fuel filter location DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 20 of 2889

MAINTENANCE SCHEDULES

LIGHT DUTY ENGINE (1500 AND 2500

MODELS EXCEPT 8.0L) MAINTENANCE

SCHEDULES

There are two maintenance schedules that show

proper service for the vehicle.

First is ScheduleªAº. It lists all the scheduled

maintenance to be performed under ªnormalº operat-

ing conditions.

Second is ScheduleªBºIt is a schedule for vehicles

that are operated under the conditions listed at the

beginning of that schedule.

Use the schedule that best describes the driving

conditions.

Where time and mileage are listed, follow the

interval that occurs first.

At Each Stop For Fuel

²Check engine oil level and add as required.

²Check windshield washer solvent and add as

required.

²Clean windshield and wiper blades as required.

Once A Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery and clean and tighten terminals

as required.

²Check fluid levels of coolant reservoir, brake

master cylinder, power steering, and transmission

and add as needed.

²Check all lights and all other electrical items for

correct operation.

²Inspect and clean wiper blades. Replace if

required.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses.

²Adjust rear brake shoe to drum clearance.

²Rotate the tires at each oil change interval

shown on schedule ªAº (7,500 Miles) or every other

interval shown on schedule ªBº (6,000 Miles).

²Check engine coolant level, hoses, and clamps.

²Lubricate steering linkage.

EMISSION CONTROL SYSTEM MAINTENANCE

The scheduled emission maintenance listed inbold

typeon the Maintenance Schedules, must be done at

the mileage specified to assure the continued proper

functioning of the emission control system. These,

and all other maintenance services included in this

manual, should be done to provide the best vehicle

performance and reliability. More frequent mainte-

nance may be needed for vehicles in severe operatingconditions such as dusty areas and very short trip

driving.

FLUID FILL LOCATIONS AND LUBRICATION

POINTS

The fluid check/fill locations and lubrication points

are located in each applicable group.

LIGHT DUTY SCHEDULE ªAº

7,500 Miles (12 000 km) or at 6 months

²Change engine oil.

²Replace engine oil filter.

²Inspect engine coolant level, hoses, and clamps.

²Inspect brake hoses.

²Lubricate the steering linkages.

²Check manual transmission fluid level.

²Inspect exhaust system.

15,000 Miles (24 000 km) or at 12 months

²Change engine oil.

²Replace engine oil filter.

²Inspect engine coolant level, hoses, and clamps.

²Inspect brake hoses.

²Lubricate the steering linkages.

²Check manual transmission fluid level.

²Inspect exhaust system.

22,500 Miles (36 000 km) or at 18 months

²Change engine oil.

²Replace engine oil filter.

²Inspect engine coolant level, hoses, and clamps.

²Inspect brake hoses.

²Inspect brake linings.

²Inspect front wheel bearings. Clean and repack,

if required (4x2).

²Lubricate the steering linkages.

²Lubricate non permanently sealed ball joints.

²Check manual transmission fluid level.

²Inspect exhaust system.

30,000 Miles (48 000 km) or at 24 months

²Replace engine air cleaner element.

²Replace spark plugs.

²Change engine oil.

²Replace engine oil filter.

²Inspect engine coolant level, hoses, and clamps.

²Inspect brake hoses.

²Lubricate the steering linkages.

²Inspect manual transmission fluid level.

²Inspect exhaust system.

37,500 Miles (60 000 km) or at 30 months

²Change engine oil.

²Replace engine oil filter.

²Inspect engine coolant level, hoses, and clamps.

BR/BELUBRICATION & MAINTENANCE 0 - 7

Page 30 of 2889

²Inspect brake linings.

³Off-the-highway operation, trailer towing snow

plowing, prolonged operation with heavy loading,

especially in hot weather require the more frequent

transmission service indicated with an ³ in Schedule

ªBº. Perform these services if the vehicle is usually

operated under these conditions.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

DESCRIPTION - HEAVY DUTY ENGINE

(FEDERAL ONLY ± 2500 8.0L HD AND 3500

5.9L& 8.0L MODELS) MAINTENANCE

SCHEDULES

There are two maintenance schedules that show

proper service based on the conditions that the vehi-

cle is subjected to. Use the schedule that best

describes these conditions.

ScheduleªAº, lists all the scheduled maintenance

to be performed under normal operating conditions

for Heavy Duty vehicles.

ScheduleªBº, lists maintenance recommended for

Heavy Duty vehicles operated under the conditions

listed at the beginning of that schedule.

²Where time and mileage are listed, follow the

interval that occurs first.

At Each Stop For Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

²Clean windshield and wiper blades as required.

Once A Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery and clean and tighten terminals

as required.

²Check fluid levels of coolant reservoir, power

steering and transmission and add as needed.

²Check all lights and all other electrical items for

correct operation.

²Inspect and clean wiper blades. Replace if

required.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses.

²Adjust rear brakes.

²Rotate the tires at each oil change interval

shown on schedule ªAº (6,000 Miles) or every other

interval shown on schedule ªBº (6,000 Miles).

²Check engine coolant level, hoses, and clamps.

²Lubricate steering linkage.

EMISSION CONTROL SYSTEM MAINTENANCE

The scheduled emission maintenance listed inbold

typeon the Maintenance Schedules, must be done at

the mileage specified to assure the continued proper

functioning of the emission control system. These,

and all other maintenance services included in this

manual, should be done to provide the best vehicle

performance and reliability. More frequent mainte-

nance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

FLUID FILL LOCATIONS AND LUBRICATION

POINTS

The fluid fill/check locations and lubrication points

are located in each applicable group.

HEAVY DUTY SCHEDULE ªAº

6,000 miles (10 000 km) or at 6 months

²Change engine oil.

²Replace engine oil filter.

12,000 Miles (19 000 km) or at 12 months

²Change engine oil.

²Replace engine oil filter.

²Inspect engine air cleaner element, replace

as necessary (8.0L only).

18,000 Miles (29 000 km) or at 18 months

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings

²Inspect front wheel bearings. Clean and repack,

if required (4x4).

24,000 Miles (38 000 km) or at 24 months

²Change engine oil.

²Replace engine oil filter.

²Replace engine air cleaner element and air

pump filter.

²Clean and lubricate crankcase inlet air filter

(5.9L).

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

²Inspect front wheel bearings. Clean and repack,

if required (4x2).

30,000 Miles (48 000 km) or at 30 months

²Change engine oil.

²Replace engine oil filter.

²Replace spark plugs.

36,000 Miles (58 000 km) or at 36 months

²Change engine oil.

²Replace engine oil filter.

BR/BELUBRICATION & MAINTENANCE 0 - 17

MAINTENANCE SCHEDULES (Continued)

Page 36 of 2889

FLUID FILL LOCATIONS AND LUBRICATION

POINTS

The fluid fill/check locations and lubrication points

are located in each applicable group.

SCHEDULE ªAº

7,500 Miles (12 000 km) or at 6 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

15,000 Miles (24 000 km) or at 12 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

²Inspect water pump weep hole for blockage.

²Replace fuel filter and clean water in fuel sen-

sor.

22,500 Miles (36 000 km) or at 18 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

²Inspect drive belts, replace as necessary.

²Inspect brake linings.

30,000 Miles (48 000 km) or at 24 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

²Inspect fan hub.

²Inspect damper.

²Inspect water pump weep hole for blockage.

²Replace fuel filter and clean water in fuel sen-

sor.

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

²Inspect front wheel bearings. Clean and repack,

if required (4x2).

²Flush and replace engine coolant if not done at

36 months.

37,500 Miles (60 000 km) or at 30 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

45,000 Miles (72 000 km) or at 36 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

²Inspect drive belts, replace as necessary.

²Inspect water pump weep hole for blockage.

²Replace fuel filter and clean water in fuel sen-

sor.

²Drain and refill transfer case fluid.

²Inspect brake linings.

²Flush and replace engine coolant if not done at

24 months

52,500 Miles (84 000 km) or at 42 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

60,000 Miles (96 000 km) or at 48 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

²Inspect fan hub.

²Inspect damper.

²Inspect front wheel bearings. Clean and repack,

if required (4x2).

²Inspect water pump weep hole for blockage.

²Replace fuel filter and clean water in fuel sen-

sor.

67,500 Miles (108 000 km) or at 54 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

²Inspect drive belts, replace as necessary.

²Inspect brake linings.

75,000 Miles (120 000 km) or at 60 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

²Inspect water pump weep hole for blockage.

²Replace fuel filter and clean water in fuel sen-

sor.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

82,500 Miles (132 000 km) or at 66 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

90,000 Miles (144 000 km) or at 72 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

²Inspect drive belt, replace as required.

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

²Drain and refill transfer case fluid.

²Inspect fan hub.

²Inspect damper.

²Inspect water pump weep hole for blockage.

²Replace fuel filter and clean water in fuel sen-

sor.

²Inspect front wheel bearings. Clean and repack,

if required (4x2).

²Inspect brake linings.

97,500 Miles (156 000 km) or at 78 months

²Change engine oil and filter.

²Drain crankcase breather canister (if equipped).

BR/BELUBRICATION & MAINTENANCE 0 - 23

MAINTENANCE SCHEDULES (Continued)

Page 464 of 2889

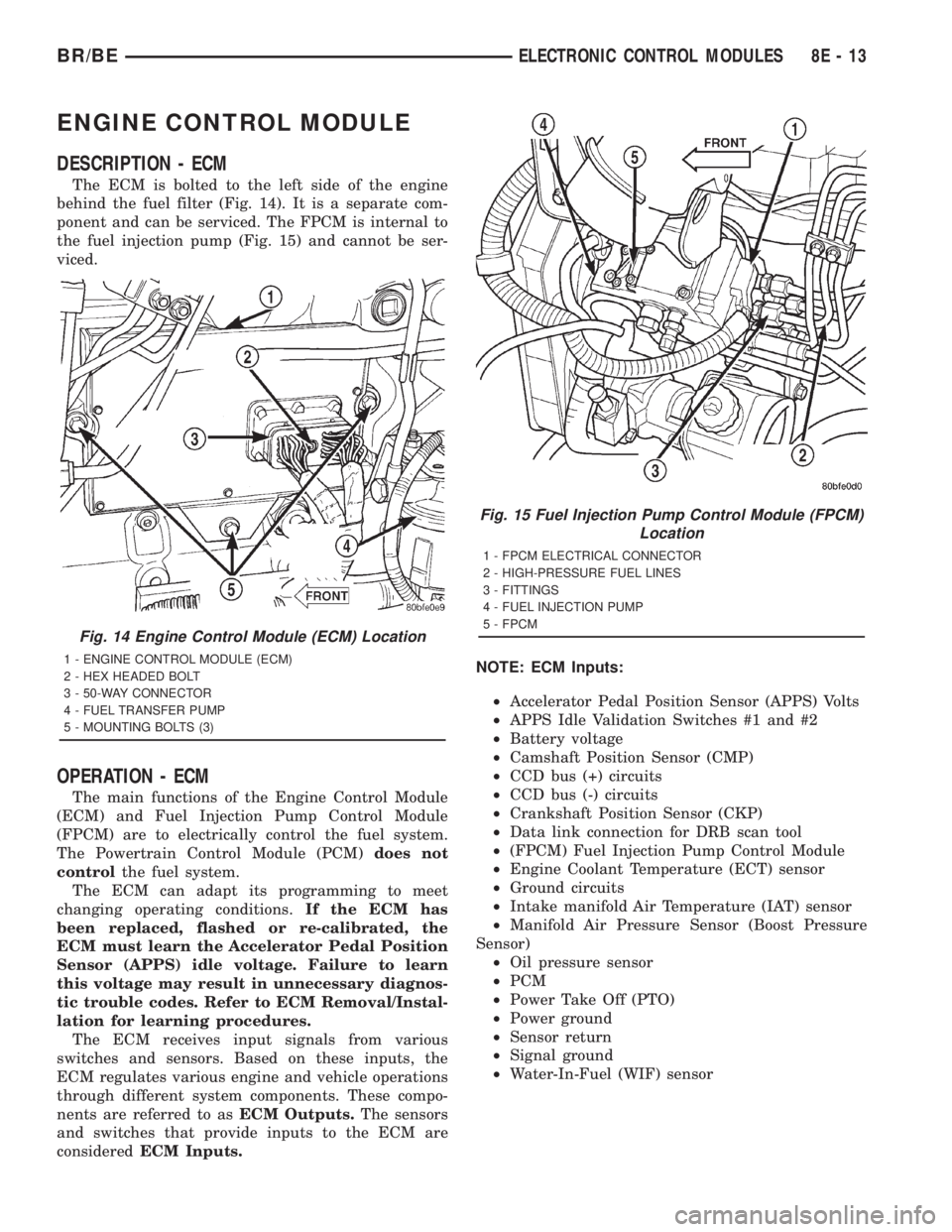

ENGINE CONTROL MODULE

DESCRIPTION - ECM

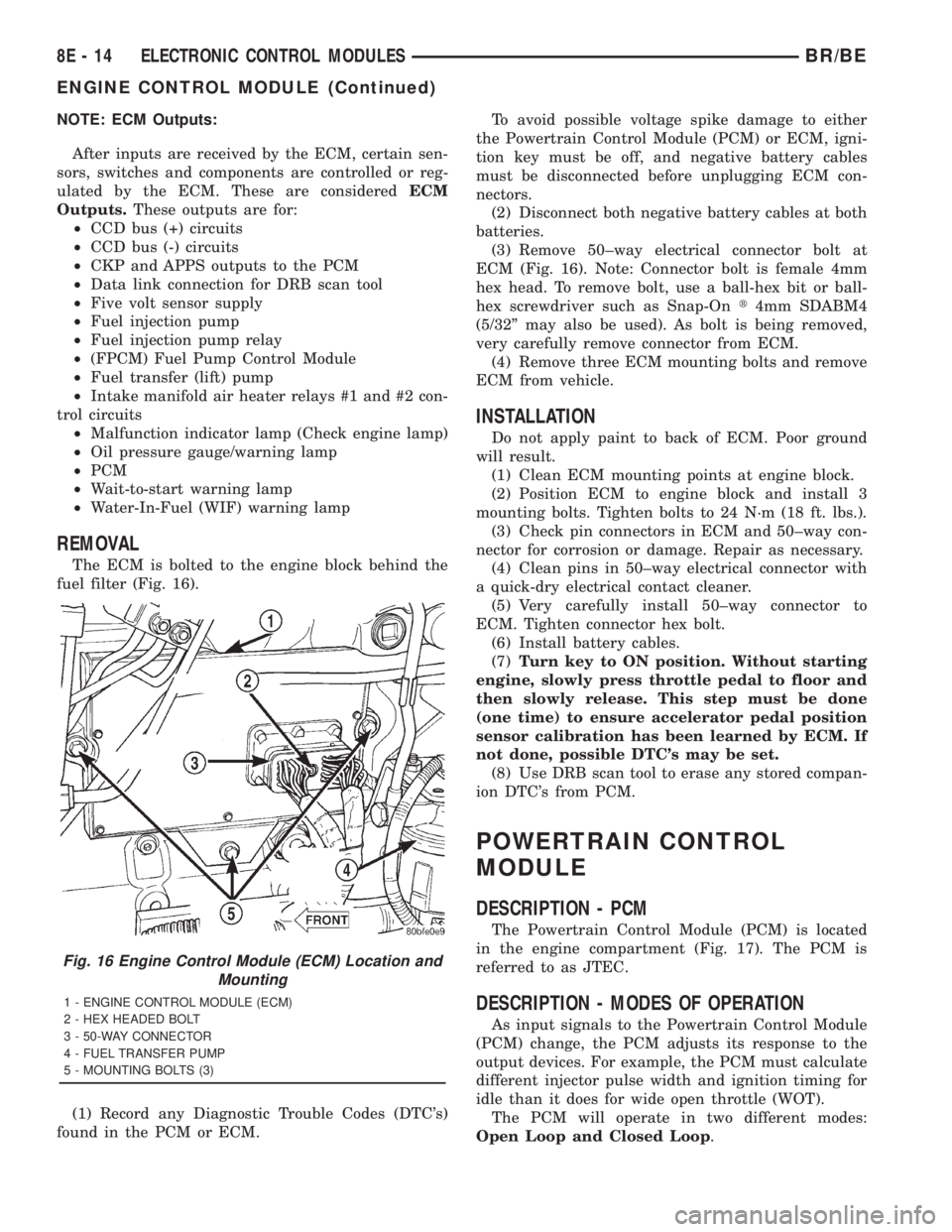

The ECM is bolted to the left side of the engine

behind the fuel filter (Fig. 14). It is a separate com-

ponent and can be serviced. The FPCM is internal to

the fuel injection pump (Fig. 15) and cannot be ser-

viced.

OPERATION - ECM

The main functions of the Engine Control Module

(ECM) and Fuel Injection Pump Control Module

(FPCM) are to electrically control the fuel system.

The Powertrain Control Module (PCM)does not

controlthe fuel system.

The ECM can adapt its programming to meet

changing operating conditions.If the ECM has

been replaced, flashed or re-calibrated, the

ECM must learn the Accelerator Pedal Position

Sensor (APPS) idle voltage. Failure to learn

this voltage may result in unnecessary diagnos-

tic trouble codes. Refer to ECM Removal/Instal-

lation for learning procedures.

The ECM receives input signals from various

switches and sensors. Based on these inputs, the

ECM regulates various engine and vehicle operations

through different system components. These compo-

nents are referred to asECM Outputs.The sensors

and switches that provide inputs to the ECM are

consideredECM Inputs.NOTE: ECM Inputs:

²Accelerator Pedal Position Sensor (APPS) Volts

²APPS Idle Validation Switches #1 and #2

²Battery voltage

²Camshaft Position Sensor (CMP)

²CCD bus (+) circuits

²CCD bus (-) circuits

²Crankshaft Position Sensor (CKP)

²Data link connection for DRB scan tool

²(FPCM) Fuel Injection Pump Control Module

²Engine Coolant Temperature (ECT) sensor

²Ground circuits

²Intake manifold Air Temperature (IAT) sensor

²Manifold Air Pressure Sensor (Boost Pressure

Sensor)

²Oil pressure sensor

²PCM

²Power Take Off (PTO)

²Power ground

²Sensor return

²Signal ground

²Water-In-Fuel (WIF) sensor

Fig. 14 Engine Control Module (ECM) Location

1 - ENGINE CONTROL MODULE (ECM)

2 - HEX HEADED BOLT

3 - 50-WAY CONNECTOR

4 - FUEL TRANSFER PUMP

5 - MOUNTING BOLTS (3)

Fig. 15 Fuel Injection Pump Control Module (FPCM)

Location

1 - FPCM ELECTRICAL CONNECTOR

2 - HIGH-PRESSURE FUEL LINES

3 - FITTINGS

4 - FUEL INJECTION PUMP

5 - FPCM

BR/BEELECTRONIC CONTROL MODULES 8E - 13

Page 465 of 2889

NOTE: ECM Outputs:

After inputs are received by the ECM, certain sen-

sors, switches and components are controlled or reg-

ulated by the ECM. These are consideredECM

Outputs.These outputs are for:

²CCD bus (+) circuits

²CCD bus (-) circuits

²CKP and APPS outputs to the PCM

²Data link connection for DRB scan tool

²Five volt sensor supply

²Fuel injection pump

²Fuel injection pump relay

²(FPCM) Fuel Pump Control Module

²Fuel transfer (lift) pump

²Intake manifold air heater relays #1 and #2 con-

trol circuits

²Malfunction indicator lamp (Check engine lamp)

²Oil pressure gauge/warning lamp

²PCM

²Wait-to-start warning lamp

²Water-In-Fuel (WIF) warning lamp

REMOVAL

The ECM is bolted to the engine block behind the

fuel filter (Fig. 16).

(1) Record any Diagnostic Trouble Codes (DTC's)

found in the PCM or ECM.To avoid possible voltage spike damage to either

the Powertrain Control Module (PCM) or ECM, igni-

tion key must be off, and negative battery cables

must be disconnected before unplugging ECM con-

nectors.

(2) Disconnect both negative battery cables at both

batteries.

(3) Remove 50±way electrical connector bolt at

ECM (Fig. 16). Note: Connector bolt is female 4mm

hex head. To remove bolt, use a ball-hex bit or ball-

hex screwdriver such as Snap-Ont4mm SDABM4

(5/32º may also be used). As bolt is being removed,

very carefully remove connector from ECM.

(4) Remove three ECM mounting bolts and remove

ECM from vehicle.

INSTALLATION

Do not apply paint to back of ECM. Poor ground

will result.

(1) Clean ECM mounting points at engine block.

(2) Position ECM to engine block and install 3

mounting bolts. Tighten bolts to 24 N´m (18 ft. lbs.).

(3) Check pin connectors in ECM and 50±way con-

nector for corrosion or damage. Repair as necessary.

(4) Clean pins in 50±way electrical connector with

a quick-dry electrical contact cleaner.

(5) Very carefully install 50±way connector to

ECM. Tighten connector hex bolt.

(6) Install battery cables.

(7)Turn key to ON position. Without starting

engine, slowly press throttle pedal to floor and

then slowly release. This step must be done

(one time) to ensure accelerator pedal position

sensor calibration has been learned by ECM. If

not done, possible DTC's may be set.

(8) Use DRB scan tool to erase any stored compan-

ion DTC's from PCM.

POWERTRAIN CONTROL

MODULE

DESCRIPTION - PCM

The Powertrain Control Module (PCM) is located

in the engine compartment (Fig. 17). The PCM is

referred to as JTEC.

DESCRIPTION - MODES OF OPERATION

As input signals to the Powertrain Control Module

(PCM) change, the PCM adjusts its response to the

output devices. For example, the PCM must calculate

different injector pulse width and ignition timing for

idle than it does for wide open throttle (WOT).

The PCM will operate in two different modes:

Open Loop and Closed Loop.

Fig. 16 Engine Control Module (ECM) Location and

Mounting

1 - ENGINE CONTROL MODULE (ECM)

2 - HEX HEADED BOLT

3 - 50-WAY CONNECTOR

4 - FUEL TRANSFER PUMP

5 - MOUNTING BOLTS (3)

8E - 14 ELECTRONIC CONTROL MODULESBR/BE

ENGINE CONTROL MODULE (Continued)

Page 1094 of 2889

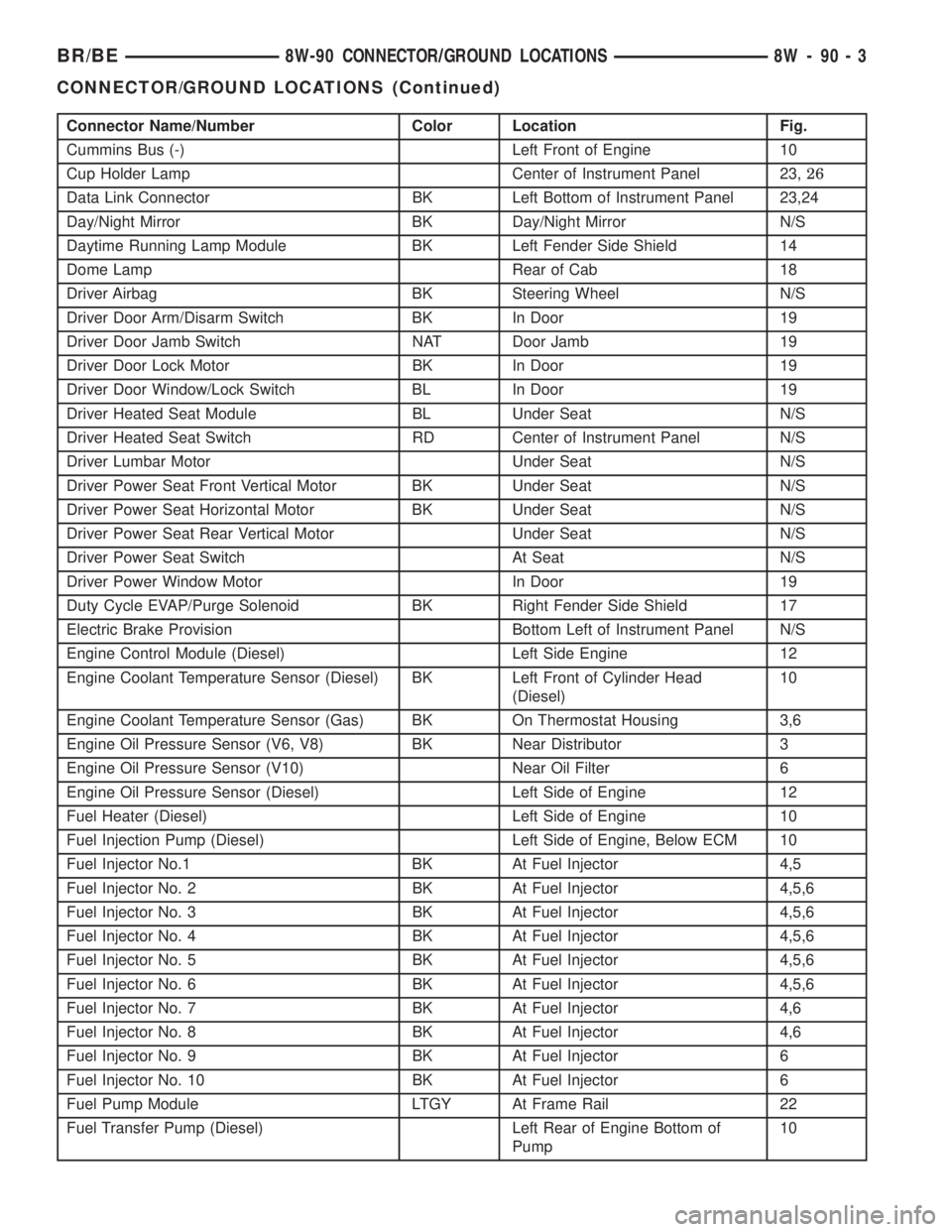

Connector Name/Number Color Location Fig.

Cummins Bus (-) Left Front of Engine 10

Cup Holder Lamp Center of Instrument Panel 23,26

Data Link Connector BK Left Bottom of Instrument Panel 23,24

Day/Night Mirror BK Day/Night Mirror N/S

Daytime Running Lamp Module BK Left Fender Side Shield 14

Dome Lamp Rear of Cab 18

Driver Airbag BK Steering Wheel N/S

Driver Door Arm/Disarm Switch BK In Door 19

Driver Door Jamb Switch NAT Door Jamb 19

Driver Door Lock Motor BK In Door 19

Driver Door Window/Lock Switch BL In Door 19

Driver Heated Seat Module BL Under Seat N/S

Driver Heated Seat Switch RD Center of Instrument Panel N/S

Driver Lumbar Motor Under Seat N/S

Driver Power Seat Front Vertical Motor BK Under Seat N/S

Driver Power Seat Horizontal Motor BK Under Seat N/S

Driver Power Seat Rear Vertical Motor Under Seat N/S

Driver Power Seat Switch At Seat N/S

Driver Power Window Motor In Door 19

Duty Cycle EVAP/Purge Solenoid BK Right Fender Side Shield 17

Electric Brake Provision Bottom Left of Instrument Panel N/S

Engine Control Module (Diesel) Left Side Engine 12

Engine Coolant Temperature Sensor (Diesel) BK Left Front of Cylinder Head

(Diesel)10

Engine Coolant Temperature Sensor (Gas) BK On Thermostat Housing 3,6

Engine Oil Pressure Sensor (V6, V8) BK Near Distributor 3

Engine Oil Pressure Sensor (V10) Near Oil Filter 6

Engine Oil Pressure Sensor (Diesel) Left Side of Engine 12

Fuel Heater (Diesel) Left Side of Engine 10

Fuel Injection Pump (Diesel) Left Side of Engine, Below ECM 10

Fuel Injector No.1 BK At Fuel Injector 4,5

Fuel Injector No. 2 BK At Fuel Injector 4,5,6

Fuel Injector No. 3 BK At Fuel Injector 4,5,6

Fuel Injector No. 4 BK At Fuel Injector 4,5,6

Fuel Injector No. 5 BK At Fuel Injector 4,5,6

Fuel Injector No. 6 BK At Fuel Injector 4,5,6

Fuel Injector No. 7 BK At Fuel Injector 4,6

Fuel Injector No. 8 BK At Fuel Injector 4,6

Fuel Injector No. 9 BK At Fuel Injector 6

Fuel Injector No. 10 BK At Fuel Injector 6

Fuel Pump Module LTGY At Frame Rail 22

Fuel Transfer Pump (Diesel) Left Rear of Engine Bottom of

Pump10

BR/BE8W-90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 3

CONNECTOR/GROUND LOCATIONS (Continued)

Page 1098 of 2889

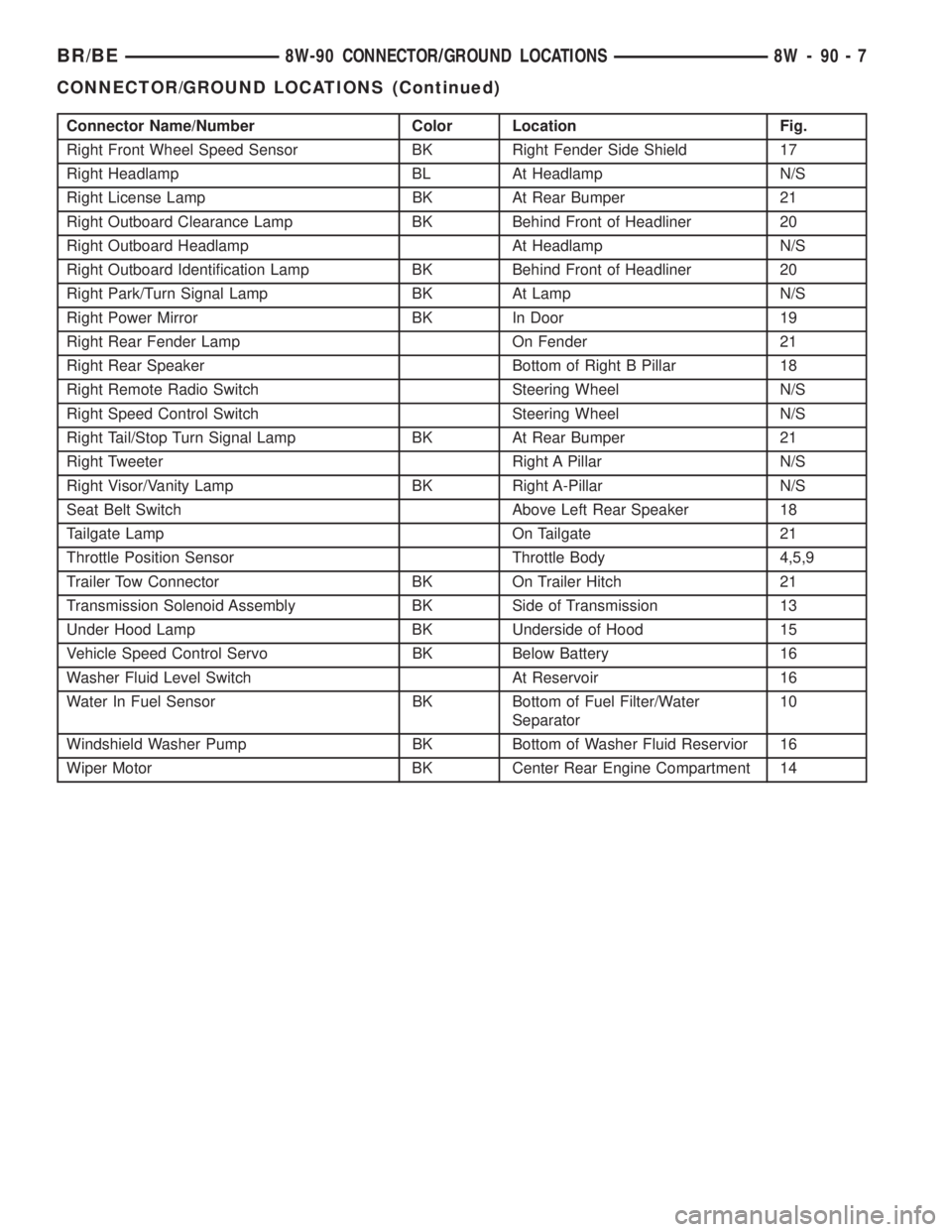

Connector Name/Number Color Location Fig.

Right Front Wheel Speed Sensor BK Right Fender Side Shield 17

Right Headlamp BL At Headlamp N/S

Right License Lamp BK At Rear Bumper 21

Right Outboard Clearance Lamp BK Behind Front of Headliner 20

Right Outboard Headlamp At Headlamp N/S

Right Outboard Identification Lamp BK Behind Front of Headliner 20

Right Park/Turn Signal Lamp BK At Lamp N/S

Right Power Mirror BK In Door 19

Right Rear Fender Lamp On Fender 21

Right Rear Speaker Bottom of Right B Pillar 18

Right Remote Radio Switch Steering Wheel N/S

Right Speed Control Switch Steering Wheel N/S

Right Tail/Stop Turn Signal Lamp BK At Rear Bumper 21

Right Tweeter Right A Pillar N/S

Right Visor/Vanity Lamp BK Right A-Pillar N/S

Seat Belt Switch Above Left Rear Speaker 18

Tailgate Lamp On Tailgate 21

Throttle Position Sensor Throttle Body 4,5,9

Trailer Tow Connector BK On Trailer Hitch 21

Transmission Solenoid Assembly BK Side of Transmission 13

Under Hood Lamp BK Underside of Hood 15

Vehicle Speed Control Servo BK Below Battery 16

Washer Fluid Level Switch At Reservoir 16

Water In Fuel Sensor BK Bottom of Fuel Filter/Water

Separator10

Windshield Washer Pump BK Bottom of Washer Fluid Reservior 16

Wiper Motor BK Center Rear Engine Compartment 14

BR/BE8W-90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 7

CONNECTOR/GROUND LOCATIONS (Continued)

Page 1158 of 2889

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

STANDARD PROCEDUREÐREPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐFORM-IN-PLACE

GASKETS & SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

BR/BEENGINE 3.9L 9 - 11

ENGINE 3.9L (Continued)

Page 1319 of 2889

LUBRICATION

DESCRIPTION..........................214

OPERATION............................214

DIAGNOSIS AND TESTING................215

ENGINE OIL LEAKS....................215

ENGINE OIL PRESSURE................215

OIL

STANDARD PROCEDURE.................217

ENGINE OIL..........................217

OIL FILTER

REMOVAL.............................218

INSTALLATION..........................218

OIL PAN

REMOVAL.............................218

CLEANING.............................218

INSPECTION...........................219

INSTALLATION..........................219

OIL PUMP

REMOVAL.............................219

CLEANING.............................220

INSPECTION...........................220

INSTALLATION..........................221INTAKE MANIFOLD

DESCRIPTION..........................222

DIAGNOSIS AND TESTING................222

INTAKE MANIFOLD LEAKAGE............222

REMOVAL.............................222

CLEANING.............................223

INSPECTION...........................223

INSTALLATION..........................223

EXHAUST MANIFOLD

DESCRIPTION..........................224

OPERATION............................224

REMOVAL.............................225

CLEANING.............................225

INSPECTION...........................225

INSTALLATION..........................225

TIMING BELT / CHAIN COVER(S)

REMOVAL.............................225

INSTALLATION..........................226

TIMING BELT/CHAIN AND SPROCKETS

REMOVAL.............................226

INSPECTION...........................227

INSTALLATION..........................227

ENGINE 8.0L

DESCRIPTION

The 8.0 Liter (488 CID) ten-cylinder engine is a

V-Type lightweight, single cam, overhead valveengine with hydraulic roller tappets. This engine is

designed for unleaded fuel.

Engine lubrication system consists of a gerotor type

oil pump mounted in the timing chain cover and driven

by the crankshaft. The V-10 uses a full flow oil filter.

The cylinders are numbered from front to rear; 1, 3,

5, 7, 9 on the left bank and 2, 4, 6, 8, 10 on the right

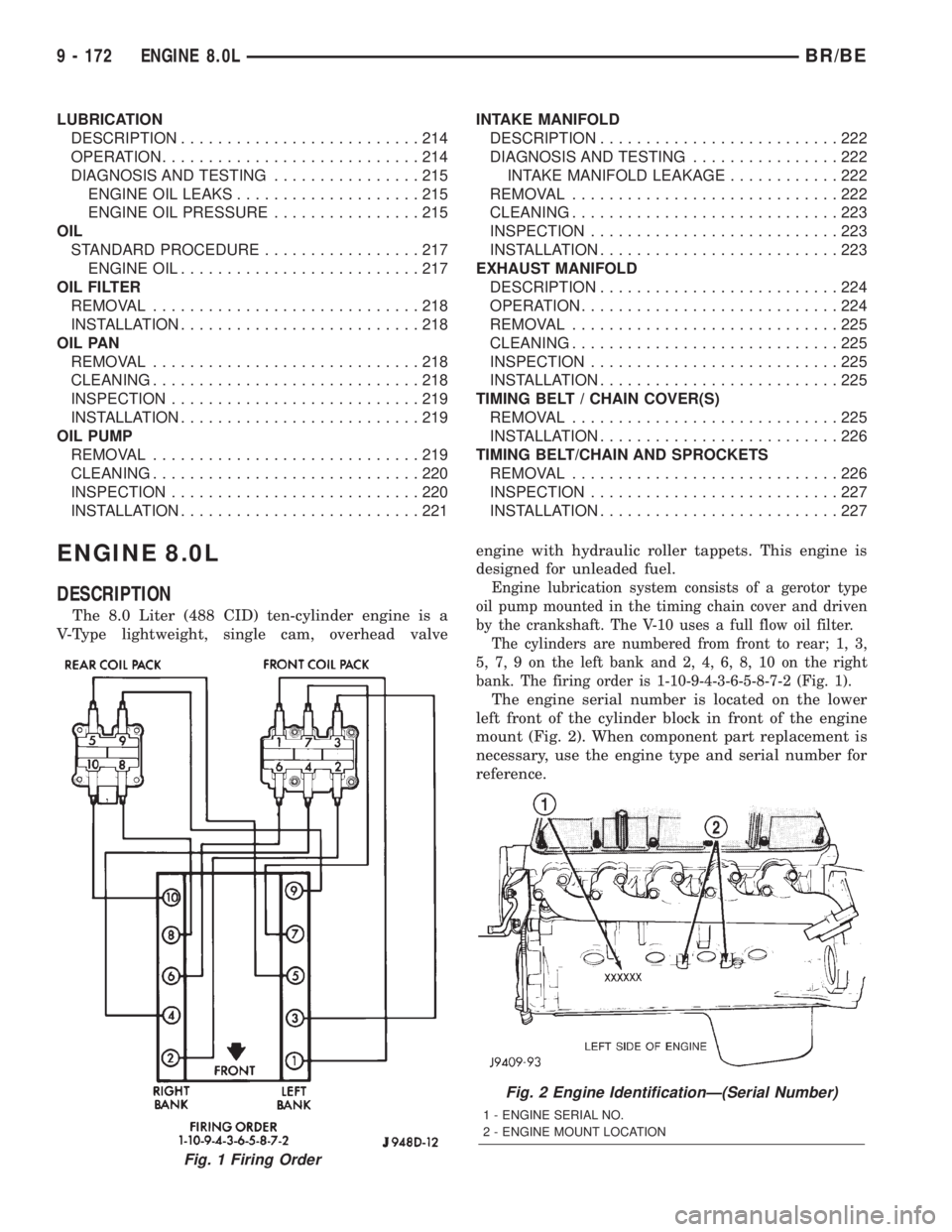

bank. The firing order is 1-10-9-4-3-6-5-8-7-2 (Fig. 1).

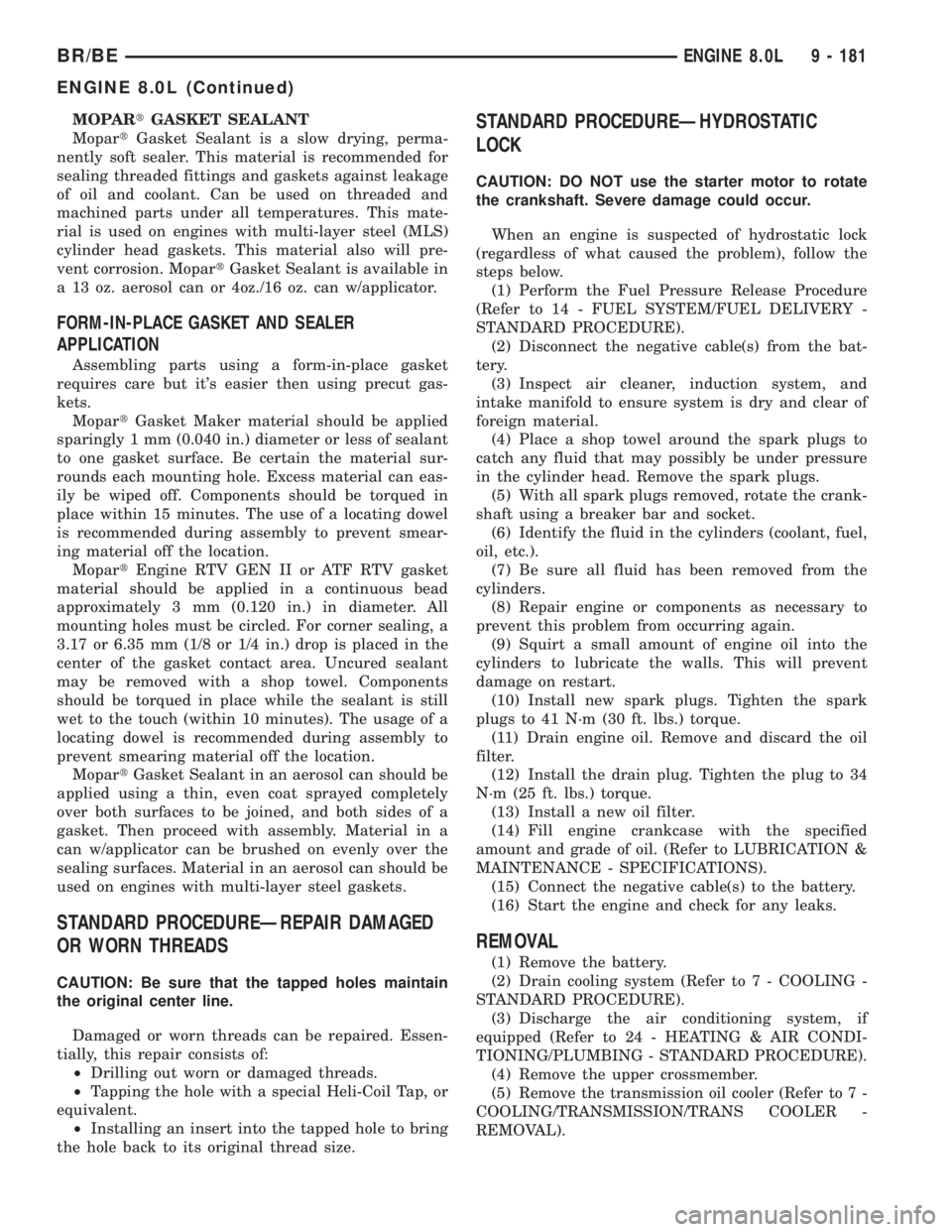

The engine serial number is located on the lower

left front of the cylinder block in front of the engine

mount (Fig. 2). When component part replacement is

necessary, use the engine type and serial number for

reference.

Fig. 1 Firing Order

Fig. 2 Engine IdentificationÐ(Serial Number)

1 - ENGINE SERIAL NO.

2 - ENGINE MOUNT LOCATION

9 - 172 ENGINE 8.0LBR/BE

Page 1328 of 2889

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDUREÐREPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

REMOVAL

(1) Remove the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Discharge the air conditioning system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(4) Remove the upper crossmember.

(5) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).

BR/BEENGINE 8.0L 9 - 181

ENGINE 8.0L (Continued)