audio DODGE RAM 2001 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 443 of 2889

(5) Reconnect the body wire harness connector to

the A-pillar tweeter wire harness connector.

(6) Engage the trim onto the A-pillar. Refer to

Body, Interior for the procedures.

(7) If the vehicle is so equipped, install the grab

handle onto the A-pillar. Refer to Body, Interior for

the procedures.

(8) Reconnect the battery negative cable.

FRONT DOOR SPEAKER

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim panel from the front door.

Refer to Body, Door Front for the procedures.

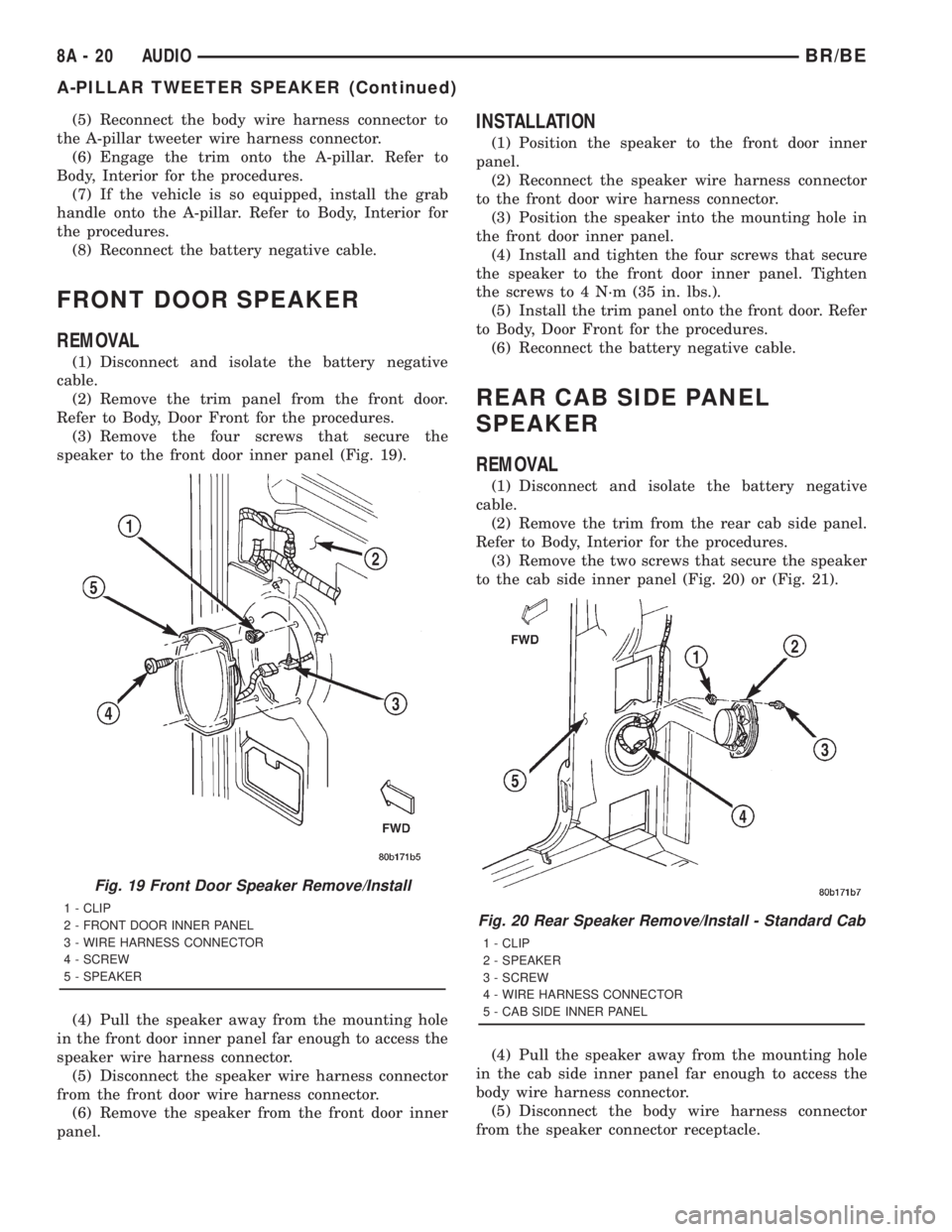

(3) Remove the four screws that secure the

speaker to the front door inner panel (Fig. 19).

(4) Pull the speaker away from the mounting hole

in the front door inner panel far enough to access the

speaker wire harness connector.

(5) Disconnect the speaker wire harness connector

from the front door wire harness connector.

(6) Remove the speaker from the front door inner

panel.

INSTALLATION

(1) Position the speaker to the front door inner

panel.

(2) Reconnect the speaker wire harness connector

to the front door wire harness connector.

(3) Position the speaker into the mounting hole in

the front door inner panel.

(4) Install and tighten the four screws that secure

the speaker to the front door inner panel. Tighten

the screws to 4 N´m (35 in. lbs.).

(5) Install the trim panel onto the front door. Refer

to Body, Door Front for the procedures.

(6) Reconnect the battery negative cable.

REAR CAB SIDE PANEL

SPEAKER

REMOVAL

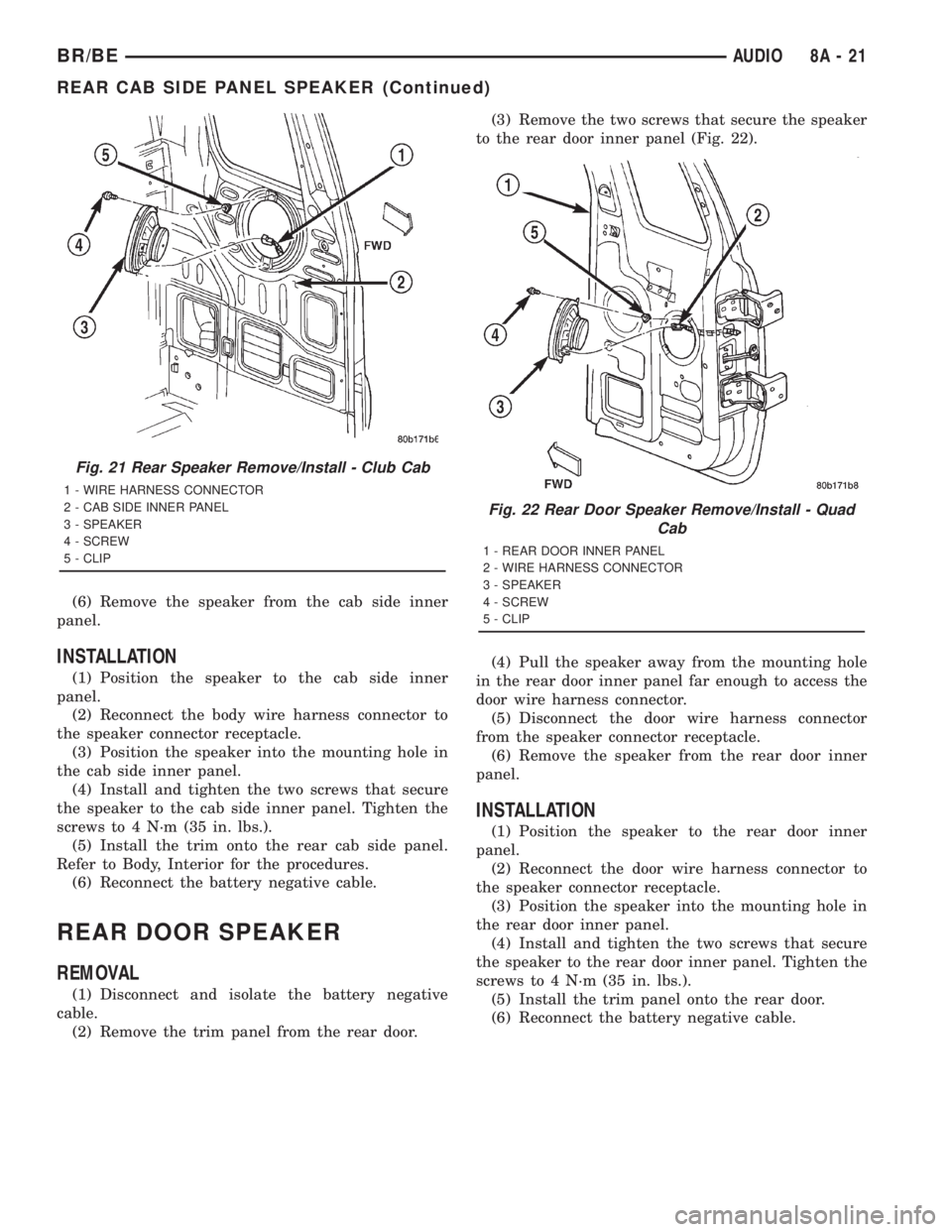

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim from the rear cab side panel.

Refer to Body, Interior for the procedures.

(3) Remove the two screws that secure the speaker

to the cab side inner panel (Fig. 20) or (Fig. 21).

(4) Pull the speaker away from the mounting hole

in the cab side inner panel far enough to access the

body wire harness connector.

(5) Disconnect the body wire harness connector

from the speaker connector receptacle.

Fig. 19 Front Door Speaker Remove/Install

1 - CLIP

2 - FRONT DOOR INNER PANEL

3 - WIRE HARNESS CONNECTOR

4 - SCREW

5 - SPEAKERFig. 20 Rear Speaker Remove/Install - Standard Cab

1 - CLIP

2 - SPEAKER

3 - SCREW

4 - WIRE HARNESS CONNECTOR

5 - CAB SIDE INNER PANEL

8A - 20 AUDIOBR/BE

A-PILLAR TWEETER SPEAKER (Continued)

Page 444 of 2889

(6) Remove the speaker from the cab side inner

panel.

INSTALLATION

(1) Position the speaker to the cab side inner

panel.

(2) Reconnect the body wire harness connector to

the speaker connector receptacle.

(3) Position the speaker into the mounting hole in

the cab side inner panel.

(4) Install and tighten the two screws that secure

the speaker to the cab side inner panel. Tighten the

screws to 4 N´m (35 in. lbs.).

(5) Install the trim onto the rear cab side panel.

Refer to Body, Interior for the procedures.

(6) Reconnect the battery negative cable.

REAR DOOR SPEAKER

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim panel from the rear door.(3) Remove the two screws that secure the speaker

to the rear door inner panel (Fig. 22).

(4) Pull the speaker away from the mounting hole

in the rear door inner panel far enough to access the

door wire harness connector.

(5) Disconnect the door wire harness connector

from the speaker connector receptacle.

(6) Remove the speaker from the rear door inner

panel.

INSTALLATION

(1) Position the speaker to the rear door inner

panel.

(2) Reconnect the door wire harness connector to

the speaker connector receptacle.

(3) Position the speaker into the mounting hole in

the rear door inner panel.

(4) Install and tighten the two screws that secure

the speaker to the rear door inner panel. Tighten the

screws to 4 N´m (35 in. lbs.).

(5) Install the trim panel onto the rear door.

(6) Reconnect the battery negative cable.

Fig. 21 Rear Speaker Remove/Install - Club Cab

1 - WIRE HARNESS CONNECTOR

2 - CAB SIDE INNER PANEL

3 - SPEAKER

4 - SCREW

5 - CLIP

Fig. 22 Rear Door Speaker Remove/Install - Quad

Cab

1 - REAR DOOR INNER PANEL

2 - WIRE HARNESS CONNECTOR

3 - SPEAKER

4 - SCREW

5 - CLIP

BR/BEAUDIO 8A - 21

REAR CAB SIDE PANEL SPEAKER (Continued)

Page 487 of 2889

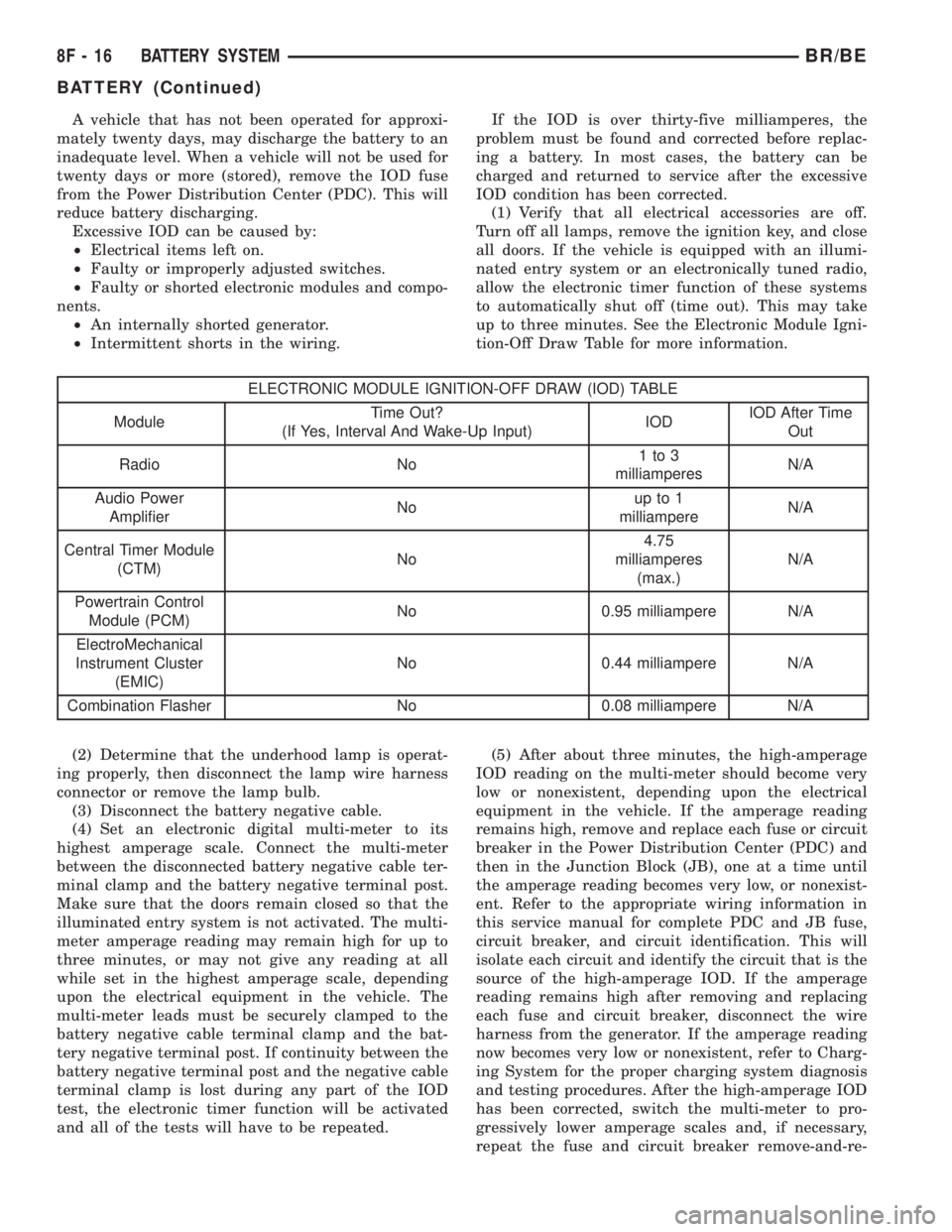

A vehicle that has not been operated for approxi-

mately twenty days, may discharge the battery to an

inadequate level. When a vehicle will not be used for

twenty days or more (stored), remove the IOD fuse

from the Power Distribution Center (PDC). This will

reduce battery discharging.

Excessive IOD can be caused by:

²Electrical items left on.

²Faulty or improperly adjusted switches.

²Faulty or shorted electronic modules and compo-

nents.

²An internally shorted generator.

²Intermittent shorts in the wiring.If the IOD is over thirty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to three minutes. See the Electronic Module Igni-

tion-Off Draw Table for more information.

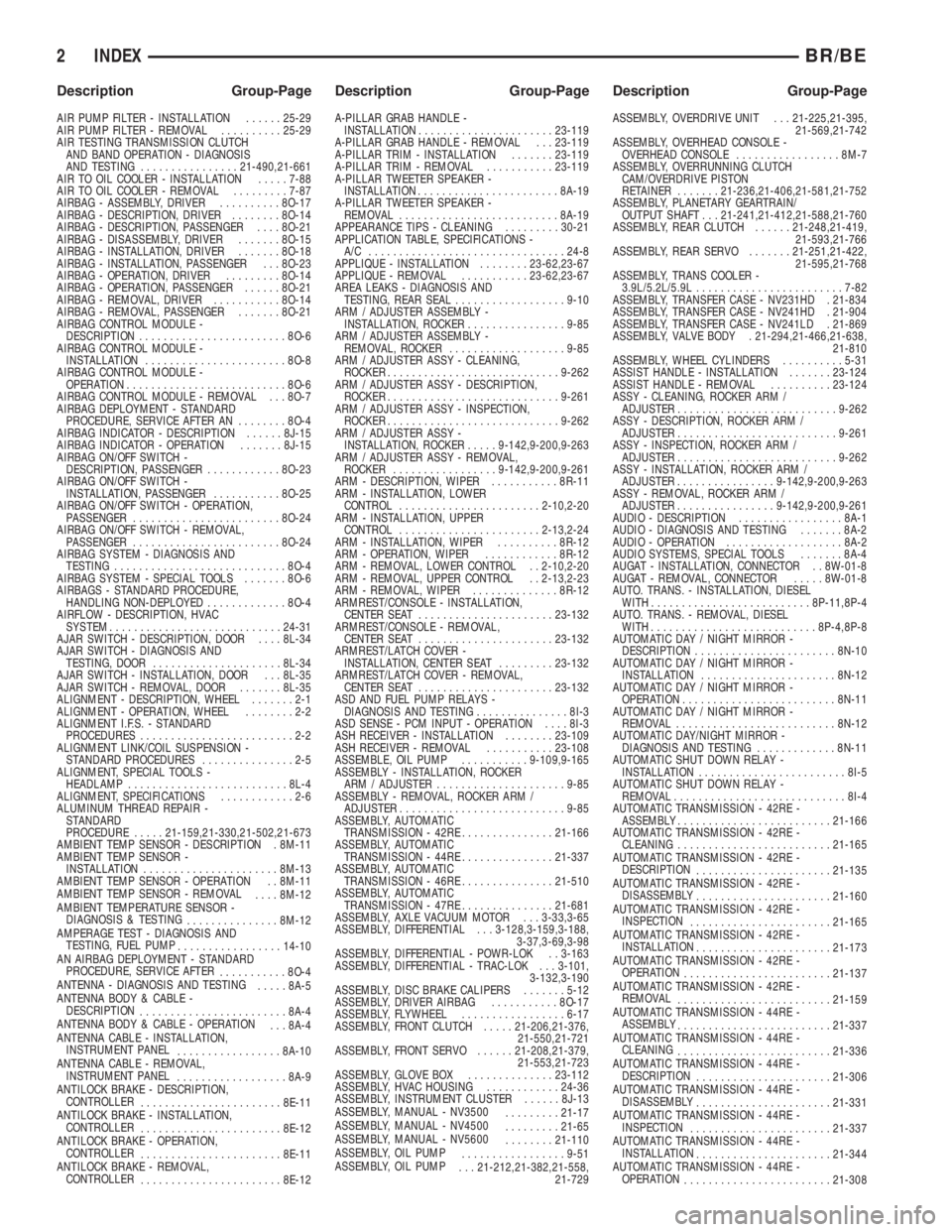

ELECTRONIC MODULE IGNITION-OFF DRAW (IOD) TABLE

ModuleTime Out?

(If Yes, Interval And Wake-Up Input)IODIOD After Time

Out

Radio No1to3

milliamperesN/A

Audio Power

AmplifierNoup to 1

milliampereN/A

Central Timer Module

(CTM)No4.75

milliamperes

(max.)N/A

Powertrain Control

Module (PCM)No 0.95 milliampere N/A

ElectroMechanical

Instrument Cluster

(EMIC)No 0.44 milliampere N/A

Combination Flasher No 0.08 milliampere N/A

(2) Determine that the underhood lamp is operat-

ing properly, then disconnect the lamp wire harness

connector or remove the lamp bulb.

(3) Disconnect the battery negative cable.

(4) Set an electronic digital multi-meter to its

highest amperage scale. Connect the multi-meter

between the disconnected battery negative cable ter-

minal clamp and the battery negative terminal post.

Make sure that the doors remain closed so that the

illuminated entry system is not activated. The multi-

meter amperage reading may remain high for up to

three minutes, or may not give any reading at all

while set in the highest amperage scale, depending

upon the electrical equipment in the vehicle. The

multi-meter leads must be securely clamped to the

battery negative cable terminal clamp and the bat-

tery negative terminal post. If continuity between the

battery negative terminal post and the negative cable

terminal clamp is lost during any part of the IOD

test, the electronic timer function will be activated

and all of the tests will have to be repeated.(5) After about three minutes, the high-amperage

IOD reading on the multi-meter should become very

low or nonexistent, depending upon the electrical

equipment in the vehicle. If the amperage reading

remains high, remove and replace each fuse or circuit

breaker in the Power Distribution Center (PDC) and

then in the Junction Block (JB), one at a time until

the amperage reading becomes very low, or nonexist-

ent. Refer to the appropriate wiring information in

this service manual for complete PDC and JB fuse,

circuit breaker, and circuit identification. This will

isolate each circuit and identify the circuit that is the

source of the high-amperage IOD. If the amperage

reading remains high after removing and replacing

each fuse and circuit breaker, disconnect the wire

harness from the generator. If the amperage reading

now becomes very low or nonexistent, refer to Charg-

ing System for the proper charging system diagnosis

and testing procedures. After the high-amperage IOD

has been corrected, switch the multi-meter to pro-

gressively lower amperage scales and, if necessary,

repeat the fuse and circuit breaker remove-and-re-

8F - 16 BATTERY SYSTEMBR/BE

BATTERY (Continued)

Page 742 of 2889

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

JUNCTION BLOCK.................... 8W-12-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

REAR WHEEL ANTILOCK BRAKES....... 8W-34-1

ALL WHEEL ANTILOCK BRAKES........ 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1INTERIOR LIGHTING.................. 8W-44-1

CENTRAL TIMER MODULE............. 8W-45-1

AUDIO SYSTEM..................... 8W-47-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND LOCATIONS...... 8W-90-1

SPLICE LOCATIONS.................. 8W-95-1

POWER DISTRIBUTION............... 8W-97-1 BR/BEWIRING 8W - 1

Page 940 of 2889

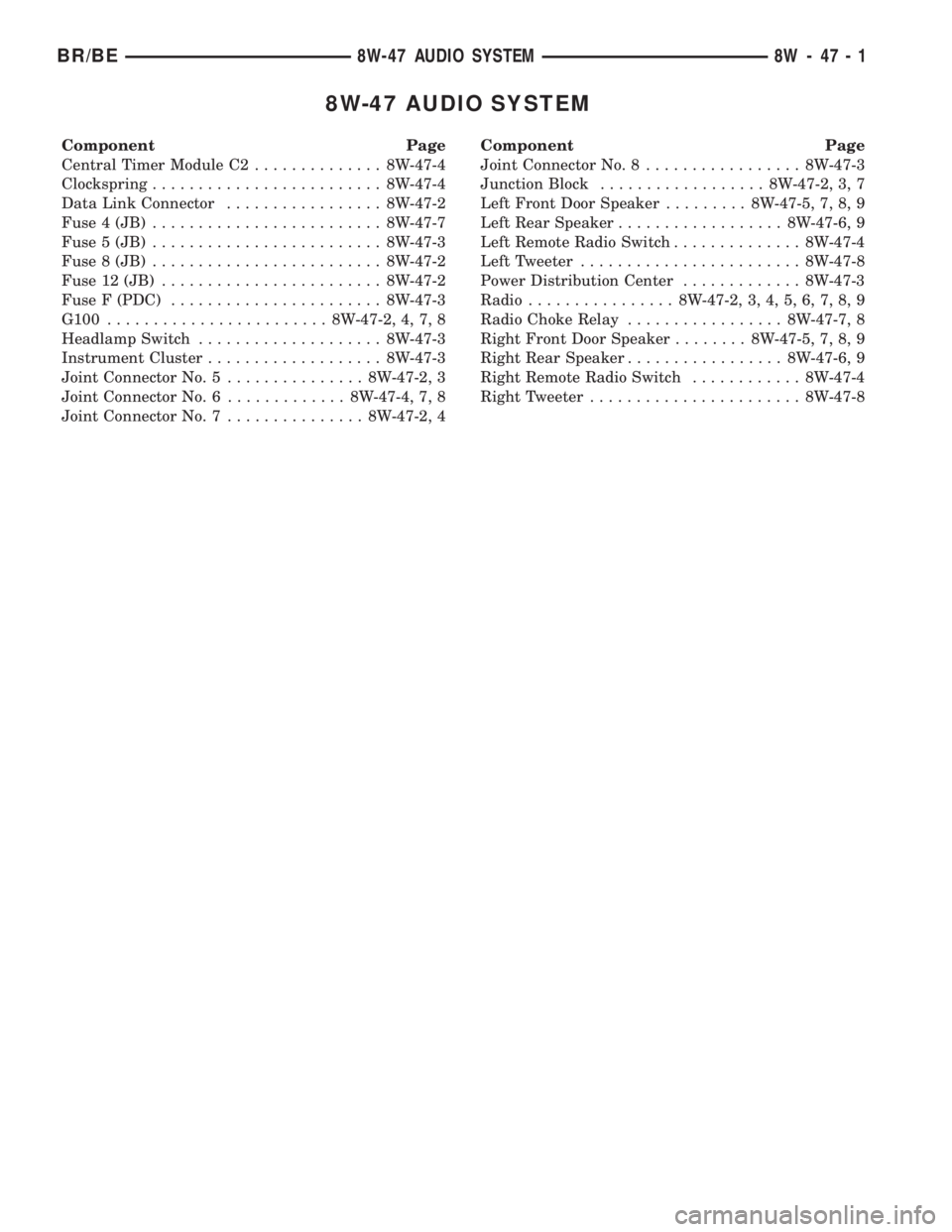

8W-47 AUDIO SYSTEM

Component Page

Central Timer Module C2.............. 8W-47-4

Clockspring......................... 8W-47-4

Data Link Connector................. 8W-47-2

Fuse 4 (JB)......................... 8W-47-7

Fuse 5 (JB)......................... 8W-47-3

Fuse 8 (JB)......................... 8W-47-2

Fuse 12 (JB)........................ 8W-47-2

Fuse F (PDC)....................... 8W-47-3

G100........................ 8W-47-2, 4, 7, 8

Headlamp Switch.................... 8W-47-3

Instrument Cluster................... 8W-47-3

Joint Connector No. 5............... 8W-47-2, 3

Joint Connector No. 6............. 8W-47-4, 7, 8

Joint Connector No. 7............... 8W-47-2, 4Component Page

Joint Connector No. 8................. 8W-47-3

Junction Block.................. 8W-47-2, 3, 7

Left Front Door Speaker......... 8W-47-5, 7, 8, 9

Left Rear Speaker.................. 8W-47-6, 9

Left Remote Radio Switch.............. 8W-47-4

Left Tweeter........................ 8W-47-8

Power Distribution Center............. 8W-47-3

Radio................ 8W-47-2, 3, 4, 5, 6, 7, 8, 9

Radio Choke Relay................. 8W-47-7, 8

Right Front Door Speaker........ 8W-47-5, 7, 8, 9

Right Rear Speaker................. 8W-47-6, 9

Right Remote Radio Switch............ 8W-47-4

Right Tweeter....................... 8W-47-8

BR/BE8W-47 AUDIO SYSTEM 8W - 47 - 1

Page 2678 of 2889

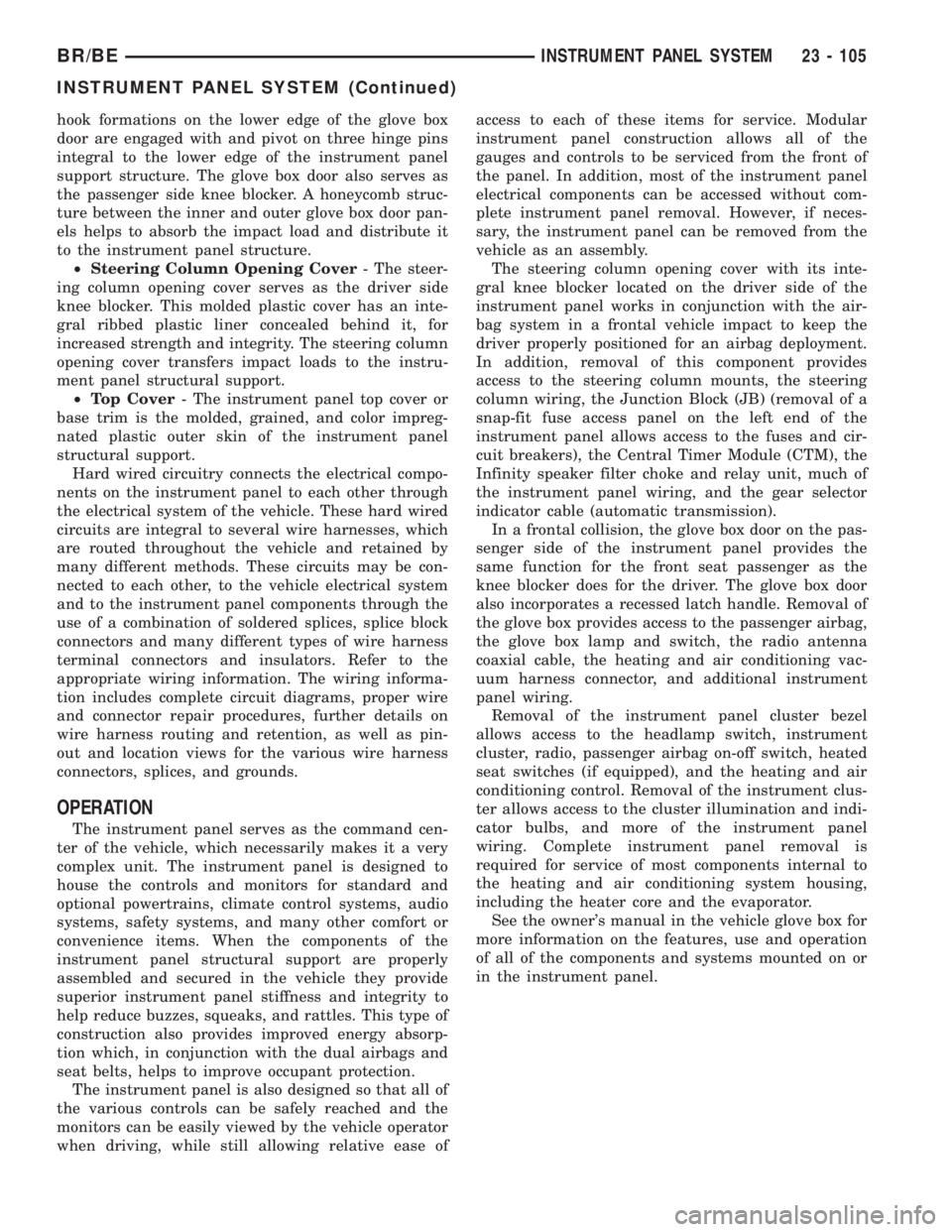

hook formations on the lower edge of the glove box

door are engaged with and pivot on three hinge pins

integral to the lower edge of the instrument panel

support structure. The glove box door also serves as

the passenger side knee blocker. A honeycomb struc-

ture between the inner and outer glove box door pan-

els helps to absorb the impact load and distribute it

to the instrument panel structure.

²Steering Column Opening Cover- The steer-

ing column opening cover serves as the driver side

knee blocker. This molded plastic cover has an inte-

gral ribbed plastic liner concealed behind it, for

increased strength and integrity. The steering column

opening cover transfers impact loads to the instru-

ment panel structural support.

²Top Cover- The instrument panel top cover or

base trim is the molded, grained, and color impreg-

nated plastic outer skin of the instrument panel

structural support.

Hard wired circuitry connects the electrical compo-

nents on the instrument panel to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the instrument panel components through the

use of a combination of soldered splices, splice block

connectors and many different types of wire harness

terminal connectors and insulators. Refer to the

appropriate wiring information. The wiring informa-

tion includes complete circuit diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices, and grounds.

OPERATION

The instrument panel serves as the command cen-

ter of the vehicle, which necessarily makes it a very

complex unit. The instrument panel is designed to

house the controls and monitors for standard and

optional powertrains, climate control systems, audio

systems, safety systems, and many other comfort or

convenience items. When the components of the

instrument panel structural support are properly

assembled and secured in the vehicle they provide

superior instrument panel stiffness and integrity to

help reduce buzzes, squeaks, and rattles. This type of

construction also provides improved energy absorp-

tion which, in conjunction with the dual airbags and

seat belts, helps to improve occupant protection.

The instrument panel is also designed so that all of

the various controls can be safely reached and the

monitors can be easily viewed by the vehicle operator

when driving, while still allowing relative ease ofaccess to each of these items for service. Modular

instrument panel construction allows all of the

gauges and controls to be serviced from the front of

the panel. In addition, most of the instrument panel

electrical components can be accessed without com-

plete instrument panel removal. However, if neces-

sary, the instrument panel can be removed from the

vehicle as an assembly.

The steering column opening cover with its inte-

gral knee blocker located on the driver side of the

instrument panel works in conjunction with the air-

bag system in a frontal vehicle impact to keep the

driver properly positioned for an airbag deployment.

In addition, removal of this component provides

access to the steering column mounts, the steering

column wiring, the Junction Block (JB) (removal of a

snap-fit fuse access panel on the left end of the

instrument panel allows access to the fuses and cir-

cuit breakers), the Central Timer Module (CTM), the

Infinity speaker filter choke and relay unit, much of

the instrument panel wiring, and the gear selector

indicator cable (automatic transmission).

In a frontal collision, the glove box door on the pas-

senger side of the instrument panel provides the

same function for the front seat passenger as the

knee blocker does for the driver. The glove box door

also incorporates a recessed latch handle. Removal of

the glove box provides access to the passenger airbag,

the glove box lamp and switch, the radio antenna

coaxial cable, the heating and air conditioning vac-

uum harness connector, and additional instrument

panel wiring.

Removal of the instrument panel cluster bezel

allows access to the headlamp switch, instrument

cluster, radio, passenger airbag on-off switch, heated

seat switches (if equipped), and the heating and air

conditioning control. Removal of the instrument clus-

ter allows access to the cluster illumination and indi-

cator bulbs, and more of the instrument panel

wiring. Complete instrument panel removal is

required for service of most components internal to

the heating and air conditioning system housing,

including the heater core and the evaporator.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the components and systems mounted on or

in the instrument panel.

BR/BEINSTRUMENT PANEL SYSTEM 23 - 105

INSTRUMENT PANEL SYSTEM (Continued)

Page 2849 of 2889

AIR PUMP FILTER - INSTALLATION......25-29

AIR PUMP FILTER - REMOVAL..........25-29

AIR TESTING TRANSMISSION CLUTCH

AND BAND OPERATION - DIAGNOSIS

AND TESTING................21-490,21-661

AIR TO OIL COOLER - INSTALLATION.....7-88

AIR TO OIL COOLER - REMOVAL.........7-87

AIRBAG - ASSEMBLY, DRIVER..........8O-17

AIRBAG - DESCRIPTION, DRIVER........8O-14

AIRBAG - DESCRIPTION, PASSENGER....8O-21

AIRBAG - DISASSEMBLY, DRIVER.......8O-15

AIRBAG - INSTALLATION, DRIVER.......8O-18

AIRBAG - INSTALLATION, PASSENGER . . . 8O-23

AIRBAG - OPERATION, DRIVER.........8O-14

AIRBAG - OPERATION, PASSENGER......8O-21

AIRBAG - REMOVAL, DRIVER...........8O-14

AIRBAG - REMOVAL, PASSENGER.......8O-21

AIRBAG CONTROL MODULE -

DESCRIPTION........................8O-6

AIRBAG CONTROL MODULE -

INSTALLATION.......................8O-8

AIRBAG CONTROL MODULE -

OPERATION..........................8O-6

AIRBAG CONTROL MODULE - REMOVAL . . . 8O-7

AIRBAG DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER AN........8O-4

AIRBAG INDICATOR - DESCRIPTION......8J-15

AIRBAG INDICATOR - OPERATION.......8J-15

AIRBAG ON/OFF SWITCH -

DESCRIPTION, PASSENGER............8O-23

AIRBAG ON/OFF SWITCH -

INSTALLATION, PASSENGER...........8O-25

AIRBAG ON/OFF SWITCH - OPERATION,

PASSENGER........................8O-24

AIRBAG ON/OFF SWITCH - REMOVAL,

PASSENGER........................8O-24

AIRBAG SYSTEM - DIAGNOSIS AND

TESTING............................8O-4

AIRBAG SYSTEM - SPECIAL TOOLS.......8O-6

AIRBAGS - STANDARD PROCEDURE,

HANDLING NON-DEPLOYED.............8O-4

AIRFLOW - DESCRIPTION, HVAC

SYSTEM............................24-31

AJAR SWITCH - DESCRIPTION, DOOR....8L-34

AJAR SWITCH - DIAGNOSIS AND

TESTING, DOOR.....................8L-34

AJAR SWITCH - INSTALLATION, DOOR . . . 8L-35

AJAR SWITCH - REMOVAL, DOOR.......8L-35

ALIGNMENT - DESCRIPTION, WHEEL.......2-1

ALIGNMENT - OPERATION, WHEEL........2-2

ALIGNMENT I.F.S. - STANDARD

PROCEDURES.........................2-2

ALIGNMENT LINK/COIL SUSPENSION -

STANDARD PROCEDURES...............2-5

ALIGNMENT, SPECIAL TOOLS -

HEADLAMP..........................8L-4

ALIGNMENT, SPECIFICATIONS............2-6

ALUMINUM THREAD REPAIR -

STANDARD

PROCEDURE.....21-159,21-330,21-502,21-673

AMBIENT TEMP SENSOR - DESCRIPTION . 8M-11

AMBIENT TEMP SENSOR -

INSTALLATION......................8M-13

AMBIENT TEMP SENSOR - OPERATION . . 8M-11

AMBIENT TEMP SENSOR - REMOVAL

....8M-12

AMBIENT TEMPERATURE SENSOR -

DIAGNOSIS & TESTING

...............8M-12

AMPERAGE TEST - DIAGNOSIS AND

TESTING, FUEL PUMP

.................14-10

AN AIRBAG DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER

...........8O-4

ANTENNA - DIAGNOSIS AND TESTING

.....8A-5

ANTENNA BODY & CABLE -

DESCRIPTION

........................8A-4

ANTENNA BODY & CABLE - OPERATION

. . . 8A-4

ANTENNA CABLE - INSTALLATION,

INSTRUMENT PANEL

.................8A-10

ANTENNA CABLE - REMOVAL,

INSTRUMENT PANEL

..................8A-9

ANTILOCK BRAKE - DESCRIPTION,

CONTROLLER

.......................8E-11

ANTILOCK BRAKE - INSTALLATION,

CONTROLLER

.......................8E-12

ANTILOCK BRAKE - OPERATION,

CONTROLLER

.......................8E-11

ANTILOCK BRAKE - REMOVAL,

CONTROLLER

.......................8E-12A-PILLAR GRAB HANDLE -

INSTALLATION......................23-119

A-PILLAR GRAB HANDLE - REMOVAL . . . 23-119

A-PILLAR TRIM - INSTALLATION.......23-119

A-PILLAR TRIM - REMOVAL...........23-119

A-PILLAR TWEETER SPEAKER -

INSTALLATION.......................8A-19

A-PILLAR TWEETER SPEAKER -

REMOVAL..........................8A-19

APPEARANCE TIPS - CLEANING.........30-21

APPLICATION TABLE, SPECIFICATIONS -

A/C ................................24-8

APPLIQUE - INSTALLATION........23-62,23-67

APPLIQUE - REMOVAL...........23-62,23-67

AREA LEAKS - DIAGNOSIS AND

TESTING, REAR SEAL..................9-10

ARM / ADJUSTER ASSEMBLY -

INSTALLATION, ROCKER................9-85

ARM / ADJUSTER ASSEMBLY -

REMOVAL, ROCKER...................9-85

ARM / ADJUSTER ASSY - CLEANING,

ROCKER............................9-262

ARM / ADJUSTER ASSY - DESCRIPTION,

ROCKER............................9-261

ARM / ADJUSTER ASSY - INSPECTION,

ROCKER............................9-262

ARM / ADJUSTER ASSY -

INSTALLATION, ROCKER.....9-142,9-200,9-263

ARM / ADJUSTER ASSY - REMOVAL,

ROCKER.................9-142,9-200,9-261

ARM - DESCRIPTION, WIPER...........8R-11

ARM - INSTALLATION, LOWER

CONTROL.......................2-10,2-20

ARM - INSTALLATION, UPPER

CONTROL.......................2-13,2-24

ARM - INSTALLATION, WIPER..........8R-12

ARM - OPERATION, WIPER............8R-12

ARM - REMOVAL, LOWER CONTROL . . 2-10,2-20

ARM - REMOVAL, UPPER CONTROL . . 2-13,2-23

ARM - REMOVAL, WIPER..............8R-12

ARMREST/CONSOLE - INSTALLATION,

CENTER SEAT......................23-132

ARMREST/CONSOLE - REMOVAL,

CENTER SEAT......................23-132

ARMREST/LATCH COVER -

INSTALLATION, CENTER SEAT.........23-132

ARMREST/LATCH COVER - REMOVAL,

CENTER SEAT......................23-132

ASD AND FUEL PUMP RELAYS -

DIAGNOSIS AND TESTING...............8I-3

ASD SENSE - PCM INPUT - OPERATION....8I-3

ASH RECEIVER - INSTALLATION........23-109

ASH RECEIVER - REMOVAL...........23-108

ASSEMBLE, OIL PUMP...........9-109,9-165

ASSEMBLY - INSTALLATION, ROCKER

ARM / ADJUSTER.....................9-85

ASSEMBLY - REMOVAL, ROCKER ARM /

ADJUSTER...........................9-85

ASSEMBLY, AUTOMATIC

TRANSMISSION - 42RE...............21-166

ASSEMBLY, AUTOMATIC

TRANSMISSION - 44RE...............21-337

ASSEMBLY, AUTOMATIC

TRANSMISSION - 46RE...............21-510

ASSEMBLY, AUTOMATIC

TRANSMISSION - 47RE...............21-681

ASSEMBLY, AXLE VACUUM MOTOR . . . 3-33,3-65

ASSEMBLY, DIFFERENTIAL . . . 3-128,3-159,3-188,

3-37,3-69,3-98

ASSEMBLY, DIFFERENTIAL - POWR-LOK . . 3-163

ASSEMBLY, DIFFERENTIAL - TRAC-LOK . . . 3-101,

3-132,3-190

ASSEMBLY, DISC BRAKE CALIPERS.......5-12

ASSEMBLY, DRIVER AIRBAG...........8O-17

ASSEMBLY, FLYWHEEL.................6-17

ASSEMBLY, FRONT CLUTCH.....21-206,21-376,

21-550,21-721

ASSEMBLY, FRONT SERVO......21-208,21-379,

21-553,21-723

ASSEMBLY, GLOVE BOX..............23-112

ASSEMBLY, HVAC HOUSING............24-36

ASSEMBLY, INSTRUMENT CLUSTER......8J-13

ASSEMBLY, MANUAL - NV3500

.........21-17

ASSEMBLY, MANUAL - NV4500

.........21-65

ASSEMBLY, MANUAL - NV5600

........21-110

ASSEMBLY, OIL PUMP

.................9-51

ASSEMBLY, OIL PUMP

. . . 21-212,21-382,21-558,

21-729ASSEMBLY, OVERDRIVE UNIT . . . 21-225,21-395,

21-569,21-742

ASSEMBLY, OVERHEAD CONSOLE -

OVERHEAD CONSOLE.................8M-7

ASSEMBLY, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER.......21-236,21-406,21-581,21-752

ASSEMBLY, PLANETARY GEARTRAIN/

OUTPUT SHAFT . . . 21-241,21-412,21-588,21-760

ASSEMBLY, REAR CLUTCH......21-248,21-419,

21-593,21-766

ASSEMBLY, REAR SERVO.......21-251,21-422,

21-595,21-768

ASSEMBLY, TRANS COOLER -

3.9L/5.2L/5.9L........................7-82

ASSEMBLY, TRANSFER CASE - NV231HD . 21-834

ASSEMBLY, TRANSFER CASE - NV241HD . 21-904

ASSEMBLY, TRANSFER CASE - NV241LD . 21-869

ASSEMBLY, VALVE BODY . 21-294,21-466,21-638,

21-810

ASSEMBLY, WHEEL CYLINDERS..........5-31

ASSIST HANDLE - INSTALLATION.......23-124

ASSIST HANDLE - REMOVAL..........23-124

ASSY - CLEANING, ROCKER ARM /

ADJUSTER..........................9-262

ASSY - DESCRIPTION, ROCKER ARM /

ADJUSTER..........................9-261

ASSY - INSPECTION, ROCKER ARM /

ADJUSTER..........................9-262

ASSY - INSTALLATION, ROCKER ARM /

ADJUSTER................9-142,9-200,9-263

ASSY - REMOVAL, ROCKER ARM /

ADJUSTER................9-142,9-200,9-261

AUDIO - DESCRIPTION.................8A-1

AUDIO - DIAGNOSIS AND TESTING.......8A-2

AUDIO - OPERATION...................8A-2

AUDIO SYSTEMS, SPECIAL TOOLS.......8A-4

AUGAT - INSTALLATION, CONNECTOR . . 8W-01-8

AUGAT - REMOVAL, CONNECTOR.....8W-01-8

AUTO. TRANS. - INSTALLATION, DIESEL

WITH..........................8P-11,8P-4

AUTO. TRANS. - REMOVAL, DIESEL

WITH...........................8P-4,8P-8

AUTOMATIC DAY / NIGHT MIRROR -

DESCRIPTION.......................8N-10

AUTOMATIC DAY / NIGHT MIRROR -

INSTALLATION......................8N-12

AUTOMATIC DAY / NIGHT MIRROR -

OPERATION.........................8N-11

AUTOMATIC DAY / NIGHT MIRROR -

REMOVAL..........................8N-12

AUTOMATIC DAY/NIGHT MIRROR -

DIAGNOSIS AND TESTING.............8N-11

AUTOMATIC SHUT DOWN RELAY -

INSTALLATION........................8I-5

AUTOMATIC SHUT DOWN RELAY -

REMOVAL............................8I-4

AUTOMATIC TRANSMISSION - 42RE -

ASSEMBLY.........................21-166

AUTOMATIC TRANSMISSION - 42RE -

CLEANING.........................21-165

AUTOMATIC TRANSMISSION - 42RE -

DESCRIPTION

......................21-135

AUTOMATIC TRANSMISSION - 42RE -

DISASSEMBLY

......................21-160

AUTOMATIC TRANSMISSION - 42RE -

INSPECTION

.......................21-165

AUTOMATIC TRANSMISSION - 42RE -

INSTALLATION

......................21-173

AUTOMATIC TRANSMISSION - 42RE -

OPERATION

........................21-137

AUTOMATIC TRANSMISSION - 42RE -

REMOVAL

.........................21-159

AUTOMATIC TRANSMISSION - 44RE -

ASSEMBLY

.........................21-337

AUTOMATIC TRANSMISSION - 44RE -

CLEANING

.........................21-336

AUTOMATIC TRANSMISSION - 44RE -

DESCRIPTION

......................21-306

AUTOMATIC TRANSMISSION - 44RE -

DISASSEMBLY

......................21-331

AUTOMATIC TRANSMISSION - 44RE -

INSPECTION

.......................21-337

AUTOMATIC TRANSMISSION - 44RE -

INSTALLATION

......................21-344

AUTOMATIC TRANSMISSION - 44RE -

OPERATION

........................21-308

2 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2879 of 2889

SHIFT LEVER - INSTALLATION . . . 21-853,21-888,

21-924

SHIFT LEVER - INSTALLATION, GEAR.....19-13

SHIFT LEVER - REMOVAL . 21-852,21-887,21-924

SHIFT LEVER - REMOVAL, GEAR........19-13

SHIFT MECHANISM - ADJUSTMENT....21-252,

21-423,21-596,21-769

SHIFT MECHANISM - DESCRIPTION....21-251,

21-422,21-595,21-768

SHIFT MECHANISM - INSTALLATION.....21-89

SHIFT MECHANISM - OPERATION......21-251,

21-422,21-595,21-768

SHIFT MECHANISM - REMOVAL.........21-88

SHIFT/CLUTCH INTERLOCK SYSTEM -

INSPECTION........................30-19

SHIPPED LOOSE ITEMS - INSTALLATION . . 30-14

SHOCK - DESCRIPTION........2-11,2-21,2-28

SHOCK - DIAGNOSIS AND TESTING . . . 2-11,2-21

SHOCK - DIAGNOSIS AND TESTING,

SPRING.............................2-26

SHOCK - INSTALLATION........2-11,2-21,2-28

SHOCK - OPERATION..........2-11,2-21,2-28

SHOCK - REMOVAL............2-11,2-21,2-28

SHOES - 2500/3500 - INSTALLATION,

REAR DRUM IN HAT PARK BRAKE........5-42

SHOES - 2500/3500 - REMOVAL, REAR

DRUM IN HAT PARK BRAKE.............5-41

SHOES-11 INCH - INSTALLATION, REAR

BRAKE..............................5-27

SHOES-11 INCH - REMOVAL, REAR

BRAKE..............................5-25

SHORT TO GROUND - STANDARD

PROCEDURE, TESTING FOR A........8W-01-6

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING....8W-01-7

SHOULDER BELTS, RETRACTORS AND

HEAD RESTRAINTS - INSPECTION,

SEAT BELTS.........................30-12

SHUT DOWN RELAY - INSTALLATION,

AUTOMATIC..........................8I-5

SHUT DOWN RELAY - REMOVAL,

AUTOMATIC..........................8I-4

SHUTFACE HANDLE - INSTALLATION.....23-83

SHUTFACE HANDLE - REMOVAL.........23-83

SIDE MOLDINGS - INSTALLATION, BODY . . 23-87

SIDE MOLDINGS - REMOVAL, BODY.....23-87

SIDE PANEL SPEAKER - INSTALLATION,

REAR CAB..........................8A-21

SIDE PANEL SPEAKER - REMOVAL,

REAR CAB..........................8A-20

SIDE VIEW MIRROR - INSTALLATION.....23-97

SIDE VIEW MIRROR - LOW MOUNTED -

INSTALLATION.......................23-98

SIDE VIEW MIRROR - LOW MOUNTED -

REMOVAL..........................23-98

SIDE VIEW MIRROR - REMOVAL........23-97

SIDE VIEW MIRROR FLAG -

INSTALLATION.......................23-74

SIDE VIEW MIRROR FLAG - REMOVAL . . . 23-74

SIDE VIEW MIRROR GLASS -

INSTALLATION.......................23-98

SIDE VIEW MIRROR GLASS - REMOVAL . . 23-98

SIDEVIEW MIRROR - DESCRIPTION......8N-13

SIDEVIEW MIRROR - DIAGNOSIS AND

TESTING...........................8N-13

SIDEVIEW MIRROR - OPERATION.......8N-13

SIDEVIEW MIRROR - REMOVAL.........8N-14

SIGNAL & HAZARD WARNING SYSTEM -

DESCRIPTION, TURN..................8L-2

SIGNAL & HAZARD WARNING SYSTEM -

DIAGNOSIS AND TESTING, TURN.........8L-3

SIGNAL & HAZARD WARNING SYSTEM -

OPERATION, TURN....................8L-2

SIGNAL CANCEL CAM - DESCRIPTION,

TURN..............................8L-30

SIGNAL CANCEL CAM - OPERATION,

TURN..............................8L-31

SIGNAL GROUND - DESCRIPTION.......8E-17

SIGNAL INDICATORS - DESCRIPTION,

TURN

..............................8J-32

SIGNAL INDICATORS - DIAGNOSIS AND

TESTING, TURN

......................8J-32

SIGNAL INDICATORS - OPERATION,

TURN

..............................8J-32

SIGNAL LAMP - INSTALLATION,

PARK/TURN

.........................8L-29

SIGNAL LAMP - REMOVAL, PARK/TURN

. . 8L-29SIGNAL LAMP UNIT - INSTALLATION,

PARK/TURN.........................8L-29

SIGNAL LAMP UNIT - REMOVAL,

PARK/TURN.........................8L-29

SIGNALS - INSPECTION, TURN AND

EMERGENCY........................30-19

SILENCER PAD - INSTALLATION........23-103

SILENCER PAD - REMOVAL...........23-103

SILL TRIM - INSTALLATION, DOOR.....23-121

SILL TRIM - REMOVAL, DOOR.........23-121

SINGLE CARDAN UNIVERSAL JOINTS -

DISASSEMBLY........................3-11

SINGLE CARDAN UNIVERSAL JOINTS -

INSTALLATION....................3-34,3-66

SINGLE CARDAN UNIVERSAL JOINTS -

REMOVAL.......................3-33,3-65

SKID PLATE - INSTALLATION, TRANSFER

CASE..............................13-11

SKID PLATE - REMOVAL, TRANSFER

CASE..............................13-11

SLAM BUMPER - INSTALLATION........23-66

SLAM BUMPER - REMOVAL............23-66

SMOKE DIAGNOSIS CHARTS -

DIAGNOSIS AND TESTING.............9-234

SOLENOID - DESCRIPTION.....21-252,21-423,

21-596,21-769

SOLENOID - DESCRIPTION, EVAP/PURGE . 25-32

SOLENOID - INSTALLATION, EVAP/

PURGE.............................25-32

SOLENOID - OPERATION . 21-253,21-424,21-597,

21-770

SOLENOID - REMOVAL, EVAP/PURGE.....25-32

SOLID LIFTERS/TAPPETS - CLEANING....9-281

SOLID LIFTERS/TAPPETS - INSPECTION . . 9-281

SOLID LIFTERS/TAPPETS -

INSTALLATION.......................9-281

SOLID LIFTERS/TAPPETS - REMOVAL....9-280

SPARE TIRE - DESCRIPTION.............22-9

SPARE TIRE WINCH - INSTALLATION.....13-10

SPARE TIRE WINCH - REMOVAL........13-10

SPARK PLUG - CLEANING..............8I-19

SPARK PLUG - DESCRIPTION...........8I-16

SPARK PLUG - INSTALLATION...........8I-19

SPARK PLUG - OPERATION.............8I-16

SPARK PLUG - REMOVAL..............8I-18

SPARK PLUG CABLE - DESCRIPTION.....8I-19

SPARK PLUG CABLE - INSTALLATION.....8I-20

SPARK PLUG CABLE - OPERATION.......8I-19

SPARK PLUG CABLE - REMOVAL........8I-20

SPARK PLUG CABLE ORDER, 8.0L V-10

ENGINE..............................8I-2

SPARK PLUG CABLE RESISTANCE,

SPECIFICATIONS......................8I-3

SPARK PLUG CABLES - DIAGNOSIS AND

TESTING............................8I-19

SPARK PLUG CONDITIONS - DIAGNOSIS

AND TESTING........................8I-16

SPARK PLUGS, SPECIFICATIONS..........8I-3

SPEAKER - DESCRIPTION..............8A-17

SPEAKER - DIAGNOSIS AND TESTING....8A-18

SPEAKER - INSTALLATION, A-PILLAR

TWEETER..........................8A-19

SPEAKER - INSTALLATION, FRONT DOOR . 8A-20

SPEAKER - INSTALLATION, REAR CAB

SIDE PANEL........................8A-21

SPEAKER - INSTALLATION, REAR DOOR . . 8A-21

SPEAKER - OPERATION...............8A-17

SPEAKER - REMOVAL, A-PILLAR

TWEETER..........................8A-19

SPEAKER - REMOVAL, FRONT DOOR.....8A-20

SPEAKER - REMOVAL, REAR CAB SIDE

PANEL.............................8A-20

SPEAKER - REMOVAL, REAR DOOR......8A-21

SPECIAL TOOLS - 5.2L ENGINE..........9-77

SPECIAL TOOLS - 5.9L DIESEL ENGINE . . . 9-244

SPECIAL TOOLS - 5.9L ENGINE.........9-134

SPECIAL TOOLS - 8.0L ENGINE.........9-188

SPECIAL TOOLS - AUDIO SYSTEMS.......8A-4

SPECIAL TOOLS - BASE BRAKES..........5-4

SPECIAL TOOLS - COOLING.............7-18

SPECIAL TOOLS - DIESEL FUEL SYSTEM . . 14-59

SPECIAL TOOLS - FRONT AXLE

..........3-58

SPECIAL TOOLS - FRONT AXLES

.........3-25

SPECIAL TOOLS - FUEL SYSTEM

....14-36,14-4

SPECIAL TOOLS - HEADLAMP

ALIGNMENT

..........................8L-4

SPECIAL TOOLS - INDEPENDENT FRONT

SUSPENSION

..........................2-9SPECIAL TOOLS - LINK/COIL

SUSPENSION.........................2-16

SPECIAL TOOLS - NV5600 MANUAL

TRANSMISSION.....................21-127

SPECIAL TOOLS - OVERHEAD CONSOLE

SYSTEMS...........................8M-8

SPECIAL TOOLS - POWER

DISTRIBUTION SYSTEMS............8W-97-2

SPECIAL TOOLS - POWER STEERING

GEAR..............................19-20

SPECIAL TOOLS - POWER STEERING

PUMP.............................19-36

SPECIAL TOOLS - PROPELLER SHAFT......3-8

SPECIAL TOOLS - RE TRANSMISSION . . 21-534,

21-704

SPECIAL TOOLS - RE TRANSMISSIONS . 21-188,

21-359

SPECIAL TOOLS - STEERING LINKAGE . . . 19-39,

19-42

SPECIAL TOOLS - SUSPENSION-REAR.....2-28

SPECIAL TOOLS, AIRBAG SYSTEM.......8O-6

SPECIAL TOOLS, WIRING/TERMINAL . . . 8W-01-8

SPECIFICATIONS - 2001 BR PAINT

COLOR CODES.....................23-129

SPECIFICATIONS - 3.9L ENGINE..........9-14

SPECIFICATIONS - 5.2L ENGINE..........9-72

SPECIFICATIONS - 5.9L DIESEL.........9-242

SPECIFICATIONS - 5.9L ENGINE.........9-129

SPECIFICATIONS - 8.OL ENGINE.........9-184

SPECIFICATIONS - A/C APPLICATION

TABLE................................24-8

SPECIFICATIONS - ALIGNMENT...........2-6

SPECIFICATIONS - BASE BRAKE...........5-2

SPECIFICATIONS - BATTERY.............8F-6

SPECIFICATIONS - BODY GAP AND

FLUSH MEASUREMENTS...............23-56

SPECIFICATIONS - BODY OPENING

DIMENSIONS........................23-60

SPECIFICATIONS - BODY SEALER

LOCATIONS.........................23-47

SPECIFICATIONS - BRAKE FLUID.........5-15

SPECIFICATIONS - FLUID CAPACITIES......0-6

SPECIFICATIONS - FRAME DIMENSION....13-7

SPECIFICATIONS - FUEL INJECTION

PUMP DATA PLATE...................14-73

SPECIFICATIONS - GENERATOR RATINGS . . 8F-28

SPECIFICATIONS - IGNITION TIMING......8I-3

SPECIFICATIONS - POWER STEERING

GEAR..............................19-19

SPECIFICATIONS - PROPELLER SHAFT......3-8

SPECIFICATIONS - SPARK PLUG CABLE

RESISTANCE..........................8I-3

SPECIFICATIONS - SPARK PLUGS.........8I-3

SPECIFICATIONS - SPECIFICATIONS......24-46

SPECIFICATIONS - SPECIFICATIONS.....21-357

SPECIFICATIONS - STARTING SYSTEM....8F-38

SPECIFICATIONS - STRUCTURAL

ADHESIVE LOCATIONS................23-44

SPECIFICATIONS - TIRE REVOLUTIONS

PER MILE...........................22-9

SPECIFICATIONS - TORQUE.............7-17

SPECIFICATIONS - TORQUE . . . 9-133,9-18,9-187,

9-243,9-76

SPECIFICATIONS - TORQUE.............11-5

SPECIFICATIONS - TORQUE CHART........5-3

SPECIFICATIONS - TORQUE CHART . 19-19,19-39,

19-41,19-9

SPECIFICATIONS - TORQUE CHART . . . 2-15,2-27,

2-8

SPECIFICATIONS - TORQUE CHART......22-11

SPECIFICATIONS - TORQUE

SPECIFICATIONS.....................23-61

SPECIFICATIONS - TORQUE

SPECIFICATIONS......................13-9

SPECIFICATIONS - TORQUE

SPECIFICATIONS......................24-8

SPECIFICATIONS - TRANSFER CASE....21-848,

21-883,21-919

SPECIFICATIONS - TRANSMISSION.....21-186,

21-532,21-702

SPECIFICATIONS - WELD LOCATIONS.....23-4

SPECIFICATIONS, CLUTCH...............6-7

SPECIFICATIONS, FUEL SYSTEM

PRESSURE - GAS ENGINES

.............14-4

SPECIFICATIONS, NV4500

..............21-83

SPECIFICATIONS, NV5600

.............21-126

SPECIFICATIONS, SPECIFICATIONS

.......24-46

SPECIFICATIONS, SPECIFICATIONS

......21-357

32 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2881 of 2889

SWITCH - DESCRIPTION, KEY-IN

IGNITION............................19-9

SWITCH - DESCRIPTION, LUMBAR

CONTROL..........................8N-17

SWITCH - DESCRIPTION, MIRROR........8G-3

SWITCH - DESCRIPTION, MULTI-

FUNCTION..........................8L-23

SWITCH - DESCRIPTION, OVERDRIVE . . . 21-385,

21-578,21-732

SWITCH - DESCRIPTION, OVERDRIVE

OFF ..............................21-215

SWITCH - DESCRIPTION, PASSENGER

AIRBAG ON/OFF.....................8O-23

SWITCH - DESCRIPTION, PASSENGER

POWER SEAT.......................8N-19

SWITCH - DESCRIPTION, PASSENGER

SEAT HEATER .......................8G-13

SWITCH - DESCRIPTION, POWER LOCK . . . 8N-8

SWITCH - DESCRIPTION, POWER

MIRROR...........................8N-12

SWITCH - DESCRIPTION, POWER

WINDOW...........................8N-24

SWITCH - DESCRIPTION, PTO..........14-48

SWITCH - DESCRIPTION, SEAT BELT.....8O-28

SWITCH - DESCRIPTION, WASHER

FLUID LEVEL.........................8R-7

SWITCH - DIAGNOSIS & TESTING, DOOR

CYLINDER LOCK......................8N-5

SWITCH - DIAGNOSIS & TESTING,

DRIVER POWER SEAT................8N-16

SWITCH - DIAGNOSIS & TESTING,

HEATED SEAT...................8G-14,8G-8

SWITCH - DIAGNOSIS & TESTING,

PASSENGER POWER SEAT.............8N-19

SWITCH - DIAGNOSIS AND TESTING,

A/C HIGH PRESSURE.................24-20

SWITCH - DIAGNOSIS AND TESTING,

A/C LOW PRESSURE..................24-21

SWITCH - DIAGNOSIS AND TESTING,

BLOWER MOTOR....................24-25

SWITCH - DIAGNOSIS AND TESTING,

BRAKE LAMP........................8L-5

SWITCH - DIAGNOSIS AND TESTING,

DOOR AJAR.........................8L-34

SWITCH - DIAGNOSIS AND TESTING,

HEADLAMP.........................8L-18

SWITCH - DIAGNOSIS AND TESTING,

HEATED MIRROR.....................8G-3

SWITCH - DIAGNOSIS AND TESTING,

HORN..............................8H-5

SWITCH - DIAGNOSIS AND TESTING,

IGNITION...........................19-11

SWITCH - DIAGNOSIS AND TESTING,

MULTI-FUNCTION....................8L-25

SWITCH - DIAGNOSIS AND TESTING,

PARK/NEUTRAL POSITION......21-237,21-408,

21-583,21-755

SWITCH - DIAGNOSIS AND TESTING,

POWER LOCK........................8N-8

SWITCH - DIAGNOSIS AND TESTING,

POWER WINDOW....................8N-24

SWITCH - DIAGNOSIS AND TESTING,

SEAT BELT .........................8O-28

SWITCH - INSPECTION, NEUTRAL

SAFETY............................30-19

SWITCH - INSTALLATION..............8P-13

SWITCH - INSTALLATION, A/C HIGH

PRESSURE.........................24-21

SWITCH - INSTALLATION, A/C LOW

PRESSURE.........................24-22

SWITCH - INSTALLATION, BRAKE LAMP . . . 8L-5

SWITCH - INSTALLATION, DOOR AJAR . . . 8L-35

SWITCH - INSTALLATION, DOOR

CYLINDER LOCK......................8N-6

SWITCH - INSTALLATION, DRIVER

POWER SEAT.......................8N-17

SWITCH - INSTALLATION, DRIVER SEAT

HEATER.............................8G-9

SWITCH - INSTALLATION, GLOVE BOX

LAMP..............................8L-35

SWITCH - INSTALLATION, HEADLAMP

....8L-20

SWITCH - INSTALLATION, IGNITION

......19-12

SWITCH - INSTALLATION, MULTI-

FUNCTION

..........................8L-28

SWITCH - INSTALLATION, OVERDRIVE

. . 21-386,

21-579,21-733

SWITCH - INSTALLATION, OVERDRIVE

OFF

..............................21-215SWITCH - INSTALLATION, PARK/

NEUTRAL POSITION.....21-238,21-408,21-583,

21-755

SWITCH - INSTALLATION, PASSENGER

AIRBAG ON/OFF.....................8O-25

SWITCH - INSTALLATION, PASSENGER

POWER SEAT.......................8N-20

SWITCH - INSTALLATION, PASSENGER

SEAT HEATER .......................8G-16

SWITCH - INSTALLATION, POWER

MIRROR...........................8N-13

SWITCH - INSTALLATION, POWER

WINDOW...........................8N-26

SWITCH - INSTALLATION, WASHER

FLUID LEVEL.........................8R-8

SWITCH - OPERATION................8P-12

SWITCH - OPERATION, A/C HIGH

PRESSURE.........................24-20

SWITCH - OPERATION, A/C LOW

PRESSURE.........................24-21

SWITCH - OPERATION, BLOWER MOTOR . . 24-25

SWITCH - OPERATION, BRAKE LAMP......8L-4

SWITCH - OPERATION, CLUTCH PEDAL

POSITION...........................6-22

SWITCH - OPERATION, DOOR CYLINDER

LOCK...............................8N-5

SWITCH - OPERATION, DRIVER POWER

SEAT ..............................8N-16

SWITCH - OPERATION, DRIVER SEAT

HEATER.............................8G-7

SWITCH - OPERATION, HEADLAMP......8L-18

SWITCH - OPERATION, HORN...........8H-5

SWITCH - OPERATION, IGNITION........19-11

SWITCH - OPERATION, LUMBAR

CONTROL..........................8N-18

SWITCH - OPERATION, MIRROR.........8G-3

SWITCH - OPERATION, MULTI-FUNCTION . 8L-24

SWITCH - OPERATION, OVERDRIVE....21-385,

21-579,21-732

SWITCH - OPERATION, OVERDRIVE OFF . 21-215

SWITCH - OPERATION, PASSENGER

AIRBAG ON/OFF.....................8O-24

SWITCH - OPERATION, PASSENGER

POWER SEAT.......................8N-19

SWITCH - OPERATION, PASSENGER

SEAT HEATER .......................8G-14

SWITCH - OPERATION, POWER LOCK.....8N-8

SWITCH - OPERATION, POWER MIRROR . . 8N-12

SWITCH - OPERATION, POWER WINDOW . 8N-24

SWITCH - OPERATION, PTO......14-104,14-48

SWITCH - OPERATION, SEAT BELT.......8O-28

SWITCH - OPERATION, WASHER FLUID

LEVEL..............................8R-7

SWITCH - REMOVAL..................8P-13

SWITCH - REMOVAL, A/C HIGH

PRESSURE.........................24-21

SWITCH - REMOVAL, A/C LOW

PRESSURE.........................24-21

SWITCH - REMOVAL, BLOWER MOTOR . . . 24-25

SWITCH - REMOVAL, BRAKE LAMP.......8L-5

SWITCH - REMOVAL, DOOR AJAR.......8L-35

SWITCH - REMOVAL, DOOR CYLINDER

LOCK...............................8N-6

SWITCH - REMOVAL, DRIVER POWER

SEAT ..............................8N-17

SWITCH - REMOVAL, DRIVER SEAT

HEATER.............................8G-9

SWITCH - REMOVAL, GLOVE BOX LAMP . . 8L-35

SWITCH - REMOVAL, HEADLAMP........8L-19

SWITCH - REMOVAL, IGNITION.........19-12

SWITCH - REMOVAL, LUMBAR

CONTROL..........................8N-18

SWITCH - REMOVAL, MULTI-FUNCTION . . . 8L-27

SWITCH - REMOVAL, OVERDRIVE......21-386,

21-579,21-733

SWITCH - REMOVAL, OVERDRIVE OFF . . . 21-215

SWITCH - REMOVAL, PARK/NEUTRAL

POSITION.......21-238,21-408,21-583,21-755

SWITCH - REMOVAL, PASSENGER

AIRBAG ON/OFF.....................8O-24

SWITCH - REMOVAL, PASSENGER

POWER SEAT

.......................8N-20

SWITCH - REMOVAL, PASSENGER SEAT

HEATER

............................8G-15

SWITCH - REMOVAL, POWER MIRROR

. . . 8N-12

SWITCH - REMOVAL, POWER WINDOW

. . 8N-25

SWITCH - REMOVAL, WASHER FLUID

LEVEL

..............................8R-8SWITCH AND KEY LOCK CYLINDER -

DIAGNOSIS AND TESTING, IGNITION.....19-10

SWITCHES - DESCRIPTION, REMOTE.....8A-15

SWITCHES - DIAGNOSIS AND TESTING,

REMOTE...........................8A-16

SWITCHES - INSPECTION, LIGHTS.......30-12

SWITCHES - OPERATION, REMOTE......8A-15

SYMBOLS - DESCRIPTION,

INTERNATIONAL....................Intro.-6

SYMBOLS - DESCRIPTION,

INTERNATIONAL.......................0-3

SYSTEM AIRFLOW - DESCRIPTION,

HVAC..............................24-31

SYSTEM CHARGE - STANDARD

PROCEDURE, REFRIGERANT............24-46

SYSTEM CLEANING/REVERSE FLUSHING

- STANDARD PROCEDURE, COOLING......7-16

SYSTEM DIESEL ENGINE - DIAGNOSIS

AND TESTING, COOLING................7-12

SYSTEM EVACUATE - STANDARD

PROCEDURE, REFRIGERANT............24-45

SYSTEM FLOW - 3.9L/5.2L/5.9L ENGINE

- DESCRIPTION, COOLING...............7-1

SYSTEM FLOW - 5.9L DIESEL -

DESCRIPTION, COOLING.................7-1

SYSTEM GAS ENGINE - DIAGNOSIS AND

TESTING, COOLING.....................7-7

SYSTEM LEAKS - DIAGNOSIS AND

TESTING, COOLING.....................7-5

SYSTEM LEAKS - DIAGNOSIS AND

TESTING, REFRIGERANT...............24-43

SYSTEM PARTS - STANDARD

PROCEDURES, CLEANING FUEL...........14-57

SYSTEM PRESSURE - GAS ENGINES -

SPECIFICATIONS, FUEL.................14-4

SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE, FUEL..........14-3

SYSTEM PRESSURES, DIESEL ENGINES

- FUEL.............................14-58

SYSTEM REQUIREMENTS -

DESCRIPTION, COOLING................24-1

SYSTEM SERVICE EQUIPMENT -

STANDARD PROCEDURE,

REFRIGERANT.......................24-44

SYSTEM SERVICE PORT - DESCRIPTION,

REFRIGERANT........................24-1

SYSTEM SERVICE PORT - OPERATION,

REFRIGERANT........................24-2

SYSTEM, SPECIAL TOOLS - DIESEL

FUEL..............................14-59

SYSTEM, SPECIAL TOOLS - FUEL . . . 14-36,14-4

SYSTEM, SPECIFICATIONS - STARTING . . . 8F-38

SYSTEMS - DESCRIPTION, MONITORED . . 25-15

SYSTEMS, SPECIAL TOOLS - AUDIO......8A-4

SYSTEMS, SPECIAL TOOLS - OVERHEAD

CONSOLE...........................8M-8

SYSTEMS, SPECIAL TOOLS - POWER

DISTRIBUTION....................8W-97-2

TABLE, SPECIFICATIONS - A/C

APPLICATION........................24-8

TACHOMETER - DESCRIPTION..........8J-30

TACHOMETER - OPERATION............8J-31

TAIL LAMP - DESCRIPTION............8L-29

TAIL LAMP - INSTALLATION............8L-30

TAIL LAMP - OPERATION..............8L-29

TAIL LAMP - REMOVAL................8L-29

TAIL LAMP UNIT - INSTALLATION.......8L-30

TAIL LAMP UNIT - REMOVAL...........8L-30

TAILGATE - INSTALLATION.............23-66

TAILGATE - REMOVAL.................23-66

TAILPIPE - 3.9L/5.2L/5.9L - INSPECTION . . 11-11

TAILPIPE - 3.9L/5.2L/5.9L -

INSTALLATION.......................11-12

TAILPIPE - 3.9L/5.2L/5.9L - REMOVAL....11-11

TAILPIPE - 5.9L DIESEL - INSPECTION....11-12

TAILPIPE - 5.9L DIESEL - INSTALLATION . . 11-12

TAILPIPE - 5.9L DIESEL - REMOVAL.....11-12

TAILPIPE - 5.9L HEAVY DUTY/8.0L -

INSPECTION........................11-12

TAILPIPE - 5.9L HEAVY DUTY/8.0L -

INSTALLATION.......................11-12

TAILPIPE - 5.9L HEAVY DUTY/8.0L -

REMOVAL..........................11-12

TANK - DESCRIPTION, DIESEL FUEL

.....14-78

TANK - DESCRIPTION, FUEL

............14-19

TANK - INSTALLATION, FUEL

...........14-20

TANK - OPERATION, FUEL

..............14-19

TANK - REMOVAL, FUEL

...............14-19

34 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2882 of 2889

TANK MODULE - DESCRIPTION, FUEL....14-78

TANK MODULE - INSTALLATION, FUEL....14-79

TANK MODULE - OPERATION, FUEL......14-78

TANK MODULE - REMOVAL, FUEL.......14-78

TAPE STRIPE - INSTALLATION..........23-88

TAPE STRIPE - REMOVAL..............23-88

TAPPETS - DIAGNOSIS AND TESTING,

HYDRAULIC............9-151,9-206,9-38,9-95

TASK MANAGER - DESCRIPTION........25-15

TASK MANAGER - OPERATION..........25-19

TEMP SENSOR - 3.9L/5.2L/5.9L -

DESCRIPTION, ENGINE COOLANT.........7-48

TEMP SENSOR - 3.9L/5.2L/5.9L -

INSTALLATION, ENGINE COOLANT........7-48

TEMP SENSOR - 3.9L/5.2L/5.9L -

OPERATION, ENGINE COOLANT..........7-48

TEMP SENSOR - 3.9L/5.2L/5.9L -

REMOVAL, ENGINE COOLANT............7-48

TEMP SENSOR - DESCRIPTION,

AMBIENT..........................8M-11

TEMP SENSOR - INSTALLATION,

AMBIENT..........................8M-13

TEMP SENSOR - OPERATION, AMBIENT . . 8M-11

TEMP SENSOR - REMOVAL, AMBIENT . . . 8M-12

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE............................8J-19

TEMPERATURE GAUGE - OPERATION,

ENGINE............................8J-19

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY...........................8F-29

TEMPERATURE SENSOR - DESCRIPTION,

FUEL..............................14-99

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION . . . 21-262,21-433,21-606,21-779

TEMPERATURE SENSOR - DIAGNOSIS &

TESTING, AMBIENT..................8M-12

TEMPERATURE SENSOR -

INSTALLATION, BATTERY..............8F-29

TEMPERATURE SENSOR - OPERATION,

BATTERY...........................8F-29

TEMPERATURE SENSOR - OPERATION,

FUEL.............................14-100

TEMPERATURE SENSOR - OPERATION,

TRANSMISSION . . . 21-262,21-433,21-606,21-779

TEMPERATURE SENSOR - REMOVAL,

BATTERY...........................8F-29

TENSIONER - ADJUSTMENT, CABLE.......5-40

TENSIONER - DESCRIPTION, TIMING

BELT/CHAIN..........................9-57

TENSIONER - OPERATION, TIMING

BELT/CHAIN..........................9-57

TENSIONERS - 3.9L/5.2L/5.9L -

DESCRIPTION, BELT...................7-19

TENSIONERS - 3.9L/5.2L/5.9L -

INSTALLATION, BELT...................7-20

TENSIONERS - 3.9L/5.2L/5.9L -

OPERATION, BELT.....................7-19

TENSIONERS - 3.9L/5.2L/5.9L -

REMOVAL, BELT......................7-20

TENSIONERS - 5.9L DIESEL -

DESCRIPTION, BELT...................7-23

TENSIONERS - 5.9L DIESEL -

INSTALLATION, BELT...................7-23

TENSIONERS - 5.9L DIESEL -

OPERATION, BELT.....................7-23

TENSIONERS - 5.9L DIESEL - REMOVAL,

BELT ...............................7-23

TENSIONERS - 8.0L - DESCRIPTION,

BELT ...............................7-20

TENSIONERS - 8.0L - INSTALLATION,

BELT ...............................7-22

TENSIONERS - 8.0L - OPERATION, BELT . . . 7-20

TENSIONERS - 8.0L - REMOVAL, BELT.....7-21

TERMINAL - INSTALLATION.........8W-01-11

TERMINAL - REMOVAL.............8W-01-11

TEST - DIAGNOSIS AND TESTING, FUEL

INJECTOR.....................14-53,14-95

TEST - DIAGNOSIS AND TESTING, FUEL

PRESSURE LEAK DOWN

................14-2

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP AMPERAGE

....................14-10

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP CAPACITY

......................14-9

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP PRESSURE

....................14-10

TEST - DIAGNOSIS AND TESTING,

HYDRAULIC PRESSURE

. . 21-144,21-315,21-487,

21-658TEST - DIAGNOSIS AND TESTING,

POWR-LOKY........................3-161

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-3

TEST - INSPECTION WINDSHIELD

WIPERS/WASHERS, ROAD.............30-18

TEST - STANDARD PROCEDURE,

BUILT-IN INDICATOR..................8F-11

TEST - STANDARD PROCEDURE,

HYDROMETER.......................8F-12

TEST - STANDARD PROCEDURE,

IGNITION-OFF DRAW..................8F-15

TEST - STANDARD PROCEDURE, LOAD . . . 8F-14

TEST - STANDARD PROCEDURE,

OPEN-CIRCUIT VOLTAGE...............8F-13

TEST - STANDARD PROCEDURE,

VERIFICATION........................8O-5

TEST INSPECTION - DESCRIPTION,

ROAD..............................30-15

TEST MODE - DESCRIPTION, CIRCUIT

ACTUATION..........................25-1

TEST MODE - DESCRIPTION, STATE

DISPLAY............................25-1

TETHER - INSTALLATION, CHILD.........8O-9

TETHER - REMOVAL, CHILD.............8O-9

THEFT SECURITY - DESCRIPTION,

VEHICLE............................8Q-1

THEFT SECURITY - OPERATION, VEHICLE . . 8Q-2

THEFT SECURITY SYSTEM - DIAGNOSIS

AND TESTING, VEHICLE................8Q-3

THERMOSTAT - 3.9L/5.2L/5.9L -

DESCRIPTION, ENGINE COOLANT.........7-49

THERMOSTAT - 3.9L/5.2L/5.9L -

INSTALLATION, ENGINE COOLANT........7-50

THERMOSTAT - 3.9L/5.2L/5.9L -

OPERATION, ENGINE COOLANT..........7-49

THERMOSTAT - 3.9L/5.2L/5.9L -

REMOVAL, ENGINE COOLANT............7-49

THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE COOLANT.........7-54

THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE COOLANT........7-55

THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE COOLANT..........7-54

THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE COOLANT............7-55

THERMOSTAT - 8.0L - DESCRIPTION,

ENGINE COOLANT.....................7-52

THERMOSTAT - 8.0L - INSTALLATION,

ENGINE COOLANT.....................7-53

THERMOSTAT - 8.0L - OPERATION,

ENGINE COOLANT.....................7-52

THERMOSTAT - 8.0L - REMOVAL,

ENGINE COOLANT.....................7-52

THERMOSTAT - DIAGNOSIS AND

TESTING....................7-49,7-52,7-54

THOMAS AND BETTS - INSTALLATION,

CONNECTOR.....................8W-01-10

THOMAS AND BETTS - REMOVAL,

CONNECTOR......................8W-01-9

THREAD REPAIR - STANDARD

PROCEDURE, ALUMINUM......21-159,21-330,

21-502,21-673

THREADED HOLE REPAIR -

DESCRIPTION......................Intro.-6

THREADS - STANDARD PROCEDURE,

REPAIR DAMAGED OR WORN . 9-11,9-125,9-181,

9-238,9-68

THROTTLE BODY - DESCRIPTION........14-48

THROTTLE BODY - OPERATION.........14-48

THROTTLE CONTROL CABLE -

INSTALLATION.................14-105,14-50

THROTTLE CONTROL CABLE -

REMOVAL....................14-104,14-50

THROTTLE POSITION SENSOR -

DESCRIPTION.......................14-51

THROTTLE POSITION SENSOR -

OPERATION.........................14-51

THROTTLE VALVE CABLE -

ADJUSTMENTS, TRANSMISSION

. 21-254,21-425,

21-598,21-771

THROTTLE VALVE CABLE -

DESCRIPTION

....21-253,21-424,21-597,21-770

TIMER MODULE - DESCRIPTION, BODY

CONTROL/CENTRAL

...................8E-1

TIMER MODULE - DIAGNOSIS AND

TESTING, CENTRAL

....................8E-4

TIMER MODULE - INSTALLATION, BODY

CONTROL/CENTRAL

...................8E-6TIMER MODULE - OPERATION, BODY

CONTROL/CENTRAL...................8E-3

TIMER MODULE - REMOVAL, BODY

CONTROL/CENTRAL...................8E-5

TIMING - DIAGNOSIS AND TESTING,

FUEL INJECTION PUMP...............14-66

TIMING BELT / CHAIN COVER(S) -

INSTALLATION........9-113,9-169,9-226,9-56

TIMING BELT / CHAIN COVER(S) -

REMOVAL............9-113,9-169,9-225,9-56

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION........9-115,9-170,9-227,9-58

TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL............9-114,9-170,9-226,9-57

TIMING BELT/CHAIN TENSIONER -

DESCRIPTION........................9-57

TIMING BELT/CHAIN TENSIONER -

OPERATION..........................9-57

TIMING CHAIN STRETCH - INSPECTION,

MEASURING..........9-114,9-170,9-227,9-58

TIMING, SPECIFICATIONS - IGNITION......8I-3

TIPS - CLEANING, APPEARANCE........30-21

TIRE - DESCRIPTION, SPARE............22-9

TIRE AND WHEEL BALANCE -

STANDARD PROCEDURES...............22-4

TIRE AND WHEEL RUNOUT - DIAGNOSIS

AND TESTING........................22-1

TIRE NOISE OR VIBRATION - DIAGNOSIS

AND TESTING........................22-8

TIRE PRESSURES - INSPECTION.........30-8

TIRE REVOLUTIONS PER MILE,

SPECIFICATIONS......................22-9

TIRE ROTATION - STANDARD

PROCEDURES........................22-2

TIRE WEAR PATTERNS - DIAGNOSIS

AND TESTING........................22-7

TIRE WINCH - INSTALLATION, SPARE....13-10

TIRE WINCH - REMOVAL, SPARE........13-10

TIRES - DESCRIPTION.............22-5,22-6

TO GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT.............8W-01-6

TO GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR SHORT....8W-01-7

TO OIL COOLER - INSTALLATION, AIR.....7-88

TO OIL COOLER - REMOVAL, AIR.........7-87

TO OIL COOLER - REMOVAL, WATER......7-87

TO USE WIRING DIAGRAMS -

DESCRIPTION, HOW................8W-01-1

TOOLS - 5.2L ENGINE, SPECIAL..........9-77

TOOLS - 5.9L DIESEL ENGINE, SPECIAL . . 9-244

TOOLS - 5.9L ENGINE, SPECIAL.........9-134

TOOLS - 8.0L ENGINE, SPECIAL.........9-188

TOOLS - AUDIO SYSTEMS, SPECIAL......8A-4

TOOLS - BASE BRAKES, SPECIAL.........5-4

TOOLS - COOLING, SPECIAL.............7-18

TOOLS - DIESEL FUEL SYSTEM,

SPECIAL...........................14-59

TOOLS - FRONT AXLE, SPECIAL..........3-58

TOOLS - FRONT AXLES, SPECIAL.........3-25

TOOLS - FUEL SYSTEM, SPECIAL . . . 14-36,14-4

TOOLS - HEADLAMP ALIGNMENT,

SPECIAL............................8L-4

TOOLS - INDEPENDENT FRONT

SUSPENSION, SPECIAL..................2-9

TOOLS - LINK/COIL SUSPENSION,

SPECIAL

............................2-16

TOOLS - NV5600 MANUAL

TRANSMISSION, SPECIAL

.............21-127

TOOLS - OVERHEAD CONSOLE

SYSTEMS, SPECIAL

...................8M-8

TOOLS - POWER DISTRIBUTION

SYSTEMS, SPECIAL

................8W-97-2

TOOLS - POWER STEERING GEAR,

SPECIAL

...........................19-20

TOOLS - POWER STEERING PUMP,

SPECIAL

...........................19-36

TOOLS - PROPELLER SHAFT, SPECIAL

......3-8

TOOLS - RE TRANSMISSION, SPECIAL

. . 21-534,

21-704

TOOLS - RE TRANSMISSIONS, SPECIAL

. 21-188,

21-359

TOOLS - STEERING LINKAGE, SPECIAL

. . . 19-39,

19-42

TOOLS - SUSPENSION-REAR, SPECIAL

....2-28

TOOLS, AIRBAG SYSTEM - SPECIAL

......8O-6

TOOLS, WIRING/TERMINAL - SPECIAL

. 8W-01-8

BR/BEINDEX 35

Description Group-Page Description Group-Page Description Group-Page