key DODGE RAM 2001 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 449 of 2889

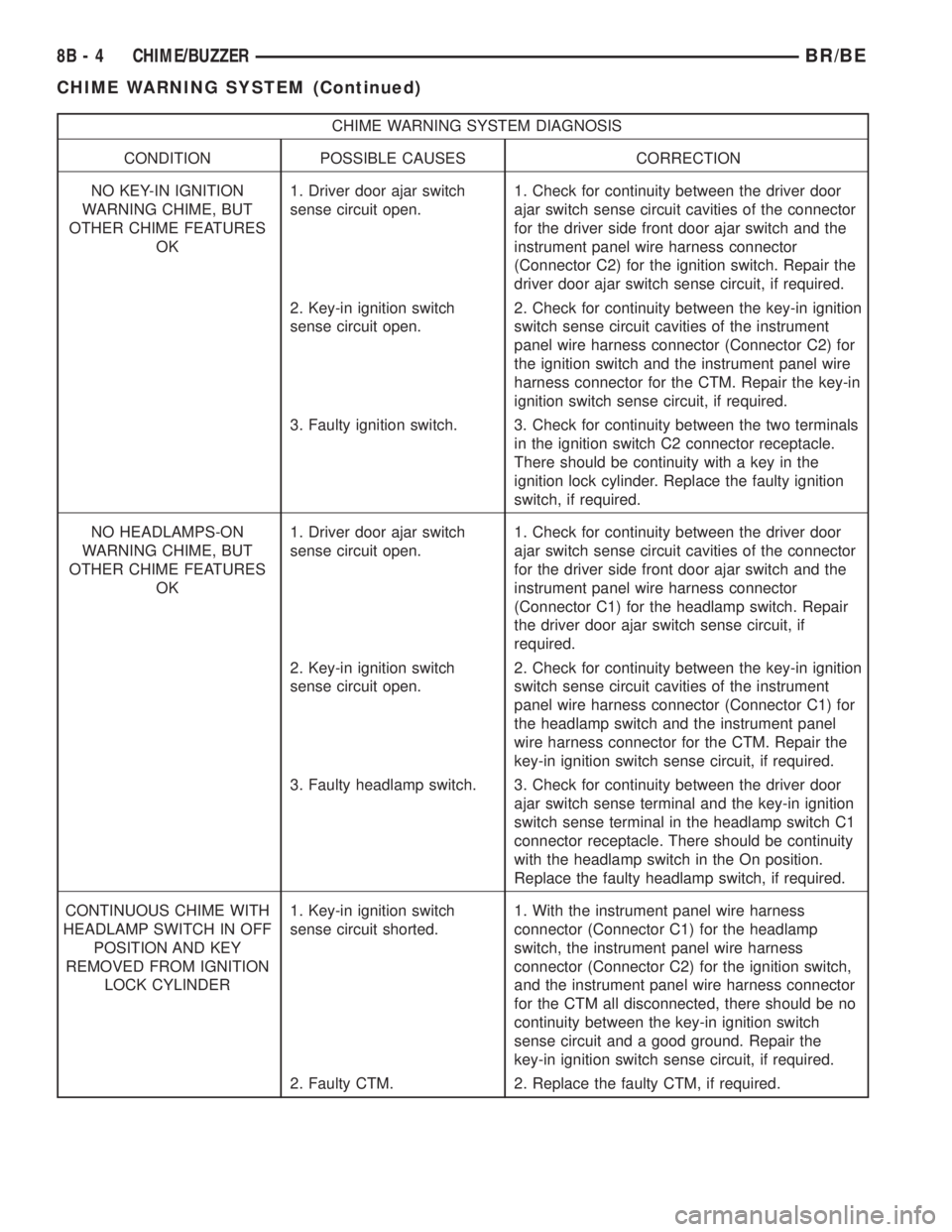

CHIME WARNING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO KEY-IN IGNITION

WARNING CHIME, BUT

OTHER CHIME FEATURES

OK1. Driver door ajar switch

sense circuit open.1. Check for continuity between the driver door

ajar switch sense circuit cavities of the connector

for the driver side front door ajar switch and the

instrument panel wire harness connector

(Connector C2) for the ignition switch. Repair the

driver door ajar switch sense circuit, if required.

2. Key-in ignition switch

sense circuit open.2. Check for continuity between the key-in ignition

switch sense circuit cavities of the instrument

panel wire harness connector (Connector C2) for

the ignition switch and the instrument panel wire

harness connector for the CTM. Repair the key-in

ignition switch sense circuit, if required.

3. Faulty ignition switch. 3. Check for continuity between the two terminals

in the ignition switch C2 connector receptacle.

There should be continuity with a key in the

ignition lock cylinder. Replace the faulty ignition

switch, if required.

NO HEADLAMPS-ON

WARNING CHIME, BUT

OTHER CHIME FEATURES

OK1. Driver door ajar switch

sense circuit open.1. Check for continuity between the driver door

ajar switch sense circuit cavities of the connector

for the driver side front door ajar switch and the

instrument panel wire harness connector

(Connector C1) for the headlamp switch. Repair

the driver door ajar switch sense circuit, if

required.

2. Key-in ignition switch

sense circuit open.2. Check for continuity between the key-in ignition

switch sense circuit cavities of the instrument

panel wire harness connector (Connector C1) for

the headlamp switch and the instrument panel

wire harness connector for the CTM. Repair the

key-in ignition switch sense circuit, if required.

3. Faulty headlamp switch. 3. Check for continuity between the driver door

ajar switch sense terminal and the key-in ignition

switch sense terminal in the headlamp switch C1

connector receptacle. There should be continuity

with the headlamp switch in the On position.

Replace the faulty headlamp switch, if required.

CONTINUOUS CHIME WITH

HEADLAMP SWITCH IN OFF

POSITION AND KEY

REMOVED FROM IGNITION

LOCK CYLINDER1. Key-in ignition switch

sense circuit shorted.1. With the instrument panel wire harness

connector (Connector C1) for the headlamp

switch, the instrument panel wire harness

connector (Connector C2) for the ignition switch,

and the instrument panel wire harness connector

for the CTM all disconnected, there should be no

continuity between the key-in ignition switch

sense circuit and a good ground. Repair the

key-in ignition switch sense circuit, if required.

2. Faulty CTM. 2. Replace the faulty CTM, if required.

8B - 4 CHIME/BUZZERBR/BE

CHIME WARNING SYSTEM (Continued)

Page 453 of 2889

external connector receptacles that connect it to the

vehicle electrical system through one (base) or two

(high-line/premium) take outs with connectors from

the instrument panel wire harness.

The base version of the CTM is used on base mod-

els of this vehicle. It is also sometimes referred to as

the Integrated Electronic Module (IEM). The base

version of the CTM combines the functions of a

chime module and an intermittent wipe module in a

single unit. The high-line version of the CTM is used

on high-line vehicles. The high-line CTM provides all

of the functions of the base version of the CTM, but

also is used to control and integrate many additional

electronic functions and features included on high-

line models. The premium version of the CTM is the

same as the high-line version, but is used only on

models equipped with the heated seat option.

The high-line and premium versions of the CTM

utilize integrated circuitry and information carried

on the Chrysler Collision Detection (CCD) data bus

network along with many hard wired inputs to mon-

itor many sensor and switch inputs throughout the

vehicle. In response to those inputs, the internal cir-

cuitry and programming of the CTM allow it to con-

trol and integrate many electronic functions and

features of the vehicle through both hard wired out-

puts and the transmission of electronic message out-

puts to other electronic modules in the vehicle over

the CCD data bus.

The features that the CTM supports or controls

include the following:

²Automatic Door Lock- The high-line/premium

CTM provides an optional automatic door lock fea-

ture (also known as rolling door locks). This is a pro-

grammable feature.

²Central Locking- The high-line/premium CTM

provides an optional central locking/unlocking fea-

ture.

²Chimes- All versions of the CTM provide chime

service through an integral chime tone generator.

²Courtesy Lamps- The high-line/premium CTM

provides courtesy lamp control with timed load shed-

ding.

²Door Lock Inhibit- The high-line/premium

CTM provides a door lock inhibit feature.

²Enhanced Accident Response- The high-line/

premium CTM provides an optional enhanced acci-

dent response feature. This is a programmable

feature.

²Heated Seats- The premium CTM controls the

optional heated seat system by controlling the opera-

tion of the heated seat relay.

²Illuminated Entry- The high-line/premium

CTM provides a timed illuminated entry feature.²Intermittent Wipe Control- All versions of

the CTM provide control of the intermittent wipe

delay, and wipe-after-wash features.

²Panic Mode- The high-line/premium CTM pro-

vides support for the optional RKE system panic

mode features.

²Power Lock Control- The high-line/premium

CTM provides the optional power lock system fea-

tures, including support for the automatic door lock

and door lock inhibit modes.

²Programmable Features- The high-line/pre-

mium CTM provides support for certain programma-

ble features.

²Remote Keyless Entry- The high-line/pre-

mium CTM provides the optional Remote Keyless

Entry (RKE) system features, including support for

the RKE Lock (with optional horn chirp), Unlock,

Panic, and illuminated entry modes, as well as the

ability to be programmed to recognize up to four

RKE transmitters. The RKE horn chirp is a program-

mable feature.

²Remote Radio Switch Interface- The high-

line/premium CTM monitors and transmits the sta-

tus of the optional remote radio switches.

²Speed Sensitive Intermittent Wipe Control-

The high-line/premium CTM provides the speed sen-

sitive intermittent wipe feature.

²Vehicle Theft Alarm- The high-line/premium

CTM provides control of the optional Vehicle Theft

Alarm features, including support for the central

locking/unlocking mode.

Hard wired circuitry connects the CTM to the elec-

trical system of the vehicle. These hard wired circuits

are integral to several wire harnesses, which are

routed throughout the vehicle and retained by many

different methods. These circuits may be connected to

each other, to the vehicle electrical system and to the

CTM through the use of a combination of soldered

splices, splice block connectors, and many different

types of wire harness terminal connectors and insu-

lators. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

All versions of the CTM for this model are serviced

only as a complete unit. Many of the electronic fea-

tures in the vehicle controlled or supported by the

high-line or premium versions of the CTM are pro-

grammable using the DRBIIItscan tool. In addition,

the high-line/premium CTM software is Flash com-

patible, which means it can be reprogrammed using

Flash reprogramming procedures. However, if any of

the CTM hardware components are damaged or

faulty, the entire CTM unit must be replaced. The

8E - 2 ELECTRONIC CONTROL MODULESBR/BE

BODY CONTROL/CENTRAL TIMER MODULE (Continued)

Page 454 of 2889

base version of the CTM and the hard wired inputs

or outputs of all CTM versions can be diagnosed

using conventional diagnostic tools and methods;

however, for diagnosis of the high-line or premium

versions of the CTM or the CCD data bus, the use of

a DRBIIItscan tool is required. Refer to the appro-

priate diagnostic information.

OPERATION

The Central Timer Module (CTM) is designed to

control and integrate many of the electronic features

and functions of the vehicle. The base version of the

CTM monitors only hard wired inputs and responds

with the proper hard wired outputs. The microproces-

sor-based high-line/premium version of the CTM

monitors many hard wired switch and sensor inputs

as well as those resources it shares with other elec-

tronic modules in the vehicle through its communica-

tion over the Chrysler Collision Detection (CCD) data

bus network. The internal programming and all of

these inputs allow the high-line/premium CTM

microprocessor to determine the tasks it needs to

perform and their priorities, as well as both the stan-

dard and optional features that it should provide.

The high-line/premium CTM programming then per-

forms those tasks and provides those features

through both CCD data bus communication with

other electronic modules and through hard wired out-

puts to a number of circuits, relays, and actuators.

These outputs allow the high-line/premium CTM the

ability to control numerous accessory systems in the

vehicle.

All versions of the CTM operate on battery current

received through fuses in the Junction Block (JB) on

a non-switched fused B(+) circuit, a fused ignition

switch output (st-run) circuit (base version only), and

a fused ignition switch output (run-acc) circuit (high-

line/premium version only). This arrangement allows

the CTM to provide some features regardless of the

ignition switch position, while other features will

operate only with the ignition switch in the Acces-

sory, On, and/or Start positions. All versions of the

CTM are grounded through their connector and take

out of the instrument panel wire harness. The high-

line/premium CTM has another ground received

through a second connector and take out of the

instrument panel wire harness. The first ground cir-

cuit receives ground through a take out with an eye-

let terminal connector of the instrument panel wire

harness that is secured by a nut to a ground stud

located on the left instrument panel end bracket,

while the second ground circuit (high-line/premium

version only) receives ground through a take out with

an eyelet terminal connector of the instrument panel

wire harness that is secured by a nut to a ground

stud located on the back of the instrument panelarmature above the inboard side of the instrument

panel steering column opening.

The high-line/premium CTM monitors its own

internal circuitry as well as many of its input and

output circuits, and will store a Diagnostic Trouble

Code (DTC) in electronic memory for any failure it

detects. These DTCs can be retrieved and diagnosed

using a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

HARD WIRED INPUTS

The hard wired inputs to the CTM include the fol-

lowing:

²CCD bus± - high-line/premium version only

²CCD bus+ - high-line/premium version only

²Cylinder lock switch mux - high-line premium

version only

²Driver door ajar switch sense

²Fused B(+)

²Fused ignition switch output (run-acc) - high-

line/premium version only

²Fused ignition switch output (st-run) - base ver-

sion only

²Ground (one circuit - base version, two circuits -

high-line/premium version)

²Key-in ignition switch sense

²Passenger door ajar switch sense - high-line/pre-

mium version only

²Power door lock motor B(+) lock - high-line/pre-

mium version only

²Power door lock motor B(+) unlock - high-line/

premium version only

²Radio control mux - high-line/premium version

only

²Tone request signal

²Washer switch sense

²Wiper park switch sense

²Wiper switch mode sense

²Wiper switch mode signal

HARD WIRED OUTPUTS

The hard wired outputs of the CTM include the fol-

lowing:

²CCD bus± - high-line/premium version only

²CCD bus+ - high-line/premium version only

²Courtesy lamp switch output - high-line/pre-

mium version only

²Door lock driver - high-line/premium version

only

²Door unlock driver - high-line/premium version

only

²Headlamp relay control - high-line/premium ver-

sion only

²Heated seat relay control - premium version

only

BR/BEELECTRONIC CONTROL MODULES 8E - 3

BODY CONTROL/CENTRAL TIMER MODULE (Continued)

Page 465 of 2889

NOTE: ECM Outputs:

After inputs are received by the ECM, certain sen-

sors, switches and components are controlled or reg-

ulated by the ECM. These are consideredECM

Outputs.These outputs are for:

²CCD bus (+) circuits

²CCD bus (-) circuits

²CKP and APPS outputs to the PCM

²Data link connection for DRB scan tool

²Five volt sensor supply

²Fuel injection pump

²Fuel injection pump relay

²(FPCM) Fuel Pump Control Module

²Fuel transfer (lift) pump

²Intake manifold air heater relays #1 and #2 con-

trol circuits

²Malfunction indicator lamp (Check engine lamp)

²Oil pressure gauge/warning lamp

²PCM

²Wait-to-start warning lamp

²Water-In-Fuel (WIF) warning lamp

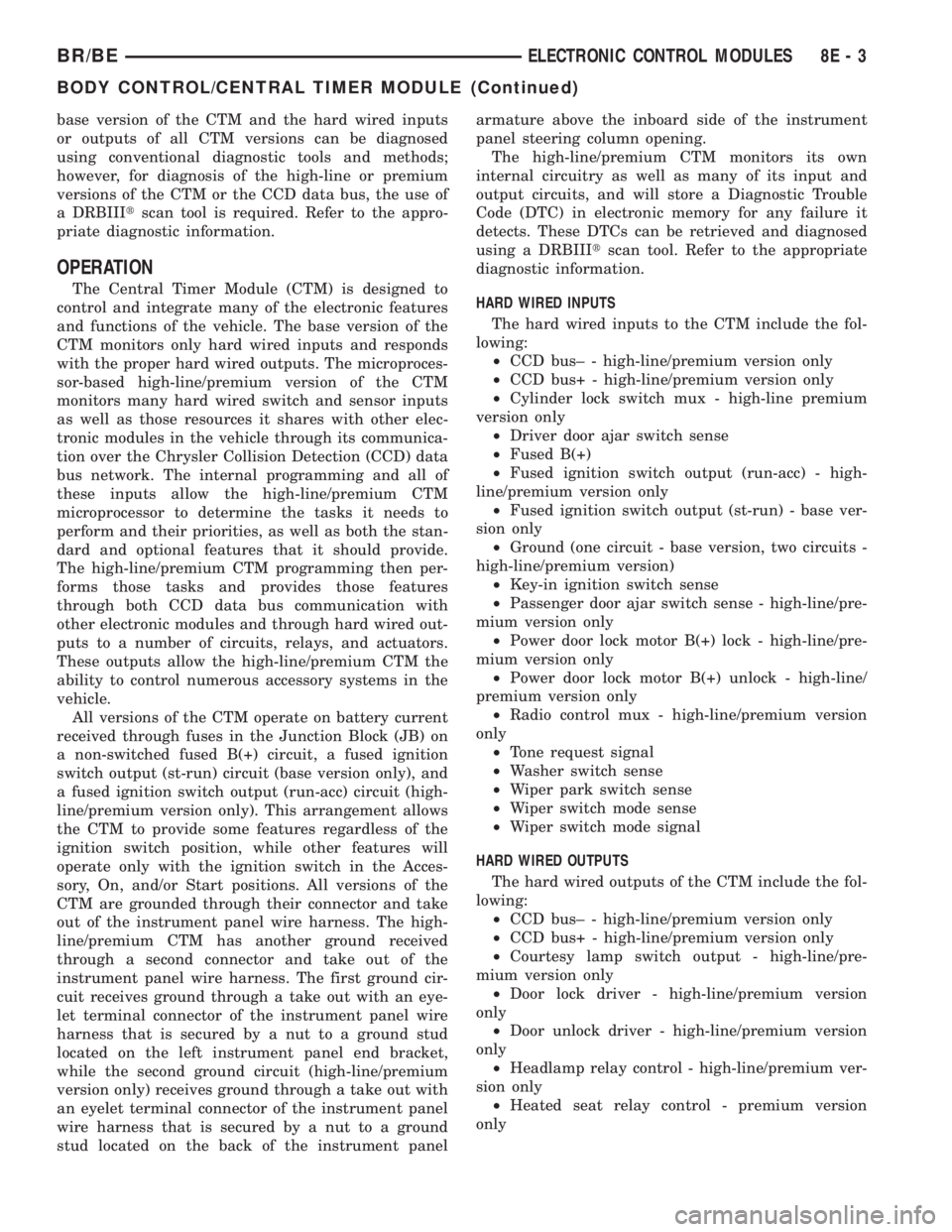

REMOVAL

The ECM is bolted to the engine block behind the

fuel filter (Fig. 16).

(1) Record any Diagnostic Trouble Codes (DTC's)

found in the PCM or ECM.To avoid possible voltage spike damage to either

the Powertrain Control Module (PCM) or ECM, igni-

tion key must be off, and negative battery cables

must be disconnected before unplugging ECM con-

nectors.

(2) Disconnect both negative battery cables at both

batteries.

(3) Remove 50±way electrical connector bolt at

ECM (Fig. 16). Note: Connector bolt is female 4mm

hex head. To remove bolt, use a ball-hex bit or ball-

hex screwdriver such as Snap-Ont4mm SDABM4

(5/32º may also be used). As bolt is being removed,

very carefully remove connector from ECM.

(4) Remove three ECM mounting bolts and remove

ECM from vehicle.

INSTALLATION

Do not apply paint to back of ECM. Poor ground

will result.

(1) Clean ECM mounting points at engine block.

(2) Position ECM to engine block and install 3

mounting bolts. Tighten bolts to 24 N´m (18 ft. lbs.).

(3) Check pin connectors in ECM and 50±way con-

nector for corrosion or damage. Repair as necessary.

(4) Clean pins in 50±way electrical connector with

a quick-dry electrical contact cleaner.

(5) Very carefully install 50±way connector to

ECM. Tighten connector hex bolt.

(6) Install battery cables.

(7)Turn key to ON position. Without starting

engine, slowly press throttle pedal to floor and

then slowly release. This step must be done

(one time) to ensure accelerator pedal position

sensor calibration has been learned by ECM. If

not done, possible DTC's may be set.

(8) Use DRB scan tool to erase any stored compan-

ion DTC's from PCM.

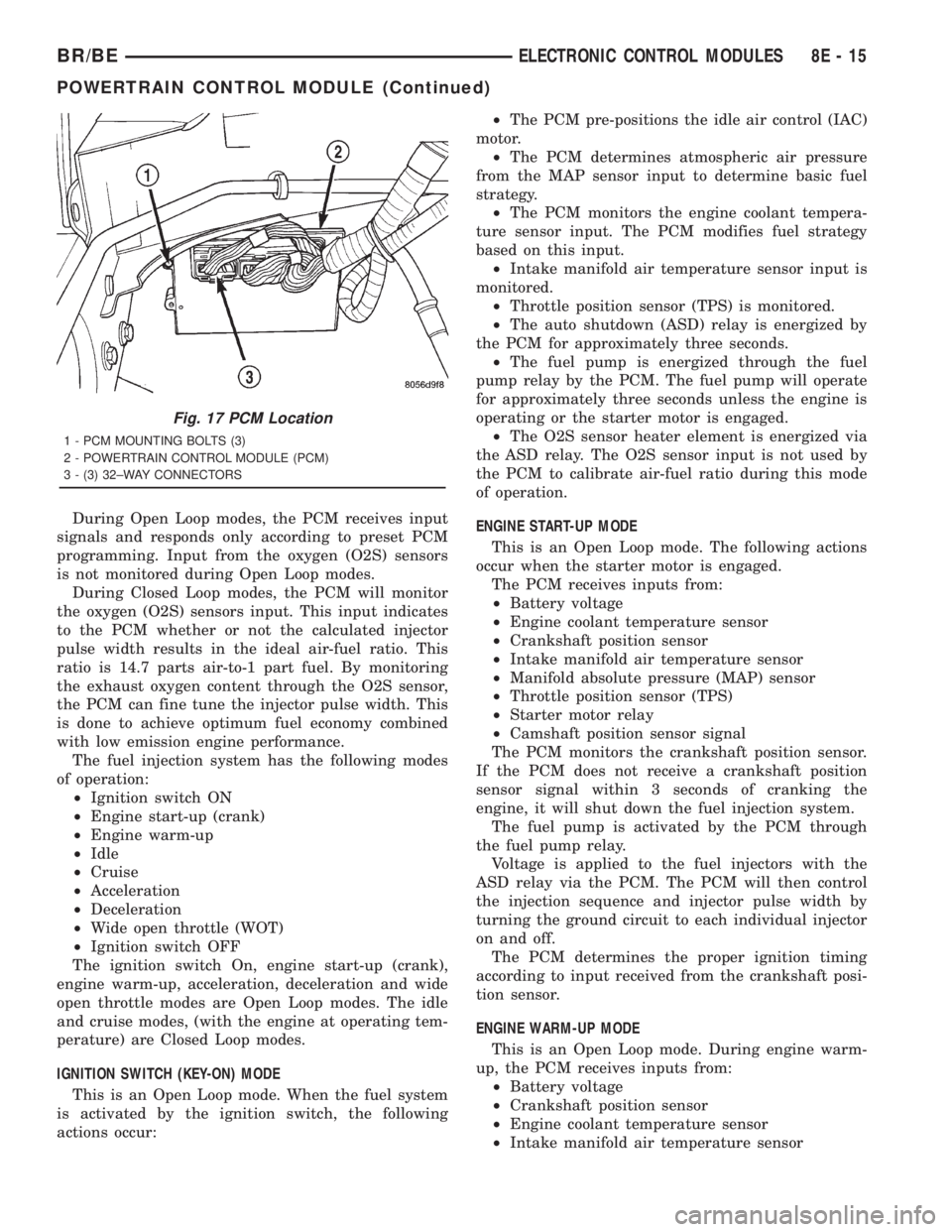

POWERTRAIN CONTROL

MODULE

DESCRIPTION - PCM

The Powertrain Control Module (PCM) is located

in the engine compartment (Fig. 17). The PCM is

referred to as JTEC.

DESCRIPTION - MODES OF OPERATION

As input signals to the Powertrain Control Module

(PCM) change, the PCM adjusts its response to the

output devices. For example, the PCM must calculate

different injector pulse width and ignition timing for

idle than it does for wide open throttle (WOT).

The PCM will operate in two different modes:

Open Loop and Closed Loop.

Fig. 16 Engine Control Module (ECM) Location and

Mounting

1 - ENGINE CONTROL MODULE (ECM)

2 - HEX HEADED BOLT

3 - 50-WAY CONNECTOR

4 - FUEL TRANSFER PUMP

5 - MOUNTING BOLTS (3)

8E - 14 ELECTRONIC CONTROL MODULESBR/BE

ENGINE CONTROL MODULE (Continued)

Page 466 of 2889

During Open Loop modes, the PCM receives input

signals and responds only according to preset PCM

programming. Input from the oxygen (O2S) sensors

is not monitored during Open Loop modes.

During Closed Loop modes, the PCM will monitor

the oxygen (O2S) sensors input. This input indicates

to the PCM whether or not the calculated injector

pulse width results in the ideal air-fuel ratio. This

ratio is 14.7 parts air-to-1 part fuel. By monitoring

the exhaust oxygen content through the O2S sensor,

the PCM can fine tune the injector pulse width. This

is done to achieve optimum fuel economy combined

with low emission engine performance.

The fuel injection system has the following modes

of operation:

²Ignition switch ON

²Engine start-up (crank)

²Engine warm-up

²Idle

²Cruise

²Acceleration

²Deceleration

²Wide open throttle (WOT)

²Ignition switch OFF

The ignition switch On, engine start-up (crank),

engine warm-up, acceleration, deceleration and wide

open throttle modes are Open Loop modes. The idle

and cruise modes, (with the engine at operating tem-

perature) are Closed Loop modes.

IGNITION SWITCH (KEY-ON) MODE

This is an Open Loop mode. When the fuel system

is activated by the ignition switch, the following

actions occur:²The PCM pre-positions the idle air control (IAC)

motor.

²The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

²The PCM monitors the engine coolant tempera-

ture sensor input. The PCM modifies fuel strategy

based on this input.

²Intake manifold air temperature sensor input is

monitored.

²Throttle position sensor (TPS) is monitored.

²The auto shutdown (ASD) relay is energized by

the PCM for approximately three seconds.

²The fuel pump is energized through the fuel

pump relay by the PCM. The fuel pump will operate

for approximately three seconds unless the engine is

operating or the starter motor is engaged.

²The O2S sensor heater element is energized via

the ASD relay. The O2S sensor input is not used by

the PCM to calibrate air-fuel ratio during this mode

of operation.

ENGINE START-UP MODE

This is an Open Loop mode. The following actions

occur when the starter motor is engaged.

The PCM receives inputs from:

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Starter motor relay

²Camshaft position sensor signal

The PCM monitors the crankshaft position sensor.

If the PCM does not receive a crankshaft position

sensor signal within 3 seconds of cranking the

engine, it will shut down the fuel injection system.

The fuel pump is activated by the PCM through

the fuel pump relay.

Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.

The PCM determines the proper ignition timing

according to input received from the crankshaft posi-

tion sensor.

ENGINE WARM-UP MODE

This is an Open Loop mode. During engine warm-

up, the PCM receives inputs from:

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

Fig. 17 PCM Location

1 - PCM MOUNTING BOLTS (3)

2 - POWERTRAIN CONTROL MODULE (PCM)

3 - (3) 32±WAY CONNECTORS

BR/BEELECTRONIC CONTROL MODULES 8E - 15

POWERTRAIN CONTROL MODULE (Continued)

Page 470 of 2889

²Power ground

²Sensor return

²Signal ground

²Speed control resume switch

²Speed control set switch

²Speed control on/off switch

²Transmission governor pressure sensor

²Transmission temperature sensor

²Vehicle speed inputs from ABS or RWAL system

NOTE: PCM Outputs:

After inputs are received by the PCM, certain sen-

sors, switches and components are controlled or reg-

ulated by the PCM. These are consideredPCM

Outputs.These outputs are for:

²A/C clutch relay and A/C clutch

²Auto shutdown (ASD) relay

²CCD bus (+/-) circuits for: speedometer, voltme-

ter, fuel gauge, oil pressure gauge/lamp, engine temp.

gauge and speed control warn. lamp

²Data link connection for DRB scan tool

²Five volt sensor supply

²Generator field driver (-)

²Generator field driver (+)

²Generator lamp (if equipped)

²Malfunction indicator lamp (Check engine lamp)

²Overdrive warning lamp (if equipped)

²Speed control vacuum solenoid

²Speed control vent solenoid

²Tachometer (if equipped)

²Transmission convertor clutch circuit

²Transmission 3±4 shift solenoid

²Transmission relay

²Transmission temperature lamp (if equipped)

²Transmission variable force solenoid (governor

sol.)

OPERATION - 5 VOLT SUPPLIES

Primary 5±volt supply:

²supplies the required 5 volt power source to the

Crankshaft Position (CKP) sensor.

²supplies the required 5 volt power source to the

Camshaft Position (CMP) sensor.

²supplies a reference voltage for the Manifold

Absolute Pressure (MAP) sensor.

²supplies a reference voltage for the Throttle

Position Sensor (TPS) sensor.

Secondary 5±volt supply:

²supplies the required 5 volt power source to the

oil pressure sensor.

²supplies the required 5 volt power source for the

Vehicle Speed Sensor (VSS) (if equipped).

²supplies the 5 volt power source to the transmis-

sion pressure sensor (if equipped with an RE auto-

matic transmission).

OPERATION - IGNITION CIRCUIT SENSE

The ignition circuit sense input tells the PCM the

ignition switch has energized the ignition circuit.

Battery voltage is also supplied to the PCM

through the ignition switch when the ignition is in

the RUN or START position. This is referred to as

the9ignition sense9circuit and is used to9wake up9

the PCM. Voltage on the ignition input can be as low

as 6 volts and the PCM will still function. Voltage is

supplied to this circuit to power the PCM's 8-volt reg-

ulator and to allow the PCM to perform fuel, ignition

and emissions control functions.

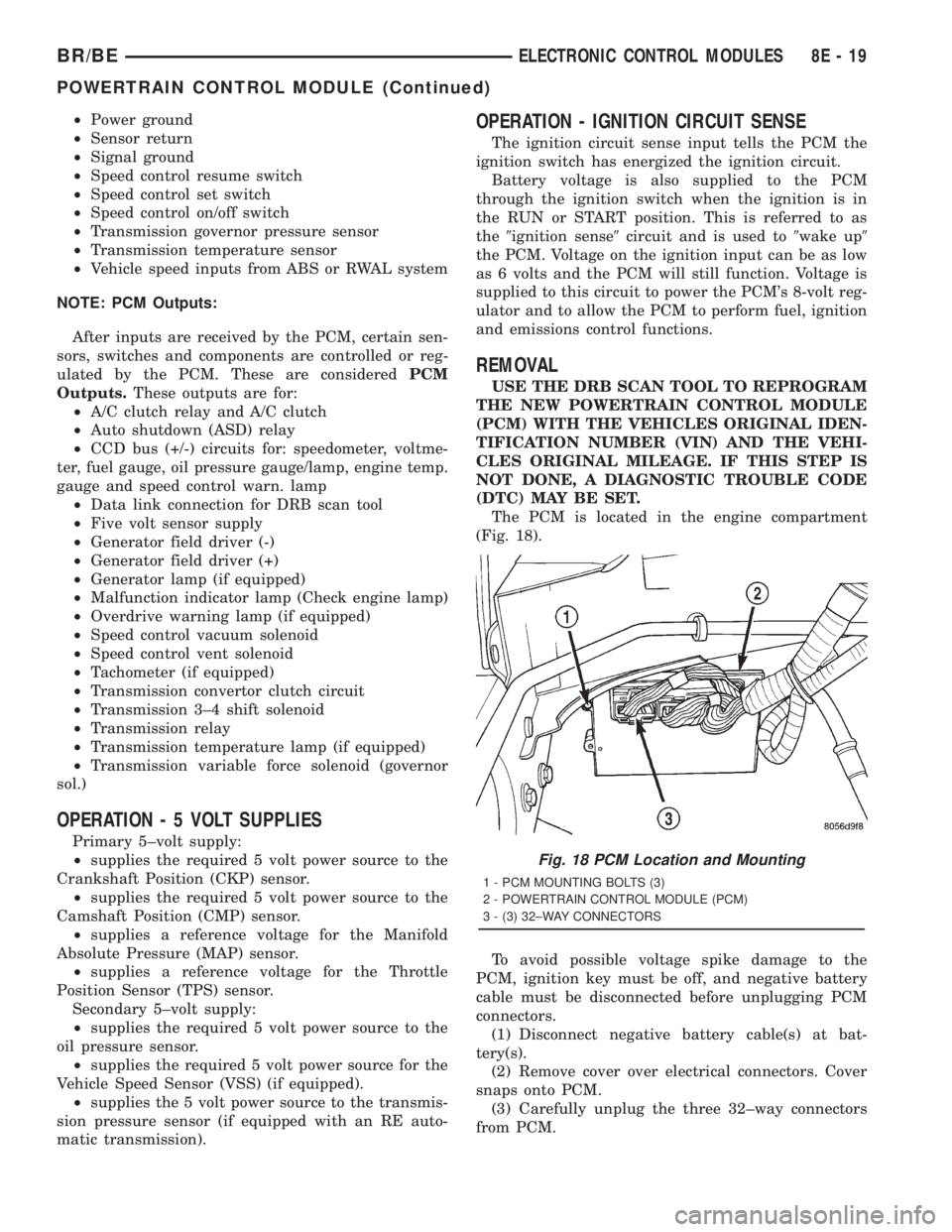

REMOVAL

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW POWERTRAIN CONTROL MODULE

(PCM) WITH THE VEHICLES ORIGINAL IDEN-

TIFICATION NUMBER (VIN) AND THE VEHI-

CLES ORIGINAL MILEAGE. IF THIS STEP IS

NOT DONE, A DIAGNOSTIC TROUBLE CODE

(DTC) MAY BE SET.

The PCM is located in the engine compartment

(Fig. 18).

To avoid possible voltage spike damage to the

PCM, ignition key must be off, and negative battery

cable must be disconnected before unplugging PCM

connectors.

(1) Disconnect negative battery cable(s) at bat-

tery(s).

(2) Remove cover over electrical connectors. Cover

snaps onto PCM.

(3) Carefully unplug the three 32±way connectors

from PCM.

Fig. 18 PCM Location and Mounting

1 - PCM MOUNTING BOLTS (3)

2 - POWERTRAIN CONTROL MODULE (PCM)

3 - (3) 32±WAY CONNECTORS

BR/BEELECTRONIC CONTROL MODULES 8E - 19

POWERTRAIN CONTROL MODULE (Continued)

Page 487 of 2889

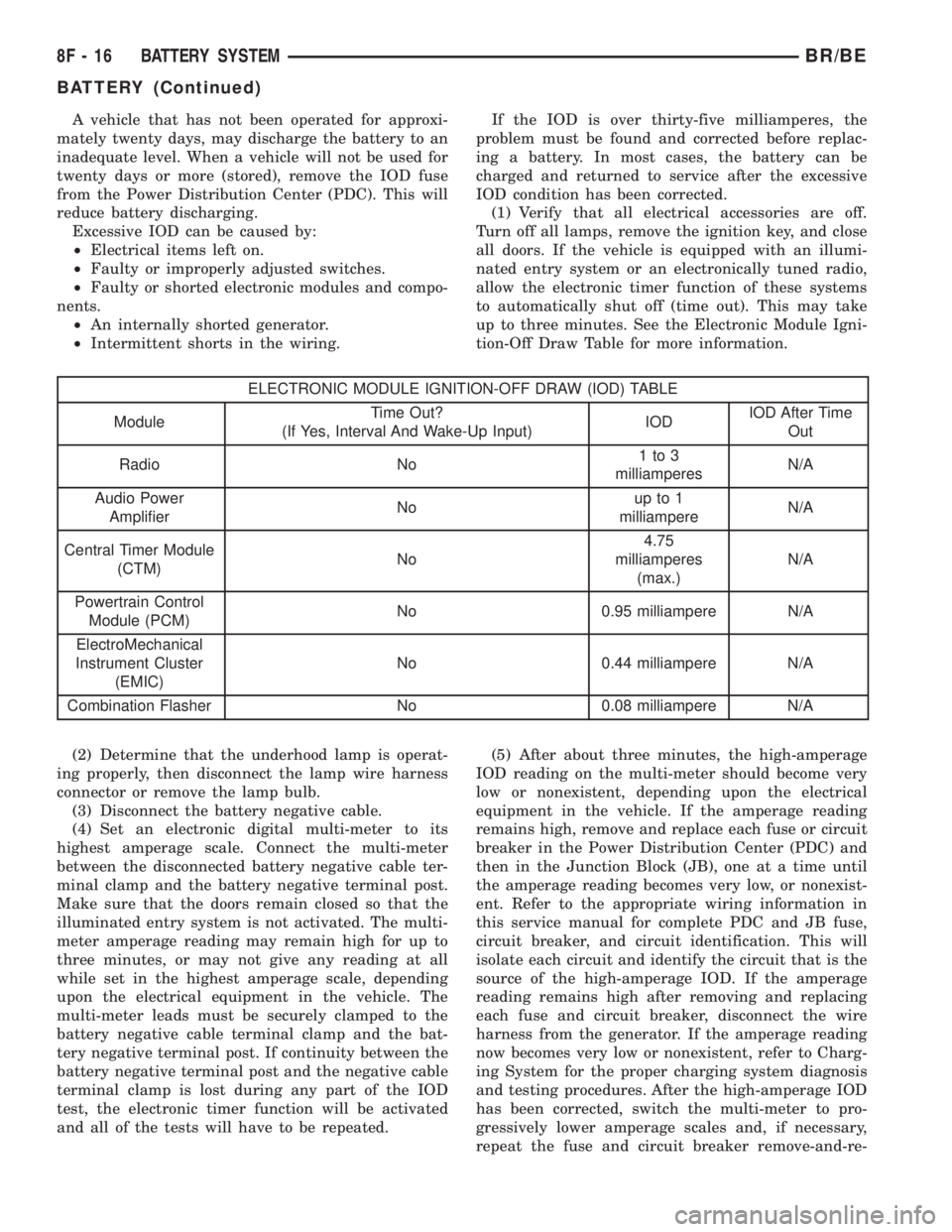

A vehicle that has not been operated for approxi-

mately twenty days, may discharge the battery to an

inadequate level. When a vehicle will not be used for

twenty days or more (stored), remove the IOD fuse

from the Power Distribution Center (PDC). This will

reduce battery discharging.

Excessive IOD can be caused by:

²Electrical items left on.

²Faulty or improperly adjusted switches.

²Faulty or shorted electronic modules and compo-

nents.

²An internally shorted generator.

²Intermittent shorts in the wiring.If the IOD is over thirty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to three minutes. See the Electronic Module Igni-

tion-Off Draw Table for more information.

ELECTRONIC MODULE IGNITION-OFF DRAW (IOD) TABLE

ModuleTime Out?

(If Yes, Interval And Wake-Up Input)IODIOD After Time

Out

Radio No1to3

milliamperesN/A

Audio Power

AmplifierNoup to 1

milliampereN/A

Central Timer Module

(CTM)No4.75

milliamperes

(max.)N/A

Powertrain Control

Module (PCM)No 0.95 milliampere N/A

ElectroMechanical

Instrument Cluster

(EMIC)No 0.44 milliampere N/A

Combination Flasher No 0.08 milliampere N/A

(2) Determine that the underhood lamp is operat-

ing properly, then disconnect the lamp wire harness

connector or remove the lamp bulb.

(3) Disconnect the battery negative cable.

(4) Set an electronic digital multi-meter to its

highest amperage scale. Connect the multi-meter

between the disconnected battery negative cable ter-

minal clamp and the battery negative terminal post.

Make sure that the doors remain closed so that the

illuminated entry system is not activated. The multi-

meter amperage reading may remain high for up to

three minutes, or may not give any reading at all

while set in the highest amperage scale, depending

upon the electrical equipment in the vehicle. The

multi-meter leads must be securely clamped to the

battery negative cable terminal clamp and the bat-

tery negative terminal post. If continuity between the

battery negative terminal post and the negative cable

terminal clamp is lost during any part of the IOD

test, the electronic timer function will be activated

and all of the tests will have to be repeated.(5) After about three minutes, the high-amperage

IOD reading on the multi-meter should become very

low or nonexistent, depending upon the electrical

equipment in the vehicle. If the amperage reading

remains high, remove and replace each fuse or circuit

breaker in the Power Distribution Center (PDC) and

then in the Junction Block (JB), one at a time until

the amperage reading becomes very low, or nonexist-

ent. Refer to the appropriate wiring information in

this service manual for complete PDC and JB fuse,

circuit breaker, and circuit identification. This will

isolate each circuit and identify the circuit that is the

source of the high-amperage IOD. If the amperage

reading remains high after removing and replacing

each fuse and circuit breaker, disconnect the wire

harness from the generator. If the amperage reading

now becomes very low or nonexistent, refer to Charg-

ing System for the proper charging system diagnosis

and testing procedures. After the high-amperage IOD

has been corrected, switch the multi-meter to pro-

gressively lower amperage scales and, if necessary,

repeat the fuse and circuit breaker remove-and-re-

8F - 16 BATTERY SYSTEMBR/BE

BATTERY (Continued)

Page 503 of 2889

STARTING

TABLE OF CONTENTS

page page

STARTING

DESCRIPTION...........................32

OPERATION.............................32

DIAGNOSIS AND TESTING.................33

STARTING SYSTEM.....................33

SPECIFICATIONS........................38

ENGINE STARTER MOTOR

DESCRIPTION...........................39

OPERATION.............................39

DIAGNOSIS AND TESTING.................39STARTERMOTOR......................39

REMOVAL..............................40

INSTALLATION...........................41

ENGINE STARTER MOTOR RELAY

DESCRIPTION...........................42

OPERATION.............................42

DIAGNOSIS AND TESTING.................42

STARTER RELAY.......................42

REMOVAL..............................43

INSTALLATION...........................43

STARTING

DESCRIPTION

The starting system consists of:

²Starter relay

²Starter motor (including an integral starter sole-

noid)

Other components to be considered as part of start-

ing system are:

²Battery

²Battery cables

²Ignition switch and key lock cylinder

²Clutch pedal position switch (manual transmis-

sion)

²Park/neutral position switch (automatic trans-

mission)

²Wire harnesses and connections.

The Battery, Starting, and Charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct operation of

starting/charging systems, all components used in

these 3 systems must perform within specifications.

When attempting to diagnose any of these systems, it

is important that you keep their interdependency in

mind.

The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Powertrain Control Mod-

ule (PCM). Use of an induction-type milliampere

ammeter, volt/ohmmeter, battery charger, carbon pile

rheostat (load tester), and 12-volt test lamp may be

required.

Certain starting system components are monitored

by the PCM and may produce a Diagnostic Trouble

Code (DTC). Refer to Diagnostic Trouble Codes for

additional information and a list of codes.

OPERATION

The starting system components form two separate

circuits. A high-amperage feed circuit that feeds the

starter motor between 150 and 350 amperes (700

amperes - diesel engine), and a low-amperage control

circuit that operates on less than 20 amperes. The

high-amperage feed circuit components include the

battery, the battery cables, the contact disc portion of

the starter solenoid, and the starter motor. The low-

amperage control circuit components include the igni-

tion switch, the clutch pedal position switch (manual

transmission), the park/neutral position switch (auto-

matic transmission), the starter relay, the electro-

magnetic windings of the starter solenoid, and the

connecting wire harness components.

If the vehicle is equipped with a manual transmis-

sion, it has a clutch pedal position switch installed in

series between the ignition switch and the coil bat-

tery terminal of the starter relay. This normally open

switch prevents the starter relay from being ener-

gized when the ignition switch is turned to the

momentary Start position, unless the clutch pedal is

depressed. This feature prevents starter motor oper-

ation while the clutch disc and the flywheel are

engaged. The starter relay coil ground terminal is

always grounded on vehicles with a manual trans-

mission.

If the vehicle is equipped with an automatic trans-

mission, battery voltage is supplied through the low-

amperage control circuit to the coil battery terminal

of the starter relay when the ignition switch is

turned to the momentary Start position. The park/

neutral position switch is installed in series between

the starter relay coil ground terminal and ground.

This normally open switch prevents the starter relay

from being energized and the starter motor from

operating unless the automatic transmission gear

selector is in the Neutral or Park positions.

8F - 32 STARTINGBR/BE

Page 504 of 2889

When the starter relay coil is energized, the nor-

mally open relay contacts close. The relay contacts

connect the relay common feed terminal to the relay

normally open terminal. The closed relay contacts

energize the starter solenoid coil windings.

The energized solenoid pull-in coil pulls in the sole-

noid plunger. The solenoid plunger pulls the shift

lever in the starter motor. This engages the starter

overrunning clutch and pinion gear with the starter

ring gear on the manual transmission flywheel or on

the automatic transmission torque converter or

torque converter drive plate.

As the solenoid plunger reaches the end of its

travel, the solenoid contact disc completes the high-

amperage starter feed circuit and energizes the sole-

noid plunger hold-in coil. Current now flows between

the solenoid battery terminal and the starter motor,

energizing the starter.

Once the engine starts, the overrunning clutch pro-

tects the starter motor from damage by allowing the

starter pinion gear to spin faster than the pinionshaft. When the driver releases the ignition switch to

the On position, the starter relay coil is de-energized.

This causes the relay contacts to open. When the

relay contacts open, the starter solenoid plunger

hold-in coil is de-energized.

When the solenoid plunger hold-in coil is de-ener-

gized, the solenoid plunger return spring returns the

plunger to its relaxed position. This causes the con-

tact disc to open the starter feed circuit, and the shift

lever to disengage the overrunning clutch and pinion

gear from the starter ring gear.

DIAGNOSIS AND TESTING - STARTING

SYSTEM

The battery, starting, and charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct starting/

charging system operation, all of the components

involved in these 3 systems must perform within

specifications.

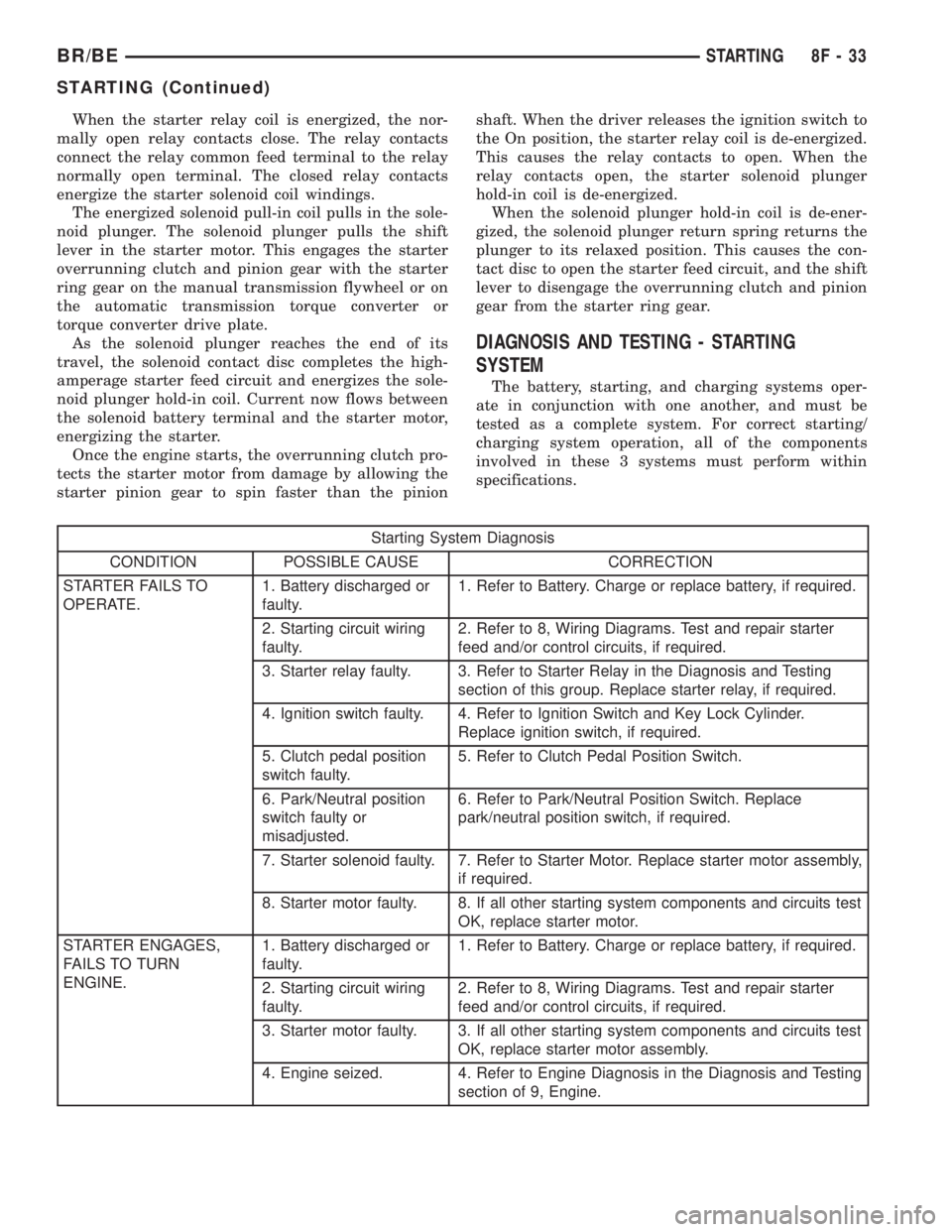

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS TO

OPERATE.1. Battery discharged or

faulty.1. Refer to Battery. Charge or replace battery, if required.

2. Starting circuit wiring

faulty.2. Refer to 8, Wiring Diagrams. Test and repair starter

feed and/or control circuits, if required.

3. Starter relay faulty. 3. Refer to Starter Relay in the Diagnosis and Testing

section of this group. Replace starter relay, if required.

4. Ignition switch faulty. 4. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch, if required.

5. Clutch pedal position

switch faulty.5. Refer to Clutch Pedal Position Switch.

6. Park/Neutral position

switch faulty or

misadjusted.6. Refer to Park/Neutral Position Switch. Replace

park/neutral position switch, if required.

7. Starter solenoid faulty. 7. Refer to Starter Motor. Replace starter motor assembly,

if required.

8. Starter motor faulty. 8. If all other starting system components and circuits test

OK, replace starter motor.

STARTER ENGAGES,

FAILS TO TURN

ENGINE.1. Battery discharged or

faulty.1. Refer to Battery. Charge or replace battery, if required.

2. Starting circuit wiring

faulty.2. Refer to 8, Wiring Diagrams. Test and repair starter

feed and/or control circuits, if required.

3. Starter motor faulty. 3. If all other starting system components and circuits test

OK, replace starter motor assembly.

4. Engine seized. 4. Refer to Engine Diagnosis in the Diagnosis and Testing

section of 9, Engine.

BR/BESTARTING 8F - 33

STARTING (Continued)

Page 505 of 2889

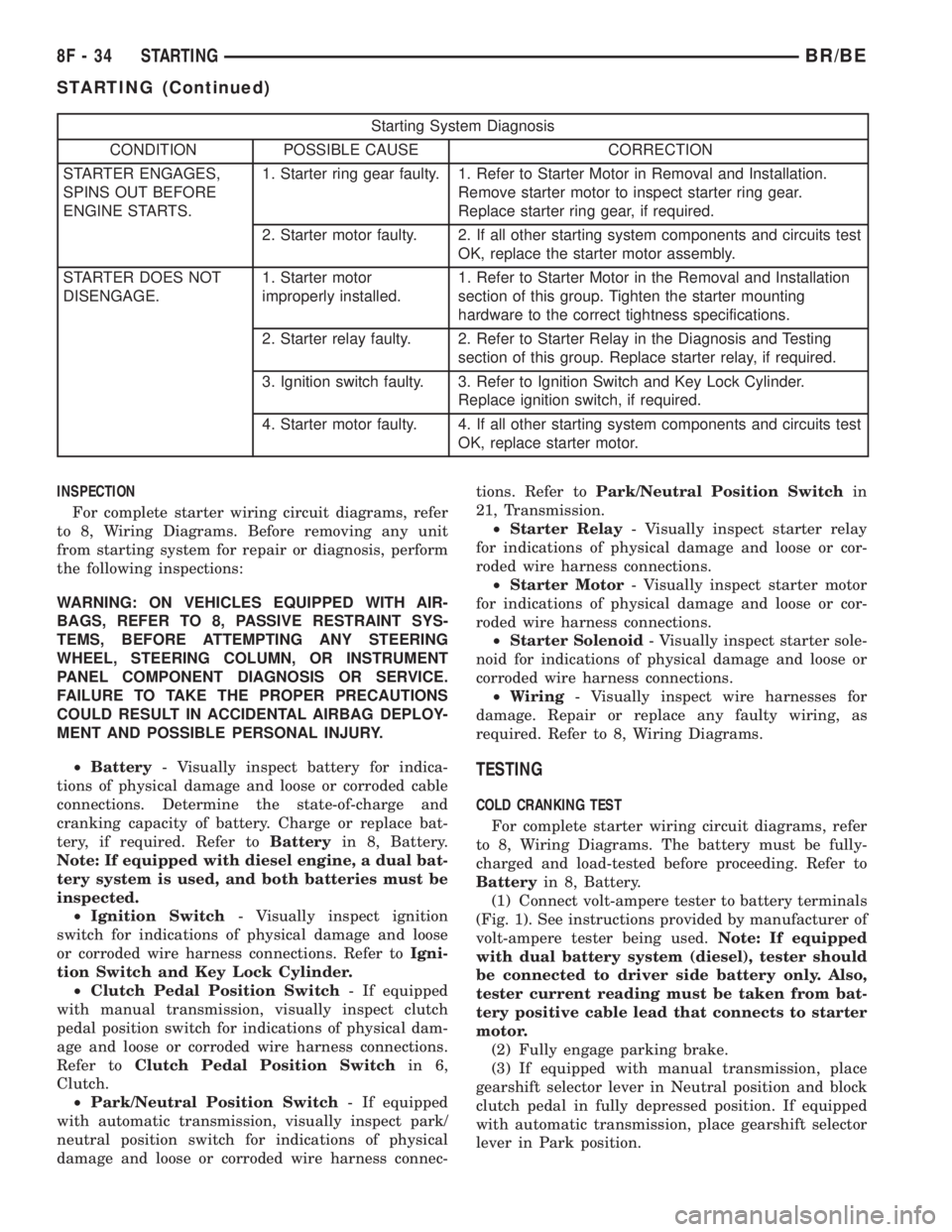

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER ENGAGES,

SPINS OUT BEFORE

ENGINE STARTS.1. Starter ring gear faulty. 1. Refer to Starter Motor in Removal and Installation.

Remove starter motor to inspect starter ring gear.

Replace starter ring gear, if required.

2. Starter motor faulty. 2. If all other starting system components and circuits test

OK, replace the starter motor assembly.

STARTER DOES NOT

DISENGAGE.1. Starter motor

improperly installed.1. Refer to Starter Motor in the Removal and Installation

section of this group. Tighten the starter mounting

hardware to the correct tightness specifications.

2. Starter relay faulty. 2. Refer to Starter Relay in the Diagnosis and Testing

section of this group. Replace starter relay, if required.

3. Ignition switch faulty. 3. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch, if required.

4. Starter motor faulty. 4. If all other starting system components and circuits test

OK, replace starter motor.

INSPECTION

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. Before removing any unit

from starting system for repair or diagnosis, perform

the following inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO 8, PASSIVE RESTRAINT SYS-

TEMS, BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY.

²Battery- Visually inspect battery for indica-

tions of physical damage and loose or corroded cable

connections. Determine the state-of-charge and

cranking capacity of battery. Charge or replace bat-

tery, if required. Refer toBatteryin 8, Battery.

Note: If equipped with diesel engine, a dual bat-

tery system is used, and both batteries must be

inspected.

²Ignition Switch- Visually inspect ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer toIgni-

tion Switch and Key Lock Cylinder.

²Clutch Pedal Position Switch- If equipped

with manual transmission, visually inspect clutch

pedal position switch for indications of physical dam-

age and loose or corroded wire harness connections.

Refer toClutch Pedal Position Switchin 6,

Clutch.

²Park/Neutral Position Switch- If equipped

with automatic transmission, visually inspect park/

neutral position switch for indications of physical

damage and loose or corroded wire harness connec-tions. Refer toPark/Neutral Position Switchin

21, Transmission.

²Starter Relay- Visually inspect starter relay

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Motor- Visually inspect starter motor

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Solenoid- Visually inspect starter sole-

noid for indications of physical damage and loose or

corroded wire harness connections.

²Wiring- Visually inspect wire harnesses for

damage. Repair or replace any faulty wiring, as

required. Refer to 8, Wiring Diagrams.

TESTING

COLD CRANKING TEST

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. The battery must be fully-

charged and load-tested before proceeding. Refer to

Batteryin 8, Battery.

(1) Connect volt-ampere tester to battery terminals

(Fig. 1). See instructions provided by manufacturer of

volt-ampere tester being used.Note: If equipped

with dual battery system (diesel), tester should

be connected to driver side battery only. Also,

tester current reading must be taken from bat-

tery positive cable lead that connects to starter

motor.

(2) Fully engage parking brake.

(3) If equipped with manual transmission, place

gearshift selector lever in Neutral position and block

clutch pedal in fully depressed position. If equipped

with automatic transmission, place gearshift selector

lever in Park position.

8F - 34 STARTINGBR/BE

STARTING (Continued)