trip computer DODGE RAM 2001 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 646 of 2889

NOTE: If the compass functions, but accuracy is

suspect, it may be necessary to perform a variation

adjustment. This procedure allows the compass

unit to accommodate variations in the earth's mag-

netic field strength, based on geographic location.

Refer to Compass Variation Adjustment in the Ser-

vice Procedures section of this group.

NOTE: If the compass reading has blanked out, and

only ªCALº appears in the display, demagnetizing

may be necessary to remove excessive residual

magnetic fields from the vehicle. Refer to Compass

Demagnetizing in the Service Procedures section of

this group.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the overhead console from the head-

liner. Refer toOverhead Consolein the Removal

and Installation section of this group for the proce-

dures.

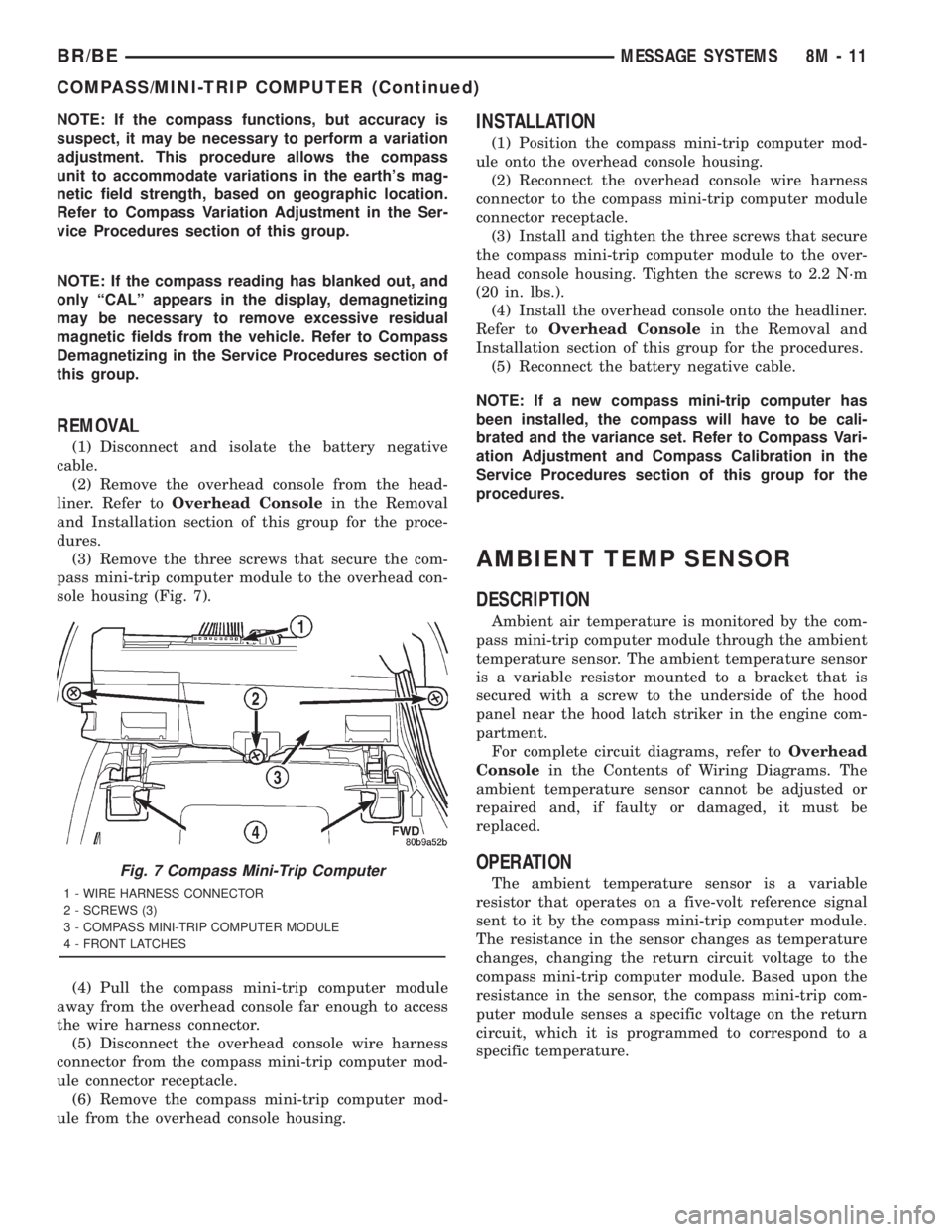

(3) Remove the three screws that secure the com-

pass mini-trip computer module to the overhead con-

sole housing (Fig. 7).

(4) Pull the compass mini-trip computer module

away from the overhead console far enough to access

the wire harness connector.

(5) Disconnect the overhead console wire harness

connector from the compass mini-trip computer mod-

ule connector receptacle.

(6) Remove the compass mini-trip computer mod-

ule from the overhead console housing.

INSTALLATION

(1) Position the compass mini-trip computer mod-

ule onto the overhead console housing.

(2) Reconnect the overhead console wire harness

connector to the compass mini-trip computer module

connector receptacle.

(3) Install and tighten the three screws that secure

the compass mini-trip computer module to the over-

head console housing. Tighten the screws to 2.2 N´m

(20 in. lbs.).

(4) Install the overhead console onto the headliner.

Refer toOverhead Consolein the Removal and

Installation section of this group for the procedures.

(5) Reconnect the battery negative cable.

NOTE: If a new compass mini-trip computer has

been installed, the compass will have to be cali-

brated and the variance set. Refer to Compass Vari-

ation Adjustment and Compass Calibration in the

Service Procedures section of this group for the

procedures.

AMBIENT TEMP SENSOR

DESCRIPTION

Ambient air temperature is monitored by the com-

pass mini-trip computer module through the ambient

temperature sensor. The ambient temperature sensor

is a variable resistor mounted to a bracket that is

secured with a screw to the underside of the hood

panel near the hood latch striker in the engine com-

partment.

For complete circuit diagrams, refer toOverhead

Consolein the Contents of Wiring Diagrams. The

ambient temperature sensor cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

OPERATION

The ambient temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent to it by the compass mini-trip computer module.

The resistance in the sensor changes as temperature

changes, changing the return circuit voltage to the

compass mini-trip computer module. Based upon the

resistance in the sensor, the compass mini-trip com-

puter module senses a specific voltage on the return

circuit, which it is programmed to correspond to a

specific temperature.Fig. 7 Compass Mini-Trip Computer

1 - WIRE HARNESS CONNECTOR

2 - SCREWS (3)

3 - COMPASS MINI-TRIP COMPUTER MODULE

4 - FRONT LATCHES

BR/BEMESSAGE SYSTEMS 8M - 11

COMPASS/MINI-TRIP COMPUTER (Continued)

Page 647 of 2889

DIAGNOSIS & TESTING - AMBIENT

TEMPERATURE SENSOR

The thermometer function is supported by the

ambient temperature sensor, a wiring circuit, and a

portion of the compass mini-trip computer module. If

any portion of the ambient temperature sensor cir-

cuit fails, the compass/thermometer display function

will self-diagnose the circuit. If 55É C (131É F)

appears in the display, the sensor is being exposed to

temperatures above 55É C (131É F), or the sensor cir-

cuit is shorted. If ±40É C (±40É F) appears in the dis-

play, the sensor is being exposed to temperatures

below ±40É C (±40É F), or the sensor circuit is open.

The ambient temperature sensor circuit can also be

diagnosed using the following Sensor Test, and Sen-

sor Circuit Test. If the temperature sensor and cir-

cuit are confirmed to be OK, but the temperature

display is inoperative or incorrect, refer toCompass

Mini-Trip Computerin the Diagnosis and Testing

section of this group. For complete circuit diagrams,

refer toOverhead Consolein the Contents of Wir-

ing Diagrams.

SENSOR TEST

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector.

(2) Measure the resistance of the ambient temper-

ature sensor. At ±40É C (±40É F), the sensor resis-

tance is 336 kilohms. At 55É C (131É F), the sensor

resistance is 2.488 kilohms. The sensor resistance

should read between these two values. If OK, refer to

Sensor Circuit Testin the Diagnosis and Testing

section of this group. If not OK, replace the faulty

ambient temperature sensor.

SENSOR CIRCUIT TEST

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector and the overhead console wire har-

ness connector.

(2) Connect a jumper wire between the two termi-

nals in the body half of the ambient temperature sen-

sor wire harness connector.

(3) Check for continuity between the sensor return

circuit and the ambient temperature sensor signal

circuit cavities of the roof wire harness overhead con-

sole connector. There should be continuity. If OK, go

to Step 4. If not OK, repair the open sensor return

circuit or ambient temperature sensor signal circuit

to the ambient temperature sensor as required.(4) Remove the jumper wire from the body half of

the ambient temperature sensor wire harness con-

nector. Check for continuity between the sensor

return circuit cavity of the roof wire harness over-

head console connector and a good ground. There

should be no continuity. If OK, go to Step 5. If not

OK, repair the shorted sensor return circuit as

required.

(5) Check for continuity between the ambient tem-

perature sensor signal circuit cavity of the roof wire

harness overhead console connector and a good

ground. There should be no continuity. If OK, refer to

Compass Mini-Trip Computerin the Diagnosis

and Testing section of this group. If not OK, repair

the shorted ambient temperature sensor signal cir-

cuit as required.

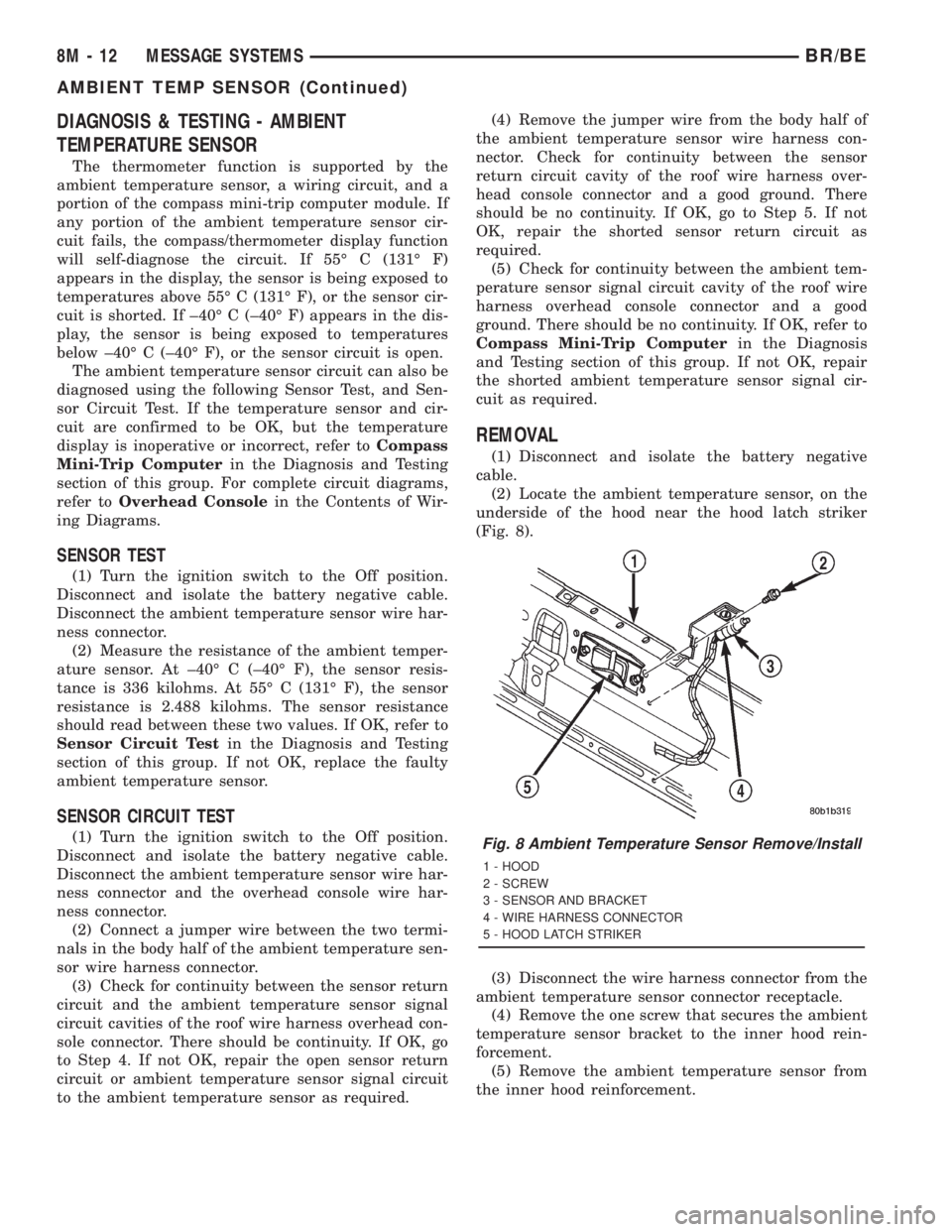

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Locate the ambient temperature sensor, on the

underside of the hood near the hood latch striker

(Fig. 8).

(3) Disconnect the wire harness connector from the

ambient temperature sensor connector receptacle.

(4) Remove the one screw that secures the ambient

temperature sensor bracket to the inner hood rein-

forcement.

(5) Remove the ambient temperature sensor from

the inner hood reinforcement.

Fig. 8 Ambient Temperature Sensor Remove/Install

1 - HOOD

2 - SCREW

3 - SENSOR AND BRACKET

4 - WIRE HARNESS CONNECTOR

5 - HOOD LATCH STRIKER

8M - 12 MESSAGE SYSTEMSBR/BE

AMBIENT TEMP SENSOR (Continued)

Page 720 of 2889

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION............................1

OPERATION.............................2

DIAGNOSIS AND TESTING..................3

VEHICLE THEFT SECURITY SYSTEM........3VTSS INDICATOR

DESCRIPTION............................3

OPERATION.............................3

DIAGNOSIS AND TESTING..................3

VTSS INDICATOR.......................3

VEHICLE THEFT SECURITY

DESCRIPTION

The Vehicle Theft Security System (VTSS) is an

available factory-installed option on this model when

it is also equipped with the high-line or premium

Central Timer Module (CTM). The VTSS is designed

to provide perimeter protection against unauthorized

use or tampering by monitoring the vehicle doors and

the ignition system. If unauthorized vehicle use or

tampering is detected, the system responds by puls-

ing the horn, flashing the headlamps, and preventing

the engine from operating.

The VTSS includes the following major compo-

nents, which are described in further detail else-

where in this service manual:

²Central Timer Module- The high-line or pre-

mium Central Timer Module (CTM) is located under

the driver side end of the instrument panel, inboard

of the instrument panel steering column opening.

The high-line or premium CTM contains a micropro-

cessor and software that allow it to provide many

electronic functions and features not available with

base version of the CTM, including the VTSS. The

CTM provides all of the proper VTSS features and

outputs based upon the monitored inputs. The CTM

circuitry monitors hard wired switch inputs, as well

as message inputs received from other vehicle elec-

tronic modules over the Chrysler Collision Detection

(CCD) data bus network. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/BODY CON-

TROL/CENTRAL TIMER MODULE -

DESCRIPTION).

²Door Ajar Switch- A door ajar switch is

located on the hinge pillar of each front door in the

vehicle. These switches provide an input to the VTSS

indicating whether the door is opened or closed.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

INTERIOR/DOOR AJAR SWITCH - DESCRIPTION).

²Door Cylinder Lock Switch- A door cylinder

lock switch is located on the back of each front door

lock cylinder. This switch provides an input to theVTSS indicating whether the system should remain

armed or be disarmed. (Refer to 8 - ELECTRICAL/

POWER LOCKS/DOOR CYLINDER LOCK SWITCH

- DESCRIPTION).

²Horn Relay- The horn relay is located in the

Power Distribution Center (PDC) in the engine com-

partment near the battery. The horn relay is nor-

mally activated by the horn switch to control the

sounding of the vehicle horn or horns. However, it

can also be activated by an output of the Central

Timer Module (CTM) to provide an audible indication

that unauthorized vehicle use or tampering has been

detected. (Refer to 8 - ELECTRICAL/HORN/HORN

RELAY - DESCRIPTION).

²Headlamp Relay- The headlamp relay (also

known as the security relay) is located in the Power

Distribution Center (PDC) in the engine compart-

ment near the battery. The headlamp relay is nor-

mally activated by the Central Timer Module (CTM)

based upon inputs from the Remote Keyless Entry

(RKE) panic mode feature. However, it can also be

activated by an output of the CTM to flash the head-

lamp low beams to provide a highly visible indication

that unauthorized vehicle use or tampering has been

detected. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/HEADLAMP RELAY - DESCRIP-

TION).

²VTSS Indicator- A red Light Emitting Diode

(LED) located on the lower surface of the overhead

console near the windshield is illuminated by an out-

put of the Central Timer Module (CTM) to indicate

the status of the VTSS. This LED is integral to the

electronic circuit board for the Compass Mini-Trip

Computer (CMTC). (Refer to 8 - ELECTRICAL/

OVERHEAD CONSOLE/COMPASS/MINI-TRIP

COMPUTER - DESCRIPTION).

The engine no-run feature of the VTSS relies upon

communication between the high-line or premium

CTM and the Powertrain Control Module (PCM) over

the Chrysler Collision Detection (CCD) data bus net-

work.

Hard wired circuitry connects many of the VTSS

components to each other through the electrical sys-

BR/BEVEHICLE THEFT SECURITY 8Q - 1

Page 722 of 2889

er-up mode will also apply if the battery goes dead

while the system is armed, and battery jump-starting

is attempted. The engine no-run feature will prevent

the engine from starting until the alarm system has

been actively or passively disarmed. The VTSS will

be armed until the technician or vehicle operator has

actively or passively disarmed the alarm system. If

the VTSS is in the disarmed mode prior to a battery

disconnect or failure, it will remain disarmed after

the battery is reconnected or replaced, or if jump-

starting is attempted.

TAMPER ALERT

The VTSS tamper alert feature will sound the horn

three times upon disarming, if the alarm was trig-

gered and has since timed-out (about fifteen min-

utes). This feature alerts the vehicle operator that

the VTSS alarm was activated while the vehicle was

unattended.

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY SYSTEM

The VTSS-related hard wired inputs to and out-

puts from the high-line or premium Central Timer

Module (CTM) may be diagnosed and tested using

conventional diagnostic tools and procedures. Refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices and grounds.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the CTM, the

Powertrain Control Module (PCM), or the Chrysler

Collision Detection (CCD) data bus network. In order

to obtain conclusive testing of the VTSS, the CTM,

the PCM, and the CCD data bus network must also

be checked. The most reliable, efficient, and accurate

means to diagnose the VTSS requires the use of a

DRBIIIž scan tool. Refer to the appropriate diagnos-

tic information. The DRBIIIž scan tool can provide

confirmation that the CCD data bus network is func-

tional, that all of the electronic modules are sending

and receiving the proper messages over the CCD

data bus, and that these modules are receiving the

proper hard wired inputs and responding with the

proper hard wired outputs needed to perform their

functions. See the ªVehicle Theft Security Systemº

menu item on the DRBIIIž scan tool.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

VTSS INDICATOR

DESCRIPTION

The Vehicle Theft Security System (VTSS) indica-

tor consists of a red Light-Emitting Diode (LED)

located on the electronic circuit board of the Compass

Mini-Trip Computer (CMTC) within the overhead

console. The LED extends through a hole in the

CMTC lens located near the forward end of the over-

head console housing near the windshield.

The VTSS indicator cannot be adjusted or repaired

and, if faulty or damaged, the entire CMTC unit

must be replaced. (Refer to 8 - ELECTRICAL/OVER-

HEAD CONSOLE/COMPASS/MINI-TRIP COM-

PUTER - DESCRIPTION).

OPERATION

The Vehicle Theft Security System (VTSS) indica-

tor gives a visible indication of the VTSS arming sta-

tus. One side of Light-Emitting Diode (LED) in the

VTSS indicator is connected to battery current

through a fused B(+) circuit and a fuse in the Junc-

tion Block (JB), so the indicator remains functional

regardless of the ignition switch position. The other

side of the LED is hard wired to the Central Timer

Module (CTM), which controls the operation of the

VTSS indicator by pulling this side of the LED cir-

cuit to ground. When the VTSS arming is in

progress, the CTM will flash the LED rapidly on and

off for about fifteen seconds. When the VTSS has

been successfully armed, the CTM will flash the LED

on and off continually at a much slower rate until

the VTSS has been disarmed. The VTSS indicator

can be diagnosed using conventional diagnostic tools

and methods.

DIAGNOSIS AND TESTING - VTSS INDICATOR

The diagnosis found here addresses an inoperative

Vehicle Theft Security System (VTSS) indicator con-

dition. If the problem being diagnosed is related to

indicator accuracy, be certain to confirm that the

problem is with the indicator and not with an inop-

erative VTSS. (Refer to 8 - ELECTRICAL/VEHICLE

THEFT SECURITY SYSTEM- DIAGNOSIS AND

BR/BEVEHICLE THEFT SECURITY 8Q - 3

VEHICLE THEFT SECURITY (Continued)

Page 723 of 2889

TESTING). If no VTSS problem is found, the follow-

ing procedure will help to locate a short or open in

the VTSS indicator control circuit. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check the fused B(+) fuse (Fuse 12 - 10

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 12 - 10 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit betweenthe JB and the Power Distribution Center (PDC) as

required.

(3) Disconnect and isolate the battery negative

cable. Disconnect the body wire harness connector for

the Compass Mini-Trip Computer (CMTC) from the

CMTC connector receptacle. Reconnect the battery

negative cable. Check for battery voltage at the fused

B(+) circuit cavity of the body wire harness connector

for the CMTC. If OK, go to Step 4. If not OK, repair

the open fused B(+) circuit between the CMTC indi-

cator and the JB as required.

(4) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector (Connector C2) for the Central Timer Mod-

ule (CTM) from the CTM connector receptacle. Check

for continuity between the VTSS indicator driver cir-

cuit cavity of the body wire harness connector for the

CMTC and a good ground. There should be no conti-

nuity. If OK, go to Step 5. If not OK, repair the

shorted VTSS indicator driver circuit between the

CMTC and the CTM as required.

(5) Check for continuity between the VTSS indica-

tor driver circuit cavities of the instrument panel

wire harness connector (Connector C2) for the CTM

and the body wire harness connector for the CMTC.

There should be continuity. If OK, replace the faulty

CMTC indicator. If not OK, repair the open VTSS

indicator driver circuit between the CMTC and the

CTM as required.

8Q - 4 VEHICLE THEFT SECURITYBR/BE

VTSS INDICATOR (Continued)

Page 2840 of 2889

ROAD TEST

DESCRIPTION - ROAD TEST INSPECTION

The following items must be inspected during the

road test portion of the new vehicle inspection.

²Check neutral safety switch operation

²Check operation of shift/clutch interlock system

²Check operation of gauges and warning lights

²Check horn operation

²Check operation of turn signals and emergency

flashers

²Check all mirror adjustments, including day/

night function

²Check windshield wipers for proper wipe pattern

and intermittent mode (if equipped)

²Check washer spray pattern

²Check heater, defroster and air conditioning for

proper operation

²Check that the fan operates quietly

²Check the rear window defroster (if equipped)

²Leave air selection lever in the fresh air position

²Check the rear heater and air conditioning for

proper operation

²Check the rear air register locations

²Check that the indicator lamps operate properly

²Check the operation of the radio, cassette and/or

compact disc player, and that sound quality is good

²Ensure that the clock displays the correct time

²Check that the trip computer/maintenance

reminder operates in all modes

²Check all speed control functions

²Check the service brakes to ensure that they

stop the vehicle in a straight line, without noise,

shudder or vibration

²Check the brake warning light

²Check the parking brake operation

²Check the engine's performance

²Check the transmission's performance for

smooth, quiet operation. If the vehicle is a 4x4, check

that the transfer case shifts easily among all ranges

²Check Autostick function (if equipped)

²Check the vehicle's steering and handling

²The steering wheel should be centered when

traveling in a straight line

²The vehicle should not pull or vibrate

²Check for squeaks, rattles and wind noise

²Check any other vehicle aspects you believe are

important, but that may not be included on the New

Vehicle Preparation Form

²Fill fuel tank with specified grade of fuel

INSPECTION - FUEL

Fill fuel tank with specified grade of gasoline (reg-

ular, midgrade or premium).

INSPECTION - OTHER

As part of DaimlerChrysler's Customer One philos-

ophy, the ªOtherº blank is provided on the New Vehi-

cle Preparation Form. This is designed to encourage

you to check any aspects of vehicle operation that

you believe are important to your customers, but that

do not appear elsewhere on the form.

INSPECTION - SQUEAKS, RATTLES AND WIND

NOISE

(1) Make sure that the instrument panel, glove

box, seats, steering wheel and column are free from

squeaks and rattles. Tighten any obvious loose fas-

teners.

(2) Check that the windows and doors are free

from squeaks, rattles and wind noise.

(3) Check that the vehicle exterior is free from

squeaks, rattles and noise, front and rear.

(4) Make sure that all interior panels are free from

squeaks and rattles.

INSPECTION - STEERING AND HANDLING

(1) Check that the power assist works properly (if

equipped). Steering should not require excessive

effort.

(2) Make sure the steering wheel does not vibrate

at idle or road speed.

(3) Ensure that the steering wheel is centered

when traveling straight ahead.

(4) Check that the vehicle does not drift to one

side.

(5) Make sure that the vehicle does not vibrate/

shake.

INSPECTION - TRANSMISSION/TRANSFER

CASE

AUTOMATIC TRANSMISSION

(1) Make sure that the park lock holds the vehicle

With the vehicle on a grade, put automatic trans-

mission in PARK and slowly release the service

brake to see if park lock holds. If it does not hold, the

transmission requires further service.

(2) Make sure shift lever operates easily/ smoothly

(Fig. 36).

Check for smooth shifting. Check for proper

upshifting and downshifting.

MANUAL TRANSMISSION

(1) Check that the shifter operates easily (Fig. 38).

(2) Make sure that the clutch operates smoothly

(Fig. 37).

(3) Look for proper synchronization.

The gears should not grind.

BR/BENEW VEHICLE PREPARATION 30 - 15

Page 2842 of 2889

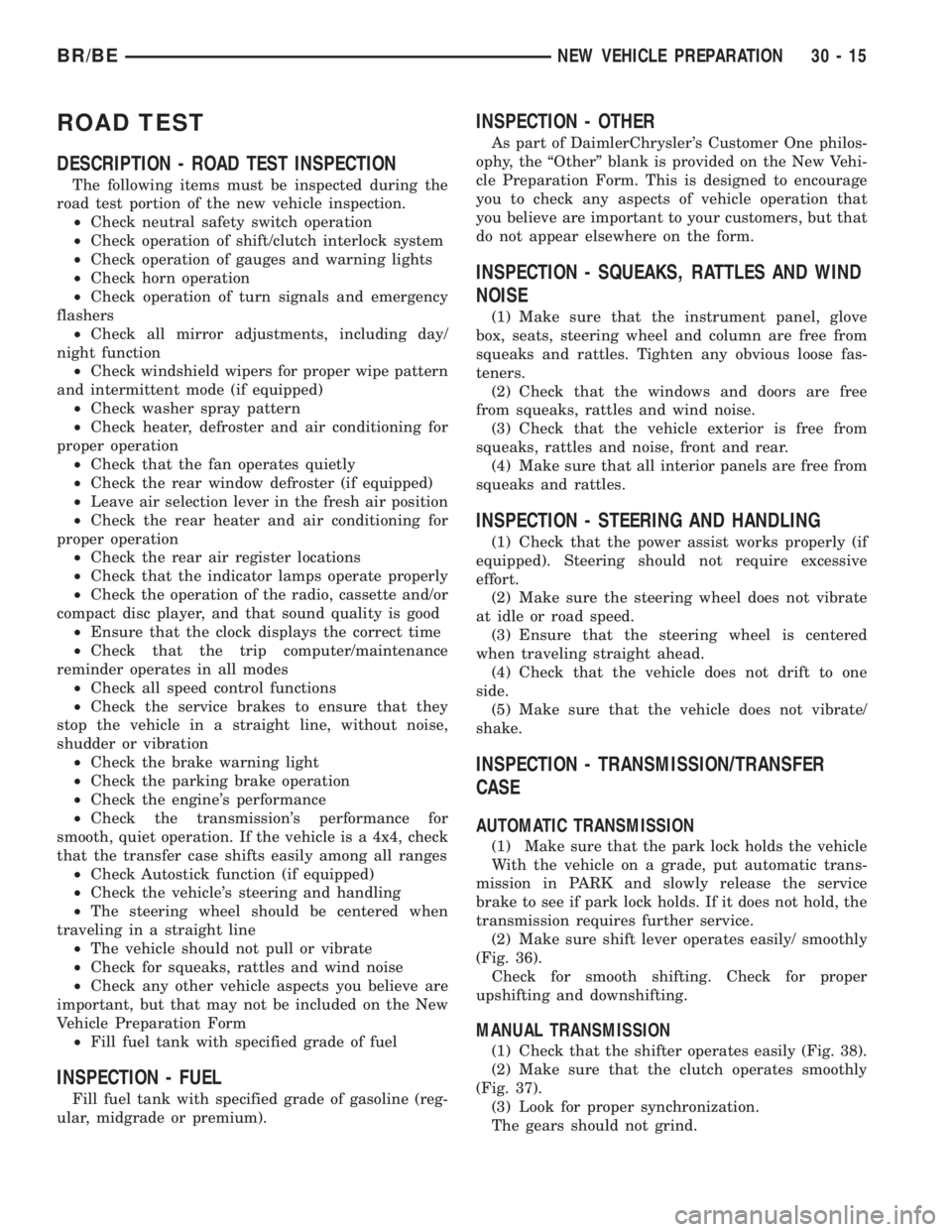

INSPECTION - PARKING BRAKE

(1) Ensure that the parking brake is easy to oper-

ate (Fig. 40).

(2) Make sure the parking brake does not drag.

(3) With the vehicle stopped on a grade, firmly

apply the service brakes, place the transmission in

NEUTRAL and set the parking brake. Slowly release

the service brakes to see if the parking brake will

hold.

(4) Check that the parking brake warning light

comes on when the parking brake is applied, and is

off when the brake is released.

INSPECTION - SERVICE BRAKES

(1) Check brake warning light operation at vehicle

startup.

(2) Check ABS warning light operation at vehicle

startup.

(3) Inspect service brake pedal travel and feel (Fig.

41).

(4) Put the vehicle in gear and apply the brakes

while the car is in motion. Be sure brake operation is

smooth and positive.

(5) Make sure that the vehicle stops in a straight

line, without pulling to one side.

(6) Check that the brakes operate quietly, without

noise.

(7) Ensure there is no shudder or vibration when

braking.

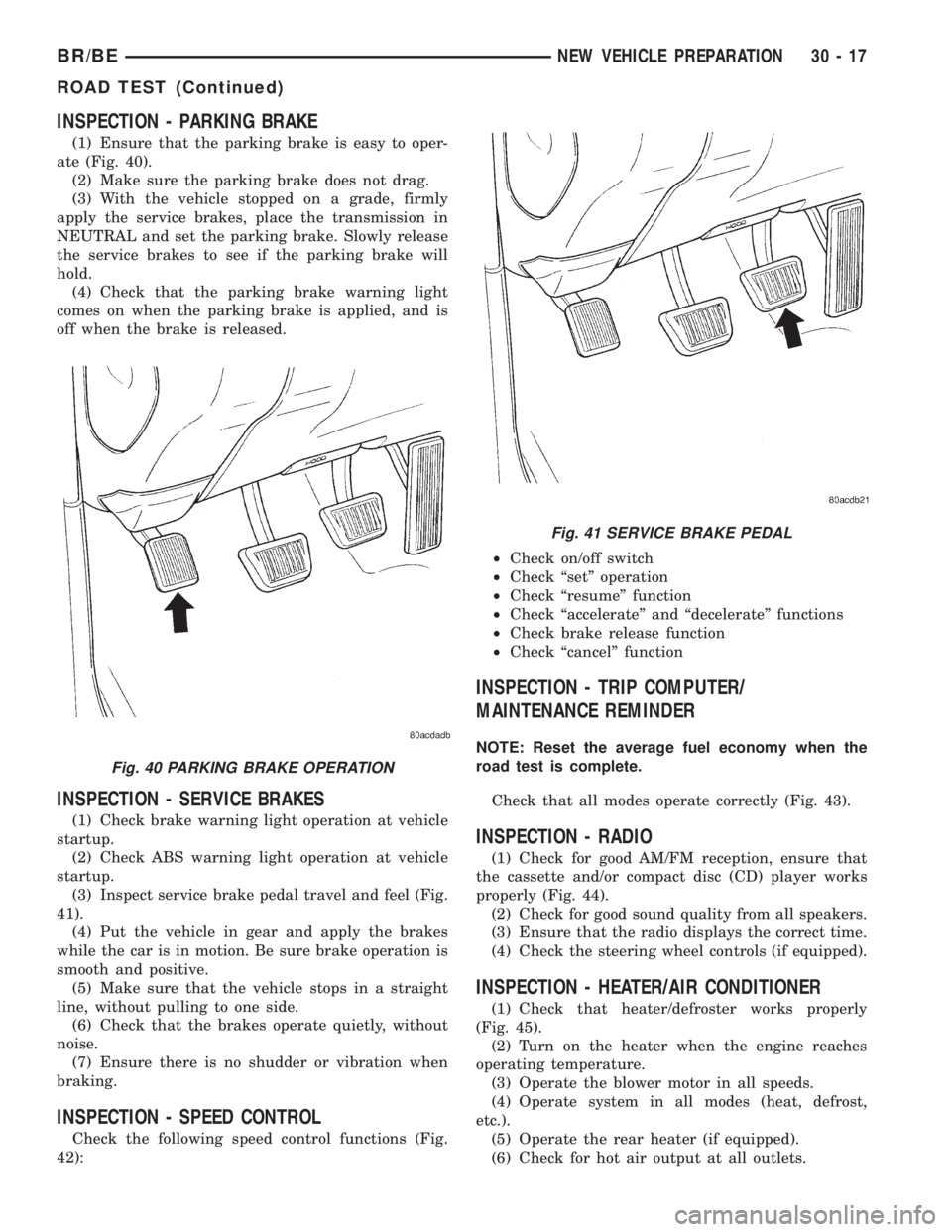

INSPECTION - SPEED CONTROL

Check the following speed control functions (Fig.

42):²Check on/off switch

²Check ªsetº operation

²Check ªresumeº function

²Check ªaccelerateº and ªdecelerateº functions

²Check brake release function

²Check ªcancelº function

INSPECTION - TRIP COMPUTER/

MAINTENANCE REMINDER

NOTE: Reset the average fuel economy when the

road test is complete.

Check that all modes operate correctly (Fig. 43).

INSPECTION - RADIO

(1) Check for good AM/FM reception, ensure that

the cassette and/or compact disc (CD) player works

properly (Fig. 44).

(2) Check for good sound quality from all speakers.

(3) Ensure that the radio displays the correct time.

(4) Check the steering wheel controls (if equipped).

INSPECTION - HEATER/AIR CONDITIONER

(1) Check that heater/defroster works properly

(Fig. 45).

(2) Turn on the heater when the engine reaches

operating temperature.

(3) Operate the blower motor in all speeds.

(4) Operate system in all modes (heat, defrost,

etc.).

(5) Operate the rear heater (if equipped).

(6) Check for hot air output at all outlets.

Fig. 40 PARKING BRAKE OPERATION

Fig. 41 SERVICE BRAKE PEDAL

BR/BENEW VEHICLE PREPARATION 30 - 17

ROAD TEST (Continued)

Page 2843 of 2889

(7) Operate temperature levers.

(8) Ensure that rear defroster works.(9) Turn on rear defroster during drive, then feel

window for warmth after drive.

(10) Check that the air conditioner cools properly.

(11) Turn on air conditioning system.

(12) Activate the A/C in all modes. (Make sure all

modes work properly including rear unit if

equipped.).

(13) Operate blower motor switch at all speeds.

(14) Check for cold output at outlets.

(15) Check that fan operation is quiet.

INSPECTION WINDSHIELD WIPERS/WASHERS

(1) Check washer spray pattern for proper opera-

tion and aim.

(2) Check intermittent wipe feature for proper

operation.

(3) Inspect wiper blades, check for proper wiping

pattern-no streaking or missed areas.

Fig. 42 SPEED CONTROL SWITCHES

1 - ON/OFF SWITCH

2 - ACCELERATE/RESUME SWITCH

3 - CANCEL SWITCH

4 - COAST SWITCH

5 - SET SWITCH

Fig. 43 TRIP COMPUTER

Fig. 44 RADIO OPERATION

Fig. 45 HEATER AND A/C CONTROLS

1 - MODE CONTROL SWITCH

2 - TEMPERATURE SWITCH

30 - 18 NEW VEHICLE PREPARATIONBR/BE

ROAD TEST (Continued)

Page 2855 of 2889

CLUTCH RELAY - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-17

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR.......................24-18

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR.......................24-17

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR.......................24-18

CLUTCH RELEASE BEARING -

DESCRIPTION........................6-14

CLUTCH RELEASE BEARING -

INSTALLATION........................6-15

CLUTCH RELEASE BEARING -

OPERATION..........................6-14

CLUTCH RELEASE BEARING - REMOVAL . . . 6-15

COAT FINISH - DESCRIPTION, BASE

COAT/CLEAR.......................23-129

COAT FINISH - OPERATION, BASE

COAT/CLEAR.......................23-129

COAT HOOK - INSTALLATION..........23-125

COAT HOOK - REMOVAL..............23-124

COAT/CLEAR COAT FINISH -

DESCRIPTION, BASE.................23-129

COAT/CLEAR COAT FINISH - OPERATION,

BASE.............................23-129

CODE - DESCRIPTION, PAINT..........23-129

CODE PLATE - DESCRIPTION, BODY....Intro.-1

CODES - DESCRIPTION, DIAGNOSTIC

TROUBLE............................25-2

CODES, SPECIFICATIONS - 2001 BR

PAINT COLOR......................23-129

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-13

COIL RESISTANCE, 3.9L/5.2L/5.9L

ENGINES - IGNITION...................8I-3

COIL RESISTANCE, 8.0L V-10 ENGINE -

IGNITION............................8I-3

COLOR CODES, SPECIFICATIONS - 2001

BR PAINT..........................23-129

COLUMN - DESCRIPTION...............19-6

COLUMN - INSTALLATION...............19-8

COLUMN - REMOVAL..................19-7

COLUMN - SERVICE PRECAUTIONS.......19-6

COLUMN OPENING COVER -

INSTALLATION, STEERING............23-116

COLUMN OPENING COVER - REMOVAL,

STEERING.........................23-115

COMBINATION FLASHER - DESCRIPTION . . . 8L-7

COMBINATION FLASHER -

INSTALLATION........................8L-8

COMBINATION FLASHER - OPERATION....8L-7

COMBINATION FLASHER - REMOVAL......8L-8

COMBINATION VALVE - DESCRIPTION......5-9

COMBINATION VALVE - DIAGNOSIS AND

TESTING.............................5-9

COMBINATION VALVE - INSTALLATION.....5-10

COMBINATION VALVE - OPERATION........5-9

COMBINATION VALVE - REMOVAL........5-10

COMBUSTION PRESSURE LEAKAGE -

DIAGNOSIS AND TESTING, CYLINDER....9-124,

9-179,9-67,9-9

COMPASS - INSPECTION..............30-12

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-4

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-5

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS & TESTING...............8M-10

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-4

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-8

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION......................8M-11

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-9

COMPASS/MINI-TRIP COMPUTER -

REMOVAL..........................8M-11

COMPRESSION PRESSURE - DIAGNOSIS

AND TESTING, CYLINDER . . 9-124,9-179,9-67,9-9

COMPRESSOR - DESCRIPTION, A/C......24-46

COMPRESSOR - DIAGNOSIS AND

TESTING, A/C

.......................24-46

COMPRESSOR - INSTALLATION, A/C

.....24-47

COMPRESSOR - OPERATION, A/C

........24-46

COMPRESSOR - REMOVAL, A/C

.........24-47

COMPRESSOR CLUTCH - DESCRIPTION,

A/C

................................24-13COMPRESSOR CLUTCH - INSPECTION,

A/C................................24-16

COMPRESSOR CLUTCH - INSTALLATION,

A/C................................24-16

COMPRESSOR CLUTCH - OPERATION,

A/C................................24-13

COMPRESSOR CLUTCH - REMOVAL, A/C . . 24-14

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE, A/C...........24-13

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING, A/C..........24-13

COMPRESSOR CLUTCH RELAY -

DESCRIPTION, A/C...................24-17

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING, A/C..........24-17

COMPRESSOR CLUTCH RELAY -

INSTALLATION, A/C...................24-18

COMPRESSOR CLUTCH RELAY -

OPERATION, A/C.....................24-17

COMPRESSOR CLUTCH RELAY -

REMOVAL, A/C......................24-18

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP..........................8M-8

COMPUTER - DIAGNOSIS & TESTING,

COMPASS MINI-TRIP.................8M-10

COMPUTER - INSTALLATION, COMPASS/

MINI-TRIP.........................8M-11

COMPUTER - OPERATION, COMPASS/

MINI-TRIP..........................8M-9

COMPUTER - REMOVAL, COMPASS/

MINI-TRIP.........................8M-11

COMPUTER/MAINTENANCE REMINDER -

INSPECTION, TRIP...................30-17

CONDENSER - DESCRIPTION, A/C.......24-48

CONDENSER - INSTALLATION, A/C.......24-49

CONDENSER - OPERATION, A/C.........24-48

CONDENSER - REMOVAL, A/C..........24-49

CONDITIONER - DESCRIPTION, HEATER

AND AIR ............................24-1

CONDITIONER - INSPECTION,

HEATER/AIR.........................30-17

CONDITIONER - OPERATION, HEATER

AND AIR ............................24-1

CONDITIONING - INSTALLATION, WATER

PUMP BYPASS HOSE WITH AIR..........7-77

CONDITIONING - INSTALLATION, WATER

PUMP BYPASS HOSE WITHOUT AIR......7-78

CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITH AIR..........7-74

CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITHOUT AIR......7-77

CONDITIONS - DIAGNOSIS AND

TESTING, SPARK PLUG................8I-16

CONNECT FITTING - DESCRIPTION,

QUICK.............................14-22

CONNECTING ROD - CLEANING, PISTON . . 9-154,

9-209,9-285,9-41,9-98

CONNECTING ROD - CONNECTING

RODS, PISTON......................9-286

CONNECTING ROD - DESCRIPTION,

PISTON..........9-153,9-208,9-282,9-40,9-97

CONNECTING ROD - INSPECTION,

PISTON..........9-154,9-209,9-285,9-41,9-98

CONNECTING ROD - INSTALLATION,

PISTON..........9-154,9-210,9-287,9-41,9-98

CONNECTING ROD - REMOVAL, PISTON . . 9-154,

9-209,9-285,9-40,9-97

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL CLEARANCE -

STANDARD PROCEDURE...............9-274

CONNECTING ROD BEARING FITTING -

STANDARD PROCEDURE......9-144,9-202,9-88

CONNECTING ROD BEARINGS -

STANDARD PROCEDURE-CONNECTING

ROD BEARING FITTING.................9-31

CONNECTING RODS, PISTON &

CONNECTING ROD...................9-286

CONNECTOR - AUGAT - INSTALLATION . 8W-01-8

CONNECTOR - AUGAT - REMOVAL.....8W-01-8

CONNECTOR - DESCRIPTION, DATA LINK . 8E-12

CONNECTOR - MOLEX - INSTALLATION . 8W-01-9

CONNECTOR - MOLEX - REMOVAL

....8W-01-9

CONNECTOR - OPERATION, DATA LINK

. . . 8E-12

CONNECTOR - THOMAS AND BETTS -

INSTALLATION

...................8W-01-10

CONNECTOR - THOMAS AND BETTS -

REMOVAL

........................8W-01-9

CONSOLE - DESCRIPTION, OVERHEAD

....8M-1CONSOLE - INSTALLATION, CENTER....23-122

CONSOLE - INSTALLATION, OVERHEAD . . . 8M-8

CONSOLE - OVERHEAD CONSOLE

ASSEMBLY, OVERHEAD................8M-7

CONSOLE - OVERHEAD CONSOLE

DISASSEMBLY, OVERHEAD.............8M-7

CONSOLE - REMOVAL, CENTER........23-122

CONSOLE - REMOVAL, OVERHEAD.......8M-6

CONSOLE ASSEMBLY, OVERHEAD

CONSOLE - OVERHEAD................8M-7

CONSOLE DISASSEMBLY, OVERHEAD

CONSOLE - OVERHEAD................8M-7

CONSOLE LID - INSTALLATION, CENTER . 23-132

CONSOLE LID - REMOVAL, CENTER.....23-131

CONSOLE SYSTEMS, SPECIAL TOOLS -

OVERHEAD..........................8M-8

CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL

- DESCRIPTION, COOLANT RECOVERY.....7-41

CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL

- INSTALLATION, COOLANT RECOVERY....7-41

CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL

- OPERATION, COOLANT RECOVERY......7-41

CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL

- REMOVAL, COOLANT RECOVERY........7-41

CONTAINER - 8.0L - DESCRIPTION,

COOLANT RECOVERY..................7-42

CONTAINER - 8.0L - OPERATION,

COOLANT RECOVERY..................7-42

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID................5-14

CONTAMINATION - DIAGNOSIS AND

TESTING, FLUID....21-199,21-370,21-545,21-715

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-6

CONTROL - DESCRIPTION, A/C HEATER . . . 24-18

CONTROL - DIAGNOSIS AND TESTING,

A/C HEATER.........................24-19

CONTROL - INSPECTION, SPEED........30-17

CONTROL - INSTALLATION, A/C HEATER . . 24-20

CONTROL - OPERATION, A/C HEATER....24-18

CONTROL - REMOVAL, A/C HEATER......24-19

CONTROL ARM - INSTALLATION, LOWER . . 2-10,

2-20

CONTROL ARM - INSTALLATION, UPPER . . 2-13,

2-24

CONTROL ARM - REMOVAL, LOWER . . 2-10,2-20

CONTROL ARM - REMOVAL, UPPER . . 2-13,2-23

CONTROL CABLE - INSTALLATION,

THROTTLE....................14-105,14-50

CONTROL CABLE - REMOVAL,

THROTTLE....................14-104,14-50

CONTROL MODULE - DESCRIPTION,

AIRBAG.............................8O-6

CONTROL MODULE - INSTALLATION,

AIRBAG.............................8O-8

CONTROL MODULE - INSTALLATION,

ENGINE............................8E-14

CONTROL MODULE - INSTALLATION,

POWERTRAIN.......................8E-20

CONTROL MODULE - OPERATION,

AIRBAG.............................8O-6

CONTROL MODULE - REMOVAL, AIRBAG . . 8O-7

CONTROL MODULE - REMOVAL, ENGINE . . 8E-14

CONTROL MODULE - REMOVAL,

POWERTRAIN.......................8E-19

CONTROL MOTOR - DESCRIPTION, IDLE

AIR

...............................14-41

CONTROL MOTOR - OPERATION, IDLE

AIR

...............................14-41

CONTROL SERVO - DESCRIPTION,

SPEED

..............................8P-5

CONTROL SERVO - INSTALLATION,

SPEED

.............................8P-10

CONTROL SERVO - OPERATION, SPEED

. . . 8P-5

CONTROL SERVO - REMOVAL, SPEED

.....8P-6

CONTROL SWITCH - DESCRIPTION,

LUMBAR

...........................8N-17

CONTROL SWITCH - OPERATION,

LUMBAR

...........................8N-18

CONTROL SWITCH - REMOVAL,

LUMBAR

...........................8N-18

CONTROL SYSTEM - DESCRIPTION,

SPEED

..............................8P-1

CONTROL SYSTEM - OPERATION, SPEED

. . 8P-2

CONTROL SYSTEM - TORQUE, SPEED

.....8P-4

CONTROL/CENTRAL TIMER MODULE -

DESCRIPTION, BODY

..................8E-1

8 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2866 of 2889

INJECTION PUMP TIMING - DIAGNOSIS

AND TESTING, FUEL..................14-66

INJECTION SYSTEM - DESCRIPTION, AIR . 25-25

INJECTION SYSTEM - DESCRIPTION,

DIESEL FUEL........................14-87

INJECTION SYSTEM - OPERATION, AIR . . . 25-27

INJECTION SYSTEM - TORQUE, AIR......25-28

INJECTOR - DESCRIPTION, FUEL . . . 14-53,14-93

INJECTOR - INSTALLATION, FUEL . . 14-53,14-98

INJECTOR - OPERATION, FUEL.....14-53,14-94

INJECTOR - REMOVAL, FUEL......14-53,14-96

INJECTOR FIRING ORDER, DIESEL -

FUEL..............................14-58

INJECTOR TEST - DIAGNOSIS AND

TESTING, FUEL.................14-53,14-95

INLET BAFFLE - INSTALLATION, HVAC

HOUSING...........................24-37

INLET BAFFLE - REMOVAL, HVAC

HOUSING...........................24-36

INLET FILTER - INSTALLATION..........14-22

INLET FILTER - REMOVAL..............14-22

INNER BELT WEATHERSTRIP -

INSTALLATION, FRONT DOOR..........23-154

INNER BELT WEATHERSTRIP -

REMOVAL, FRONT DOOR.............23-154

IN/OUT - ADJUSTMENT, FRONT DOOR....23-69

INPUT - DESCRIPTION, VEHICLE SPEED . . . 8P-1

INPUT - OPERATION, ASD SENSE - PCM . . . 8I-3

INSIDE HANDLE ACTUATOR -

INSTALLATION...................23-71,23-80

INSIDE HANDLE ACTUATOR - REMOVAL . . 23-71,

23-80

INSPECTION - DESCRIPTION, ROAD

TEST..............................30-15

INSPECTION - DIAGNOSIS AND

TESTING, WHEEL....................22-10

INSPECTION - INFORMATION LABELS -

STANDARD PROCEDURE...............30-22

INSPECTION, 3.9L/5.2L/5.9L ENGINES -

VISUAL............................14-28

INSPECTION, 8.0L ENGINE - VISUAL.....14-32

INSPECTION, A/C COMPRESSOR

CLUTCH............................24-16

INSPECTION, ACCUMULATOR . . . 21-192,21-363,

21-538,21-708

INSPECTION, AUTOMATIC

TRANSMISSION - 42RE...............21-165

INSPECTION, AUTOMATIC

TRANSMISSION - 44RE...............21-337

INSPECTION, AUTOMATIC

TRANSMISSION - 46RE...............21-510

INSPECTION, AUTOMATIC

TRANSMISSION - 47RE...............21-681

INSPECTION, BATTERY.................30-7

INSPECTION, BATTERY SYSTEM..........8F-5

INSPECTION, BODY SEALING...........30-10

INSPECTION, CAMSHAFT & BEARINGS

(IN BLOCK).........................9-272

INSPECTION, CATALYTIC CONVERTER -

3.9L/5.2L/5.9L........................11-5

INSPECTION, CATALYTIC CONVERTER -

5.9L HEAVY DUTY/8.0L.................11-7

INSPECTION, CHARGE AIR COOLER AND

PLUMBING.........................11-18

INSPECTION, COMPASS...............30-12

INSPECTION, CROSSHEADS............9-250

INSPECTION, CYLINDER HEAD....9-137,9-193,

9-23,9-250,9-80

INSPECTION, CYLINDER HEAD COVER(S) . 9-138,

9-194,9-24,9-253,9-81

INSPECTION, DISC BRAKE CALIPERS......5-12

INSPECTION, DOORS AND DOOR LOCKS . . 30-11

INSPECTION, DRUM...................5-33

INSPECTION, ENGINE BLOCK . 9-142,9-200,9-267,

9-28,9-86

INSPECTION, ENGINE PERFORMANCE....30-16

INSPECTION, EXHAUST MANIFOLD . 9-112,9-168,

9-225,9-304,9-55

INSPECTION, EXHAUST PIPE -

3.9L/5.2L/5.9L........................11-7

INSPECTION, EXHAUST PIPE - 5.9L

DIESEL

.............................11-9

INSPECTION, EXHAUST PIPE - 5.9L

HEAVY DUTY/8.0L

.....................11-9

INSPECTION, FIT AND FINISH

......30-10,30-12

INSPECTION, FLUID LEVELS

.............30-4

INSPECTION, FRONT CLUTCH

. . . 21-205,21-376,

21-550,21-721INSPECTION, FRONT SERVO....21-207,21-378,

21-553,21-723

INSPECTION, FUEL...................30-15

INSPECTION, GAUGES/WARNING LIGHTS . 30-19

INSPECTION, HEATER/AIR CONDITIONER . . 30-17

INSPECTION, HOOD LATCH/SAFETY

CATCH ..............................30-4

INSPECTION, HORN..................30-19

INSPECTION, INTAKE MANIFOLD . . . 9-110,9-166,

9-223,9-302,9-53

INSPECTION, INTAKE/EXHAUST VALVES

& SEATS ..............9-141,9-198,9-27,9-84

INSPECTION, KEYLESS ENTRY..........30-11

INSPECTION, LIGHTS AND SWITCHES....30-12

INSPECTION, LINES/HOSES.............30-6

INSPECTION, MANUAL - NV3500........21-15

INSPECTION, MEASURING TIMING

CHAIN STRETCH.......9-114,9-170,9-227,9-58

INSPECTION, MIRROR................30-19

INSPECTION, NEUTRAL SAFETY SWITCH . . 30-19

INSPECTION, OIL COOLER & LINES -

CLEANING..........................9-296

INSPECTION, OIL PAN . 9-106,9-162,9-219,9-297,

9-49

INSPECTION, OIL PRESSURE RELIEF

VALVE .............................9-297

INSPECTION, OIL PUMP....9-107,9-163,9-220,

9-299,9-50

INSPECTION, OIL PUMP . . 21-211,21-382,21-557,

21-728

INSPECTION, OTHER..................30-15

INSPECTION, OVERDRIVE UNIT . . 21-224,21-394,

21-569,21-741

INSPECTION, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON RETAINER....21-236,

21-406,21-580,21-752

INSPECTION, PARKING BRAKE..........30-17

INSPECTION, PISTON & CONNECTING

ROD ............9-154,9-209,9-285,9-41,9-98

INSPECTION, PLANETARY GEARTRAIN/

OUTPUT SHAFT . . . 21-241,21-411,21-587,21-760

INSPECTION, PUSHRODS..............9-250

INSPECTION, RADIATOR - 3.9L/5.2L/5.9L . . . 7-61

INSPECTION, RADIATOR - 5.9L DIESEL....7-65

INSPECTION, RADIATOR - 8.0L..........7-62

INSPECTION, RADIATOR FAN -

3.9L/5.2L/5.9L/8.0L....................7-43

INSPECTION, RADIATOR FAN - 5.9L

DIESEL.............................7-44

INSPECTION, RADIATOR PRESSURE CAP . . . 7-66

INSPECTION, RADIO..................30-17

INSPECTION, REAR CLUTCH....21-248,21-419,

21-593,21-765

INSPECTION, RECEIVING...............30-3

INSPECTION, ROCKER ARM / ADJUSTER

ASSY..............................9-262

INSPECTION, SEAT BELTS, SHOULDER

BELTS, RETRACTORS AND HEAD

RESTRAINTS........................30-12

INSPECTION, SEATS..................30-13

INSPECTION, SERVICE BRAKES.........30-17

INSPECTION, SHIFT/CLUTCH INTERLOCK

SYSTEM............................30-19

INSPECTION, SOLID LIFTERS/TAPPETS . . . 9-281

INSPECTION, SPEED CONTROL.........30-17

INSPECTION, SQUEAKS, RATTLES AND

WIND NOISE........................30-15

INSPECTION, STEERING AND HANDLING

. . 30-15

INSPECTION, TAILPIPE - 3.9L/5.2L/5.9L

. . . 11-11

INSPECTION, TAILPIPE - 5.9L DIESEL

....11-12

INSPECTION, TAILPIPE - 5.9L HEAVY

DUTY/8.0L

..........................11-12

INSPECTION, TIRE PRESSURES

..........30-8

INSPECTION, TRANSFER CASE -

NV231HD

..........................21-832

INSPECTION, TRANSFER CASE -

NV241HD

..........................21-902

INSPECTION, TRANSFER CASE -

NV241LD

..........................21-867

INSPECTION, TRANSMISSION

.....21-109,21-64

INSPECTION, TRANSMISSION/TRANSFER

CASE

..............................30-15

INSPECTION, TRIP COMPUTER/

MAINTENANCE REMINDER

.............30-17

INSPECTION, TURBOCHARGER

..........11-16

INSPECTION, TURN AND EMERGENCY

SIGNALS

...........................30-19INSPECTION, VALVE BODY......21-293,21-465,

21-637,21-809

INSPECTION, VIBRATION DAMPER.......9-289

INSPECTION, VISUAL..................30-8

INSPECTION, WATER PUMP -

3.9L/5.2L/5.9L........................7-69

INSPECTION, WATER PUMP - 5.9L

DIESEL.............................7-73

INSPECTION, WATER PUMP - 8.0L........7-72

INSPECTION, WHEEL CYLINDERS........5-31

INSPECTION, WINDOWS, DOORS AND

LOCKS.............................30-14

INSPECTION WINDSHIELD WIPERS/

WASHERS, ROAD TEST................30-18

INSPECTION, WIPER & WASHER

SYSTEM............................8R-6

INSPECTION, WIRING..................30-7

INSTALLED - INSTALLATION, FRONT OIL

SEAL - FRONT COVER.................9-205

INSTALLED - REMOVAL, FRONT OIL

SEAL - FRONT COVER.................9-204

INSTRUMENT CLUSTER - ASSEMBLY.....8J-13

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-2

INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING........................8J-6

INSTRUMENT CLUSTER - DISASSEMBLY . . 8J-11

INSTRUMENT CLUSTER - INSTALLATION . . 8J-14

INSTRUMENT CLUSTER - OPERATION.....8J-3

INSTRUMENT CLUSTER - REMOVAL.....8J-10

INSTRUMENT PANEL ANTENNA CABLE -

INSTALLATION.......................8A-10

INSTRUMENT PANEL ANTENNA CABLE -

REMOVAL...........................8A-9

INSTRUMENT PANEL DEMISTER DUCTS

- REMOVAL.........................24-37

INSTRUMENT PANEL DUCTS - REMOVAL . 24-37

INSTRUMENT PANEL SYSTEM -

DESCRIPTION......................23-104

INSTRUMENT PANEL SYSTEM -

INSTALLATION......................23-107

INSTRUMENT PANEL SYSTEM -

OPERATION........................23-105

INSTRUMENT PANEL SYSTEM -

REMOVAL.........................23-106

INSTRUMENT PANEL TOP COVER -

INSTALLATION......................23-115

INSTRUMENT PANEL TOP COVER -

REMOVAL.........................23-114

INTAKE AIR HEATER - DESCRIPTION....14-100

INTAKE AIR HEATER - INSTALLATION....14-101

INTAKE AIR HEATER - OPERATION......14-100

INTAKE AIR HEATER - REMOVAL.......14-100

INTAKE AIR HEATER RELAY -

DESCRIPTION......................14-101

INTAKE AIR HEATER RELAY -

INSTALLATION......................14-102

INTAKE AIR HEATER RELAY -

OPERATION........................14-102

INTAKE AIR HEATER RELAY - REMOVAL . 14-102

INTAKE MANIFOLD - CLEANING

....9-110,9-166,

9-223,9-302,9-53

INTAKE MANIFOLD - DESCRIPTION

. 9-109,9-165,

9-222,9-52

INTAKE MANIFOLD - INSPECTION

. . 9-110,9-166,

9-223,9-302,9-53

INTAKE MANIFOLD - INSTALLATION

.....9-111,

9-166,9-223,9-302,9-53

INTAKE MANIFOLD - OPERATION

. . 9-109,9-165,

9-52

INTAKE MANIFOLD - REMOVAL

....9-110,9-166,

9-222,9-301,9-53

INTAKE MANIFOLD LEAKAGE -

DIAGNOSIS AND TESTING

. . . 9-110,9-165,9-222,

9-53

INTAKE/EXHAUST VALVES & SEATS -

CLEANING

.............9-140,9-198,9-27,9-84

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION

.....9-138,9-195,9-25,9-253,9-81

INTAKE/EXHAUST VALVES & SEATS -

INSPECTION

...........9-141,9-198,9-27,9-84

INTAKE/EXHAUST VALVES & SEATS -

INSTALLATION

.........9-141,9-260,9-28,9-85

INTAKE/EXHAUST VALVES & SEATS -

REMOVAL

.............9-140,9-258,9-27,9-84

INTAKE/EXHAUST VALVES & SEATS -

STANDARD PROCEDURE-

VALVES,GUIDES AND SPRINGS

.........9-253

BR/BEINDEX 19

Description Group-Page Description Group-Page Description Group-Page