length DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 19 of 2889

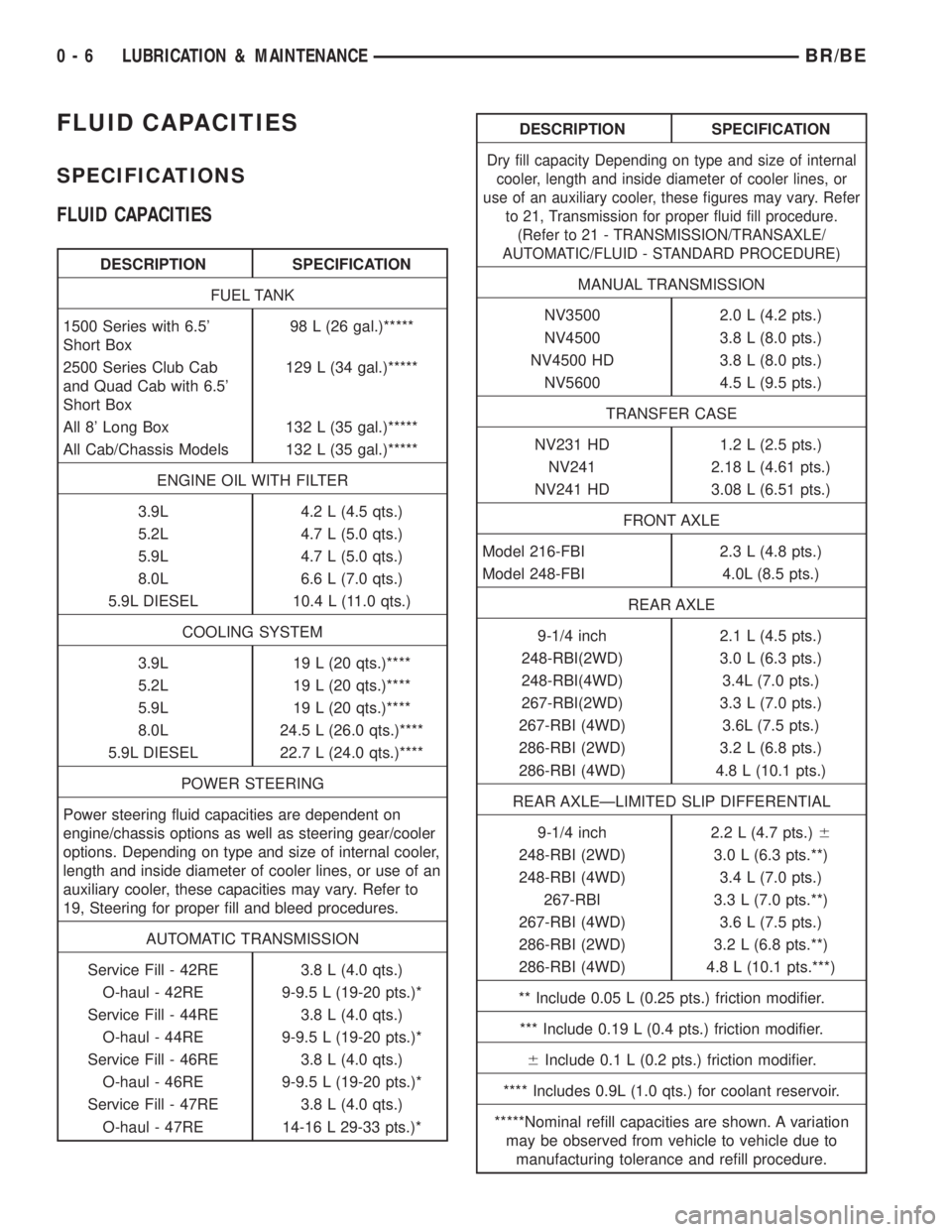

FLUID CAPACITIES

SPECIFICATIONS

FLUID CAPACITIES

DESCRIPTION SPECIFICATION

FUEL TANK

1500 Series with 6.5'

Short Box98 L (26 gal.)*****

2500 Series Club Cab

and Quad Cab with 6.5'

Short Box129 L (34 gal.)*****

All 8' Long Box 132 L (35 gal.)*****

All Cab/Chassis Models 132 L (35 gal.)*****

ENGINE OIL WITH FILTER

3.9L 4.2 L (4.5 qts.)

5.2L 4.7 L (5.0 qts.)

5.9L 4.7 L (5.0 qts.)

8.0L 6.6 L (7.0 qts.)

5.9L DIESEL 10.4 L (11.0 qts.)

COOLING SYSTEM

3.9L 19 L (20 qts.)****

5.2L 19 L (20 qts.)****

5.9L 19 L (20 qts.)****

8.0L 24.5 L (26.0 qts.)****

5.9L DIESEL 22.7 L (24.0 qts.)****

POWER STEERING

Power steering fluid capacities are dependent on

engine/chassis options as well as steering gear/cooler

options. Depending on type and size of internal cooler,

length and inside diameter of cooler lines, or use of an

auxiliary cooler, these capacities may vary. Refer to

19, Steering for proper fill and bleed procedures.

AUTOMATIC TRANSMISSION

Service Fill - 42RE 3.8 L (4.0 qts.)

O-haul - 42RE 9-9.5 L (19-20 pts.)*

Service Fill - 44RE 3.8 L (4.0 qts.)

O-haul - 44RE 9-9.5 L (19-20 pts.)*

Service Fill - 46RE 3.8 L (4.0 qts.)

O-haul - 46RE 9-9.5 L (19-20 pts.)*

Service Fill - 47RE 3.8 L (4.0 qts.)

O-haul - 47RE 14-16 L 29-33 pts.)*

DESCRIPTION SPECIFICATION

Dry fill capacity Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or

use of an auxiliary cooler, these figures may vary. Refer

to 21, Transmission for proper fluid fill procedure.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC/FLUID - STANDARD PROCEDURE)

MANUAL TRANSMISSION

NV3500 2.0 L (4.2 pts.)

NV4500 3.8 L (8.0 pts.)

NV4500 HD 3.8 L (8.0 pts.)

NV5600 4.5 L (9.5 pts.)

TRANSFER CASE

NV231 HD 1.2 L (2.5 pts.)

NV241 2.18 L (4.61 pts.)

NV241 HD 3.08 L (6.51 pts.)

FRONT AXLE

Model 216-FBI 2.3 L (4.8 pts.)

Model 248-FBI 4.0L (8.5 pts.)

REAR AXLE

9-1/4 inch 2.1 L (4.5 pts.)

248-RBI(2WD) 3.0 L (6.3 pts.)

248-RBI(4WD) 3.4L (7.0 pts.)

267-RBI(2WD) 3.3 L (7.0 pts.)

267-RBI (4WD) 3.6L (7.5 pts.)

286-RBI (2WD) 3.2 L (6.8 pts.)

286-RBI (4WD) 4.8 L (10.1 pts.)

REAR AXLEÐLIMITED SLIP DIFFERENTIAL

9-1/4 inch 2.2 L (4.7 pts.)6

248-RBI (2WD) 3.0 L (6.3 pts.**)

248-RBI (4WD) 3.4 L (7.0 pts.)

267-RBI 3.3 L (7.0 pts.**)

267-RBI (4WD) 3.6 L (7.5 pts.)

286-RBI (2WD) 3.2 L (6.8 pts.**)

286-RBI (4WD) 4.8 L (10.1 pts.***)

** Include 0.05 L (0.25 pts.) friction modifier.

*** Include 0.19 L (0.4 pts.) friction modifier.

6Include 0.1 L (0.2 pts.) friction modifier.

**** Includes 0.9L (1.0 qts.) for coolant reservoir.

*****Nominal refill capacities are shown. A variation

may be observed from vehicle to vehicle due to

manufacturing tolerance and refill procedure.

0 - 6 LUBRICATION & MAINTENANCEBR/BE

Page 71 of 2889

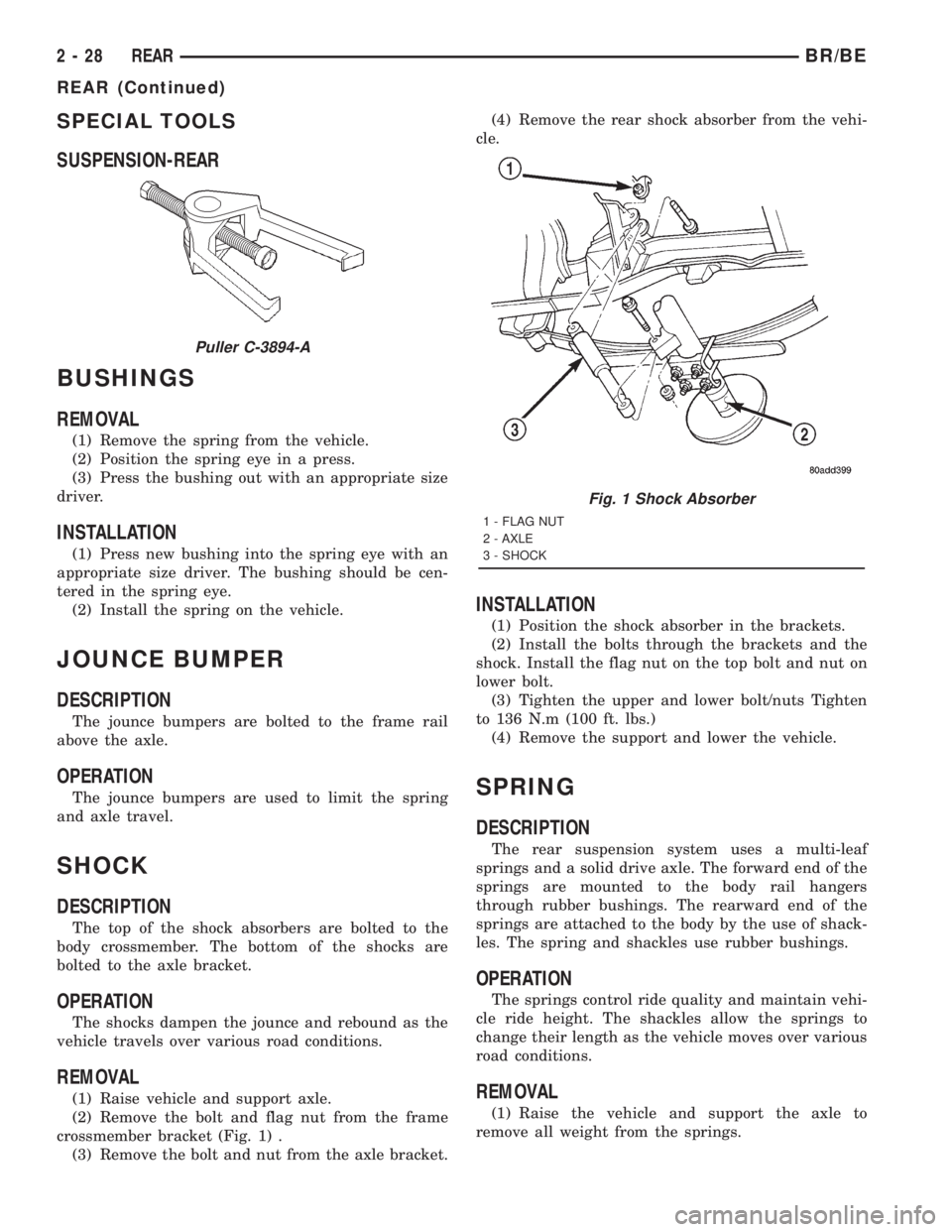

SPECIAL TOOLS

SUSPENSION-REAR

BUSHINGS

REMOVAL

(1) Remove the spring from the vehicle.

(2) Position the spring eye in a press.

(3) Press the bushing out with an appropriate size

driver.

INSTALLATION

(1) Press new bushing into the spring eye with an

appropriate size driver. The bushing should be cen-

tered in the spring eye.

(2) Install the spring on the vehicle.

JOUNCE BUMPER

DESCRIPTION

The jounce bumpers are bolted to the frame rail

above the axle.

OPERATION

The jounce bumpers are used to limit the spring

and axle travel.

SHOCK

DESCRIPTION

The top of the shock absorbers are bolted to the

body crossmember. The bottom of the shocks are

bolted to the axle bracket.

OPERATION

The shocks dampen the jounce and rebound as the

vehicle travels over various road conditions.

REMOVAL

(1) Raise vehicle and support axle.

(2) Remove the bolt and flag nut from the frame

crossmember bracket (Fig. 1) .

(3) Remove the bolt and nut from the axle bracket.(4) Remove the rear shock absorber from the vehi-

cle.

INSTALLATION

(1) Position the shock absorber in the brackets.

(2) Install the bolts through the brackets and the

shock. Install the flag nut on the top bolt and nut on

lower bolt.

(3) Tighten the upper and lower bolt/nuts Tighten

to 136 N.m (100 ft. lbs.)

(4) Remove the support and lower the vehicle.

SPRING

DESCRIPTION

The rear suspension system uses a multi-leaf

springs and a solid drive axle. The forward end of the

springs are mounted to the body rail hangers

through rubber bushings. The rearward end of the

springs are attached to the body by the use of shack-

les. The spring and shackles use rubber bushings.

OPERATION

The springs control ride quality and maintain vehi-

cle ride height. The shackles allow the springs to

change their length as the vehicle moves over various

road conditions.

REMOVAL

(1) Raise the vehicle and support the axle to

remove all weight from the springs.

Puller C-3894-A

Fig. 1 Shock Absorber

1 - FLAG NUT

2 - AXLE

3 - SHOCK

2 - 28 REARBR/BE

REAR (Continued)

Page 74 of 2889

DIFFERENTIAL & DRIVELINE

TABLE OF CONTENTS

page page

PROPELLER SHAFT.......................1

FRONT AXLE - 216FBI....................12

FRONT AXLE - 248FBI....................45

REAR AXLE-91/4.......................77REAR AXLE - 248RBI....................109

REAR AXLE - 267RBI....................140

REAR AXLE - 286RBI....................169

PROPELLER SHAFT

TABLE OF CONTENTS

page page

PROPELLER SHAFT

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................3

PROPELLER SHAFT.....................3

STANDARD PROCEDURE...................5

SPECIFICATIONS.........................8

SPECIAL TOOLS..........................8

PROPELLER SHAFT - FRONT

REMOVAL...............................8

INSTALLATION............................8PROPELLER SHAFT - REAR

REMOVAL...............................9

INSTALLATION............................9

CENTER BEARING

DESCRIPTION...........................10

OPERATION.............................10

REMOVAL..............................10

INSTALLATION...........................10

ADJUSTMENTS..........................10

SINGLE CARDAN UNIVERSAL JOINTS

DISASSEMBLY...........................11

PROPELLER SHAFT

DESCRIPTION

A propeller shaft (Fig. 1), (Fig. 2), (Fig. 3), and

(Fig. 4) is a shaft which connects the transmission/

transfer case to the axle differential. This is the link

through which the engine power is transmitted to the

axle.

The propeller shaft is designed and built with the

yoke lugs in line with each other which is called zero

phasing. This design produces the smoothest running

condition, an out-of-phase shaft can cause a vibra-

tion.

Tubular propeller shafts are balanced by the man-

ufacturer with weights spot welded to the tube.

Use the exact replacement parts when installing

the propeller shafts. The use of the correct replace-

ment parts helps to ensure safe operation. All fasten-

ers must be torqued to the specified values for safe

operation.Also make alignment reference marks (Fig. 5)on

the propeller shaft yoke and axle, or transmission,

yoke prior to servicing. This helps to eliminate possi-

ble vibration.

CAUTION: Do not allow the propeller shaft to drop

or hang from any propeller shaft joint during

removal. Attach the propeller shaft to the vehicle

underside with wire to prevent damage to the joints.

OPERATION

The propeller shaft must operate through con-

stantly changing relative angles between the trans-

mission and axle. It must also be capable of changing

length while transmitting torque. The axle rides sus-

pended by springs in a floating motion. The propeller

shaft must be able to change operating angles when

going over various road surfaces. This is accom-

plished through universal joints, which permit the

propeller shaft to operate at different angles. The slip

joints (or yokes) permit contraction or expansion.

BR/BEDIFFERENTIAL & DRIVELINE 3 - 1

Page 78 of 2889

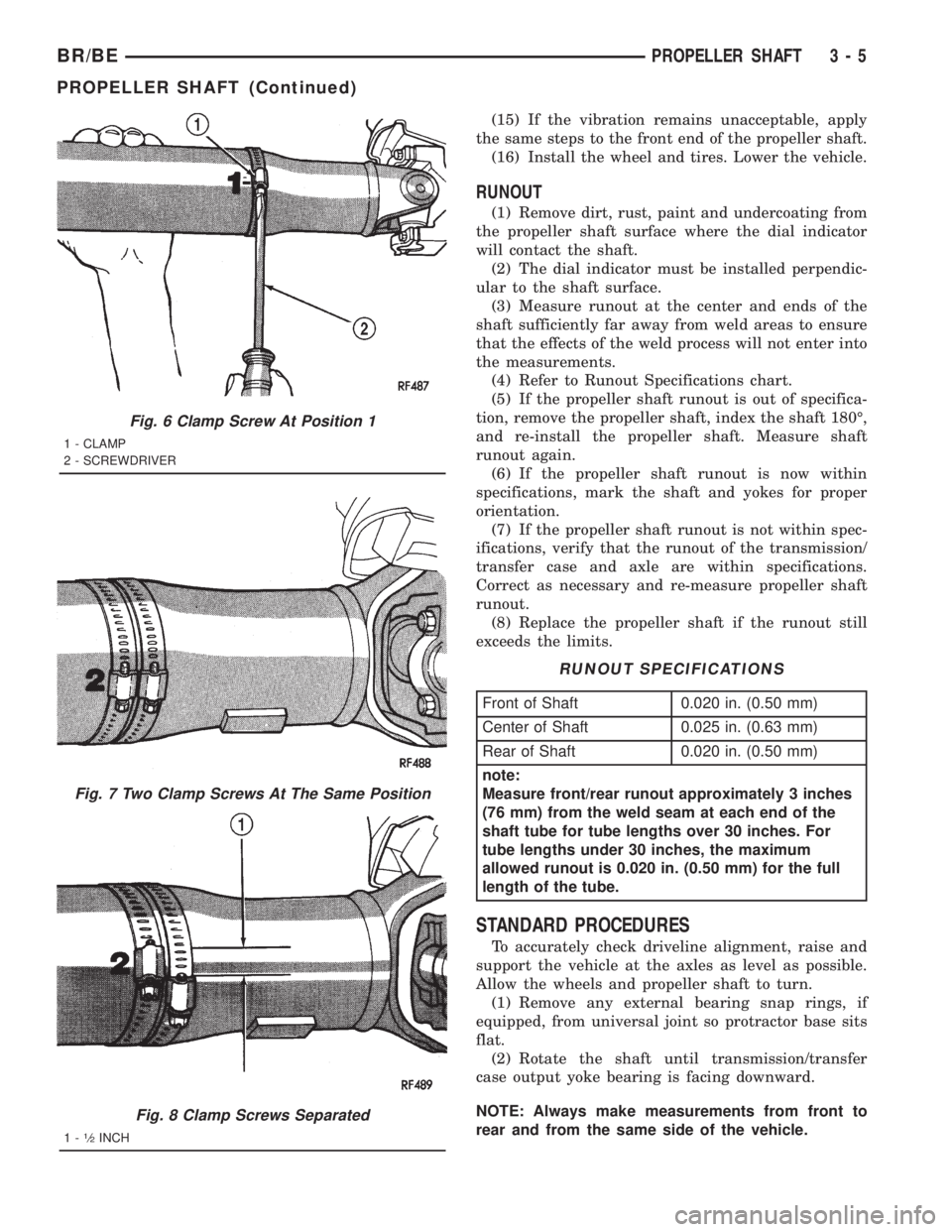

(15) If the vibration remains unacceptable, apply

the same steps to the front end of the propeller shaft.

(16) Install the wheel and tires. Lower the vehicle.

RUNOUT

(1) Remove dirt, rust, paint and undercoating from

the propeller shaft surface where the dial indicator

will contact the shaft.

(2) The dial indicator must be installed perpendic-

ular to the shaft surface.

(3) Measure runout at the center and ends of the

shaft sufficiently far away from weld areas to ensure

that the effects of the weld process will not enter into

the measurements.

(4) Refer to Runout Specifications chart.

(5) If the propeller shaft runout is out of specifica-

tion, remove the propeller shaft, index the shaft 180É,

and re-install the propeller shaft. Measure shaft

runout again.

(6) If the propeller shaft runout is now within

specifications, mark the shaft and yokes for proper

orientation.

(7) If the propeller shaft runout is not within spec-

ifications, verify that the runout of the transmission/

transfer case and axle are within specifications.

Correct as necessary and re-measure propeller shaft

runout.

(8) Replace the propeller shaft if the runout still

exceeds the limits.

RUNOUT SPECIFICATIONS

Front of Shaft 0.020 in. (0.50 mm)

Center of Shaft 0.025 in. (0.63 mm)

Rear of Shaft 0.020 in. (0.50 mm)

note:

Measure front/rear runout approximately 3 inches

(76 mm) from the weld seam at each end of the

shaft tube for tube lengths over 30 inches. For

tube lengths under 30 inches, the maximum

allowed runout is 0.020 in. (0.50 mm) for the full

length of the tube.

STANDARD PROCEDURES

To accurately check driveline alignment, raise and

support the vehicle at the axles as level as possible.

Allow the wheels and propeller shaft to turn.

(1) Remove any external bearing snap rings, if

equipped, from universal joint so protractor base sits

flat.

(2) Rotate the shaft until transmission/transfer

case output yoke bearing is facing downward.

NOTE: Always make measurements from front to

rear and from the same side of the vehicle.

Fig. 6 Clamp Screw At Position 1

1 - CLAMP

2 - SCREWDRIVER

Fig. 7 Two Clamp Screws At The Same Position

Fig. 8 Clamp Screws Separated

1-1¤2INCH

BR/BEPROPELLER SHAFT 3 - 5

PROPELLER SHAFT (Continued)

Page 83 of 2889

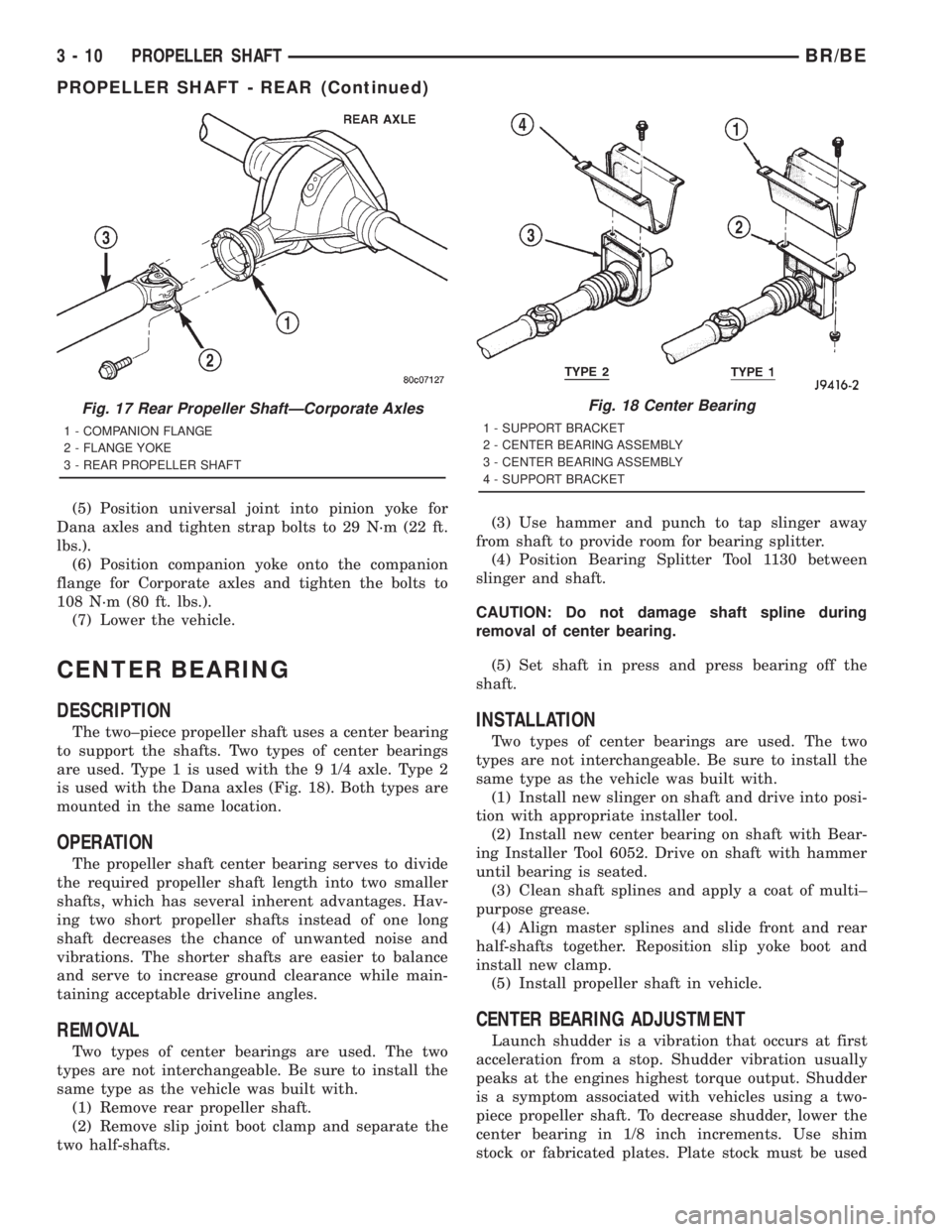

(5) Position universal joint into pinion yoke for

Dana axles and tighten strap bolts to 29 N´m (22 ft.

lbs.).

(6) Position companion yoke onto the companion

flange for Corporate axles and tighten the bolts to

108 N´m (80 ft. lbs.).

(7) Lower the vehicle.

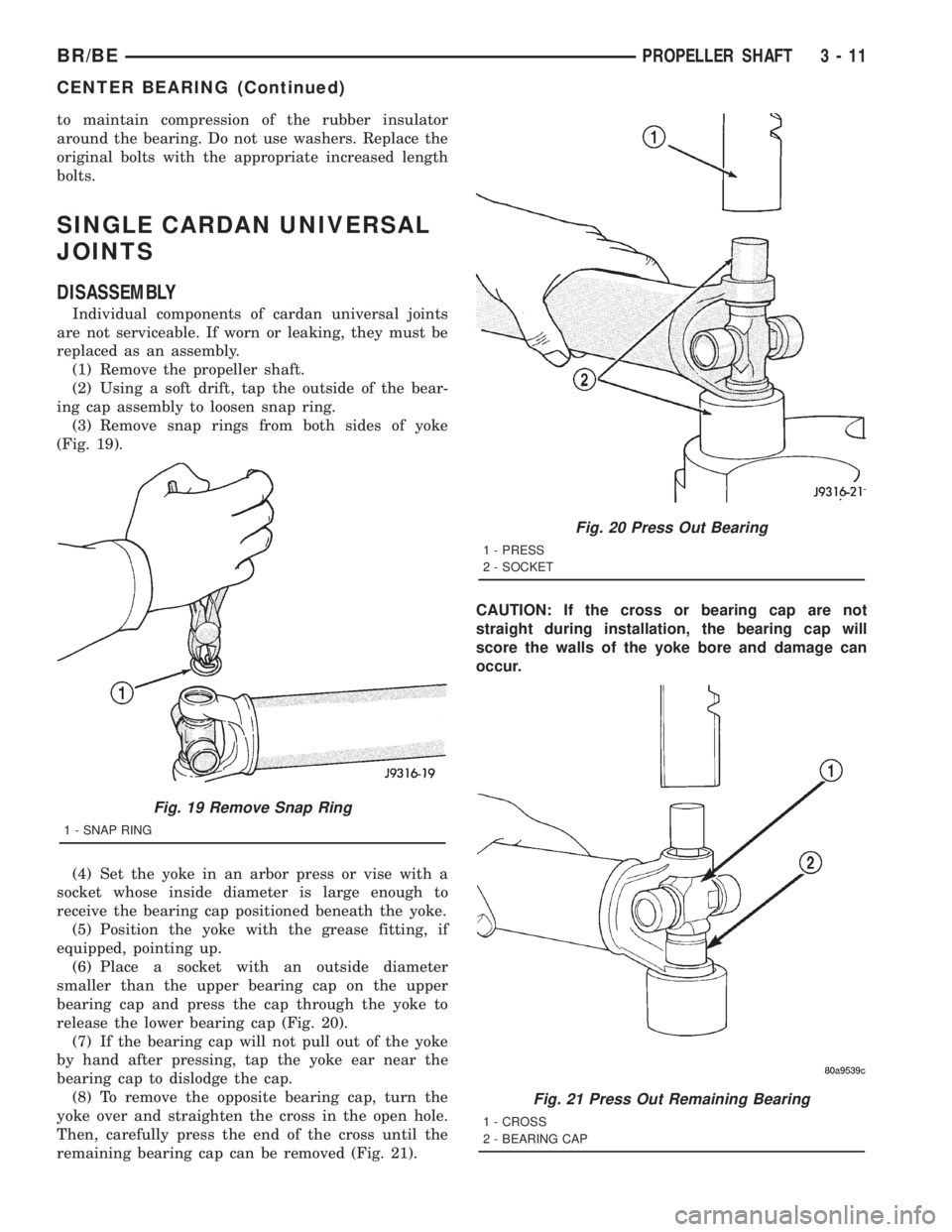

CENTER BEARING

DESCRIPTION

The two±piece propeller shaft uses a center bearing

to support the shafts. Two types of center bearings

are used. Type 1 is used with the 9 1/4 axle. Type 2

is used with the Dana axles (Fig. 18). Both types are

mounted in the same location.

OPERATION

The propeller shaft center bearing serves to divide

the required propeller shaft length into two smaller

shafts, which has several inherent advantages. Hav-

ing two short propeller shafts instead of one long

shaft decreases the chance of unwanted noise and

vibrations. The shorter shafts are easier to balance

and serve to increase ground clearance while main-

taining acceptable driveline angles.

REMOVAL

Two types of center bearings are used. The two

types are not interchangeable. Be sure to install the

same type as the vehicle was built with.

(1) Remove rear propeller shaft.

(2) Remove slip joint boot clamp and separate the

two half-shafts.(3) Use hammer and punch to tap slinger away

from shaft to provide room for bearing splitter.

(4) Position Bearing Splitter Tool 1130 between

slinger and shaft.

CAUTION: Do not damage shaft spline during

removal of center bearing.

(5) Set shaft in press and press bearing off the

shaft.

INSTALLATION

Two types of center bearings are used. The two

types are not interchangeable. Be sure to install the

same type as the vehicle was built with.

(1) Install new slinger on shaft and drive into posi-

tion with appropriate installer tool.

(2) Install new center bearing on shaft with Bear-

ing Installer Tool 6052. Drive on shaft with hammer

until bearing is seated.

(3) Clean shaft splines and apply a coat of multi±

purpose grease.

(4) Align master splines and slide front and rear

half-shafts together. Reposition slip yoke boot and

install new clamp.

(5) Install propeller shaft in vehicle.

CENTER BEARING ADJUSTMENT

Launch shudder is a vibration that occurs at first

acceleration from a stop. Shudder vibration usually

peaks at the engines highest torque output. Shudder

is a symptom associated with vehicles using a two-

piece propeller shaft. To decrease shudder, lower the

center bearing in 1/8 inch increments. Use shim

stock or fabricated plates. Plate stock must be used

Fig. 17 Rear Propeller ShaftÐCorporate Axles

1 - COMPANION FLANGE

2 - FLANGE YOKE

3 - REAR PROPELLER SHAFT

Fig. 18 Center Bearing

1 - SUPPORT BRACKET

2 - CENTER BEARING ASSEMBLY

3 - CENTER BEARING ASSEMBLY

4 - SUPPORT BRACKET

3 - 10 PROPELLER SHAFTBR/BE

PROPELLER SHAFT - REAR (Continued)

Page 84 of 2889

to maintain compression of the rubber insulator

around the bearing. Do not use washers. Replace the

original bolts with the appropriate increased length

bolts.

SINGLE CARDAN UNIVERSAL

JOINTS

DISASSEMBLY

Individual components of cardan universal joints

are not serviceable. If worn or leaking, they must be

replaced as an assembly.

(1) Remove the propeller shaft.

(2) Using a soft drift, tap the outside of the bear-

ing cap assembly to loosen snap ring.

(3) Remove snap rings from both sides of yoke

(Fig. 19).

(4) Set the yoke in an arbor press or vise with a

socket whose inside diameter is large enough to

receive the bearing cap positioned beneath the yoke.

(5) Position the yoke with the grease fitting, if

equipped, pointing up.

(6) Place a socket with an outside diameter

smaller than the upper bearing cap on the upper

bearing cap and press the cap through the yoke to

release the lower bearing cap (Fig. 20).

(7) If the bearing cap will not pull out of the yoke

by hand after pressing, tap the yoke ear near the

bearing cap to dislodge the cap.

(8) To remove the opposite bearing cap, turn the

yoke over and straighten the cross in the open hole.

Then, carefully press the end of the cross until the

remaining bearing cap can be removed (Fig. 21).CAUTION: If the cross or bearing cap are not

straight during installation, the bearing cap will

score the walls of the yoke bore and damage can

occur.

Fig. 19 Remove Snap Ring

1 - SNAP RING

Fig. 20 Press Out Bearing

1 - PRESS

2 - SOCKET

Fig. 21 Press Out Remaining Bearing

1 - CROSS

2 - BEARING CAP

BR/BEPROPELLER SHAFT 3 - 11

CENTER BEARING (Continued)

Page 300 of 2889

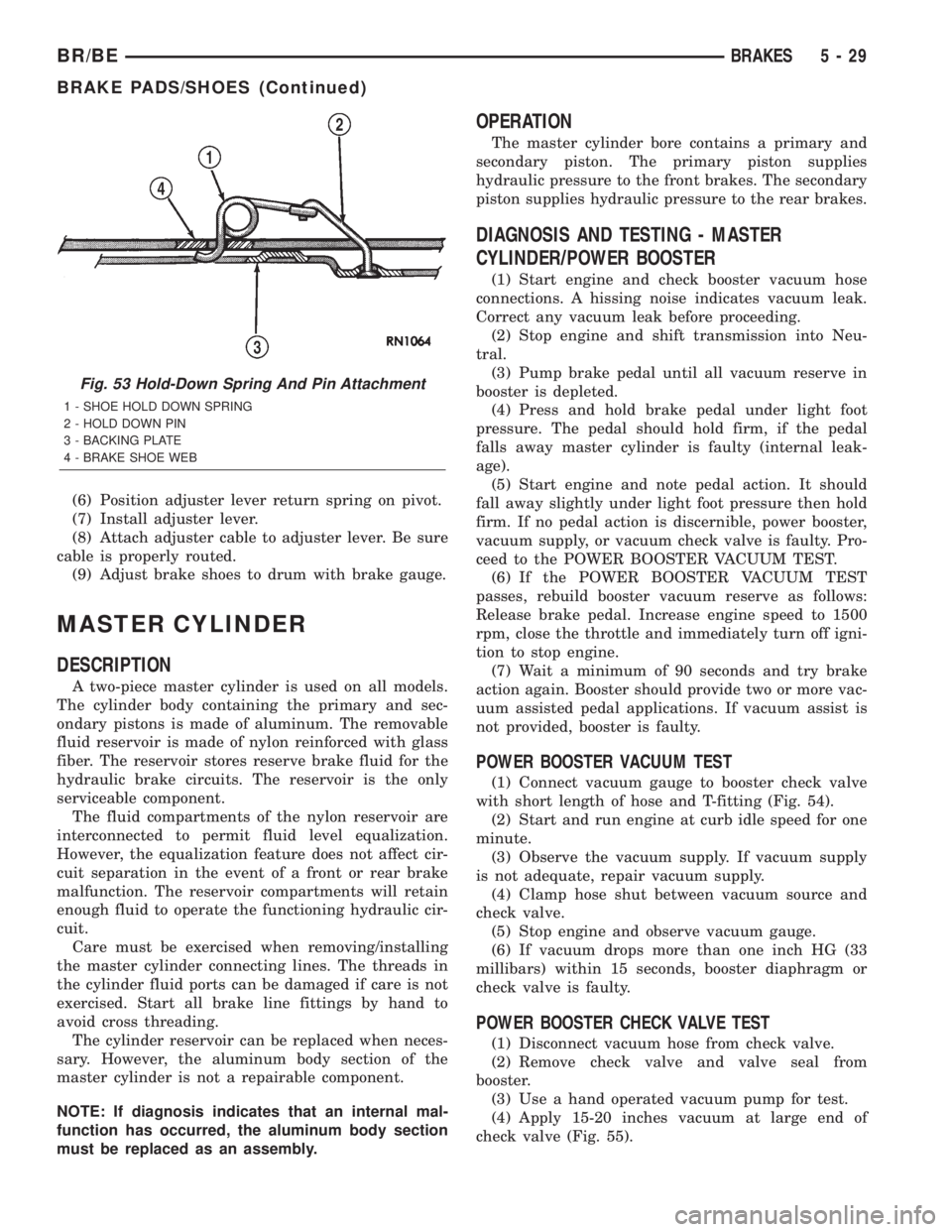

(6) Position adjuster lever return spring on pivot.

(7) Install adjuster lever.

(8) Attach adjuster cable to adjuster lever. Be sure

cable is properly routed.

(9) Adjust brake shoes to drum with brake gauge.

MASTER CYLINDER

DESCRIPTION

A two-piece master cylinder is used on all models.

The cylinder body containing the primary and sec-

ondary pistons is made of aluminum. The removable

fluid reservoir is made of nylon reinforced with glass

fiber. The reservoir stores reserve brake fluid for the

hydraulic brake circuits. The reservoir is the only

serviceable component.

The fluid compartments of the nylon reservoir are

interconnected to permit fluid level equalization.

However, the equalization feature does not affect cir-

cuit separation in the event of a front or rear brake

malfunction. The reservoir compartments will retain

enough fluid to operate the functioning hydraulic cir-

cuit.

Care must be exercised when removing/installing

the master cylinder connecting lines. The threads in

the cylinder fluid ports can be damaged if care is not

exercised. Start all brake line fittings by hand to

avoid cross threading.

The cylinder reservoir can be replaced when neces-

sary. However, the aluminum body section of the

master cylinder is not a repairable component.

NOTE: If diagnosis indicates that an internal mal-

function has occurred, the aluminum body section

must be replaced as an assembly.

OPERATION

The master cylinder bore contains a primary and

secondary piston. The primary piston supplies

hydraulic pressure to the front brakes. The secondary

piston supplies hydraulic pressure to the rear brakes.

DIAGNOSIS AND TESTING - MASTER

CYLINDER/POWER BOOSTER

(1) Start engine and check booster vacuum hose

connections. A hissing noise indicates vacuum leak.

Correct any vacuum leak before proceeding.

(2) Stop engine and shift transmission into Neu-

tral.

(3) Pump brake pedal until all vacuum reserve in

booster is depleted.

(4) Press and hold brake pedal under light foot

pressure. The pedal should hold firm, if the pedal

falls away master cylinder is faulty (internal leak-

age).

(5) Start engine and note pedal action. It should

fall away slightly under light foot pressure then hold

firm. If no pedal action is discernible, power booster,

vacuum supply, or vacuum check valve is faulty. Pro-

ceed to the POWER BOOSTER VACUUM TEST.

(6) If the POWER BOOSTER VACUUM TEST

passes, rebuild booster vacuum reserve as follows:

Release brake pedal. Increase engine speed to 1500

rpm, close the throttle and immediately turn off igni-

tion to stop engine.

(7) Wait a minimum of 90 seconds and try brake

action again. Booster should provide two or more vac-

uum assisted pedal applications. If vacuum assist is

not provided, booster is faulty.

POWER BOOSTER VACUUM TEST

(1) Connect vacuum gauge to booster check valve

with short length of hose and T-fitting (Fig. 54).

(2) Start and run engine at curb idle speed for one

minute.

(3) Observe the vacuum supply. If vacuum supply

is not adequate, repair vacuum supply.

(4) Clamp hose shut between vacuum source and

check valve.

(5) Stop engine and observe vacuum gauge.

(6) If vacuum drops more than one inch HG (33

millibars) within 15 seconds, booster diaphragm or

check valve is faulty.

POWER BOOSTER CHECK VALVE TEST

(1) Disconnect vacuum hose from check valve.

(2) Remove check valve and valve seal from

booster.

(3) Use a hand operated vacuum pump for test.

(4) Apply 15-20 inches vacuum at large end of

check valve (Fig. 55).

Fig. 53 Hold-Down Spring And Pin Attachment

1 - SHOE HOLD DOWN SPRING

2 - HOLD DOWN PIN

3 - BACKING PLATE

4 - BRAKE SHOE WEB

BR/BEBRAKES 5 - 29

BRAKE PADS/SHOES (Continued)

Page 356 of 2889

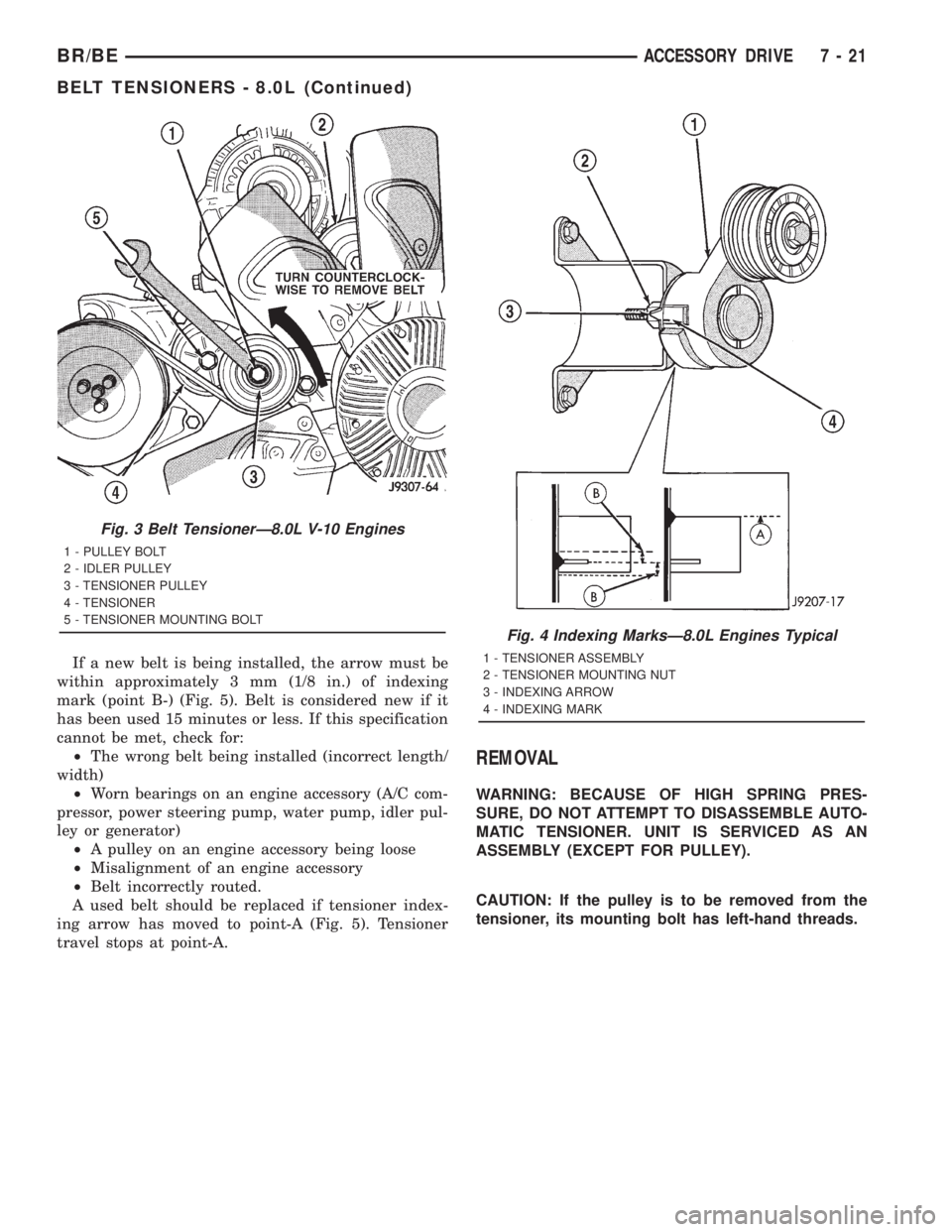

If a new belt is being installed, the arrow must be

within approximately 3 mm (1/8 in.) of indexing

mark (point B-) (Fig. 5). Belt is considered new if it

has been used 15 minutes or less. If this specification

cannot be met, check for:

²The wrong belt being installed (incorrect length/

width)

²Worn bearings on an engine accessory (A/C com-

pressor, power steering pump, water pump, idler pul-

ley or generator)

²A pulley on an engine accessory being loose

²Misalignment of an engine accessory

²Belt incorrectly routed.

A used belt should be replaced if tensioner index-

ing arrow has moved to point-A (Fig. 5). Tensioner

travel stops at point-A.

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY (EXCEPT FOR PULLEY).

CAUTION: If the pulley is to be removed from the

tensioner, its mounting bolt has left-hand threads.

Fig. 3 Belt TensionerÐ8.0L V-10 Engines

1 - PULLEY BOLT

2 - IDLER PULLEY

3 - TENSIONER PULLEY

4 - TENSIONER

5 - TENSIONER MOUNTING BOLT

Fig. 4 Indexing MarksÐ8.0L Engines Typical

1 - TENSIONER ASSEMBLY

2 - TENSIONER MOUNTING NUT

3 - INDEXING ARROW

4 - INDEXING MARK

BR/BEACCESSORY DRIVE 7 - 21

BELT TENSIONERS - 8.0L (Continued)

Page 358 of 2889

BELT TENSIONERS - 5.9L

DIESEL

DESCRIPTION

Drive belts on all engines are equipped with a

spring loaded automatic belt tensioner (Fig. 9). This

tensioner maintains constant belt tension at all times

and requires no maintenance or adjustment.

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner.

OPERATION

WARNING: THE AUTOMATIC BELT TENSIONER

ASSEMBLY IS SPRING LOADED. DO NOT ATTEMPT

TO DISASSEMBLE THE TENSIONER ASSEMBLY.

The automatic belt tensioner maintains correct belt

tension using a coiled spring within the tensioner

housing. The spring applies pressure to the tensioner

arm pressing the arm into the belt, tensioning the

belt.

If a new belt is being installed, the arrow must be

within approximately 3 mm (1/8 in.) of indexing

mark. Belt is considered new if it has been used 15

minutes or less. If this specification cannot be met,

check for:

²The wrong belt being installed (incorrect length/

width)

²Worn bearings on an engine accessory (A/C com-

pressor, power steering pump, water pump, idler pul-

ley or generator)

²A pulley on an engine accessory being loose

²Misalignment of an engine accessory

²Belt incorrectly routed.

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY.

(1) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

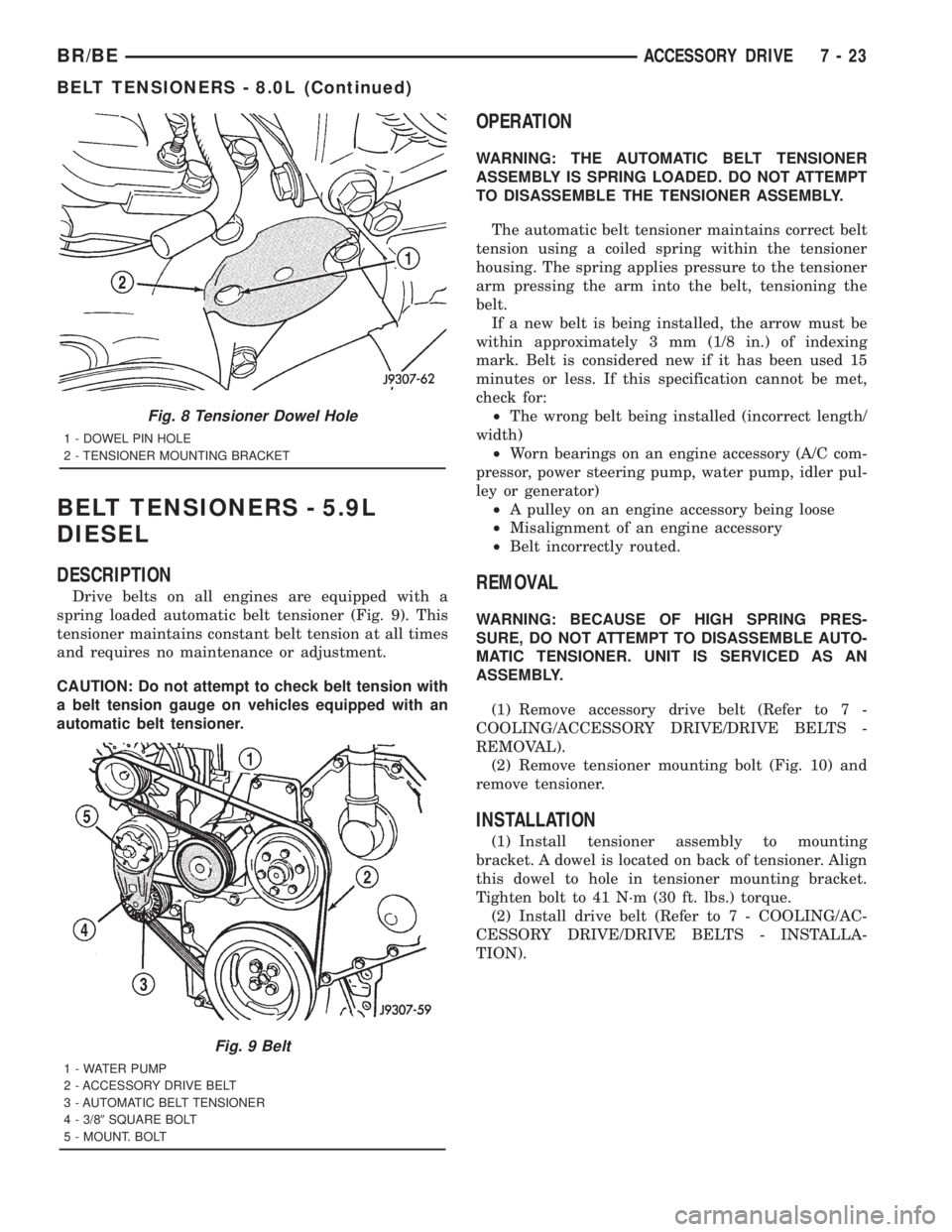

(2) Remove tensioner mounting bolt (Fig. 10) and

remove tensioner.

INSTALLATION

(1) Install tensioner assembly to mounting

bracket. A dowel is located on back of tensioner. Align

this dowel to hole in tensioner mounting bracket.

Tighten bolt to 41 N´m (30 ft. lbs.) torque.

(2) Install drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

Fig. 8 Tensioner Dowel Hole

1 - DOWEL PIN HOLE

2 - TENSIONER MOUNTING BRACKET

Fig. 9 Belt

1 - WATER PUMP

2 - ACCESSORY DRIVE BELT

3 - AUTOMATIC BELT TENSIONER

4 - 3/89SQUARE BOLT

5 - MOUNT. BOLT

BR/BEACCESSORY DRIVE 7 - 23

BELT TENSIONERS - 8.0L (Continued)

Page 362 of 2889

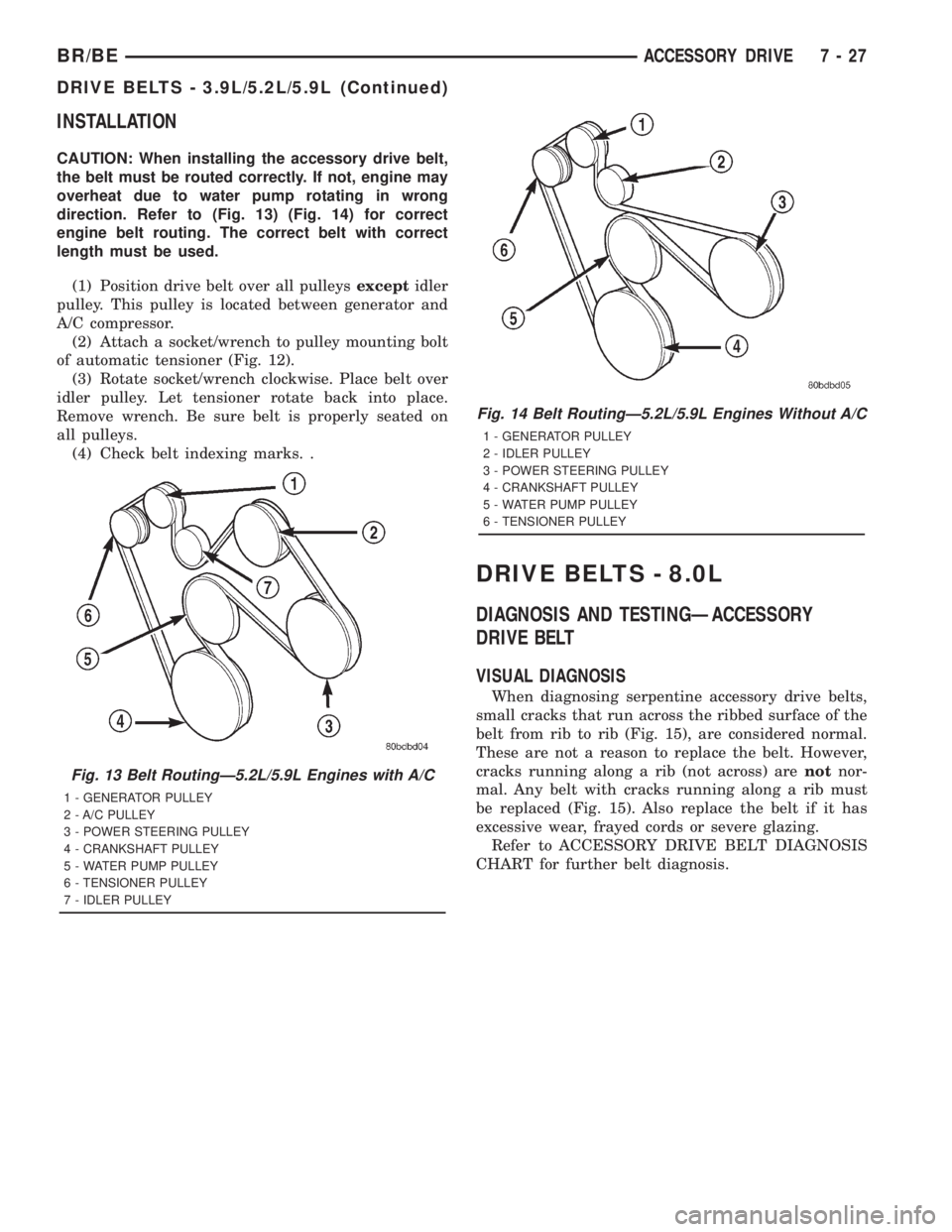

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine may

overheat due to water pump rotating in wrong

direction. Refer to (Fig. 13) (Fig. 14) for correct

engine belt routing. The correct belt with correct

length must be used.

(1) Position drive belt over all pulleysexceptidler

pulley. This pulley is located between generator and

A/C compressor.

(2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 12).

(3) Rotate socket/wrench clockwise. Place belt over

idler pulley. Let tensioner rotate back into place.

Remove wrench. Be sure belt is properly seated on

all pulleys.

(4) Check belt indexing marks. .

DRIVE BELTS - 8.0L

DIAGNOSIS AND TESTINGÐACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 15), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib must

be replaced (Fig. 15). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Refer to ACCESSORY DRIVE BELT DIAGNOSIS

CHART for further belt diagnosis.

Fig. 13 Belt RoutingÐ5.2L/5.9L Engines with A/C

1 - GENERATOR PULLEY

2 - A/C PULLEY

3 - POWER STEERING PULLEY

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - TENSIONER PULLEY

7 - IDLER PULLEY

Fig. 14 Belt RoutingÐ5.2L/5.9L Engines Without A/C

1 - GENERATOR PULLEY

2 - IDLER PULLEY

3 - POWER STEERING PULLEY

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - TENSIONER PULLEY

BR/BEACCESSORY DRIVE 7 - 27

DRIVE BELTS - 3.9L/5.2L/5.9L (Continued)