tow DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2412 of 2889

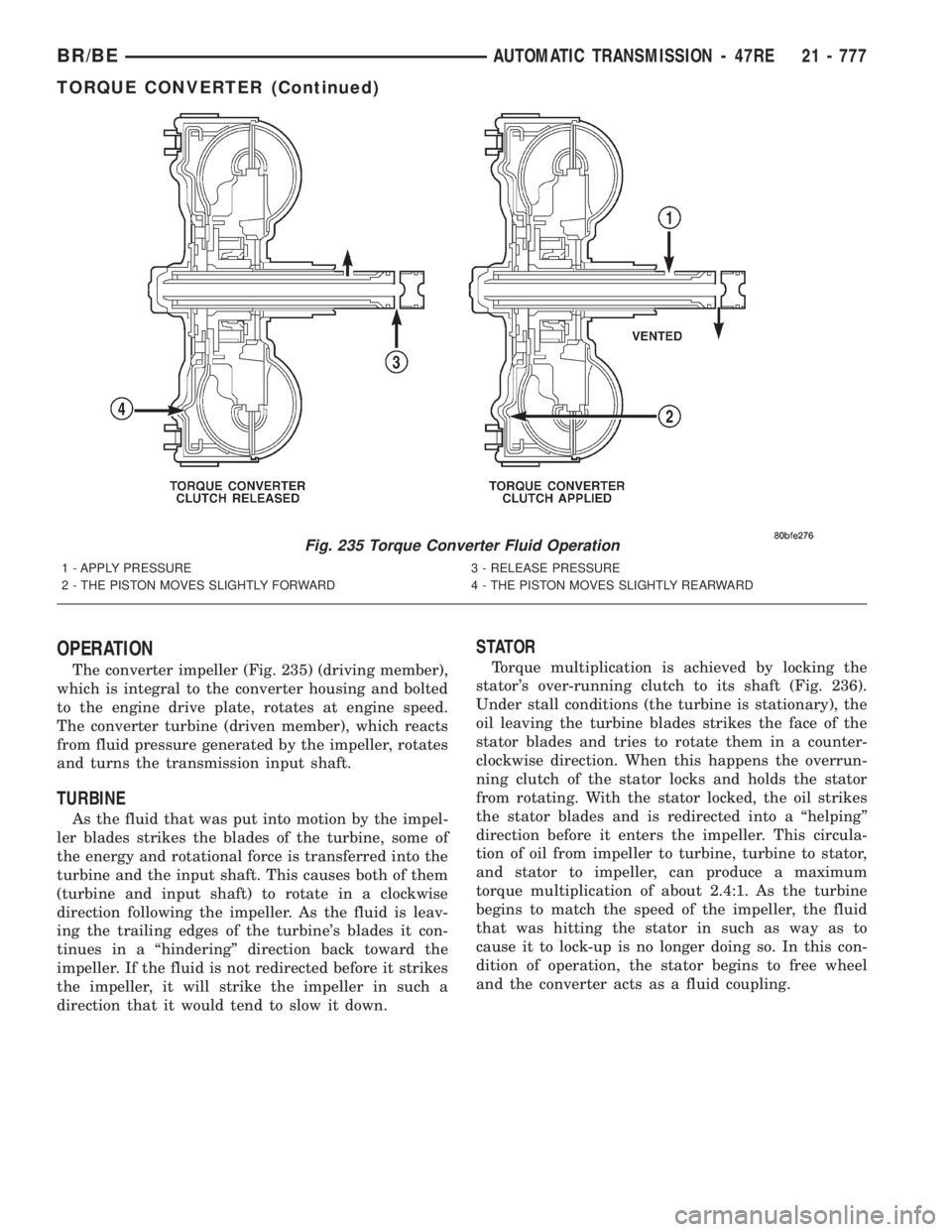

OPERATION

The converter impeller (Fig. 235) (driving member),

which is integral to the converter housing and bolted

to the engine drive plate, rotates at engine speed.

The converter turbine (driven member), which reacts

from fluid pressure generated by the impeller, rotates

and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some of

the energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a

direction that it would tend to slow it down.

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 236).

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-

clockwise direction. When this happens the overrun-

ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.4:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock-up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

Fig. 235 Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 777

TORQUE CONVERTER (Continued)

Page 2422 of 2889

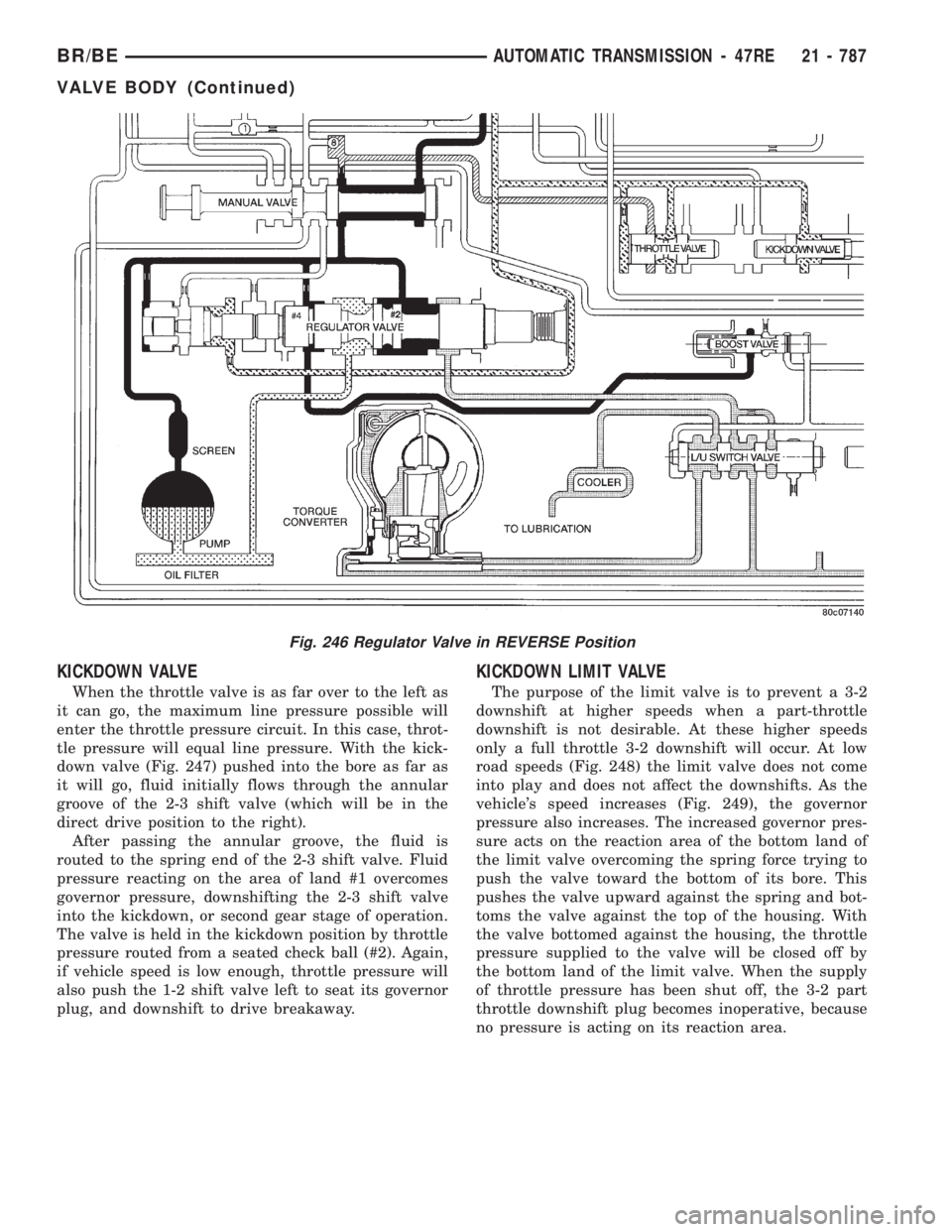

KICKDOWN VALVE

When the throttle valve is as far over to the left as

it can go, the maximum line pressure possible will

enter the throttle pressure circuit. In this case, throt-

tle pressure will equal line pressure. With the kick-

down valve (Fig. 247) pushed into the bore as far as

it will go, fluid initially flows through the annular

groove of the 2-3 shift valve (which will be in the

direct drive position to the right).

After passing the annular groove, the fluid is

routed to the spring end of the 2-3 shift valve. Fluid

pressure reacting on the area of land #1 overcomes

governor pressure, downshifting the 2-3 shift valve

into the kickdown, or second gear stage of operation.

The valve is held in the kickdown position by throttle

pressure routed from a seated check ball (#2). Again,

if vehicle speed is low enough, throttle pressure will

also push the 1-2 shift valve left to seat its governor

plug, and downshift to drive breakaway.

KICKDOWN LIMIT VALVE

The purpose of the limit valve is to prevent a 3-2

downshift at higher speeds when a part-throttle

downshift is not desirable. At these higher speeds

only a full throttle 3-2 downshift will occur. At low

road speeds (Fig. 248) the limit valve does not come

into play and does not affect the downshifts. As the

vehicle's speed increases (Fig. 249), the governor

pressure also increases. The increased governor pres-

sure acts on the reaction area of the bottom land of

the limit valve overcoming the spring force trying to

push the valve toward the bottom of its bore. This

pushes the valve upward against the spring and bot-

toms the valve against the top of the housing. With

the valve bottomed against the housing, the throttle

pressure supplied to the valve will be closed off by

the bottom land of the limit valve. When the supply

of throttle pressure has been shut off, the 3-2 part

throttle downshift plug becomes inoperative, because

no pressure is acting on its reaction area.

Fig. 246 Regulator Valve in REVERSE Position

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 787

VALVE BODY (Continued)

Page 2429 of 2889

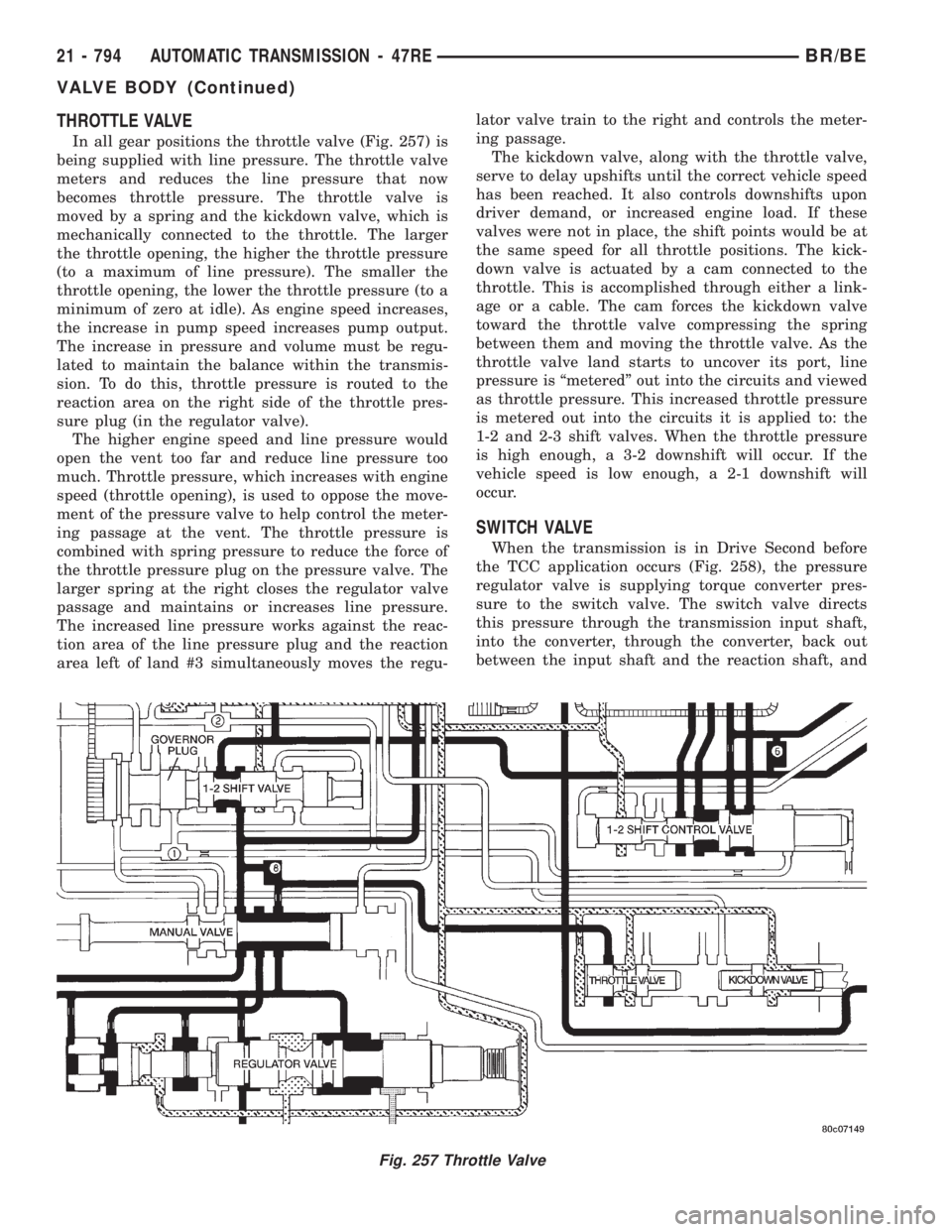

THROTTLE VALVE

In all gear positions the throttle valve (Fig. 257) is

being supplied with line pressure. The throttle valve

meters and reduces the line pressure that now

becomes throttle pressure. The throttle valve is

moved by a spring and the kickdown valve, which is

mechanically connected to the throttle. The larger

the throttle opening, the higher the throttle pressure

(to a maximum of line pressure). The smaller the

throttle opening, the lower the throttle pressure (to a

minimum of zero at idle). As engine speed increases,

the increase in pump speed increases pump output.

The increase in pressure and volume must be regu-

lated to maintain the balance within the transmis-

sion. To do this, throttle pressure is routed to the

reaction area on the right side of the throttle pres-

sure plug (in the regulator valve).

The higher engine speed and line pressure would

open the vent too far and reduce line pressure too

much. Throttle pressure, which increases with engine

speed (throttle opening), is used to oppose the move-

ment of the pressure valve to help control the meter-

ing passage at the vent. The throttle pressure is

combined with spring pressure to reduce the force of

the throttle pressure plug on the pressure valve. The

larger spring at the right closes the regulator valve

passage and maintains or increases line pressure.

The increased line pressure works against the reac-

tion area of the line pressure plug and the reaction

area left of land #3 simultaneously moves the regu-lator valve train to the right and controls the meter-

ing passage.

The kickdown valve, along with the throttle valve,

serve to delay upshifts until the correct vehicle speed

has been reached. It also controls downshifts upon

driver demand, or increased engine load. If these

valves were not in place, the shift points would be at

the same speed for all throttle positions. The kick-

down valve is actuated by a cam connected to the

throttle. This is accomplished through either a link-

age or a cable. The cam forces the kickdown valve

toward the throttle valve compressing the spring

between them and moving the throttle valve. As the

throttle valve land starts to uncover its port, line

pressure is ªmeteredº out into the circuits and viewed

as throttle pressure. This increased throttle pressure

is metered out into the circuits it is applied to: the

1-2 and 2-3 shift valves. When the throttle pressure

is high enough, a 3-2 downshift will occur. If the

vehicle speed is low enough, a 2-1 downshift will

occur.

SWITCH VALVE

When the transmission is in Drive Second before

the TCC application occurs (Fig. 258), the pressure

regulator valve is supplying torque converter pres-

sure to the switch valve. The switch valve directs

this pressure through the transmission input shaft,

into the converter, through the converter, back out

between the input shaft and the reaction shaft, and

Fig. 257 Throttle Valve

21 - 794 AUTOMATIC TRANSMISSION - 47REBR/BE

VALVE BODY (Continued)

Page 2443 of 2889

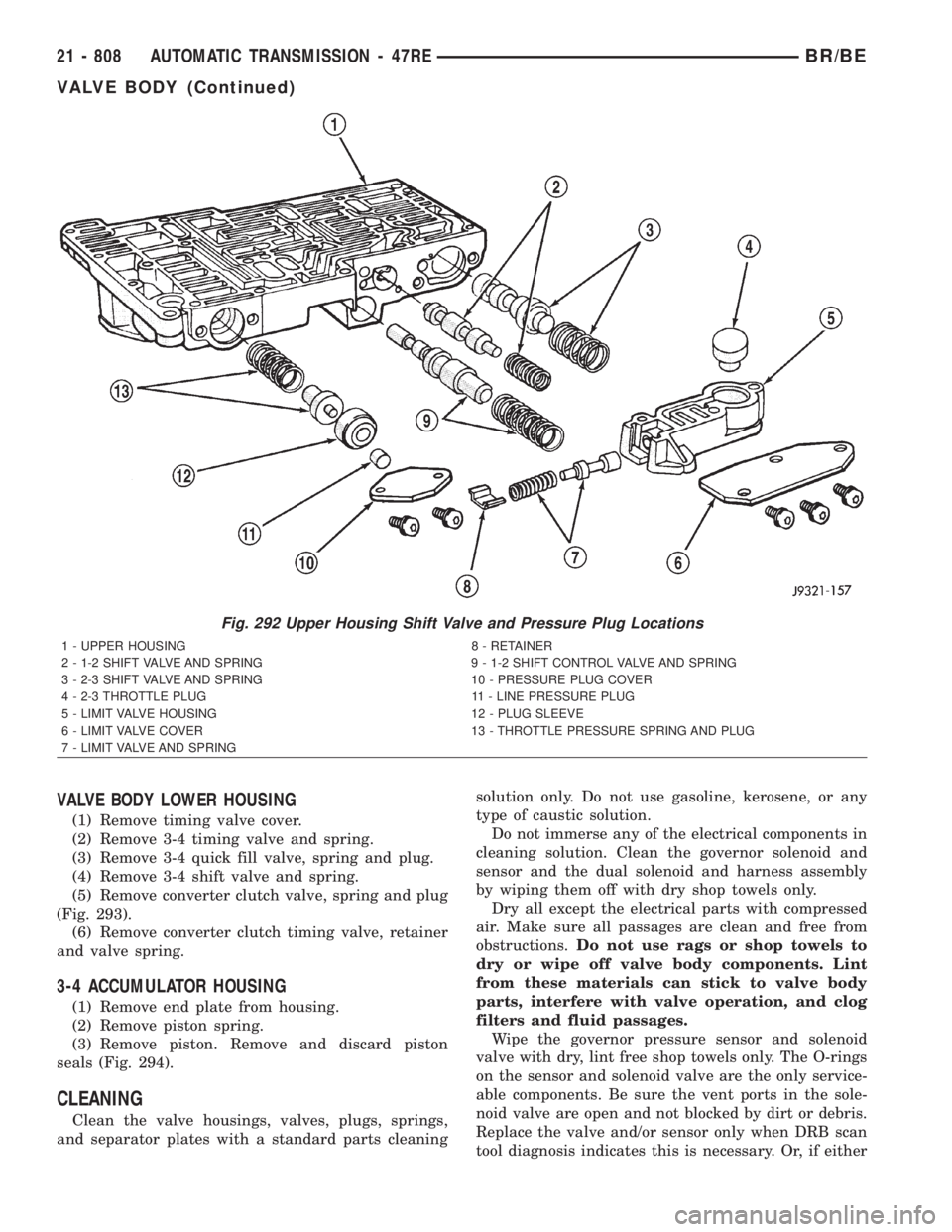

VALVE BODY LOWER HOUSING

(1) Remove timing valve cover.

(2) Remove 3-4 timing valve and spring.

(3) Remove 3-4 quick fill valve, spring and plug.

(4) Remove 3-4 shift valve and spring.

(5) Remove converter clutch valve, spring and plug

(Fig. 293).

(6) Remove converter clutch timing valve, retainer

and valve spring.

3-4 ACCUMULATOR HOUSING

(1) Remove end plate from housing.

(2) Remove piston spring.

(3) Remove piston. Remove and discard piston

seals (Fig. 294).

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaningsolution only. Do not use gasoline, kerosene, or any

type of caustic solution.

Do not immerse any of the electrical components in

cleaning solution. Clean the governor solenoid and

sensor and the dual solenoid and harness assembly

by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

Wipe the governor pressure sensor and solenoid

valve with dry, lint free shop towels only. The O-rings

on the sensor and solenoid valve are the only service-

able components. Be sure the vent ports in the sole-

noid valve are open and not blocked by dirt or debris.

Replace the valve and/or sensor only when DRB scan

tool diagnosis indicates this is necessary. Or, if either

Fig. 292 Upper Housing Shift Valve and Pressure Plug Locations

1 - UPPER HOUSING 8 - RETAINER

2 - 1-2 SHIFT VALVE AND SPRING 9 - 1-2 SHIFT CONTROL VALVE AND SPRING

3 - 2-3 SHIFT VALVE AND SPRING 10 - PRESSURE PLUG COVER

4 - 2-3 THROTTLE PLUG 11 - LINE PRESSURE PLUG

5 - LIMIT VALVE HOUSING 12 - PLUG SLEEVE

6 - LIMIT VALVE COVER 13 - THROTTLE PRESSURE SPRING AND PLUG

7 - LIMIT VALVE AND SPRING

21 - 808 AUTOMATIC TRANSMISSION - 47REBR/BE

VALVE BODY (Continued)

Page 2469 of 2889

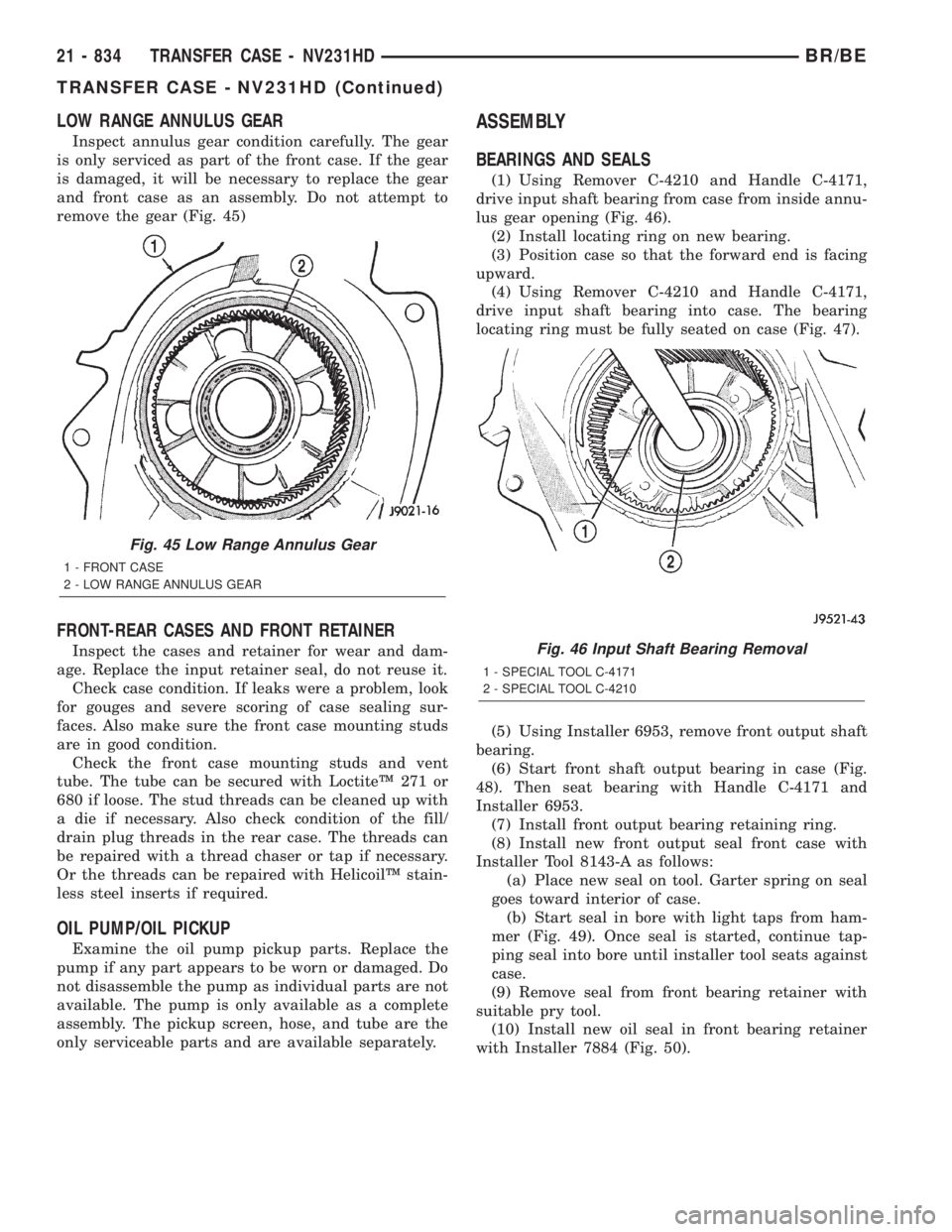

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 45)

FRONT-REAR CASES AND FRONT RETAINER

Inspect the cases and retainer for wear and dam-

age. Replace the input retainer seal, do not reuse it.

Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with HelicoilŸ stain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

ASSEMBLY

BEARINGS AND SEALS

(1) Using Remover C-4210 and Handle C-4171,

drive input shaft bearing from case from inside annu-

lus gear opening (Fig. 46).

(2) Install locating ring on new bearing.

(3) Position case so that the forward end is facing

upward.

(4) Using Remover C-4210 and Handle C-4171,

drive input shaft bearing into case. The bearing

locating ring must be fully seated on case (Fig. 47).

(5) Using Installer 6953, remove front output shaft

bearing.

(6) Start front shaft output bearing in case (Fig.

48). Then seat bearing with Handle C-4171 and

Installer 6953.

(7) Install front output bearing retaining ring.

(8) Install new front output seal front case with

Installer Tool 8143-A as follows:

(a) Place new seal on tool. Garter spring on seal

goes toward interior of case.

(b) Start seal in bore with light taps from ham-

mer (Fig. 49). Once seal is started, continue tap-

ping seal into bore until installer tool seats against

case.

(9) Remove seal from front bearing retainer with

suitable pry tool.

(10) Install new oil seal in front bearing retainer

with Installer 7884 (Fig. 50).

Fig. 45 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEAR

Fig. 46 Input Shaft Bearing Removal

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL C-4210

21 - 834 TRANSFER CASE - NV231HDBR/BE

TRANSFER CASE - NV231HD (Continued)

Page 2474 of 2889

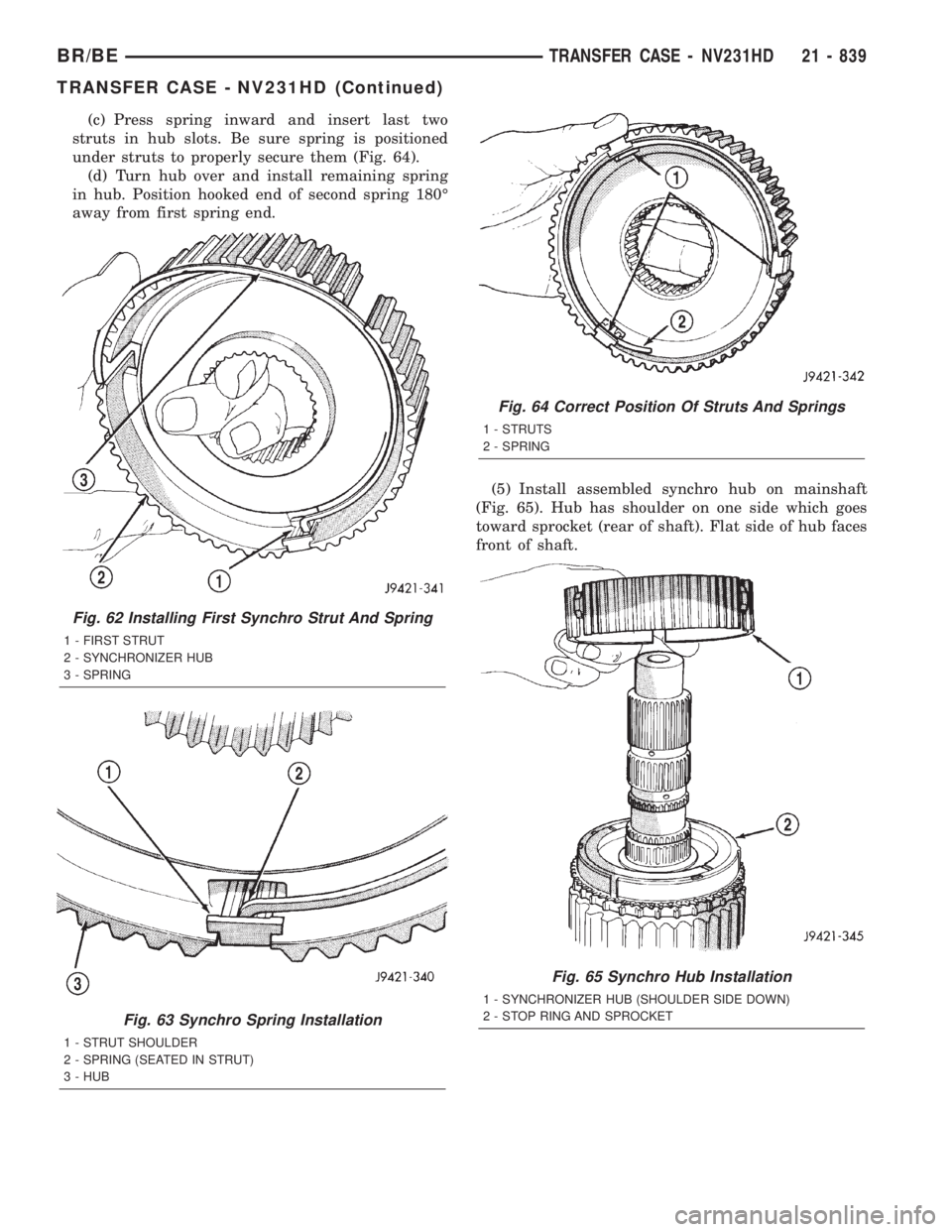

(c) Press spring inward and insert last two

struts in hub slots. Be sure spring is positioned

under struts to properly secure them (Fig. 64).

(d) Turn hub over and install remaining spring

in hub. Position hooked end of second spring 180É

away from first spring end.

(5) Install assembled synchro hub on mainshaft

(Fig. 65). Hub has shoulder on one side which goes

toward sprocket (rear of shaft). Flat side of hub faces

front of shaft.

Fig. 62 Installing First Synchro Strut And Spring

1 - FIRST STRUT

2 - SYNCHRONIZER HUB

3 - SPRING

Fig. 63 Synchro Spring Installation

1 - STRUT SHOULDER

2 - SPRING (SEATED IN STRUT)

3 - HUB

Fig. 64 Correct Position Of Struts And Springs

1 - STRUTS

2 - SPRING

Fig. 65 Synchro Hub Installation

1 - SYNCHRONIZER HUB (SHOULDER SIDE DOWN)

2 - STOP RING AND SPROCKET

BR/BETRANSFER CASE - NV231HD 21 - 839

TRANSFER CASE - NV231HD (Continued)

Page 2487 of 2889

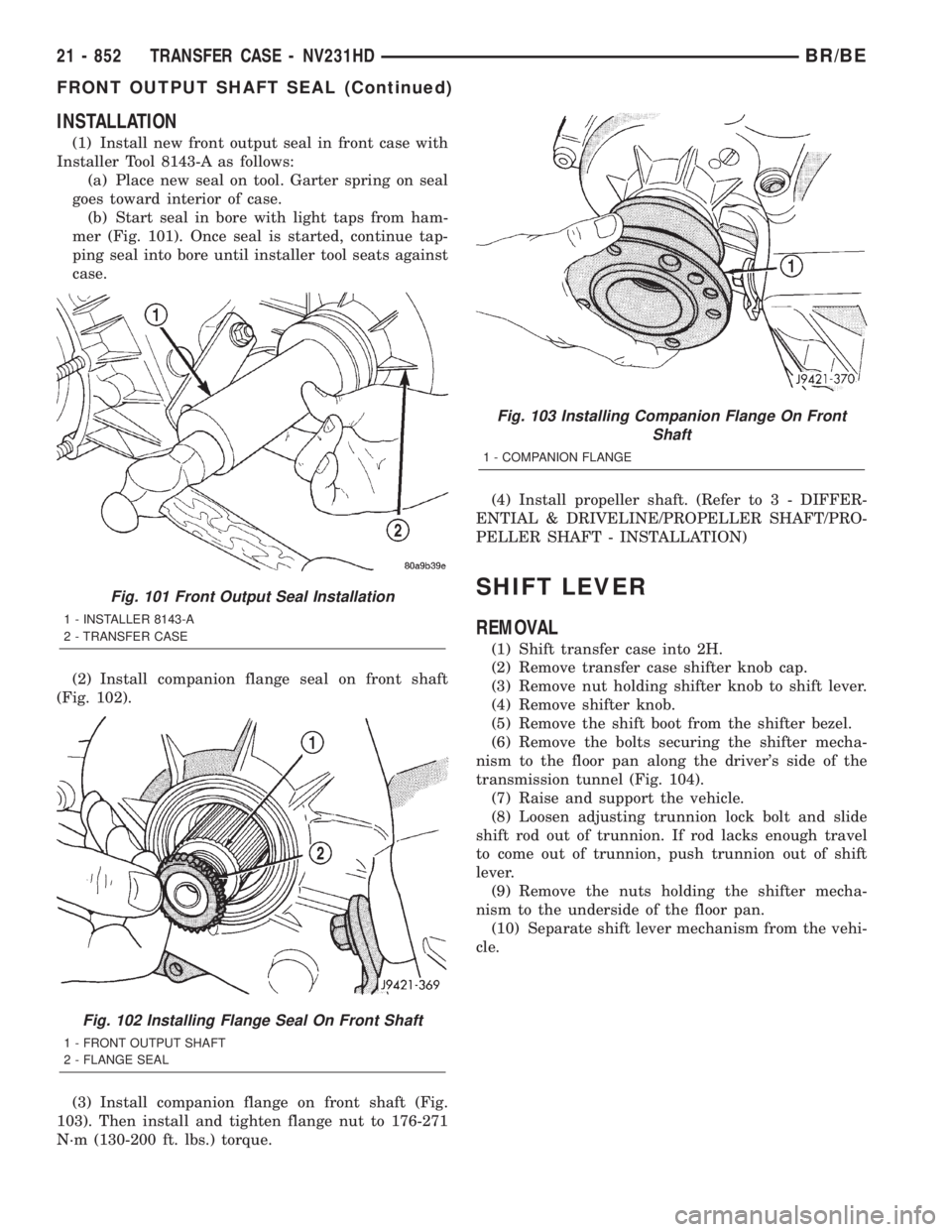

INSTALLATION

(1) Install new front output seal in front case with

Installer Tool 8143-A as follows:

(a) Place new seal on tool. Garter spring on seal

goes toward interior of case.

(b) Start seal in bore with light taps from ham-

mer (Fig. 101). Once seal is started, continue tap-

ping seal into bore until installer tool seats against

case.

(2) Install companion flange seal on front shaft

(Fig. 102).

(3) Install companion flange on front shaft (Fig.

103). Then install and tighten flange nut to 176-271

N´m (130-200 ft. lbs.) torque.(4) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)

SHIFT LEVER

REMOVAL

(1) Shift transfer case into 2H.

(2) Remove transfer case shifter knob cap.

(3) Remove nut holding shifter knob to shift lever.

(4) Remove shifter knob.

(5) Remove the shift boot from the shifter bezel.

(6) Remove the bolts securing the shifter mecha-

nism to the floor pan along the driver's side of the

transmission tunnel (Fig. 104).

(7) Raise and support the vehicle.

(8) Loosen adjusting trunnion lock bolt and slide

shift rod out of trunnion. If rod lacks enough travel

to come out of trunnion, push trunnion out of shift

lever.

(9) Remove the nuts holding the shifter mecha-

nism to the underside of the floor pan.

(10) Separate shift lever mechanism from the vehi-

cle.

Fig. 101 Front Output Seal Installation

1 - INSTALLER 8143-A

2 - TRANSFER CASE

Fig. 102 Installing Flange Seal On Front Shaft

1 - FRONT OUTPUT SHAFT

2 - FLANGE SEAL

Fig. 103 Installing Companion Flange On Front

Shaft

1 - COMPANION FLANGE

21 - 852 TRANSFER CASE - NV231HDBR/BE

FRONT OUTPUT SHAFT SEAL (Continued)

Page 2504 of 2889

REAR RETAINER COMPONENTS

Inspect the retainer components. Replace the bear-

ing if rough or noisy. Check the retainer for cracks or

wear in the bearing bore.

Inspect the retaining rings and washers. Replace

any part if distorted, bent, or broken. Reuse is not

recommended.

Inspect rear extension bushing. Replace if worn or

scored.

DRIVE CHAIN

Examine the drive chain and shaft bearings.

replace the chain if stretched, distorted, or if any of

the links bind. Replace the bearings if rough, or

noisy.

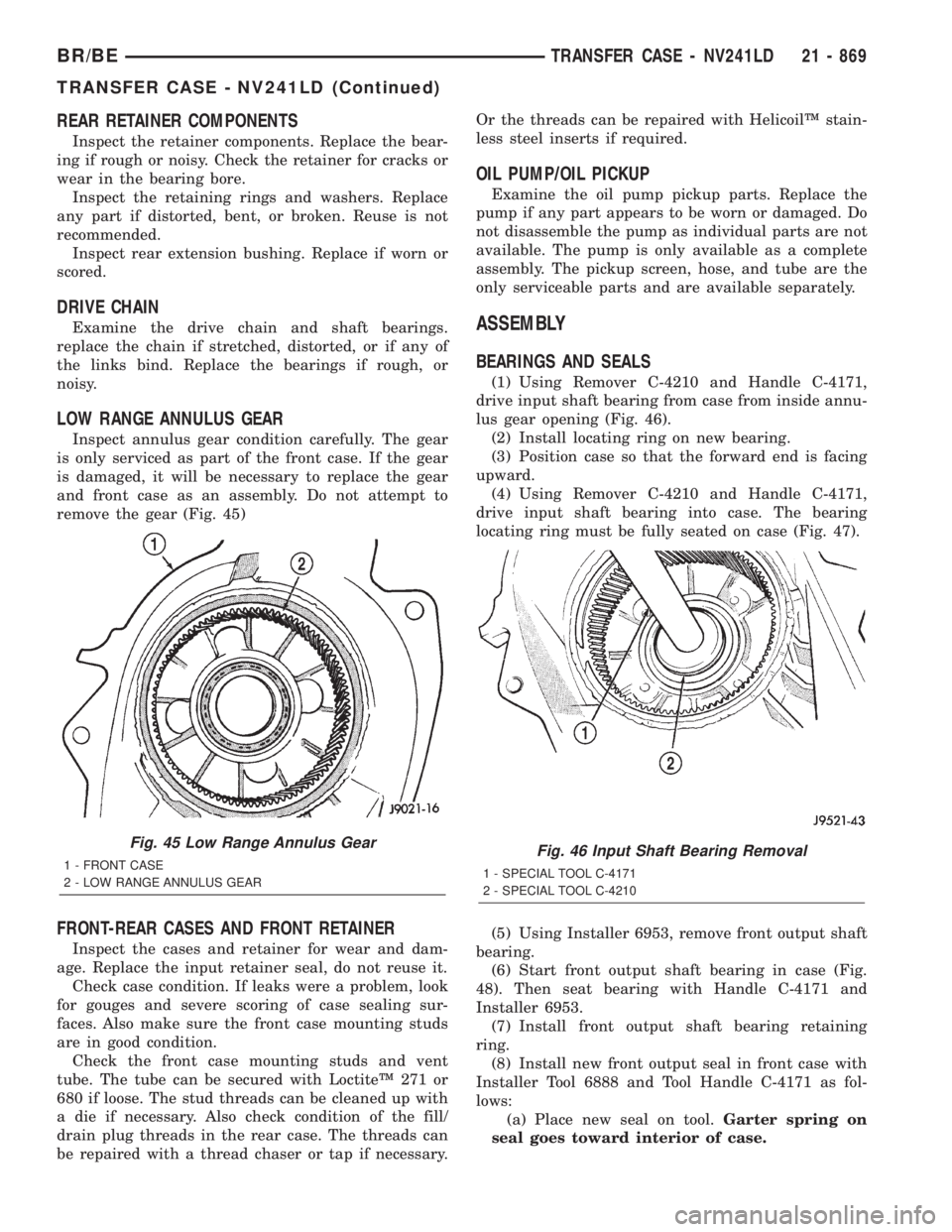

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 45)

FRONT-REAR CASES AND FRONT RETAINER

Inspect the cases and retainer for wear and dam-

age. Replace the input retainer seal, do not reuse it.

Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.Or the threads can be repaired with HelicoilŸ stain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

ASSEMBLY

BEARINGS AND SEALS

(1) Using Remover C-4210 and Handle C-4171,

drive input shaft bearing from case from inside annu-

lus gear opening (Fig. 46).

(2) Install locating ring on new bearing.

(3) Position case so that the forward end is facing

upward.

(4) Using Remover C-4210 and Handle C-4171,

drive input shaft bearing into case. The bearing

locating ring must be fully seated on case (Fig. 47).

(5) Using Installer 6953, remove front output shaft

bearing.

(6) Start front output shaft bearing in case (Fig.

48). Then seat bearing with Handle C-4171 and

Installer 6953.

(7) Install front output shaft bearing retaining

ring.

(8) Install new front output seal in front case with

Installer Tool 6888 and Tool Handle C-4171 as fol-

lows:

(a) Place new seal on tool.Garter spring on

seal goes toward interior of case.

Fig. 45 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEARFig. 46 Input Shaft Bearing Removal

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL C-4210

BR/BETRANSFER CASE - NV241LD 21 - 869

TRANSFER CASE - NV241LD (Continued)

Page 2510 of 2889

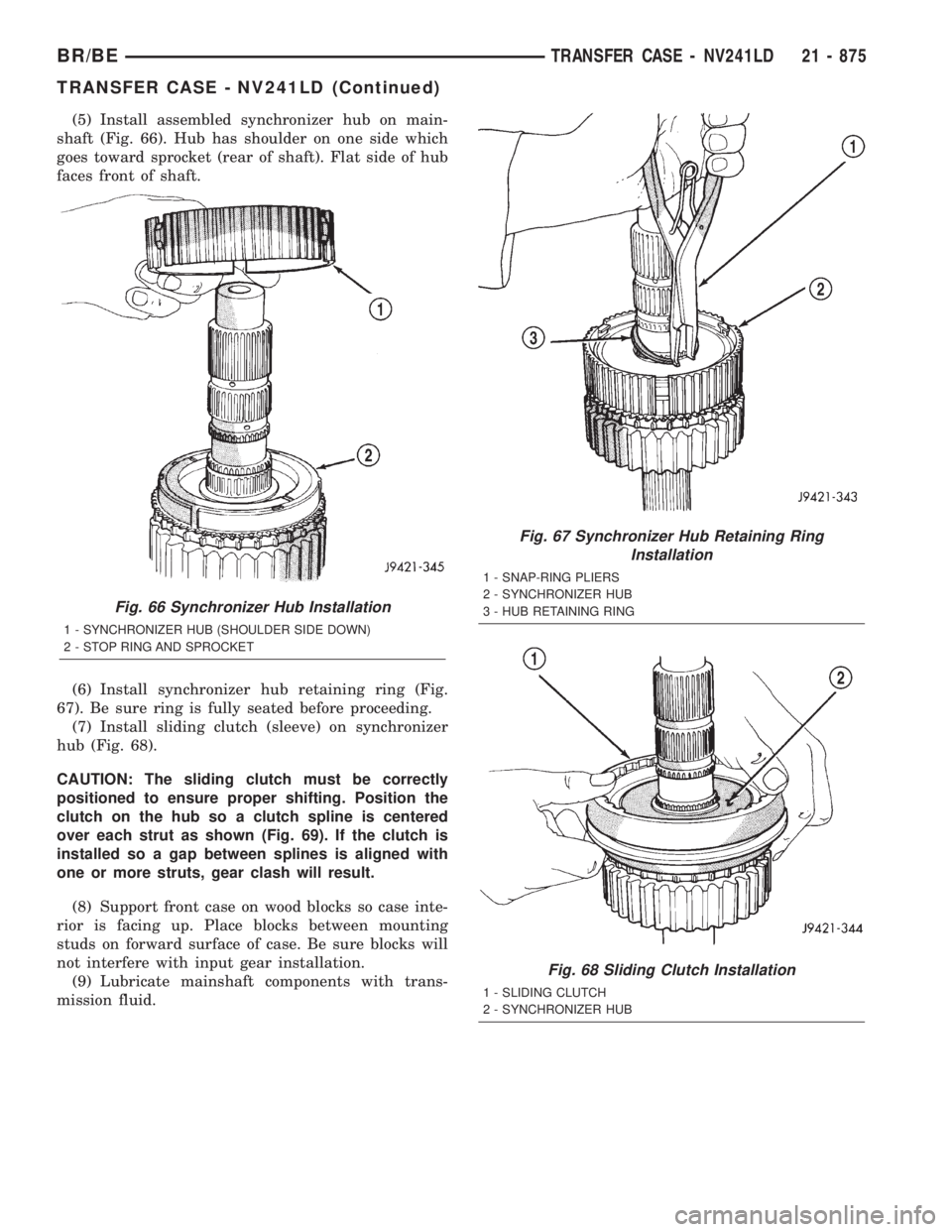

(5) Install assembled synchronizer hub on main-

shaft (Fig. 66). Hub has shoulder on one side which

goes toward sprocket (rear of shaft). Flat side of hub

faces front of shaft.

(6) Install synchronizer hub retaining ring (Fig.

67). Be sure ring is fully seated before proceeding.

(7) Install sliding clutch (sleeve) on synchronizer

hub (Fig. 68).

CAUTION: The sliding clutch must be correctly

positioned to ensure proper shifting. Position the

clutch on the hub so a clutch spline is centered

over each strut as shown (Fig. 69). If the clutch is

installed so a gap between splines is aligned with

one or more struts, gear clash will result.

(8) Support front case on wood blocks so case inte-

rior is facing up. Place blocks between mounting

studs on forward surface of case. Be sure blocks will

not interfere with input gear installation.

(9) Lubricate mainshaft components with trans-

mission fluid.

Fig. 66 Synchronizer Hub Installation

1 - SYNCHRONIZER HUB (SHOULDER SIDE DOWN)

2 - STOP RING AND SPROCKET

Fig. 67 Synchronizer Hub Retaining Ring

Installation

1 - SNAP-RING PLIERS

2 - SYNCHRONIZER HUB

3 - HUB RETAINING RING

Fig. 68 Sliding Clutch Installation

1 - SLIDING CLUTCH

2 - SYNCHRONIZER HUB

BR/BETRANSFER CASE - NV241LD 21 - 875

TRANSFER CASE - NV241LD (Continued)

Page 2521 of 2889

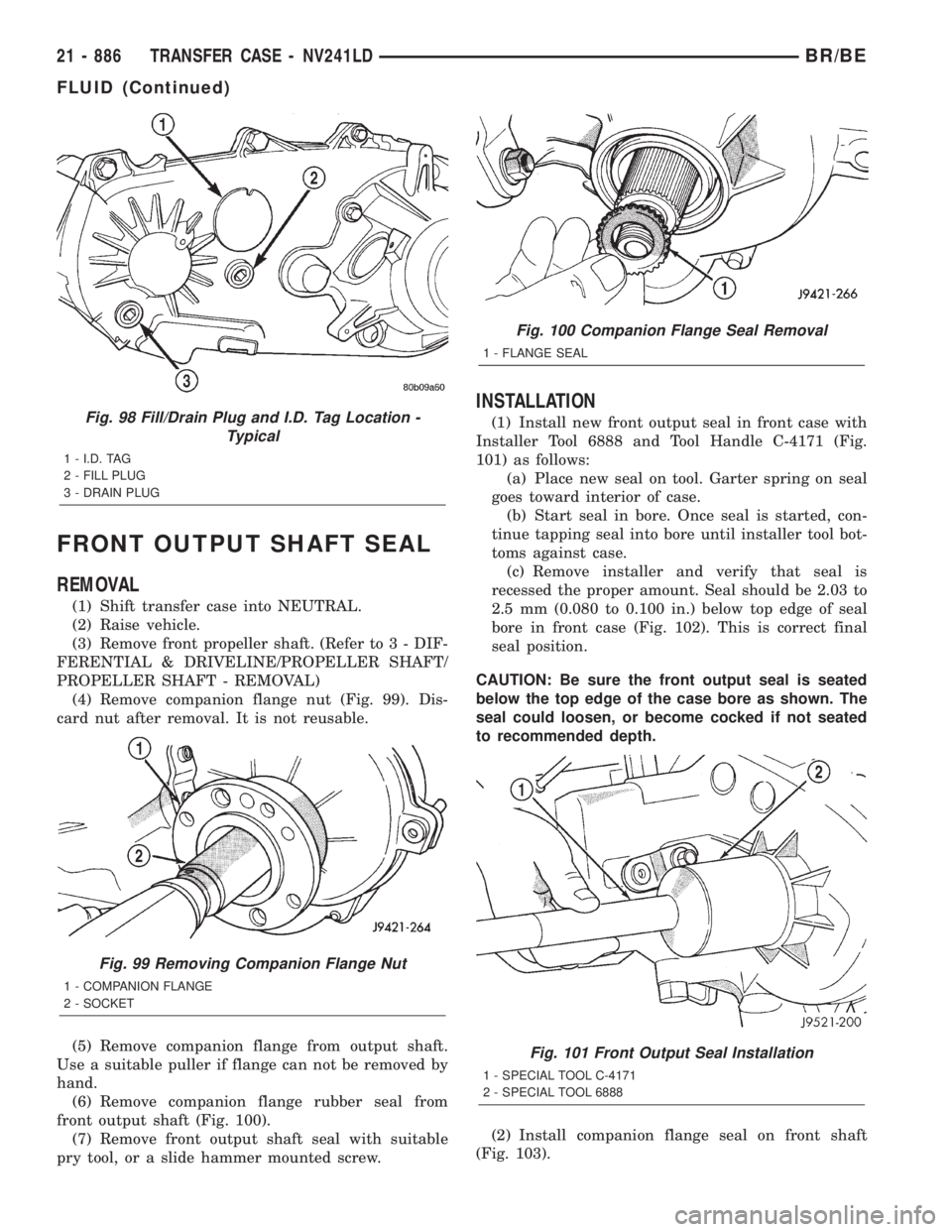

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Shift transfer case into NEUTRAL.

(2) Raise vehicle.

(3) Remove front propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(4) Remove companion flange nut (Fig. 99). Dis-

card nut after removal. It is not reusable.

(5) Remove companion flange from output shaft.

Use a suitable puller if flange can not be removed by

hand.

(6) Remove companion flange rubber seal from

front output shaft (Fig. 100).

(7) Remove front output shaft seal with suitable

pry tool, or a slide hammer mounted screw.

INSTALLATION

(1) Install new front output seal in front case with

Installer Tool 6888 and Tool Handle C-4171 (Fig.

101) as follows:

(a) Place new seal on tool. Garter spring on seal

goes toward interior of case.

(b) Start seal in bore. Once seal is started, con-

tinue tapping seal into bore until installer tool bot-

toms against case.

(c) Remove installer and verify that seal is

recessed the proper amount. Seal should be 2.03 to

2.5 mm (0.080 to 0.100 in.) below top edge of seal

bore in front case (Fig. 102). This is correct final

seal position.

CAUTION: Be sure the front output seal is seated

below the top edge of the case bore as shown. The

seal could loosen, or become cocked if not seated

to recommended depth.

(2) Install companion flange seal on front shaft

(Fig. 103).Fig. 98 Fill/Drain Plug and I.D. Tag Location -

Typical

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

Fig. 99 Removing Companion Flange Nut

1 - COMPANION FLANGE

2 - SOCKET

Fig. 100 Companion Flange Seal Removal

1 - FLANGE SEAL

Fig. 101 Front Output Seal Installation

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL 6888

21 - 886 TRANSFER CASE - NV241LDBR/BE

FLUID (Continued)