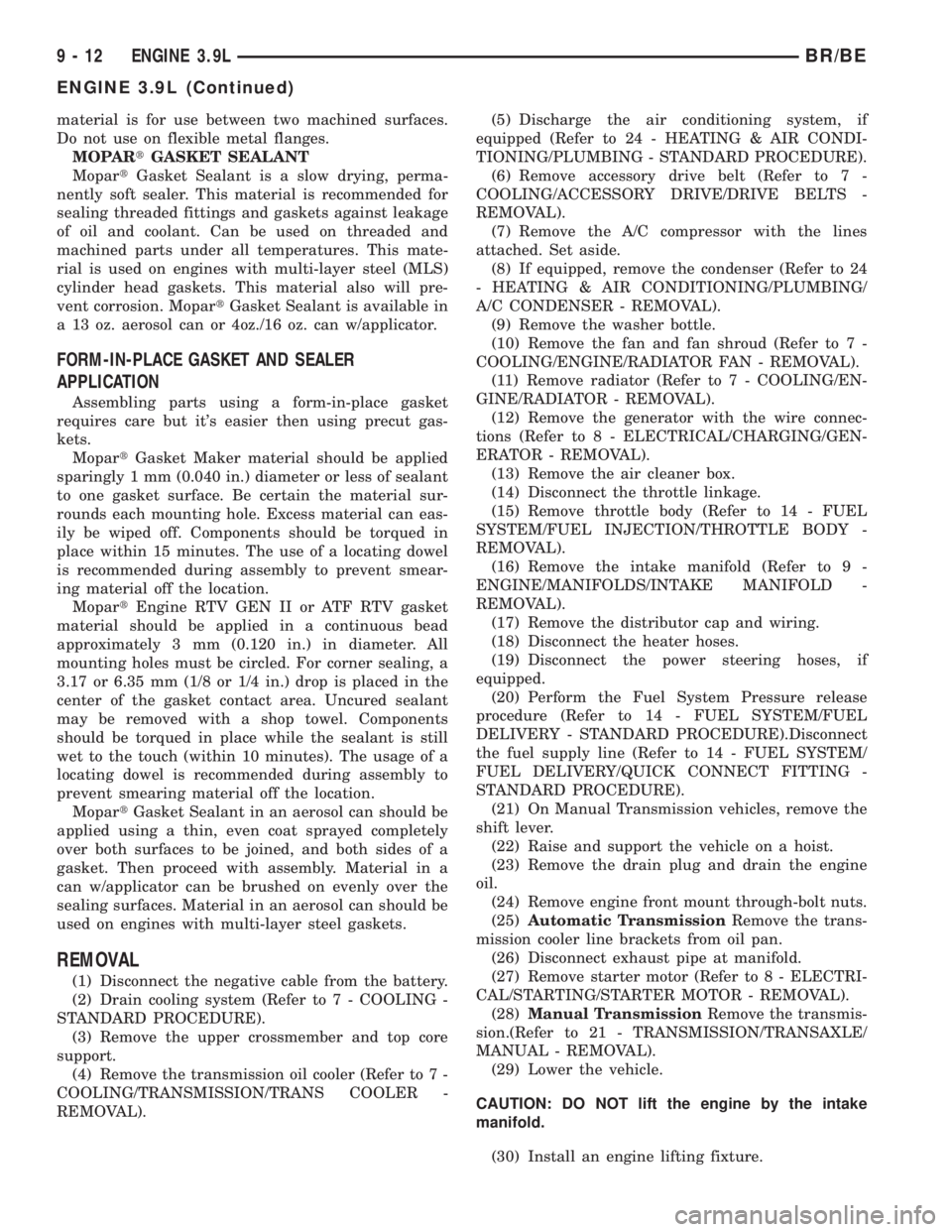

The cast iron cylinder heads (Fig. 5) are mounted

to the cylinder block using eight bolts. The spark

plugs are located in the peak of the wedge between

the valves.

DESCRIPTIONÐCYLINDER HEAD COVER

GASKET

The cylinder head cover gasket (Fig. 6) is a steel-

backed silicone gasket, designed for long life usage.

OPERATIONÐCYLINDER HEAD

The cylinder head closes the combustion chamber

allowing the pistons to compress the air fuel mixture to

the correct ratio for ignition. The valves located in the

cylinder head open and close to either allow clean air

into the combustion chamber or to allow the exhaust

gases out, depending on the stroke of the engine.

OPERATIONÐCYLINDER HEAD COVER

GASKET

The steel-backed silicone gasket is designed to seal

the cylinder head cover for long periods of time

through extensive heat and cold, without failure. The

gasket is designed to be reusable.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

²Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approxi-

mately a 50±70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

Fig. 5 Cylinder Head AssemblyÐ3.9L Engine

1 - SPARK PLUGS

2 - SPARK PLUG

3 - INTAKE VALVE

4 - EXHAUST VALVES

5 - INTAKE VALVES

6 - EXHAUST VALVE

Fig. 6 Cylinder Head Cover Gasket

1 - CYLINDER HEAD COVER GASKET

9 - 22 ENGINE 3.9LBR/BE

Page 1170 of 2889

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

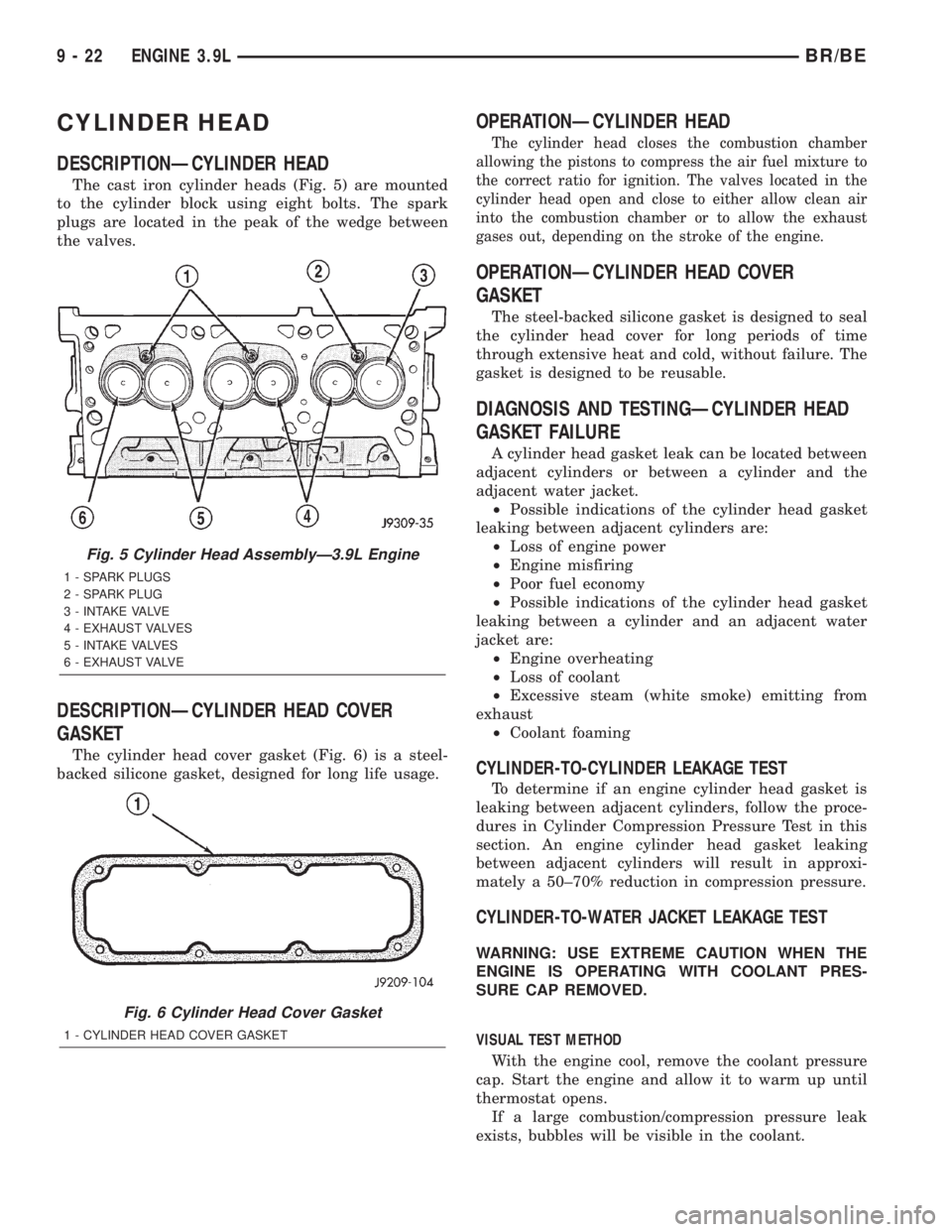

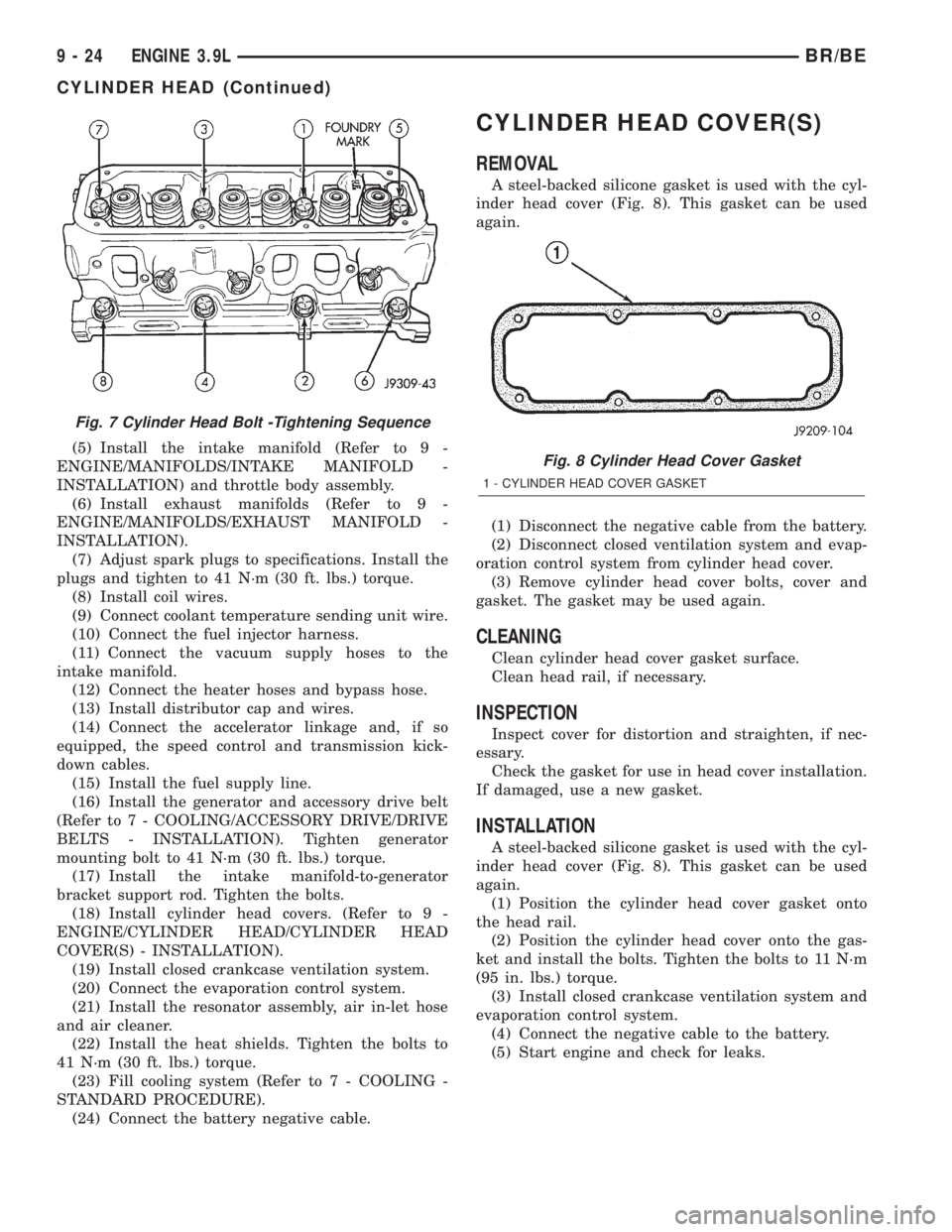

The alloy cast iron cylinder heads (Fig. 7) are held

in place by eight bolts. The spark plugs are located

at the peak of the wedge between the valves.

(1) Disconnect the battery negative cable from the

battery.

(2) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the intake manifold-to-generator

bracket support rod. Remove the generator.

(4) Remove closed crankcase ventilation system.

(5) Disconnect the evaporation control system.

(6) Remove the air cleaner, air in-let hose and res-

onator.

(7) Perform fuel system pressure release procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(8) Disconnect the fuel supply line from the fuel

rail (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

QUICK CONNECT FITTING - STANDARD PROCE-

DURE).

(9) Disconnect accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(10) Remove distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect coolant temperature sending unit

wire.

(13) Disconnect heater hoses and bypass hose.

(14) Disconnect the vacuum supply hoses from the

intake manifold.

(15) Disconnect the fuel injector harness and

secure out of the way.

(16) Remove cylinder head covers and gaskets

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).(17) Remove intake manifold and throttle body as

an assembly. Discard the flange side gaskets and the

front and rear cross-over gaskets.

(18) Remove exhaust manifolds (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

REMOVAL).

(19) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(20) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

(21) Remove spark plugs.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out-of-flatness

exceeds 0.00075mm (0.0001in.) times the span length

in any direction, either replace head or lightly

machine the head surface.

FOR EXAMPLE:ÐA 305 mm (12 in.) span is

0.102 mm (0.004 in.) out-of-flat. The allowable out-of-

flat is 305 x 0.00075 (12 x 0.00075) equals 0.23 mm

(0.009 in.). This amount of out-of-flat is acceptable.

The cylinder head surface finish should be

1.78-3.00 microns (70-125 microinches).

Inspect push rods. Replace worn or bent rods.

INSTALLATION

The alloy cast iron cylinder heads (Fig. 7) are held

in place by eight bolts. The spark plugs are located

at the peak of the wedge between the valves.

(1) Position the new cylinder head gaskets onto

the cylinder block.

(2) Position the cylinder heads onto head gaskets

and cylinder block.

(3) Starting at top center, tighten all cylinder head

bolts, in sequence, to 68 N´m (50 ft. lbs.) torque (Fig.

7). Repeat procedure, tighten all cylinder head bolts

to 143 N´m (105 ft. lbs.) torque. Repeat procedure to

confirm that all bolts are at 143 N´m (105 ft. lbs.)

torque.

CAUTION: When tightening the rocker arm bolts, be

sure the piston in that cylinder is NOT at TDC. Con-

tact between the valves and piston could occur.

(4) Install push rods and rocker arm assemblies in

their original positions. Tighten the bolts to 28 N´m

(21 ft. lbs.) torque.

BR/BEENGINE 3.9L 9 - 23

CYLINDER HEAD (Continued)

Page 1171 of 2889

(5) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION) and throttle body assembly.

(6) Install exhaust manifolds (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

INSTALLATION).

(7) Adjust spark plugs to specifications. Install the

plugs and tighten to 41 N´m (30 ft. lbs.) torque.

(8) Install coil wires.

(9) Connect coolant temperature sending unit wire.

(10) Connect the fuel injector harness.

(11) Connect the vacuum supply hoses to the

intake manifold.

(12) Connect the heater hoses and bypass hose.

(13) Install distributor cap and wires.

(14) Connect the accelerator linkage and, if so

equipped, the speed control and transmission kick-

down cables.

(15) Install the fuel supply line.

(16) Install the generator and accessory drive belt

(Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - INSTALLATION). Tighten generator

mounting bolt to 41 N´m (30 ft. lbs.) torque.

(17) Install the intake manifold-to-generator

bracket support rod. Tighten the bolts.

(18) Install cylinder head covers. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(19) Install closed crankcase ventilation system.

(20) Connect the evaporation control system.

(21) Install the resonator assembly, air in-let hose

and air cleaner.

(22) Install the heat shields. Tighten the bolts to

41 N´m (30 ft. lbs.) torque.

(23) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(24) Connect the battery negative cable.

CYLINDER HEAD COVER(S)

REMOVAL

A steel-backed silicone gasket is used with the cyl-

inder head cover (Fig. 8). This gasket can be used

again.

(1) Disconnect the negative cable from the battery.

(2) Disconnect closed ventilation system and evap-

oration control system from cylinder head cover.

(3) Remove cylinder head cover bolts, cover and

gasket. The gasket may be used again.

CLEANING

Clean cylinder head cover gasket surface.

Clean head rail, if necessary.

INSPECTION

Inspect cover for distortion and straighten, if nec-

essary.

Check the gasket for use in head cover installation.

If damaged, use a new gasket.

INSTALLATION

A steel-backed silicone gasket is used with the cyl-

inder head cover (Fig. 8). This gasket can be used

again.

(1) Position the cylinder head cover gasket onto

the head rail.

(2) Position the cylinder head cover onto the gas-

ket and install the bolts. Tighten the bolts to 11 N´m

(95 in. lbs.) torque.

(3) Install closed crankcase ventilation system and

evaporation control system.

(4) Connect the negative cable to the battery.

(5) Start engine and check for leaks.

Fig. 7 Cylinder Head Bolt -Tightening Sequence

Fig. 8 Cylinder Head Cover Gasket

1 - CYLINDER HEAD COVER GASKET

9 - 24 ENGINE 3.9LBR/BE

CYLINDER HEAD (Continued)

Page 1199 of 2889

(3) Install the relief valve and spring. Insert the

cotter pin.

(4) Tap on a new retainer cap.

(5) Prime oil pump before installation by filling

rotor cavity with engine oil.

INSTALLATION

(1) Install oil pump. During installation, slowly

rotate pump body to ensure driveshaft-to-pump rotor

shaft engagement.(2) Hold the oil pump base flush against mating

surface on No. 4 main bearing cap. Finger-tighten

pump attaching bolts. Tighten attaching bolts to 41

N´m (30 ft. lbs.) torque.

(3) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

INTAKE MANIFOLD

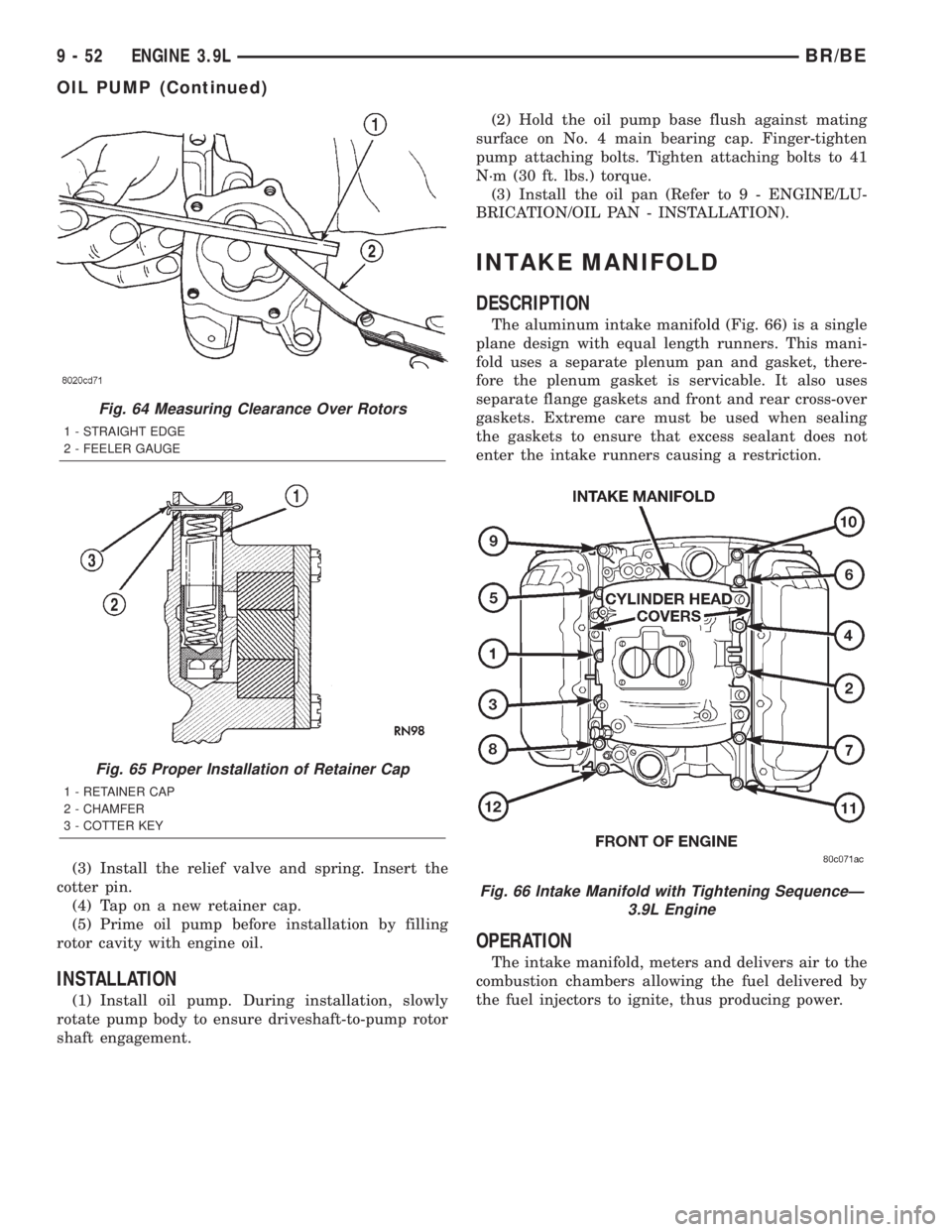

DESCRIPTION

The aluminum intake manifold (Fig. 66) is a single

plane design with equal length runners. This mani-

fold uses a separate plenum pan and gasket, there-

fore the plenum gasket is servicable. It also uses

separate flange gaskets and front and rear cross-over

gaskets. Extreme care must be used when sealing

the gaskets to ensure that excess sealant does not

enter the intake runners causing a restriction.

OPERATION

The intake manifold, meters and delivers air to the

combustion chambers allowing the fuel delivered by

the fuel injectors to ignite, thus producing power.

Fig. 64 Measuring Clearance Over Rotors

1 - STRAIGHT EDGE

2 - FEELER GAUGE

Fig. 65 Proper Installation of Retainer Cap

1 - RETAINER CAP

2 - CHAMFER

3 - COTTER KEY

Fig. 66 Intake Manifold with Tightening SequenceÐ

3.9L Engine

9 - 52 ENGINE 3.9LBR/BE

OIL PUMP (Continued)