remote start DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 686 of 2889

STANDARD PROCEDURE - CLOCKSPRING

CENTERING

The clockspring is designed to wind and unwind

when the steering wheel is rotated, but is only

designed to rotate the same number of turns (about

five complete rotations) as the steering wheel can be

turned from stop to stop. Centering the clockspring

indexes the clockspring tape to other steering compo-

nents so that it can operate within its designed

travel limits. The rotor of a centered clockspring can

be rotated two and one-half turns in either direction

from the centered position, without damaging the

clockspring tape.

However, if the clockspring is removed for service

or if the steering column is disconnected from the

steering gear, the clockspring tape can change posi-

tion relative to the other steering components. The

clockspring must then be re-centered following com-

pletion of such service or the clockspring tape may be

damaged. Service replacement clocksprings are

shipped pre-centered and with the auto-locking tabs

engaged (raised). These auto-locking tabs should not

be disengaged until the clockspring has been

installed on the steering column. If the auto-locking

tabs are disengaged before the clockspring is

installed on a steering column, the clockspring cen-

tering procedure must be performed.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Place the front wheels in the straight-ahead

position.

(2) Remove the clockspring from the steering col-

umn. (Refer to 8 - ELECTRICAL/RESTRAINTS/

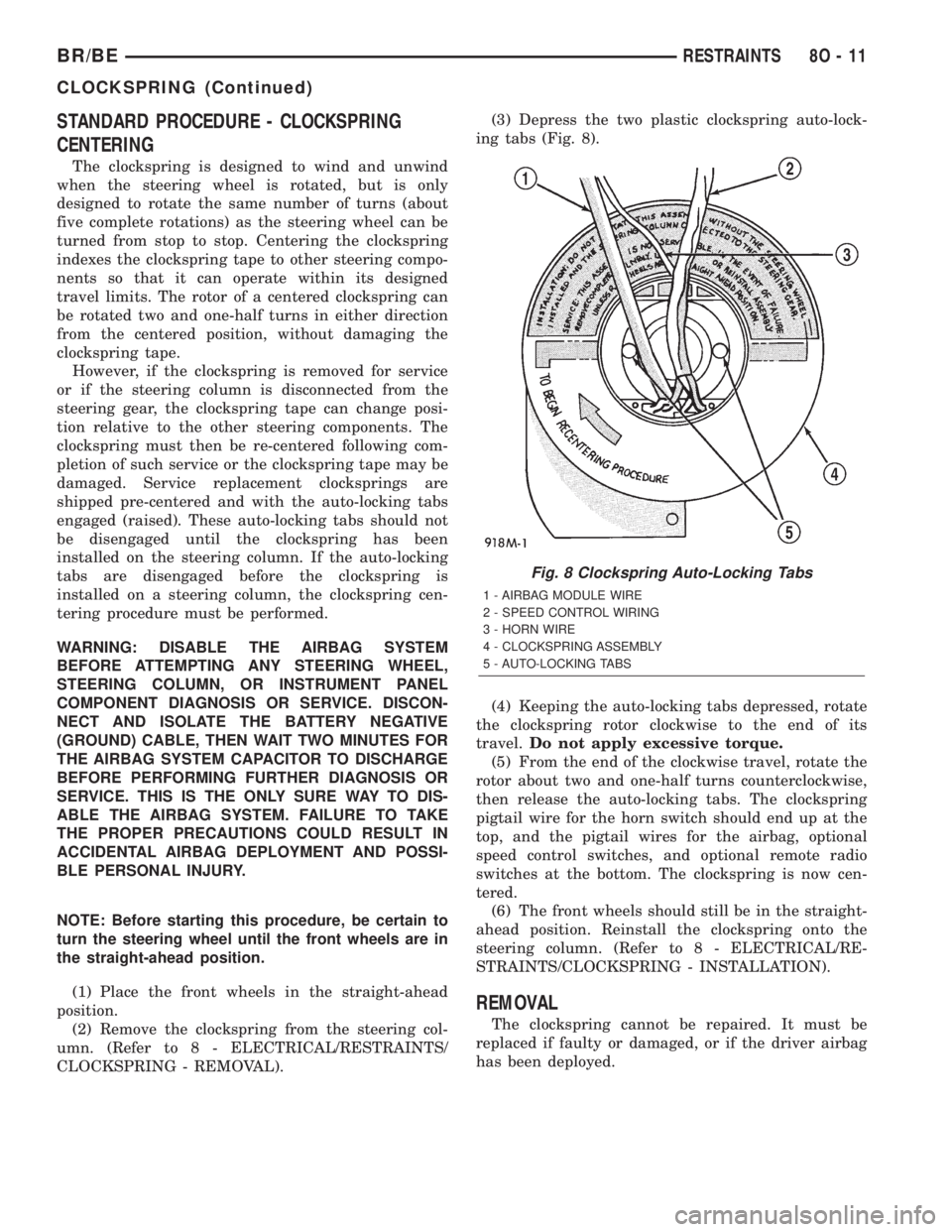

CLOCKSPRING - REMOVAL).(3) Depress the two plastic clockspring auto-lock-

ing tabs (Fig. 8).

(4) Keeping the auto-locking tabs depressed, rotate

the clockspring rotor clockwise to the end of its

travel.Do not apply excessive torque.

(5) From the end of the clockwise travel, rotate the

rotor about two and one-half turns counterclockwise,

then release the auto-locking tabs. The clockspring

pigtail wire for the horn switch should end up at the

top, and the pigtail wires for the airbag, optional

speed control switches, and optional remote radio

switches at the bottom. The clockspring is now cen-

tered.

(6) The front wheels should still be in the straight-

ahead position. Reinstall the clockspring onto the

steering column. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/CLOCKSPRING - INSTALLATION).

REMOVAL

The clockspring cannot be repaired. It must be

replaced if faulty or damaged, or if the driver airbag

has been deployed.

Fig. 8 Clockspring Auto-Locking Tabs

1 - AIRBAG MODULE WIRE

2 - SPEED CONTROL WIRING

3 - HORN WIRE

4 - CLOCKSPRING ASSEMBLY

5 - AUTO-LOCKING TABS

BR/BERESTRAINTS 8O - 11

CLOCKSPRING (Continued)

Page 687 of 2889

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Place the front wheels in the straight-ahead

position.

(2) Remove the driver airbag from the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

(3) If the vehicle is so equipped, disconnect the

clockspring pigtail wire connectors from the speed

control switches and the remote radio switches

located within the hub cavity of the steering wheel.

(4) Remove the nut that secures the steering wheel

armature to the steering column upper shaft, which

is located within the hub cavity of the steering wheel.

(5) Pull the steering wheel off of the steering col-

umn upper shaft spline using a steering wheel puller

(Special Tool C-3428-B).

(6) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

(7) If the vehicle is so equipped, unscrew the lever

from the tilt steering column adjuster mechanism

located on the left side of the column just below the

multi-function switch control stalk. Turn the lever

counterclockwise to unscrew it from the adjuster.

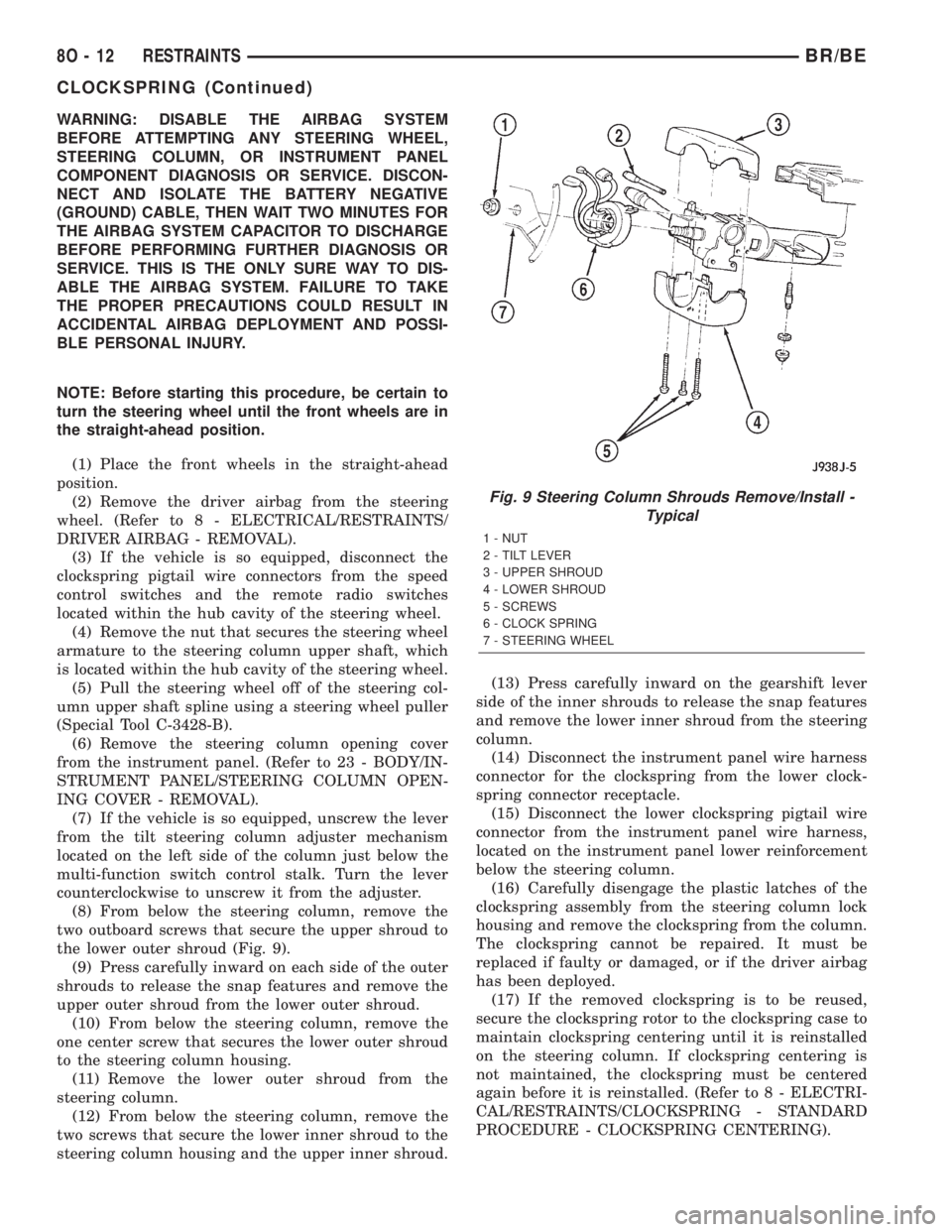

(8) From below the steering column, remove the

two outboard screws that secure the upper shroud to

the lower outer shroud (Fig. 9).

(9) Press carefully inward on each side of the outer

shrouds to release the snap features and remove the

upper outer shroud from the lower outer shroud.

(10) From below the steering column, remove the

one center screw that secures the lower outer shroud

to the steering column housing.

(11) Remove the lower outer shroud from the

steering column.

(12) From below the steering column, remove the

two screws that secure the lower inner shroud to the

steering column housing and the upper inner shroud.(13) Press carefully inward on the gearshift lever

side of the inner shrouds to release the snap features

and remove the lower inner shroud from the steering

column.

(14) Disconnect the instrument panel wire harness

connector for the clockspring from the lower clock-

spring connector receptacle.

(15) Disconnect the lower clockspring pigtail wire

connector from the instrument panel wire harness,

located on the instrument panel lower reinforcement

below the steering column.

(16) Carefully disengage the plastic latches of the

clockspring assembly from the steering column lock

housing and remove the clockspring from the column.

The clockspring cannot be repaired. It must be

replaced if faulty or damaged, or if the driver airbag

has been deployed.

(17) If the removed clockspring is to be reused,

secure the clockspring rotor to the clockspring case to

maintain clockspring centering until it is reinstalled

on the steering column. If clockspring centering is

not maintained, the clockspring must be centered

again before it is reinstalled. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - STANDARD

PROCEDURE - CLOCKSPRING CENTERING).

Fig. 9 Steering Column Shrouds Remove/Install -

Typical

1 - NUT

2 - TILT LEVER

3 - UPPER SHROUD

4 - LOWER SHROUD

5 - SCREWS

6 - CLOCK SPRING

7 - STEERING WHEEL

8O - 12 RESTRAINTSBR/BE

CLOCKSPRING (Continued)

Page 688 of 2889

INSTALLATION

The clockspring cannot be repaired. It must be

replaced if faulty or damaged, or if the driver airbag

has been deployed.

If the clockspring is not properly centered in rela-

tion to the steering wheel, steering shaft and steer-

ing gear, it may be damaged. (Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

STANDARD PROCEDURE - CLOCKSPRING CEN-

TERING). Service replacement clocksprings are

shipped pre-centered and with a piece of tape cover-

ing the engaged clockspring auto-locking tabs. This

tape should not be removed until the clockspring has

been installed on the steering column. If the tape is

removed before the clockspring is installed on a

steering column, the clockspring centering procedure

must be performed.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

NOTE: Before starting this procedure, be certain

that the front wheels are still in the straight-ahead

position.

(1) Carefully slide the centered clockspring down

over the steering column upper shaft until the clock-

spring latches engage the steering column lock hous-

ing (Fig. 9).

(2) Reconnect the lower clockspring pigtail wire

connector to the instrument panel wire harness con-

nector located near the instrument panel lower rein-

forcement, below the steering column. Be certain that

the pigtail wire locator clips are properly seated on

the outside of the wiring trough and that the connec-

tor latches are fully engaged.

(3) Reconnect the instrument panel wire harness

connector for the clockspring to the lower clockspring

connector receptacle.

(4) Position the lower inner shroud onto the steer-

ing column. Be certain to insert the gearshift lever

hider strip into the channel located on the inside sur-

face of the shroud.

(5) Align the locking tabs on the gearshift lever

side of the upper inner shroud with the receptacleson the lower inner shroud and apply hand pressure

to snap them together.

(6) From below the steering column, install and

tighten the two screws that secure the lower inner

shroud to the steering column housing and the upper

inner shroud. Tighten the screws to 2 N´m (18 in.

lbs.).

(7) Position the lower outer shroud onto the steer-

ing column. Be certain that the lower clockspring

pigtail wire is routed inside the shrouds.

(8) From below the steering column, install and

tighten the one center screw that secures the lower

outer shroud to the steering column housing. Tighten

the screw to 2 N´m (18 in. lbs.).

(9) Align the locking tabs on the upper outer

shroud with the receptacles on the lower outer

shroud and apply hand pressure to snap them

together.

(10) From below the steering column, install and

tighten the two outboard screws that secure the

lower outer shroud to the upper outer shroud.

Tighten the screws to 2 N´m (18 in. lbs.).

(11) If the vehicle is so equipped, reinstall the

lever into the tilt steering column adjuster on the left

side of the column. Turn the lever clockwise to screw

it into the adjuster.

(12) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(13) Reinstall the steering wheel onto the steering

column upper shaft. Be certain to index the flats on

the hub of the steering wheel with the formations on

the inside of the clockspring hub. Pull the upper

clockspring pigtail wires through the upper and

lower holes between the steering wheel back trim

cover and the steering wheel armature.

(14) Install and tighten the steering wheel mount-

ing nut. Tighten the nut to 61 N´m (45 ft. lbs.). Be

certain not to pinch the pigtail wires between the

steering wheel and the nut.

(15) If the vehicle is so equipped, reconnect the

upper clockspring pigtail wire connectors to the

speed control switches and/or the remote radio

switches. Be certain that the upper clockspring pig-

tail wires are routed between the steering wheel back

trim cover and the steering wheel armature.

(16) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

BR/BERESTRAINTS 8O - 13

CLOCKSPRING (Continued)

Page 721 of 2889

tem of the vehicle. These hard wired circuits are

integral to several wire harnesses, which are routed

throughout the vehicle and retained by many differ-

ent methods. These circuits may be connected to each

other, to the vehicle electrical system and to the

VTSS components through the use of a combination

of soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

OPERATION

A Central Timer Module (CTM) is used on this

model to control and integrate many of the electronic

functions and features included in the Vehicle Theft

Security System (VTSS). In the VTSS, the CTM

receives inputs indicating the status of the door ajar

switches, the door cylinder lock switch, and the igni-

tion switch. The programming in the CTM allows it

to process the information from all of these inputs

and send control outputs to energize or de-energize

the horn relay, the headlamp relay, and the VTSS

indicator. The control of these inputs and outputs are

what constitute all of the features of the VTSS. Fol-

lowing is information on the operation of each of the

VTSS features. Refer to the owner's manual in the

vehicle glove box for more information on the fea-

tures, use and operation of the VTSS.

ENABLING

The high-line or premium version of the CTM must

have the VTSS function electronically enabled in

order for the VTSS to perform as designed. The logic

in the CTM keeps its VTSS function dormant until it

is enabled using a DRBIIIž scan tool. The VTSS

function of the high-line or premium CTM is enabled

on vehicles equipped with the VTSS option at the

factory, but a service replacement CTM must be

VTSS-enabled by the dealer using a DRBIIIž scan

tool. Refer to the appropriate diagnostic information.

The VTSS engine no-run feature is disabled when

it is shipped from the factory. This is done by pro-

gramming within the Powertrain Control Module

(PCM). The logic in the PCM prevents the VTSS

engine no-run feature from arming until the engine

start counter within the PCM sees twenty engine

starts. The VTSS no-run feature must be enabled by

the dealer when the vehicle is received from the

assembly plant. Once the VTSS engine no-run fea-

ture has been enabled, it cannot be disabled unless

the PCM is replaced with a new unit. The sameVTSS engine no-run feature enable logic will apply

anytime the PCM is replaced with a new unit.

ARMING

Passive arming of the VTSS occurs when the vehi-

cle is exited with the key removed from the ignition

switch, the headlamps are turned off, and the doors

are locked while they are open using the power lock

switch, or locked after they are closed by turning

either front door lock cylinder to the lock position

using the key. The power lock switch will not func-

tion if the key is in the ignition switch or the head-

lamps are turned on with the driver side front door

open. The VTSS will not arm if the doors are locked

using the mechanical lock button. Active arming of

the VTSS occurs when the ªLockº button on the

Remote Keyless Entry (RKE) transmitter is

depressed to lock the vehicle. For active arming to

occur, the doors must be closed and the ignition

switch must be in the Off position when the RKE

transmitter ªLockº button is depressed. However,

once the VTSS arming process has been completed,

the ignition switch can be turned to the Accessory

position without triggering the alarm.

Once the VTSS begins passive or active arming,

the security indicator lamp in the overhead console

will flash rapidly for about fifteen seconds. This indi-

cates that the VTSS arming is in progress. Turning a

key in the ignition switch, opening a door, or unlock-

ing a door by any means during the fifteen second

arming process will cause the VTSS indicator to stop

flashing and the arming process to abort. Once the

fifteen second arming function is successfully com-

pleted, the indicator will flash at a slower rate, indi-

cating that the VTSS is armed.

DISARMING

Passive disarming of the VTSS occurs when the

vehicle is unlocked using the key to unlock either

front door. Active disarming of the VTSS occurs when

the vehicle is unlocked by depressing the ªUnlockº

button of the RKE transmitter. Once the alarm has

been activated (horn pulsing, headlamps flashing,

and the engine no-run feature), either disarming

method will also deactivate the alarm. Depressing

the ªPanicº button on the RKE transmitter willnot

disarm the VTSS.

POWER-UP MODE

When the armed VTSS senses that the battery has

been disconnected and reconnected, it enters its pow-

er-up mode. In the power-up mode the alarm system

remains armed following a battery failure or discon-

nect. If the VTSS was armed prior to a battery dis-

connect or failure, the technician or vehicle operator

will have to actively or passively disarm the alarm

system after the battery is reconnected. The pow-

8Q - 2 VEHICLE THEFT SECURITYBR/BE

VEHICLE THEFT SECURITY (Continued)

Page 808 of 2889

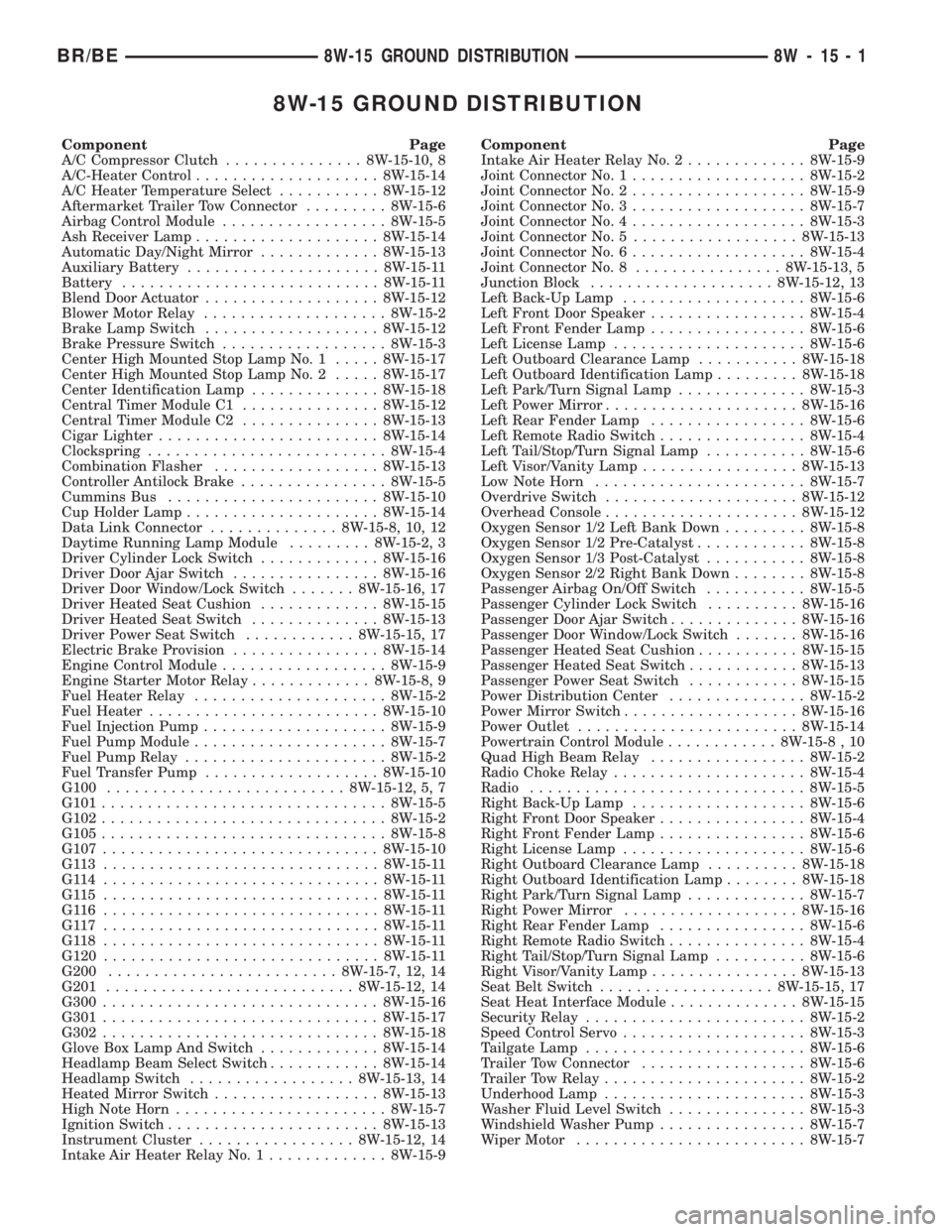

8W-15 GROUND DISTRIBUTION

Component Page

A/C Compressor Clutch............... 8W-15-10, 8

A/C-Heater Control.................... 8W-15-14

A/C Heater Temperature Select........... 8W-15-12

Aftermarket Trailer Tow Connector......... 8W-15-6

Airbag Control Module.................. 8W-15-5

Ash Receiver Lamp.................... 8W-15-14

Automatic Day/Night Mirror............. 8W-15-13

Auxiliary Battery..................... 8W-15-11

Battery............................ 8W-15-11

Blend Door Actuator................... 8W-15-12

Blower Motor Relay.................... 8W-15-2

Brake Lamp Switch................... 8W-15-12

Brake Pressure Switch.................. 8W-15-3

Center High Mounted Stop Lamp No. 1..... 8W-15-17

Center High Mounted Stop Lamp No. 2..... 8W-15-17

Center Identification Lamp.............. 8W-15-18

Central Timer Module C1............... 8W-15-12

Central Timer Module C2............... 8W-15-13

Cigar Lighter........................ 8W-15-14

Clockspring.......................... 8W-15-4

Combination Flasher.................. 8W-15-13

Controller Antilock Brake................ 8W-15-5

Cummins Bus....................... 8W-15-10

Cup Holder Lamp..................... 8W-15-14

Data Link Connector.............. 8W-15-8, 10, 12

Daytime Running Lamp Module......... 8W-15-2, 3

Driver Cylinder Lock Switch............. 8W-15-16

Driver Door Ajar Switch................ 8W-15-16

Driver Door Window/Lock Switch....... 8W-15-16, 17

Driver Heated Seat Cushion............. 8W-15-15

Driver Heated Seat Switch.............. 8W-15-13

Driver Power Seat Switch............ 8W-15-15, 17

Electric Brake Provision................ 8W-15-14

Engine Control Module.................. 8W-15-9

Engine Starter Motor Relay............. 8W-15-8, 9

Fuel Heater Relay..................... 8W-15-2

Fuel Heater......................... 8W-15-10

Fuel Injection Pump.................... 8W-15-9

Fuel Pump Module..................... 8W-15-7

Fuel Pump Relay...................... 8W-15-2

Fuel Transfer Pump................... 8W-15-10

G100.......................... 8W-15-12, 5, 7

G101............................... 8W-15-5

G102............................... 8W-15-2

G105............................... 8W-15-8

G107.............................. 8W-15-10

G113 .............................. 8W-15-11

G114 .............................. 8W-15-11

G115 .............................. 8W-15-11

G116 .............................. 8W-15-11

G117 .............................. 8W-15-11

G118 .............................. 8W-15-11

G120.............................. 8W-15-11

G200......................... 8W-15-7, 12, 14

G201........................... 8W-15-12, 14

G300.............................. 8W-15-16

G301.............................. 8W-15-17

G302.............................. 8W-15-18

Glove Box Lamp And Switch............. 8W-15-14

Headlamp Beam Select Switch............ 8W-15-14

Headlamp Switch.................. 8W-15-13, 14

Heated Mirror Switch.................. 8W-15-13

High Note Horn....................... 8W-15-7

Ignition Switch....................... 8W-15-13

Instrument Cluster................. 8W-15-12, 14

Intake Air Heater Relay No. 1............. 8W-15-9Component Page

Intake Air Heater Relay No. 2............. 8W-15-9

Joint Connector No. 1................... 8W-15-2

Joint Connector No. 2................... 8W-15-9

Joint Connector No. 3................... 8W-15-7

Joint Connector No. 4................... 8W-15-3

Joint Connector No. 5.................. 8W-15-13

Joint Connector No. 6................... 8W-15-4

Joint Connector No. 8................ 8W-15-13, 5

Junction Block.................... 8W-15-12, 13

Left Back-Up Lamp.................... 8W-15-6

Left Front Door Speaker................. 8W-15-4

Left Front Fender Lamp................. 8W-15-6

Left License Lamp..................... 8W-15-6

Left Outboard Clearance Lamp........... 8W-15-18

Left Outboard Identification Lamp......... 8W-15-18

Left Park/Turn Signal Lamp.............. 8W-15-3

Left Power Mirror..................... 8W-15-16

Left Rear Fender Lamp................. 8W-15-6

Left Remote Radio Switch................ 8W-15-4

Left Tail/Stop/Turn Signal Lamp........... 8W-15-6

Left Visor/Vanity Lamp................. 8W-15-13

Low Note Horn....................... 8W-15-7

Overdrive Switch..................... 8W-15-12

Overhead Console..................... 8W-15-12

Oxygen Sensor 1/2 Left Bank Down......... 8W-15-8

Oxygen Sensor 1/2 Pre-Catalyst............ 8W-15-8

Oxygen Sensor 1/3 Post-Catalyst........... 8W-15-8

Oxygen Sensor 2/2 Right Bank Down........ 8W-15-8

Passenger Airbag On/Off Switch........... 8W-15-5

Passenger Cylinder Lock Switch.......... 8W-15-16

Passenger Door Ajar Switch.............. 8W-15-16

Passenger Door Window/Lock Switch....... 8W-15-16

Passenger Heated Seat Cushion........... 8W-15-15

Passenger Heated Seat Switch............ 8W-15-13

Passenger Power Seat Switch............ 8W-15-15

Power Distribution Center............... 8W-15-2

Power Mirror Switch................... 8W-15-16

Power Outlet........................ 8W-15-14

Powertrain Control Module............ 8W-15-8 , 10

Quad High Beam Relay................. 8W-15-2

Radio Choke Relay..................... 8W-15-4

Radio.............................. 8W-15-5

Right Back-Up Lamp................... 8W-15-6

Right Front Door Speaker................ 8W-15-4

Right Front Fender Lamp................ 8W-15-6

Right License Lamp.................... 8W-15-6

Right Outboard Clearance Lamp.......... 8W-15-18

Right Outboard Identification Lamp........ 8W-15-18

Right Park/Turn Signal Lamp............. 8W-15-7

Right Power Mirror................... 8W-15-16

Right Rear Fender Lamp................ 8W-15-6

Right Remote Radio Switch............... 8W-15-4

Right Tail/Stop/Turn Signal Lamp.......... 8W-15-6

Right Visor/Vanity Lamp................ 8W-15-13

Seat Belt Switch................... 8W-15-15, 17

Seat Heat Interface Module.............. 8W-15-15

Security Relay........................ 8W-15-2

Speed Control Servo.................... 8W-15-3

Tailgate Lamp........................ 8W-15-6

Trailer Tow Connector.................. 8W-15-6

Trailer Tow Relay...................... 8W-15-2

Underhood Lamp...................... 8W-15-3

Washer Fluid Level Switch............... 8W-15-3

Windshield Washer Pump................ 8W-15-7

Wiper Motor......................... 8W-15-7

BR/BE8W-15 GROUND DISTRIBUTION 8W - 15 - 1

Page 1046 of 2889

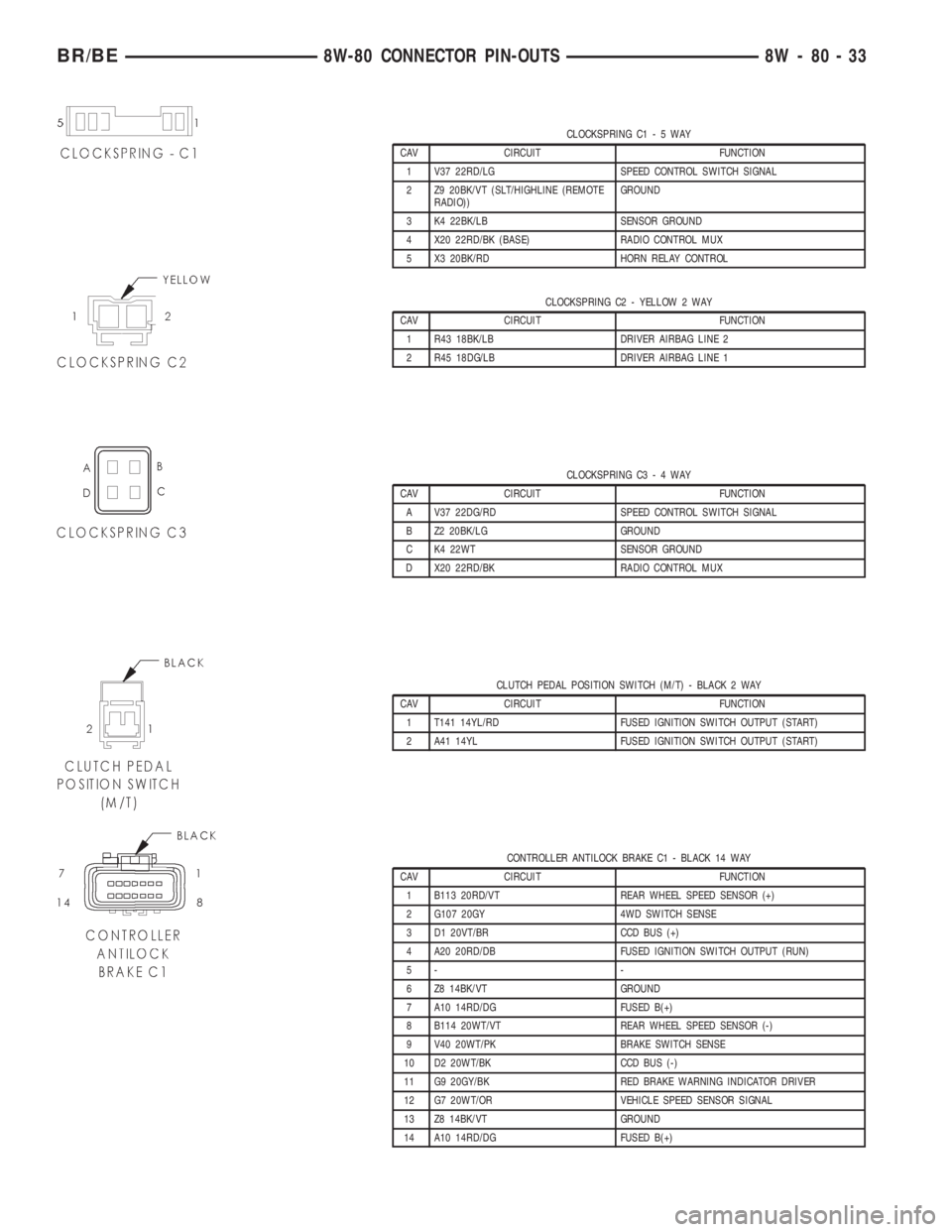

CLOCKSPRING C1-5WAY

CAV CIRCUIT FUNCTION

1 V37 22RD/LG SPEED CONTROL SWITCH SIGNAL

2 Z9 20BK/VT (SLT/HIGHLINE (REMOTE

RADIO))GROUND

3 K4 22BK/LB SENSOR GROUND

4 X20 22RD/BK (BASE) RADIO CONTROL MUX

5 X3 20BK/RD HORN RELAY CONTROL

CLOCKSPRING C2 - YELLOW 2 WAY

CAV CIRCUIT FUNCTION

1 R43 18BK/LB DRIVER AIRBAG LINE 2

2 R45 18DG/LB DRIVER AIRBAG LINE 1

CLOCKSPRING C3-4WAY

CAV CIRCUIT FUNCTION

A V37 22DG/RD SPEED CONTROL SWITCH SIGNAL

B Z2 20BK/LG GROUND

C K4 22WT SENSOR GROUND

D X20 22RD/BK RADIO CONTROL MUX

CLUTCH PEDAL POSITION SWITCH (M/T) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 T141 14YL/RD FUSED IGNITION SWITCH OUTPUT (START)

2 A41 14YL FUSED IGNITION SWITCH OUTPUT (START)

CONTROLLER ANTILOCK BRAKE C1 - BLACK 14 WAY

CAV CIRCUIT FUNCTION

1 B113 20RD/VT REAR WHEEL SPEED SENSOR (+)

2 G107 20GY 4WD SWITCH SENSE

3 D1 20VT/BR CCD BUS (+)

4 A20 20RD/DB FUSED IGNITION SWITCH OUTPUT (RUN)

5- -

6 Z8 14BK/VT GROUND

7 A10 14RD/DG FUSED B(+)

8 B114 20WT/VT REAR WHEEL SPEED SENSOR (-)

9 V40 20WT/PK BRAKE SWITCH SENSE

10 D2 20WT/BK CCD BUS (-)

11 G9 20GY/BK RED BRAKE WARNING INDICATOR DRIVER

12 G7 20WT/OR VEHICLE SPEED SENSOR SIGNAL

13 Z8 14BK/VT GROUND

14 A10 14RD/DG FUSED B(+)

BR/BE8W-80 CONNECTOR PIN-OUTS 8W - 80 - 33

Page 1064 of 2889

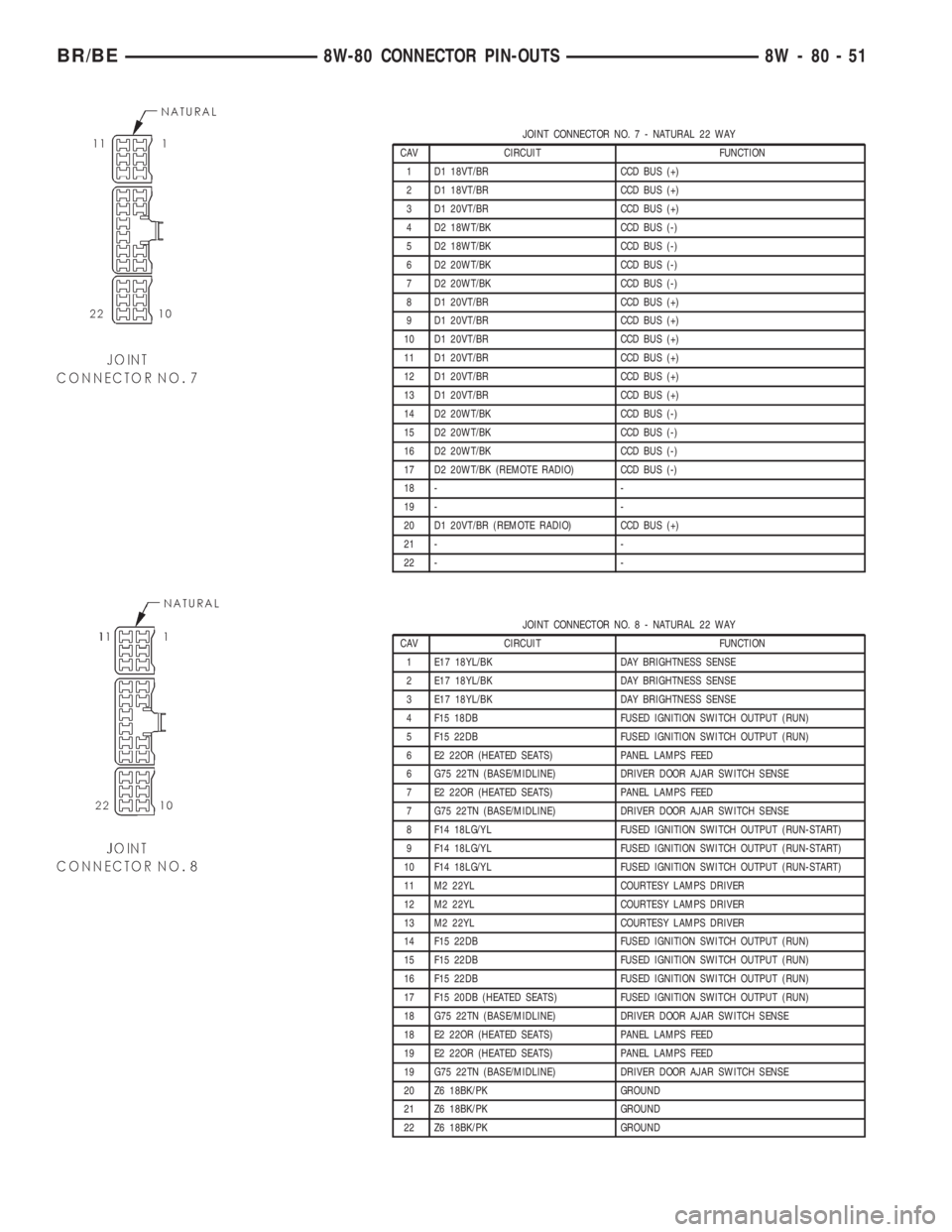

JOINT CONNECTOR NO.7-NATURAL 22 WAY

CAV CIRCUIT FUNCTION

1 D1 18VT/BR CCD BUS (+)

2 D1 18VT/BR CCD BUS (+)

3 D1 20VT/BR CCD BUS (+)

4 D2 18WT/BK CCD BUS (-)

5 D2 18WT/BK CCD BUS (-)

6 D2 20WT/BK CCD BUS (-)

7 D2 20WT/BK CCD BUS (-)

8 D1 20VT/BR CCD BUS (+)

9 D1 20VT/BR CCD BUS (+)

10 D1 20VT/BR CCD BUS (+)

11 D1 20VT/BR CCD BUS (+)

12 D1 20VT/BR CCD BUS (+)

13 D1 20VT/BR CCD BUS (+)

14 D2 20WT/BK CCD BUS (-)

15 D2 20WT/BK CCD BUS (-)

16 D2 20WT/BK CCD BUS (-)

17 D2 20WT/BK (REMOTE RADIO) CCD BUS (-)

18 - -

19 - -

20 D1 20VT/BR (REMOTE RADIO) CCD BUS (+)

21 - -

22 - -

JOINT CONNECTOR NO.8-NATURAL 22 WAY

CAV CIRCUIT FUNCTION

1 E17 18YL/BK DAY BRIGHTNESS SENSE

2 E17 18YL/BK DAY BRIGHTNESS SENSE

3 E17 18YL/BK DAY BRIGHTNESS SENSE

4 F15 18DB FUSED IGNITION SWITCH OUTPUT (RUN)

5 F15 22DB FUSED IGNITION SWITCH OUTPUT (RUN)

6 E2 22OR (HEATED SEATS) PANEL LAMPS FEED

6 G75 22TN (BASE/MIDLINE) DRIVER DOOR AJAR SWITCH SENSE

7 E2 22OR (HEATED SEATS) PANEL LAMPS FEED

7 G75 22TN (BASE/MIDLINE) DRIVER DOOR AJAR SWITCH SENSE

8 F14 18LG/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

9 F14 18LG/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

10 F14 18LG/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

11 M2 22YL COURTESY LAMPS DRIVER

12 M2 22YL COURTESY LAMPS DRIVER

13 M2 22YL COURTESY LAMPS DRIVER

14 F15 22DB FUSED IGNITION SWITCH OUTPUT (RUN)

15 F15 22DB FUSED IGNITION SWITCH OUTPUT (RUN)

16 F15 22DB FUSED IGNITION SWITCH OUTPUT (RUN)

17 F15 20DB (HEATED SEATS) FUSED IGNITION SWITCH OUTPUT (RUN)

18 G75 22TN (BASE/MIDLINE) DRIVER DOOR AJAR SWITCH SENSE

18 E2 22OR (HEATED SEATS) PANEL LAMPS FEED

19 E2 22OR (HEATED SEATS) PANEL LAMPS FEED

19 G75 22TN (BASE/MIDLINE) DRIVER DOOR AJAR SWITCH SENSE

20 Z6 18BK/PK GROUND

21 Z6 18BK/PK GROUND

22 Z6 18BK/PK GROUND

BR/BE8W-80 CONNECTOR PIN-OUTS 8W - 80 - 51

Page 2860 of 2889

ENGINE (1500 AND 2500 MODELS

EXCEPT 8.0L) MAINTENANCE

SCHEDULES, MAINTENANCE

SCHEDULES - LIGHT DUTY...............0-7

ENGINE, 3.9L.........................9-19

ENGINE 3.9L - DESCRIPTION.............9-3

ENGINE 3.9L - INSTALLATION............9-13

ENGINE 3.9L - REMOVAL...............9-12

ENGINE 5.2L - DESCRIPTION............9-60

ENGINE 5.2L - INSTALLATION............9-70

ENGINE 5.2L - REMOVAL...............9-69

ENGINE 5.9L - DESCRIPTION...........9-117

ENGINE 5.9L - INSTALLATION...........9-127

ENGINE 5.9L - REMOVAL..............9-126

ENGINE 5.9L DIESEL - DESCRIPTION.....9-231

ENGINE 8.0L - DESCRIPTION...........9-172

ENGINE 8.0L - INSTALLATION...........9-182

ENGINE 8.0L - REMOVAL..............9-181

ENGINE BLOCK - CLEANING . . 9-142,9-200,9-28,

9-86

ENGINE BLOCK - INSPECTION.....9-142,9-200,

9-267,9-28,9-86

ENGINE BLOCK - STANDARD

PROCEDURE-CYLINDER BLOCK

REFACING..........................9-263

ENGINE BLOCK HEATER - 3.9L/5.2L/

5.9L - DESCRIPTION...................7-45

ENGINE BLOCK HEATER - 3.9L/5.2L/

5.9L - INSTALLATION..................7-45

ENGINE BLOCK HEATER - 3.9L/5.2L/

5.9L - OPERATION.....................7-45

ENGINE BLOCK HEATER - 3.9L/5.2L/

5.9L - REMOVAL......................7-45

ENGINE BLOCK HEATER - 5.9L DIESEL -

DESCRIPTION........................7-47

ENGINE BLOCK HEATER - 5.9L DIESEL -

INSTALLATION........................7-47

ENGINE BLOCK HEATER - 5.9L DIESEL -

OPERATION..........................7-47

ENGINE BLOCK HEATER - 5.9L DIESEL -

REMOVAL...........................7-47

ENGINE BLOCK HEATER - 8.0L -

DESCRIPTION........................7-46

ENGINE BLOCK HEATER - 8.0L -

INSTALLATION........................7-46

ENGINE BLOCK HEATER - 8.0L -

OPERATION..........................7-46

ENGINE BLOCK HEATER - 8.0L -

REMOVAL...........................7-46

ENGINE CONTROL MODULE -

INSTALLATION.......................8E-14

ENGINE CONTROL MODULE - REMOVAL . . 8E-14

ENGINE COOLANT TEMP SENSOR -

3.9L/5.2L/5.9L - DESCRIPTION...........7-48

ENGINE COOLANT TEMP SENSOR -

3.9L/5.2L/5.9L - INSTALLATION..........7-48

ENGINE COOLANT TEMP SENSOR -

3.9L/5.2L/5.9L - OPERATION.............7-48

ENGINE COOLANT TEMP SENSOR -

3.9L/5.2L/5.9L - REMOVAL..............7-48

ENGINE COOLANT THERMOSTAT -

3.9L/5.2L/5.9L - DESCRIPTION...........7-49

ENGINE COOLANT THERMOSTAT -

3.9L/5.2L/5.9L - INSTALLATION

..........7-50

ENGINE COOLANT THERMOSTAT -

3.9L/5.2L/5.9L - OPERATION

.............7-49

ENGINE COOLANT THERMOSTAT -

3.9L/5.2L/5.9L - REMOVAL

..............7-49

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - DESCRIPTION

................7-54

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - INSTALLATION

................7-55

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - OPERATION

..................7-54

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - REMOVAL

....................7-55

ENGINE COOLANT THERMOSTAT - 8.0L -

DESCRIPTION

........................7-52

ENGINE COOLANT THERMOSTAT - 8.0L -

INSTALLATION

........................7-53

ENGINE COOLANT THERMOSTAT - 8.0L -

OPERATION

..........................7-52

ENGINE COOLANT THERMOSTAT - 8.0L -

REMOVAL

...........................7-52

ENGINE DATA PLATE - DESCRIPTION

.....9-244

ENGINE DIAGNOSIS - INTRODUCTION -

DIAGNOSIS AND TESTING

.....9-118,9-173,9-3ENGINE DIAGNOSIS - MECHANICAL -

DIAGNOSIS AND TESTING.............9-232

ENGINE (FEDERAL ONLY - 2500 8.0L HD

AND 3500 5.9L& 8.0L MODELS)

MAINTENANCE SCHEDULES -

DESCRIPTION, HEAVY DUTY.............0-17

ENGINE FIRING ORDER, 3.9L V-6

ENGINE..............................8I-2

ENGINE FIRING ORDER, 5.2L/5.9L V-8

ENGINES............................8I-2

ENGINE OIL - DESCRIPTION...........0-3,0-4

ENGINE OIL - STANDARD PROCEDURE . . . 9-104,

9-160,9-217,9-47

ENGINE OIL LEAKS - DIAGNOSIS AND

TESTING.............9-104,9-160,9-215,9-47

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING....9-104,9-160,9-215,9-295,9-47

ENGINE PERFORMANCE - INSPECTION . . . 30-16

ENGINE, SPECIAL TOOLS - 5.2L..........9-77

ENGINE, SPECIAL TOOLS - 5.9L.........9-134

ENGINE, SPECIAL TOOLS - 5.9L DIESEL . . 9-244

ENGINE, SPECIAL TOOLS - 8.0L.........9-188

ENGINE, SPECIFICATIONS - 3.9L.........9-14

ENGINE, SPECIFICATIONS - 5.2L.........9-72

ENGINE, SPECIFICATIONS - 5.9L........9-129

ENGINE, SPECIFICATIONS - 8.OL........9-184

ENGINE STARTER MOTOR -

DESCRIPTION.......................8F-39

ENGINE STARTER MOTOR -

INSTALLATION.......................8F-41

ENGINE STARTER MOTOR - OPERATION....8F-39

ENGINE STARTER MOTOR - REMOVAL....8F-40

ENGINE STARTER MOTOR RELAY -

DESCRIPTION.......................8F-42

ENGINE STARTER MOTOR RELAY -

INSTALLATION.......................8F-43

ENGINE STARTER MOTOR RELAY -

OPERATION.........................8F-42

ENGINE STARTER MOTOR RELAY -

REMOVAL..........................8F-43

ENGINE TEMPERATURE GAUGE -

DESCRIPTION.......................8J-19

ENGINE TEMPERATURE GAUGE -

OPERATION.........................8J-19

ENGINES - DESCRIPTION, COMPONENT

MONITORS - DIESEL..................25-18

ENGINES - DESCRIPTION, COMPONENT

MONITORS - GAS....................25-18

ENGINES - DESCRIPTION, FUEL

REQUIREMENTS - GAS..................0-1

ENGINES - DESCRIPTION, V-6/V-8

.......25-35

ENGINES - DIAGNOSIS AND TESTING,

PCV VALVE - V-6/V-8

..................25-36

ENGINES - ENGINE FIRING ORDER,

5.2L/5.9L V-8

.........................8I-2

ENGINES - FUEL SYSTEM PRESSURES,

DIESEL

............................14-58

ENGINES - IGNITION COIL RESISTANCE,

3.9L/5.2L/5.9L

........................8I-3

ENGINES - INSTALLATION, GAS

..........8P-4

ENGINES - OPERATION, GAS

...........25-18

ENGINES - OPERATION, NON-

MONITORED CIRCUITS - GAS

...........25-22

ENGINES - OPERATION, PCM - GAS

......8E-17

ENGINES - OPERATION, V-6/V-8

.........25-35

ENGINES - REMOVAL, GAS

..............8P-4

ENGINES - SPECIFICATIONS, FUEL

SYSTEM PRESSURE - GAS

..............14-4

ENGINES - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM

3.9L/5.2L/5.9L/8.0L

....................7-15

ENGINES - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM

3.9L/5.2L/5.9L/8.0L

....................7-15

ENGINES - VISUAL INSPECTION,

3.9L/5.2L/5.9L

.......................14-28

ENGINE-TO-BODY GROUND STRAP -

INSTALLATION

.......................8A-13

ENGINE-TO-BODY GROUND STRAP -

REMOVAL

..........................8A-13

ENTRY - INSPECTION, KEYLESS

.........30-11

ENTRY SEAT TRACK - INSTALLATION,

EASY

.............................23-142

ENTRY SEAT TRACK - REMOVAL, EASY

. . 23-142

ENTRY SYSTEM - DESCRIPTION,

REMOTE KEYLESS

....................8N-2ENTRY SYSTEM - DIAGNOSIS AND

TESTING, POWER LOCK & REMOTE

KEYLESS............................8N-4

ENTRY SYSTEM - OPERATION, REMOTE

KEYLESS............................8N-3

ENTRY TRANSMITTER - DESCRIPTION,

REMOTE KEYLESS....................8N-7

ENTRY TRANSMITTER - DIAGNOSIS AND

TESTING, REMOTE KEYLESS............8N-7

ENTRY TRANSMITTER - OPERATION,

REMOTE KEYLESS....................8N-7

EQUIPMENT - STANDARD PROCEDURE,

REFRIGERANT SYSTEM SERVICE........24-44

EQUIPMENT IDENTIFICATION PLATE -

DESCRIPTION.....................Intro.-12

ESCUTCHEON - INSTALLATION, HANDLE . . 23-63

ESCUTCHEON - REMOVAL, HANDLE......23-63

EVACUATE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-45

EVAP SYSTEM - DESCRIPTION..........25-31

EVAP SYSTEM - TORQUE..............25-31

EVAPORATOR - DESCRIPTION, A/C.......24-52

EVAPORATOR - INSTALLATION, A/C......24-53

EVAPORATOR - OPERATION, A/C........24-53

EVAPORATOR - REMOVAL, A/C..........24-53

EVAP/PURGE SOLENOID - DESCRIPTION . . 25-32

EVAP/PURGE SOLENOID - INSTALLATION . 25-32

EVAP/PURGE SOLENOID - REMOVAL.....25-32

EXHAUST MANIFOLD - CLEANING . . 9-112,9-168,

9-225,9-304,9-55

EXHAUST MANIFOLD - DESCRIPTION....9-112,

9-168,9-224,9-55

EXHAUST MANIFOLD - INSPECTION.....9-112,

9-168,9-225,9-304,9-55

EXHAUST MANIFOLD - INSTALLATION . . . 9-113,

9-168,9-225,9-304,9-55

EXHAUST MANIFOLD - OPERATION . 9-112,9-168,

9-224,9-55

EXHAUST MANIFOLD - REMOVAL . . 9-112,9-168,

9-225,9-303,9-55

EXHAUST PIPE - 3.9L/5.2L/5.9L -

INSPECTION.........................11-7

EXHAUST PIPE - 3.9L/5.2L/5.9L -

INSTALLATION........................11-7

EXHAUST PIPE - 3.9L/5.2L/5.9L -

REMOVAL...........................11-7

EXHAUST PIPE - 5.9L DIESEL -

INSPECTION.........................11-9

EXHAUST PIPE - 5.9L DIESEL -

INSTALLATION.......................11-10

EXHAUST PIPE - 5.9L DIESEL -

REMOVAL...........................11-9

EXHAUST PIPE - 5.9L HEAVY DUTY/8.0L

- INSPECTION........................11-9

EXHAUST PIPE - 5.9L HEAVY DUTY/8.0L

- INSTALLATION......................11-9

EXHAUST PIPE - 5.9L HEAVY DUTY/8.0L

- REMOVAL..........................11-8

EXHAUST VENT - INSTALLATION........23-79

EXHAUST VENT - REMOVAL............23-79

EXHAUSTER - INSTALLATION, AIR.......23-77

EXHAUSTER - REMOVAL, AIR...........23-77

EXTENSION HOUSING BUSHING -

INSTALLATION....21-198,21-369,21-544,21-714

EXTENSION HOUSING BUSHING -

REMOVAL.......21-198,21-369,21-544,21-714

EXTENSION HOUSING BUSHING AND

SEAL - INSTALLATION....21-850,21-885,21-921

EXTENSION HOUSING BUSHING AND

SEAL - REMOVAL.......21-850,21-885,21-921

EXTENSION HOUSING SEAL -

INSTALLATION . . . 21-132,21-198,21-369,21-544,

21-715,21-87

EXTENSION HOUSING SEAL - REMOVAL . 21-132,

21-198,21-369,21-544,21-714,21-87

EXTERIOR - DESCRIPTION.............23-86

EXTERIOR - OPERATION...............23-86

EXTERIOR HANDLE - INSTALLATION.....23-70

EXTERIOR HANDLE - REMOVAL.........23-70

EXTERIOR NAME PLATES -

INSTALLATION

.......................23-89

EXTERIOR NAME PLATES - REMOVAL

....23-89

FAILURE - DIAGNOSIS AND TESTING,

CYLINDER HEAD GASKET

. 9-136,9-191,9-22,9-79

FAN - 3.9L/5.2L/5.9L/8.0L - CLEANING,

RADIATOR

...........................7-43

FAN - 3.9L/5.2L/5.9L/8.0L - INSPECTION,

RADIATOR

...........................7-43

BR/BEINDEX 13

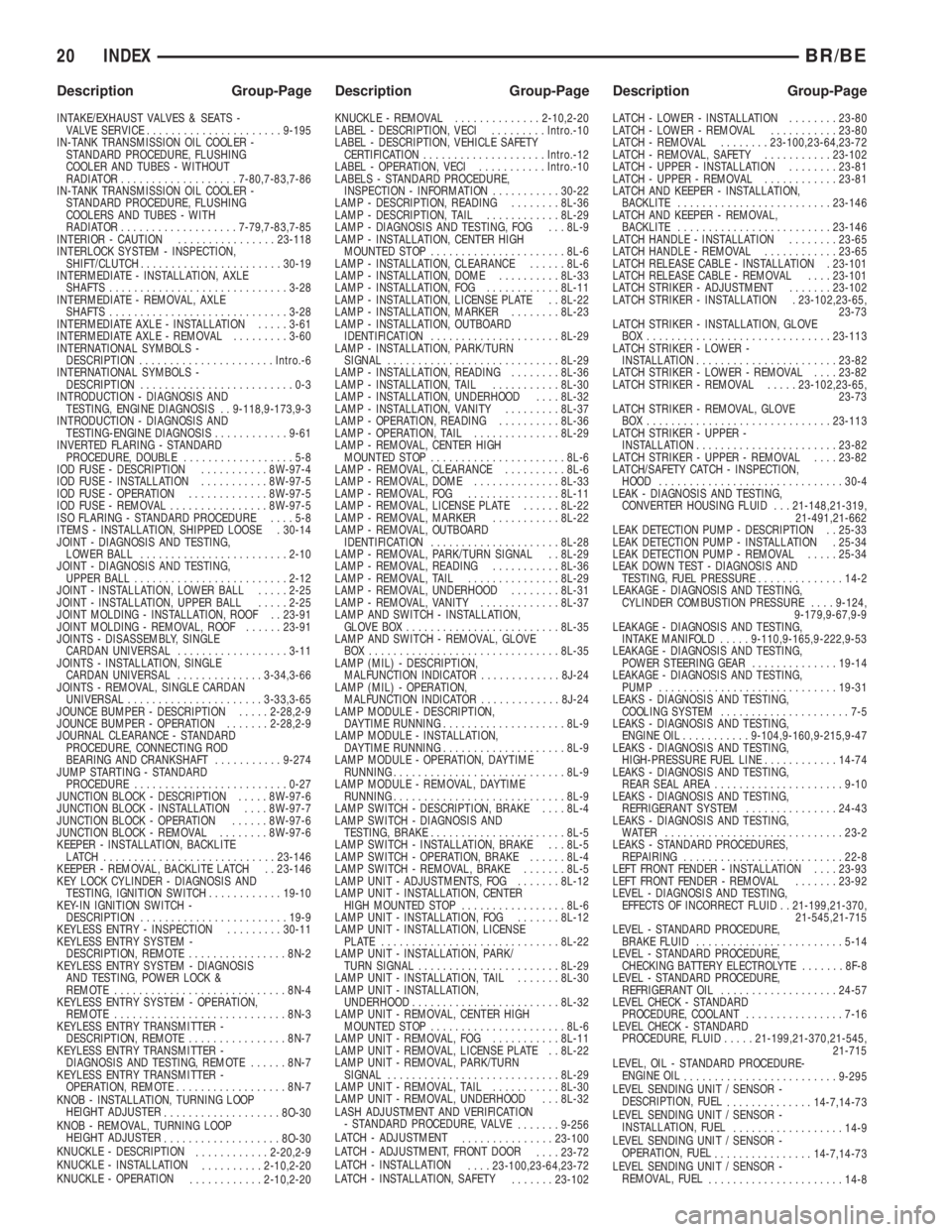

Description Group-Page Description Group-Page Description Group-Page

Page 2867 of 2889

INTAKE/EXHAUST VALVES & SEATS -

VALVE SERVICE......................9-195

IN-TANK TRANSMISSION OIL COOLER -

STANDARD PROCEDURE, FLUSHING

COOLER AND TUBES - WITHOUT

RADIATOR...................7-80,7-83,7-86

IN-TANK TRANSMISSION OIL COOLER -

STANDARD PROCEDURE, FLUSHING

COOLERS AND TUBES - WITH

RADIATOR...................7-79,7-83,7-85

INTERIOR - CAUTION................23-118

INTERLOCK SYSTEM - INSPECTION,

SHIFT/CLUTCH.......................30-19

INTERMEDIATE - INSTALLATION, AXLE

SHAFTS.............................3-28

INTERMEDIATE - REMOVAL, AXLE

SHAFTS.............................3-28

INTERMEDIATE AXLE - INSTALLATION.....3-61

INTERMEDIATE AXLE - REMOVAL.........3-60

INTERNATIONAL SYMBOLS -

DESCRIPTION......................Intro.-6

INTERNATIONAL SYMBOLS -

DESCRIPTION.........................0-3

INTRODUCTION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS . . 9-118,9-173,9-3

INTRODUCTION - DIAGNOSIS AND

TESTING-ENGINE DIAGNOSIS............9-61

INVERTED FLARING - STANDARD

PROCEDURE, DOUBLE..................5-8

IOD FUSE - DESCRIPTION...........8W-97-4

IOD FUSE - INSTALLATION...........8W-97-5

IOD FUSE - OPERATION.............8W-97-5

IOD FUSE - REMOVAL................8W-97-5

ISO FLARING - STANDARD PROCEDURE....5-8

ITEMS - INSTALLATION, SHIPPED LOOSE . 30-14

JOINT - DIAGNOSIS AND TESTING,

LOWER BALL........................2-10

JOINT - DIAGNOSIS AND TESTING,

UPPER BALL.........................2-12

JOINT - INSTALLATION, LOWER BALL.....2-25

JOINT - INSTALLATION, UPPER BALL.....2-25

JOINT MOLDING - INSTALLATION, ROOF . . 23-91

JOINT MOLDING - REMOVAL, ROOF......23-91

JOINTS - DISASSEMBLY, SINGLE

CARDAN UNIVERSAL..................3-11

JOINTS - INSTALLATION, SINGLE

CARDAN UNIVERSAL..............3-34,3-66

JOINTS - REMOVAL, SINGLE CARDAN

UNIVERSAL......................3-33,3-65

JOUNCE BUMPER - DESCRIPTION.....2-28,2-9

JOUNCE BUMPER - OPERATION.......2-28,2-9

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD

BEARING AND CRANKSHAFT...........9-274

JUMP STARTING - STANDARD

PROCEDURE.........................0-27

JUNCTION BLOCK - DESCRIPTION.....8W-97-6

JUNCTION BLOCK - INSTALLATION....8W-97-7

JUNCTION BLOCK - OPERATION......8W-97-6

JUNCTION BLOCK - REMOVAL........8W-97-6

KEEPER - INSTALLATION, BACKLITE

LATCH ............................23-146

KEEPER - REMOVAL, BACKLITE LATCH . . 23-146

KEY LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH............19-10

KEY-IN IGNITION SWITCH -

DESCRIPTION........................19-9

KEYLESS ENTRY - INSPECTION.........30-11

KEYLESS ENTRY SYSTEM -

DESCRIPTION, REMOTE................8N-2

KEYLESS ENTRY SYSTEM - DIAGNOSIS

AND TESTING, POWER LOCK &

REMOTE............................8N-4

KEYLESS ENTRY SYSTEM - OPERATION,

REMOTE............................8N-3

KEYLESS ENTRY TRANSMITTER -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-7

KEYLESS ENTRY TRANSMITTER -

OPERATION, REMOTE..................8N-7

KNOB - INSTALLATION, TURNING LOOP

HEIGHT ADJUSTER

...................8O-30

KNOB - REMOVAL, TURNING LOOP

HEIGHT ADJUSTER

...................8O-30

KNUCKLE - DESCRIPTION

............2-20,2-9

KNUCKLE - INSTALLATION

..........2-10,2-20

KNUCKLE - OPERATION

............2-10,2-20KNUCKLE - REMOVAL..............2-10,2-20

LABEL - DESCRIPTION, VECI.........Intro.-10

LABEL - DESCRIPTION, VEHICLE SAFETY

CERTIFICATION....................Intro.-12

LABEL - OPERATION, VECI...........Intro.-10

LABELS - STANDARD PROCEDURE,

INSPECTION - INFORMATION...........30-22

LAMP - DESCRIPTION, READING........8L-36

LAMP - DESCRIPTION, TAIL............8L-29

LAMP - DIAGNOSIS AND TESTING, FOG . . . 8L-9

LAMP - INSTALLATION, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP - INSTALLATION, CLEARANCE......8L-6

LAMP - INSTALLATION, DOME..........8L-33

LAMP - INSTALLATION, FOG............8L-11

LAMP - INSTALLATION, LICENSE PLATE . . 8L-22

LAMP - INSTALLATION, MARKER........8L-23

LAMP - INSTALLATION, OUTBOARD

IDENTIFICATION.....................8L-29

LAMP - INSTALLATION, PARK/TURN

SIGNAL............................8L-29

LAMP - INSTALLATION, READING........8L-36

LAMP - INSTALLATION, TAIL...........8L-30

LAMP - INSTALLATION, UNDERHOOD....8L-32

LAMP - INSTALLATION, VANITY.........8L-37

LAMP - OPERATION, READING..........8L-36

LAMP - OPERATION, TAIL..............8L-29

LAMP - REMOVAL, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP - REMOVAL, CLEARANCE..........8L-6

LAMP - REMOVAL, DOME..............8L-33

LAMP - REMOVAL, FOG...............8L-11

LAMP - REMOVAL, LICENSE PLATE......8L-22

LAMP - REMOVAL, MARKER...........8L-22

LAMP - REMOVAL, OUTBOARD

IDENTIFICATION.....................8L-28

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-29

LAMP - REMOVAL, READING...........8L-36

LAMP - REMOVAL, TAIL...............8L-29

LAMP - REMOVAL, UNDERHOOD........8L-31

LAMP - REMOVAL, VANITY.............8L-37

LAMP AND SWITCH - INSTALLATION,

GLOVE BOX.........................8L-35

LAMP AND SWITCH - REMOVAL, GLOVE

BOX ...............................8L-35

LAMP (MIL) - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-24

LAMP (MIL) - OPERATION,

MALFUNCTION INDICATOR.............8J-24

LAMP MODULE - DESCRIPTION,

DAYTIME RUNNING....................8L-9

LAMP MODULE - INSTALLATION,

DAYTIME RUNNING....................8L-9

LAMP MODULE - OPERATION, DAYTIME

RUNNING............................8L-9

LAMP MODULE - REMOVAL, DAYTIME

RUNNING............................8L-9

LAMP SWITCH - DESCRIPTION, BRAKE....8L-4

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE......................8L-5

LAMP SWITCH - INSTALLATION, BRAKE . . . 8L-5

LAMP SWITCH - OPERATION, BRAKE......8L-4

LAMP SWITCH - REMOVAL, BRAKE.......8L-5

LAMP UNIT - ADJUSTMENTS, FOG.......8L-12

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP.................8L-6

LAMP UNIT - INSTALLATION, FOG.......8L-12

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-22

LAMP UNIT - INSTALLATION, PARK/

TURN SIGNAL.......................8L-29

LAMP UNIT - INSTALLATION, TAIL.......8L-30

LAMP UNIT - INSTALLATION,

UNDERHOOD........................8L-32

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP UNIT - REMOVAL, FOG...........8L-11

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-22

LAMP UNIT - REMOVAL, PARK/TURN

SIGNAL............................8L-29

LAMP UNIT - REMOVAL, TAIL...........8L-30

LAMP UNIT - REMOVAL, UNDERHOOD . . . 8L-32

LASH ADJUSTMENT AND VERIFICATION

- STANDARD PROCEDURE, VALVE

.......9-256

LATCH - ADJUSTMENT

...............23-100

LATCH - ADJUSTMENT, FRONT DOOR

....23-72

LATCH - INSTALLATION

....23-100,23-64,23-72

LATCH - INSTALLATION, SAFETY

.......23-102LATCH - LOWER - INSTALLATION........23-80

LATCH - LOWER - REMOVAL...........23-80

LATCH - REMOVAL........23-100,23-64,23-72

LATCH - REMOVAL, SAFETY...........23-102

LATCH - UPPER - INSTALLATION........23-81

LATCH - UPPER - REMOVAL............23-81

LATCH AND KEEPER - INSTALLATION,

BACKLITE.........................23-146

LATCH AND KEEPER - REMOVAL,

BACKLITE.........................23-146

LATCH HANDLE - INSTALLATION........23-65

LATCH HANDLE - REMOVAL............23-65

LATCH RELEASE CABLE - INSTALLATION . 23-101

LATCH RELEASE CABLE - REMOVAL....23-101

LATCH STRIKER - ADJUSTMENT.......23-102

LATCH STRIKER - INSTALLATION . 23-102,23-65,

23-73

LATCH STRIKER - INSTALLATION, GLOVE

BOX ..............................23-113

LATCH STRIKER - LOWER -

INSTALLATION.......................23-82

LATCH STRIKER - LOWER - REMOVAL....23-82

LATCH STRIKER - REMOVAL.....23-102,23-65,

23-73

LATCH STRIKER - REMOVAL, GLOVE

BOX ..............................23-113

LATCH STRIKER - UPPER -

INSTALLATION.......................23-82

LATCH STRIKER - UPPER - REMOVAL....23-82

LATCH/SAFETY CATCH - INSPECTION,

HOOD..............................30-4

LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING FLUID . . . 21-148,21-319,

21-491,21-662

LEAK DETECTION PUMP - DESCRIPTION . . 25-33

LEAK DETECTION PUMP - INSTALLATION . 25-34

LEAK DETECTION PUMP - REMOVAL.....25-34

LEAK DOWN TEST - DIAGNOSIS AND

TESTING, FUEL PRESSURE..............14-2

LEAKAGE - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE....9-124,

9-179,9-67,9-9

LEAKAGE - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD.....9-110,9-165,9-222,9-53

LEAKAGE - DIAGNOSIS AND TESTING,

POWER STEERING GEAR..............19-14

LEAKAGE - DIAGNOSIS AND TESTING,

PUMP.............................19-31

LEAKS - DIAGNOSIS AND TESTING,

COOLING SYSTEM.....................7-5

LEAKS - DIAGNOSIS AND TESTING,

ENGINE OIL...........9-104,9-160,9-215,9-47

LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL LINE............14-74

LEAKS - DIAGNOSIS AND TESTING,

REAR SEAL AREA.....................9-10

LEAKS - DIAGNOSIS AND TESTING,

REFRIGERANT SYSTEM...............24-43

LEAKS - DIAGNOSIS AND TESTING,

WATER .............................23-2

LEAKS - STANDARD PROCEDURES,

REPAIRING..........................22-8

LEFT FRONT FENDER - INSTALLATION....23-93

LEFT FRONT FENDER - REMOVAL.......23-92

LEVEL - DIAGNOSIS AND TESTING,

EFFECTS OF INCORRECT FLUID . . 21-199,21-370,

21-545,21-715

LEVEL - STANDARD PROCEDURE,

BRAKE FLUID........................5-14

LEVEL - STANDARD PROCEDURE,

CHECKING BATTERY ELECTROLYTE.......8F-8

LEVEL - STANDARD PROCEDURE,

REFRIGERANT OIL...................24-57

LEVEL CHECK - STANDARD

PROCEDURE, COOLANT................7-16

LEVEL CHECK - STANDARD

PROCEDURE, FLUID.....21-199,21-370,21-545,

21-715

LEVEL, OIL - STANDARD PROCEDURE-

ENGINE OIL

.........................9-295

LEVEL SENDING UNIT / SENSOR -

DESCRIPTION, FUEL

..............14-7,14-73

LEVEL SENDING UNIT / SENSOR -

INSTALLATION, FUEL

..................14-9

LEVEL SENDING UNIT / SENSOR -

OPERATION, FUEL

................14-7,14-73

LEVEL SENDING UNIT / SENSOR -

REMOVAL, FUEL

......................14-8

20 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2876 of 2889

RELAY - OPERATION, A/C COMPRESSOR

CLUTCH............................24-17

RELAY - OPERATION, BLOWER MOTOR . . . 24-22

RELAY - OPERATION, ENGINE STARTER

MOTOR............................8F-42

RELAY - OPERATION, FUEL HEATER......14-63

RELAY - OPERATION, FUEL INJECTION

PUMP.............................14-99

RELAY - OPERATION, FUEL PUMP.......14-41

RELAY - OPERATION, HEADLAMP........8L-17

RELAY - OPERATION, HEATED SEAT.....8G-12

RELAY - OPERATION, HORN.............8H-3

RELAY - OPERATION, INTAKE AIR

HEATER ...........................14-102

RELAY - OPERATION, RADIO CHOKE......8A-8

RELAY - OPERATION, WIPER...........8R-15

RELAY - REMOVAL, A/C COMPRESSOR

CLUTCH............................24-18

RELAY - REMOVAL, AUTOMATIC SHUT

DOWN..............................8I-4

RELAY - REMOVAL, BLOWER MOTOR....24-23

RELAY - REMOVAL, ENGINE STARTER

MOTOR............................8F-43

RELAY - REMOVAL, FUEL HEATER.......14-65

RELAY - REMOVAL, FUEL PUMP........14-41

RELAY - REMOVAL, HEADLAMP.........8L-18

RELAY - REMOVAL, HEATED SEAT.......8G-13

RELAY - REMOVAL, INTAKE AIR HEATER . 14-102

RELAY - REMOVAL, RADIO CHOKE.........8A-9

RELAY - REMOVAL, WIPER............8R-17

RELAYS - DIAGNOSIS AND TESTING,

ASD AND FUEL PUMP..................8I-3

RELEASE - INSTALLATION..............5-41

RELEASE - REMOVAL..................5-40

RELEASE - STANDARD PROCEDURE,

FUEL SYSTEM PRESSURE..............14-3

RELEASE BEARING - DESCRIPTION,

CLUTCH.............................6-14

RELEASE BEARING - INSTALLATION,

CLUTCH.............................6-15

RELEASE BEARING - OPERATION,

CLUTCH.............................6-14

RELEASE BEARING - REMOVAL, CLUTCH . . . 6-15

RELEASE CABLE - INSTALLATION........23-83

RELEASE CABLE - INSTALLATION, LATCH . 23-101

RELEASE CABLE - REMOVAL...........23-82

RELEASE CABLE - REMOVAL, LATCH....23-101

RELIEF VALVE - CLEANING, OIL

PRESSURE.........................9-297

RELIEF VALVE - DESCRIPTION, HIGH

PRESSURE.........................24-46

RELIEF VALVE - INSPECTION, OIL

PRESSURE.........................9-297

RELIEF VALVE - INSTALLATION, OIL

PRESSURE.........................9-298

RELIEF VALVE - OPERATION, HIGH

PRESSURE.........................24-46

RELIEF VALVE - REMOVAL, OIL

PRESSURE.........................9-297

REMINDER - INSPECTION, TRIP

COMPUTER/MAINTENANCE.............30-17

REMINDER INDICATOR - DESCRIPTION,

SERVICE...........................8J-28

REMINDER INDICATOR - OPERATION,

SERVICE...........................8J-28

REMOTE KEYLESS ENTRY SYSTEM -

DESCRIPTION........................8N-2

REMOTE KEYLESS ENTRY SYSTEM -

DIAGNOSIS AND TESTING, POWER

LOCK...............................8N-4

REMOTE KEYLESS ENTRY SYSTEM -

OPERATION..........................8N-3

REMOTE KEYLESS ENTRY

TRANSMITTER - DESCRIPTION..........8N-7

REMOTE KEYLESS ENTRY

TRANSMITTER - DIAGNOSIS AND

TESTING............................8N-7

REMOTE KEYLESS ENTRY

TRANSMITTER - OPERATION............8N-7

REMOTE SWITCHES - DESCRIPTION.....8A-15

REMOTE SWITCHES - DIAGNOSIS AND

TESTING

...........................8A-16

REMOTE SWITCHES - OPERATION

.......8A-15

REMOVAL/INSTALLATION, FUEL FILLER

CAP

...............................25-33

REMOVAL/INSTALLATION, FUEL HEATER

. . 14-63

REPAIR - DESCRIPTION, THREADED

HOLE

.............................Intro.-6REPAIR - STANDARD PROCEDURE,

ALUMINUM THREAD....21-159,21-330,21-502,

21-673

REPAIR - STANDARD PROCEDURE, CAM

BORE..............................9-267

REPAIR - STANDARD PROCEDURE,

CYLINDER BORE.....................9-265

REPAIR DAMAGED OR WORN THREADS

- STANDARD PROCEDURE....9-11,9-125,9-181,

9-238,9-68

REPAIRING LEAKS - STANDARD

PROCEDURES........................22-8

REQUIREMENTS - DESCRIPTION,

COOLING SYSTEM....................24-1

REQUIREMENTS - DIESEL ENGINE -

DESCRIPTION, FUEL....................0-2

REQUIREMENTS - GAS ENGINES -

DESCRIPTION, FUEL....................0-1

RESERVOIR - DESCRIPTION, VACUUM....24-29

RESERVOIR - DESCRIPTION, VACUUM . . . 8P-13

RESERVOIR - DESCRIPTION, WASHER . . . 8R-10

RESERVOIR - INSTALLATION, FLUID......5-15

RESERVOIR - INSTALLATION, VACUUM . . . 24-30

RESERVOIR - INSTALLATION, VACUUM . . . 8P-14

RESERVOIR - INSTALLATION, WASHER . . . 8R-11

RESERVOIR - OPERATION, VACUUM.....24-29

RESERVOIR - OPERATION, WASHER.....8R-10

RESERVOIR - REMOVAL, FLUID..........5-15

RESERVOIR - REMOVAL, VACUUM.......24-30

RESERVOIR - REMOVAL, VACUUM.......8P-13

RESERVOIR - REMOVAL, WASHER......8R-10

RESISTANCE, 3.9L/5.2L/5.9L ENGINES -

IGNITION COIL........................8I-3

RESISTANCE, 8.0L V-10 ENGINE -

IGNITION COIL........................8I-3

RESISTANCE, SPECIFICATIONS - SPARK

PLUG CABLE.........................8I-3

RESISTOR BLOCK - DESCRIPTION,

BLOWER MOTOR....................24-23

RESISTOR BLOCK - DIAGNOSIS AND

TESTING, BLOWER MOTOR

............24-24

RESISTOR BLOCK - INSTALLATION,

BLOWER MOTOR

....................24-24

RESISTOR BLOCK - OPERATION,

BLOWER MOTOR

....................24-23

RESISTOR BLOCK - REMOVAL, BLOWER

MOTOR

............................24-24

RESONATOR - INSTALLATION

...........11-13

RESONATOR - REMOVAL

..............11-13

RESTRAINTS - DESCRIPTION

............8O-1

RESTRAINTS - INSPECTION, SEAT

BELTS, SHOULDER BELTS,

RETRACTORS AND HEAD

..............30-12

RESTRAINTS - OPERATION

.............8O-2

RESTRAINTS - WARNING

...............8O-3

RESTRICTIONS - DIAGNOSIS AND

TESTING, FUEL SUPPLY

...............14-56

RETAINER - ASSEMBLY, OVERRUNNING

CLUTCH CAM/OVERDRIVE PISTON

.....21-236,

21-406,21-581,21-752

RETAINER - CLEANING, OVERRUNNING

CLUTCH CAM/OVERDRIVE PISTON

.....21-236,

21-406,21-580,21-752

RETAINER - DESCRIPTION,

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON

.....21-235,21-405,21-580,

21-751

RETAINER - DISASSEMBLY,

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON

.....21-235,21-405,21-580,

21-751

RETAINER - INSPECTION,

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON

.....21-236,21-406,21-580,

21-752

RETAINER - INSTALLATION,

CRANKSHAFT REAR OIL SEAL

.....9-206,9-279

RETAINER - OPERATION, OVERRUNNING

CLUTCH CAM/OVERDRIVE PISTON

.....21-235,

21-405,21-580,21-751

RETAINER - REMOVAL, CRANKSHAFT

REAR OIL SEAL

.................9-206,9-278

RETRACTOR - INSTALLATION, REAR

SEAT BELT

.........................8O-26

RETRACTOR - REMOVAL, REAR SEAT

BELT

..............................8O-26RETRACTORS AND HEAD RESTRAINTS -

INSPECTION, SEAT BELTS, SHOULDER

BELTS .............................30-12

RETURN - DESCRIPTION, HOSES........19-37

RETURN - DESCRIPTION, SENSOR.......8E-17

RETURN - OPERATION, HOSES..........19-37

REVOLUTIONS PER MILE,

SPECIFICATIONS - TIRE................22-9

RIGHT FRONT FENDER - INSTALLATION . . 23-94

RIGHT FRONT FENDER - REMOVAL......23-94

RING - INSTALLATION, PINION

GEAR/RING GEAR/TONE.....3-105,3-137,3-166,

3-195

RING - REMOVAL, PINION GEAR/RING

GEAR/TONE..........3-103,3-135,3-165,3-193

RING FITTING - STANDARD

PROCEDURE, PISTON.........9-154,9-41,9-98

RING FITTING, PISTON RINGS -

STANDARD PROCEDURE-PISTON........9-288

RINGS - STANDARD PROCEDURE,

FITTING PISTON.....................9-211

RINGS - STANDARD PROCEDURE-

PISTON RING FITTING, PISTON.........9-288

RISER - INSTALLATION, SEAT..........23-141

RISER - REMOVAL, SEAT.............23-141

RKE TRANSMITTER BATTERIES -

STANDARD PROCEDURE...............8N-8

RKE TRANSMITTER PROGRAMMING -

STANDARD PROCEDURE...............8N-8

ROAD TEST - DIAGNOSIS AND TESTING . . . 8P-3

ROAD TEST - INSPECTION WINDSHIELD

WIPERS/WASHERS....................30-18

ROAD TEST INSPECTION - DESCRIPTION . 30-15

ROAD TESTING - DIAGNOSIS AND

TESTING........21-143,21-314,21-486,21-657

ROCKER ARM / ADJUSTER ASSEMBLY -

INSTALLATION........................9-85

ROCKER ARM / ADJUSTER ASSEMBLY -

REMOVAL...........................9-85

ROCKER ARM / ADJUSTER ASSY -

CLEANING..........................9-262

ROCKER ARM / ADJUSTER ASSY -

DESCRIPTION.......................9-261

ROCKER ARM / ADJUSTER ASSY -

INSPECTION........................9-262

ROCKER ARM / ADJUSTER ASSY -

INSTALLATION.............9-142,9-200,9-263

ROCKER ARM / ADJUSTER ASSY -

REMOVAL................9-142,9-200,9-261

ROD - CLEANING, PISTON &

CONNECTING.....9-154,9-209,9-285,9-41,9-98

ROD - CONNECTING RODS, PISTON &

CONNECTING........................9-286

ROD - DESCRIPTION, PISTON &

CONNECTING.....9-153,9-208,9-282,9-40,9-97

ROD - INSPECTION, PISTON &

CONNECTING.....9-154,9-209,9-285,9-41,9-98

ROD - INSTALLATION, PISTON &

CONNECTING.....9-154,9-210,9-287,9-41,9-98

ROD - REMOVAL, PISTON &

CONNECTING.....9-154,9-209,9-285,9-40,9-97

ROD BEARING AND CRANKSHAFT

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING............9-274

ROD BEARING FITTING - STANDARD

PROCEDURE, CONNECTING . . . 9-144,9-202,9-88

ROD BEARING FITTING, CONNECTING

ROD BEARINGS - STANDARD

PROCEDURE-CONNECTING

..............9-31

ROD BEARINGS - STANDARD

PROCEDURE-CONNECTING ROD

BEARING FITTING, CONNECTING

.........9-31

RODS, PISTON & CONNECTING ROD -

CONNECTING

........................9-286

ROLLOVER VALVE - DESCRIPTION

.......14-25

ROLLOVER VALVE - INSTALLATION

......14-27

ROLLOVER VALVE - REMOVAL

..........14-26

ROOF JOINT MOLDING - INSTALLATION

. . 23-91

ROOF JOINT MOLDING - REMOVAL

......23-91

ROTATION - STANDARD PROCEDURES,

TIRE

................................22-2

ROTOR - DIAGNOSIS AND TESTING,

DISC BRAKE

.........................5-20

ROTOR - DIAGNOSIS AND TESTING,

DISTRIBUTOR

.......................8I-13

RUN CHANNEL - INSTALLATION, GLASS

. . 23-70

RUN CHANNEL - REMOVAL, GLASS

......23-70

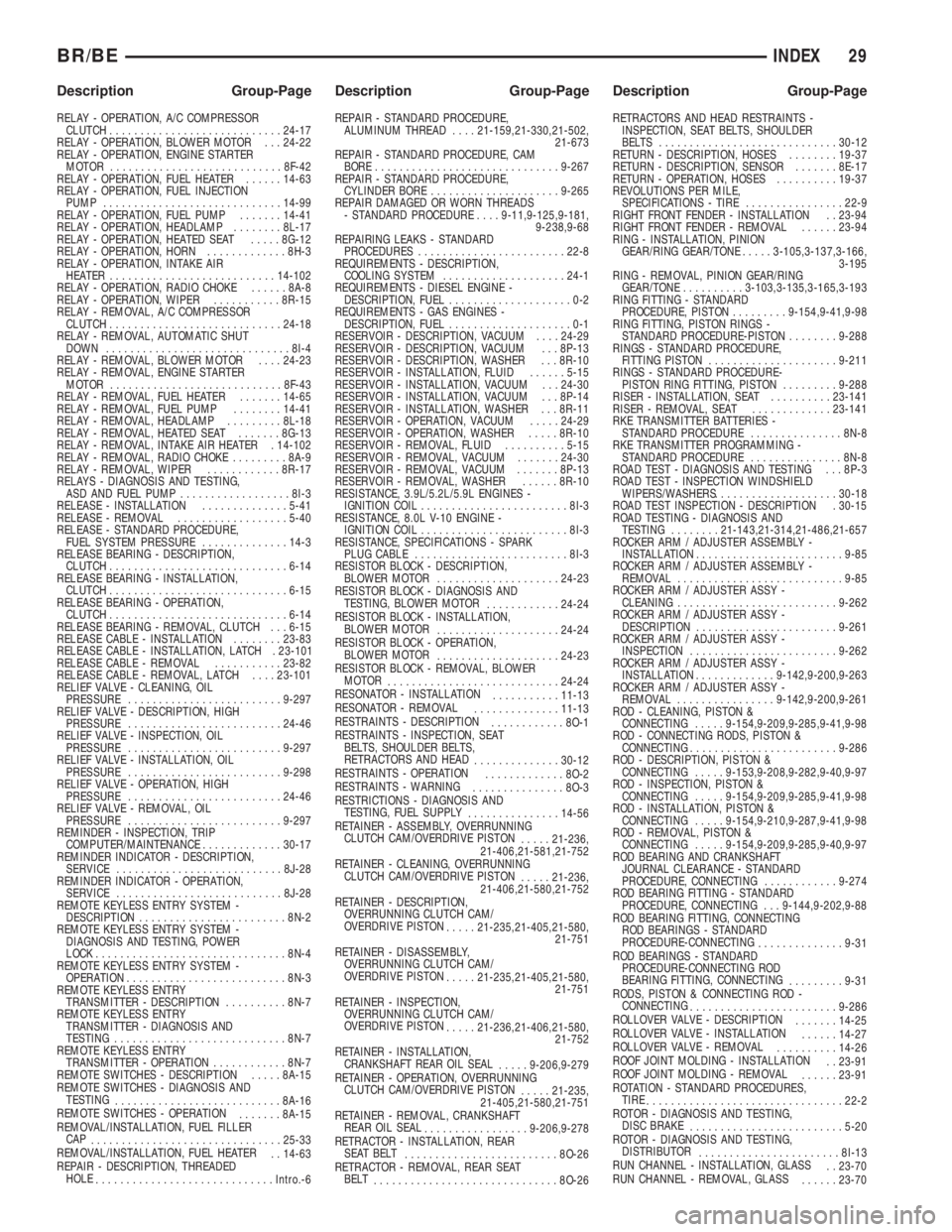

BR/BEINDEX 29

Description Group-Page Description Group-Page Description Group-Page