tow DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2699 of 2889

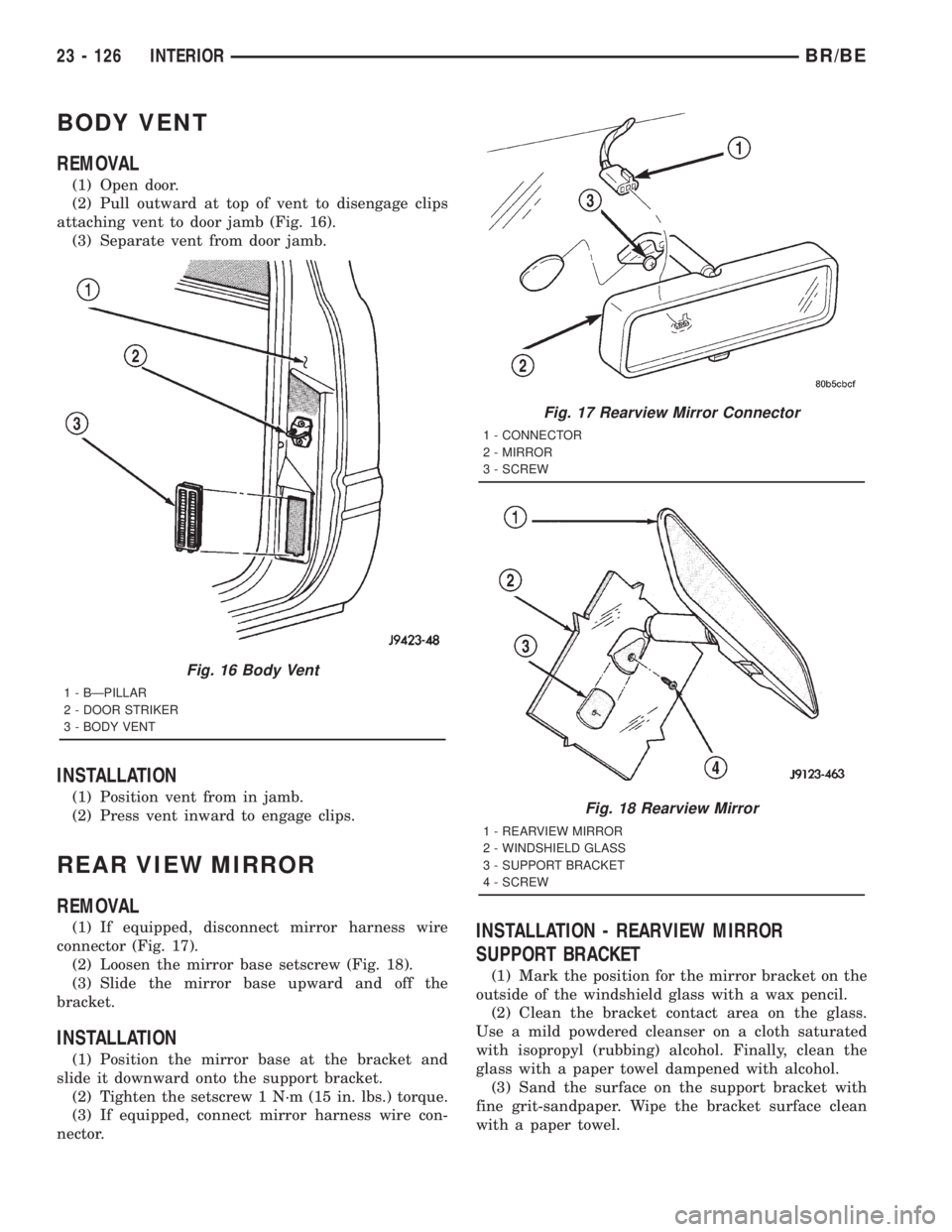

BODY VENT

REMOVAL

(1) Open door.

(2) Pull outward at top of vent to disengage clips

attaching vent to door jamb (Fig. 16).

(3) Separate vent from door jamb.

INSTALLATION

(1) Position vent from in jamb.

(2) Press vent inward to engage clips.

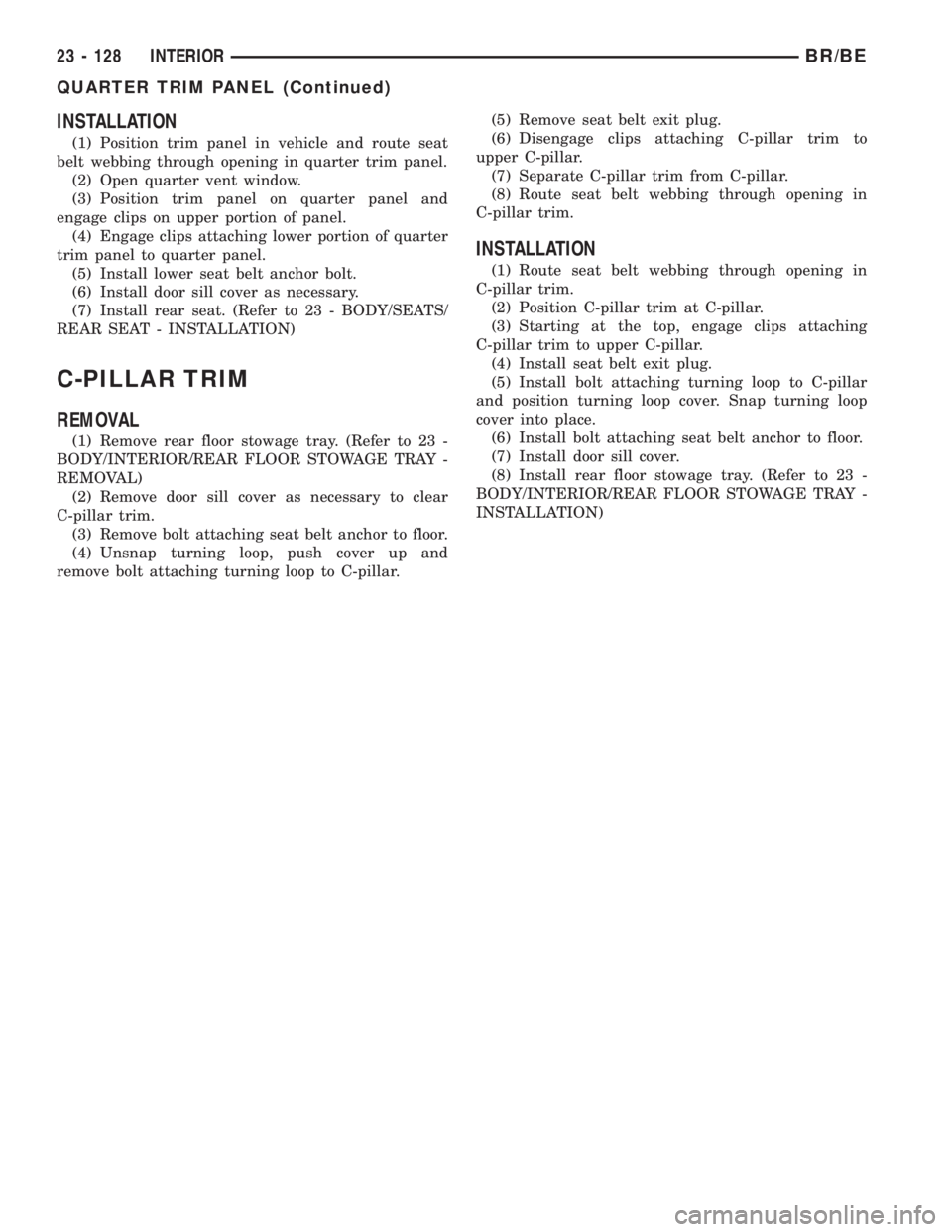

REAR VIEW MIRROR

REMOVAL

(1) If equipped, disconnect mirror harness wire

connector (Fig. 17).

(2) Loosen the mirror base setscrew (Fig. 18).

(3) Slide the mirror base upward and off the

bracket.

INSTALLATION

(1) Position the mirror base at the bracket and

slide it downward onto the support bracket.

(2) Tighten the setscrew 1 N´m (15 in. lbs.) torque.

(3) If equipped, connect mirror harness wire con-

nector.

INSTALLATION - REARVIEW MIRROR

SUPPORT BRACKET

(1) Mark the position for the mirror bracket on the

outside of the windshield glass with a wax pencil.

(2) Clean the bracket contact area on the glass.

Use a mild powdered cleanser on a cloth saturated

with isopropyl (rubbing) alcohol. Finally, clean the

glass with a paper towel dampened with alcohol.

(3) Sand the surface on the support bracket with

fine grit-sandpaper. Wipe the bracket surface clean

with a paper towel.

Fig. 16 Body Vent

1 - BÐPILLAR

2 - DOOR STRIKER

3 - BODY VENT

Fig. 17 Rearview Mirror Connector

1 - CONNECTOR

2 - MIRROR

3 - SCREW

Fig. 18 Rearview Mirror

1 - REARVIEW MIRROR

2 - WINDSHIELD GLASS

3 - SUPPORT BRACKET

4 - SCREW

23 - 126 INTERIORBR/BE

Page 2701 of 2889

INSTALLATION

(1) Position trim panel in vehicle and route seat

belt webbing through opening in quarter trim panel.

(2) Open quarter vent window.

(3) Position trim panel on quarter panel and

engage clips on upper portion of panel.

(4) Engage clips attaching lower portion of quarter

trim panel to quarter panel.

(5) Install lower seat belt anchor bolt.

(6) Install door sill cover as necessary.

(7) Install rear seat. (Refer to 23 - BODY/SEATS/

REAR SEAT - INSTALLATION)

C-PILLAR TRIM

REMOVAL

(1) Remove rear floor stowage tray. (Refer to 23 -

BODY/INTERIOR/REAR FLOOR STOWAGE TRAY -

REMOVAL)

(2) Remove door sill cover as necessary to clear

C-pillar trim.

(3) Remove bolt attaching seat belt anchor to floor.

(4) Unsnap turning loop, push cover up and

remove bolt attaching turning loop to C-pillar.(5) Remove seat belt exit plug.

(6) Disengage clips attaching C-pillar trim to

upper C-pillar.

(7) Separate C-pillar trim from C-pillar.

(8) Route seat belt webbing through opening in

C-pillar trim.

INSTALLATION

(1) Route seat belt webbing through opening in

C-pillar trim.

(2) Position C-pillar trim at C-pillar.

(3) Starting at the top, engage clips attaching

C-pillar trim to upper C-pillar.

(4) Install seat belt exit plug.

(5) Install bolt attaching turning loop to C-pillar

and position turning loop cover. Snap turning loop

cover into place.

(6) Install bolt attaching seat belt anchor to floor.

(7) Install door sill cover.

(8) Install rear floor stowage tray. (Refer to 23 -

BODY/INTERIOR/REAR FLOOR STOWAGE TRAY -

INSTALLATION)

23 - 128 INTERIORBR/BE

QUARTER TRIM PANEL (Continued)

Page 2716 of 2889

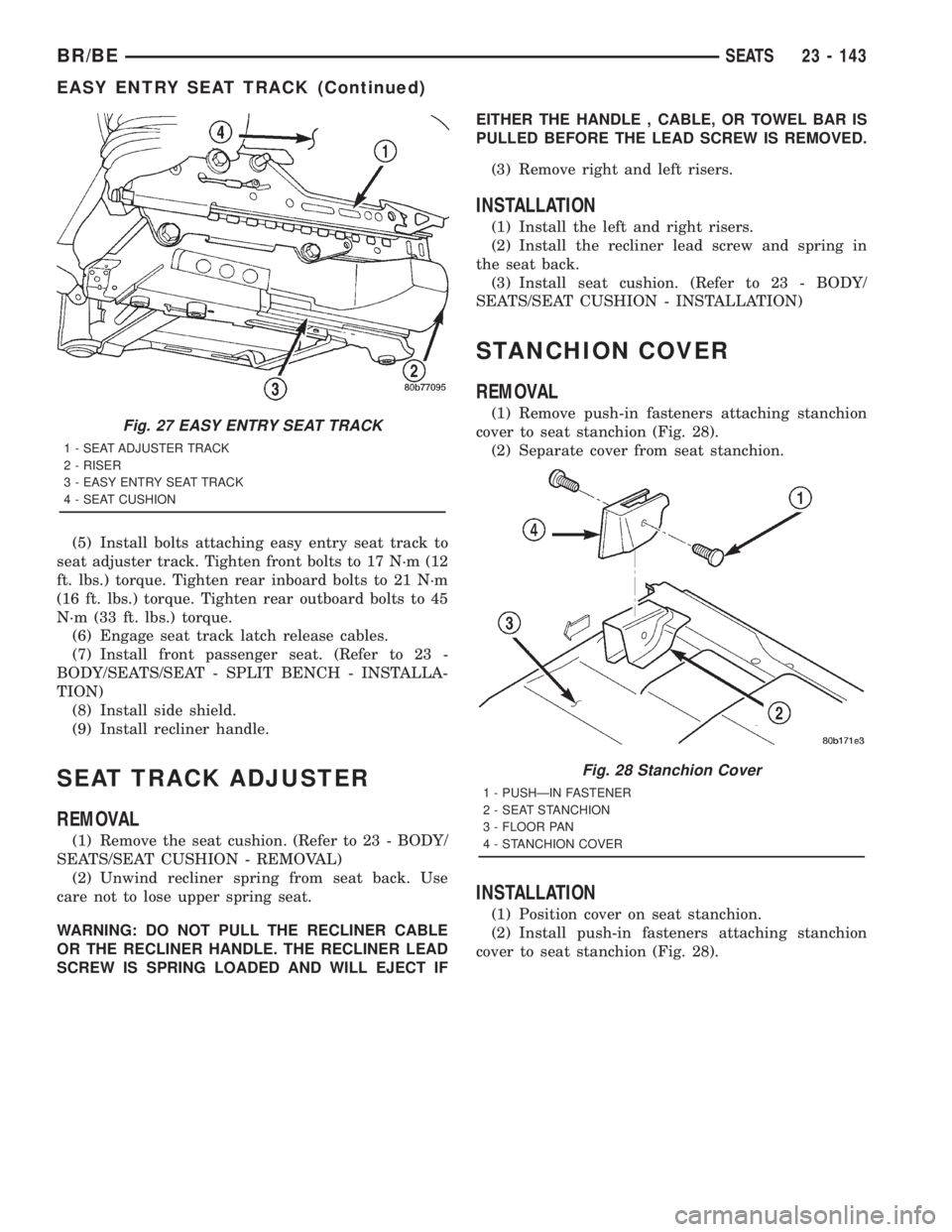

(5) Install bolts attaching easy entry seat track to

seat adjuster track. Tighten front bolts to 17 N´m (12

ft. lbs.) torque. Tighten rear inboard bolts to 21 N´m

(16 ft. lbs.) torque. Tighten rear outboard bolts to 45

N´m (33 ft. lbs.) torque.

(6) Engage seat track latch release cables.

(7) Install front passenger seat. (Refer to 23 -

BODY/SEATS/SEAT - SPLIT BENCH - INSTALLA-

TION)

(8) Install side shield.

(9) Install recliner handle.

SEAT TRACK ADJUSTER

REMOVAL

(1) Remove the seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - REMOVAL)

(2) Unwind recliner spring from seat back. Use

care not to lose upper spring seat.

WARNING: DO NOT PULL THE RECLINER CABLE

OR THE RECLINER HANDLE. THE RECLINER LEAD

SCREW IS SPRING LOADED AND WILL EJECT IFEITHER THE HANDLE , CABLE, OR TOWEL BAR IS

PULLED BEFORE THE LEAD SCREW IS REMOVED.

(3) Remove right and left risers.

INSTALLATION

(1) Install the left and right risers.

(2) Install the recliner lead screw and spring in

the seat back.

(3) Install seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - INSTALLATION)

STANCHION COVER

REMOVAL

(1) Remove push-in fasteners attaching stanchion

cover to seat stanchion (Fig. 28).

(2) Separate cover from seat stanchion.

INSTALLATION

(1) Position cover on seat stanchion.

(2) Install push-in fasteners attaching stanchion

cover to seat stanchion (Fig. 28).

Fig. 27 EASY ENTRY SEAT TRACK

1 - SEAT ADJUSTER TRACK

2 - RISER

3 - EASY ENTRY SEAT TRACK

4 - SEAT CUSHION

Fig. 28 Stanchion Cover

1 - PUSHÐIN FASTENER

2 - SEAT STANCHION

3 - FLOOR PAN

4 - STANCHION COVER

BR/BESEATS 23 - 143

EASY ENTRY SEAT TRACK (Continued)

Page 2717 of 2889

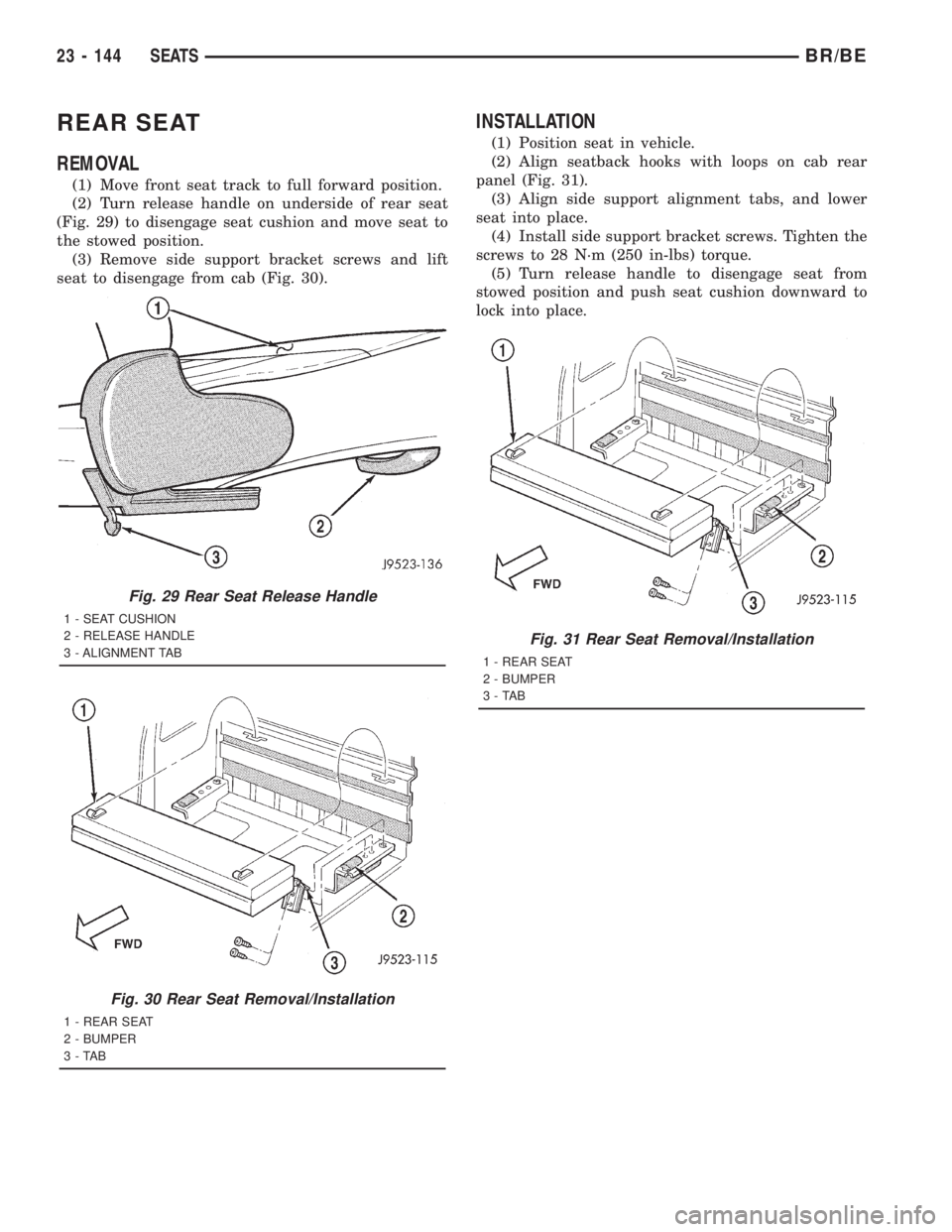

REAR SEAT

REMOVAL

(1) Move front seat track to full forward position.

(2) Turn release handle on underside of rear seat

(Fig. 29) to disengage seat cushion and move seat to

the stowed position.

(3) Remove side support bracket screws and lift

seat to disengage from cab (Fig. 30).

INSTALLATION

(1) Position seat in vehicle.

(2) Align seatback hooks with loops on cab rear

panel (Fig. 31).

(3) Align side support alignment tabs, and lower

seat into place.

(4) Install side support bracket screws. Tighten the

screws to 28 N´m (250 in-lbs) torque.

(5) Turn release handle to disengage seat from

stowed position and push seat cushion downward to

lock into place.

Fig. 29 Rear Seat Release Handle

1 - SEAT CUSHION

2 - RELEASE HANDLE

3 - ALIGNMENT TAB

Fig. 30 Rear Seat Removal/Installation

1 - REAR SEAT

2 - BUMPER

3-TAB

Fig. 31 Rear Seat Removal/Installation

1 - REAR SEAT

2 - BUMPER

3-TAB

23 - 144 SEATSBR/BE

Page 2779 of 2889

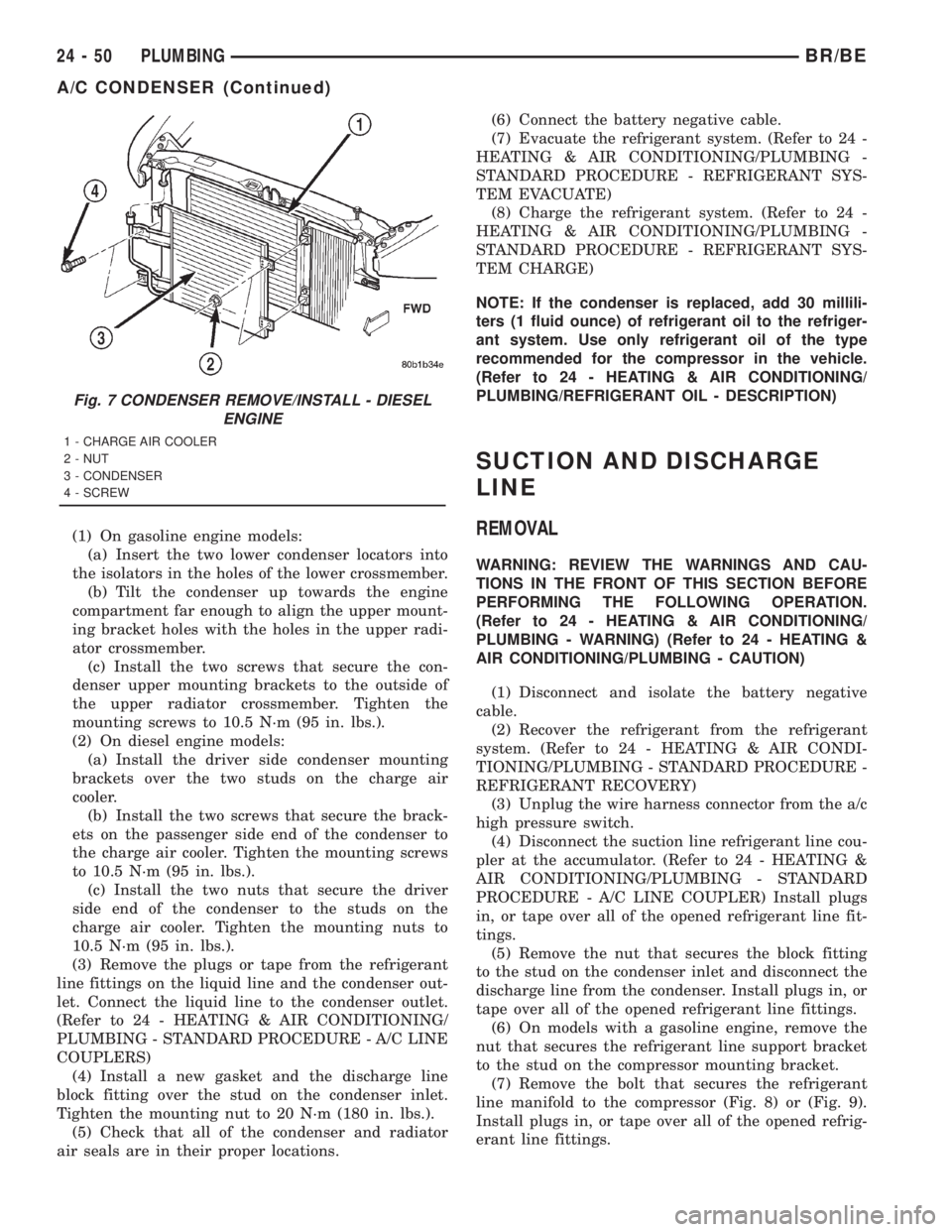

(1) On gasoline engine models:

(a) Insert the two lower condenser locators into

the isolators in the holes of the lower crossmember.

(b) Tilt the condenser up towards the engine

compartment far enough to align the upper mount-

ing bracket holes with the holes in the upper radi-

ator crossmember.

(c) Install the two screws that secure the con-

denser upper mounting brackets to the outside of

the upper radiator crossmember. Tighten the

mounting screws to 10.5 N´m (95 in. lbs.).

(2) On diesel engine models:

(a) Install the driver side condenser mounting

brackets over the two studs on the charge air

cooler.

(b) Install the two screws that secure the brack-

ets on the passenger side end of the condenser to

the charge air cooler. Tighten the mounting screws

to 10.5 N´m (95 in. lbs.).

(c) Install the two nuts that secure the driver

side end of the condenser to the studs on the

charge air cooler. Tighten the mounting nuts to

10.5 N´m (95 in. lbs.).

(3) Remove the plugs or tape from the refrigerant

line fittings on the liquid line and the condenser out-

let. Connect the liquid line to the condenser outlet.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE - A/C LINE

COUPLERS)

(4) Install a new gasket and the discharge line

block fitting over the stud on the condenser inlet.

Tighten the mounting nut to 20 N´m (180 in. lbs.).

(5) Check that all of the condenser and radiator

air seals are in their proper locations.(6) Connect the battery negative cable.

(7) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

NOTE: If the condenser is replaced, add 30 millili-

ters (1 fluid ounce) of refrigerant oil to the refriger-

ant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT OIL - DESCRIPTION)

SUCTION AND DISCHARGE

LINE

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Unplug the wire harness connector from the a/c

high pressure switch.

(4) Disconnect the suction line refrigerant line cou-

pler at the accumulator. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - A/C LINE COUPLER) Install plugs

in, or tape over all of the opened refrigerant line fit-

tings.

(5) Remove the nut that secures the block fitting

to the stud on the condenser inlet and disconnect the

discharge line from the condenser. Install plugs in, or

tape over all of the opened refrigerant line fittings.

(6) On models with a gasoline engine, remove the

nut that secures the refrigerant line support bracket

to the stud on the compressor mounting bracket.

(7) Remove the bolt that secures the refrigerant

line manifold to the compressor (Fig. 8) or (Fig. 9).

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

Fig. 7 CONDENSER REMOVE/INSTALL - DIESEL

ENGINE

1 - CHARGE AIR COOLER

2 - NUT

3 - CONDENSER

4 - SCREW

24 - 50 PLUMBINGBR/BE

A/C CONDENSER (Continued)

Page 2814 of 2889

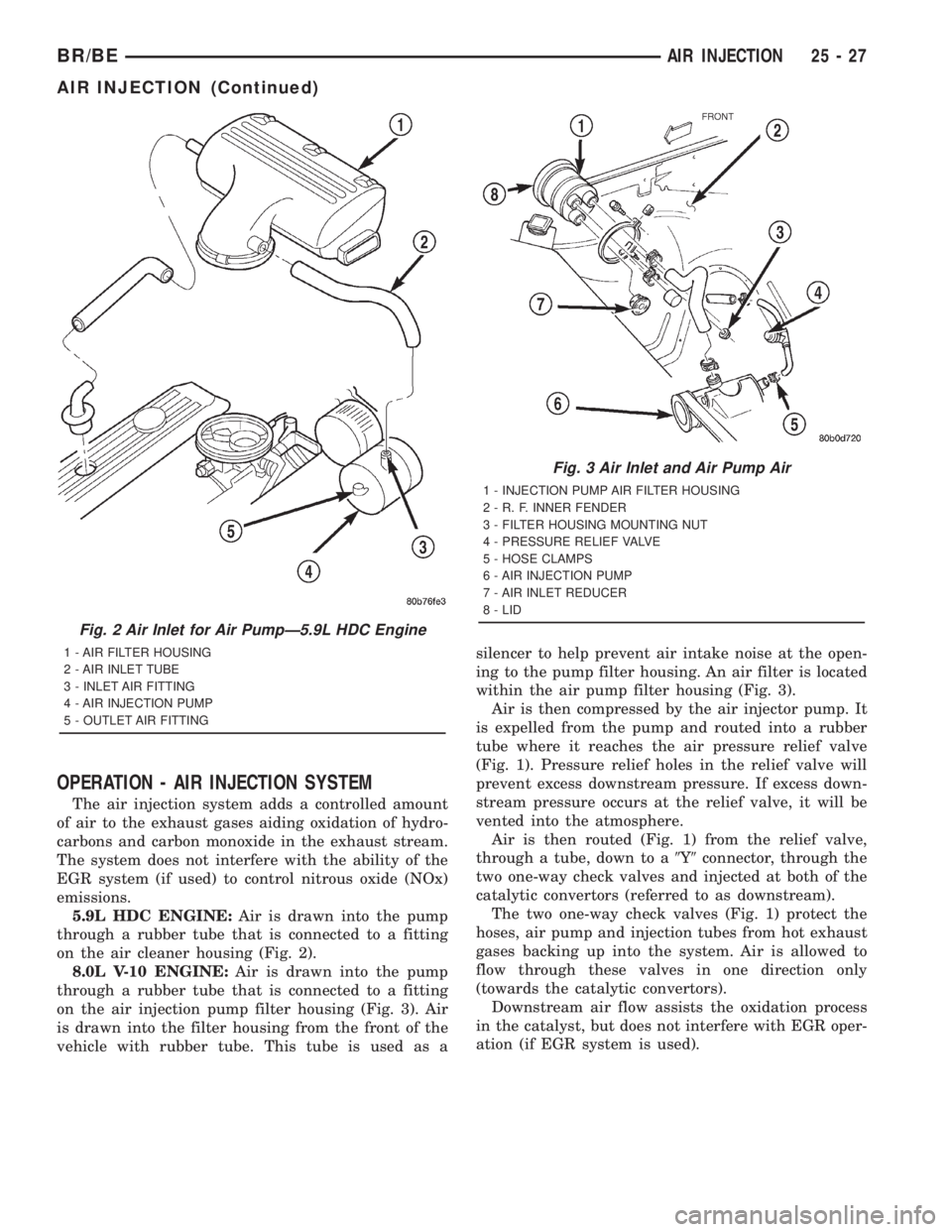

OPERATION - AIR INJECTION SYSTEM

The air injection system adds a controlled amount

of air to the exhaust gases aiding oxidation of hydro-

carbons and carbon monoxide in the exhaust stream.

The system does not interfere with the ability of the

EGR system (if used) to control nitrous oxide (NOx)

emissions.

5.9L HDC ENGINE:Air is drawn into the pump

through a rubber tube that is connected to a fitting

on the air cleaner housing (Fig. 2).

8.0L V-10 ENGINE:Air is drawn into the pump

through a rubber tube that is connected to a fitting

on the air injection pump filter housing (Fig. 3). Air

is drawn into the filter housing from the front of the

vehicle with rubber tube. This tube is used as asilencer to help prevent air intake noise at the open-

ing to the pump filter housing. An air filter is located

within the air pump filter housing (Fig. 3).

Air is then compressed by the air injector pump. It

is expelled from the pump and routed into a rubber

tube where it reaches the air pressure relief valve

(Fig. 1). Pressure relief holes in the relief valve will

prevent excess downstream pressure. If excess down-

stream pressure occurs at the relief valve, it will be

vented into the atmosphere.

Air is then routed (Fig. 1) from the relief valve,

through a tube, down to a9Y9connector, through the

two one-way check valves and injected at both of the

catalytic convertors (referred to as downstream).

The two one-way check valves (Fig. 1) protect the

hoses, air pump and injection tubes from hot exhaust

gases backing up into the system. Air is allowed to

flow through these valves in one direction only

(towards the catalytic convertors).

Downstream air flow assists the oxidation process

in the catalyst, but does not interfere with EGR oper-

ation (if EGR system is used).

Fig. 2 Air Inlet for Air PumpÐ5.9L HDC Engine

1 - AIR FILTER HOUSING

2 - AIR INLET TUBE

3 - INLET AIR FITTING

4 - AIR INJECTION PUMP

5 - OUTLET AIR FITTING

Fig. 3 Air Inlet and Air Pump Air

1 - INJECTION PUMP AIR FILTER HOUSING

2 - R. F. INNER FENDER

3 - FILTER HOUSING MOUNTING NUT

4 - PRESSURE RELIEF VALVE

5 - HOSE CLAMPS

6 - AIR INJECTION PUMP

7 - AIR INLET REDUCER

8 - LID

BR/BEAIR INJECTION 25 - 27

AIR INJECTION (Continued)

Page 2845 of 2889

STANDARD PROCEDURE - PRE DELIVERY

STORAGE

(1) If possible, store vehicles indoors, in clean, dry

places. If vehicles must be stored outdoors:

²Try to avoid storage locations that are near any

obvious sources of industrial or environmental con-

tamination (e.g., trees, factories, steam or vapor

vents, railroad tracks, etc.)

²Maintain tight security to help prevent pilferage

and vandalism, and inspect each vehicle regularly to

check for such damage

²If the vehicle must be parked on an incline, park

it with the front end higher than the rear; this will

prevent ªhydrostatic lockº caused by fuel draining

into the engine

²Rinse the vehicle at least once a week. Snow

should be washed away more often, since it can trap

harmful contaminants. Dry all horizontal surfaces

(2) The IOD fuse should be removed in order to

prevent battery drain and possible damage.

(3) Check the vehicle's coolant and anti-freeze pro-

tection.

(4) Check the vehicle's battery at least once a

month for a proper charge (at least 12.4 volts).

Charge the battery if necessary. This will help pre-

vent freezing and deterioration.

(5) Check the vehicle's tires and inflate them to

their maximum recommended levels. Move the vehi-

cles periodically to avoid ªflatspottingº the tires.

(6) Do not engage the parking brake; keep it in the

OFF position.

(7) Keep all windows closed, all doors locked, and

all trim covers intact and in place.

(8) Do not use chalks, crayons or any marker con-

taining abrasives on painted, plated or glass sur-

faces.

(9) Always use seat covers when moving a vehicle.

PROGRAMMABLE

ELECTRONIC FEATURES

DESCRIPTION

The programming of electronic features applies to

specific DaimlerChrysler Corporation vehicles. Not

all vehicles are equipped with these electronic fea-

tures, and not all vehicles equipped with electronic

features have all the available features. Programma-

ble electronic features are subject to change and may

be added or deleted from specific vehicle models.

(1) The programmable electronic features that may

be provided on the vehicle are:

²Rolling Power Door Locks

²Horn Chirp (When Doors Locked With Remote

Keyless Entry)²Headlamp Flash (When Doors Locked or

Unlocked With Remote Keyless Entry)

²Low Fuel Chime

²Remote Keyless Entry Door Unlock Sequence

²Headlights On Automatically With Wipers

²Turn Signal Chime

²12V Power Outlet

²Remote Unlock

²Remote Linked To Memory

²Headlamp Delay

²Service Interval

²Easy Exit Seat

(2) Programming any of the above features is to be

performed prior to vehicle delivery to the customer,

depending on customer preference.

NOTE: For all vehicles except Caravan/Town and

Country, the programming must be performed using

the DRB IIITscan tool. On Caravan/Town and Coun-

try vehicles the features can be programmed using

the DRB IIITscan tool or by button pushing

sequences. The customer can perform program-

ming, if desired, by following the instructions out-

lined in the owner manual.

OPERATION

NOTE: The programmable features provided on

vehicles need to be explained to the customer at

the time of sale. The customer's preferences con-

cerning the features should be noted and pro-

grammed accordingly during predelivery.

NOTE: When using the DRB IIITscan tool to enable/

disable any programmable electronic features, go to

the main menu item #9 on the DRB IIITscan tool.

This is ªCustomer Preferencesº. You must choose

ªCustomer Preferencesº on the main menu to pro-

gram the desired features.

ROLLING POWER DOOR LOCKS

With this feature enabled, the vehicle's door lock-

ing mechanisms automatically lock when the vehicle

reaches approximately 24 Km/h (15 mph).

HORN CHIRP

NOTE: This feature can be enabled with or without

the headlamp flash feature.

The horn chirp function is a feature that can be

enabled or disabled on vehicles equipped with

30 - 20 NEW VEHICLE PREPARATIONBR/BE

PRE DELIVERY STORAGE (Continued)

Page 2846 of 2889

Remote Keyless Entry (RKE). The horn chirps when

the vehicle is locked with the RKE transmitter.

HEADLAMP FLASH

NOTE: This feature can be enabled with or without

the horn chirp feature.

The headlamp flash function is a feature that can

be enabled or disabled on vehicles equipped with

Remote Keyless Entry (RKE). The headlamps flash

once when the vehicle is locked with the RKE trans-

mitter, and flash twice when the vehicle is unlocked

with the RKE transmitter.

LOW FUEL CHIME

All vehicles equipped with the audible low fuel

chime are shipped with this feature enabled.

REMOTE KEYLESS ENTRY (RKE) DOOR UNLOCK

SEQUENCE

Two door unlock sequences are provided on vehi-

cles equipped with this feature. When using the RKE

transmitter to unlock the doors, pressing the unlock

button once when the feature is enabled unlocks only

the driver's door. Pushing the RKE transmitter

unlock button a second time unlocks the remaining

doors. When the RKE door unlock feature is disabled,

all doors unlock with one press of the RKE transmit-

ter unlock button.

HEADLIGHTS ON AUTOMATICALLY WITH WIPERS

This feature appears on vehicles that have, as an

option, automatic headlights. When the windshield

wipers are turned on, the headlights automatically

turn on.

12V POWER OUTLET

This feature currently appears on Caravan/Voyag-

er/Town and Country vehicles. The vehicles are

shipped with the 12V power outlets turned off with

the ignition key. The relay can be changed to make

the outlets powered at all times. This feature may be

of interest to customers with cell phones.

TURN SIGNAL CHIME

This feature is an audible turn signal warning

chime. The chime sounds if the turn signal is on, the

vehicle has traveled one mile and vehicle speed has

exceeded 40 Km/h (25 mph).

REMOTE UNLOCK

The remote unlock function is a feature that can be

enabled or disabled on vehicles equipped with

Remote Keyless Entry (RKE). With the first press of

the RKE transmitter to unlock the doors, the driver's

door only unlocks. With the second press of the RKEtransmitter, the remaining doors and the liftgate

unlock. With the remote unlock feature enabled, the

first press of the RKE transmitter unlocks all doors.

REMOTE LINKED TO MEMORY

The remote linked to memory function is currently

only available only on Jeep Grand Cherokee Limited

vehicles. When enabled, this feature recalls a mem-

ory of seats, mirror and radio presets and positions

when unlocking the vehicle with the RKE transmit-

ter.

HEADLAMP DELAY

Currently available only on Jeep Grand Cherokee

vehicles, the headlamp delay timeout can be set to

30, 60 or 90 seconds. This timeout only occurs when

the ignition is turned off prior to turning the head-

lamps off, or when leaving the headlamps in AUTO

mode.

SERVICE INTERVAL

Currently available only on Jeep Grand Cherokee

vehicles, the interval for the service reminder mes-

sage can be set from 3,219 kilometers to 12,070 kilo-

meters (2,000 miles to 7,500 miles).

EASY EXIT SEAT

Currently available only on Jeep Grand Cherokee

Limited vehicles, the driver's seat will reposition

55mm (2.1 inches) rearward, or the end of travel if

less than 55mm (2.1 inches) and full downward when

the key is removed from the ignition. This feature

allows ease of exiting the vehicle. The seat will repo-

sition itself to the memory location when the vehicle

is unlocked using the RKE transmitter or by pressing

the memory buttons on the door panel.

APPEARANCE TIPS

CLEANING

(1) Before delivering the new vehicle to the cus-

tomer, the following checks on appearance details are

recommended:

²Wash the vehicle to remove all traces of road

grime and other dirt on the car from new vehicle

preparation operations

²Clean the tire sidewalls

²Clean exterior and interior glass surfaces

²Remove all protective covers

²Remove undercoat overspray, excess window

sealer, and excess weatherstrip adhesive

²Inspect interior trim, seats, carpeting, and mold-

ings. Clean as necessary

²Remove shipping and inspection stickers

BR/BENEW VEHICLE PREPARATION 30 - 21

PROGRAMMABLE ELECTRONIC FEATURES (Continued)

Page 2861 of 2889

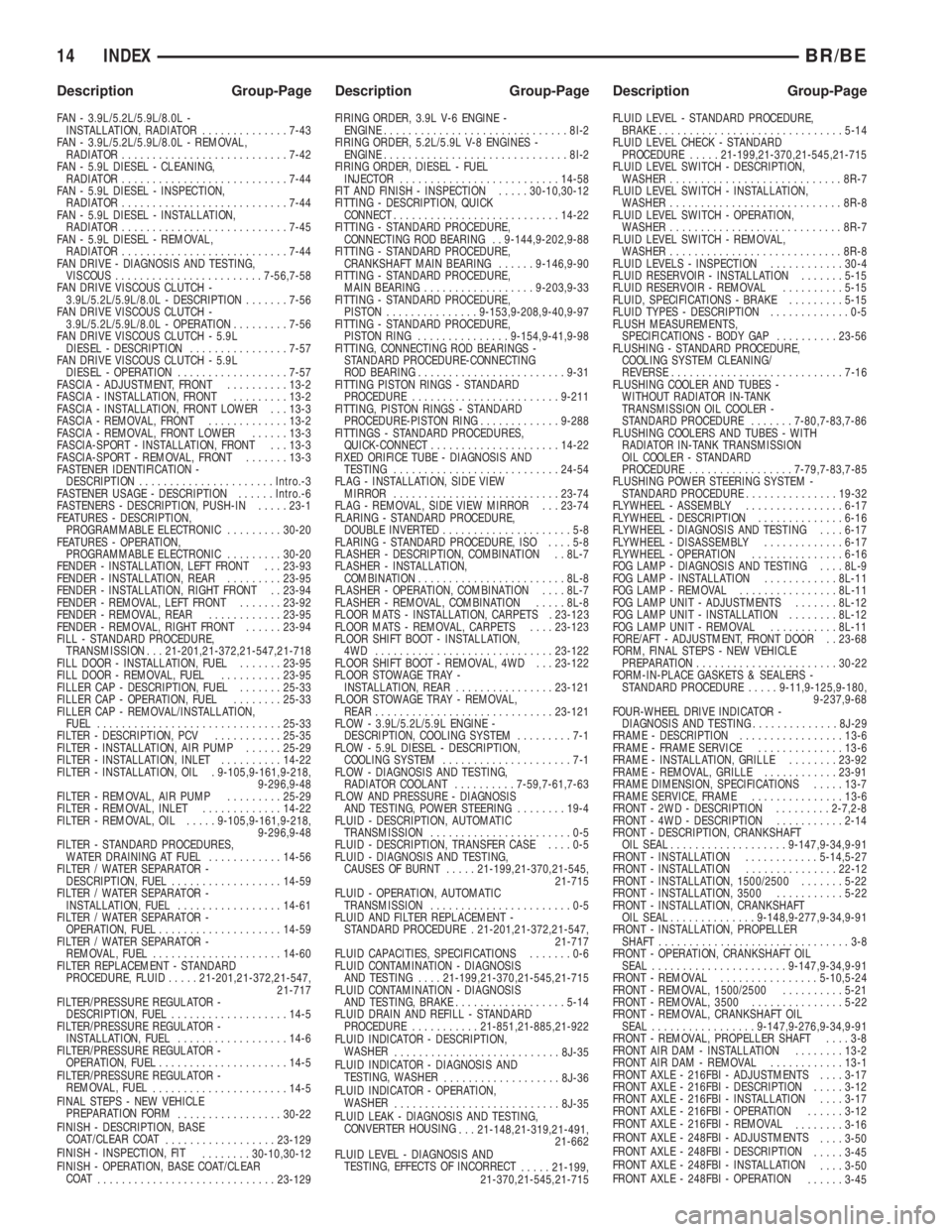

FAN - 3.9L/5.2L/5.9L/8.0L -

INSTALLATION, RADIATOR..............7-43

FAN - 3.9L/5.2L/5.9L/8.0L - REMOVAL,

RADIATOR...........................7-42

FAN - 5.9L DIESEL - CLEANING,

RADIATOR...........................7-44

FAN - 5.9L DIESEL - INSPECTION,

RADIATOR...........................7-44

FAN - 5.9L DIESEL - INSTALLATION,

RADIATOR...........................7-45

FAN - 5.9L DIESEL - REMOVAL,

RADIATOR...........................7-44

FAN DRIVE - DIAGNOSIS AND TESTING,

VISCOUS........................7-56,7-58

FAN DRIVE VISCOUS CLUTCH -

3.9L/5.2L/5.9L/8.0L - DESCRIPTION.......7-56

FAN DRIVE VISCOUS CLUTCH -

3.9L/5.2L/5.9L/8.0L - OPERATION.........7-56

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - DESCRIPTION................7-57

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - OPERATION..................7-57

FASCIA - ADJUSTMENT, FRONT..........13-2

FASCIA - INSTALLATION, FRONT.........13-2

FASCIA - INSTALLATION, FRONT LOWER . . . 13-3

FASCIA - REMOVAL, FRONT.............13-2

FASCIA - REMOVAL, FRONT LOWER......13-3

FASCIA-SPORT - INSTALLATION, FRONT . . . 13-3

FASCIA-SPORT - REMOVAL, FRONT.......13-3

FASTENER IDENTIFICATION -

DESCRIPTION......................Intro.-3

FASTENER USAGE - DESCRIPTION......Intro.-6

FASTENERS - DESCRIPTION, PUSH-IN.....23-1

FEATURES - DESCRIPTION,

PROGRAMMABLE ELECTRONIC.........30-20

FEATURES - OPERATION,

PROGRAMMABLE ELECTRONIC.........30-20

FENDER - INSTALLATION, LEFT FRONT . . . 23-93

FENDER - INSTALLATION, REAR.........23-95

FENDER - INSTALLATION, RIGHT FRONT . . 23-94

FENDER - REMOVAL, LEFT FRONT.......23-92

FENDER - REMOVAL, REAR............23-95

FENDER - REMOVAL, RIGHT FRONT......23-94

FILL - STANDARD PROCEDURE,

TRANSMISSION . . . 21-201,21-372,21-547,21-718

FILL DOOR - INSTALLATION, FUEL.......23-95

FILL DOOR - REMOVAL, FUEL..........23-95

FILLER CAP - DESCRIPTION, FUEL.......25-33

FILLER CAP - OPERATION, FUEL........25-33

FILLER CAP - REMOVAL/INSTALLATION,

FUEL..............................25-33

FILTER - DESCRIPTION, PCV...........25-35

FILTER - INSTALLATION, AIR PUMP......25-29

FILTER - INSTALLATION, INLET..........14-22

FILTER - INSTALLATION, OIL . 9-105,9-161,9-218,

9-296,9-48

FILTER - REMOVAL, AIR PUMP.........25-29

FILTER - REMOVAL, INLET.............14-22

FILTER - REMOVAL, OIL.....9-105,9-161,9-218,

9-296,9-48

FILTER - STANDARD PROCEDURES,

WATER DRAINING AT FUEL............14-56

FILTER / WATER SEPARATOR -

DESCRIPTION, FUEL..................14-59

FILTER / WATER SEPARATOR -

INSTALLATION, FUEL.................14-61

FILTER / WATER SEPARATOR -

OPERATION, FUEL....................14-59

FILTER / WATER SEPARATOR -

REMOVAL, FUEL.....................14-60

FILTER REPLACEMENT - STANDARD

PROCEDURE, FLUID.....21-201,21-372,21-547,

21-717

FILTER/PRESSURE REGULATOR -

DESCRIPTION, FUEL...................14-5

FILTER/PRESSURE REGULATOR -

INSTALLATION, FUEL..................14-6

FILTER/PRESSURE REGULATOR -

OPERATION, FUEL.....................14-5

FILTER/PRESSURE REGULATOR -

REMOVAL, FUEL

......................14-5

FINAL STEPS - NEW VEHICLE

PREPARATION FORM

.................30-22

FINISH - DESCRIPTION, BASE

COAT/CLEAR COAT

..................23-129

FINISH - INSPECTION, FIT

........30-10,30-12

FINISH - OPERATION, BASE COAT/CLEAR

COAT

.............................23-129FIRING ORDER, 3.9L V-6 ENGINE -

ENGINE..............................8I-2

FIRING ORDER, 5.2L/5.9L V-8 ENGINES -

ENGINE..............................8I-2

FIRING ORDER, DIESEL - FUEL

INJECTOR..........................14-58

FIT AND FINISH - INSPECTION.....30-10,30-12

FITTING - DESCRIPTION, QUICK

CONNECT...........................14-22

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING . . 9-144,9-202,9-88

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING......9-146,9-90

FITTING - STANDARD PROCEDURE,

MAIN BEARING..................9-203,9-33

FITTING - STANDARD PROCEDURE,

PISTON...............9-153,9-208,9-40,9-97

FITTING - STANDARD PROCEDURE,

PISTON RING...............9-154,9-41,9-98

FITTING, CONNECTING ROD BEARINGS -

STANDARD PROCEDURE-CONNECTING

ROD BEARING........................9-31

FITTING PISTON RINGS - STANDARD

PROCEDURE........................9-211

FITTING, PISTON RINGS - STANDARD

PROCEDURE-PISTON RING.............9-288

FITTINGS - STANDARD PROCEDURES,

QUICK-CONNECT.....................14-22

FIXED ORIFICE TUBE - DIAGNOSIS AND

TESTING...........................24-54

FLAG - INSTALLATION, SIDE VIEW

MIRROR...........................23-74

FLAG - REMOVAL, SIDE VIEW MIRROR . . . 23-74

FLARING - STANDARD PROCEDURE,

DOUBLE INVERTED.....................5-8

FLARING - STANDARD PROCEDURE, ISO....5-8

FLASHER - DESCRIPTION, COMBINATION . . 8L-7

FLASHER - INSTALLATION,

COMBINATION........................8L-8

FLASHER - OPERATION, COMBINATION....8L-7

FLASHER - REMOVAL, COMBINATION.....8L-8

FLOOR MATS - INSTALLATION, CARPETS . 23-123

FLOOR MATS - REMOVAL, CARPETS....23-123

FLOOR SHIFT BOOT - INSTALLATION,

4WD .............................23-122

FLOOR SHIFT BOOT - REMOVAL, 4WD . . . 23-122

FLOOR STOWAGE TRAY -

INSTALLATION, REAR................23-121

FLOOR STOWAGE TRAY - REMOVAL,

REAR.............................23-121

FLOW - 3.9L/5.2L/5.9L ENGINE -

DESCRIPTION, COOLING SYSTEM.........7-1

FLOW - 5.9L DIESEL - DESCRIPTION,

COOLING SYSTEM.....................7-1

FLOW - DIAGNOSIS AND TESTING,

RADIATOR COOLANT..........7-59,7-61,7-63

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-4

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID - DESCRIPTION, TRANSFER CASE....0-5

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT.....21-199,21-370,21-545,

21-715

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE . 21-201,21-372,21-547,

21-717

FLUID CAPACITIES, SPECIFICATIONS.......0-6

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING....21-199,21-370,21-545,21-715

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE..................5-14

FLUID DRAIN AND REFILL - STANDARD

PROCEDURE...........21-851,21-885,21-922

FLUID INDICATOR - DESCRIPTION,

WASHER

...........................8J-35

FLUID INDICATOR - DIAGNOSIS AND

TESTING, WASHER

...................8J-36

FLUID INDICATOR - OPERATION,

WASHER

...........................8J-35

FLUID LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING

. . . 21-148,21-319,21-491,

21-662

FLUID LEVEL - DIAGNOSIS AND

TESTING, EFFECTS OF INCORRECT

.....21-199,

21-370,21-545,21-715FLUID LEVEL - STANDARD PROCEDURE,

BRAKE..............................5-14

FLUID LEVEL CHECK - STANDARD

PROCEDURE.....21-199,21-370,21-545,21-715

FLUID LEVEL SWITCH - DESCRIPTION,

WASHER............................8R-7

FLUID LEVEL SWITCH - INSTALLATION,

WASHER............................8R-8

FLUID LEVEL SWITCH - OPERATION,

WASHER............................8R-7

FLUID LEVEL SWITCH - REMOVAL,

WASHER............................8R-8

FLUID LEVELS - INSPECTION............30-4

FLUID RESERVOIR - INSTALLATION.......5-15

FLUID RESERVOIR - REMOVAL..........5-15

FLUID, SPECIFICATIONS - BRAKE.........5-15

FLUID TYPES - DESCRIPTION.............0-5

FLUSH MEASUREMENTS,

SPECIFICATIONS - BODY GAP..........23-56

FLUSHING - STANDARD PROCEDURE,

COOLING SYSTEM CLEANING/

REVERSE............................7-16

FLUSHING COOLER AND TUBES -

WITHOUT RADIATOR IN-TANK

TRANSMISSION OIL COOLER -

STANDARD PROCEDURE.......7-80,7-83,7-86

FLUSHING COOLERS AND TUBES - WITH

RADIATOR IN-TANK TRANSMISSION

OIL COOLER - STANDARD

PROCEDURE.................7-79,7-83,7-85

FLUSHING POWER STEERING SYSTEM -

STANDARD PROCEDURE...............19-32

FLYWHEEL - ASSEMBLY................6-17

FLYWHEEL - DESCRIPTION..............6-16

FLYWHEEL - DIAGNOSIS AND TESTING....6-17

FLYWHEEL - DISASSEMBLY.............6-17

FLYWHEEL - OPERATION...............6-16

FOG LAMP - DIAGNOSIS AND TESTING....8L-9

FOG LAMP - INSTALLATION............8L-11

FOG LAMP - REMOVAL................8L-11

FOG LAMP UNIT - ADJUSTMENTS.......8L-12

FOG LAMP UNIT - INSTALLATION........8L-12

FOG LAMP UNIT - REMOVAL...........8L-11

FORE/AFT - ADJUSTMENT, FRONT DOOR . . 23-68

FORM, FINAL STEPS - NEW VEHICLE

PREPARATION.......................30-22

FORM-IN-PLACE GASKETS & SEALERS -

STANDARD PROCEDURE.....9-11,9-125,9-180,

9-237,9-68

FOUR-WHEEL DRIVE INDICATOR -

DIAGNOSIS AND TESTING..............8J-29

FRAME - DESCRIPTION.................13-6

FRAME - FRAME SERVICE..............13-6

FRAME - INSTALLATION, GRILLE........23-92

FRAME - REMOVAL, GRILLE............23-91

FRAME DIMENSION, SPECIFICATIONS.....13-7

FRAME SERVICE, FRAME...............13-6

FRONT - 2WD - DESCRIPTION.........2-7,2-8

FRONT - 4WD - DESCRIPTION...........2-14

FRONT - DESCRIPTION, CRANKSHAFT

OIL SEAL...................9-147,9-34,9-91

FRONT - INSTALLATION............5-14,5-27

FRONT - INSTALLATION...............22-12

FRONT - INSTALLATION, 1500/2500.......5-22

FRONT - INSTALLATION, 3500...........5-22

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL..............9-148,9-277,9-34,9-91

FRONT - INSTALLATION, PROPELLER

SHAFT...............................3-8

FRONT - OPERATION, CRANKSHAFT OIL

SEAL......................9-147,9-34,9-91

FRONT - REMOVAL................5-10,5-24

FRONT - REMOVAL, 1500/2500..........5-21

FRONT - REMOVAL, 3500...............5-22

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL.................9-147,9-276,9-34,9-91

FRONT - REMOVAL, PROPELLER SHAFT....3-8

FRONT AIR DAM - INSTALLATION........13-2

FRONT AIR DAM - REMOVAL............13-1

FRONT AXLE - 216FBI - ADJUSTMENTS....3-17

FRONT AXLE - 216FBI - DESCRIPTION.....3-12

FRONT AXLE - 216FBI - INSTALLATION....3-17

FRONT AXLE - 216FBI - OPERATION......3-12

FRONT AXLE - 216FBI - REMOVAL

........3-16

FRONT AXLE - 248FBI - ADJUSTMENTS

....3-50

FRONT AXLE - 248FBI - DESCRIPTION

.....3-45

FRONT AXLE - 248FBI - INSTALLATION

....3-50

FRONT AXLE - 248FBI - OPERATION

......3-45

14 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2862 of 2889

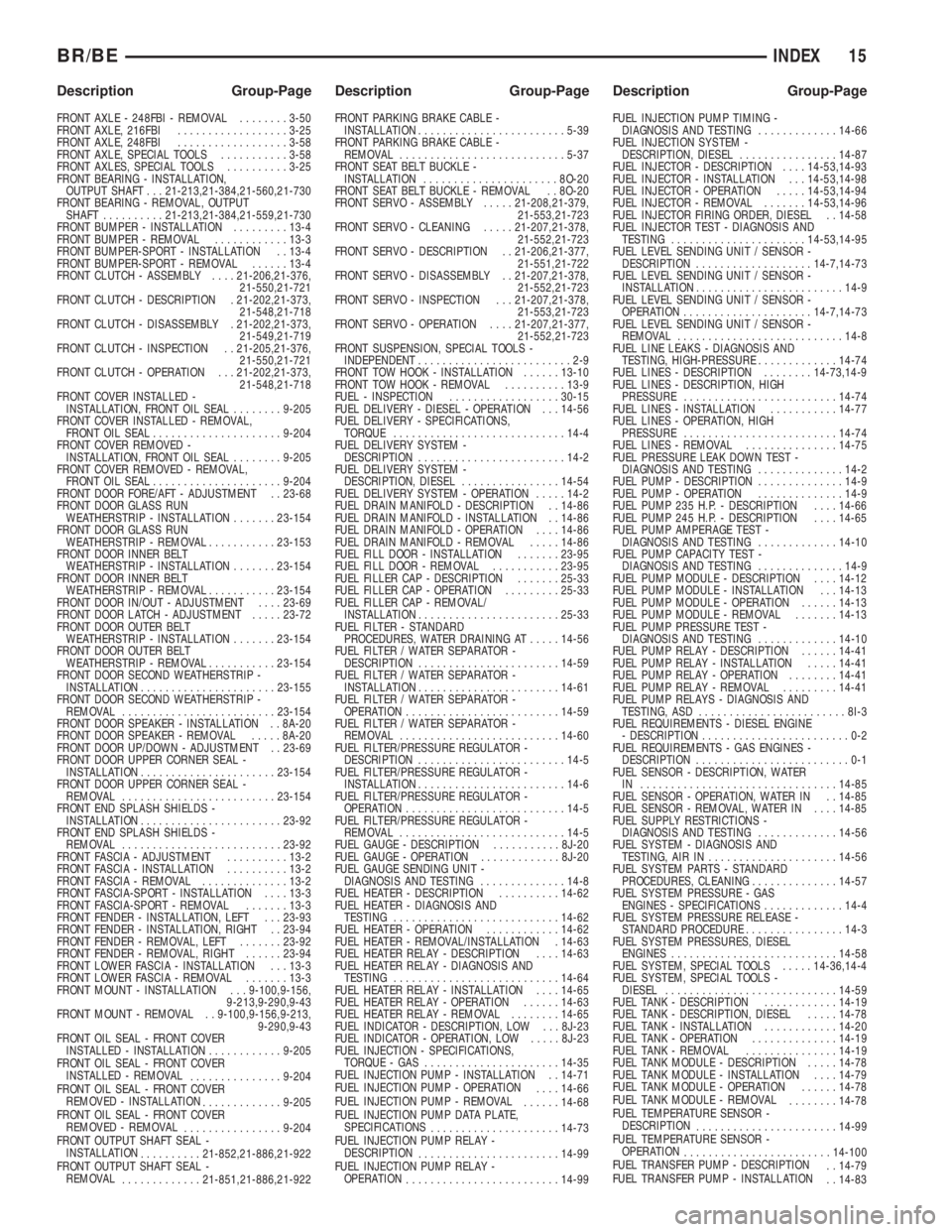

FRONT AXLE - 248FBI - REMOVAL........3-50

FRONT AXLE, 216FBI..................3-25

FRONT AXLE, 248FBI..................3-58

FRONT AXLE, SPECIAL TOOLS...........3-58

FRONT AXLES, SPECIAL TOOLS..........3-25

FRONT BEARING - INSTALLATION,

OUTPUT SHAFT . . . 21-213,21-384,21-560,21-730

FRONT BEARING - REMOVAL, OUTPUT

SHAFT..........21-213,21-384,21-559,21-730

FRONT BUMPER - INSTALLATION.........13-4

FRONT BUMPER - REMOVAL............13-3

FRONT BUMPER-SPORT - INSTALLATION . . 13-4

FRONT BUMPER-SPORT - REMOVAL......13-4

FRONT CLUTCH - ASSEMBLY....21-206,21-376,

21-550,21-721

FRONT CLUTCH - DESCRIPTION . 21-202,21-373,

21-548,21-718

FRONT CLUTCH - DISASSEMBLY . 21-202,21-373,

21-549,21-719

FRONT CLUTCH - INSPECTION . . 21-205,21-376,

21-550,21-721

FRONT CLUTCH - OPERATION . . . 21-202,21-373,

21-548,21-718

FRONT COVER INSTALLED -

INSTALLATION, FRONT OIL SEAL........9-205

FRONT COVER INSTALLED - REMOVAL,

FRONT OIL SEAL.....................9-204

FRONT COVER REMOVED -

INSTALLATION, FRONT OIL SEAL........9-205

FRONT COVER REMOVED - REMOVAL,

FRONT OIL SEAL......................9-204

FRONT DOOR FORE/AFT - ADJUSTMENT . . 23-68

FRONT DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION.......23-154

FRONT DOOR GLASS RUN

WEATHERSTRIP - REMOVAL...........23-153

FRONT DOOR INNER BELT

WEATHERSTRIP - INSTALLATION.......23-154

FRONT DOOR INNER BELT

WEATHERSTRIP - REMOVAL...........23-154

FRONT DOOR IN/OUT - ADJUSTMENT....23-69

FRONT DOOR LATCH - ADJUSTMENT.....23-72

FRONT DOOR OUTER BELT

WEATHERSTRIP - INSTALLATION.......23-154

FRONT DOOR OUTER BELT

WEATHERSTRIP - REMOVAL...........23-154

FRONT DOOR SECOND WEATHERSTRIP -

INSTALLATION......................23-155

FRONT DOOR SECOND WEATHERSTRIP -

REMOVAL.........................23-154

FRONT DOOR SPEAKER - INSTALLATION . . 8A-20

FRONT DOOR SPEAKER - REMOVAL.....8A-20

FRONT DOOR UP/DOWN - ADJUSTMENT . . 23-69

FRONT DOOR UPPER CORNER SEAL -

INSTALLATION......................23-154

FRONT DOOR UPPER CORNER SEAL -

REMOVAL.........................23-154

FRONT END SPLASH SHIELDS -

INSTALLATION.......................23-92

FRONT END SPLASH SHIELDS -

REMOVAL..........................23-92

FRONT FASCIA - ADJUSTMENT..........13-2

FRONT FASCIA - INSTALLATION..........13-2

FRONT FASCIA - REMOVAL..............13-2

FRONT FASCIA-SPORT - INSTALLATION....13-3

FRONT FASCIA-SPORT - REMOVAL.......13-3

FRONT FENDER - INSTALLATION, LEFT . . . 23-93

FRONT FENDER - INSTALLATION, RIGHT . . 23-94

FRONT FENDER - REMOVAL, LEFT.......23-92

FRONT FENDER - REMOVAL, RIGHT......23-94

FRONT LOWER FASCIA - INSTALLATION . . . 13-3

FRONT LOWER FASCIA - REMOVAL.......13-3

FRONT MOUNT - INSTALLATION . . . 9-100,9-156,

9-213,9-290,9-43

FRONT MOUNT - REMOVAL . . 9-100,9-156,9-213,

9-290,9-43

FRONT OIL SEAL - FRONT COVER

INSTALLED - INSTALLATION............9-205

FRONT OIL SEAL - FRONT COVER

INSTALLED - REMOVAL

...............9-204

FRONT OIL SEAL - FRONT COVER

REMOVED - INSTALLATION

.............9-205

FRONT OIL SEAL - FRONT COVER

REMOVED - REMOVAL

................9-204

FRONT OUTPUT SHAFT SEAL -

INSTALLATION

..........21-852,21-886,21-922

FRONT OUTPUT SHAFT SEAL -

REMOVAL

.............21-851,21-886,21-922FRONT PARKING BRAKE CABLE -

INSTALLATION........................5-39

FRONT PARKING BRAKE CABLE -

REMOVAL...........................5-37

FRONT SEAT BELT BUCKLE -

INSTALLATION......................8O-20

FRONT SEAT BELT BUCKLE - REMOVAL . . 8O-20

FRONT SERVO - ASSEMBLY.....21-208,21-379,

21-553,21-723

FRONT SERVO - CLEANING.....21-207,21-378,

21-552,21-723

FRONT SERVO - DESCRIPTION . . 21-206,21-377,

21-551,21-722

FRONT SERVO - DISASSEMBLY . . 21-207,21-378,

21-552,21-723

FRONT SERVO - INSPECTION . . . 21-207,21-378,

21-553,21-723

FRONT SERVO - OPERATION....21-207,21-377,

21-552,21-723

FRONT SUSPENSION, SPECIAL TOOLS -

INDEPENDENT.........................2-9

FRONT TOW HOOK - INSTALLATION......13-10

FRONT TOW HOOK - REMOVAL..........13-9

FUEL - INSPECTION..................30-15

FUEL DELIVERY - DIESEL - OPERATION . . . 14-56

FUEL DELIVERY - SPECIFICATIONS,

TORQUE............................14-4

FUEL DELIVERY SYSTEM -

DESCRIPTION........................14-2

FUEL DELIVERY SYSTEM -

DESCRIPTION, DIESEL................14-54

FUEL DELIVERY SYSTEM - OPERATION.....14-2

FUEL DRAIN MANIFOLD - DESCRIPTION . . 14-86

FUEL DRAIN MANIFOLD - INSTALLATION . . 14-86

FUEL DRAIN MANIFOLD - OPERATION....14-86

FUEL DRAIN MANIFOLD - REMOVAL.....14-86

FUEL FILL DOOR - INSTALLATION.......23-95

FUEL FILL DOOR - REMOVAL...........23-95

FUEL FILLER CAP - DESCRIPTION.......25-33

FUEL FILLER CAP - OPERATION.........25-33

FUEL FILLER CAP - REMOVAL/

INSTALLATION.......................25-33

FUEL FILTER - STANDARD

PROCEDURES, WATER DRAINING AT.....14-56

FUEL FILTER / WATER SEPARATOR -

DESCRIPTION.......................14-59

FUEL FILTER / WATER SEPARATOR -

INSTALLATION.......................14-61

FUEL FILTER / WATER SEPARATOR -

OPERATION.........................14-59

FUEL FILTER / WATER SEPARATOR -

REMOVAL..........................14-60

FUEL FILTER/PRESSURE REGULATOR -

DESCRIPTION........................14-5

FUEL FILTER/PRESSURE REGULATOR -

INSTALLATION........................14-6

FUEL FILTER/PRESSURE REGULATOR -

OPERATION..........................14-5

FUEL FILTER/PRESSURE REGULATOR -

REMOVAL...........................14-5

FUEL GAUGE - DESCRIPTION...........8J-20

FUEL GAUGE - OPERATION.............8J-20

FUEL GAUGE SENDING UNIT -

DIAGNOSIS AND TESTING..............14-8

FUEL HEATER - DESCRIPTION..........14-62

FUEL HEATER - DIAGNOSIS AND

TESTING...........................14-62

FUEL HEATER - OPERATION............14-62

FUEL HEATER - REMOVAL/INSTALLATION . 14-63

FUEL HEATER RELAY - DESCRIPTION....14-63

FUEL HEATER RELAY - DIAGNOSIS AND

TESTING...........................14-64

FUEL HEATER RELAY - INSTALLATION....14-65

FUEL HEATER RELAY - OPERATION......14-63

FUEL HEATER RELAY - REMOVAL........14-65

FUEL INDICATOR - DESCRIPTION, LOW . . . 8J-23

FUEL INDICATOR - OPERATION, LOW.....8J-23

FUEL INJECTION - SPECIFICATIONS,

TORQUE - GAS......................14-35

FUEL INJECTION PUMP - INSTALLATION . . 14-71

FUEL INJECTION PUMP - OPERATION

....14-66

FUEL INJECTION PUMP - REMOVAL

......14-68

FUEL INJECTION PUMP DATA PLATE,

SPECIFICATIONS

.....................14-73

FUEL INJECTION PUMP RELAY -

DESCRIPTION

.......................14-99

FUEL INJECTION PUMP RELAY -

OPERATION

.........................14-99FUEL INJECTION PUMP TIMING -

DIAGNOSIS AND TESTING.............14-66

FUEL INJECTION SYSTEM -

DESCRIPTION, DIESEL................14-87

FUEL INJECTOR - DESCRIPTION....14-53,14-93

FUEL INJECTOR - INSTALLATION . . . 14-53,14-98

FUEL INJECTOR - OPERATION.....14-53,14-94

FUEL INJECTOR - REMOVAL.......14-53,14-96

FUEL INJECTOR FIRING ORDER, DIESEL . . 14-58

FUEL INJECTOR TEST - DIAGNOSIS AND

TESTING......................14-53,14-95

FUEL LEVEL SENDING UNIT / SENSOR -

DESCRIPTION...................14-7,14-73

FUEL LEVEL SENDING UNIT / SENSOR -

INSTALLATION........................14-9

FUEL LEVEL SENDING UNIT / SENSOR -

OPERATION.....................14-7,14-73

FUEL LEVEL SENDING UNIT / SENSOR -

REMOVAL...........................14-8

FUEL LINE LEAKS - DIAGNOSIS AND

TESTING, HIGH-PRESSURE.............14-74

FUEL LINES - DESCRIPTION........14-73,14-9

FUEL LINES - DESCRIPTION, HIGH

PRESSURE.........................14-74

FUEL LINES - INSTALLATION...........14-77

FUEL LINES - OPERATION, HIGH

PRESSURE.........................14-74

FUEL LINES - REMOVAL...............14-75

FUEL PRESSURE LEAK DOWN TEST -

DIAGNOSIS AND TESTING..............14-2

FUEL PUMP - DESCRIPTION..............14-9

FUEL PUMP - OPERATION..............14-9

FUEL PUMP 235 H.P. - DESCRIPTION....14-66

FUEL PUMP 245 H.P. - DESCRIPTION....14-65

FUEL PUMP AMPERAGE TEST -

DIAGNOSIS AND TESTING.............14-10

FUEL PUMP CAPACITY TEST -

DIAGNOSIS AND TESTING..............14-9

FUEL PUMP MODULE - DESCRIPTION....14-12

FUEL PUMP MODULE - INSTALLATION . . . 14-13

FUEL PUMP MODULE - OPERATION......14-13

FUEL PUMP MODULE - REMOVAL.......14-13

FUEL PUMP PRESSURE TEST -

DIAGNOSIS AND TESTING.............14-10

FUEL PUMP RELAY - DESCRIPTION......14-41

FUEL PUMP RELAY - INSTALLATION.....14-41

FUEL PUMP RELAY - OPERATION........14-41

FUEL PUMP RELAY - REMOVAL.........14-41

FUEL PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD........................8I-3

FUEL REQUIREMENTS - DIESEL ENGINE

- DESCRIPTION........................0-2

FUEL REQUIREMENTS - GAS ENGINES -

DESCRIPTION.........................0-1

FUEL SENSOR - DESCRIPTION, WATER

IN ................................14-85

FUEL SENSOR - OPERATION, WATER IN . . 14-85

FUEL SENSOR - REMOVAL, WATER IN....14-85

FUEL SUPPLY RESTRICTIONS -

DIAGNOSIS AND TESTING.............14-56

FUEL SYSTEM - DIAGNOSIS AND

TESTING, AIR IN.....................14-56

FUEL SYSTEM PARTS - STANDARD

PROCEDURES, CLEANING..............14-57

FUEL SYSTEM PRESSURE - GAS

ENGINES - SPECIFICATIONS.............14-4

FUEL SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE................14-3

FUEL SYSTEM PRESSURES, DIESEL

ENGINES...........................14-58

FUEL SYSTEM, SPECIAL TOOLS.....14-36,14-4

FUEL SYSTEM, SPECIAL TOOLS -

DIESEL............................14-59

FUEL TANK - DESCRIPTION............14-19

FUEL TANK - DESCRIPTION, DIESEL.....14-78

FUEL TANK - INSTALLATION............14-20

FUEL TANK - OPERATION..............14-19

FUEL TANK - REMOVAL...............14-19

FUEL TANK MODULE - DESCRIPTION.....14-78

FUEL TANK MODULE - INSTALLATION....14-79

FUEL TANK MODULE - OPERATION......14-78

FUEL TANK MODULE - REMOVAL

........14-78

FUEL TEMPERATURE SENSOR -

DESCRIPTION

.......................14-99

FUEL TEMPERATURE SENSOR -

OPERATION

........................14-100

FUEL TRANSFER PUMP - DESCRIPTION

. . 14-79

FUEL TRANSFER PUMP - INSTALLATION

. . 14-83

BR/BEINDEX 15

Description Group-Page Description Group-Page Description Group-Page