tailgate DODGE RAM 2001 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1098 of 2889

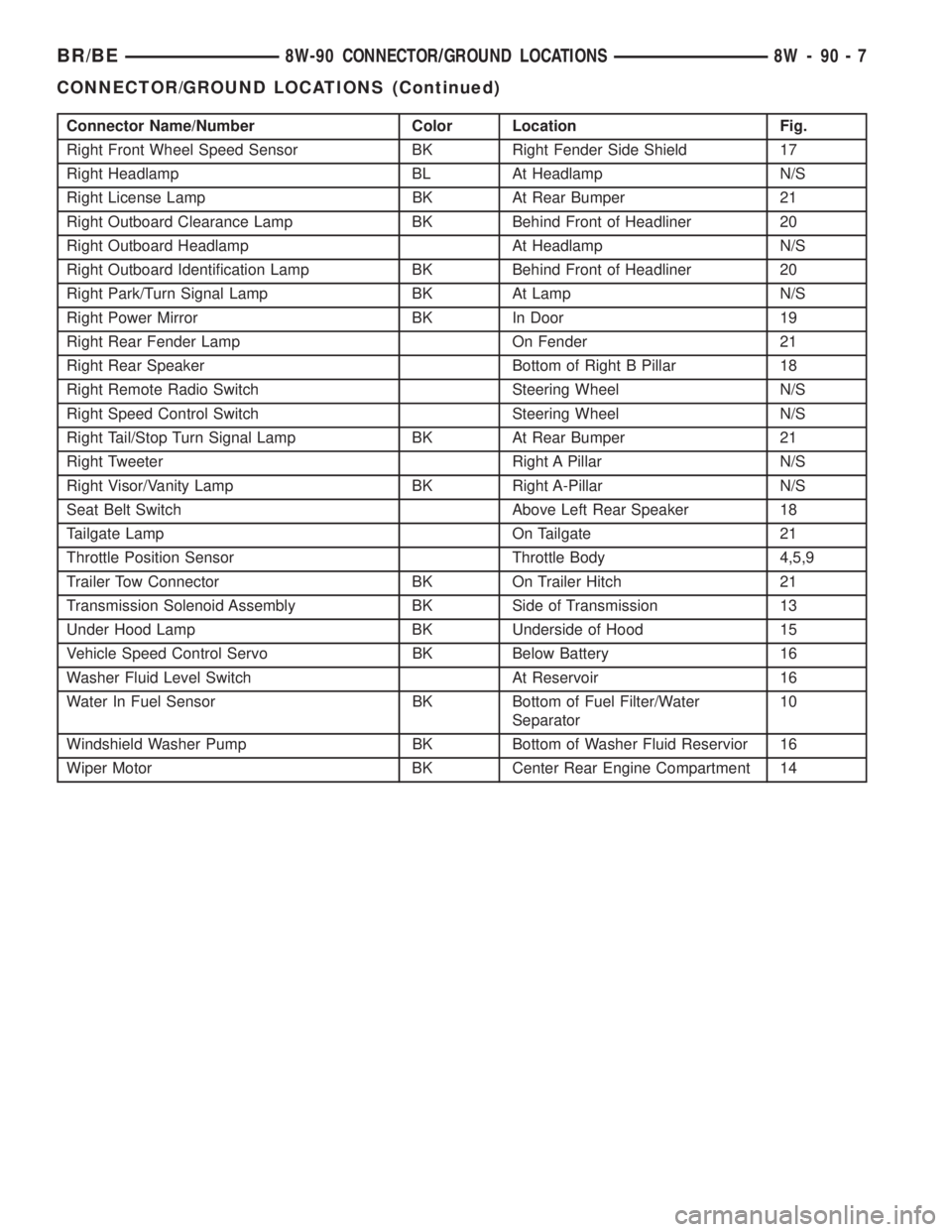

Connector Name/Number Color Location Fig.

Right Front Wheel Speed Sensor BK Right Fender Side Shield 17

Right Headlamp BL At Headlamp N/S

Right License Lamp BK At Rear Bumper 21

Right Outboard Clearance Lamp BK Behind Front of Headliner 20

Right Outboard Headlamp At Headlamp N/S

Right Outboard Identification Lamp BK Behind Front of Headliner 20

Right Park/Turn Signal Lamp BK At Lamp N/S

Right Power Mirror BK In Door 19

Right Rear Fender Lamp On Fender 21

Right Rear Speaker Bottom of Right B Pillar 18

Right Remote Radio Switch Steering Wheel N/S

Right Speed Control Switch Steering Wheel N/S

Right Tail/Stop Turn Signal Lamp BK At Rear Bumper 21

Right Tweeter Right A Pillar N/S

Right Visor/Vanity Lamp BK Right A-Pillar N/S

Seat Belt Switch Above Left Rear Speaker 18

Tailgate Lamp On Tailgate 21

Throttle Position Sensor Throttle Body 4,5,9

Trailer Tow Connector BK On Trailer Hitch 21

Transmission Solenoid Assembly BK Side of Transmission 13

Under Hood Lamp BK Underside of Hood 15

Vehicle Speed Control Servo BK Below Battery 16

Washer Fluid Level Switch At Reservoir 16

Water In Fuel Sensor BK Bottom of Fuel Filter/Water

Separator10

Windshield Washer Pump BK Bottom of Washer Fluid Reservior 16

Wiper Motor BK Center Rear Engine Compartment 14

BR/BE8W-90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 7

CONNECTOR/GROUND LOCATIONS (Continued)

Page 1126 of 2889

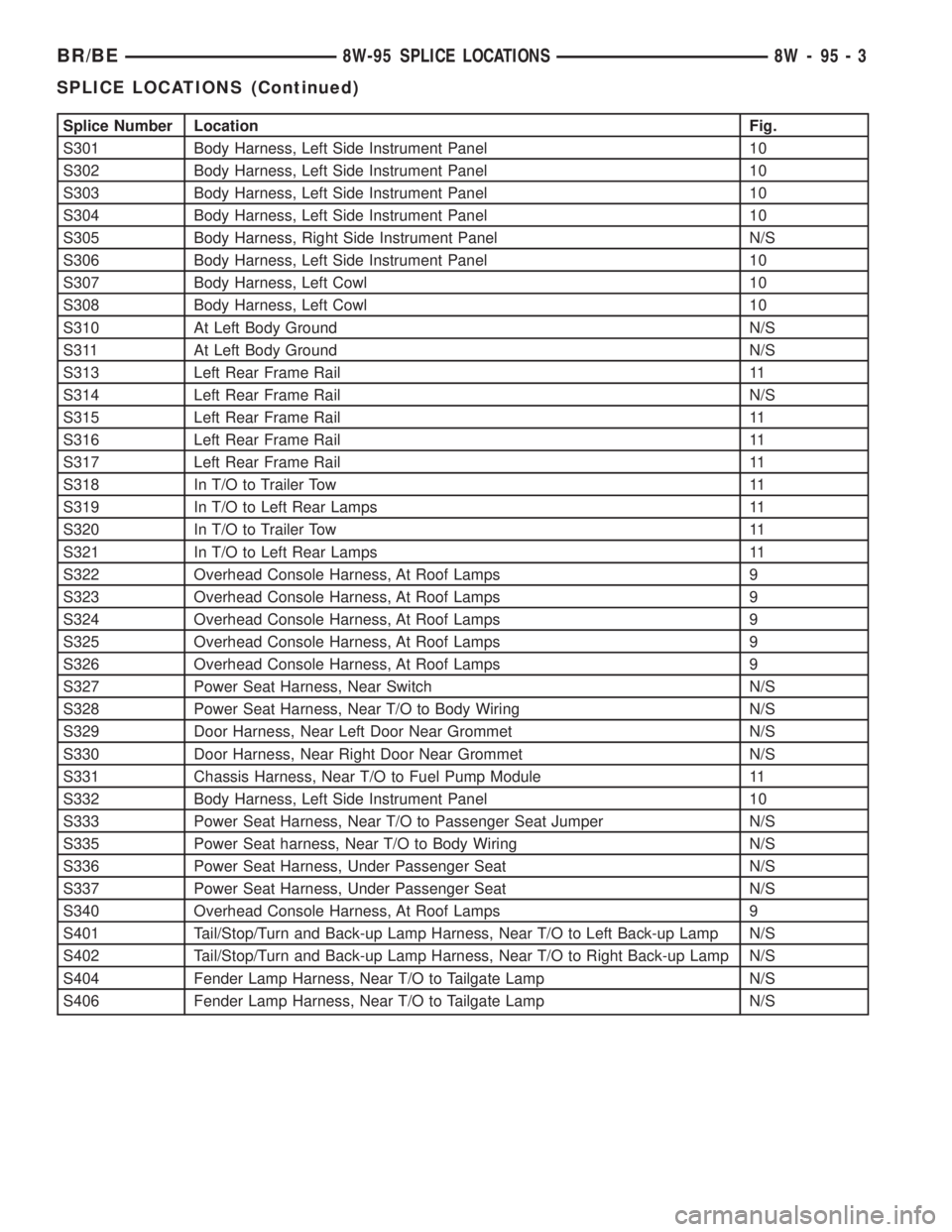

Splice Number Location Fig.

S301 Body Harness, Left Side Instrument Panel 10

S302 Body Harness, Left Side Instrument Panel 10

S303 Body Harness, Left Side Instrument Panel 10

S304 Body Harness, Left Side Instrument Panel 10

S305 Body Harness, Right Side Instrument Panel N/S

S306 Body Harness, Left Side Instrument Panel 10

S307 Body Harness, Left Cowl 10

S308 Body Harness, Left Cowl 10

S310 At Left Body Ground N/S

S311 At Left Body Ground N/S

S313 Left Rear Frame Rail 11

S314 Left Rear Frame Rail N/S

S315 Left Rear Frame Rail 11

S316 Left Rear Frame Rail 11

S317 Left Rear Frame Rail 11

S318 In T/O to Trailer Tow 11

S319 In T/O to Left Rear Lamps 11

S320 In T/O to Trailer Tow 11

S321 In T/O to Left Rear Lamps 11

S322 Overhead Console Harness, At Roof Lamps 9

S323 Overhead Console Harness, At Roof Lamps 9

S324 Overhead Console Harness, At Roof Lamps 9

S325 Overhead Console Harness, At Roof Lamps 9

S326 Overhead Console Harness, At Roof Lamps 9

S327 Power Seat Harness, Near Switch N/S

S328 Power Seat Harness, Near T/O to Body Wiring N/S

S329 Door Harness, Near Left Door Near Grommet N/S

S330 Door Harness, Near Right Door Near Grommet N/S

S331 Chassis Harness, Near T/O to Fuel Pump Module 11

S332 Body Harness, Left Side Instrument Panel 10

S333 Power Seat Harness, Near T/O to Passenger Seat Jumper N/S

S335 Power Seat harness, Near T/O to Body Wiring N/S

S336 Power Seat Harness, Under Passenger Seat N/S

S337 Power Seat Harness, Under Passenger Seat N/S

S340 Overhead Console Harness, At Roof Lamps 9

S401 Tail/Stop/Turn and Back-up Lamp Harness, Near T/O to Left Back-up Lamp N/S

S402 Tail/Stop/Turn and Back-up Lamp Harness, Near T/O to Right Back-up Lamp N/S

S404 Fender Lamp Harness, Near T/O to Tailgate Lamp N/S

S406 Fender Lamp Harness, Near T/O to Tailgate Lamp N/S

BR/BE8W-95 SPLICE LOCATIONS 8W - 95 - 3

SPLICE LOCATIONS (Continued)

Page 2574 of 2889

BODY

TABLE OF CONTENTS

page page

BODY

DESCRIPTION............................1

WARNING...............................1

DIAGNOSIS AND TESTING..................2

WATER LEAKS..........................2

WIND NOISE...........................3

SPECIFICATIONS.........................4

DECKLID/HATCH/LIFTGATE/TAILGATE........62

DOOR - FRONT..........................67DOOR - CARGO.........................77

EXTERIOR..............................86

HOOD.................................99

INSTRUMENT PANEL SYSTEM.............104

INTERIOR.............................118

PAINT................................129

SEATS................................131

STATIONARY GLASS.....................145

WEATHERSTRIP/SEALS..................152

BODY

DESCRIPTION ± PUSH-IN FASTENERS

DaimlerChrysler Corporation uses many different

types of push-in fasteners to secure the interior and

exterior trim to the body. Most of these fasteners can

be reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

DESCRIPTION ± LOCK CYLINDERS

Ignition, door, deck lid, and rear hatch lock cylin-

ders are all codable to the key. Lock barrels, tum-

blers, and tumbler springs are available to allow the

technician to change replacement locks cylinders to

match the customer's original key set. See the appro-

priate section in this manual for lock cylinder

removal. See the Moparž catalogue for part numbers

and lock coding procedures.

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE THAT

IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.

Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning solvents

on painted or upholstered surfaces. Damage to fin-

ish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

BR/BEBODY 23 - 1

Page 2632 of 2889

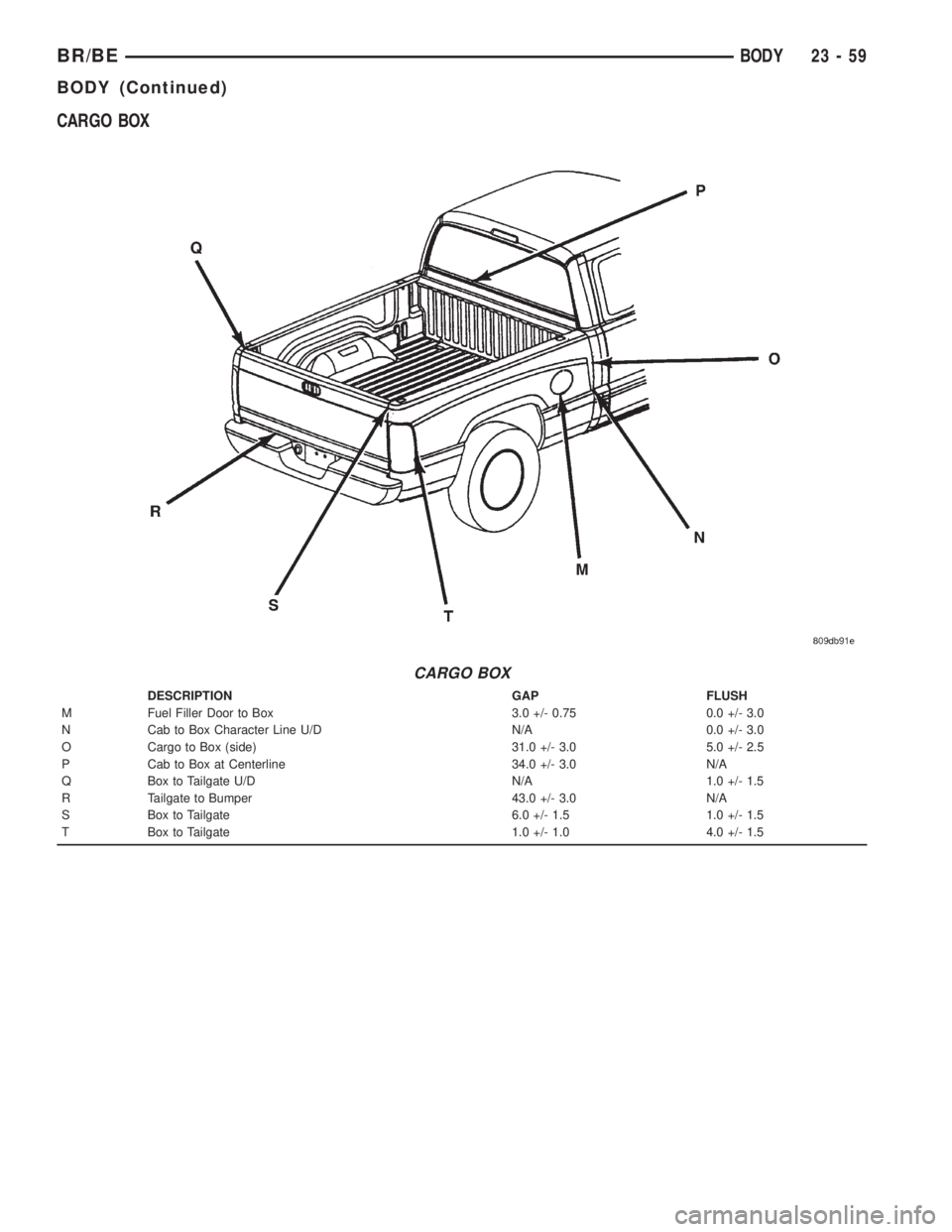

CARGO BOX

CARGO BOX

DESCRIPTION GAP FLUSH

M Fuel Filler Door to Box 3.0 +/- 0.75 0.0 +/- 3.0

N Cab to Box Character Line U/D N/A 0.0 +/- 3.0

O Cargo to Box (side) 31.0 +/- 3.0 5.0 +/- 2.5

P Cab to Box at Centerline 34.0 +/- 3.0 N/A

Q Box to Tailgate U/D N/A 1.0 +/- 1.5

R Tailgate to Bumper 43.0 +/- 3.0 N/A

S Box to Tailgate 6.0 +/- 1.5 1.0 +/- 1.5

T Box to Tailgate 1.0 +/- 1.0 4.0 +/- 1.5

BR/BEBODY 23 - 59

BODY (Continued)

Page 2635 of 2889

DECKLID/HATCH/LIFTGATE/TAILGATE

TABLE OF CONTENTS

page page

APPLIQUE

REMOVAL..............................62

INSTALLATION...........................62

CHECK CABLE

REMOVAL..............................62

INSTALLATION...........................63

DECALS

REMOVAL..............................63

INSTALLATION...........................63

HANDLE ESCUTCHEON

REMOVAL..............................63

INSTALLATION...........................63

LATCH

REMOVAL..............................64INSTALLATION...........................64

LATCH HANDLE

REMOVAL..............................65

INSTALLATION...........................65

LATCH STRIKER

REMOVAL..............................65

INSTALLATION...........................65

SLAM BUMPER

REMOVAL..............................66

INSTALLATION...........................66

TAILGATE

REMOVAL..............................66

INSTALLATION...........................66

APPLIQUE

REMOVAL

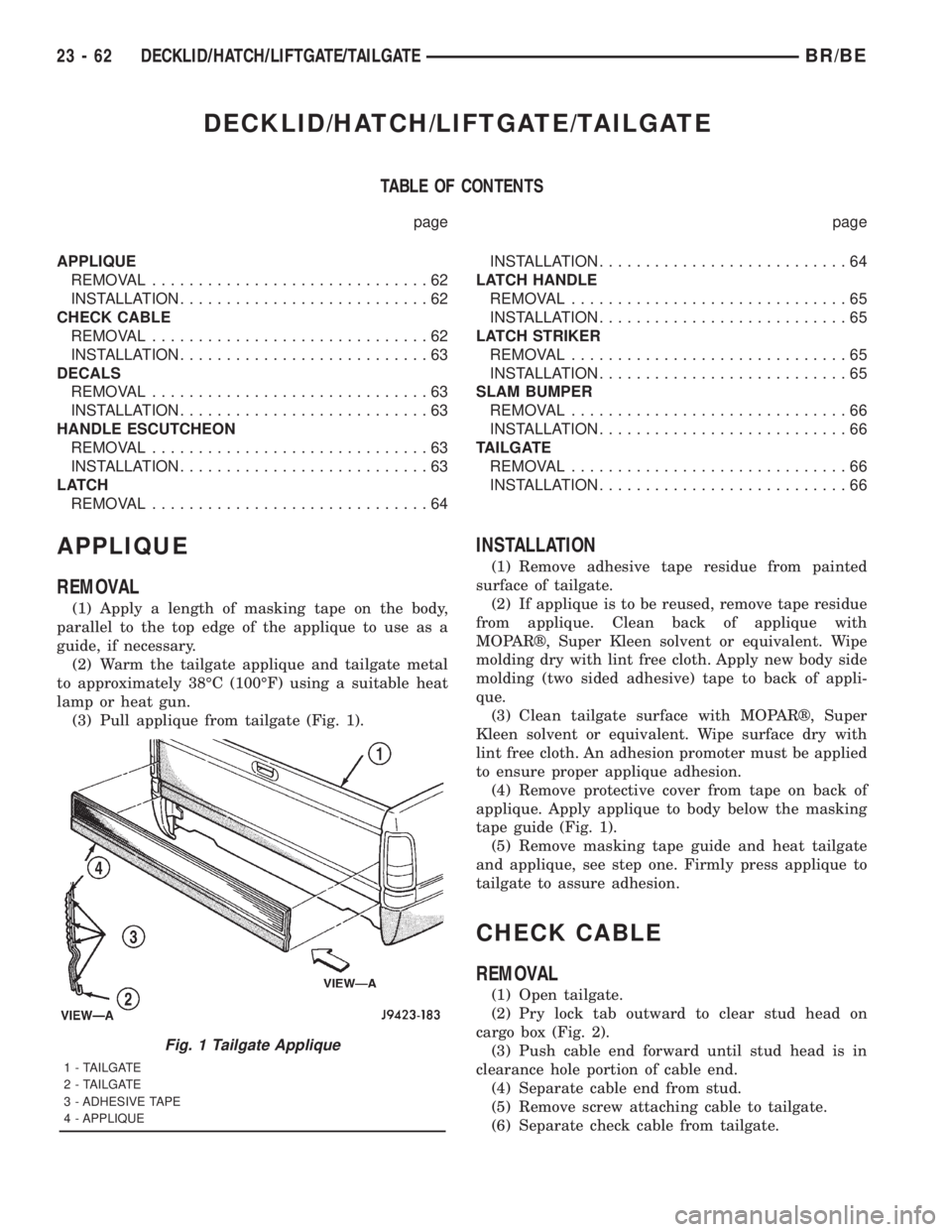

(1) Apply a length of masking tape on the body,

parallel to the top edge of the applique to use as a

guide, if necessary.

(2) Warm the tailgate applique and tailgate metal

to approximately 38ÉC (100ÉF) using a suitable heat

lamp or heat gun.

(3) Pull applique from tailgate (Fig. 1).

INSTALLATION

(1) Remove adhesive tape residue from painted

surface of tailgate.

(2) If applique is to be reused, remove tape residue

from applique. Clean back of applique with

MOPARž, Super Kleen solvent or equivalent. Wipe

molding dry with lint free cloth. Apply new body side

molding (two sided adhesive) tape to back of appli-

que.

(3) Clean tailgate surface with MOPARž, Super

Kleen solvent or equivalent. Wipe surface dry with

lint free cloth. An adhesion promoter must be applied

to ensure proper applique adhesion.

(4) Remove protective cover from tape on back of

applique. Apply applique to body below the masking

tape guide (Fig. 1).

(5) Remove masking tape guide and heat tailgate

and applique, see step one. Firmly press applique to

tailgate to assure adhesion.

CHECK CABLE

REMOVAL

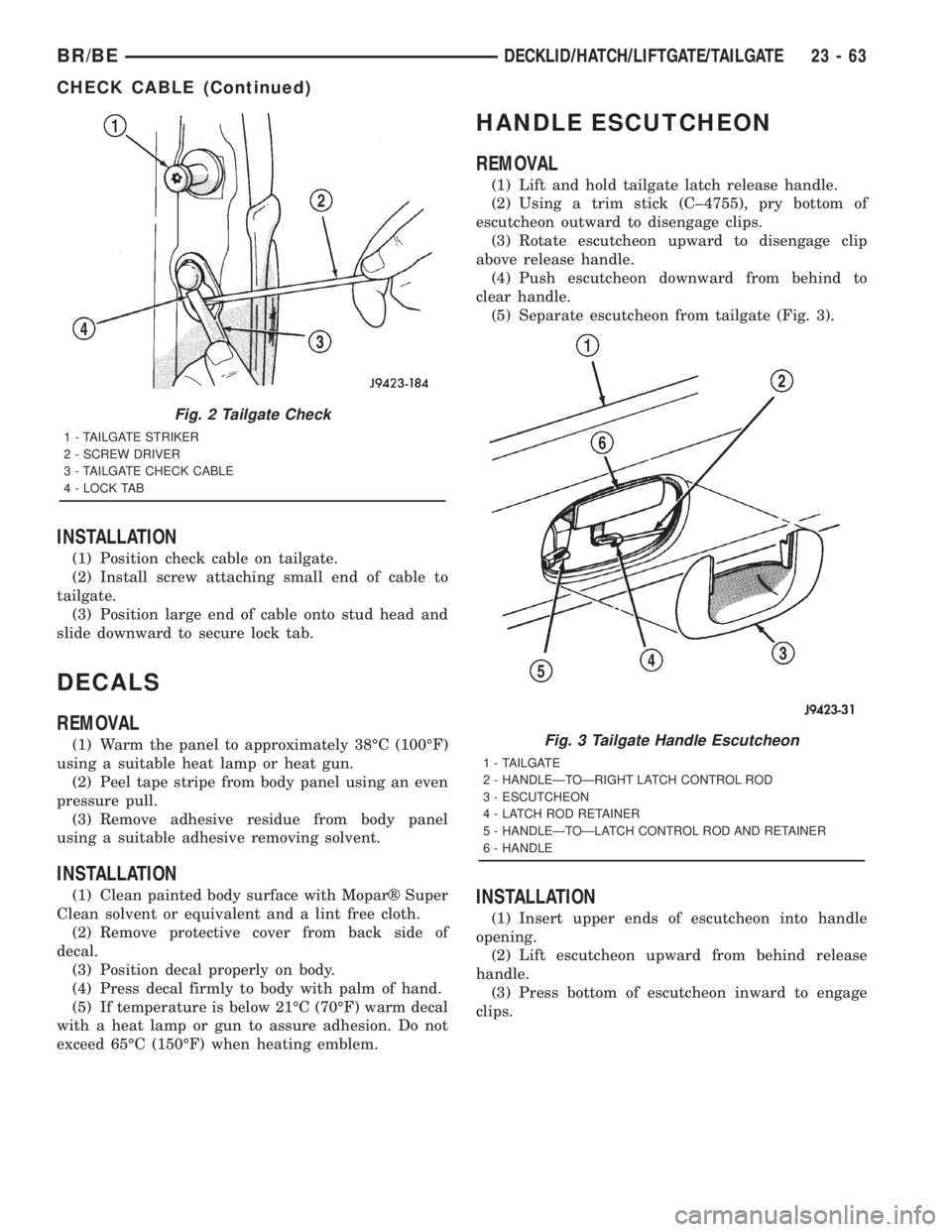

(1) Open tailgate.

(2) Pry lock tab outward to clear stud head on

cargo box (Fig. 2).

(3) Push cable end forward until stud head is in

clearance hole portion of cable end.

(4) Separate cable end from stud.

(5) Remove screw attaching cable to tailgate.

(6) Separate check cable from tailgate.

Fig. 1 Tailgate Applique

1 - TAILGATE

2 - TAILGATE

3 - ADHESIVE TAPE

4 - APPLIQUE

23 - 62 DECKLID/HATCH/LIFTGATE/TAILGATEBR/BE

Page 2636 of 2889

INSTALLATION

(1) Position check cable on tailgate.

(2) Install screw attaching small end of cable to

tailgate.

(3) Position large end of cable onto stud head and

slide downward to secure lock tab.

DECALS

REMOVAL

(1) Warm the panel to approximately 38ÉC (100ÉF)

using a suitable heat lamp or heat gun.

(2) Peel tape stripe from body panel using an even

pressure pull.

(3) Remove adhesive residue from body panel

using a suitable adhesive removing solvent.

INSTALLATION

(1) Clean painted body surface with Moparž Super

Clean solvent or equivalent and a lint free cloth.

(2) Remove protective cover from back side of

decal.

(3) Position decal properly on body.

(4) Press decal firmly to body with palm of hand.

(5) If temperature is below 21ÉC (70ÉF) warm decal

with a heat lamp or gun to assure adhesion. Do not

exceed 65ÉC (150ÉF) when heating emblem.

HANDLE ESCUTCHEON

REMOVAL

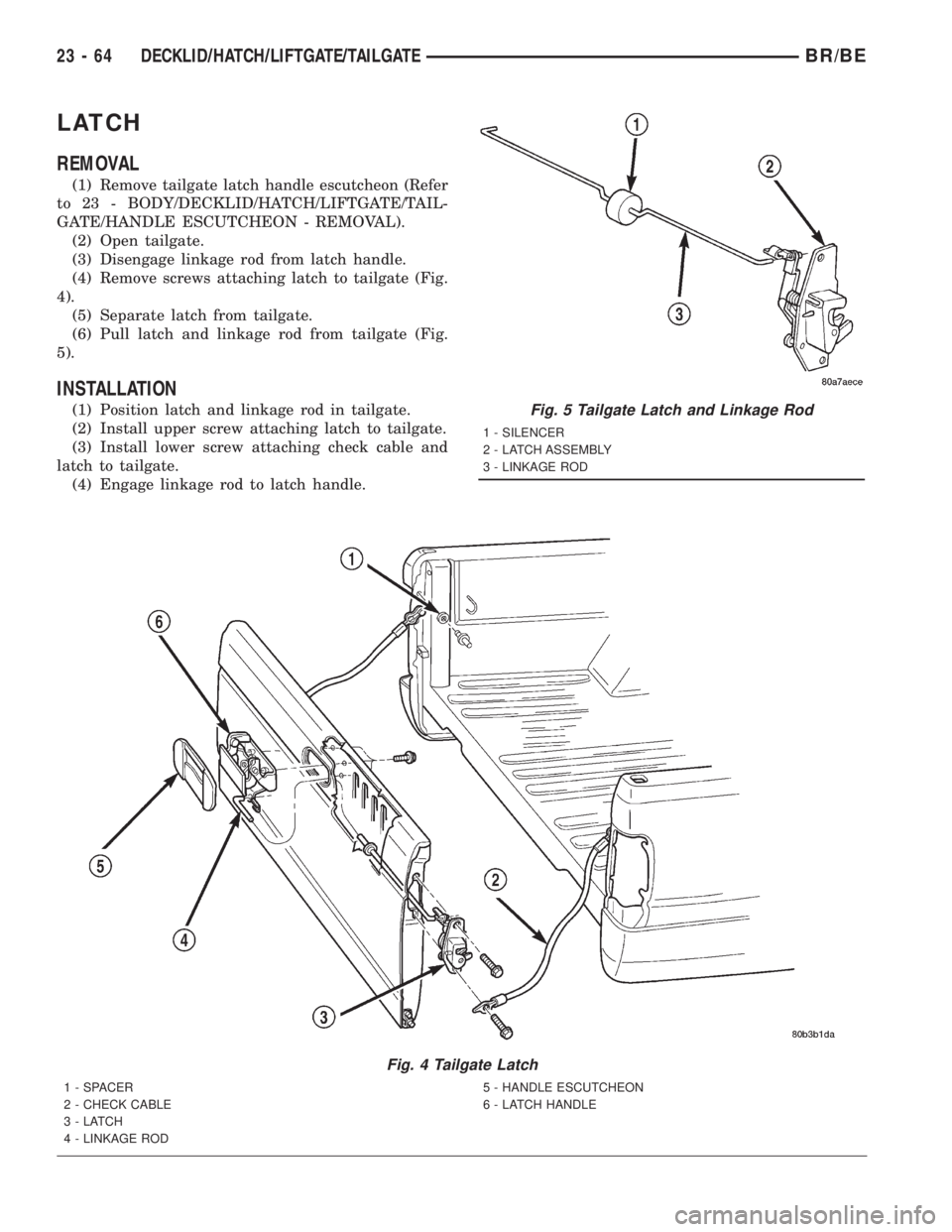

(1) Lift and hold tailgate latch release handle.

(2) Using a trim stick (C±4755), pry bottom of

escutcheon outward to disengage clips.

(3) Rotate escutcheon upward to disengage clip

above release handle.

(4) Push escutcheon downward from behind to

clear handle.

(5) Separate escutcheon from tailgate (Fig. 3).

INSTALLATION

(1) Insert upper ends of escutcheon into handle

opening.

(2) Lift escutcheon upward from behind release

handle.

(3) Press bottom of escutcheon inward to engage

clips.

Fig. 2 Tailgate Check

1 - TAILGATE STRIKER

2 - SCREW DRIVER

3 - TAILGATE CHECK CABLE

4 - LOCK TAB

Fig. 3 Tailgate Handle Escutcheon

1 - TAILGATE

2 - HANDLEÐTOÐRIGHT LATCH CONTROL ROD

3 - ESCUTCHEON

4 - LATCH ROD RETAINER

5 - HANDLEÐTOÐLATCH CONTROL ROD AND RETAINER

6 - HANDLE

BR/BEDECKLID/HATCH/LIFTGATE/TAILGATE 23 - 63

CHECK CABLE (Continued)

Page 2637 of 2889

LATCH

REMOVAL

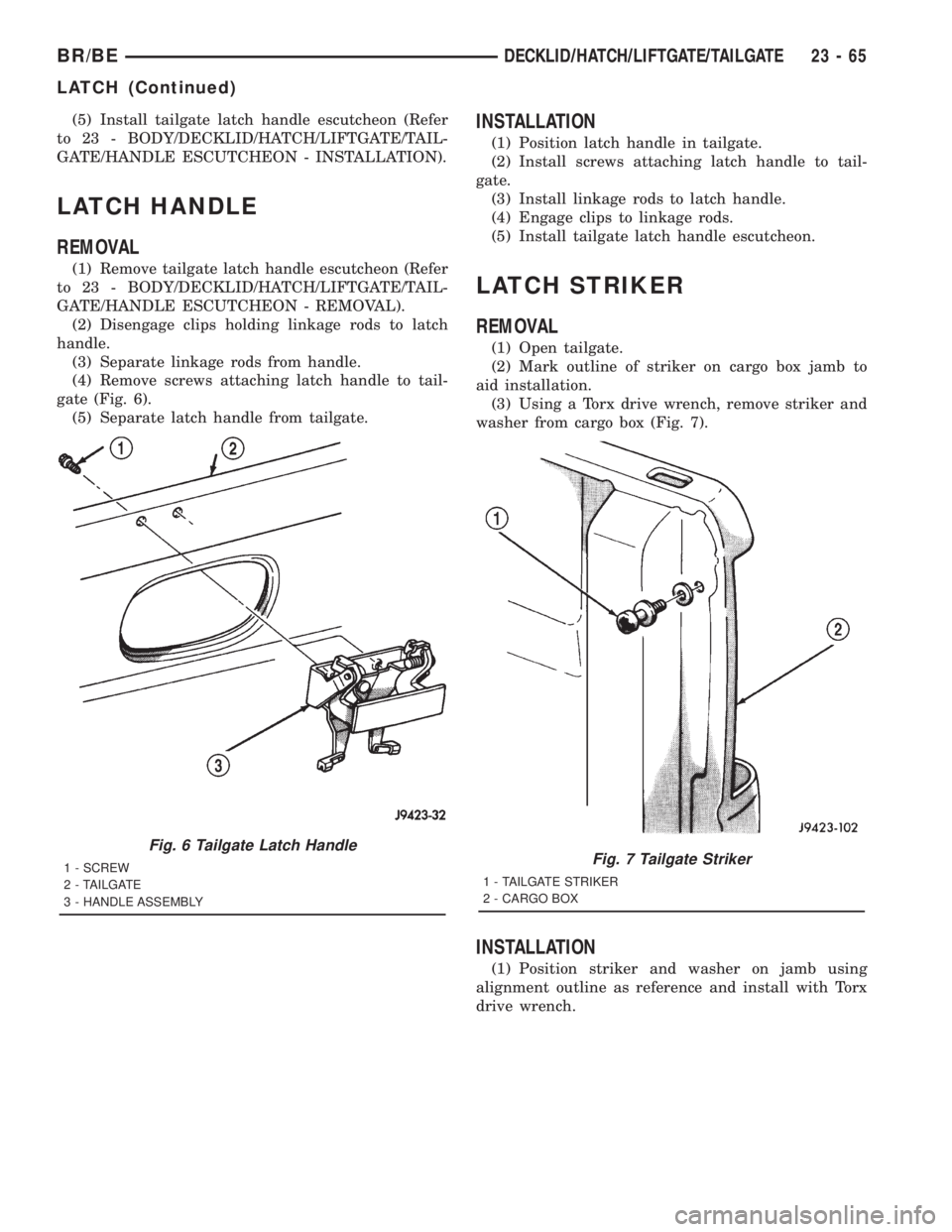

(1) Remove tailgate latch handle escutcheon (Refer

to 23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/HANDLE ESCUTCHEON - REMOVAL).

(2) Open tailgate.

(3) Disengage linkage rod from latch handle.

(4) Remove screws attaching latch to tailgate (Fig.

4).

(5) Separate latch from tailgate.

(6) Pull latch and linkage rod from tailgate (Fig.

5).

INSTALLATION

(1) Position latch and linkage rod in tailgate.

(2) Install upper screw attaching latch to tailgate.

(3) Install lower screw attaching check cable and

latch to tailgate.

(4) Engage linkage rod to latch handle.

Fig. 4 Tailgate Latch

1 - SPACER

2 - CHECK CABLE

3-LATCH

4 - LINKAGE ROD5 - HANDLE ESCUTCHEON

6 - LATCH HANDLE

Fig. 5 Tailgate Latch and Linkage Rod

1 - SILENCER

2 - LATCH ASSEMBLY

3 - LINKAGE ROD

23 - 64 DECKLID/HATCH/LIFTGATE/TAILGATEBR/BE

Page 2638 of 2889

(5) Install tailgate latch handle escutcheon (Refer

to 23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/HANDLE ESCUTCHEON - INSTALLATION).

LATCH HANDLE

REMOVAL

(1) Remove tailgate latch handle escutcheon (Refer

to 23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/HANDLE ESCUTCHEON - REMOVAL).

(2) Disengage clips holding linkage rods to latch

handle.

(3) Separate linkage rods from handle.

(4) Remove screws attaching latch handle to tail-

gate (Fig. 6).

(5) Separate latch handle from tailgate.

INSTALLATION

(1) Position latch handle in tailgate.

(2) Install screws attaching latch handle to tail-

gate.

(3) Install linkage rods to latch handle.

(4) Engage clips to linkage rods.

(5) Install tailgate latch handle escutcheon.

LATCH STRIKER

REMOVAL

(1) Open tailgate.

(2) Mark outline of striker on cargo box jamb to

aid installation.

(3) Using a Torx drive wrench, remove striker and

washer from cargo box (Fig. 7).

INSTALLATION

(1) Position striker and washer on jamb using

alignment outline as reference and install with Torx

drive wrench.

Fig. 6 Tailgate Latch Handle

1 - SCREW

2 - TAILGATE

3 - HANDLE ASSEMBLYFig. 7 Tailgate Striker

1 - TAILGATE STRIKER

2 - CARGO BOX

BR/BEDECKLID/HATCH/LIFTGATE/TAILGATE 23 - 65

LATCH (Continued)

Page 2639 of 2889

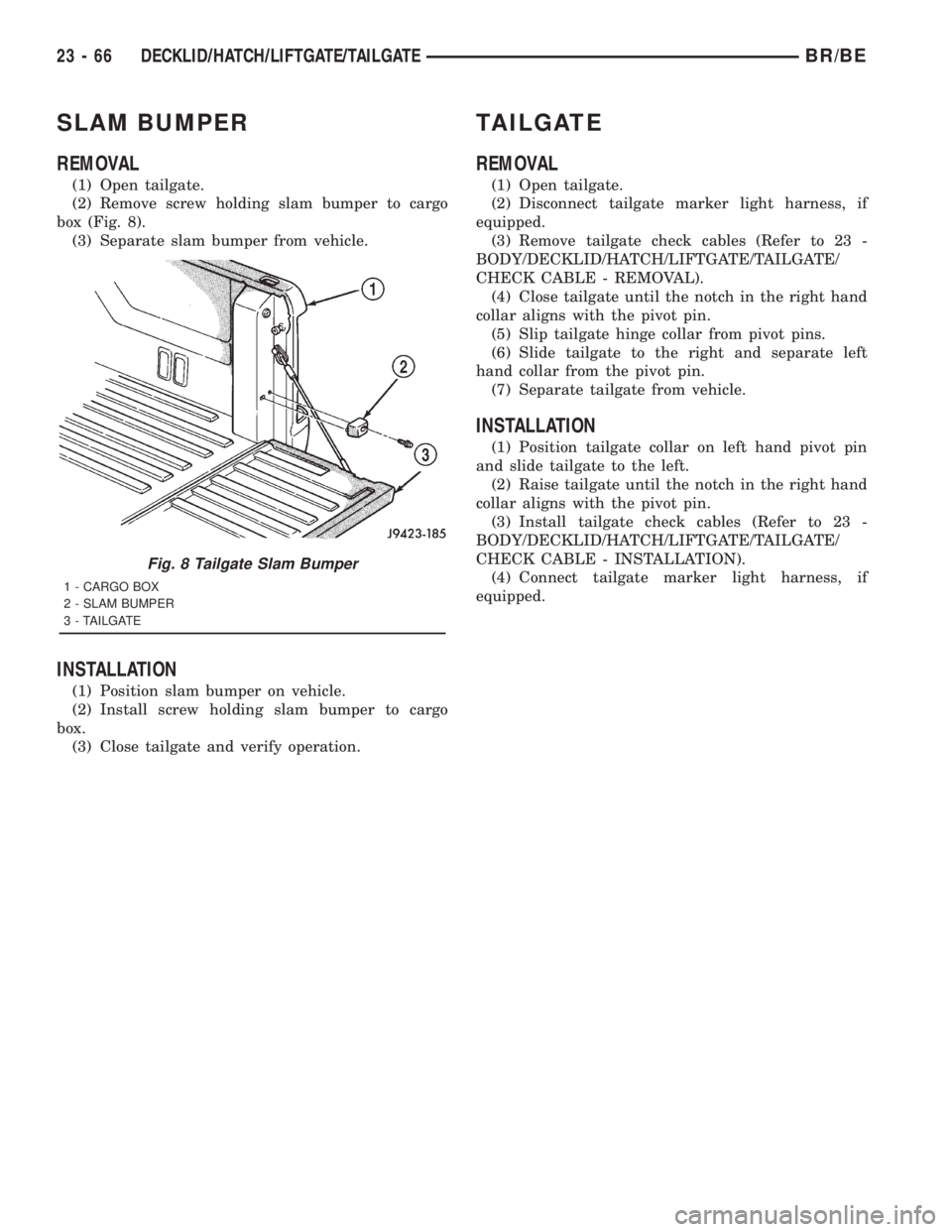

SLAM BUMPER

REMOVAL

(1) Open tailgate.

(2) Remove screw holding slam bumper to cargo

box (Fig. 8).

(3) Separate slam bumper from vehicle.

INSTALLATION

(1) Position slam bumper on vehicle.

(2) Install screw holding slam bumper to cargo

box.

(3) Close tailgate and verify operation.

TAILGATE

REMOVAL

(1) Open tailgate.

(2) Disconnect tailgate marker light harness, if

equipped.

(3) Remove tailgate check cables (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

CHECK CABLE - REMOVAL).

(4) Close tailgate until the notch in the right hand

collar aligns with the pivot pin.

(5) Slip tailgate hinge collar from pivot pins.

(6) Slide tailgate to the right and separate left

hand collar from the pivot pin.

(7) Separate tailgate from vehicle.

INSTALLATION

(1) Position tailgate collar on left hand pivot pin

and slide tailgate to the left.

(2) Raise tailgate until the notch in the right hand

collar aligns with the pivot pin.

(3) Install tailgate check cables (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

CHECK CABLE - INSTALLATION).

(4) Connect tailgate marker light harness, if

equipped.

Fig. 8 Tailgate Slam Bumper

1 - CARGO BOX

2 - SLAM BUMPER

3 - TAILGATE

23 - 66 DECKLID/HATCH/LIFTGATE/TAILGATEBR/BE

Page 2835 of 2889

INSTALLATION - WHEEL COVERS

(1) Install cover on wheel by hand only (Fig. 20).

(2) Install and torque wheel nuts to 135 N´m (100

lb. ft.).

(3) Install nut caps, if equipped using lug wrench,

do not over tighten.

(4) Remove release liner from removal instructions

label and install label next to jacking instructions

label. Surface must be clean and flat for proper adhe-

sion of label.

EXTERIOR

INSPECTIONÐBODY SEALING

Visually inspect the following seals during the nor-

mal recommended wash. Look for areas where water

may have entered the vehicle.

²Door and window seals

²Windshield

²Backlight

INSPECTION - FIT AND FINISH

(1) Remove all protective coatings/covers.

²Remove protective film from body moldings.

(2) Make sure body is free from paint chips,

scratches, sags, run, dirt or corrosion. Touch up any

minor paint chips and scratches as required.

(3) Ensure that moldings and stripes are aligned

properly.

²Ensure that moldings and stripes are present

and securely fastened to the body.NOTE: Painted-on accent strips require a unique

paint for touch-ups.

(4) Check that the door panels have even gaps and

fit well with adjacent body panels (Fig. 21).

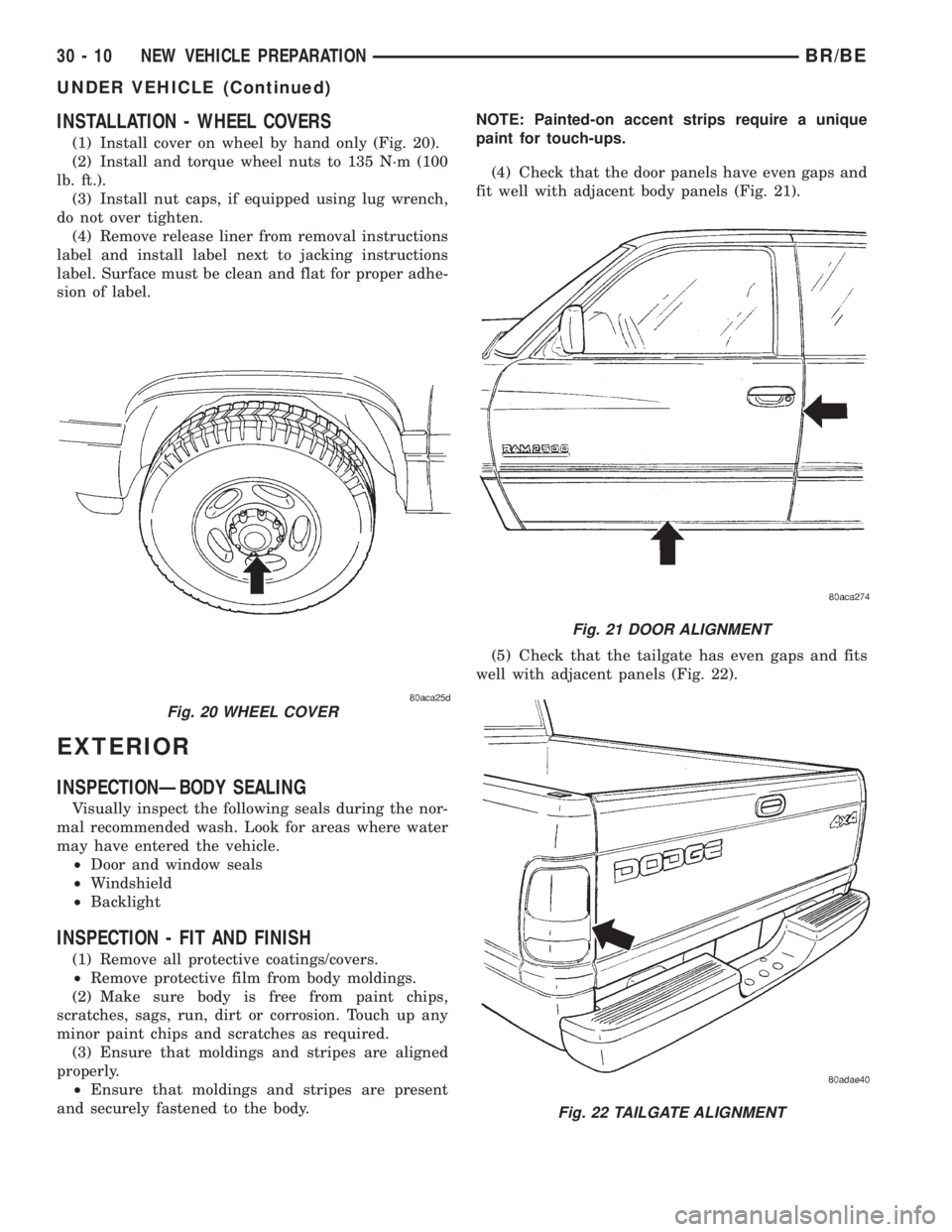

(5) Check that the tailgate has even gaps and fits

well with adjacent panels (Fig. 22).

Fig. 20 WHEEL COVER

Fig. 21 DOOR ALIGNMENT

Fig. 22 TAILGATE ALIGNMENT

30 - 10 NEW VEHICLE PREPARATIONBR/BE

UNDER VEHICLE (Continued)