tow DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2540 of 2889

(5) Using Installer 6953, remove front output shaft

bearing.

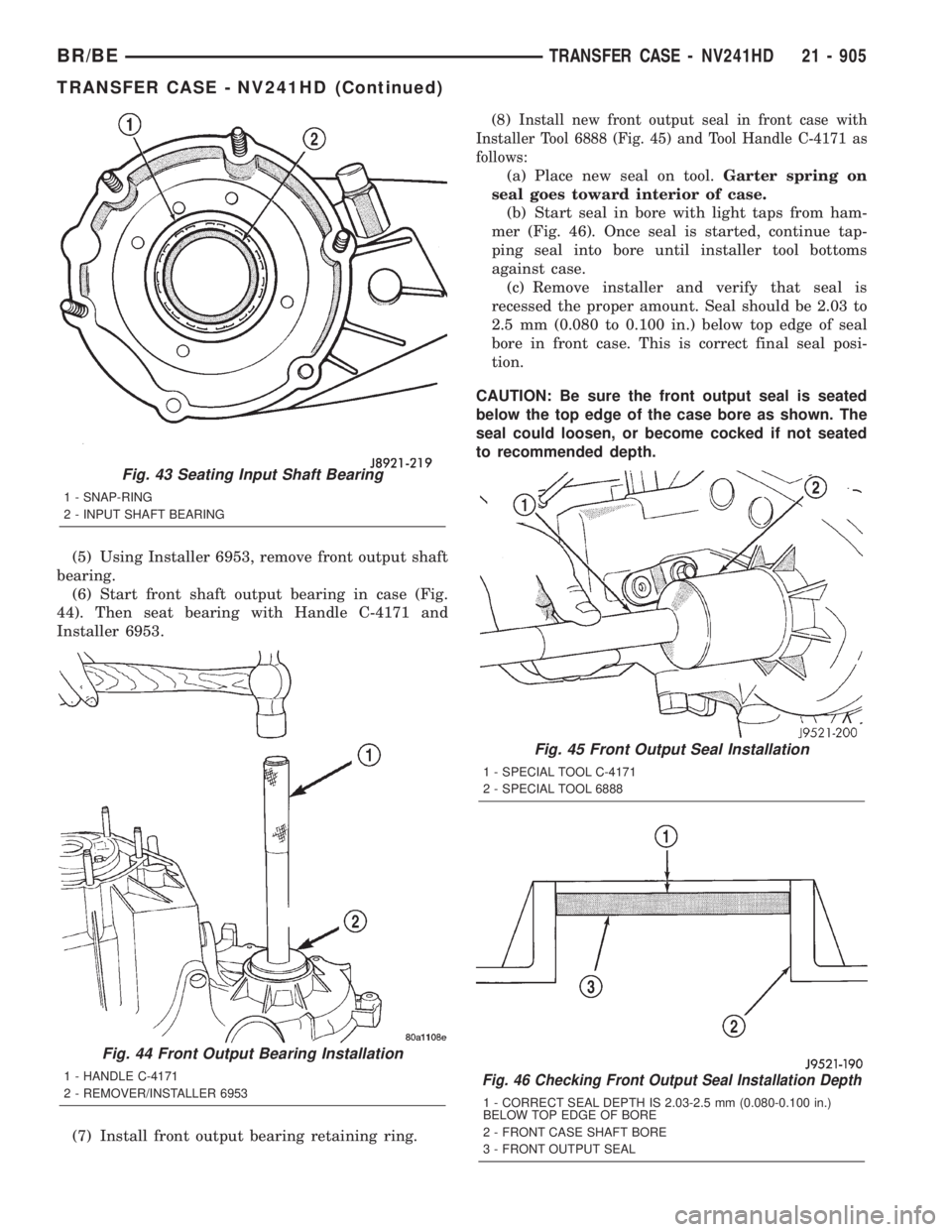

(6) Start front shaft output bearing in case (Fig.

44). Then seat bearing with Handle C-4171 and

Installer 6953.

(7) Install front output bearing retaining ring.(8)

Install new front output seal in front case with

Installer Tool 6888 (Fig. 45) and Tool Handle C-4171 as

follows:

(a) Place new seal on tool.Garter spring on

seal goes toward interior of case.

(b) Start seal in bore with light taps from ham-

mer (Fig. 46). Once seal is started, continue tap-

ping seal into bore until installer tool bottoms

against case.

(c) Remove installer and verify that seal is

recessed the proper amount. Seal should be 2.03 to

2.5 mm (0.080 to 0.100 in.) below top edge of seal

bore in front case. This is correct final seal posi-

tion.

CAUTION: Be sure the front output seal is seated

below the top edge of the case bore as shown. The

seal could loosen, or become cocked if not seated

to recommended depth.

Fig. 43 Seating Input Shaft Bearing

1 - SNAP-RING

2 - INPUT SHAFT BEARING

Fig. 44 Front Output Bearing Installation

1 - HANDLE C-4171

2 - REMOVER/INSTALLER 6953

Fig. 45 Front Output Seal Installation

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL 6888

Fig. 46 Checking Front Output Seal Installation Depth

1 - CORRECT SEAL DEPTH IS 2.03-2.5 mm (0.080-0.100 in.)

BELOW TOP EDGE OF BORE

2 - FRONT CASE SHAFT BORE

3 - FRONT OUTPUT SEAL

BR/BETRANSFER CASE - NV241HD 21 - 905

TRANSFER CASE - NV241HD (Continued)

Page 2546 of 2889

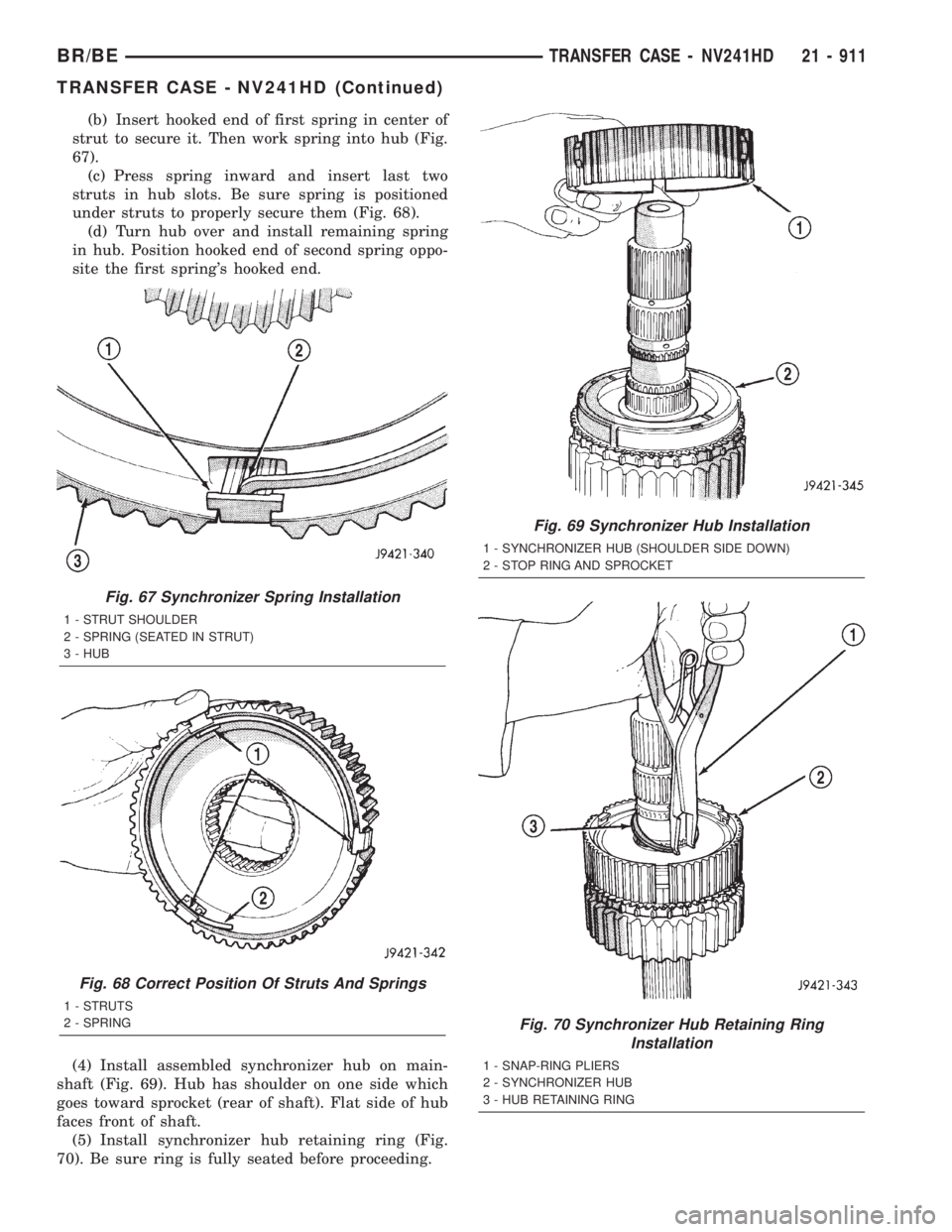

(b) Insert hooked end of first spring in center of

strut to secure it. Then work spring into hub (Fig.

67).

(c) Press spring inward and insert last two

struts in hub slots. Be sure spring is positioned

under struts to properly secure them (Fig. 68).

(d) Turn hub over and install remaining spring

in hub. Position hooked end of second spring oppo-

site the first spring's hooked end.

(4) Install assembled synchronizer hub on main-

shaft (Fig. 69). Hub has shoulder on one side which

goes toward sprocket (rear of shaft). Flat side of hub

faces front of shaft.

(5) Install synchronizer hub retaining ring (Fig.

70). Be sure ring is fully seated before proceeding.

Fig. 67 Synchronizer Spring Installation

1 - STRUT SHOULDER

2 - SPRING (SEATED IN STRUT)

3 - HUB

Fig. 68 Correct Position Of Struts And Springs

1 - STRUTS

2 - SPRING

Fig. 69 Synchronizer Hub Installation

1 - SYNCHRONIZER HUB (SHOULDER SIDE DOWN)

2 - STOP RING AND SPROCKET

Fig. 70 Synchronizer Hub Retaining Ring

Installation

1 - SNAP-RING PLIERS

2 - SYNCHRONIZER HUB

3 - HUB RETAINING RING

BR/BETRANSFER CASE - NV241HD 21 - 911

TRANSFER CASE - NV241HD (Continued)

Page 2557 of 2889

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 41-54 N´m

(30-40 ft. lbs.).

(5) Remove drain pan.

(6) Fill transfer case to bottom edge of fill plug

opening with MopartATF +4, type 9602, Automatic

Transmission fluid.

(7) Install and tighten fill plug to 41-54 N´m

(30-40 ft. lbs.).

(8) Lower vehicle.

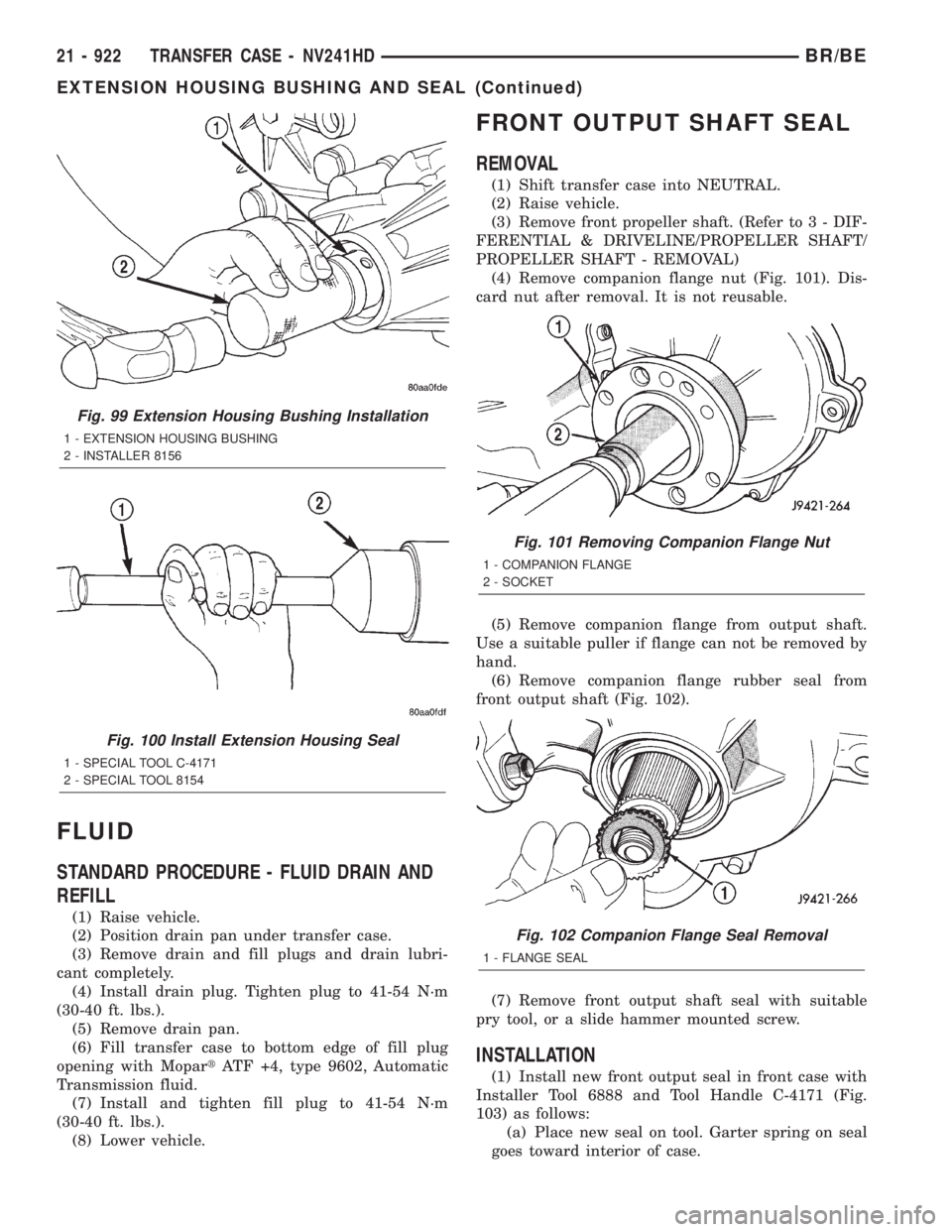

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Shift transfer case into NEUTRAL.

(2) Raise vehicle.

(3) Remove front propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(4) Remove companion flange nut (Fig. 101). Dis-

card nut after removal. It is not reusable.

(5) Remove companion flange from output shaft.

Use a suitable puller if flange can not be removed by

hand.

(6) Remove companion flange rubber seal from

front output shaft (Fig. 102).

(7) Remove front output shaft seal with suitable

pry tool, or a slide hammer mounted screw.

INSTALLATION

(1) Install new front output seal in front case with

Installer Tool 6888 and Tool Handle C-4171 (Fig.

103) as follows:

(a) Place new seal on tool. Garter spring on seal

goes toward interior of case.

Fig. 99 Extension Housing Bushing Installation

1 - EXTENSION HOUSING BUSHING

2 - INSTALLER 8156

Fig. 100 Install Extension Housing Seal

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL 8154

Fig. 101 Removing Companion Flange Nut

1 - COMPANION FLANGE

2 - SOCKET

Fig. 102 Companion Flange Seal Removal

1 - FLANGE SEAL

21 - 922 TRANSFER CASE - NV241HDBR/BE

EXTENSION HOUSING BUSHING AND SEAL (Continued)

Page 2652 of 2889

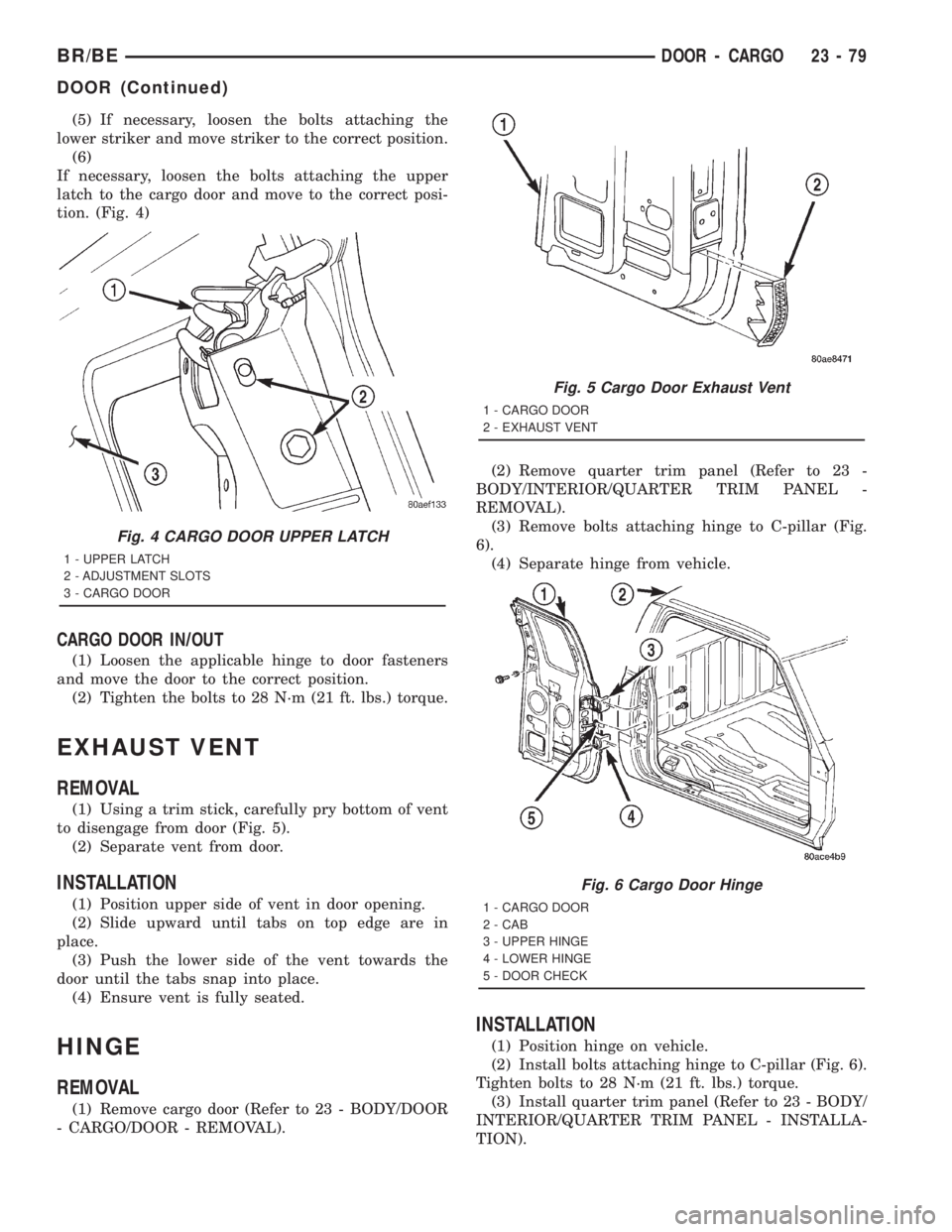

(5) If necessary, loosen the bolts attaching the

lower striker and move striker to the correct position.

(6)

If necessary, loosen the bolts attaching the upper

latch to the cargo door and move to the correct posi-

tion. (Fig. 4)

CARGO DOOR IN/OUT

(1) Loosen the applicable hinge to door fasteners

and move the door to the correct position.

(2) Tighten the bolts to 28 N´m (21 ft. lbs.) torque.

EXHAUST VENT

REMOVAL

(1) Using a trim stick, carefully pry bottom of vent

to disengage from door (Fig. 5).

(2) Separate vent from door.

INSTALLATION

(1) Position upper side of vent in door opening.

(2) Slide upward until tabs on top edge are in

place.

(3) Push the lower side of the vent towards the

door until the tabs snap into place.

(4) Ensure vent is fully seated.

HINGE

REMOVAL

(1) Remove cargo door (Refer to 23 - BODY/DOOR

- CARGO/DOOR - REMOVAL).(2) Remove quarter trim panel (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

REMOVAL).

(3) Remove bolts attaching hinge to C-pillar (Fig.

6).

(4) Separate hinge from vehicle.

INSTALLATION

(1) Position hinge on vehicle.

(2) Install bolts attaching hinge to C-pillar (Fig. 6).

Tighten bolts to 28 N´m (21 ft. lbs.) torque.

(3) Install quarter trim panel (Refer to 23 - BODY/

INTERIOR/QUARTER TRIM PANEL - INSTALLA-

TION).

Fig. 4 CARGO DOOR UPPER LATCH

1 - UPPER LATCH

2 - ADJUSTMENT SLOTS

3 - CARGO DOOR

Fig. 5 Cargo Door Exhaust Vent

1 - CARGO DOOR

2 - EXHAUST VENT

Fig. 6 Cargo Door Hinge

1 - CARGO DOOR

2 - CAB

3 - UPPER HINGE

4 - LOWER HINGE

5 - DOOR CHECK

BR/BEDOOR - CARGO 23 - 79

DOOR (Continued)

Page 2685 of 2889

GLOVE BOX

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Open the glove box.

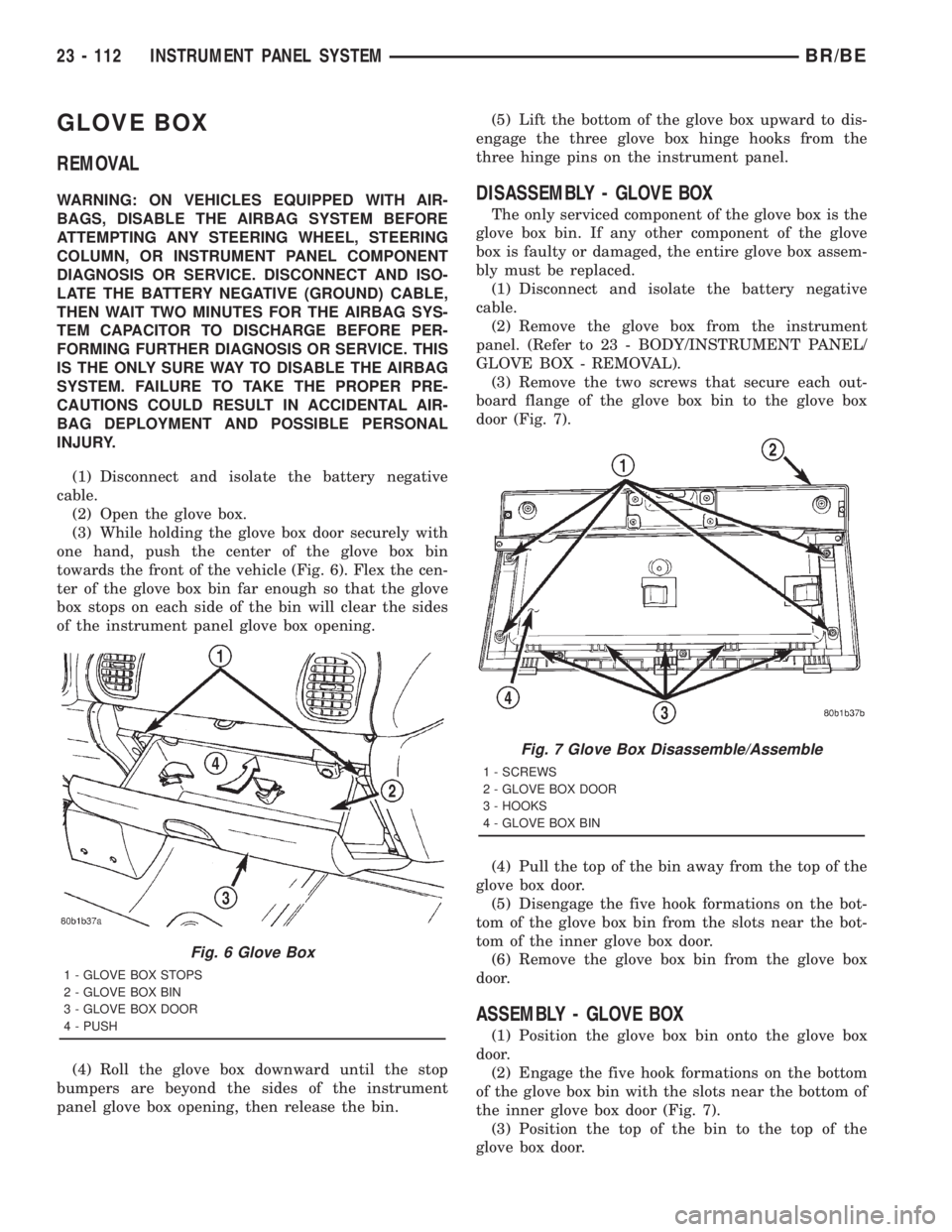

(3) While holding the glove box door securely with

one hand, push the center of the glove box bin

towards the front of the vehicle (Fig. 6). Flex the cen-

ter of the glove box bin far enough so that the glove

box stops on each side of the bin will clear the sides

of the instrument panel glove box opening.

(4) Roll the glove box downward until the stop

bumpers are beyond the sides of the instrument

panel glove box opening, then release the bin.(5) Lift the bottom of the glove box upward to dis-

engage the three glove box hinge hooks from the

three hinge pins on the instrument panel.DISASSEMBLY - GLOVE BOX

The only serviced component of the glove box is the

glove box bin. If any other component of the glove

box is faulty or damaged, the entire glove box assem-

bly must be replaced.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the glove box from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL).

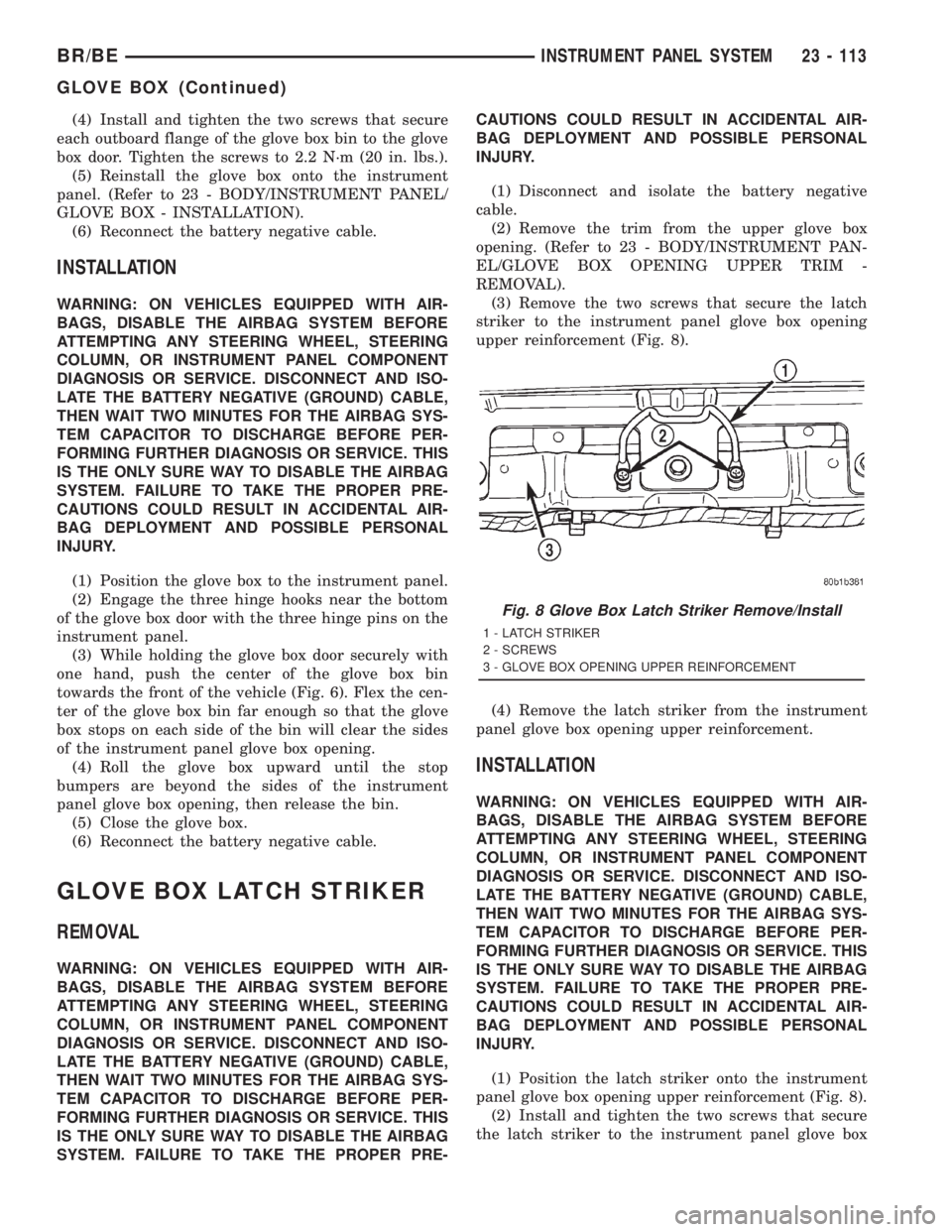

(3) Remove the two screws that secure each out-

board flange of the glove box bin to the glove box

door (Fig. 7).

(4) Pull the top of the bin away from the top of the

glove box door.

(5) Disengage the five hook formations on the bot-

tom of the glove box bin from the slots near the bot-

tom of the inner glove box door.

(6) Remove the glove box bin from the glove box

door.

ASSEMBLY - GLOVE BOX

(1) Position the glove box bin onto the glove box

door.

(2) Engage the five hook formations on the bottom

of the glove box bin with the slots near the bottom of

the inner glove box door (Fig. 7).

(3) Position the top of the bin to the top of the

glove box door.

Fig. 6 Glove Box

1 - GLOVE BOX STOPS

2 - GLOVE BOX BIN

3 - GLOVE BOX DOOR

4 - PUSH

Fig. 7 Glove Box Disassemble/Assemble

1 - SCREWS

2 - GLOVE BOX DOOR

3 - HOOKS

4 - GLOVE BOX BIN

23 - 112 INSTRUMENT PANEL SYSTEMBR/BE

Page 2686 of 2889

(4) Install and tighten the two screws that secure

each outboard flange of the glove box bin to the glove

box door. Tighten the screws to 2.2 N´m (20 in. lbs.).

(5) Reinstall the glove box onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - INSTALLATION).

(6) Reconnect the battery negative cable.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the glove box to the instrument panel.

(2) Engage the three hinge hooks near the bottom

of the glove box door with the three hinge pins on the

instrument panel.

(3) While holding the glove box door securely with

one hand, push the center of the glove box bin

towards the front of the vehicle (Fig. 6). Flex the cen-

ter of the glove box bin far enough so that the glove

box stops on each side of the bin will clear the sides

of the instrument panel glove box opening.

(4) Roll the glove box upward until the stop

bumpers are beyond the sides of the instrument

panel glove box opening, then release the bin.

(5) Close the glove box.

(6) Reconnect the battery negative cable.

GLOVE BOX LATCH STRIKER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim from the upper glove box

opening. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/GLOVE BOX OPENING UPPER TRIM -

REMOVAL).

(3) Remove the two screws that secure the latch

striker to the instrument panel glove box opening

upper reinforcement (Fig. 8).

(4) Remove the latch striker from the instrument

panel glove box opening upper reinforcement.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the latch striker onto the instrument

panel glove box opening upper reinforcement (Fig. 8).

(2) Install and tighten the two screws that secure

the latch striker to the instrument panel glove box

Fig. 8 Glove Box Latch Striker Remove/Install

1 - LATCH STRIKER

2 - SCREWS

3 - GLOVE BOX OPENING UPPER REINFORCEMENT

BR/BEINSTRUMENT PANEL SYSTEM 23 - 113

GLOVE BOX (Continued)

Page 2691 of 2889

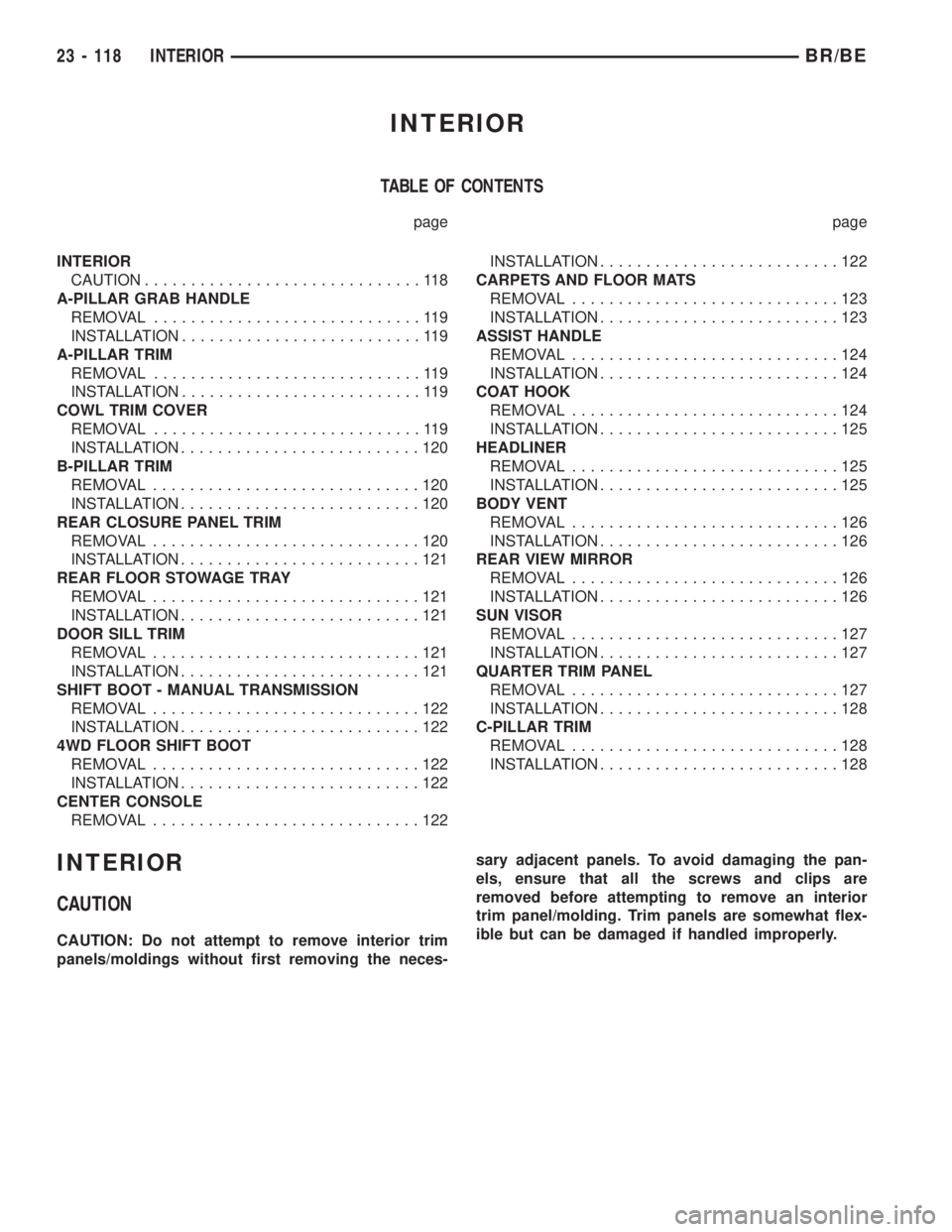

INTERIOR

TABLE OF CONTENTS

page page

INTERIOR

CAUTION..............................118

A-PILLAR GRAB HANDLE

REMOVAL.............................119

INSTALLATION..........................119

A-PILLAR TRIM

REMOVAL.............................119

INSTALLATION..........................119

COWL TRIM COVER

REMOVAL.............................119

INSTALLATION..........................120

B-PILLAR TRIM

REMOVAL.............................120

INSTALLATION..........................120

REAR CLOSURE PANEL TRIM

REMOVAL.............................120

INSTALLATION..........................121

REAR FLOOR STOWAGE TRAY

REMOVAL.............................121

INSTALLATION..........................121

DOOR SILL TRIM

REMOVAL.............................121

INSTALLATION..........................121

SHIFT BOOT - MANUAL TRANSMISSION

REMOVAL.............................122

INSTALLATION..........................122

4WD FLOOR SHIFT BOOT

REMOVAL.............................122

INSTALLATION..........................122

CENTER CONSOLE

REMOVAL.............................122INSTALLATION..........................122

CARPETS AND FLOOR MATS

REMOVAL.............................123

INSTALLATION..........................123

ASSIST HANDLE

REMOVAL.............................124

INSTALLATION..........................124

COAT HOOK

REMOVAL.............................124

INSTALLATION..........................125

HEADLINER

REMOVAL.............................125

INSTALLATION..........................125

BODY VENT

REMOVAL.............................126

INSTALLATION..........................126

REAR VIEW MIRROR

REMOVAL.............................126

INSTALLATION..........................126

SUN VISOR

REMOVAL.............................127

INSTALLATION..........................127

QUARTER TRIM PANEL

REMOVAL.............................127

INSTALLATION..........................128

C-PILLAR TRIM

REMOVAL.............................128

INSTALLATION..........................128

INTERIOR

CAUTION

CAUTION: Do not attempt to remove interior trim

panels/moldings without first removing the neces-sary adjacent panels. To avoid damaging the pan-

els, ensure that all the screws and clips are

removed before attempting to remove an interior

trim panel/molding. Trim panels are somewhat flex-

ible but can be damaged if handled improperly.

23 - 118 INTERIORBR/BE

Page 2693 of 2889

INSTALLATION

(1) Position cowl trim cover on lower cowl.

(2) Press into place.

(3) Install front door sill trim cover (Refer to 23 -

BODY/INTERIOR/DOOR SILL TRIM - INSTALLA-

TION).

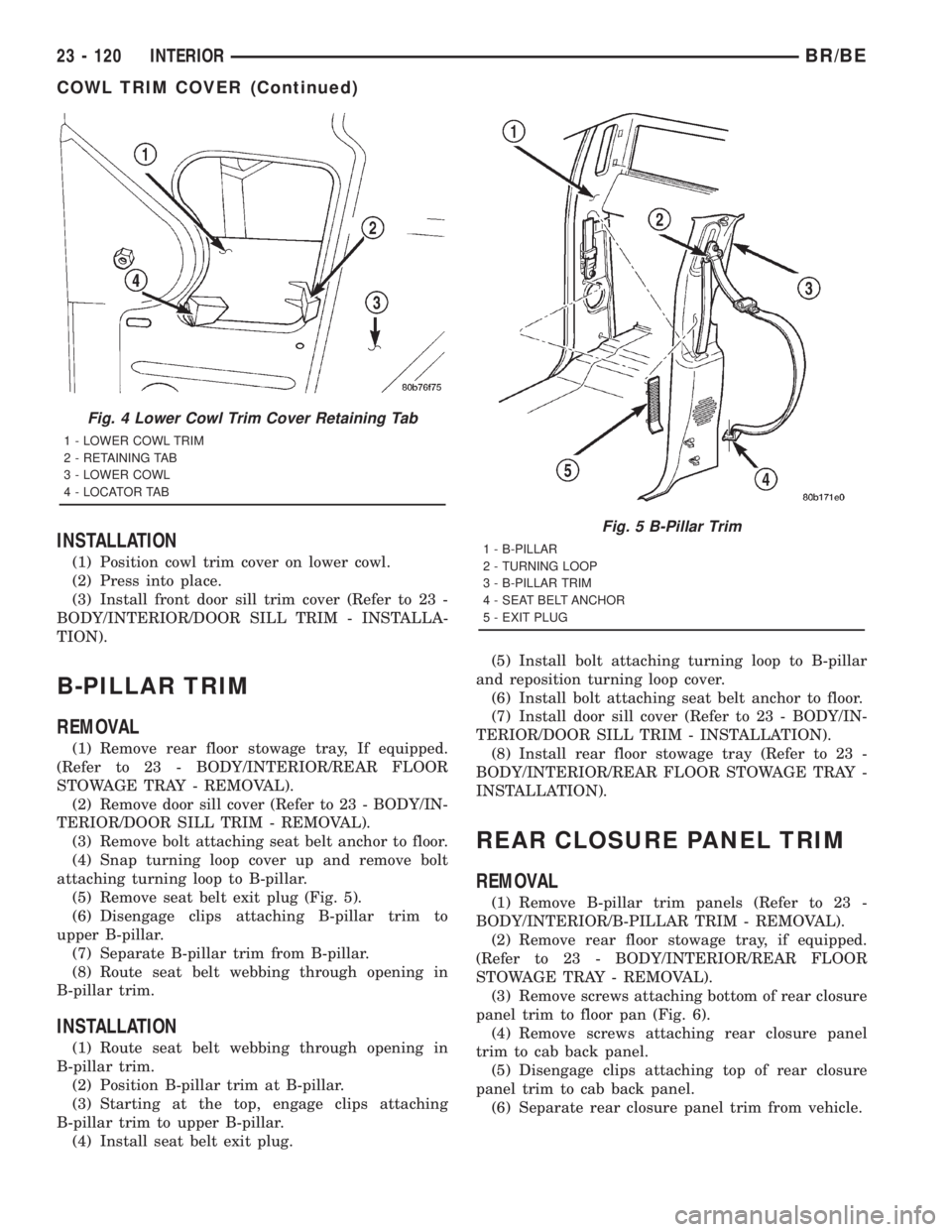

B-PILLAR TRIM

REMOVAL

(1) Remove rear floor stowage tray, If equipped.

(Refer to 23 - BODY/INTERIOR/REAR FLOOR

STOWAGE TRAY - REMOVAL).

(2) Remove door sill cover (Refer to 23 - BODY/IN-

TERIOR/DOOR SILL TRIM - REMOVAL).

(3) Remove bolt attaching seat belt anchor to floor.

(4) Snap turning loop cover up and remove bolt

attaching turning loop to B-pillar.

(5) Remove seat belt exit plug (Fig. 5).

(6) Disengage clips attaching B-pillar trim to

upper B-pillar.

(7) Separate B-pillar trim from B-pillar.

(8) Route seat belt webbing through opening in

B-pillar trim.

INSTALLATION

(1) Route seat belt webbing through opening in

B-pillar trim.

(2) Position B-pillar trim at B-pillar.

(3) Starting at the top, engage clips attaching

B-pillar trim to upper B-pillar.

(4) Install seat belt exit plug.(5) Install bolt attaching turning loop to B-pillar

and reposition turning loop cover.

(6) Install bolt attaching seat belt anchor to floor.

(7) Install door sill cover (Refer to 23 - BODY/IN-

TERIOR/DOOR SILL TRIM - INSTALLATION).

(8) Install rear floor stowage tray (Refer to 23 -

BODY/INTERIOR/REAR FLOOR STOWAGE TRAY -

INSTALLATION).

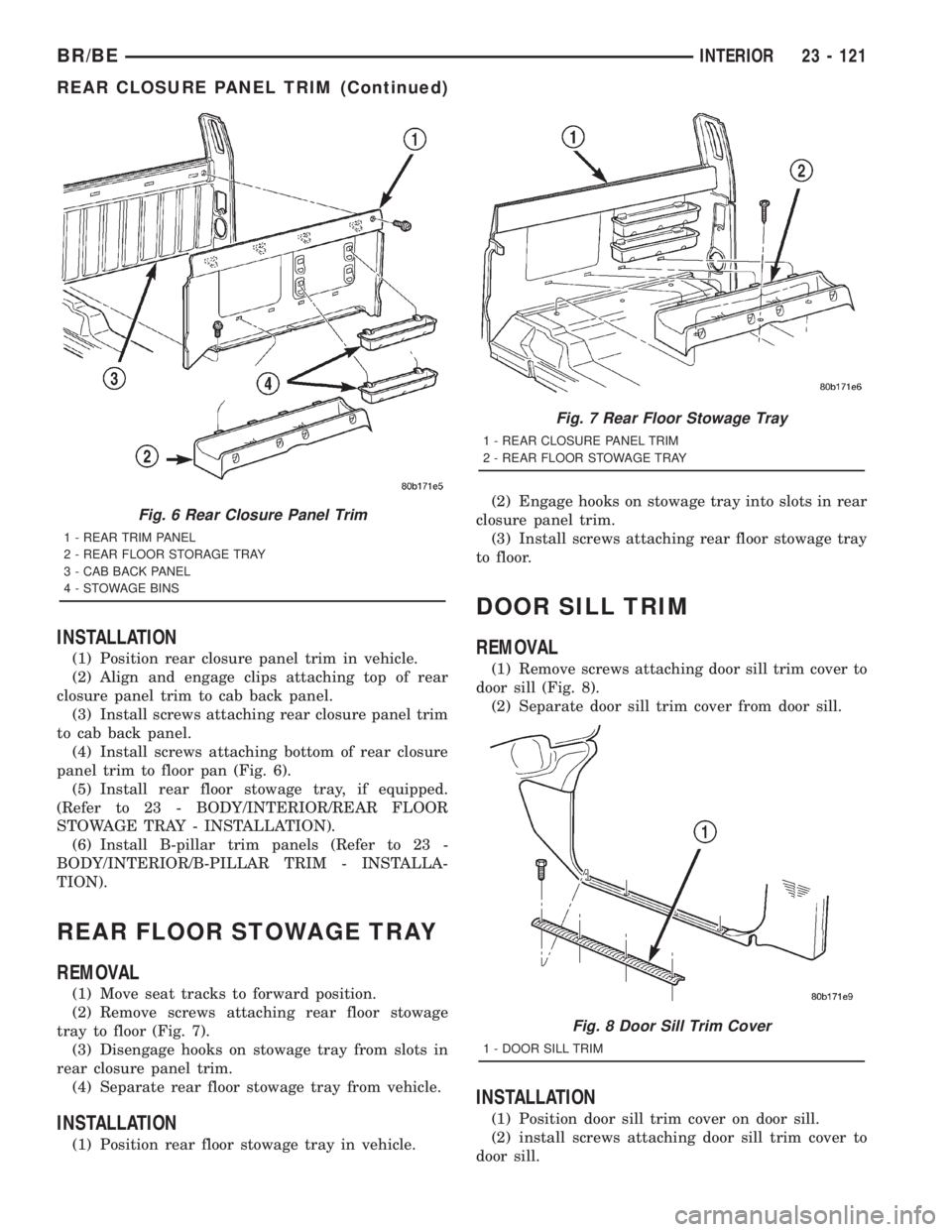

REAR CLOSURE PANEL TRIM

REMOVAL

(1) Remove B-pillar trim panels (Refer to 23 -

BODY/INTERIOR/B-PILLAR TRIM - REMOVAL).

(2) Remove rear floor stowage tray, if equipped.

(Refer to 23 - BODY/INTERIOR/REAR FLOOR

STOWAGE TRAY - REMOVAL).

(3) Remove screws attaching bottom of rear closure

panel trim to floor pan (Fig. 6).

(4) Remove screws attaching rear closure panel

trim to cab back panel.

(5) Disengage clips attaching top of rear closure

panel trim to cab back panel.

(6) Separate rear closure panel trim from vehicle.

Fig. 4 Lower Cowl Trim Cover Retaining Tab

1 - LOWER COWL TRIM

2 - RETAINING TAB

3 - LOWER COWL

4 - LOCATOR TAB

Fig. 5 B-Pillar Trim

1 - B-PILLAR

2 - TURNING LOOP

3 - B-PILLAR TRIM

4 - SEAT BELT ANCHOR

5 - EXIT PLUG

23 - 120 INTERIORBR/BE

COWL TRIM COVER (Continued)

Page 2694 of 2889

INSTALLATION

(1) Position rear closure panel trim in vehicle.

(2) Align and engage clips attaching top of rear

closure panel trim to cab back panel.

(3) Install screws attaching rear closure panel trim

to cab back panel.

(4) Install screws attaching bottom of rear closure

panel trim to floor pan (Fig. 6).

(5) Install rear floor stowage tray, if equipped.

(Refer to 23 - BODY/INTERIOR/REAR FLOOR

STOWAGE TRAY - INSTALLATION).

(6) Install B-pillar trim panels (Refer to 23 -

BODY/INTERIOR/B-PILLAR TRIM - INSTALLA-

TION).

REAR FLOOR STOWAGE TRAY

REMOVAL

(1) Move seat tracks to forward position.

(2) Remove screws attaching rear floor stowage

tray to floor (Fig. 7).

(3) Disengage hooks on stowage tray from slots in

rear closure panel trim.

(4) Separate rear floor stowage tray from vehicle.

INSTALLATION

(1) Position rear floor stowage tray in vehicle.(2) Engage hooks on stowage tray into slots in rear

closure panel trim.

(3) Install screws attaching rear floor stowage tray

to floor.

DOOR SILL TRIM

REMOVAL

(1) Remove screws attaching door sill trim cover to

door sill (Fig. 8).

(2) Separate door sill trim cover from door sill.

INSTALLATION

(1) Position door sill trim cover on door sill.

(2) install screws attaching door sill trim cover to

door sill.

Fig. 6 Rear Closure Panel Trim

1 - REAR TRIM PANEL

2 - REAR FLOOR STORAGE TRAY

3 - CAB BACK PANEL

4 - STOWAGE BINS

Fig. 7 Rear Floor Stowage Tray

1 - REAR CLOSURE PANEL TRIM

2 - REAR FLOOR STOWAGE TRAY

Fig. 8 Door Sill Trim Cover

1 - DOOR SILL TRIM

BR/BEINTERIOR 23 - 121

REAR CLOSURE PANEL TRIM (Continued)

Page 2696 of 2889

(4) Install the screws attaching the console to

mounting brackets.

(5) Install the transmission shifter boot, (Refer to

23 - BODY/INTERIOR/SHIFT BOOT - INSTALLA-

TION).

(6) Install the transfer case shifter boot, if

equipped. (Refer to 23 - BODY/INTERIOR/SHIFT

BOOT - INSTALLATION).

(7) Install cup holder in console, if equipped.

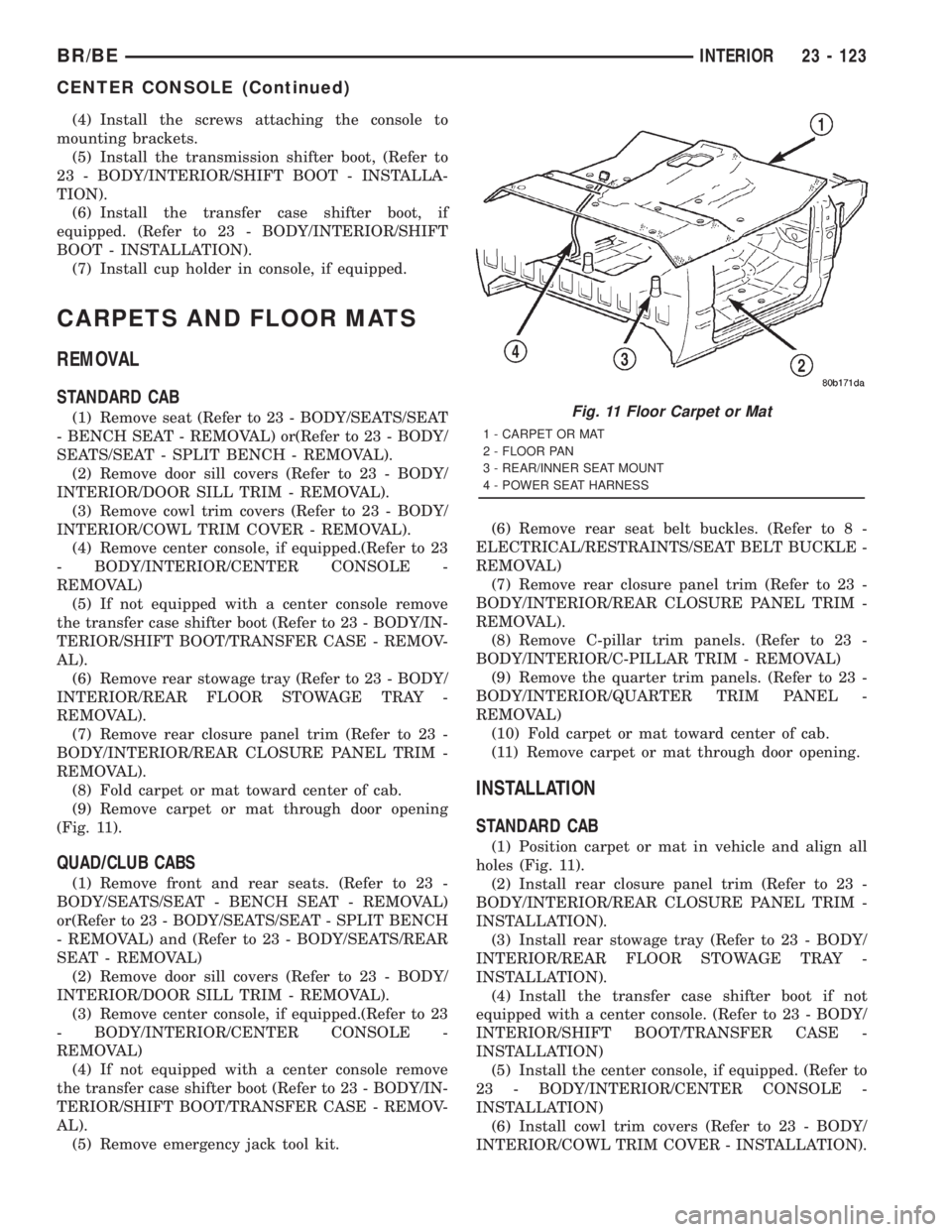

CARPETS AND FLOOR MATS

REMOVAL

STANDARD CAB

(1) Remove seat (Refer to 23 - BODY/SEATS/SEAT

- BENCH SEAT - REMOVAL) or(Refer to 23 - BODY/

SEATS/SEAT - SPLIT BENCH - REMOVAL).

(2) Remove door sill covers (Refer to 23 - BODY/

INTERIOR/DOOR SILL TRIM - REMOVAL).

(3) Remove cowl trim covers (Refer to 23 - BODY/

INTERIOR/COWL TRIM COVER - REMOVAL).

(4) Remove center console, if equipped.(Refer to 23

- BODY/INTERIOR/CENTER CONSOLE -

REMOVAL)

(5) If not equipped with a center console remove

the transfer case shifter boot (Refer to 23 - BODY/IN-

TERIOR/SHIFT BOOT/TRANSFER CASE - REMOV-

AL).

(6) Remove rear stowage tray (Refer to 23 - BODY/

INTERIOR/REAR FLOOR STOWAGE TRAY -

REMOVAL).

(7) Remove rear closure panel trim (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

REMOVAL).

(8) Fold carpet or mat toward center of cab.

(9) Remove carpet or mat through door opening

(Fig. 11).

QUAD/CLUB CABS

(1) Remove front and rear seats. (Refer to 23 -

BODY/SEATS/SEAT - BENCH SEAT - REMOVAL)

or(Refer to 23 - BODY/SEATS/SEAT - SPLIT BENCH

- REMOVAL) and (Refer to 23 - BODY/SEATS/REAR

SEAT - REMOVAL)

(2) Remove door sill covers (Refer to 23 - BODY/

INTERIOR/DOOR SILL TRIM - REMOVAL).

(3) Remove center console, if equipped.(Refer to 23

- BODY/INTERIOR/CENTER CONSOLE -

REMOVAL)

(4) If not equipped with a center console remove

the transfer case shifter boot (Refer to 23 - BODY/IN-

TERIOR/SHIFT BOOT/TRANSFER CASE - REMOV-

AL).

(5) Remove emergency jack tool kit.(6) Remove rear seat belt buckles. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT BUCKLE -

REMOVAL)

(7) Remove rear closure panel trim (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

REMOVAL).

(8) Remove C-pillar trim panels. (Refer to 23 -

BODY/INTERIOR/C-PILLAR TRIM - REMOVAL)

(9) Remove the quarter trim panels. (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

REMOVAL)

(10) Fold carpet or mat toward center of cab.

(11) Remove carpet or mat through door opening.

INSTALLATION

STANDARD CAB

(1) Position carpet or mat in vehicle and align all

holes (Fig. 11).

(2) Install rear closure panel trim (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

INSTALLATION).

(3) Install rear stowage tray (Refer to 23 - BODY/

INTERIOR/REAR FLOOR STOWAGE TRAY -

INSTALLATION).

(4) Install the transfer case shifter boot if not

equipped with a center console. (Refer to 23 - BODY/

INTERIOR/SHIFT BOOT/TRANSFER CASE -

INSTALLATION)

(5) Install the center console, if equipped. (Refer to

23 - BODY/INTERIOR/CENTER CONSOLE -

INSTALLATION)

(6) Install cowl trim covers (Refer to 23 - BODY/

INTERIOR/COWL TRIM COVER - INSTALLATION).

Fig. 11 Floor Carpet or Mat

1 - CARPET OR MAT

2 - FLOOR PAN

3 - REAR/INNER SEAT MOUNT

4 - POWER SEAT HARNESS

BR/BEINTERIOR 23 - 123

CENTER CONSOLE (Continued)