fuel DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2632 of 2889

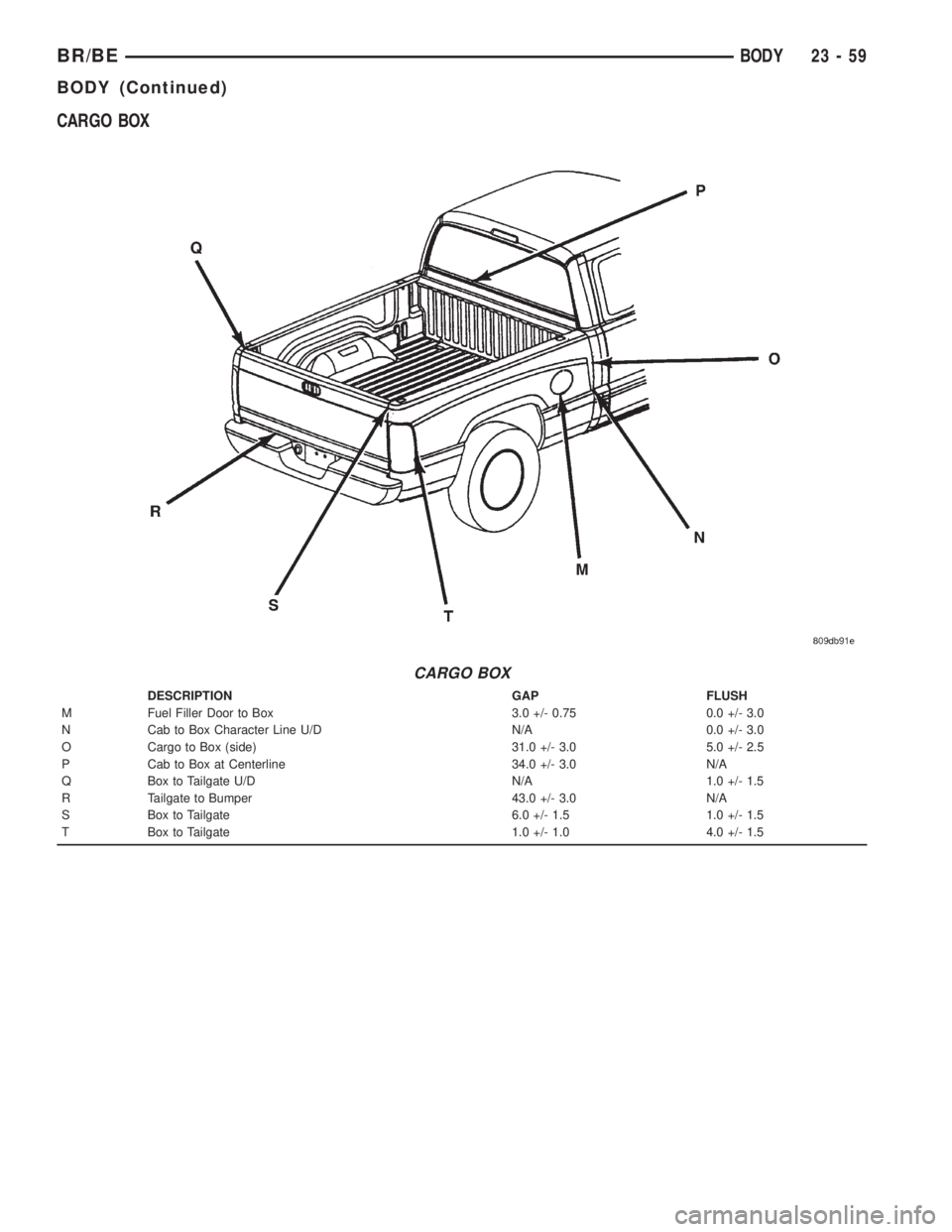

CARGO BOX

CARGO BOX

DESCRIPTION GAP FLUSH

M Fuel Filler Door to Box 3.0 +/- 0.75 0.0 +/- 3.0

N Cab to Box Character Line U/D N/A 0.0 +/- 3.0

O Cargo to Box (side) 31.0 +/- 3.0 5.0 +/- 2.5

P Cab to Box at Centerline 34.0 +/- 3.0 N/A

Q Box to Tailgate U/D N/A 1.0 +/- 1.5

R Tailgate to Bumper 43.0 +/- 3.0 N/A

S Box to Tailgate 6.0 +/- 1.5 1.0 +/- 1.5

T Box to Tailgate 1.0 +/- 1.0 4.0 +/- 1.5

BR/BEBODY 23 - 59

BODY (Continued)

Page 2659 of 2889

EXTERIOR

TABLE OF CONTENTS

page page

EXTERIOR

DESCRIPTION...........................86

OPERATION.............................86

BODY SIDE MOLDINGS

REMOVAL..............................87

INSTALLATION...........................87

BODY STRIPES AND DECALS

REMOVAL..............................87

INSTALLATION...........................87

TAPE STRIPE

REMOVAL..............................88

INSTALLATION...........................88

EXTERIOR NAME PLATES

REMOVAL..............................89

INSTALLATION...........................89

COWL GRILLE

REMOVAL..............................90

INSTALLATION...........................90

ROOF JOINT MOLDING

REMOVAL..............................91

INSTALLATION...........................91

GRILLE

REMOVAL..............................91

INSTALLATION...........................91

GRILLE FRAME

REMOVAL..............................91

INSTALLATION...........................92

FRONT END SPLASH SHIELDS

REMOVAL..............................92

INSTALLATION...........................92LEFT FRONT FENDER

REMOVAL..............................92

INSTALLATION...........................93

RIGHT FRONT FENDER

REMOVAL..............................94

INSTALLATION...........................94

FUEL FILL DOOR

REMOVAL..............................95

INSTALLATION...........................95

REAR FENDER

REMOVAL..............................95

INSTALLATION...........................95

REAR SPLASH SHIELD

REMOVAL..............................96

INSTALLATION...........................96

REAR WHEELHOUSE LINER

REMOVAL..............................96

INSTALLATION...........................96

CARGO BOX

REMOVAL..............................96

INSTALLATION...........................97

SIDE VIEW MIRROR

REMOVAL..............................97

INSTALLATION...........................97

SIDE VIEW MIRROR - LOW MOUNTED

REMOVAL..............................98

INSTALLATION...........................98

SIDE VIEW MIRROR GLASS

REMOVAL..............................98

INSTALLATION...........................98

EXTERIOR

DESCRIPTION

Exterior sheet metal components make up the

exterior of the vehicle. Some exterior metal systems

are welded assemblies, such as doors and hoods.

Some exterior trim items are made of composite.

OPERATION

The exterior is finished in various metal stampings

and composite moldings. These assemblies give the

vehicle a finished appearance and protect the occu-

pants from the elements. Some components are partof the energy absorbing system used to protect the

occupants in collisions. The exterior sheet metal is

repairable and adjustable for fit and finish. Welded

and bonded component systems are adjustable as a

system. Trim components made of composite are

stamped with the type of material used. Daimler-

Chrysler uses various fasteners to retain trim items.

At times, it is not possible to remove trim items

without damaging the fastener. If it is not possible to

remove an item without damaging a component, cut

or break the fasteners and use new ones when

installing the component.

23 - 86 EXTERIORBR/BE

Page 2668 of 2889

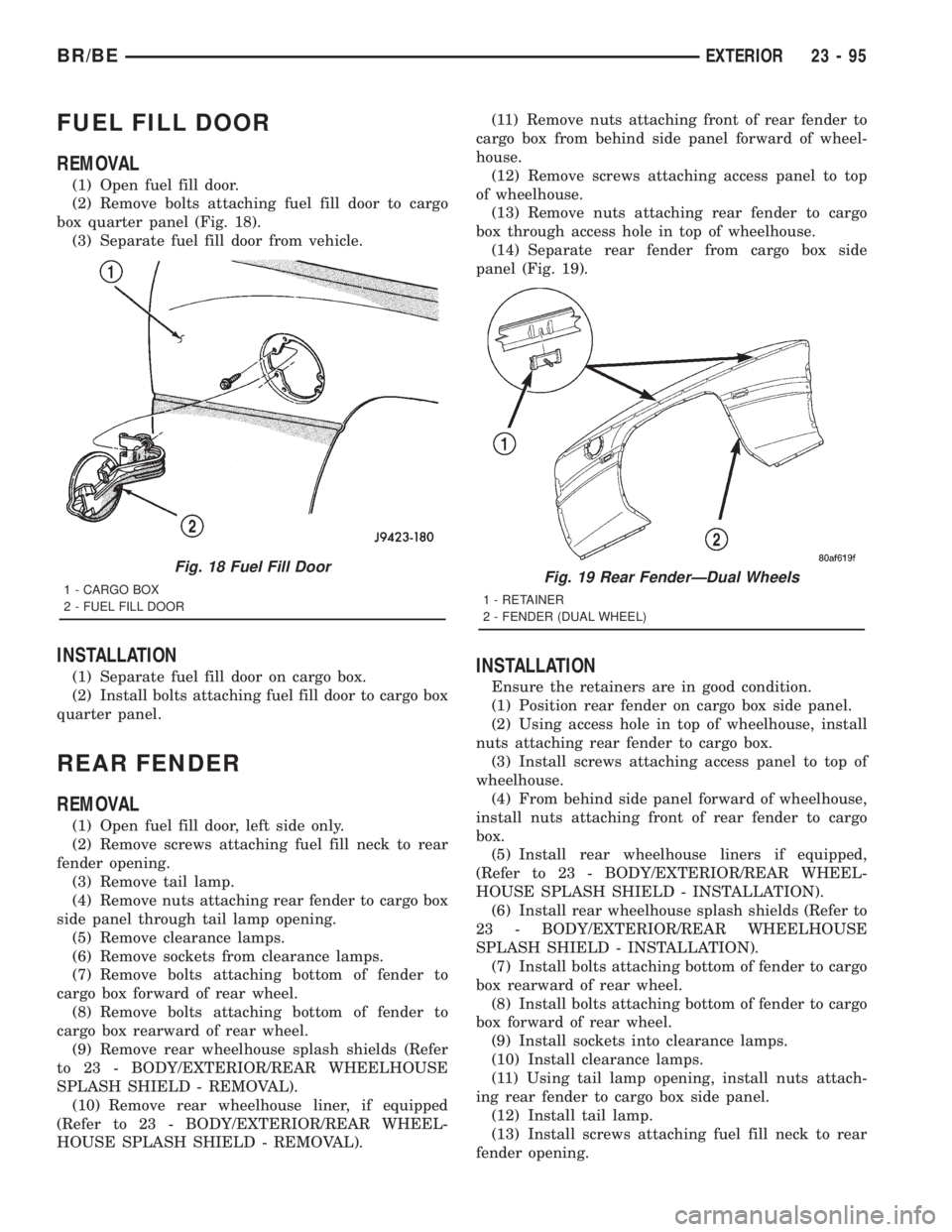

FUEL FILL DOOR

REMOVAL

(1) Open fuel fill door.

(2) Remove bolts attaching fuel fill door to cargo

box quarter panel (Fig. 18).

(3) Separate fuel fill door from vehicle.

INSTALLATION

(1) Separate fuel fill door on cargo box.

(2) Install bolts attaching fuel fill door to cargo box

quarter panel.

REAR FENDER

REMOVAL

(1) Open fuel fill door, left side only.

(2) Remove screws attaching fuel fill neck to rear

fender opening.

(3) Remove tail lamp.

(4) Remove nuts attaching rear fender to cargo box

side panel through tail lamp opening.

(5) Remove clearance lamps.

(6) Remove sockets from clearance lamps.

(7) Remove bolts attaching bottom of fender to

cargo box forward of rear wheel.

(8) Remove bolts attaching bottom of fender to

cargo box rearward of rear wheel.

(9) Remove rear wheelhouse splash shields (Refer

to 23 - BODY/EXTERIOR/REAR WHEELHOUSE

SPLASH SHIELD - REMOVAL).

(10) Remove rear wheelhouse liner, if equipped

(Refer to 23 - BODY/EXTERIOR/REAR WHEEL-

HOUSE SPLASH SHIELD - REMOVAL).(11) Remove nuts attaching front of rear fender to

cargo box from behind side panel forward of wheel-

house.

(12) Remove screws attaching access panel to top

of wheelhouse.

(13) Remove nuts attaching rear fender to cargo

box through access hole in top of wheelhouse.

(14) Separate rear fender from cargo box side

panel (Fig. 19).

INSTALLATION

Ensure the retainers are in good condition.

(1) Position rear fender on cargo box side panel.

(2) Using access hole in top of wheelhouse, install

nuts attaching rear fender to cargo box.

(3) Install screws attaching access panel to top of

wheelhouse.

(4) From behind side panel forward of wheelhouse,

install nuts attaching front of rear fender to cargo

box.

(5) Install rear wheelhouse liners if equipped,

(Refer to 23 - BODY/EXTERIOR/REAR WHEEL-

HOUSE SPLASH SHIELD - INSTALLATION).

(6) Install rear wheelhouse splash shields (Refer to

23 - BODY/EXTERIOR/REAR WHEELHOUSE

SPLASH SHIELD - INSTALLATION).

(7) Install bolts attaching bottom of fender to cargo

box rearward of rear wheel.

(8) Install bolts attaching bottom of fender to cargo

box forward of rear wheel.

(9) Install sockets into clearance lamps.

(10) Install clearance lamps.

(11) Using tail lamp opening, install nuts attach-

ing rear fender to cargo box side panel.

(12) Install tail lamp.

(13) Install screws attaching fuel fill neck to rear

fender opening.

Fig. 18 Fuel Fill Door

1 - CARGO BOX

2 - FUEL FILL DOORFig. 19 Rear FenderÐDual Wheels

1 - RETAINER

2 - FENDER (DUAL WHEEL)

BR/BEEXTERIOR 23 - 95

Page 2669 of 2889

REAR SPLASH SHIELD

REMOVAL

(1) Remove screws holding rear splash shield to

rear wheel opening lip (Fig. 20).

(2) Remove push in fasteners holding rear splash

shield to rear wheelhouse.

(3) Separate splash shield from vehicle.

INSTALLATION

(1) Position splash shield in wheelhouse opening.

(2) Install plastic rivets holding rear splash shield

to rear wheelhouse.

(3) Install plastic rivets holding rear splash shield

to rear wheel opening lip.

REAR WHEELHOUSE LINER

REMOVAL

(1) Remove plastic rivets attaching rear wheel-

house liner to rear wheel opening lip (Fig. 21).

(2) Remove plastic rivets attaching rear wheel-

house liner to rear wheelhouse.

(3) Separate rear wheelhouse liner form vehicle.

INSTALLATION

(1) Position rear wheelhouse liner in wheelhouse

opening.

(2) Install plastic rivets attaching rear wheelhouse

liner to rear wheelhouse.

(3) Working front to rear, install plastic rivets

attaching rear wheelhouse liner to rear wheel open-

ing lip.

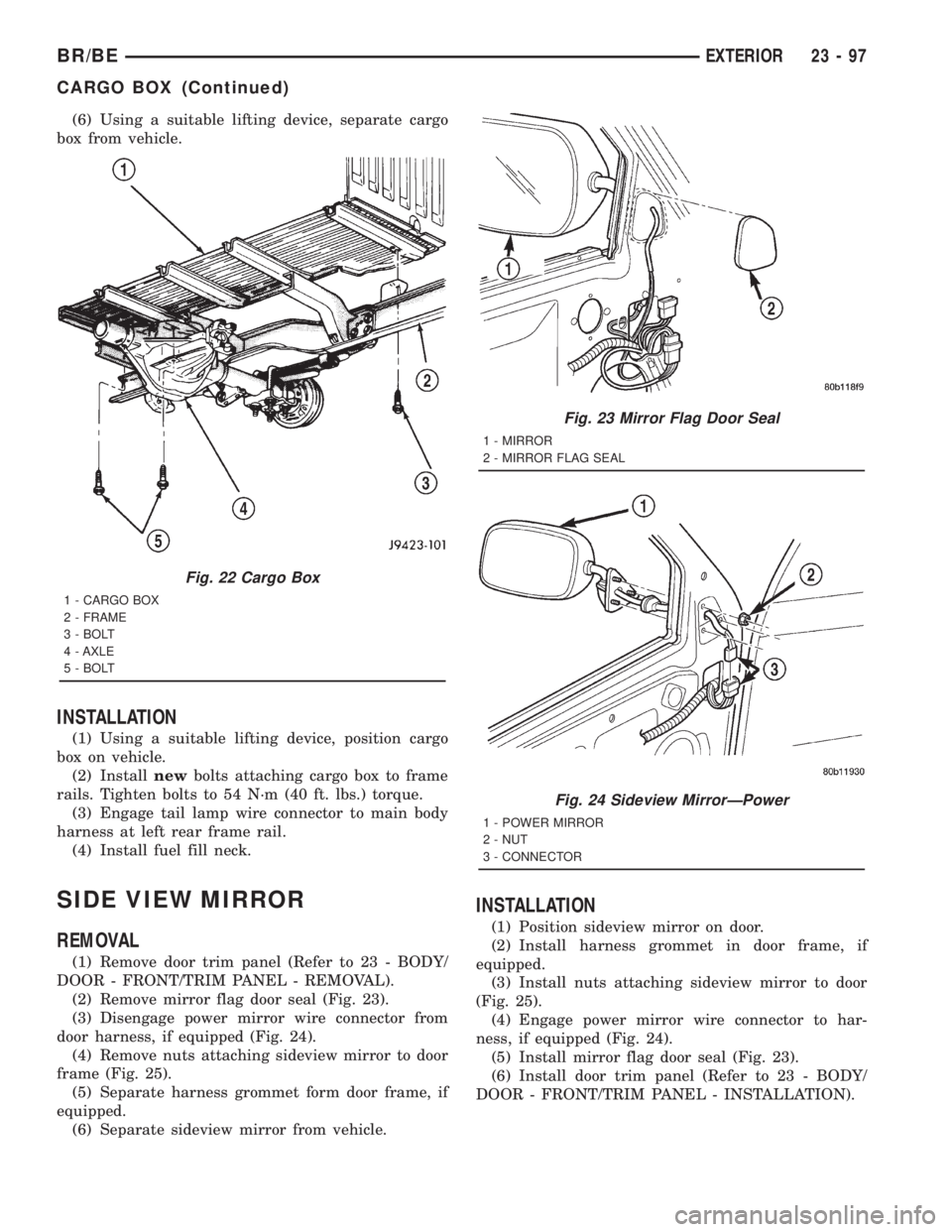

CARGO BOX

REMOVAL

CAUTION: The bolts attaching the cargo box to the

frame are specially coated to provide a locking

action. These bolts are not reusable and must be

replaced each time the cargo box is removed or

replaced.

(1) Open fuel fill door.

(2) Remove screws attaching fuel fill neck adaptor

to cargo box side wall.

(3) Separate fuel fill neck from cargo box.

(4) Disengage tail lamp wire connector from main

body harness at left rear frame rail.

(5) Remove bolts attaching cargo box to frame rails

(Fig. 22).

Fig. 20 REAR SPLASH SHIELDS

1 - FUEL FILLER DOOR

2 - REAR FENDER

3 - REAR SECTION REAR WHEEL HOUSE LINER

4 - PUSH IN FASTENERS

Fig. 21 Rear Wheelhouse Liner

1 - FENDER

2 - WHEEL HOUSELINER

3 - PLASTIC RIVET

23 - 96 EXTERIORBR/BE

Page 2670 of 2889

(6) Using a suitable lifting device, separate cargo

box from vehicle.

INSTALLATION

(1) Using a suitable lifting device, position cargo

box on vehicle.

(2) Installnewbolts attaching cargo box to frame

rails. Tighten bolts to 54 N´m (40 ft. lbs.) torque.

(3) Engage tail lamp wire connector to main body

harness at left rear frame rail.

(4) Install fuel fill neck.

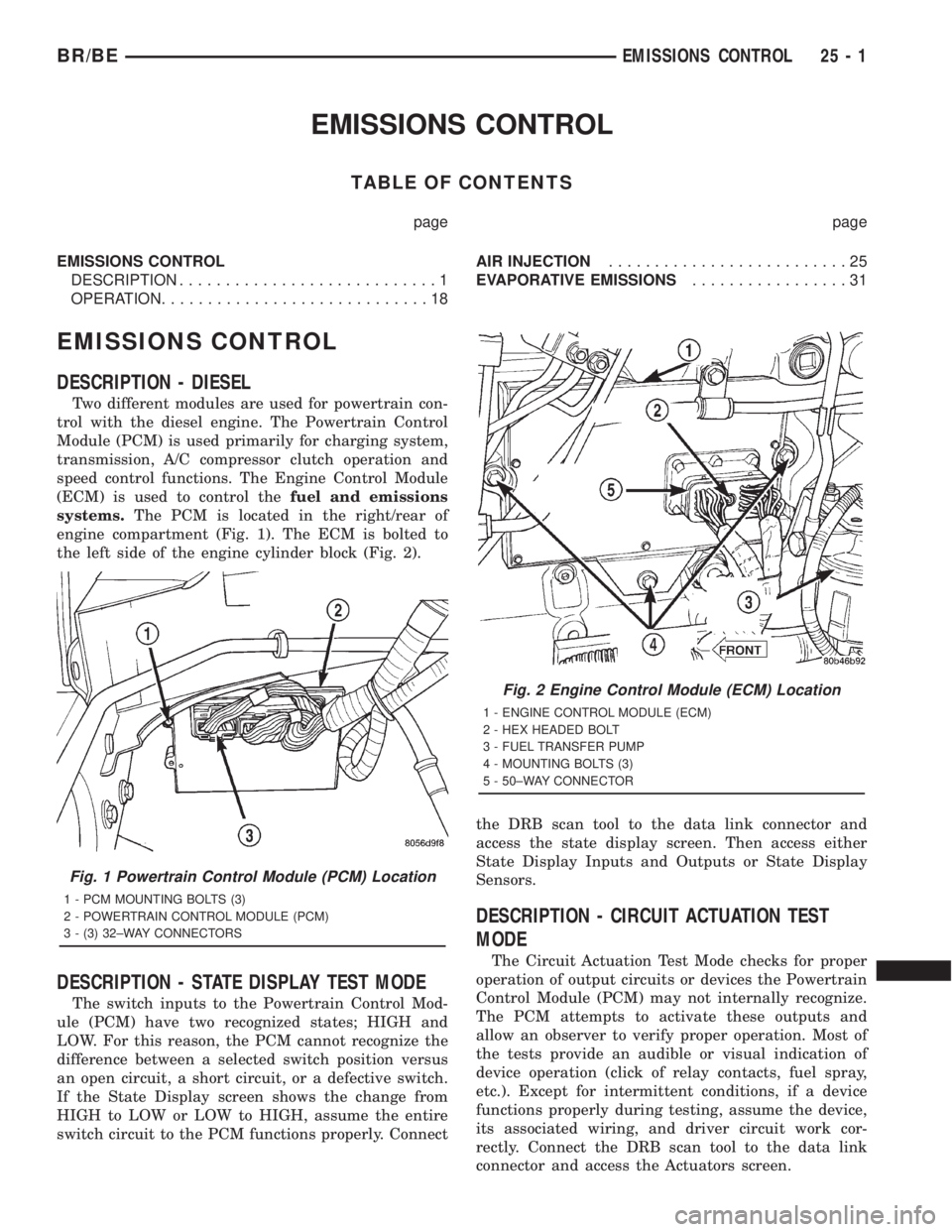

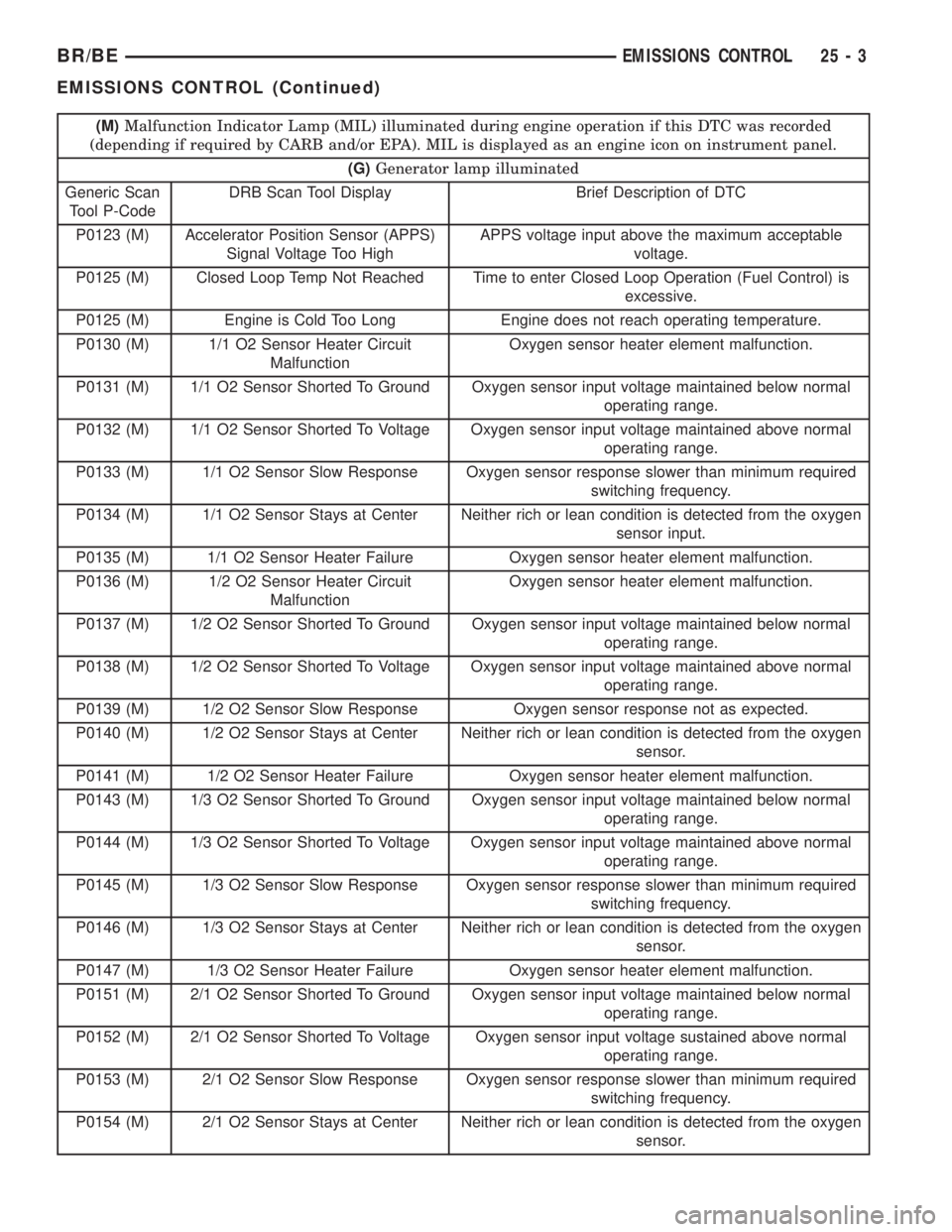

SIDE VIEW MIRROR

REMOVAL

(1) Remove door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL).

(2) Remove mirror flag door seal (Fig. 23).

(3) Disengage power mirror wire connector from

door harness, if equipped (Fig. 24).

(4) Remove nuts attaching sideview mirror to door

frame (Fig. 25).

(5) Separate harness grommet form door frame, if

equipped.

(6) Separate sideview mirror from vehicle.

INSTALLATION

(1) Position sideview mirror on door.

(2) Install harness grommet in door frame, if

equipped.

(3) Install nuts attaching sideview mirror to door

(Fig. 25).

(4) Engage power mirror wire connector to har-

ness, if equipped (Fig. 24).

(5) Install mirror flag door seal (Fig. 23).

(6) Install door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION).

Fig. 22 Cargo Box

1 - CARGO BOX

2 - FRAME

3 - BOLT

4 - AXLE

5 - BOLT

Fig. 23 Mirror Flag Door Seal

1 - MIRROR

2 - MIRROR FLAG SEAL

Fig. 24 Sideview MirrorÐPower

1 - POWER MIRROR

2 - NUT

3 - CONNECTOR

BR/BEEXTERIOR 23 - 97

CARGO BOX (Continued)

Page 2788 of 2889

EMISSIONS CONTROL

TABLE OF CONTENTS

page page

EMISSIONS CONTROL

DESCRIPTION............................1

OPERATION.............................18AIR INJECTION..........................25

EVAPORATIVE EMISSIONS.................31

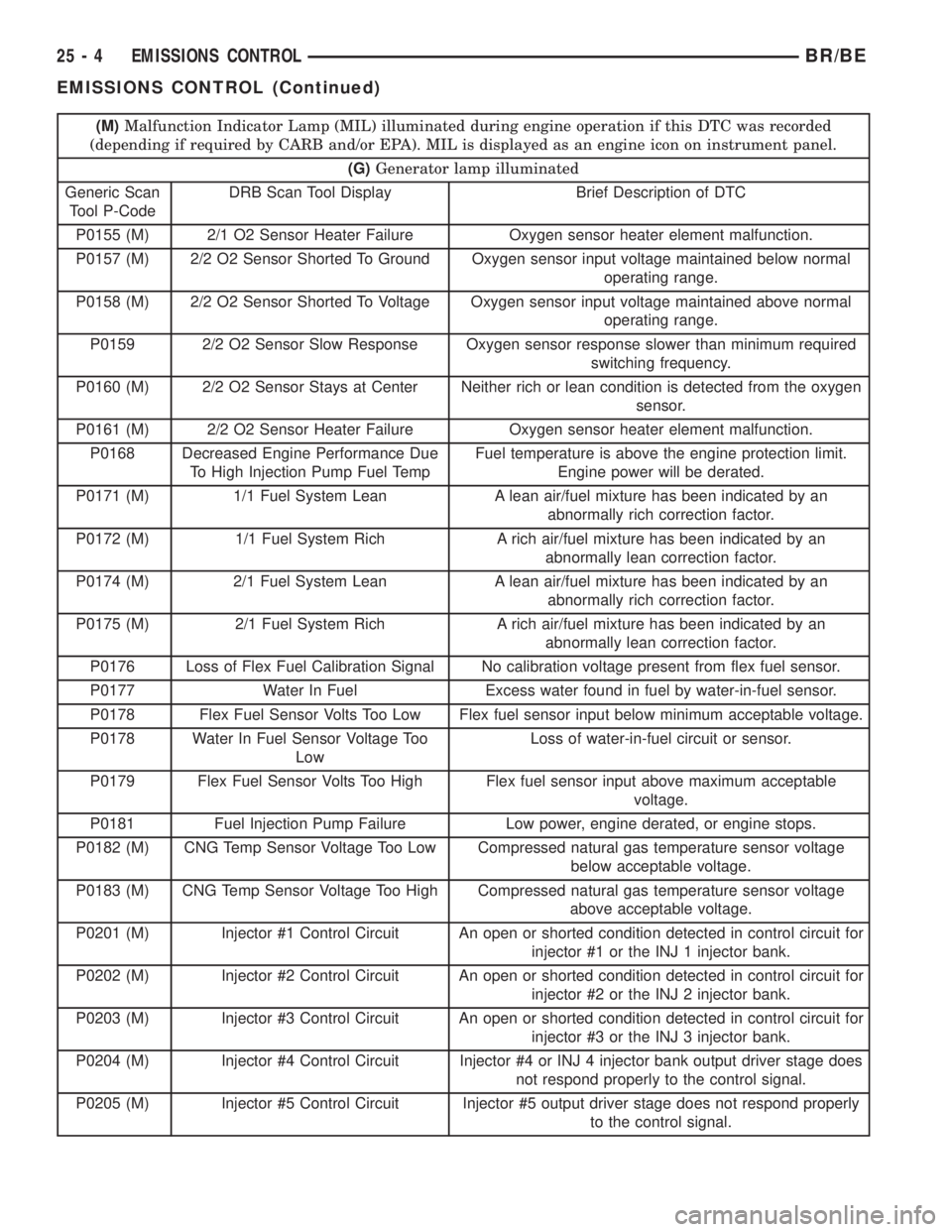

EMISSIONS CONTROL

DESCRIPTION - DIESEL

Two different modules are used for powertrain con-

trol with the diesel engine. The Powertrain Control

Module (PCM) is used primarily for charging system,

transmission, A/C compressor clutch operation and

speed control functions. The Engine Control Module

(ECM) is used to control thefuel and emissions

systems.The PCM is located in the right/rear of

engine compartment (Fig. 1). The ECM is bolted to

the left side of the engine cylinder block (Fig. 2).

DESCRIPTION - STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. Connectthe DRB scan tool to the data link connector and

access the state display screen. Then access either

State Display Inputs and Outputs or State Display

Sensors.

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly. Connect the DRB scan tool to the data link

connector and access the Actuators screen.

Fig. 1 Powertrain Control Module (PCM) Location

1 - PCM MOUNTING BOLTS (3)

2 - POWERTRAIN CONTROL MODULE (PCM)

3 - (3) 32±WAY CONNECTORS

Fig. 2 Engine Control Module (ECM) Location

1 - ENGINE CONTROL MODULE (ECM)

2 - HEX HEADED BOLT

3 - FUEL TRANSFER PUMP

4 - MOUNTING BOLTS (3)

5 - 50±WAY CONNECTOR

BR/BEEMISSIONS CONTROL 25 - 1

Page 2790 of 2889

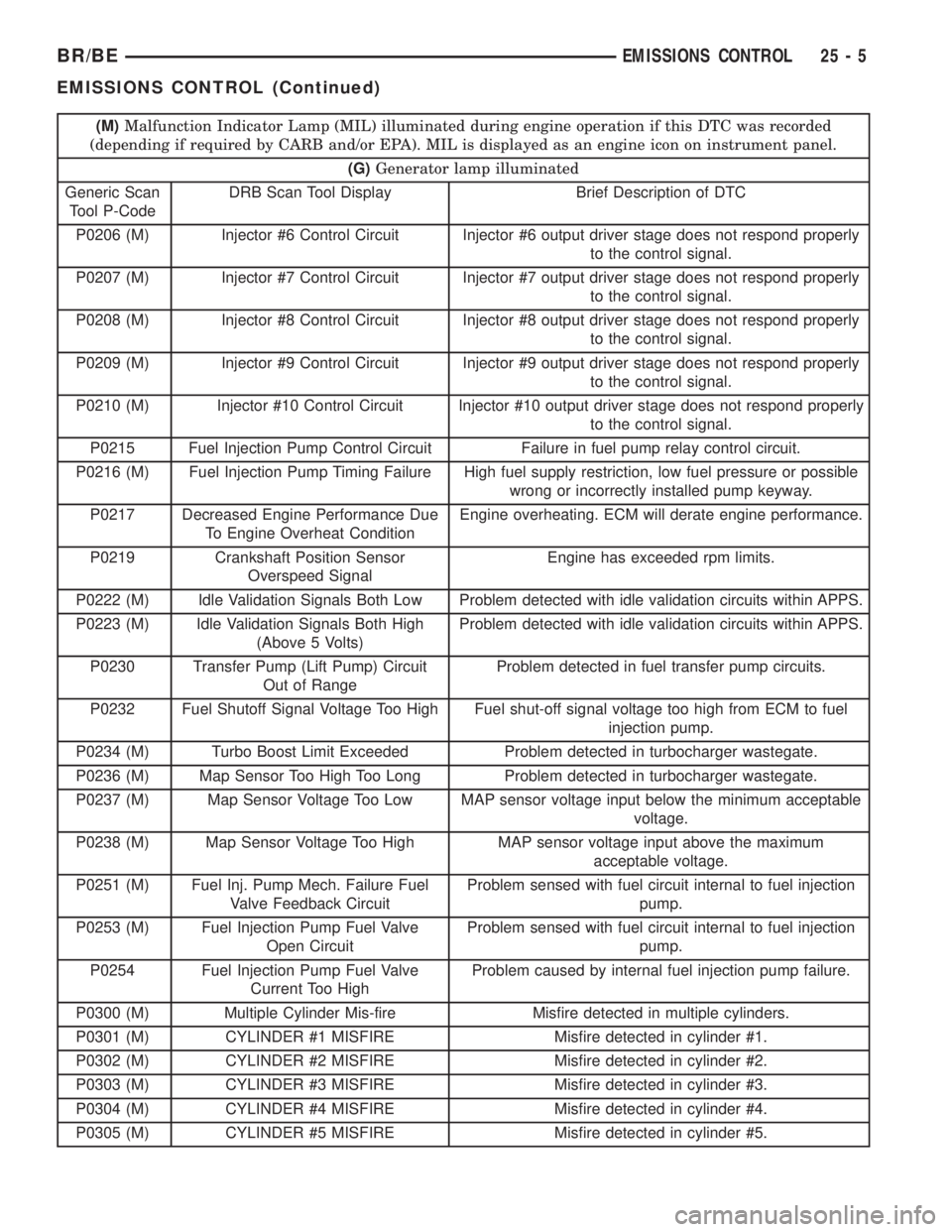

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0123 (M) Accelerator Position Sensor (APPS)

Signal Voltage Too HighAPPS voltage input above the maximum acceptable

voltage.

P0125 (M) Closed Loop Temp Not Reached Time to enter Closed Loop Operation (Fuel Control) is

excessive.

P0125 (M) Engine is Cold Too Long Engine does not reach operating temperature.

P0130 (M) 1/1 O2 Sensor Heater Circuit

MalfunctionOxygen sensor heater element malfunction.

P0131 (M) 1/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0132 (M) 1/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0133 (M) 1/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0134 (M) 1/1 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor input.

P0135 (M) 1/1 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0136 (M) 1/2 O2 Sensor Heater Circuit

MalfunctionOxygen sensor heater element malfunction.

P0137 (M) 1/2 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0138 (M) 1/2 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0139 (M) 1/2 O2 Sensor Slow Response Oxygen sensor response not as expected.

P0140 (M) 1/2 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0141 (M) 1/2 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0143 (M) 1/3 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0144 (M) 1/3 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0145 (M) 1/3 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0146 (M) 1/3 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0147 (M) 1/3 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0151 (M) 2/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0152 (M) 2/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage sustained above normal

operating range.

P0153 (M) 2/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0154 (M) 2/1 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

BR/BEEMISSIONS CONTROL 25 - 3

EMISSIONS CONTROL (Continued)

Page 2791 of 2889

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0155 (M) 2/1 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0157 (M) 2/2 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0158 (M) 2/2 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0159 2/2 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0160 (M) 2/2 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0161 (M) 2/2 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0168 Decreased Engine Performance Due

To High Injection Pump Fuel TempFuel temperature is above the engine protection limit.

Engine power will be derated.

P0171 (M) 1/1 Fuel System Lean A lean air/fuel mixture has been indicated by an

abnormally rich correction factor.

P0172 (M) 1/1 Fuel System Rich A rich air/fuel mixture has been indicated by an

abnormally lean correction factor.

P0174 (M) 2/1 Fuel System Lean A lean air/fuel mixture has been indicated by an

abnormally rich correction factor.

P0175 (M) 2/1 Fuel System Rich A rich air/fuel mixture has been indicated by an

abnormally lean correction factor.

P0176 Loss of Flex Fuel Calibration Signal No calibration voltage present from flex fuel sensor.

P0177 Water In Fuel Excess water found in fuel by water-in-fuel sensor.

P0178 Flex Fuel Sensor Volts Too Low Flex fuel sensor input below minimum acceptable voltage.

P0178 Water In Fuel Sensor Voltage Too

LowLoss of water-in-fuel circuit or sensor.

P0179 Flex Fuel Sensor Volts Too High Flex fuel sensor input above maximum acceptable

voltage.

P0181 Fuel Injection Pump Failure Low power, engine derated, or engine stops.

P0182 (M) CNG Temp Sensor Voltage Too Low Compressed natural gas temperature sensor voltage

below acceptable voltage.

P0183 (M) CNG Temp Sensor Voltage Too High Compressed natural gas temperature sensor voltage

above acceptable voltage.

P0201 (M) Injector #1 Control Circuit An open or shorted condition detected in control circuit for

injector #1 or the INJ 1 injector bank.

P0202 (M) Injector #2 Control Circuit An open or shorted condition detected in control circuit for

injector #2 or the INJ 2 injector bank.

P0203 (M) Injector #3 Control Circuit An open or shorted condition detected in control circuit for

injector #3 or the INJ 3 injector bank.

P0204 (M) Injector #4 Control Circuit Injector #4 or INJ 4 injector bank output driver stage does

not respond properly to the control signal.

P0205 (M) Injector #5 Control Circuit Injector #5 output driver stage does not respond properly

to the control signal.

25 - 4 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)

Page 2792 of 2889

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0206 (M) Injector #6 Control Circuit Injector #6 output driver stage does not respond properly

to the control signal.

P0207 (M) Injector #7 Control Circuit Injector #7 output driver stage does not respond properly

to the control signal.

P0208 (M) Injector #8 Control Circuit Injector #8 output driver stage does not respond properly

to the control signal.

P0209 (M) Injector #9 Control Circuit Injector #9 output driver stage does not respond properly

to the control signal.

P0210 (M) Injector #10 Control Circuit Injector #10 output driver stage does not respond properly

to the control signal.

P0215 Fuel Injection Pump Control Circuit Failure in fuel pump relay control circuit.

P0216 (M) Fuel Injection Pump Timing Failure High fuel supply restriction, low fuel pressure or possible

wrong or incorrectly installed pump keyway.

P0217 Decreased Engine Performance Due

To Engine Overheat ConditionEngine overheating. ECM will derate engine performance.

P0219 Crankshaft Position Sensor

Overspeed SignalEngine has exceeded rpm limits.

P0222 (M) Idle Validation Signals Both Low Problem detected with idle validation circuits within APPS.

P0223 (M) Idle Validation Signals Both High

(Above 5 Volts)Problem detected with idle validation circuits within APPS.

P0230 Transfer Pump (Lift Pump) Circuit

Out of RangeProblem detected in fuel transfer pump circuits.

P0232 Fuel Shutoff Signal Voltage Too High Fuel shut-off signal voltage too high from ECM to fuel

injection pump.

P0234 (M) Turbo Boost Limit Exceeded Problem detected in turbocharger wastegate.

P0236 (M) Map Sensor Too High Too Long Problem detected in turbocharger wastegate.

P0237 (M) Map Sensor Voltage Too Low MAP sensor voltage input below the minimum acceptable

voltage.

P0238 (M) Map Sensor Voltage Too High MAP sensor voltage input above the maximum

acceptable voltage.

P0251 (M) Fuel Inj. Pump Mech. Failure Fuel

Valve Feedback CircuitProblem sensed with fuel circuit internal to fuel injection

pump.

P0253 (M) Fuel Injection Pump Fuel Valve

Open CircuitProblem sensed with fuel circuit internal to fuel injection

pump.

P0254 Fuel Injection Pump Fuel Valve

Current Too HighProblem caused by internal fuel injection pump failure.

P0300 (M) Multiple Cylinder Mis-fire Misfire detected in multiple cylinders.

P0301 (M) CYLINDER #1 MISFIRE Misfire detected in cylinder #1.

P0302 (M) CYLINDER #2 MISFIRE Misfire detected in cylinder #2.

P0303 (M) CYLINDER #3 MISFIRE Misfire detected in cylinder #3.

P0304 (M) CYLINDER #4 MISFIRE Misfire detected in cylinder #4.

P0305 (M) CYLINDER #5 MISFIRE Misfire detected in cylinder #5.

BR/BEEMISSIONS CONTROL 25 - 5

EMISSIONS CONTROL (Continued)

Page 2793 of 2889

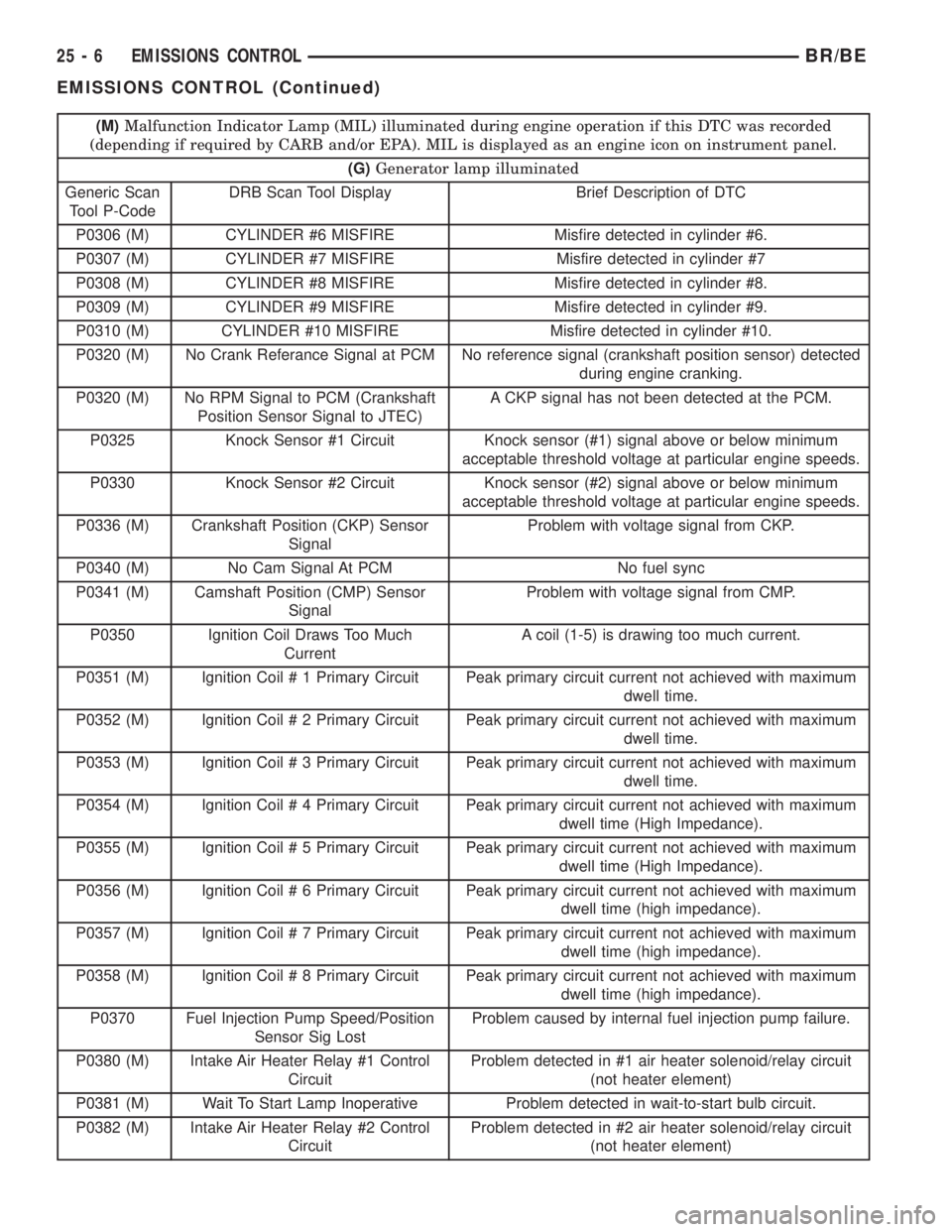

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0306 (M) CYLINDER #6 MISFIRE Misfire detected in cylinder #6.

P0307 (M) CYLINDER #7 MISFIRE Misfire detected in cylinder #7

P0308 (M) CYLINDER #8 MISFIRE Misfire detected in cylinder #8.

P0309 (M) CYLINDER #9 MISFIRE Misfire detected in cylinder #9.

P0310 (M) CYLINDER #10 MISFIRE Misfire detected in cylinder #10.

P0320 (M) No Crank Referance Signal at PCM No reference signal (crankshaft position sensor) detected

during engine cranking.

P0320 (M) No RPM Signal to PCM (Crankshaft

Position Sensor Signal to JTEC)A CKP signal has not been detected at the PCM.

P0325 Knock Sensor #1 Circuit Knock sensor (#1) signal above or below minimum

acceptable threshold voltage at particular engine speeds.

P0330 Knock Sensor #2 Circuit Knock sensor (#2) signal above or below minimum

acceptable threshold voltage at particular engine speeds.

P0336 (M) Crankshaft Position (CKP) Sensor

SignalProblem with voltage signal from CKP.

P0340 (M) No Cam Signal At PCM No fuel sync

P0341 (M) Camshaft Position (CMP) Sensor

SignalProblem with voltage signal from CMP.

P0350 Ignition Coil Draws Too Much

CurrentA coil (1-5) is drawing too much current.

P0351 (M) Ignition Coil # 1 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0352 (M) Ignition Coil # 2 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0353 (M) Ignition Coil # 3 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0354 (M) Ignition Coil # 4 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0355 (M) Ignition Coil # 5 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0356 (M) Ignition Coil # 6 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0357 (M) Ignition Coil # 7 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0358 (M) Ignition Coil # 8 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0370 Fuel Injection Pump Speed/Position

Sensor Sig LostProblem caused by internal fuel injection pump failure.

P0380 (M) Intake Air Heater Relay #1 Control

CircuitProblem detected in #1 air heater solenoid/relay circuit

(not heater element)

P0381 (M) Wait To Start Lamp Inoperative Problem detected in wait-to-start bulb circuit.

P0382 (M) Intake Air Heater Relay #2 Control

CircuitProblem detected in #2 air heater solenoid/relay circuit

(not heater element)

25 - 6 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)