central timer module DODGE RAM 2001 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1045 of 2889

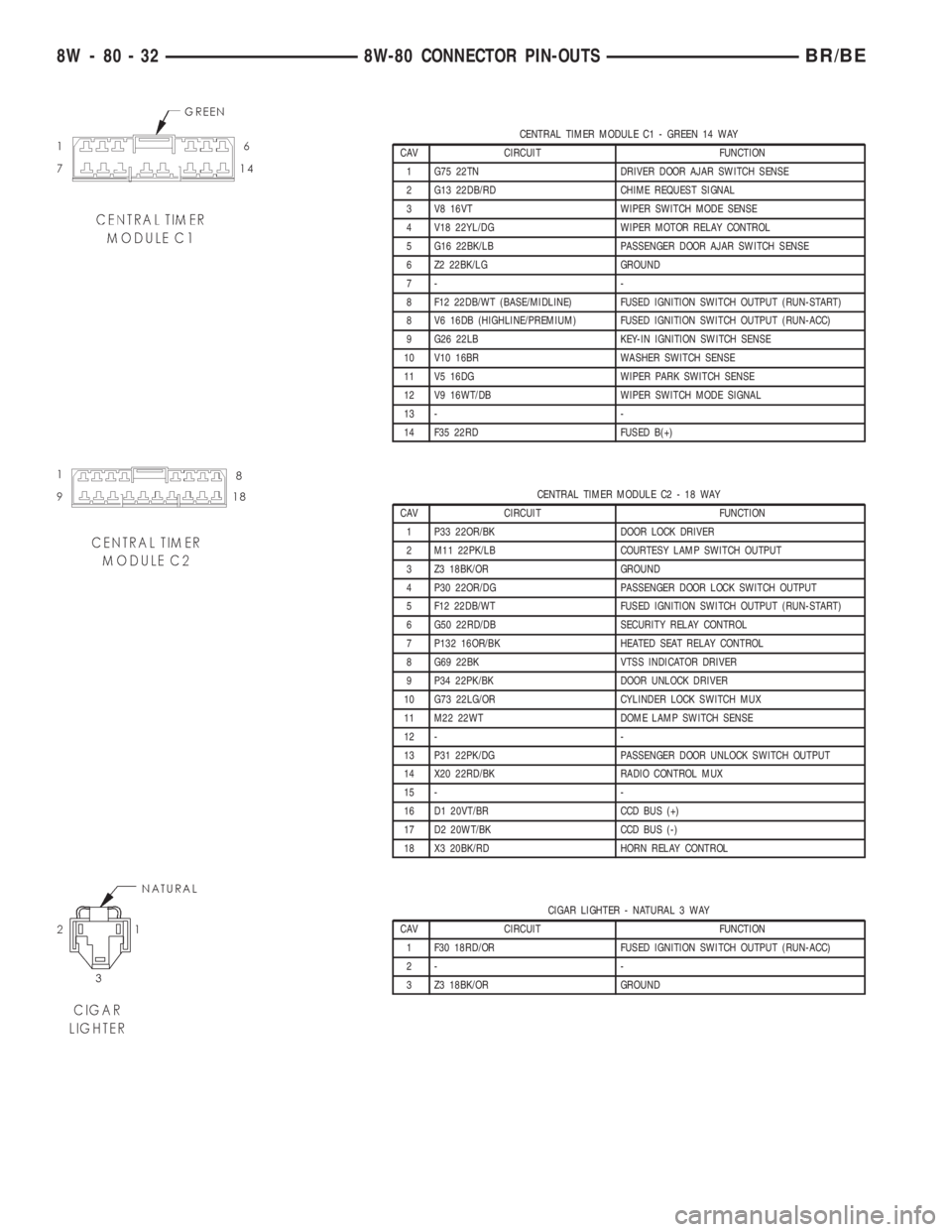

CENTRAL TIMER MODULE C1 - GREEN 14 WAY

CAV CIRCUIT FUNCTION

1 G75 22TN DRIVER DOOR AJAR SWITCH SENSE

2 G13 22DB/RD CHIME REQUEST SIGNAL

3 V8 16VT WIPER SWITCH MODE SENSE

4 V18 22YL/DG WIPER MOTOR RELAY CONTROL

5 G16 22BK/LB PASSENGER DOOR AJAR SWITCH SENSE

6 Z2 22BK/LG GROUND

7- -

8 F12 22DB/WT (BASE/MIDLINE) FUSED IGNITION SWITCH OUTPUT (RUN-START)

8 V6 16DB (HIGHLINE/PREMIUM) FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

9 G26 22LB KEY-IN IGNITION SWITCH SENSE

10 V10 16BR WASHER SWITCH SENSE

11 V5 16DG WIPER PARK SWITCH SENSE

12 V9 16WT/DB WIPER SWITCH MODE SIGNAL

13 - -

14 F35 22RD FUSED B(+)

CENTRAL TIMER MODULE C2 - 18 WAY

CAV CIRCUIT FUNCTION

1 P33 22OR/BK DOOR LOCK DRIVER

2 M11 22PK/LB COURTESY LAMP SWITCH OUTPUT

3 Z3 18BK/OR GROUND

4 P30 22OR/DG PASSENGER DOOR LOCK SWITCH OUTPUT

5 F12 22DB/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

6 G50 22RD/DB SECURITY RELAY CONTROL

7 P132 16OR/BK HEATED SEAT RELAY CONTROL

8 G69 22BK VTSS INDICATOR DRIVER

9 P34 22PK/BK DOOR UNLOCK DRIVER

10 G73 22LG/OR CYLINDER LOCK SWITCH MUX

11 M22 22WT DOME LAMP SWITCH SENSE

12 - -

13 P31 22PK/DG PASSENGER DOOR UNLOCK SWITCH OUTPUT

14 X20 22RD/BK RADIO CONTROL MUX

15 - -

16 D1 20VT/BR CCD BUS (+)

17 D2 20WT/BK CCD BUS (-)

18 X3 20BK/RD HORN RELAY CONTROL

CIGAR LIGHTER - NATURAL 3 WAY

CAV CIRCUIT FUNCTION

1 F30 18RD/OR FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

2- -

3 Z3 18BK/OR GROUND

8W - 80 - 32 8W-80 CONNECTOR PIN-OUTSBR/BE

Page 1093 of 2889

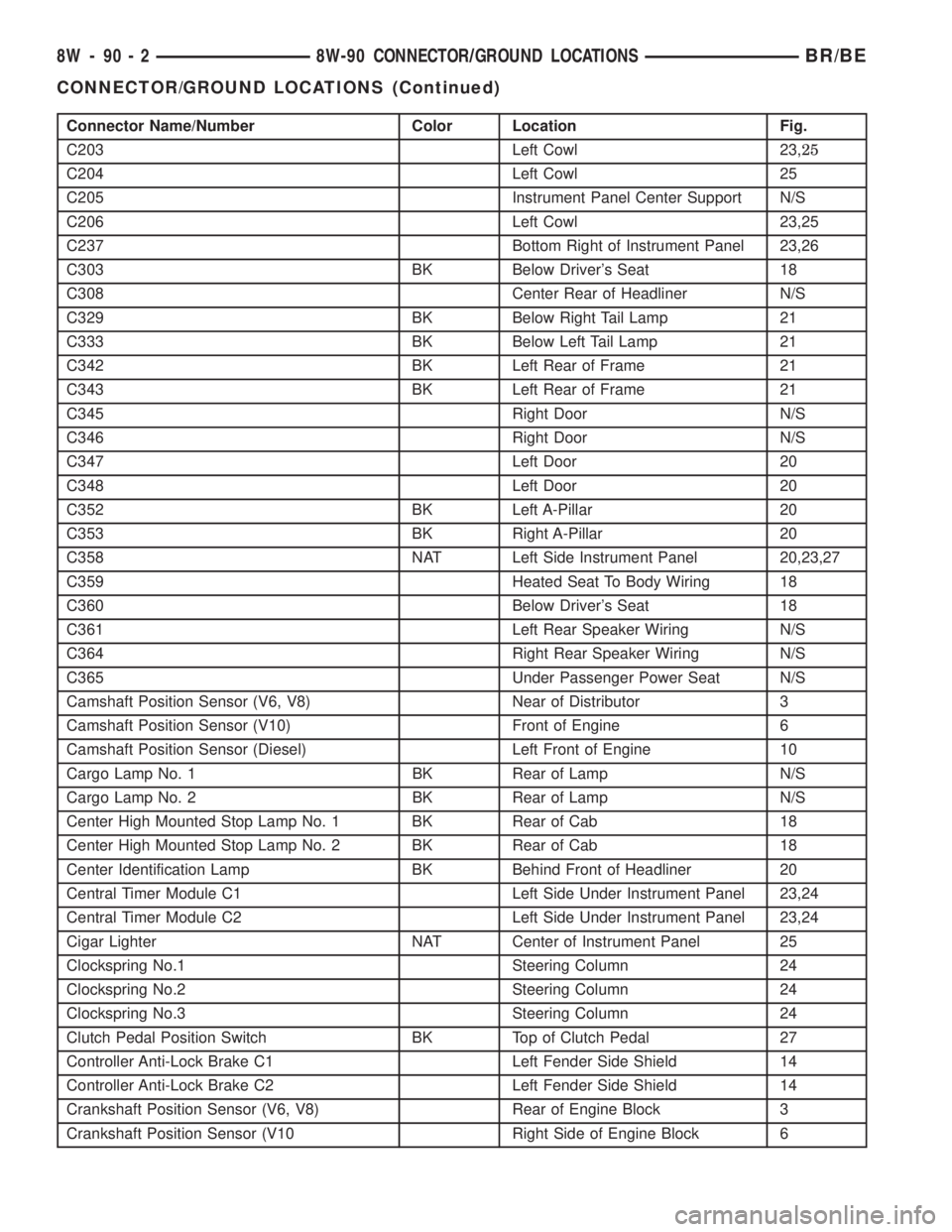

Connector Name/Number Color Location Fig.

C203 Left Cowl 23,25

C204 Left Cowl 25

C205 Instrument Panel Center Support N/S

C206 Left Cowl 23,25

C237 Bottom Right of Instrument Panel 23,26

C303 BK Below Driver's Seat 18

C308 Center Rear of Headliner N/S

C329 BK Below Right Tail Lamp 21

C333 BK Below Left Tail Lamp 21

C342 BK Left Rear of Frame 21

C343 BK Left Rear of Frame 21

C345 Right Door N/S

C346 Right Door N/S

C347 Left Door 20

C348 Left Door 20

C352 BK Left A-Pillar 20

C353 BK Right A-Pillar 20

C358 NAT Left Side Instrument Panel 20,23,27

C359 Heated Seat To Body Wiring 18

C360 Below Driver's Seat 18

C361 Left Rear Speaker Wiring N/S

C364 Right Rear Speaker Wiring N/S

C365 Under Passenger Power Seat N/S

Camshaft Position Sensor (V6, V8) Near of Distributor 3

Camshaft Position Sensor (V10) Front of Engine 6

Camshaft Position Sensor (Diesel) Left Front of Engine 10

Cargo Lamp No. 1 BK Rear of Lamp N/S

Cargo Lamp No. 2 BK Rear of Lamp N/S

Center High Mounted Stop Lamp No. 1 BK Rear of Cab 18

Center High Mounted Stop Lamp No. 2 BK Rear of Cab 18

Center Identification Lamp BK Behind Front of Headliner 20

Central Timer Module C1 Left Side Under Instrument Panel 23,24

Central Timer Module C2 Left Side Under Instrument Panel 23,24

Cigar Lighter NAT Center of Instrument Panel 25

Clockspring No.1 Steering Column 24

Clockspring No.2 Steering Column 24

Clockspring No.3 Steering Column 24

Clutch Pedal Position Switch BK Top of Clutch Pedal 27

Controller Anti-Lock Brake C1 Left Fender Side Shield 14

Controller Anti-Lock Brake C2 Left Fender Side Shield 14

Crankshaft Position Sensor (V6, V8) Rear of Engine Block 3

Crankshaft Position Sensor (V10 Right Side of Engine Block 6

8W - 90 - 2 8W-90 CONNECTOR/GROUND LOCATIONSBR/BE

CONNECTOR/GROUND LOCATIONS (Continued)

Page 1602 of 2889

NOTE: A new grommet should be used when ever

the rod is disconnected from the lever.

(3) Remove the shipping lock pin if necessary.

(4) Install the column through the floor pan.

(5) Position the column bracket breakaway cap-

sules on the mounting studs. Install, butloose

assemblethe two upper bracket nuts.

(6) With the front wheels in the straight-ahead

position. Align steering column shaft to the coupler.

Install anewpinch bolt and tighten to 49 N´m (36

ft. lbs.).

(7) Clip the wiring harness on the steering column.

Connect the multi- function switch wiring and

tighten with 7mm socket.

(8) Install the upper fixed shroud.

(9) Be sure both breakaway capsules are fully

seated in the slots in the column support bracket.

Pull the column rearward then tighten upper bracket

nuts to 12 N´m (105 in. lbs.).

(10) Tighten the toe plate to floor pan attaching

nuts to 22.5 N´m (200 in. lbs.).

(11) Install the wiring connections to the column.

Install the lower fixed shroud.(12) Column shift vehicles, install the PRNDL

driver cable. Place shifter in Park position. If indica-

tor needs adjusting, turn thumb screw on cable

retainer to adjust cable.

(13) Install the lock housing shrouds. Install the

tilt lever (if equipped).

(14) Install the knee blocker and steering column

opening cover, (Refer to 23 - BODY/INSTRUMENT

PANEL/STEERING COLUMN OPENING COVER -

INSTALLATION).

(15) Install steering wheel and tighten nut to 61

N´m (45 ft. lbs.), (Refer to 19 - STEERING/COL-

UMN/STEERING WHEEL - INSTALLATION).

(16) Install the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(17) Column shift vehicles, connect the shift link

rod to the transmission shift lever. Use multi-purpose

lubricant, or an equivalent product, to aid the instal-

lation.

(18) Install the battery ground (negative) cable.

(19) Verify operation of the automatic transmission

shift linkage and adjust as necessary, (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

44RE/GEAR SHIFT CABLE - ADJUSTMENTS).

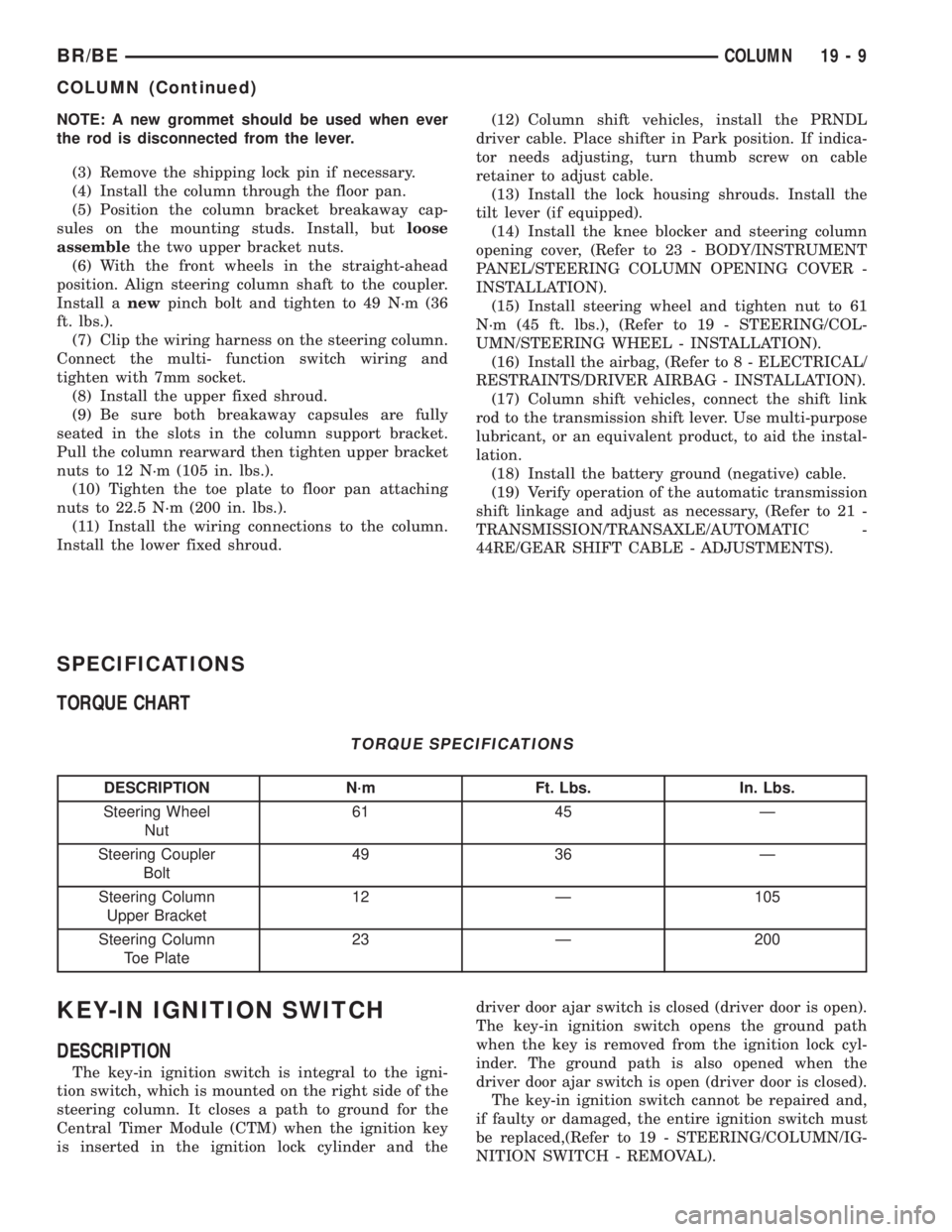

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Steering Wheel

Nut61 45 Ð

Steering Coupler

Bolt49 36 Ð

Steering Column

Upper Bracket12 Ð 105

Steering Column

Toe Plate23 Ð 200

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is integral to the igni-

tion switch, which is mounted on the right side of the

steering column. It closes a path to ground for the

Central Timer Module (CTM) when the ignition key

is inserted in the ignition lock cylinder and thedriver door ajar switch is closed (driver door is open).

The key-in ignition switch opens the ground path

when the key is removed from the ignition lock cyl-

inder. The ground path is also opened when the

driver door ajar switch is open (driver door is closed).

The key-in ignition switch cannot be repaired and,

if faulty or damaged, the entire ignition switch must

be replaced,(Refer to 19 - STEERING/COLUMN/IG-

NITION SWITCH - REMOVAL).

BR/BECOLUMN 19 - 9

COLUMN (Continued)

Page 2677 of 2889

INSTRUMENT PANEL SYSTEM

TABLE OF CONTENTS

page page

INSTRUMENT PANEL SYSTEM

DESCRIPTION..........................104

OPERATION............................105

REMOVAL.............................106

INSTALLATION..........................107

ASH RECEIVER

REMOVAL.............................108

INSTALLATION..........................109

CLUSTER BEZEL

REMOVAL.............................109

INSTALLATION..........................110

CUBBY BIN

REMOVAL.............................110

INSTALLATION..........................110

CUP HOLDER

REMOVAL.............................110

INSTALLATION..........................111

GLOVE BOX

REMOVAL.............................112DISASSEMBLY..........................112

ASSEMBLY.............................112

INSTALLATION..........................113

GLOVE BOX LATCH STRIKER

REMOVAL.............................113

INSTALLATION..........................113

GLOVE BOX OPENING UPPER TRIM

REMOVAL.............................114

INSTALLATION..........................114

INSTRUMENT PANEL TOP COVER

REMOVAL.............................114

INSTALLATION..........................115

STEERING COLUMN OPENING COVER

REMOVAL.............................115

INSTALLATION..........................116

STORAGE BIN

REMOVAL.............................116

INSTALLATION..........................116

INSTRUMENT PANEL SYSTEM

DESCRIPTION

The instrument panel is located at the front of the

passenger compartment. This instrument panel is

molded from a blend of various plastics that are

mechanically attached to the vehicle. Colors are

molded into the plastic components to minimize

appearance degradation from scratches or abrasions.

The panel components are internally ribbed and riv-

eted to steel reinforcements for additional structural

integrity and dimensional stability. The instrument

panel surface components are designed to deform

upon impact without breaking. This type of construc-

tion provides improved energy absorption which, in

conjunction with the dual airbags and seat belts,

helps to improve occupant protection.

The top of the instrument panel is secured to the

top of the dash panel near the base of the windshield

using screws. An end bracket integral to each end of

the instrument panel structure is secured to each

cowl side inner panel with a screw. A stamped metal

bracket supports the center of the instrument panel

by securing it to the top of the floor panel transmis-

sion tunnel below the instrument panel with screws.

The instrument cluster, radio, heater-air conditioner

control, passenger airbag, glove box, electrical junc-

tion block, Central Timer Module (CTM), accessoryswitches, ash receiver, cigar lighter, accessory power

outlet, park brake release handle, inside hood release

handle, as well as numerous other components are

secured to and supported by this unit.

The instrument panel for this vehicle includes the

following major features:

²Cluster Bezel- This molded plastic bezel is

secured with snap clips to the instrument panel sup-

porting structure. It trims out the edges of the head-

lamp switch, instrument cluster, radio, heater-air

conditioner controls, passenger airbag on-off switch,

and the heated seat switches on vehicles so equipped.

On vehicles without the heated seat option, a small

storage cubby bin is provided in the cluster bezel.

This bezel also incorporates three completely adjust-

able panel outlets for the climate control system, and

fills the opening between the instrument cluster and

the top of the steering column where it passes

through the instrument panel.

²Cup Holder/Storage Bin- Vehicles equipped

with an automatic transmission feature a latching

fold-down, adjustable cup holder located on the lower

instrument panel between the glove box and the ash

receiver. Vehicles equipped with a manual transmis-

sion have a lighted storage bin on the instrument

panel in place of the cup holder.

²Glove Box- The hinged bin-type glove box in

the passenger side of the instrument panel features a

recessed paddle-operated latch handle. Three molded

23 - 104 INSTRUMENT PANEL SYSTEMBR/BE

Page 2678 of 2889

hook formations on the lower edge of the glove box

door are engaged with and pivot on three hinge pins

integral to the lower edge of the instrument panel

support structure. The glove box door also serves as

the passenger side knee blocker. A honeycomb struc-

ture between the inner and outer glove box door pan-

els helps to absorb the impact load and distribute it

to the instrument panel structure.

²Steering Column Opening Cover- The steer-

ing column opening cover serves as the driver side

knee blocker. This molded plastic cover has an inte-

gral ribbed plastic liner concealed behind it, for

increased strength and integrity. The steering column

opening cover transfers impact loads to the instru-

ment panel structural support.

²Top Cover- The instrument panel top cover or

base trim is the molded, grained, and color impreg-

nated plastic outer skin of the instrument panel

structural support.

Hard wired circuitry connects the electrical compo-

nents on the instrument panel to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the instrument panel components through the

use of a combination of soldered splices, splice block

connectors and many different types of wire harness

terminal connectors and insulators. Refer to the

appropriate wiring information. The wiring informa-

tion includes complete circuit diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices, and grounds.

OPERATION

The instrument panel serves as the command cen-

ter of the vehicle, which necessarily makes it a very

complex unit. The instrument panel is designed to

house the controls and monitors for standard and

optional powertrains, climate control systems, audio

systems, safety systems, and many other comfort or

convenience items. When the components of the

instrument panel structural support are properly

assembled and secured in the vehicle they provide

superior instrument panel stiffness and integrity to

help reduce buzzes, squeaks, and rattles. This type of

construction also provides improved energy absorp-

tion which, in conjunction with the dual airbags and

seat belts, helps to improve occupant protection.

The instrument panel is also designed so that all of

the various controls can be safely reached and the

monitors can be easily viewed by the vehicle operator

when driving, while still allowing relative ease ofaccess to each of these items for service. Modular

instrument panel construction allows all of the

gauges and controls to be serviced from the front of

the panel. In addition, most of the instrument panel

electrical components can be accessed without com-

plete instrument panel removal. However, if neces-

sary, the instrument panel can be removed from the

vehicle as an assembly.

The steering column opening cover with its inte-

gral knee blocker located on the driver side of the

instrument panel works in conjunction with the air-

bag system in a frontal vehicle impact to keep the

driver properly positioned for an airbag deployment.

In addition, removal of this component provides

access to the steering column mounts, the steering

column wiring, the Junction Block (JB) (removal of a

snap-fit fuse access panel on the left end of the

instrument panel allows access to the fuses and cir-

cuit breakers), the Central Timer Module (CTM), the

Infinity speaker filter choke and relay unit, much of

the instrument panel wiring, and the gear selector

indicator cable (automatic transmission).

In a frontal collision, the glove box door on the pas-

senger side of the instrument panel provides the

same function for the front seat passenger as the

knee blocker does for the driver. The glove box door

also incorporates a recessed latch handle. Removal of

the glove box provides access to the passenger airbag,

the glove box lamp and switch, the radio antenna

coaxial cable, the heating and air conditioning vac-

uum harness connector, and additional instrument

panel wiring.

Removal of the instrument panel cluster bezel

allows access to the headlamp switch, instrument

cluster, radio, passenger airbag on-off switch, heated

seat switches (if equipped), and the heating and air

conditioning control. Removal of the instrument clus-

ter allows access to the cluster illumination and indi-

cator bulbs, and more of the instrument panel

wiring. Complete instrument panel removal is

required for service of most components internal to

the heating and air conditioning system housing,

including the heater core and the evaporator.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the components and systems mounted on or

in the instrument panel.

BR/BEINSTRUMENT PANEL SYSTEM 23 - 105

INSTRUMENT PANEL SYSTEM (Continued)

Page 2851 of 2889

BEARING FITTING, CONNECTING ROD

BEARINGS - STANDARD PROCEDURE-

CONNECTING ROD....................9-31

BEARINGS - DESCRIPTION,

CRANKSHAFT MAIN..........9-146,9-32,9-90

BEARINGS - INSTALLATION, AXLE . . 3-125,3-156,

3-185,3-95

BEARINGS - INSTALLATION, CAMSHAFT . . 9-144,

9-201,9-273,9-29,9-87

BEARINGS - INSTALLATION,

CRANKSHAFT MAIN.....9-147,9-204,9-34,9-90

BEARINGS - INSTALLATION,

DIFFERENTIAL CASE . . 3-103,3-134,3-164,3-192,

3-39,3-71

BEARINGS - OPERATION, CRANKSHAFT

MAIN......................9-146,9-32,9-90

BEARINGS - REMOVAL, AXLE.....3-125,3-156,

3-185,3-94

BEARINGS - REMOVAL, CAMSHAFT.....9-143,

9-200,9-268,9-29,9-86

BEARINGS - REMOVAL, CRANKSHAFT

MAIN.................9-147,9-204,9-33,9-90

BEARINGS - REMOVAL, DIFFERENTIAL

CASE.......3-103,3-134,3-164,3-192,3-39,3-71

BEARINGS - STANDARD PROCEDURE-

CONNECTING ROD BEARING FITTING,

CONNECTING ROD....................9-31

BEARINGS (IN BLOCK) - INSPECTION,

CAMSHAFT.........................9-272

BED GROUND STRAP - INSTALLATION,

CAB-TO............................8A-14

BED GROUND STRAP - REMOVAL,

CAB-TO............................8A-14

BELT / CHAIN COVER(S) -

INSTALLATION, TIMING. . . 9-113,9-169,9-226,9-56

BELT / CHAIN COVER(S) - REMOVAL,

TIMING..............9-113,9-169,9-225,9-56

BELT - DIAGNOSIS AND TESTING,

ACCESSORY DRIVE............7-24,7-27,7-31

BELT & RETRACTOR - INSTALLATION,

REAR SEAT.........................8O-26

BELT & RETRACTOR - REMOVAL, REAR

SEAT ..............................8O-26

BELT BUCKLE - INSTALLATION, FRONT

SEAT ..............................8O-20

BELT BUCKLE - INSTALLATION, REAR

SEAT ..............................8O-27

BELT BUCKLE - REMOVAL, FRONT SEAT . . 8O-20

BELT BUCKLE - REMOVAL, REAR SEAT . . . 8O-27

BELT SWITCH - DESCRIPTION, SEAT.....8O-28

BELT SWITCH - DIAGNOSIS AND

TESTING, SEAT......................8O-28

BELT SWITCH - OPERATION, SEAT.......8O-28

BELT TENSIONERS - 3.9L/5.2L/5.9L -

DESCRIPTION........................7-19

BELT TENSIONERS - 3.9L/5.2L/5.9L -

INSTALLATION........................7-20

BELT TENSIONERS - 3.9L/5.2L/5.9L -

OPERATION..........................7-19

BELT TENSIONERS - 3.9L/5.2L/5.9L -

REMOVAL...........................7-20

BELT TENSIONERS - 5.9L DIESEL -

DESCRIPTION........................7-23

BELT TENSIONERS - 5.9L DIESEL -

INSTALLATION

........................7-23

BELT TENSIONERS - 5.9L DIESEL -

OPERATION

..........................7-23

BELT TENSIONERS - 5.9L DIESEL -

REMOVAL

...........................7-23

BELT TENSIONERS - 8.0L -

DESCRIPTION

........................7-20

BELT TENSIONERS - 8.0L -

INSTALLATION

........................7-22

BELT TENSIONERS - 8.0L - OPERATION

....7-20

BELT TENSIONERS - 8.0L - REMOVAL

.....7-21

BELT TURNING LOOP ADJUSTER -

INSTALLATION, SEAT

.................8O-29

BELT TURNING LOOP ADJUSTER -

REMOVAL, SEAT

.....................8O-29

BELT WEATHERSTRIP - INSTALLATION,

FRONT DOOR INNER

.................23-154

BELT WEATHERSTRIP - INSTALLATION,

FRONT DOOR OUTER

................23-154

BELT WEATHERSTRIP - REMOVAL,

FRONT DOOR INNER

.................23-154

BELT WEATHERSTRIP - REMOVAL,

FRONT DOOR OUTER

................23-154BELT/CHAIN AND SPROCKETS -

INSTALLATION, TIMING . 9-115,9-170,9-227,9-58

BELT/CHAIN AND SPROCKETS -

REMOVAL, TIMING.....9-114,9-170,9-226,9-57

BELT/CHAIN TENSIONER - DESCRIPTION,

TIMING.............................9-57

BELT/CHAIN TENSIONER - OPERATION,

TIMING.............................9-57

BELTS - 3.9L/5.2L/5.9L - INSTALLATION,

DRIVE..............................7-27

BELTS - 3.9L/5.2L/5.9L - REMOVAL,

DRIVE..............................7-26

BELTS - 5.9L DIESEL - INSTALLATION,

DRIVE..............................7-34

BELTS - 5.9L DIESEL - REMOVAL, DRIVE . . 7-33

BELTS - 8.0L - INSTALLATION, DRIVE.....7-30

BELTS - 8.0L - REMOVAL, DRIVE.........7-30

BELTS, RETRACTORS AND HEAD

RESTRAINTS - INSPECTION, SEAT

BELTS, SHOULDER...................30-12

BELTS, SHOULDER BELTS, RETRACTORS

AND HEAD RESTRAINTS -

INSPECTION, SEAT...................30-12

BENCH - INSTALLATION, SEAT - SPLIT . . 23-134

BENCH - INSTALLATION, SEAT BACK -

SPLIT.............................23-136

BENCH - INSTALLATION, SEAT BACK

COVER - SPLIT.....................23-138

BENCH - INSTALLATION, SEAT CUSHION

COVER - SPLIT.....................23-140

BENCH - INSTALLATION, SEAT TRACK -

SPLIT.............................23-142

BENCH - REMOVAL, SEAT - SPLIT........23-134

BENCH - REMOVAL, SEAT BACK - SPLIT . 23-135

BENCH - REMOVAL, SEAT BACK COVER

- SPLIT...........................23-137

BENCH - REMOVAL, SEAT CUSHION

COVER - SPLIT.....................23-139

BENCH - REMOVAL, SEAT TRACK -

SPLIT.............................23-142

BENCH SEAT - INSTALLATION, SEAT....23-133

BENCH SEAT - INSTALLATION, SEAT

BACK.............................23-135

BENCH SEAT - REMOVAL, SEAT........23-133

BENCH SEAT - REMOVAL, SEAT BACK . . . 23-135

BETTS - INSTALLATION, CONNECTOR -

THOMAS........................8W-01-10

BETTS - REMOVAL, CONNECTOR -

THOMAS.........................8W-01-9

BEZEL - INSTALLATION, CLUSTER......23-110

BEZEL - REMOVAL, CLUSTER..........23-109

BIN - INSTALLATION, CUBBY..........23-110

BIN - INSTALLATION, STORAGE........23-116

BIN - REMOVAL, CUBBY..............23-110

BIN - REMOVAL, STORAGE............23-116

BLADE - DESCRIPTION, WIPER.........8R-12

BLADE - INSTALLATION, WIPER.........8R-13

BLADE - OPERATION, WIPER...........8R-13

BLADE - REMOVAL, WIPER............8R-13

BLEED - STANDARD PROCEDURE, AIR....14-57

BLEEDING - STANDARD PROCEDURE......5-19

BLEEDING - STANDARD PROCEDURE,

MANUAL.............................5-7

BLEEDING - STANDARD PROCEDURE,

MASTER CYLINDER...................5-30

BLEEDING - STANDARD PROCEDURE,

PRESSURE...........................5-8

BLEND DOOR - INSTALLATION

..........24-38

BLEND DOOR - REMOVAL

.............24-38

BLEND DOOR ACTUATOR -

INSTALLATION

.......................24-26

BLEND DOOR ACTUATOR - REMOVAL

....24-25

BLOCK - CLEANING, ENGINE

. . 9-142,9-200,9-28,

9-86

BLOCK - DESCRIPTION, BLOWER

MOTOR RESISTOR

...................24-23

BLOCK - DESCRIPTION, JUNCTION

....8W-97-6

BLOCK - DIAGNOSIS AND TESTING,

BLOWER MOTOR RESISTOR

............24-24

BLOCK - INSPECTION, ENGINE

....9-142,9-200,

9-267,9-28,9-86

BLOCK - INSTALLATION, BLOWER

MOTOR RESISTOR

...................24-24

BLOCK - INSTALLATION, JUNCTION

....8W-97-7

BLOCK - OPERATION, BLOWER MOTOR

RESISTOR

..........................24-23

BLOCK - OPERATION, JUNCTION

......8W-97-6BLOCK - REMOVAL, BLOWER MOTOR

RESISTOR..........................24-24

BLOCK - REMOVAL, JUNCTION.......8W-97-6

BLOCK - STANDARD PROCEDURE-

CYLINDER BLOCK REFACING, ENGINE....9-263

BLOCK HEATER - 3.9L/5.2L/5.9L -

DESCRIPTION, ENGINE.................7-45

BLOCK HEATER - 3.9L/5.2L/5.9L -

INSTALLATION, ENGINE................7-45

BLOCK HEATER - 3.9L/5.2L/5.9L -

OPERATION, ENGINE...................7-45

BLOCK HEATER - 3.9L/5.2L/5.9L -

REMOVAL, ENGINE....................7-45

BLOCK HEATER - 5.9L DIESEL -

DESCRIPTION, ENGINE.................7-47

BLOCK HEATER - 5.9L DIESEL -

INSTALLATION, ENGINE................7-47

BLOCK HEATER - 5.9L DIESEL -

OPERATION, ENGINE...................7-47

BLOCK HEATER - 5.9L DIESEL -

REMOVAL, ENGINE....................7-47

BLOCK HEATER - 8.0L - DESCRIPTION,

ENGINE.............................7-46

BLOCK HEATER - 8.0L - INSTALLATION,

ENGINE.............................7-46

BLOCK HEATER - 8.0L - OPERATION,

ENGINE.............................7-46

BLOCK HEATER - 8.0L - REMOVAL,

ENGINE.............................7-46

BLOCK REFACING, ENGINE BLOCK -

STANDARD PROCEDURE-CYLINDER......9-263

BLOWER MOTOR - DESCRIPTION.......24-32

BLOWER MOTOR - DIAGNOSIS AND

TESTING...........................24-33

BLOWER MOTOR - INSTALLATION.......24-33

BLOWER MOTOR - OPERATION.........24-32

BLOWER MOTOR - REMOVAL...........24-33

BLOWER MOTOR RELAY - DESCRIPTION . . 24-22

BLOWER MOTOR RELAY - DIAGNOSIS

AND TESTING.......................24-22

BLOWER MOTOR RELAY -

INSTALLATION.......................24-23

BLOWER MOTOR RELAY - OPERATION . . . 24-22

BLOWER MOTOR RELAY - REMOVAL.....24-23

BLOWER MOTOR RESISTOR BLOCK -

DESCRIPTION.......................24-23

BLOWER MOTOR RESISTOR BLOCK -

DIAGNOSIS AND TESTING.............24-24

BLOWER MOTOR RESISTOR BLOCK -

INSTALLATION.......................24-24

BLOWER MOTOR RESISTOR BLOCK -

OPERATION.........................24-23

BLOWER MOTOR RESISTOR BLOCK -

REMOVAL..........................24-24

BLOWER MOTOR SWITCH -

DESCRIPTION.......................24-24

BLOWER MOTOR SWITCH - DIAGNOSIS

AND TESTING.......................24-25

BLOWER MOTOR SWITCH - OPERATION . . 24-25

BLOWER MOTOR SWITCH - REMOVAL . . . 24-25

BODY - ADJUSTMENTS, VALVE . . 21-304,21-476,

21-646,21-818

BODY - ASSEMBLY, VALVE......21-294,21-466,

21-638,21-810

BODY & CABLE - DESCRIPTION,

ANTENNA...........................8A-4

BODY & CABLE - OPERATION, ANTENNA . . . 8A-4

BODY - CLEANING, VALVE......21-293,21-465,

21-637,21-808

BODY - DESCRIPTION, THROTTLE.......14-48

BODY - DESCRIPTION, VALVE . . . 21-263,21-433,

21-607,21-780

BODY - DISASSEMBLY, VALVE . . . 21-282,21-453,

21-626,21-799

BODY - INSPECTION, VALVE....21-293,21-465,

21-637,21-809

BODY - INSTALLATION, VALVE . . . 21-303,21-475,

21-645,21-818

BODY - OPERATION, THROTTLE.........14-48

BODY - OPERATION, VALVE

.....21-267,21-438,

21-611,21-783

BODY - REMOVAL, VALVE

......21-281,21-452,

21-625,21-798

BODY - SAFETY PRECAUTIONS AND

WARNINGS

..........................23-1

BODY CODE PLATE - DESCRIPTION

.....Intro.-1

BODY CONTROL/CENTRAL TIMER

MODULE - DESCRIPTION

...............8E-1

4 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2852 of 2889

BODY CONTROL/CENTRAL TIMER

MODULE - INSTALLATION...............8E-6

BODY CONTROL/CENTRAL TIMER

MODULE - OPERATION.................8E-3

BODY CONTROL/CENTRAL TIMER

MODULE - REMOVAL..................8E-5

BODY GAP AND FLUSH

MEASUREMENTS, SPECIFICATIONS......23-56

BODY OPENING DIMENSIONS,

SPECIFICATIONS.....................23-60

BODY SEALER LOCATIONS,

SPECIFICATIONS.....................23-47

BODY SEALING - INSPECTION..........30-10

BODY SIDE MOLDINGS - INSTALLATION . . 23-87

BODY SIDE MOLDINGS - REMOVAL......23-87

BODY STRIPES AND DECALS -

INSTALLATION.......................23-87

BODY STRIPES AND DECALS -

REMOVAL..........................23-87

BODY VENT - INSTALLATION..........23-126

BODY VENT - REMOVAL..............23-126

BOOST PRESSURE - DIAGNOSIS AND

TESTING...........................14-89

BOOSTER - DIAGNOSIS AND TESTING,

HYDRAULIC..........................5-17

BOOSTER - DIAGNOSIS AND TESTING,

MASTER CYLINDER/POWER.............5-29

BOOSTER - INSTALLATION, POWER

BRAKE..............................5-20

BOOSTER - REMOVAL, POWER BRAKE....5-19

BOOT - INSTALLATION, 4WD FLOOR

SHIFT..............................23-122

BOOT - MANUAL TRANSMISSION -

INSTALLATION, SHIFT................23-122

BOOT - MANUAL TRANSMISSION -

REMOVAL, SHIFT....................23-122

BOOT - REMOVAL, 4WD FLOOR SHIFT . . . 23-122

BORE, DE-GLAZE - STANDARD

PROCEDURE-CYLINDER...............9-264

BORE HONING - STANDARD

PROCEDURE, CYLINDER . . 9-10,9-126,9-180,9-69

BORE REPAIR - STANDARD

PROCEDURE, CAM...................9-267

BORE REPAIR - STANDARD

PROCEDURE, CYLINDER...............9-265

BOX - ASSEMBLY, GLOVE.............23-112

BOX - DISASSEMBLY, GLOVE..........23-112

BOX - INSTALLATION, CARGO..........23-97

BOX - INSTALLATION, GLOVE..........23-113

BOX - REMOVAL, CARGO..............23-96

BOX - REMOVAL, GLOVE.............23-112

BOX LAMP AND SWITCH -

INSTALLATION, GLOVE................8L-35

BOX LAMP AND SWITCH - REMOVAL,

GLOVE.............................8L-35

BOX LATCH STRIKER - INSTALLATION,

GLOVE............................23-113

BOX LATCH STRIKER - REMOVAL,

GLOVE............................23-113

BOX OPENING UPPER TRIM -

INSTALLATION, GLOVE...............23-114

BOX OPENING UPPER TRIM - REMOVAL,

GLOVE............................23-114

B-PILLAR DOOR SEAL - INSTALLATION . . 23-152

B-PILLAR DOOR SEAL - REMOVAL......23-152

B-PILLAR TRIM - INSTALLATION

.......23-120

B-PILLAR TRIM - REMOVAL

...........23-120

BR PAINT COLOR CODES,

SPECIFICATIONS - 2001

..............23-129

BRACKET - INSTALLATION, CAB

CHASSIS ADAPTER

....................13-9

BRACKET - INSTALLATION, REARVIEW

MIRROR SUPPORT

..................23-126

BRACKET - REMOVAL, CAB CHASSIS

ADAPTER

............................13-9

BRAKE - DESCRIPTION, CONTROLLER

ANTILOCK

..........................8E-11

BRAKE - INSPECTION, PARKING

.........30-17

BRAKE - INSTALLATION, CONTROLLER

ANTILOCK

..........................8E-12

BRAKE - OPERATION, CONTROLLER

ANTILOCK

..........................8E-11

BRAKE - REMOVAL, CONTROLLER

ANTILOCK

..........................8E-12

BRAKE BOOSTER - INSTALLATION,

POWER

.............................5-20

BRAKE BOOSTER - REMOVAL, POWER

....5-19BRAKE CABLE - 2500/3500 WITH REAR

DISC BRAKES - INSTALLATION, REAR

PARK...............................5-38

BRAKE CABLE - 2500/3500 WITH REAR

DISC BRAKES - REMOVAL, REAR

PARK...............................5-37

BRAKE CABLE - INSTALLATION, FRONT

PARKING............................5-39

BRAKE CABLE - REMOVAL, FRONT

PARKING............................5-37

BRAKE CABLE 2500/3500 SERIES WITH

DRUM BRAKES - INSTALLATION, REAR

PARK...............................5-39

BRAKE CABLES - 1500 SERIES -

INSTALLATION, REAR PARK.............5-39

BRAKE CABLES - 1500 SERIES -

REMOVAL, REAR PARK.................5-37

BRAKE CABLES 2500/3500 SERIES WITH

DRUM BRAKES - REMOVAL, REAR

PARK...............................5-38

BRAKE CALIPERS - ASSEMBLY, DISC......5-12

BRAKE CALIPERS - CLEANING, DISC......5-12

BRAKE CALIPERS - DISASSEMBLY, DISC . . . 5-11

BRAKE CALIPERS - INSPECTION, DISC....5-12

BRAKE DRUM - ADJUSTMENT, REAR......5-34

BRAKE DRUM - DIAGNOSIS AND

TESTING............................5-33

BRAKE DRUM MACHINING - STANDARD

PROCEDURE.........................5-33

BRAKE FLUID CONTAMINATION -

DIAGNOSIS AND TESTING..............5-14

BRAKE FLUID LEVEL - STANDARD

PROCEDURE.........................5-14

BRAKE FLUID, SPECIFICATIONS..........5-15

BRAKE INDICATOR - DESCRIPTION,

BRAKE/PARK........................8J-16

BRAKE INDICATOR - DIAGNOSIS AND

TESTING...........................8J-16

BRAKE INDICATOR - OPERATION,

BRAKE/PARK........................8J-16

BRAKE LAMP SWITCH - DESCRIPTION....8L-4

BRAKE LAMP SWITCH - DIAGNOSIS

AND TESTING........................8L-5

BRAKE LAMP SWITCH - INSTALLATION....8L-5

BRAKE LAMP SWITCH - OPERATION......8L-4

BRAKE LAMP SWITCH - REMOVAL.......8L-5

BRAKE ROTOR - DIAGNOSIS AND

TESTING, DISC.......................5-20

BRAKE SHOES - 2500/3500 -

INSTALLATION, REAR DRUM IN HAT

PARK...............................5-42

BRAKE SHOES - 2500/3500 - REMOVAL,

REAR DRUM IN HAT PARK..............5-41

BRAKE SHOES-11 INCH - INSTALLATION,

REAR...............................5-27

BRAKE SHOES-11 INCH - REMOVAL,

REAR...............................5-25

BRAKE, SPECIFICATIONS - BASE..........5-2

BRAKE SYSTEM - DIAGNOSIS AND

TESTING, BASE........................5-5

BRAKE/PARK BRAKE INDICATOR -

DESCRIPTION

.......................8J-16

BRAKE/PARK BRAKE INDICATOR -

OPERATION

.........................8J-16

BRAKES - DESCRIPTION, 2500/3500

WITH REAR DISC

.....................5-35

BRAKES - INSPECTION, SERVICE

........30-17

BRAKES - INSTALLATION, REAR PARK

BRAKE CABLE - 2500/3500 WITH

REAR DISC

..........................5-38

BRAKES - INSTALLATION, REAR PARK

BRAKE CABLE 2500/3500 SERIES

WITH DRUM

.........................5-39

BRAKES - OPERATION, 2500/3500 WITH

REAR DISC

..........................5-36

BRAKES - REMOVAL, REAR PARK

BRAKE CABLE - 2500/3500 WITH

REAR DISC

..........................5-37

BRAKES - REMOVAL, REAR PARK

BRAKE CABLES 2500/3500 SERIES

WITH DRUM

.........................5-38

BRAKES, SPECIAL TOOLS - BASE

.........5-4

BREAKER - DESCRIPTION, CIRCUIT

....8W-97-4

BREAKER - DIAGNOSIS & TESTING,

CIRCUIT

.........................8W-97-4

BREAK-IN - STANDARD PROCEDURE,

A/C COMPRESSOR CLUTCH

............24-13BREATHER VAPOR CANISTER -

INSTALLATION, CRANKCASE............9-242

BREATHER VAPOR CANISTER -

REMOVAL, CRANKCASE...............9-241

BUCKLE - INSTALLATION, FRONT SEAT

BELT ..............................8O-20

BUCKLE - INSTALLATION, REAR SEAT

BELT ..............................8O-27

BUCKLE - REMOVAL, FRONT SEAT BELT . . 8O-20

BUCKLE - REMOVAL, REAR SEAT BELT . . . 8O-27

BUILT-IN INDICATOR TEST - STANDARD

PROCEDURE........................8F-11

BUMPER - DESCRIPTION, JOUNCE....2-28,2-9

BUMPER - INSTALLATION, FRONT........13-4

BUMPER - INSTALLATION, REAR.........13-5

BUMPER - INSTALLATION, SLAM........23-66

BUMPER - OPERATION, JOUNCE......2-28,2-9

BUMPER - REMOVAL, FRONT............13-3

BUMPER - REMOVAL, REAR.............13-5

BUMPER - REMOVAL, SLAM...........23-66

BUMPERS - DESCRIPTION..............13-1

BUMPER-SPORT - INSTALLATION,

FRONT..............................13-4

BUMPER-SPORT - REMOVAL, FRONT......13-4

BURNT FLUID - DIAGNOSIS AND

TESTING, CAUSES OF . . . 21-199,21-370,21-545,

21-715

BUS - DESCRIPTION, CCD DATA..........8E-6

BUS - DIAGNOSIS AND TESTING, CCD

D ATA................................8E-11

BUS - OPERATION, CCD DATA...........8E-7

BUSHING - INSTALLATION,

DISTRIBUTOR...............9-150,9-37,9-94

BUSHING - INSTALLATION, EXTENSION

HOUSING........21-198,21-369,21-544,21-714

BUSHING - REMOVAL, DISTRIBUTOR....9-150,

9-37,9-94

BUSHING - REMOVAL, EXTENSION

HOUSING........21-198,21-369,21-544,21-714

BUSHING AND SEAL - INSTALLATION,

EXTENSION HOUSING....21-850,21-885,21-921

BUSHING AND SEAL - REMOVAL,

EXTENSION HOUSING....21-850,21-885,21-921

BUSHINGS - INSTALLATION.............2-28

BUSHINGS - REMOVAL.................2-28

BYPASS HOSE WITH AIR CONDITIONING

- INSTALLATION, WATER PUMP..........7-77

BYPASS HOSE WITH AIR CONDITIONING

- REMOVAL, WATER PUMP..............7-74

BYPASS HOSE WITHOUT AIR

CONDITIONING - INSTALLATION,

WATER PUMP........................7-78

BYPASS HOSE WITHOUT AIR

CONDITIONING - REMOVAL, WATER

PUMP..............................7-77

CAB - INSTALLATION, CLUB/QUAD.......8O-20

CAB - INSTALLATION, STANDARD.......8O-19

CAB - REMOVAL, CLUB/QUAD..........8O-19

CAB - REMOVAL, STANDARD...........8O-18

CAB CHASSIS ADAPTER BRACKET -

INSTALLATION........................13-9

CAB CHASSIS ADAPTER BRACKET -

REMOVAL...........................13-9

CAB SIDE PANEL SPEAKER -

INSTALLATION, REAR.................8A-21

CAB SIDE PANEL SPEAKER - REMOVAL,

REAR..............................8A-20

CABLE - 2500/3500 WITH REAR DISC

BRAKES - INSTALLATION, REAR PARK

BRAKE..............................5-38

CABLE - 2500/3500 WITH REAR DISC

BRAKES - REMOVAL, REAR PARK

BRAKE..............................5-37

CABLE - ADJUSTMENTS,

TRANSMISSION THROTTLE VALVE.....21-254,

21-425,21-598,21-771

CABLE - DESCRIPTION.................8P-4

CABLE - DESCRIPTION, ANTENNA BODY . . . 8A-4

CABLE - DESCRIPTION, BATTERY........8F-19

CABLE - DESCRIPTION, SPARK PLUG.....8I-19

CABLE - DESCRIPTION, THROTTLE

VALVE

..........21-253,21-424,21-597,21-770

CABLE - INSTALLATION, CHECK

.........23-63

CABLE - INSTALLATION, FRONT

PARKING BRAKE

......................5-39

CABLE - INSTALLATION, INSTRUMENT

PANEL ANTENNA

.....................8A-10

CABLE - INSTALLATION, LATCH RELEASE

. 23-101

BR/BEINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 2854 of 2889

CENTER HIGH MOUNTED STOP LAMP -

INSTALLATION........................8L-6

CENTER HIGH MOUNTED STOP LAMP -

REMOVAL...........................8L-6

CENTER HIGH MOUNTED STOP LAMP

UNIT - INSTALLATION..................8L-6

CENTER HIGH MOUNTED STOP LAMP

UNIT - REMOVAL.....................8L-6

CENTER SEAT ARMREST/CONSOLE -

INSTALLATION......................23-132

CENTER SEAT ARMREST/CONSOLE -

REMOVAL.........................23-132

CENTER SEAT ARMREST/LATCH COVER -

INSTALLATION......................23-132

CENTER SEAT ARMREST/LATCH COVER -

REMOVAL.........................23-132

CENTERING - STANDARD PROCEDURE,

CLOCKSPRING......................8O-11

CENTRAL TIMER MODULE - DIAGNOSIS

AND TESTING........................8E-4

CERTIFICATION LABEL - DESCRIPTION,

VEHICLE SAFETY..................Intro.-12

CHAIN COVER(S) - INSTALLATION,

TIMING BELT..........9-113,9-169,9-226,9-56

CHAIN COVER(S) - REMOVAL, TIMING

BELT ................9-113,9-169,9-225,9-56

CHAIN STRETCH - INSPECTION,

MEASURING TIMING....9-114,9-170,9-227,9-58

CHANNEL - INSTALLATION, GLASS RUN . . 23-70

CHANNEL - REMOVAL, GLASS RUN......23-70

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-46

CHARGE AIR COOLER AND PLUMBING -

CLEANING..........................11-18

CHARGE AIR COOLER AND PLUMBING -

DESCRIPTION.......................11-17

CHARGE AIR COOLER AND PLUMBING -

INSPECTION........................11-18

CHARGE AIR COOLER AND PLUMBING -

INSTALLATION.......................11-18

CHARGE AIR COOLER AND PLUMBING -

OPERATION.........................11-17

CHARGE AIR COOLER AND PLUMBING -

REMOVAL..........................11-17

CHARGING - DESCRIPTION.............8F-27

CHARGING - OPERATION..............8F-27

CHARGING - STANDARD PROCEDURE,

BATTERY............................8F-9

CHARGING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-27

CHART, SPECIFICATIONS - TORQUE........5-3

CHART, SPECIFICATIONS -

TORQUE.............19-19,19-39,19-41,19-9

CHART, SPECIFICATIONS -

TORQUE.....................2-15,2-27,2-8

CHART, SPECIFICATIONS - TORQUE......22-11

CHARTS - DIAGNOSIS AND TESTING,

DIAGNOSIS......21-149,21-320,21-492,21-663

CHARTS - DIAGNOSIS AND TESTING,

SMOKE DIAGNOSIS...................9-234

CHASSIS ADAPTER BRACKET -

INSTALLATION, CAB...................13-9

CHASSIS ADAPTER BRACKET -

REMOVAL, CAB.......................13-9

CHECK - INSTALLATION...............23-78

CHECK - REMOVAL...................23-78

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL......................7-16

CHECK - STANDARD PROCEDURE, FLUID

LEVEL..........21-199,21-370,21-545,21-715

CHECK - STANDARD PROCEDURE, OIL

PUMP VOLUME . . . 21-209,21-379,21-554,21-724

CHECK CABLE - INSTALLATION.........23-63

CHECK CABLE - REMOVAL.............23-62

CHECK GAUGES INDICATOR -

DESCRIPTION.......................8J-17

CHECK GAUGES INDICATOR -

OPERATION.........................8J-17

CHECK OUT - STANDARD PROCEDURE,

OWNER............................30-22

CHECK VALVE - DESCRIPTION, ONE WAY . 25-30

CHECK VALVE - DESCRIPTION, VACUUM

. . 24-28

CHECK VALVE - DIAGNOSIS AND

TESTING, ONE-WAY

..................25-30

CHECK VALVE - INSTALLATION, ONE

WAY

...............................25-30

CHECK VALVE - INSTALLATION, VACUUM

. 24-29

CHECK VALVE - OPERATION, ONE WAY

. . . 25-30CHECK VALVE - OPERATION, VACUUM....24-28

CHECK VALVE - REMOVAL, ONE WAY....25-30

CHECK VALVE - REMOVAL, VACUUM.....24-29

CHECKING BATTERY ELECTROLYTE

LEVEL - STANDARD PROCEDURE.........8F-8

CHECKING TRANSMISSION CLUTCH AND

BAND OPERATION - DIAGNOSIS AND

TESTING, AIR................21-147,21-318

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY.........................7-4

CHILD TETHER - INSTALLATION..........8O-9

CHILD TETHER - REMOVAL.............8O-9

CHIME WARNING SYSTEM -

DESCRIPTION........................8B-1

CHIME WARNING SYSTEM - DIAGNOSIS

AND TESTING........................8B-2

CHIME WARNING SYSTEM - OPERATION . . . 8B-1

CHOKE RELAY - DESCRIPTION, RADIO....8A-8

CHOKE RELAY - DIAGNOSIS AND

TESTING, RADIO......................8A-8

CHOKE RELAY - INSTALLATION, RADIO....8A-9

CHOKE RELAY - OPERATION, RADIO......8A-8

CHOKE RELAY - REMOVAL, RADIO.......8A-9

CIGAR LIGHTER - DIAGNOSIS &

TESTING.........................8W-97-2

CIGAR LIGHTER OUTLET - DESCRIPTION . 8W-97-2

CIGAR LIGHTER OUTLET -

INSTALLATION....................8W-97-3

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CIGAR LIGHTER OUTLET - REMOVAL....8W-97-3

CIRCUIT ACTUATION TEST MODE -

DESCRIPTION........................25-1

CIRCUIT BREAKER - DESCRIPTION....8W-97-4

CIRCUIT BREAKER - DIAGNOSIS &

TESTING.........................8W-97-4

CIRCUIT SENSE - DESCRIPTION,

IGNITION...........................8E-17

CIRCUIT SENSE - OPERATION, IGNITION . . 8E-19

CIRCUITS - DIESEL - OPERATION,

NON-MONITORED....................25-23

CIRCUITS - GAS ENGINES - OPERATION,

NON-MONITORED....................25-22

CLAMPS - DESCRIPTION, HOSE...........7-2

CLAMPS - OPERATION, HOSE.............7-2

CLASSIFICATION OF LUBRICANTS -

STANDARD PROCEDURE.................0-3

CLEANER ELEMENT - INSTALLATION,

AIR ...............................9-245

CLEANER ELEMENT - REMOVAL, AIR.....9-244

CLEANING AND INSPECTION, OIL

COOLER & LINES....................9-296

CLEANING, APPEARANCE TIPS..........30-21

CLEANING/REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING

SYSTEM............................7-16

CLEARANCE - STANDARD PROCEDURE,

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL...............9-274

CLEARANCE - STANDARD PROCEDURE,

MAIN BEARING......................9-275

CLEARANCE LAMP - INSTALLATION.......8L-6

CLEARANCE LAMP - REMOVAL..........8L-6

CLOCKSPRING - DESCRIPTION.........8O-10

CLOCKSPRING - INSTALLATION.........8O-13

CLOCKSPRING - OPERATION...........8O-10

CLOCKSPRING - REMOVAL............8O-11

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-11

CLOSURE PANEL TRIM - INSTALLATION,

REAR.............................23-121

CLOSURE PANEL TRIM - REMOVAL,

REAR.............................23-120

CLUB/QUAD CAB - INSTALLATION.......8O-20

CLUB/QUAD CAB - REMOVAL...........8O-19

CLUSTER - ASSEMBLY, INSTRUMENT....8J-13

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-6

CLUSTER - DISASSEMBLY, INSTRUMENT . . 8J-11

CLUSTER - INSTALLATION, INSTRUMENT . 8J-14

CLUSTER - OPERATION, INSTRUMENT.....8J-3

CLUSTER - REMOVAL, INSTRUMENT

.....8J-10

CLUSTER BEZEL - INSTALLATION

.......23-110

CLUSTER BEZEL - REMOVAL

..........23-109

CLUTCH - 3.9L/5.2L/5.9L/8.0L -

DESCRIPTION, FAN DRIVE VISCOUS

......7-56

CLUTCH - 3.9L/5.2L/5.9L/8.0L -

OPERATION, FAN DRIVE VISCOUS

........7-56CLUTCH - 5.9L DIESEL - DESCRIPTION,

FAN DRIVE VISCOUS...................7-57

CLUTCH - 5.9L DIESEL - OPERATION,

FAN DRIVE VISCOUS...................7-57

CLUTCH - ASSEMBLY, FRONT . . . 21-206,21-376,

21-550,21-721

CLUTCH - ASSEMBLY, REAR....21-248,21-419,

21-593,21-766

CLUTCH - CLEANING, REAR....21-247,21-418,

21-593,21-765

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, A/C

COMPRESSOR.......................24-13

CLUTCH - DESCRIPTION, FRONT . 21-202,21-373,

21-548,21-718

CLUTCH - DESCRIPTION, OVERDRIVE . . . 21-214,

21-385,21-560,21-731

CLUTCH - DESCRIPTION, REAR . . 21-246,21-417,

21-591,21-764

CLUTCH - DIAGNOSTIC AND TESTING......6-2

CLUTCH - DISASSEMBLY, FRONT......21-202,

21-373,21-549,21-719

CLUTCH - DISASSEMBLY, REAR . 21-247,21-418,

21-592,21-765

CLUTCH - INSPECTION, A/C

COMPRESSOR.......................24-16

CLUTCH - INSPECTION, FRONT . . 21-205,21-376,

21-550,21-721

CLUTCH - INSPECTION, REAR . . . 21-248,21-419,

21-593,21-765

CLUTCH - INSTALLATION, A/C

COMPRESSOR.......................24-16

CLUTCH - OPERATION....................6-1

CLUTCH - OPERATION, A/C

COMPRESSOR.......................24-13

CLUTCH - OPERATION, FRONT . . 21-202,21-373,

21-548,21-718

CLUTCH - OPERATION, OVERDRIVE....21-214,

21-385,21-560,21-731

CLUTCH - OPERATION, REAR . . . 21-246,21-417,

21-592,21-764

CLUTCH - REMOVAL, A/C COMPRESSOR . . 24-14

CLUTCH - SPECIFICATIONS...............6-7

CLUTCH - WARNING....................6-2

CLUTCH AND BAND OPERATION -

DIAGNOSIS AND TESTING, AIR

CHECKING TRANSMISSION......21-147,21-318

CLUTCH AND BAND OPERATION -

DIAGNOSIS AND TESTING, AIR

TESTING TRANSMISSION.......21-490,21-661

CLUTCH BREAK-IN - STANDARD

PROCEDURE, A/C COMPRESSOR........24-13

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - ASSEMBLY,

OVERRUNNING . . . 21-236,21-406,21-581,21-752

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - CLEANING, OVERRUNNING . 21-236,

21-406,21-580,21-752

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DESCRIPTION,

OVERRUNNING . . . 21-235,21-405,21-580,21-751

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DISASSEMBLY,

OVERRUNNING . . . 21-235,21-405,21-580,21-751

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - INSPECTION,

OVERRUNNING . . . 21-236,21-406,21-580,21-752

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - OPERATION,

OVERRUNNING . . . 21-235,21-405,21-580,21-751

CLUTCH COIL - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-13

CLUTCH DISC - DESCRIPTION............6-7

CLUTCH DISC - INSTALLATION............6-9

CLUTCH DISC - OPERATION..............6-8

CLUTCH DISC - REMOVAL...............6-8

CLUTCH HOUSING - DIAGNOSIS AND

TESTING............................6-11

CLUTCH HOUSING - INSTALLATION.......6-13

CLUTCH HOUSING - REMOVAL...........6-13

CLUTCH PEDAL - INSTALLATION

.........6-19

CLUTCH PEDAL - REMOVAL

.............6-18

CLUTCH PEDAL POSITION SWITCH -

DESCRIPTION

........................6-22

CLUTCH PEDAL POSITION SWITCH -

OPERATION

..........................6-22

CLUTCH RELAY - DESCRIPTION, A/C

COMPRESSOR

.......................24-17

BR/BEINDEX 7

Description Group-Page Description Group-Page Description Group-Page

Page 2855 of 2889

CLUTCH RELAY - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-17

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR.......................24-18

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR.......................24-17

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR.......................24-18

CLUTCH RELEASE BEARING -

DESCRIPTION........................6-14

CLUTCH RELEASE BEARING -

INSTALLATION........................6-15

CLUTCH RELEASE BEARING -

OPERATION..........................6-14

CLUTCH RELEASE BEARING - REMOVAL . . . 6-15

COAT FINISH - DESCRIPTION, BASE

COAT/CLEAR.......................23-129

COAT FINISH - OPERATION, BASE

COAT/CLEAR.......................23-129

COAT HOOK - INSTALLATION..........23-125

COAT HOOK - REMOVAL..............23-124

COAT/CLEAR COAT FINISH -

DESCRIPTION, BASE.................23-129

COAT/CLEAR COAT FINISH - OPERATION,

BASE.............................23-129

CODE - DESCRIPTION, PAINT..........23-129

CODE PLATE - DESCRIPTION, BODY....Intro.-1

CODES - DESCRIPTION, DIAGNOSTIC

TROUBLE............................25-2

CODES, SPECIFICATIONS - 2001 BR

PAINT COLOR......................23-129

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-13

COIL RESISTANCE, 3.9L/5.2L/5.9L

ENGINES - IGNITION...................8I-3

COIL RESISTANCE, 8.0L V-10 ENGINE -

IGNITION............................8I-3

COLOR CODES, SPECIFICATIONS - 2001

BR PAINT..........................23-129

COLUMN - DESCRIPTION...............19-6

COLUMN - INSTALLATION...............19-8

COLUMN - REMOVAL..................19-7

COLUMN - SERVICE PRECAUTIONS.......19-6

COLUMN OPENING COVER -

INSTALLATION, STEERING............23-116

COLUMN OPENING COVER - REMOVAL,

STEERING.........................23-115

COMBINATION FLASHER - DESCRIPTION . . . 8L-7

COMBINATION FLASHER -

INSTALLATION........................8L-8

COMBINATION FLASHER - OPERATION....8L-7

COMBINATION FLASHER - REMOVAL......8L-8

COMBINATION VALVE - DESCRIPTION......5-9

COMBINATION VALVE - DIAGNOSIS AND

TESTING.............................5-9

COMBINATION VALVE - INSTALLATION.....5-10

COMBINATION VALVE - OPERATION........5-9

COMBINATION VALVE - REMOVAL........5-10

COMBUSTION PRESSURE LEAKAGE -

DIAGNOSIS AND TESTING, CYLINDER....9-124,

9-179,9-67,9-9

COMPASS - INSPECTION..............30-12

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-4

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-5

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS & TESTING...............8M-10

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-4

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-8

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION......................8M-11

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-9

COMPASS/MINI-TRIP COMPUTER -

REMOVAL..........................8M-11

COMPRESSION PRESSURE - DIAGNOSIS

AND TESTING, CYLINDER . . 9-124,9-179,9-67,9-9

COMPRESSOR - DESCRIPTION, A/C......24-46

COMPRESSOR - DIAGNOSIS AND

TESTING, A/C

.......................24-46

COMPRESSOR - INSTALLATION, A/C

.....24-47

COMPRESSOR - OPERATION, A/C

........24-46

COMPRESSOR - REMOVAL, A/C

.........24-47

COMPRESSOR CLUTCH - DESCRIPTION,

A/C

................................24-13COMPRESSOR CLUTCH - INSPECTION,

A/C................................24-16

COMPRESSOR CLUTCH - INSTALLATION,

A/C................................24-16

COMPRESSOR CLUTCH - OPERATION,

A/C................................24-13

COMPRESSOR CLUTCH - REMOVAL, A/C . . 24-14

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE, A/C...........24-13

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING, A/C..........24-13

COMPRESSOR CLUTCH RELAY -

DESCRIPTION, A/C...................24-17

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING, A/C..........24-17

COMPRESSOR CLUTCH RELAY -

INSTALLATION, A/C...................24-18

COMPRESSOR CLUTCH RELAY -

OPERATION, A/C.....................24-17

COMPRESSOR CLUTCH RELAY -

REMOVAL, A/C......................24-18

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP..........................8M-8

COMPUTER - DIAGNOSIS & TESTING,

COMPASS MINI-TRIP.................8M-10

COMPUTER - INSTALLATION, COMPASS/

MINI-TRIP.........................8M-11

COMPUTER - OPERATION, COMPASS/

MINI-TRIP..........................8M-9

COMPUTER - REMOVAL, COMPASS/

MINI-TRIP.........................8M-11

COMPUTER/MAINTENANCE REMINDER -

INSPECTION, TRIP...................30-17

CONDENSER - DESCRIPTION, A/C.......24-48

CONDENSER - INSTALLATION, A/C.......24-49

CONDENSER - OPERATION, A/C.........24-48

CONDENSER - REMOVAL, A/C..........24-49

CONDITIONER - DESCRIPTION, HEATER

AND AIR ............................24-1

CONDITIONER - INSPECTION,

HEATER/AIR.........................30-17

CONDITIONER - OPERATION, HEATER

AND AIR ............................24-1

CONDITIONING - INSTALLATION, WATER

PUMP BYPASS HOSE WITH AIR..........7-77

CONDITIONING - INSTALLATION, WATER

PUMP BYPASS HOSE WITHOUT AIR......7-78

CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITH AIR..........7-74

CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITHOUT AIR......7-77

CONDITIONS - DIAGNOSIS AND

TESTING, SPARK PLUG................8I-16

CONNECT FITTING - DESCRIPTION,

QUICK.............................14-22

CONNECTING ROD - CLEANING, PISTON . . 9-154,

9-209,9-285,9-41,9-98

CONNECTING ROD - CONNECTING

RODS, PISTON......................9-286

CONNECTING ROD - DESCRIPTION,

PISTON..........9-153,9-208,9-282,9-40,9-97

CONNECTING ROD - INSPECTION,

PISTON..........9-154,9-209,9-285,9-41,9-98

CONNECTING ROD - INSTALLATION,

PISTON..........9-154,9-210,9-287,9-41,9-98

CONNECTING ROD - REMOVAL, PISTON . . 9-154,

9-209,9-285,9-40,9-97

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL CLEARANCE -

STANDARD PROCEDURE...............9-274

CONNECTING ROD BEARING FITTING -

STANDARD PROCEDURE......9-144,9-202,9-88

CONNECTING ROD BEARINGS -

STANDARD PROCEDURE-CONNECTING

ROD BEARING FITTING.................9-31

CONNECTING RODS, PISTON &

CONNECTING ROD...................9-286

CONNECTOR - AUGAT - INSTALLATION . 8W-01-8

CONNECTOR - AUGAT - REMOVAL.....8W-01-8

CONNECTOR - DESCRIPTION, DATA LINK . 8E-12

CONNECTOR - MOLEX - INSTALLATION . 8W-01-9

CONNECTOR - MOLEX - REMOVAL

....8W-01-9

CONNECTOR - OPERATION, DATA LINK

. . . 8E-12

CONNECTOR - THOMAS AND BETTS -

INSTALLATION

...................8W-01-10

CONNECTOR - THOMAS AND BETTS -

REMOVAL

........................8W-01-9

CONSOLE - DESCRIPTION, OVERHEAD

....8M-1CONSOLE - INSTALLATION, CENTER....23-122

CONSOLE - INSTALLATION, OVERHEAD . . . 8M-8

CONSOLE - OVERHEAD CONSOLE

ASSEMBLY, OVERHEAD................8M-7

CONSOLE - OVERHEAD CONSOLE

DISASSEMBLY, OVERHEAD.............8M-7

CONSOLE - REMOVAL, CENTER........23-122

CONSOLE - REMOVAL, OVERHEAD.......8M-6

CONSOLE ASSEMBLY, OVERHEAD

CONSOLE - OVERHEAD................8M-7

CONSOLE DISASSEMBLY, OVERHEAD

CONSOLE - OVERHEAD................8M-7

CONSOLE LID - INSTALLATION, CENTER . 23-132

CONSOLE LID - REMOVAL, CENTER.....23-131

CONSOLE SYSTEMS, SPECIAL TOOLS -

OVERHEAD..........................8M-8

CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL

- DESCRIPTION, COOLANT RECOVERY.....7-41

CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL

- INSTALLATION, COOLANT RECOVERY....7-41

CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL

- OPERATION, COOLANT RECOVERY......7-41

CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL

- REMOVAL, COOLANT RECOVERY........7-41

CONTAINER - 8.0L - DESCRIPTION,

COOLANT RECOVERY..................7-42

CONTAINER - 8.0L - OPERATION,

COOLANT RECOVERY..................7-42

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID................5-14

CONTAMINATION - DIAGNOSIS AND

TESTING, FLUID....21-199,21-370,21-545,21-715

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-6

CONTROL - DESCRIPTION, A/C HEATER . . . 24-18

CONTROL - DIAGNOSIS AND TESTING,

A/C HEATER.........................24-19

CONTROL - INSPECTION, SPEED........30-17

CONTROL - INSTALLATION, A/C HEATER . . 24-20

CONTROL - OPERATION, A/C HEATER....24-18

CONTROL - REMOVAL, A/C HEATER......24-19

CONTROL ARM - INSTALLATION, LOWER . . 2-10,

2-20

CONTROL ARM - INSTALLATION, UPPER . . 2-13,

2-24

CONTROL ARM - REMOVAL, LOWER . . 2-10,2-20

CONTROL ARM - REMOVAL, UPPER . . 2-13,2-23

CONTROL CABLE - INSTALLATION,

THROTTLE....................14-105,14-50

CONTROL CABLE - REMOVAL,

THROTTLE....................14-104,14-50

CONTROL MODULE - DESCRIPTION,

AIRBAG.............................8O-6

CONTROL MODULE - INSTALLATION,

AIRBAG.............................8O-8

CONTROL MODULE - INSTALLATION,

ENGINE............................8E-14

CONTROL MODULE - INSTALLATION,

POWERTRAIN.......................8E-20

CONTROL MODULE - OPERATION,

AIRBAG.............................8O-6

CONTROL MODULE - REMOVAL, AIRBAG . . 8O-7

CONTROL MODULE - REMOVAL, ENGINE . . 8E-14

CONTROL MODULE - REMOVAL,

POWERTRAIN.......................8E-19

CONTROL MOTOR - DESCRIPTION, IDLE

AIR

...............................14-41

CONTROL MOTOR - OPERATION, IDLE

AIR

...............................14-41

CONTROL SERVO - DESCRIPTION,

SPEED

..............................8P-5

CONTROL SERVO - INSTALLATION,

SPEED

.............................8P-10

CONTROL SERVO - OPERATION, SPEED

. . . 8P-5

CONTROL SERVO - REMOVAL, SPEED

.....8P-6

CONTROL SWITCH - DESCRIPTION,

LUMBAR

...........................8N-17

CONTROL SWITCH - OPERATION,

LUMBAR

...........................8N-18

CONTROL SWITCH - REMOVAL,

LUMBAR

...........................8N-18

CONTROL SYSTEM - DESCRIPTION,

SPEED

..............................8P-1

CONTROL SYSTEM - OPERATION, SPEED

. . 8P-2

CONTROL SYSTEM - TORQUE, SPEED

.....8P-4

CONTROL/CENTRAL TIMER MODULE -

DESCRIPTION, BODY

..................8E-1

8 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2856 of 2889

CONTROL/CENTRAL TIMER MODULE -

INSTALLATION, BODY..................8E-6

CONTROL/CENTRAL TIMER MODULE -

OPERATION, BODY....................8E-3

CONTROL/CENTRAL TIMER MODULE -

REMOVAL, BODY......................8E-5

CONTROLLER ANTILOCK BRAKE -

DESCRIPTION.......................8E-11

CONTROLLER ANTILOCK BRAKE -

INSTALLATION.......................8E-12

CONTROLLER ANTILOCK BRAKE -

OPERATION.........................8E-11

CONTROLLER ANTILOCK BRAKE -

REMOVAL..........................8E-12

CONTROLS - DIAGNOSIS AND TESTING,

OVERDRIVE

ELECTRICAL.....21-215,21-386,21-579,21-732

CONVERTER - 3.9L/5.2L/5.9L -

DESCRIPTION, CATALYTIC...............11-5

CONVERTER - 3.9L/5.2L/5.9L -

INSPECTION, CATALYTIC................11-5

CONVERTER - 3.9L/5.2L/5.9L -

INSTALLATION, CATALYTIC..............11-5

CONVERTER - 3.9L/5.2L/5.9L -

OPERATION, CATALYTIC................11-5

CONVERTER - 3.9L/5.2L/5.9L -

REMOVAL, CATALYTIC..................11-5

CONVERTER - 5.9L HEAVY DUTY/8.0L -

DESCRIPTION, CATALYTIC...............11-6

CONVERTER - 5.9L HEAVY DUTY/8.0L -

INSPECTION, CATALYTIC................11-7

CONVERTER - 5.9L HEAVY DUTY/8.0L -

INSTALLATION, CATALYTIC..............11-7

CONVERTER - 5.9L HEAVY DUTY/8.0L -

OPERATION, CATALYTIC................11-6

CONVERTER - 5.9L HEAVY DUTY/8.0L -

REMOVAL, CATALYTIC..................11-6

CONVERTER - DESCRIPTION,

TORQUE........21-256,21-427,21-600,21-773

CONVERTER - INSTALLATION,

TORQUE........21-261,21-432,21-605,21-778

CONVERTER - OPERATION,

TORQUE........21-260,21-430,21-604,21-777

CONVERTER - REMOVAL,

TORQUE........21-261,21-432,21-605,21-778

CONVERTER DRAINBACK VALVE -

DESCRIPTION,

TORQUE........21-262,21-432,21-605,21-778

CONVERTER DRAINBACK VALVE -

OPERATION,

TORQUE........21-262,21-432,21-605,21-778

CONVERTER DRAINBACK VALVE -

STANDARD PROCEDURE,

TORQUE........21-262,21-432,21-606,21-778

CONVERTER HOUSING FLUID LEAK -

DIAGNOSIS AND

TESTING........21-148,21-319,21-491,21-662

COOLANT - DESCRIPTION...............7-40

COOLANT - OPERATION

................7-40

COOLANT - STANDARD PROCEDURE,

ADDING ADDITIONAL

..................7-16

COOLANT FLOW - DIAGNOSIS AND

TESTING, RADIATOR

...........7-59,7-61,7-63

COOLANT LEVEL CHECK - STANDARD

PROCEDURE

.........................7-16

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

DESCRIPTION

........................7-41

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

INSTALLATION

........................7-41

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

OPERATION

..........................7-41

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

REMOVAL

...........................7-41

COOLANT RECOVERY CONTAINER - 8.0L

- DESCRIPTION

.......................7-42

COOLANT RECOVERY CONTAINER - 8.0L

- OPERATION

.........................7-42

COOLANT SELECTION-ADDITIVES -

STANDARD PROCEDURE

................7-17

COOLANT TEMP SENSOR - 3.9L/5.2L/

5.9L - DESCRIPTION, ENGINE

............7-48

COOLANT TEMP SENSOR - 3.9L/5.2L/

5.9L - INSTALLATION, ENGINE

...........7-48COOLANT TEMP SENSOR - 3.9L/5.2L/

5.9L - OPERATION, ENGINE.............7-48

COOLANT TEMP SENSOR - 3.9L/5.2L/

5.9L - REMOVAL, ENGINE...............7-48

COOLANT THERMOSTAT - 3.9L/5.2L/

5.9L - DESCRIPTION, ENGINE............7-49

COOLANT THERMOSTAT - 3.9L/5.2L/

5.9L - INSTALLATION, ENGINE...........7-50

COOLANT THERMOSTAT - 3.9L/5.2L/

5.9L - OPERATION, ENGINE.............7-49

COOLANT THERMOSTAT - 3.9L/5.2L/

5.9L - REMOVAL, ENGINE...............7-49

COOLANT THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE.................7-54

COOLANT THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE................7-55

COOLANT THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE...................7-54

COOLANT THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE....................7-55

COOLANT THERMOSTAT - 8.0L -

DESCRIPTION, ENGINE.................7-52

COOLANT THERMOSTAT - 8.0L -

INSTALLATION, ENGINE................7-53

COOLANT THERMOSTAT - 8.0L -

OPERATION, ENGINE...................7-52

COOLANT THERMOSTAT - 8.0L -

REMOVAL, ENGINE....................7-52

COOLER - 3.9L/5.2L/5.9L - ASSEMBLY,

TRANS..............................7-82

COOLER - 3.9L/5.2L/5.9L -

DESCRIPTION, TRANS.................7-79

COOLER - 3.9L/5.2L/5.9L -

DISASSEMBLY, TRANS...................7-81

COOLER - 3.9L/5.2L/5.9L -

INSTALLATION, TRANS.................7-82

COOLER - 3.9L/5.2L/5.9L - OPERATION,

TRANS..............................7-79

COOLER - 3.9L/5.2L/5.9L - REMOVAL,

TRANS..............................7-81

COOLER - 5.9L DIESEL - DESCRIPTION,

TRANS..............................7-85

COOLER - 5.9L DIESEL - INSTALLATION,

TRANS..............................7-88

COOLER - 5.9L DIESEL - OPERATION,

TRANS..............................7-85

COOLER - 8.0L - DESCRIPTION, TRANS....7-82

COOLER - 8.0L - INSTALLATION, TRANS . . . 7-85

COOLER - 8.0L - OPERATION, TRANS.....7-82

COOLER - 8.0L - REMOVAL, TRANS.......7-84

COOLER - INSTALLATION, AIR TO OIL.....7-88

COOLER & LINES - CLEANING AND

INSPECTION, OIL.....................9-296

COOLER - REMOVAL, AIR TO OIL.........7-87

COOLER - REMOVAL, WATER TO OIL......7-87

COOLER - STANDARD PROCEDURE,

FLUSHING COOLER AND TUBES -

WITHOUT RADIATOR IN-TANK

TRANSMISSION OIL...........7-80,7-83,7-86

COOLER - STANDARD PROCEDURE,

FLUSHING COOLERS AND TUBES -

WITH RADIATOR IN-TANK

TRANSMISSION OIL...........7-79,7-83,7-85

COOLER AND PLUMBING - CLEANING,

CHARGE AIR........................11-18

COOLER AND PLUMBING -

DESCRIPTION, CHARGE AIR............11-17

COOLER AND PLUMBING - INSPECTION,

CHARGE AIR........................11-18

COOLER AND PLUMBING -

INSTALLATION, CHARGE AIR...........11-18

COOLER AND PLUMBING - OPERATION,

CHARGE AIR........................11-17

COOLER AND PLUMBING - REMOVAL,

CHARGE AIR........................11-17

COOLER AND TUBES - WITHOUT

RADIATOR IN-TANK TRANSMISSION

OIL COOLER - STANDARD

PROCEDURE, FLUSHING

........7-80,7-83,7-86

COOLERS AND TUBES - WITH

RADIATOR IN-TANK TRANSMISSION

OIL COOLER - STANDARD

PROCEDURE, FLUSHING

........7-79,7-83,7-85

COOLING, SPECIAL TOOLS

..............7-18

COOLING SYSTEM - OPERATION

..........7-4

COOLING SYSTEM 3.9L/5.2L/5.9L/8.0L

ENGINES - STANDARD PROCEDURE,

DRAINING

...........................7-15COOLING SYSTEM 3.9L/5.2L/5.9L/8.0L

ENGINES - STANDARD PROCEDURE,

REFILLING...........................7-15

COOLING SYSTEM 5.9L DIESEL ENGINE

- STANDARD PROCEDURE, DRAINING.....7-15

COOLING SYSTEM 5.9L DIESEL ENGINE

- STANDARD PROCEDURE, REFILLING.....7-15

COOLING SYSTEM CLEANING/REVERSE

FLUSHING - STANDARD PROCEDURE.....7-16

COOLING SYSTEM DIESEL ENGINE -

DIAGNOSIS AND TESTING..............7-12

COOLING SYSTEM FLOW - 3.9L/5.2L/

5.9L ENGINE - DESCRIPTION.............7-1

COOLING SYSTEM FLOW - 5.9L DIESEL

- DESCRIPTION........................7-1

COOLING SYSTEM GAS ENGINE -

DIAGNOSIS AND TESTING...............7-7

COOLING SYSTEM LEAKS - DIAGNOSIS

AND TESTING.........................7-5

COOLING SYSTEM REQUIREMENTS -

DESCRIPTION........................24-1

CORE - DESCRIPTION, HEATER.........24-55

CORE - INSTALLATION, HEATER.........24-56

CORE - OPERATION, HEATER...........24-55

CORE - REMOVAL, HEATER............24-56

CORE GROUND STRAP - INSTALLATION,

HEATER............................8A-15

CORE GROUND STRAP - REMOVAL,

HEATER............................8A-14

CORNER SEAL - INSTALLATION, FRONT

DOOR UPPER......................23-154

CORNER SEAL - REMOVAL, FRONT

DOOR UPPER........................23-154

COUPLERS - DESCRIPTION, A/C LINE....24-40

COUPLERS - OPERATION, A/C LINE......24-41

COUPLERS - STANDARD PROCEDURE,

A/C LINE...........................24-43

COVER - INSTALLATION, CENTER SEAT

ARMREST/LATCH...................23-132

COVER - INSTALLATION, COWL TRIM . . . 23-120

COVER - INSTALLATION, GEAR HOUSING . 9-307

COVER - INSTALLATION, INSTRUMENT

PANEL TOP........................23-115

COVER - INSTALLATION, SEAT BACK....23-137

COVER - INSTALLATION, SEAT CUSHION . 23-139

COVER - INSTALLATION, SHIFT . . . 21-133,21-90

COVER - INSTALLATION, STANCHION....23-143

COVER - INSTALLATION, STEERING

COLUMN OPENING..................23-116

COVER - REMOVAL, CENTER SEAT

ARMREST/LATCH...................23-132

COVER - REMOVAL, COWL TRIM.......23-119

COVER - REMOVAL, GEAR HOUSING.....9-306

COVER - REMOVAL, INSTRUMENT

PANEL TOP........................23-114

COVER - REMOVAL, SEAT BACK........23-137

COVER - REMOVAL, SEAT CUSHION.....23-139

COVER - REMOVAL, SHIFT.......21-132,21-90

COVER - REMOVAL, STANCHION.......23-143

COVER - REMOVAL, STEERING COLUMN

OPENING..........................23-115

COVER - REMOVAL, WHEEL............22-12

COVER - SPLIT BENCH - INSTALLATION,

SEAT BACK........................23-138

COVER - SPLIT BENCH - INSTALLATION,

SEAT CUSHION.....................23-140

COVER - SPLIT BENCH - REMOVAL,

SEAT BACK........................23-137

COVER - SPLIT BENCH - REMOVAL,

SEAT CUSHION.....................23-139

COVER GASKET - DESCRIPTION,

CYLINDER...........................9-79

COVER GASKET - DESCRIPTION,

CYLINDER HEAD......................9-22

COVER GASKET - OPERATION,

CYLINDER HEAD......................9-22

COVER INSTALLED - INSTALLATION,

FRONT OIL SEAL - FRONT.............9-205

COVER INSTALLED - REMOVAL, FRONT

OIL SEAL - FRONT

...................9-204

COVER REMOVED - INSTALLATION,

FRONT OIL SEAL - FRONT

.............9-205

COVER REMOVED - REMOVAL, FRONT

OIL SEAL - FRONT

...................9-204

COVER(S) - CLEANING, CYLINDER HEAD

. 9-138,

9-194,9-24,9-253,9-81

COVER(S) - DESCRIPTION, CYLINDER

HEAD

..............................9-194

BR/BEINDEX 9

Description Group-Page Description Group-Page Description Group-Page